Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Guaranteed leaching rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

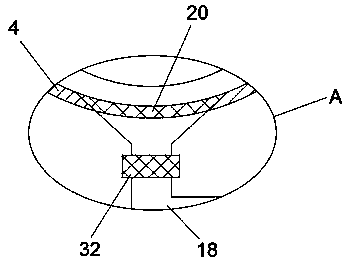

Electroplating sludge recycling technology

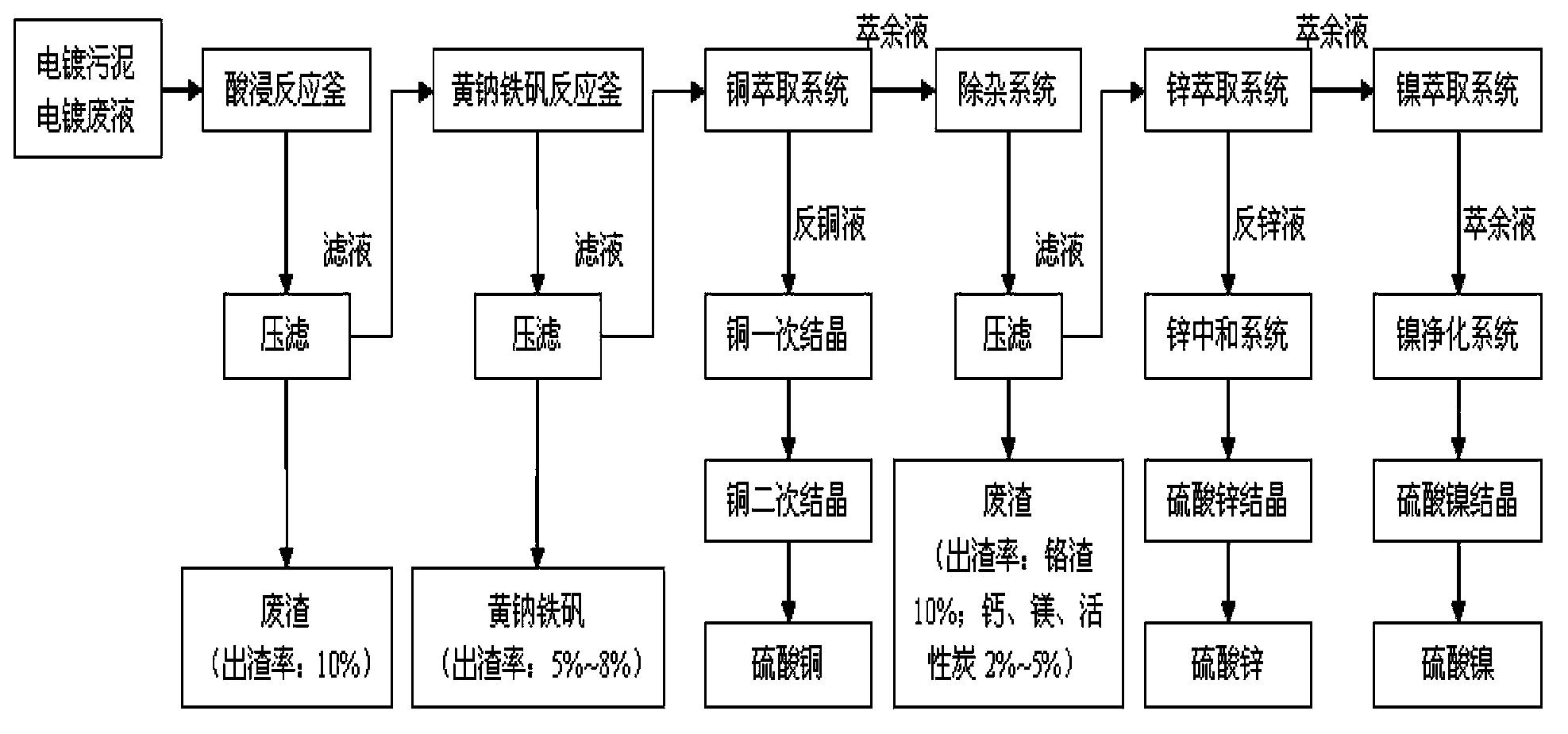

InactiveCN104099474AReduce dosageGuaranteed leaching rateZinc sulatesSludge treatmentLiquid wasteSludge

The invention discloses an electroplating sludge recycling technology. The technology comprises the steps of acid dipping, iron removal, copper extraction, impurity removal, zinc extraction, nickel extraction, low acid leaching and high acid leaching, tailings are washed with water, the iron removal step is carried out through a sodium jarosite process, copper extraction adopts two stage extraction, two stage water washing, four stage back extraction, and second stage extraction is carried out after first stage extraction, precipitation, washing and acid dissolution. The technology has the advantages of technological period shortening, guarantee of the product purity through multiple stage extraction, effective use of the waste resource, and reduction of the emission of a waste liquid.

Owner:ZHENJIANG HUAKE ENVIRONMENTAL PROTECTION TECH

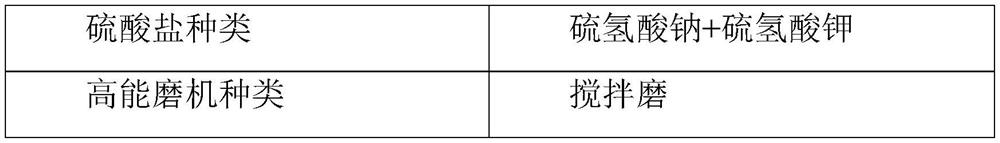

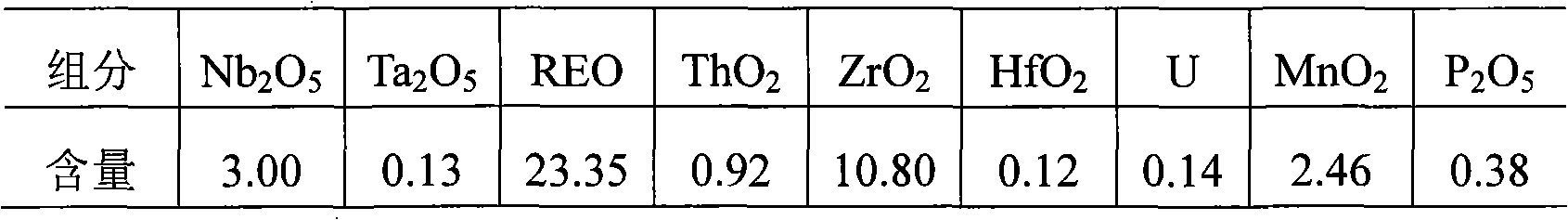

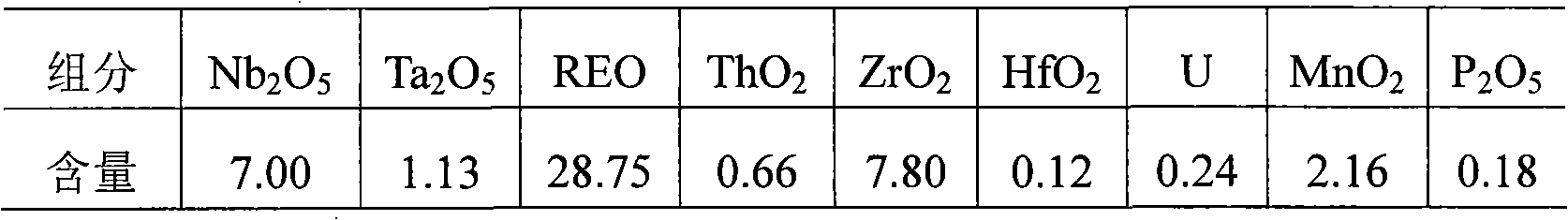

Hingganite ore concentrate decomposition method

InactiveCN101492771AGuaranteed leaching rateImprove leaching rateProcess efficiency improvementNiobiumRare earth

A decomposition method of Xinganite ore concentrate comprises steps of mixing uniformly Xinganite ore concentrate, concentrated sulfuric acid and sulphate with weight ratio of 1:0.8-2.5:0.8-1.5, roasting at 180 DEG C to 400 DEG C for 0.5h to 8h, adding roasted material in water, at 20 DEG C to 80 DEG C, agitating for 0.5h to 3h, filtering and washing, thus lanthanon, beryllium, tantalum and niobium are contained in the solution. In the invention, the Xinganite ore concentrate, concentrated sulfuric acid and sulphate are roasted and composed, and lanthanon, beryllium, tantalum and niobium are leached out by water. In assurance of lanthanon leaching ratio, leaching ratios of beryllium, tantalum and niobium are improved. The lanthanon leaching ratio of the invention reaches 90% above, which prepares for next element separation.

Owner:GUANGDONG INST OF RARE METALS

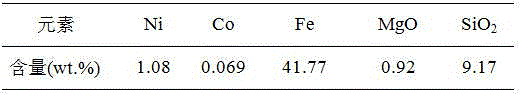

Method for extracting nickel and cobalt from nickel laterite by chloride roasting

The invention relates to the pyrometallurgical and hydrometallurgical field of non-ferrous metals, in particular to a method for extracting nickel and cobalt from nickel laterite by chloride roasting. The method provided by the invention comprises the following steps: grinding a chlorinating agent and ore material together and uniformly pelletizing, wherein the amount of the chlorinating agent accounts for 15-20wt% of the ore material; loading an ore sample which is well ground into a porcelain crucible, covering a cover, and placing into a tube furnace for roasting, wherein the roasting temperature is 600-800 DEG C and the roasting time is 2-3 hours; leaching the ore sample after roasting with acidified water with the pH value of 2-4.5 at the temperature of 50-80 DEG C for 20-40 minutes, then performing solid-liquid separation, and performing vacuum suction filtration to obtain nickel and cobalt filtrate. According to the method provided by the invention, the laterite with low nickel content is treated by a chloride roasting technology, and the selective chlorination of the nickel, the cobalt and other valuable metals, as well as iron and magnesium is realized; by using the acidified water method to leach the valuable metals, namely the nickel and the cobalt, the hydrolysis of ferric chloride is simultaneously inhibited, the loss of the nickel and the cobalt caused by precipitation is prevented, and the high leaching rate of above 85% of the nickel and high leaching rate of above 70% of the cobalt are simultaneously ensured.

Owner:JIANGXI UNIV OF SCI & TECH

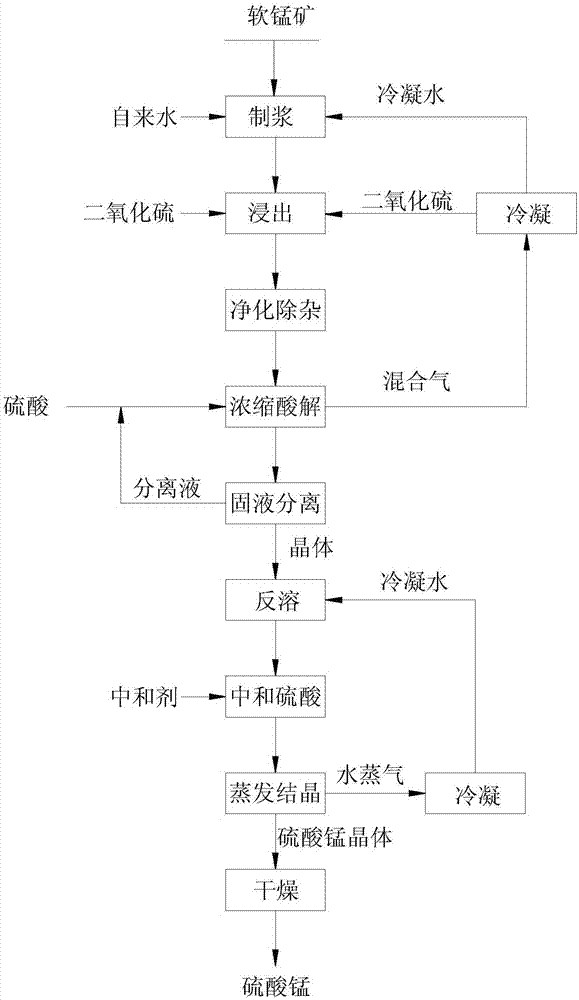

Method for removing manganous dithionate in pyrolusite slurry leaching solution to prepare saturated manganese sulfate slurry and manganese sulfate

ActiveCN107445209AProcess flow is easy to operateHigh resource utilizationManganese sulfatesHeavy metalsDithionate

The invention provides a method for removing manganous dithionate in a pyrolusite slurry leaching solution to prepare saturated manganese sulfate slurry and manganese sulfate. The method comprises the following steps: performing solid-liquid separation to obtain pyrolusite slag and a separated solution containing manganese sulfate and manganous dithionate; performing neutral oxidation on the separated solution to remove iron and aluminum; vulcanizing to remove heavy metal; heating an obtained mixed solution of manganese sulfate and manganous dithionate to evaporate and concentrate to obtain a crystal-containing saturated solution; adding sulfuric acid or a saturated manganese sulfate solution containing sulfuric acid to decompose manganous dithionate into manganese sulfate and sulfur dioxide; discharging mixed gas of sulfur dioxide and water vapor to obtain the saturated manganese sulfate slurry without the manganous dithionate. The invention also provides a method for preparing manganese sulfate through the saturated manganese sulfate slurry prepared by the method. The method is low in cost, easy to operate, and capable of removing manganous dithionate in the leaching solution without additional subsequent purifying process, and high-level manganese sulfate product is prepared.

Owner:SICHUAN UNIV

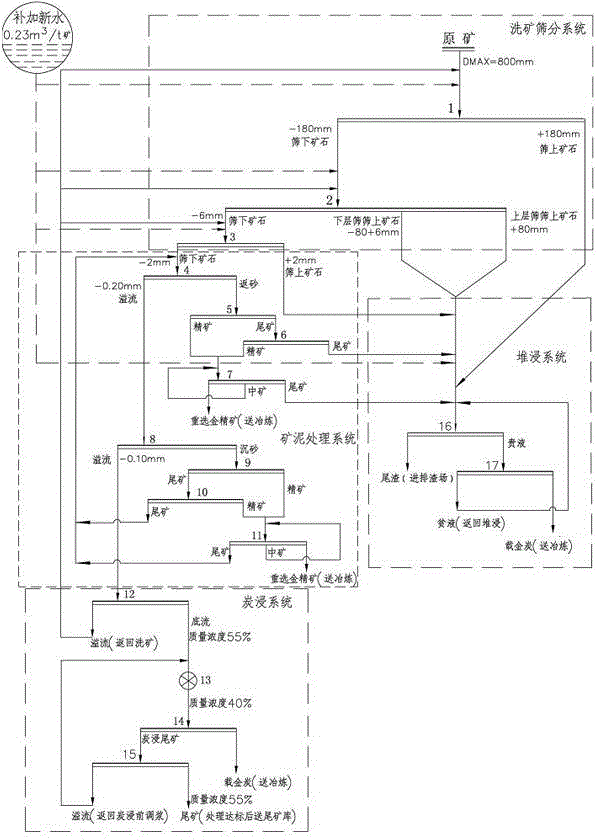

Dressing technology for recycling ultra-low-level gold ore

ActiveCN104307626AGuaranteed leaching rateImprove leaching rateProcess efficiency improvementWet separationMining engineeringGold content

The invention provides a dressing technology for recycling ultra-low-level gold ore. The dressing technology for recycling the ultra-low-level gold ore is composed of an ore washing and screening system, a slime processing system, a carbon leaching system and a dump leaching system, wherein the technological raw ore is directly screened and washed, the ore sand is subjected to dump leaching, the slime is subjected to the stage classification, stage reelecting recycling particle minding and the carbon leaching, gold concentrate, dump leaching gold loaded carbon and carbon leaching gold loaded carbon of a first segment reelecting returning path and a second segment reelecting returning path are obtained, and the reelecting gold concentrate and the gold loaded carbon are sent to a gold melting plant for treatment to obtain gold ingot. According to the dressing technology, the oxidized gold ore with the gold content of the raw ore being under 0.4g / t and the mud content being above 25% is adopted, the gold dressing recycling rate reaches above 75%, the ultra-low-level gold ore resource is fully used, the gold ore resource is enlarged, the water returning use is strengthened in all steps, the corresponding work is returned according to the water returning quality, water is saved, and the ore per unit consumes under 0.23m3 / t of water.

Owner:CHINA NERIN ENG

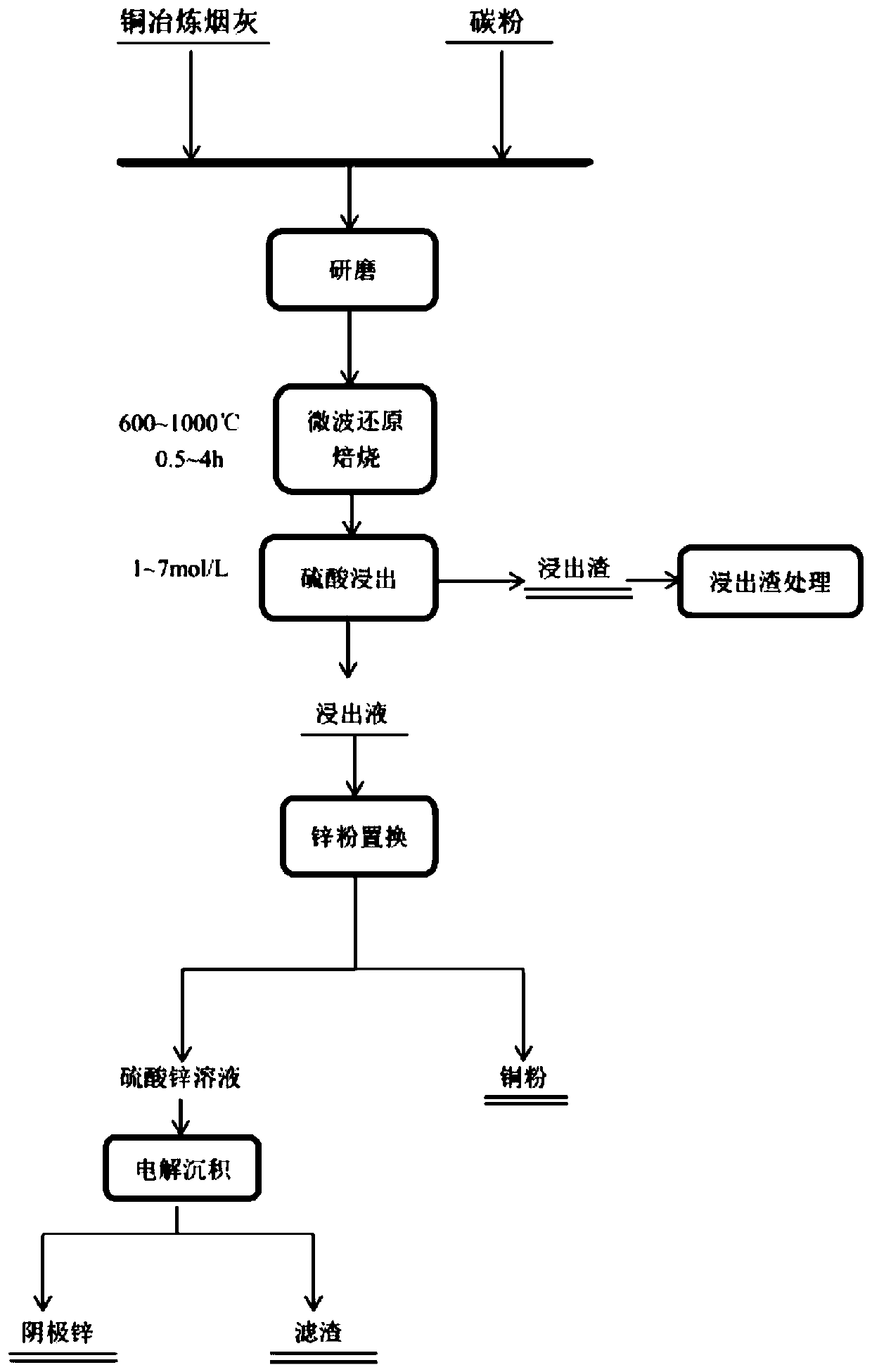

Method for recovering copper and zinc element in copper soot by microwave reduction roasting-sulfuric acid leaching

InactiveCN109735700AReduce the difficulty of leachingImprove leaching ratePhotography auxillary processesProcess efficiency improvementElectrolysisMicrowave

The invention discloses a method for recovering copper and zinc element in copper soot by microwave reduction roasting-sulfuric acid leaching, and belongs to the technical field of metallic element recovery. The method includes steps of microwave reduction roasting, sulfuric acid leaching of copper and zinc, zinc powder replacement, and electrolytic deposition of zinc sulfate. According to the method, the leaching rate the copper and the zinc element in copper soot can be effectively improved to be as high as 95% by adopting the microwave reduction roasting-sulfuric acid leaching process, acidconsumption and energy consumption are effectively reduced, production costs are relatively low, and the needs of economic development of China are met.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

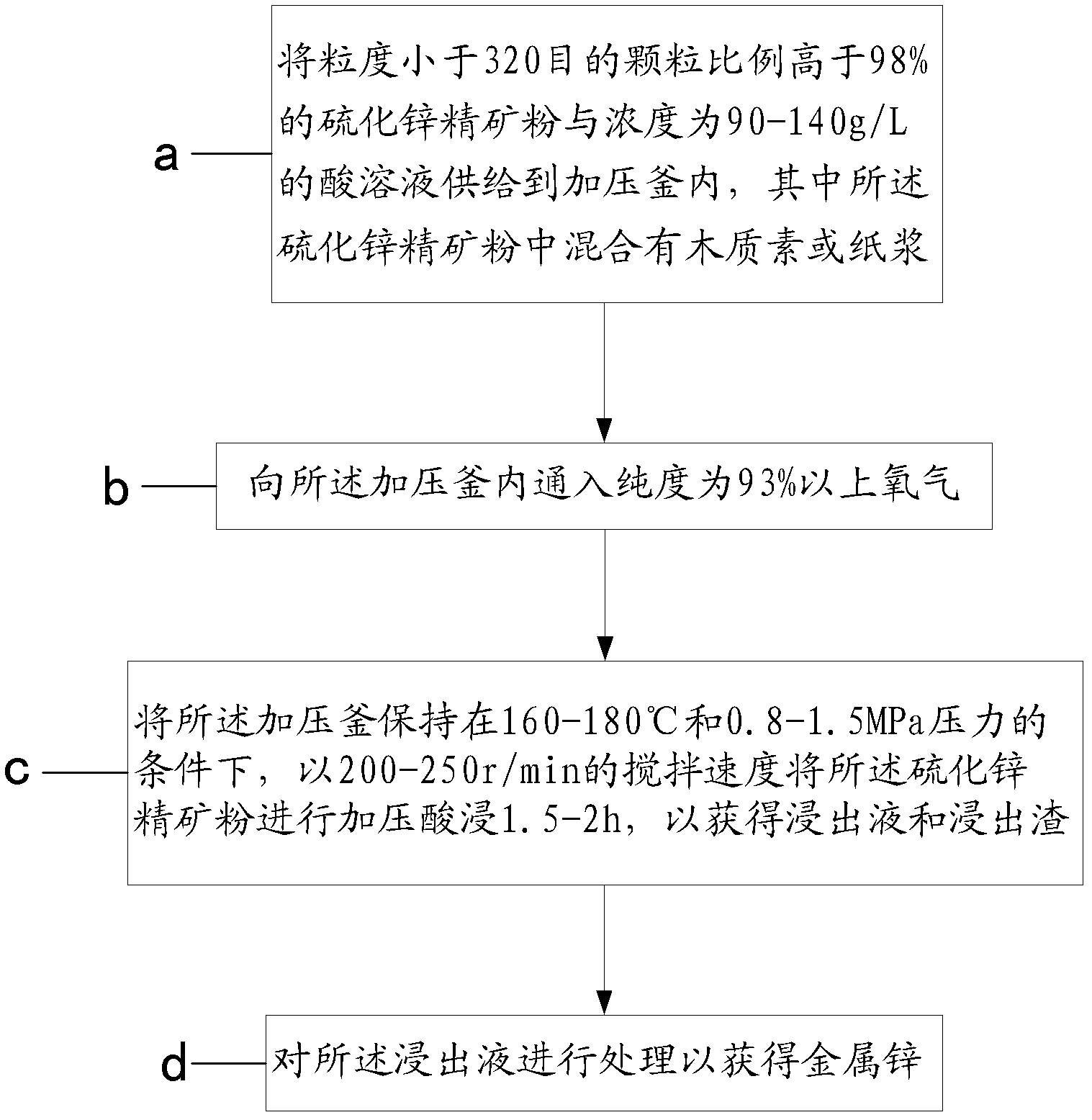

Pressure leaching method of zinc sulfide concentrate

InactiveCN102586597AReduce labor intensityReduce riskProcess efficiency improvementPregnant leach solutionOxygen

The invention discloses a pressure leaching method of zinc sulfide concentrate. The method comprises the following steps of: (a) supplying zinc sulfide concentrate powder and an acid solution into an autoclave; (b) introducing oxygen into the autoclave; (c) keeping the autoclave under the conditions with preset temperature and preset pressure and performing pressure leaching on the zinc sulfide concentrate powder at a certain stirring speed for a preset period of time so as to get leachate and leaching residue; and (d) performing the treatment on the leachate for preparation. By utilizing the pressure leaching method of the zinc sulfide concentrate according to the embodiment of the invention, sulfuric acid can be produced in the autoclave, and concentrated sulfuric acid does not need to be supplemented into a system during the pressure leaching process, so that the production cost can be greatly reduced, and the labor intensity of operation staff and the risk during the production process can be further reduced.

Owner:YUNNAN METALLURGICAL GROUP +2

Method for extracting rubidium chloride from kaolin tailings

The invention discloses a method for extracting rubidium chloride from kaolin tailings. Firstly, the kaolin tailings are subjected to millstone mill crushing and sieving to obtain kaolin fine mineralpowder, the kaolin fine mineral powder and a leaching agent are mixed evenly, the evenly-mixed powder is poured into an acid solution which is heated in advance, acid leaching is conducted, and an acid leaching liquid is obtained; the pH of the obtained leaching liquid is adjusted to approach neutral, calcium is removed, and leaching liquid containing rubidium is obtained; and the processes that 4-tert-butyl-2-(alpha-xylyl) which is diluted by adding sulfonated kerosene is adopted for extraction, a hydrochloric acid solution is adopted for reverse extraction and the like are adopted to obtaina rough rubidium salt product, and the rough rubidium salt product is dissolved and recrystallized to obtain a rubidium salt product with high purity. The rubidium salt extraction process free of chloridizing roasting has the advantages of being simple and feasible in process procedure, low in cost, environmentally friendly, free of pollution and suitable for industrialization.

Owner:CENT SOUTH UNIV

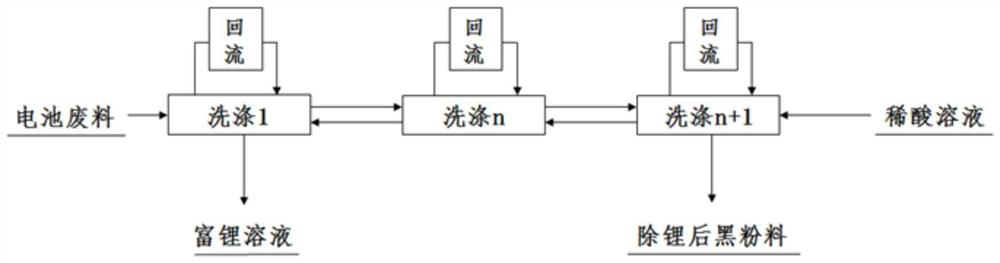

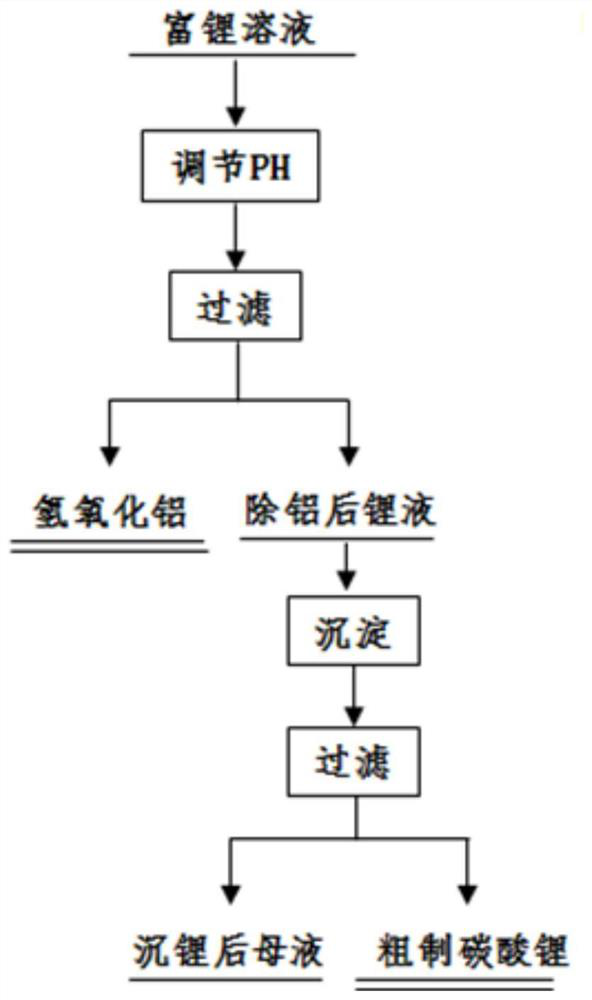

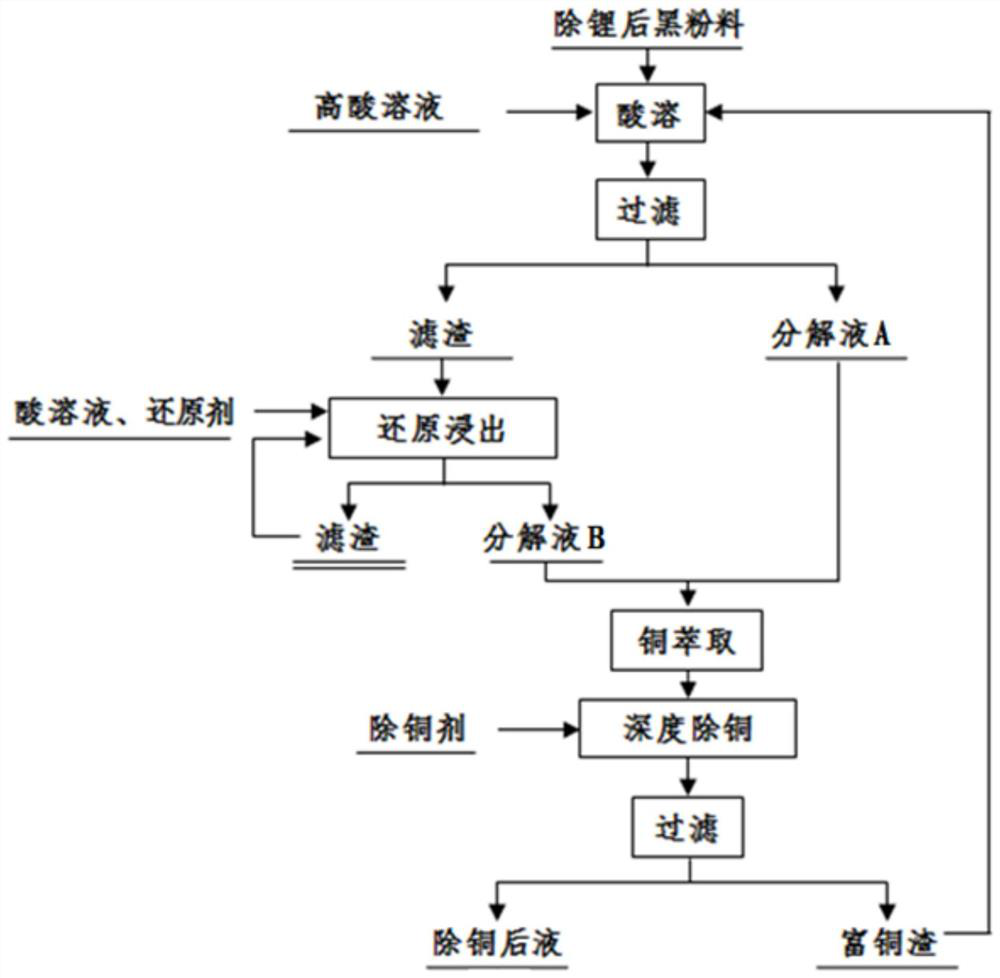

Lithium battery waste recycling method and application thereof

ActiveCN113106257AHigh recovery rateNo lossProcess efficiency improvementBattery recyclingAluminium hydroxidePhysical chemistry

The invention provides a lithium battery waste recycling method and application thereof, and relates to the technical field of waste battery recycling. The method comprises the following steps that firstly, reflux extraction is carried out on lithium battery waste by utilizing a countercurrent washing method to obtain a lithium-rich solution and lithium-removed black powder; then the lithium-rich solution and the lithium-removed black powder are treated respectively, aluminum hydroxide and crude lithium carbonate are extracted from the lithium-rich solution through precipitation and reduction methods, and meanwhile, the lithium-removed black powder is subjected to acid dissolution leaching before reduction leaching; metal impurity ions except cobalt, nickel and manganese in a leaching solution are removed by combining the oxidation-reduction property of metal with the modes of extraction, precipitation and the like; and finally, concentrating and crystallizing are carried out, and cobalt-nickel-manganese mixed salt crystals with high manganese content and cobalt-nickel-manganese mixed salt crystals with high cobalt and nickel contents are respectively prepared by utilizing a hot filtering method and a cooling filtering method. The recycling method has the advantages of being simple in technological process and easy to operate, and the purpose of comprehensively recycling valuable metal from the lithium battery waste is achieved.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

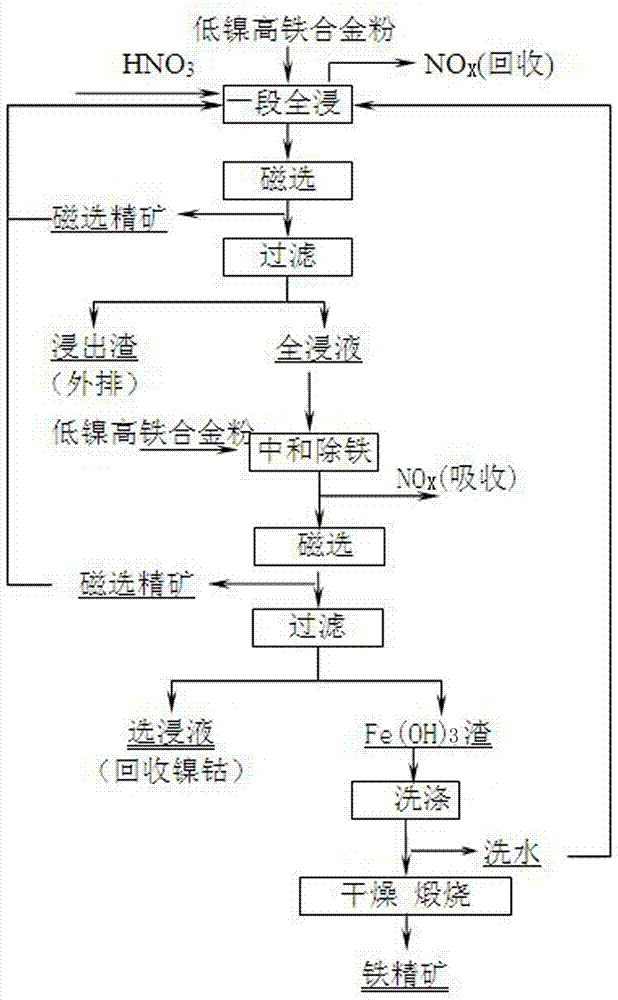

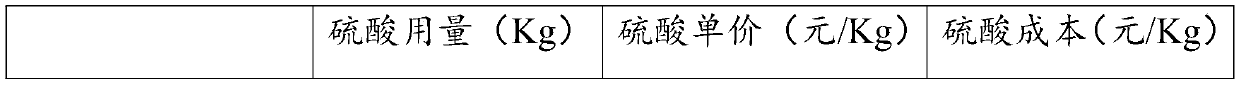

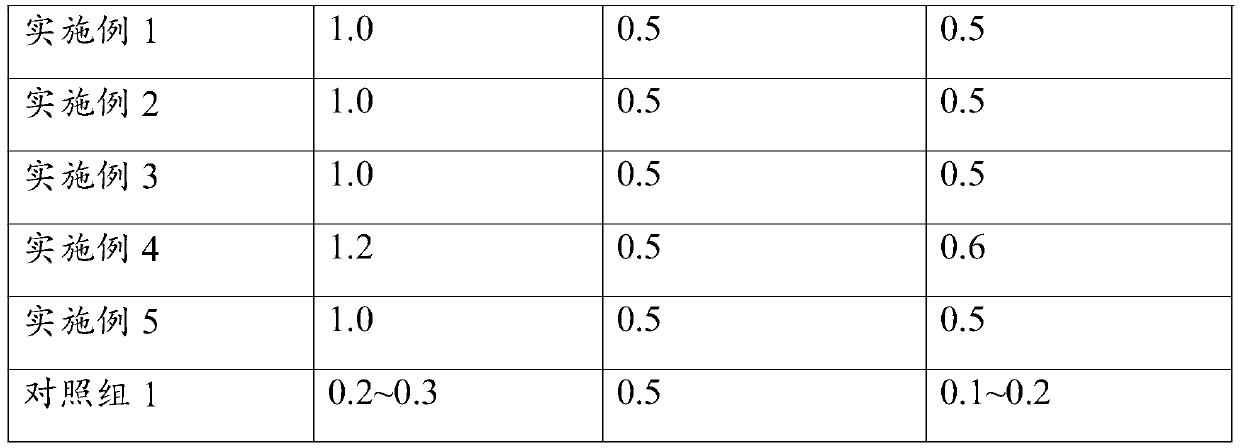

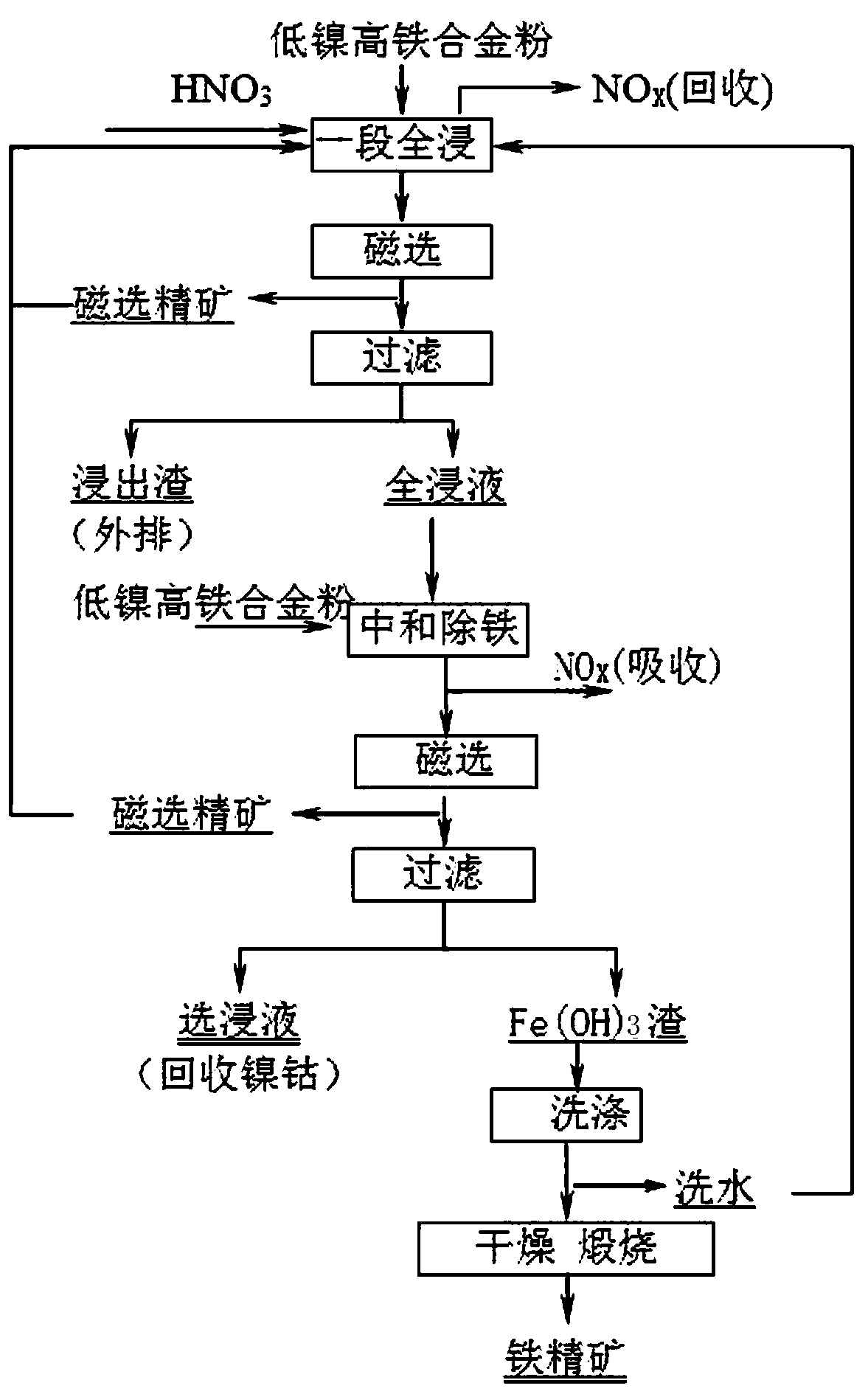

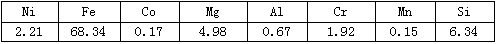

Method for leaching low-nickel high-iron alloy powder selectively through nitric acid

ActiveCN107338357AReduce consumptionSelective leaching achievedProcess efficiency improvementFiltrationSlag

The invention discloses a method for leaching low-nickel high-iron alloy powder selectively through nitric acid. The method comprises the steps that firstly, primary leaching is conducted on the low-nickel high-iron alloy powder through the concentrated nitric acid; when total immersion is ended, magnetic separation is conducted; magnetic separation concentrate is returned for further leaching, so that after remaining ore pulp is filtered, leaching residues and a leaching solution are obtained, and the leaching solution enters a neutralization-for-iron-removal procedure; the low-nickel high-iron alloy powder is added to the leaching solution, so that neutralization for iron removal is conducted; after a neutralization-for-iron-removal reaction is ended, magnetic separation is conducted; magnetic separation concentrate is returned to the primary total immersion procedure, so that after ore pulp is filtered, neutralization iron slag and a separation and immersion solution are obtained; and the neutralization iron slag obtained after filtration is subjected to washing, drying and calcinations, so that an iron ore concentrate product with the iron content ranging from 60% to 65% is obtained. By means of the method, nickel and cobalt leaching and iron removal are completed through one step, and selective leaching of nickel, cobalt and iron is achieved; the nickel and the cobalt enter the solution, and the iron is inhibited in the slag, so that the nickel and the cobalt are effectively separated from the iron; and the leaching rate of the nickel and the cobalt is greater than 98%; the nickel content of the leaching residues is less than 0.5%, the iron content of the leaching residues is less than 10%, and the cobalt content of the leaching residues is less than 0.02%; the iron content of the neutralization iron slag is greater than 50%, and the nickel content o the neutralization iron slag is less than 0.1%; and the iron content of the separation and immersion solution is less than 3 g / L.

Owner:JINCHUAN GROUP LIMITED

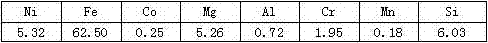

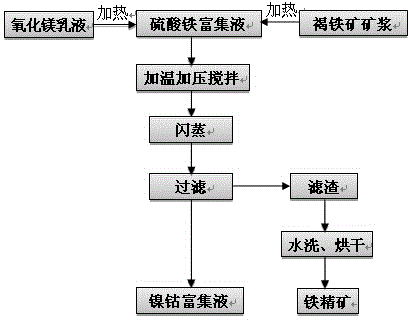

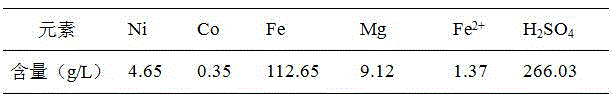

Method of using ferric sulfate solution to perform acid leaching on laterite-nickel ore for extracting nickel and cobalt

InactiveCN104611549AGuaranteed leaching rateFully realize comprehensive utilizationProcess efficiency improvementFiltrationLaterite

The invention discloses a method of using ferric sulfate solution to perform acid leaching on a laterite-nickel ore for extracting nickel and cobalt. The method particularly comprises the following steps: mixing magnesium oxide powder with water to prepare a magnesium oxide emulsion for later use; using a brown iron ore containing 30-55% of iron as a raw material, adding water to the brown iron ore to prepare ore pulp for later use; adding a sulfate leaching agent and the brown iron ore pulp into an autoclave to be mixed and stirred, heating the liquid to a temperature of 150-250 DEG C to perform leaching, adding the prepared magnesium oxide emulsion, when the pH value of the solution is invariable, stopping adding the magnesium oxide emulsion, then performing solid-liquid separation to obtain a filtrate containing iron filter residues and rich in nickel and cobalt. According to the method disclosed by the invention, the laterite-nickel ore atmospheric pressure leaching agent or acidic wastewater containing higher iron and the low-grade brown iron ore type laterite-nickel ore are used as the raw materials; the reaction is taken at the pressure higher than atmospheric pressure, and most of soluble valuable metals is dissolved; at last, flash evaporation and filtration are carried out to obtain the nickel (cobalt) sulfate solution with a low impurity content as well as an iron ore concentrate product with a high iron content, so that the purpose of treatment of wastes with another wastes can be achieved, and the comprehensive utilization of the resources can be realized.

Owner:JINCHUAN GROUP LIMITED

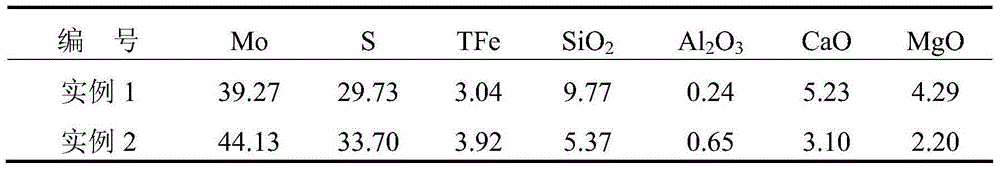

Sulfur fixation method of roasting low-grade molybdenite concentrate through lime method

The invention discloses a sulfur fixation method of roasting a low-grade molybdenite concentrate through a lime method. The sulfur fixation method comprises the steps that the low-grade molybdenite concentrate is divided into two parts; one part is mixed with quick lime and MnO2 for pelletizing; obtained pellets, the other part of the low-grade molybdenite concentrate, high-activity quick lime and NaOH or Na2CO3 are mixed for secondary pelletizing, and low-grade molybdenite concentrate pellets of core-shell structures are obtained; the obtained low-grade molybdenite concentrate pellets are dried and roasted in sequence, and reactions including molybdenite concentrate oxidation and sulfur fixation occur. By means of the sulfur fixation method, the concentration of SO2 in roasting flue gas can be reduced to below 200 mg / Nm<3>, the requirements for flue gas emission are met, and it is guaranteed that the molybdenum leaching rate through calcining and acid leaching reaches over 98%.

Owner:CENT SOUTH UNIV +1

Production method of Tieguanyin tea leaves high in amino acid content

InactiveCN105875914AIncrease the content of amino acidsUnique tastePre-extraction tea treatmentCelluloseArginine

The present invention discloses a production method of Tieguanyin tea leaves high in amino acid content. The production method comprises the following steps: cystine, tyrosine, aspartic acids, valine, alanine, glycine, proline, arginine and lysine are mixed evenly, and the mixture is added into water to be mixed evenly to obtain material A; and fresh Tieguanyin leaves are weighed, the material A is sprayed on the Tieguanyin leaves, the Tieguanyin leaves are air-spread, the air-spread Tieguanyin leaves are placed under gentle sunlight at 4-5 pm for 30-50 min, protease and cellulose are added, the treated Tieguanyin leaves are subjected to rocking and cooling alternately, the rocked and cooled Tieguanyin leaves are rolled, the material A is sprayed on the rolled Tieguanyin leaves, the treated Tieguanyin leaves are put into a sealed fermentation tank to conduct fermentation until 75-80% of the materials turn red, the fermented materials are air-spread to a room temperature, then the air-spread materials are sent into a green tea roasting machine to conduct enzyme deactivating, the remaining material A is added into the enzyme deactivated materials to be mixed evenly, the treated materials are dried to the moisture content of 5-8wt%, the dried materials are baked, and the baked materials are cooled to a room temperature to obtain the Tieguanyin tea leaves. The Tieguanyin tea leaves are high in amino acid content, unique in taste, simple in technology, and low in costs.

Owner:FUJIAN FUYUAN TEA IND CO LTD

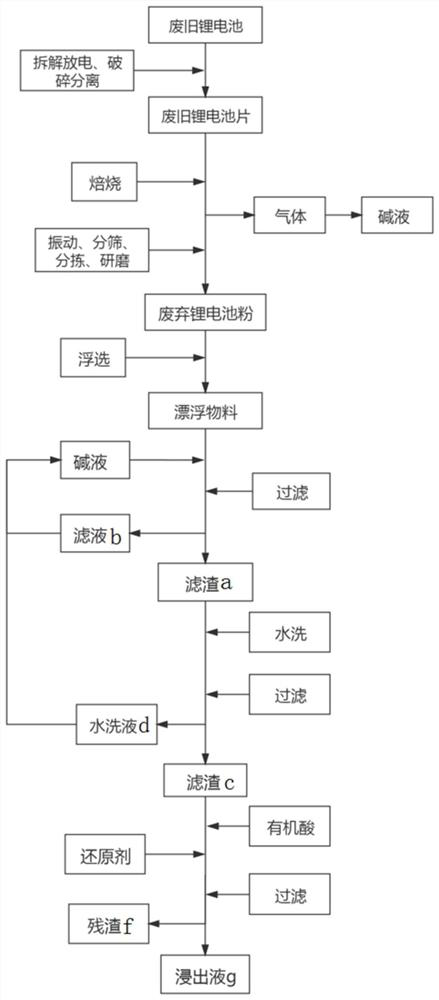

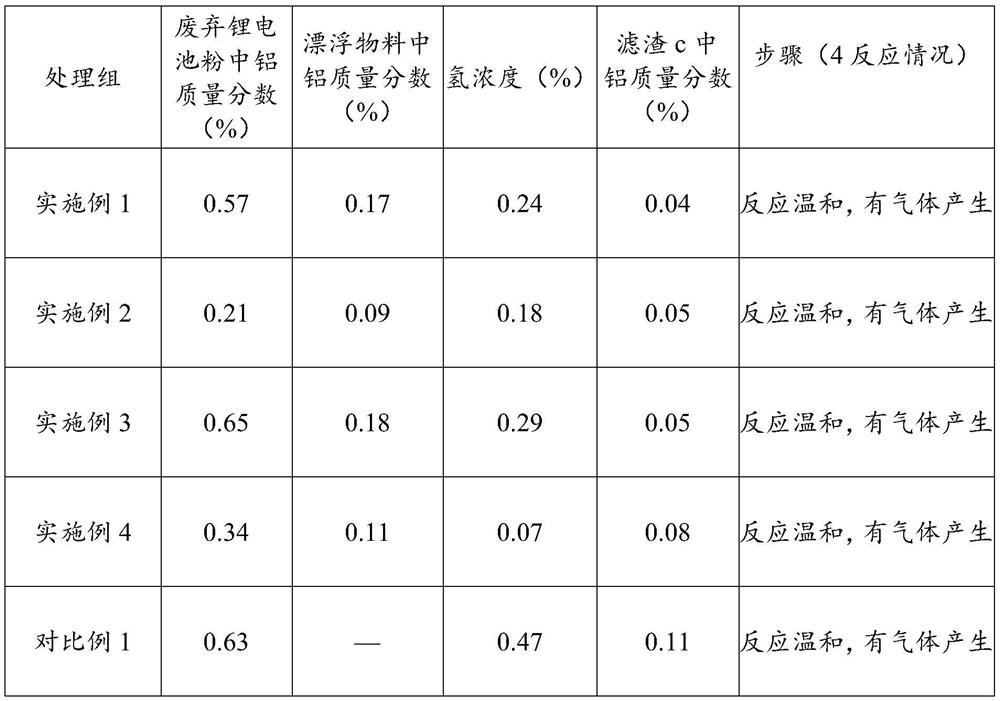

Method for safely leaching waste batteries and application

InactiveCN113502396AReduce energy consumptionAvoid it happening againWaste accumulators reclaimingFlotationPregnant leach solutionEnvironmental engineering

The invention belongs to the technical field of waste battery recovery, and discloses a method for safely leaching waste batteries and application. The method comprises the following steps that discharging, roasting and screening are carried out on a waste lithium battery to obtain copper aluminum foil and battery powder; the battery powder is added into water, then a flotation agent is added for flotation, and a floating material and a sediment substance are obtained; leaching is carried out on the floating material by using alkali liquor filtering is carried out, and filtrate b and filter residues a are obtained; washing and filtering are carried out on the filter residues a, filter residues c are taken, a leaching agent and a reducing agent are added for leaching, and leaching liquid is obtained. According to the method, safe, efficient and low-energy-consumption physical methods such as roasting, screening and flotation are combined with chemical methods such as dilute alkali dissolution, and aluminum in the waste lithium batteries can be removed from the source.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

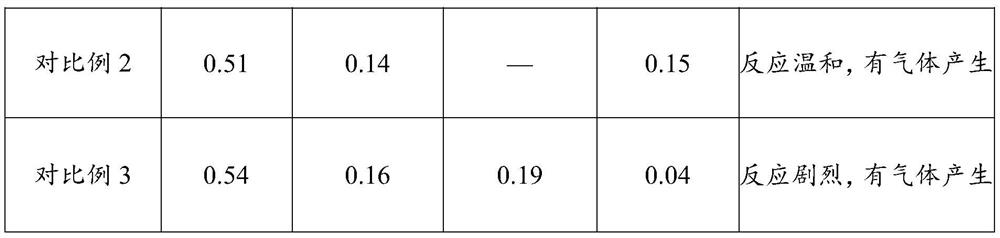

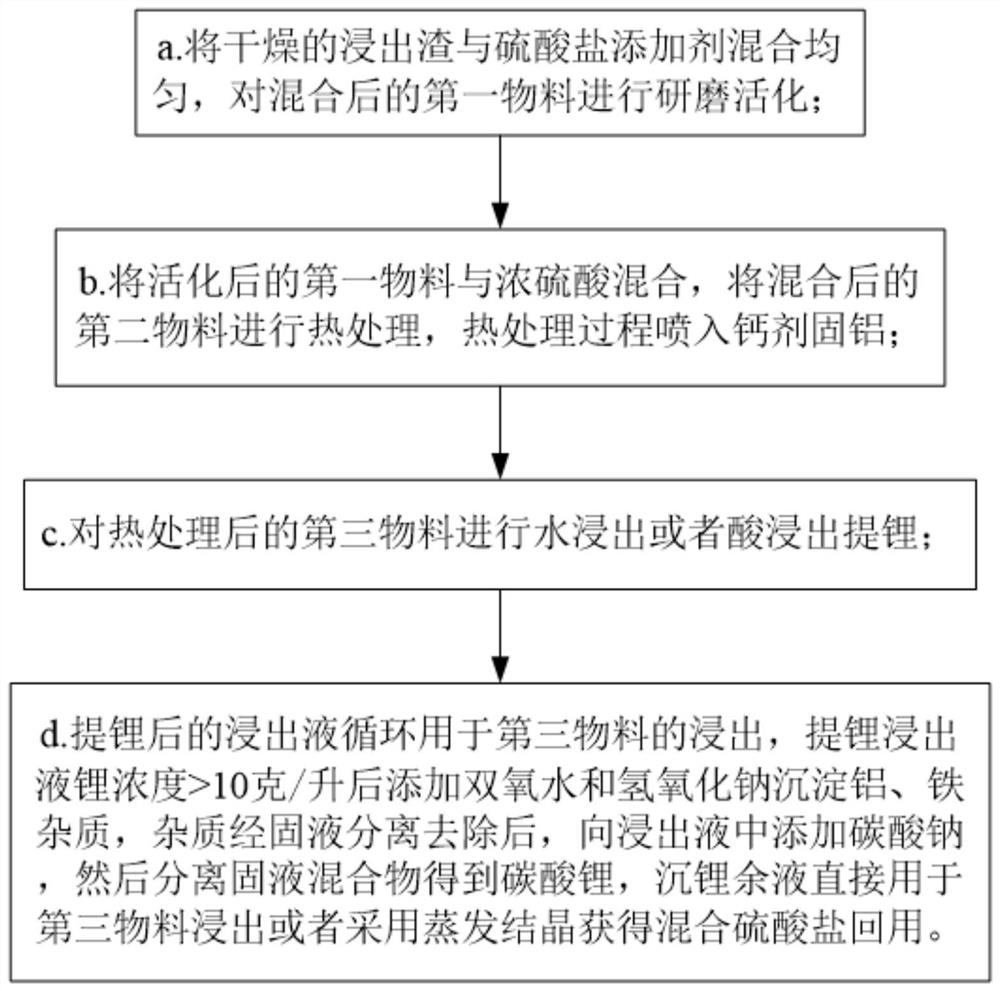

Method for extracting lithium from lithium ore leaching residues

PendingCN114737066AEfficient recyclingGuaranteed leaching rateProcess efficiency improvementAluminum IonPregnant leach solution

The invention relates to the technical field of metal smelting, and particularly provides a method for extracting lithium from lithium ore leaching residues, which comprises the following steps: uniformly mixing the dried leaching residues with a sulfate additive, and grinding and activating the mixed first material; mixing the activated first material with concentrated sulfuric acid, carrying out heat treatment on the mixed second material, and spraying a calcium agent in the heat treatment process to fix aluminum; carrying out water leaching or acid leaching on the third material subjected to heat treatment to extract lithium; and recycling the lixivium subjected to lithium extraction for leaching of a third material, adding hydrogen peroxide and sodium hydroxide into the lixivium subjected to lithium extraction to precipitate aluminum and iron impurities, removing the impurities through solid-liquid separation, adding sodium carbonate into the lixivium, and then separating a solid-liquid mixture to obtain lithium carbonate, the lithium precipitation residual liquid is directly used for leaching a third material or mixed sulfate is obtained through evaporative crystallization for reuse. According to the scheme, the lithium leaching rate of the lithium ore leaching residues is gt; the concentration of aluminum ions in the leachate is 1t; the lithium comprehensive recovery rate gt is 0.5 g / L; and the lithium resource in the lithium leaching residue is effectively recovered.

Owner:北京中科云腾科技有限公司

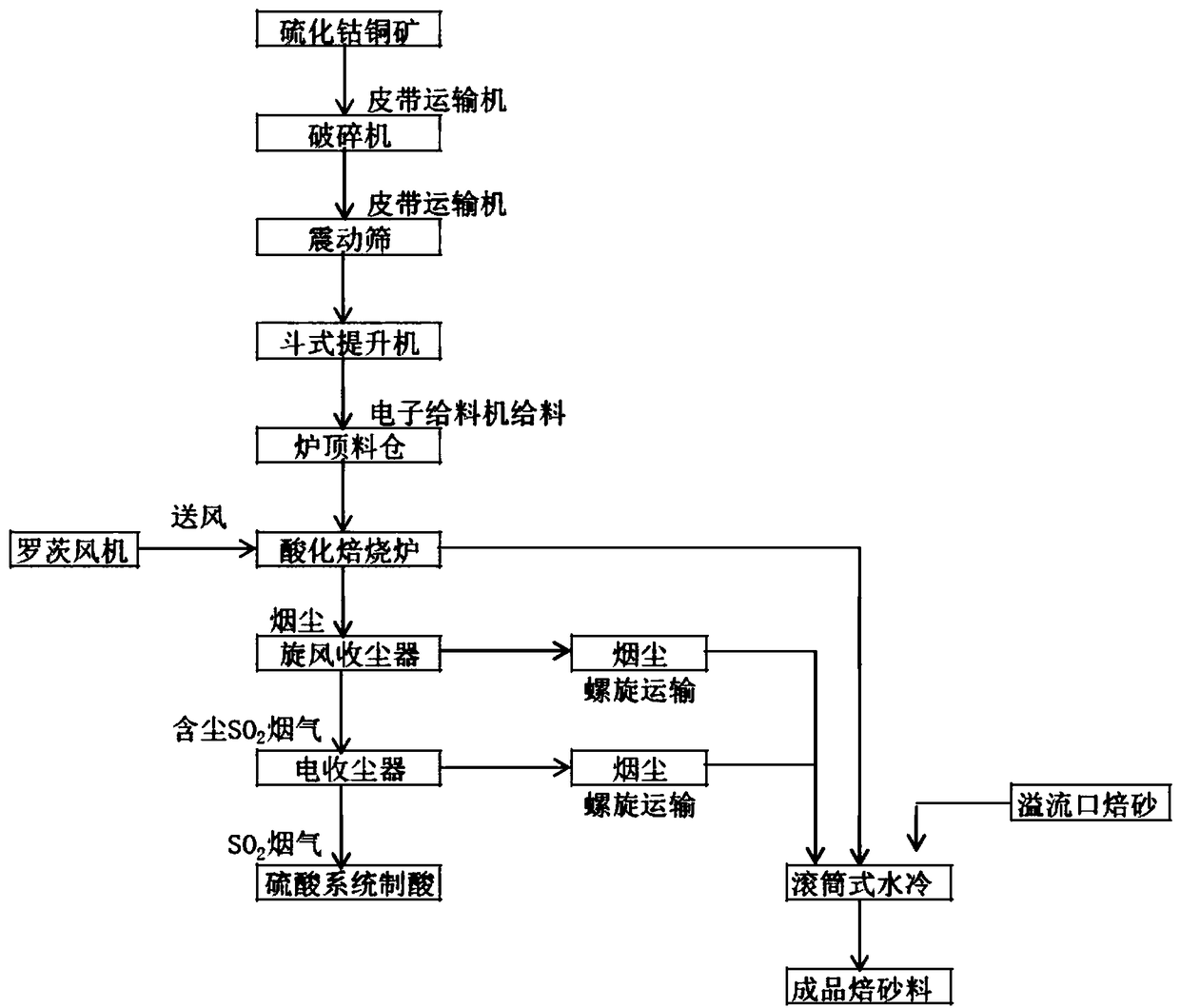

Novel technology for roasting cobalt sulfide copper ore through sulfating

ActiveCN108374083ASolve the granularity of incoming furnaceSolve acidification roasting conditionsWater coolingBucket elevator

The invention relates to the field of roasting of cobalt sulfide copper ores, and provides a novel technology for roasting a cobalt sulfide copper ore through sulfating. The cobalt sulfide copper orepasses through a crushing machine, a vibrating screen, a bucket-type elevator, a furnace top material bin, an sulfating roaster and drum-type water cooling to obtain a finished calcine material, air is sent into the sulfating roaster through a Roots blower, smoke dust containing SO2 of the sulfating roaster sequentially passes through a cyclone dust collector and an electric dust collector and enters a sulfuric acid system for acid making. The smoke dust removed by the cyclone dust collector and the electric dust collector is spirally conveyed to the drum-type water cooling stage, and the drum-type water cooling stage is provided with an overflow opening for discharging calcine. According to the novel technology for roasting the cobalt sulfide copper ore through sulfating, the problems ofthe sulfating roasting condition of the sulfating roaster and the enter-furnace grain size of the cobalt sulfide copper ore are solved, the harm of the smoke dust containing SO2 is controlled, and thus the finished calcine quality, and the leaching rate, being greater than or equal to 96%, of copper and cobalt in the calcine material are ensured.

Owner:GANZHOU TENGYUAN COBALT INDAL

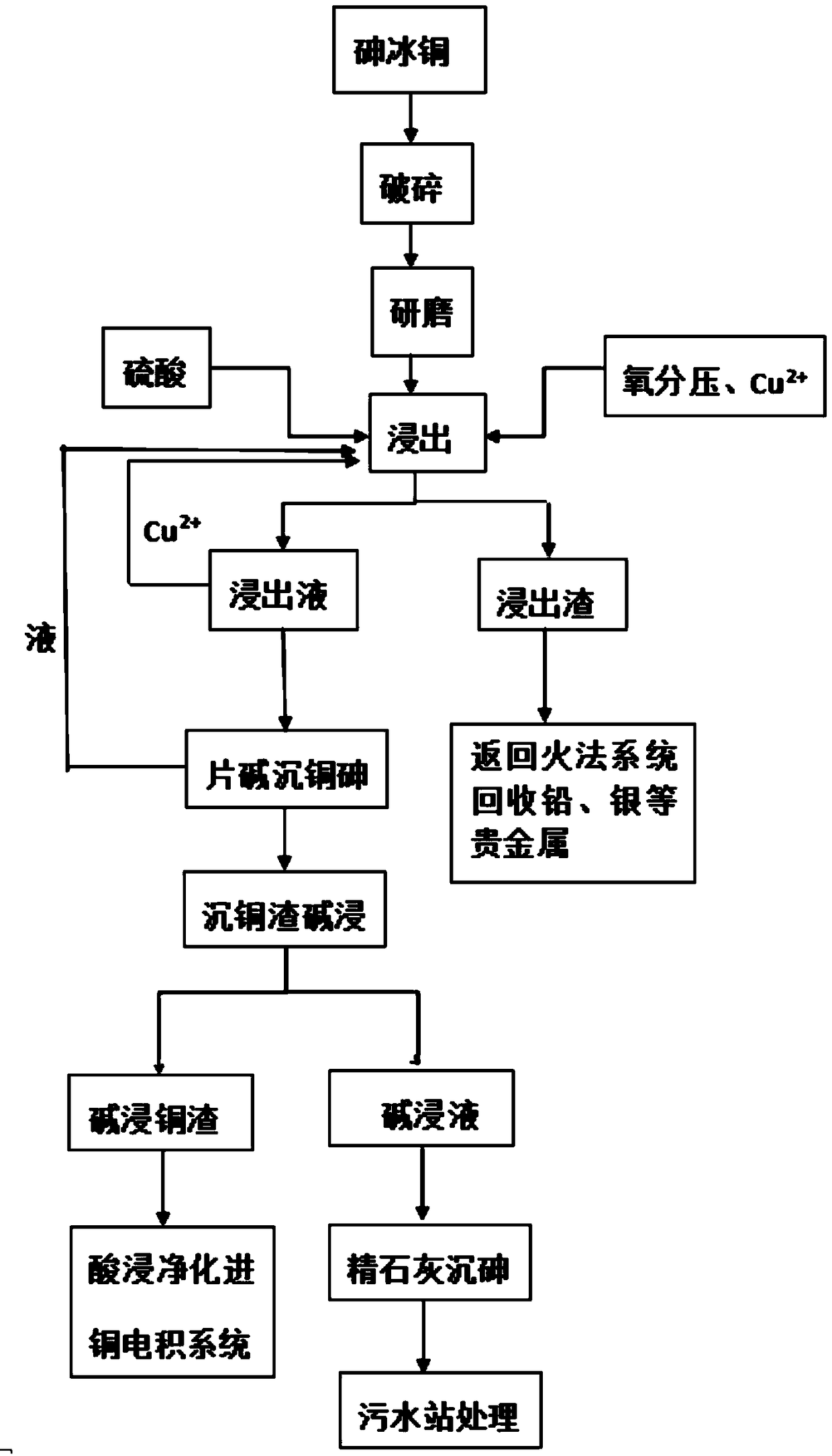

Method for efficiently separating copper arsenic in arsenic matte

InactiveCN109136550APollution is notElectrowinning requires noProcess efficiency improvementPregnant leach solutionArsine

The invention belongs to the field of chemical engineering, and discloses a method for efficiently separating copper arsenic in arsenic matte. The method includes the steps: (1) crushing the arsenic matte, grinding the crushed arsenic matte, and screening the grinded arsenic matte to obtain arsenic matte powder; (2) oxygen pressure leaching: performing oxygen pressure leaching on the arsenic mattepowder by the aid of sulfuric acid solution and Cu2<+> ions, and performing liquid solid separation after leaching is completed to obtain copper-containing leaching solution and lead-silver-containing leaching slag; (3) depositing the copper arsenic in the leaching solution, and performing alkaline leaching on copper arsenic slag to obtain alkaline leaching copper slag and high-arsenic-containing alkaline leaching solution; (4) fine lime arsenic depositing: adding fine lime into the alkaline leaching solution acquired in the step (3) to deposit the arsenic to obtain calcium arsenate. The method is simple in process and free from pollution, a works can not directly contact with harm of generated arsenide hydrogen in the production process, environments cannot be polluted, and precious metals such as copper, lead and silver in lead matte can be effectively recycled.

Owner:CHENZHOU FENGYUE ENVIRONMENTAL PROTECTION TECH

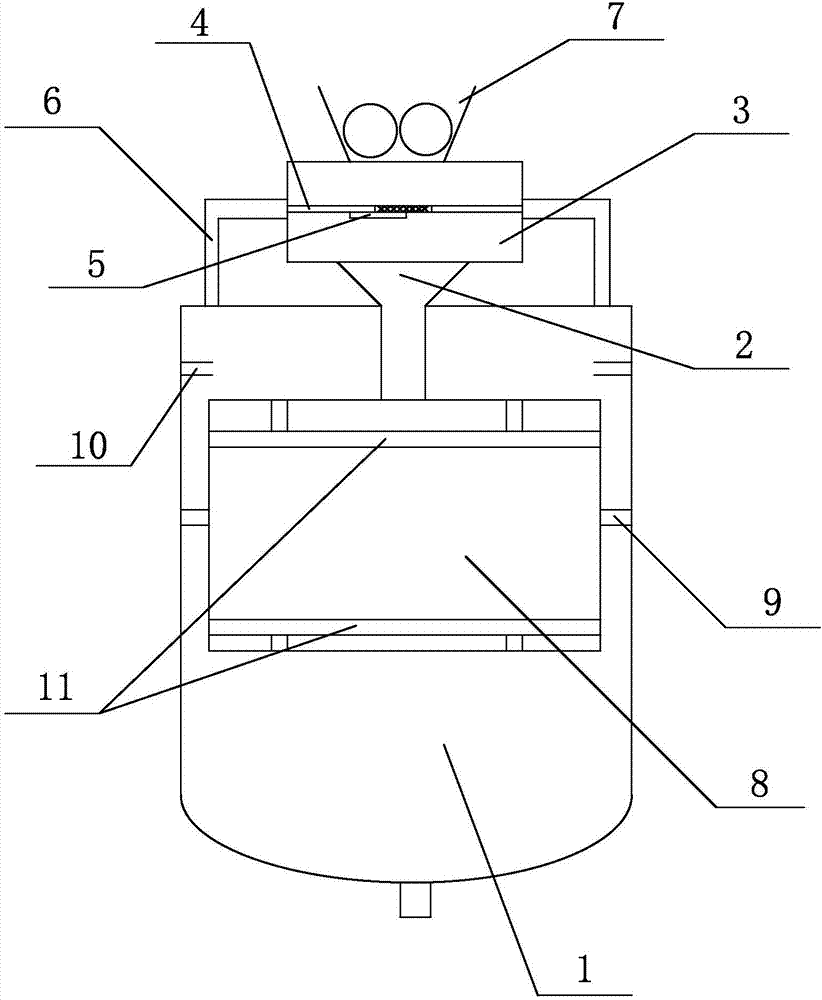

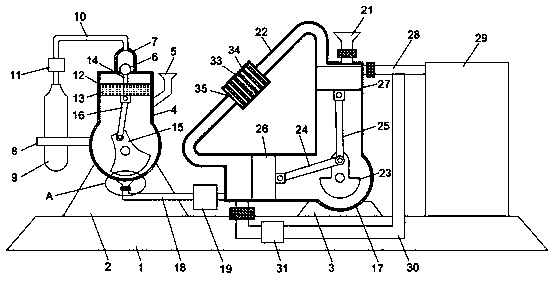

Processing device for edible oil preparation

InactiveCN107129861AImprove processing efficiencyIncrease contact areaFatty-oils/fats productionEdible oils/fatsEngineeringSolvent

The invention discloses a processing device for edible oil preparation. The processing device for the edible oil preparation comprises a leaching kettle body, wherein a feeding inlet is formed in the lower side of the leaching kettle body, a liquid outlet is formed in the lower side of the leaching kettle body, a screening box is arranged above the feeding inlet, a partition board is arranged in the screening box, a filter screen is arranged in the center of the partition board, the bottom of the partition board is slidably connected with a closing plate moving horizontally, a hopper is arranged above the screening box, the hopper communicates with the screening box, a rotating rod is connected with the outside of the screening box, the leaching kettle body is provided with a cylindrical leaching box arranged horizontally, a valve is ranged on the surface of the leaching box, a plurality of liquid inlet holes are formed in the surface of the leaching box, and two sides of the leaching box are slidably connected with the inner walls of the leaching kettle body through rotating shafts. The edible oil processing device can quickly separate particles with too small particle size after the crushing of soybeans, and then continuously increases the contact area between the soybeans and leaching solvent through the rotatable leaching box to improve the soybean oil leaching yield and speed up the processing efficiency of edible oil.

Owner:德阳市华盛植物油有限公司

Method for decomposing ore concentrate containing tantalum, niobium and rare-earth element

The invention relates to a method for decomposing a concentrated ore containing tantalum, niobium and rare-earth elements, which is characterized by comprising the following steps: evenly mixing the concentrated ore containing the tantalum, niobium and rare-earth elements, concentrated sulfuric acid and sulfate according to a weight ratio of 1:0.8-2.5:0.8:1.5, roasting the mixture for 0.5 to 8 hours at a temperature of between 180 and 400 DEG C; adding water into the mixture after roasting, stirring the mixture for 0.5 to 3 hours at a temperature of between 20 and 80 DEG C; and filtering and washing the mixture, wherein the tantalum, the niobium and the rare-earth elements enter the solution. The method decomposes the tantalum, the niobium and the rare-earth elements, and improves leaching rate of the tantalum and the niobium at the same time, wherein the leaching rate of the rare-earth elements reaches more than 90 percent, and the method prepares for next separation.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +1

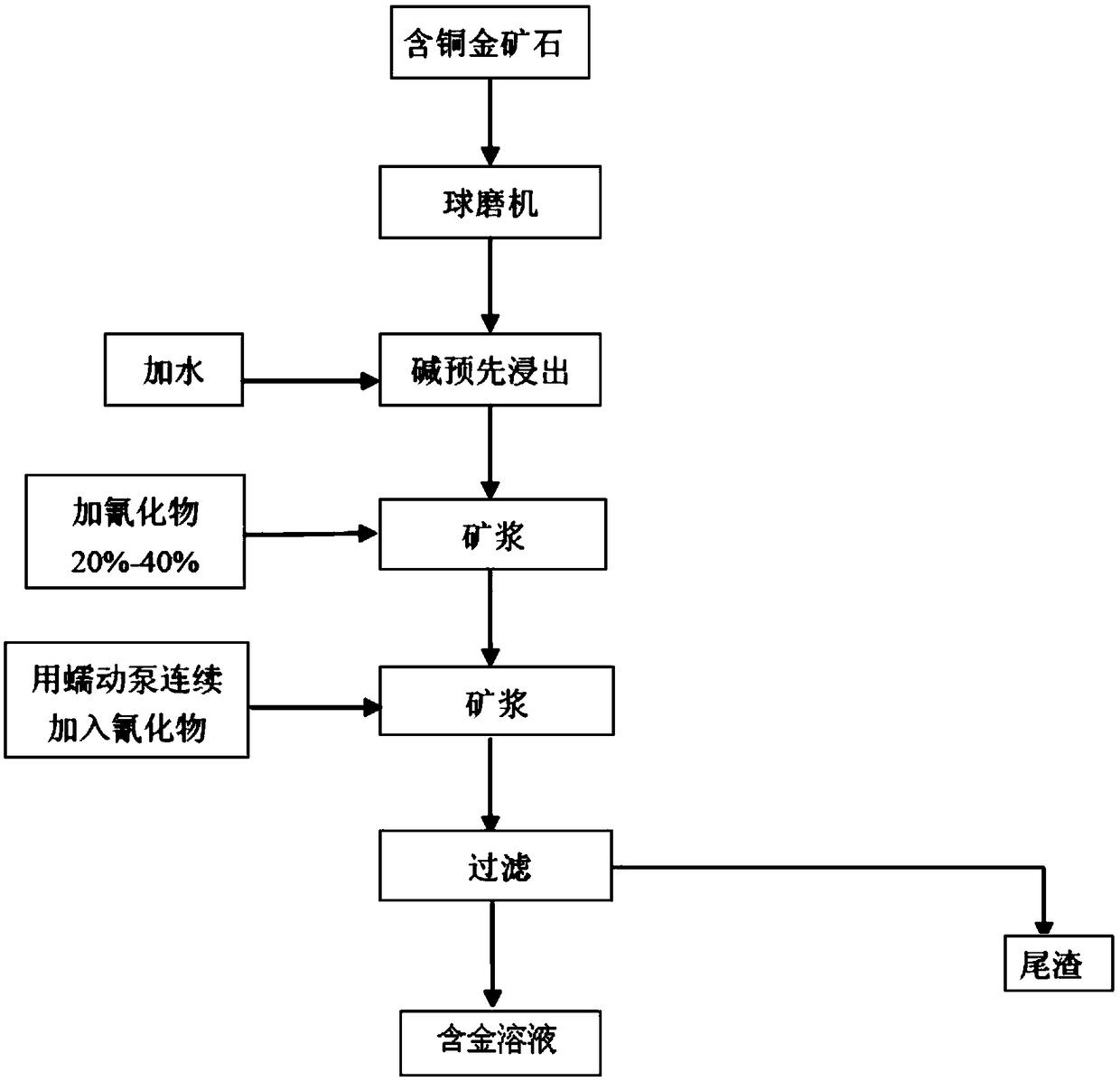

Method of adding chemical reagents continuously for cyanidation leaching copper-bearing gold ores by peristaltic pump in laboratory

InactiveCN108796240AGuaranteed leaching rateReduce consumptionProcess efficiency improvementPeristaltic pumpFiltration

The invention relates to a method of adding chemical reagents continuously for cyanidation leaching copper-bearing gold ores by a peristaltic pump in a laboratory and belongs to the technical field ofgold cyanidation of gold ores. The method comprises the following four steps of ore grinding, alkali pre-leaching, cyanidation leaching and filtration. According to the method provided by the invention, the addition of a cyanide solution is controlled effectively by means of the peristaltic pump under the circumstance of considering the gold leaching efficiency and the consumption of cyanide is reduced to the maximum extent, so that a cyanidation test tends to a mechanical dosing operation and the manual operating error is avoided. By means of the method, over 30% of the consumption of cyanide can be reduced effectively while the gold leaching efficiency is guaranteed. A charge pump is used in industrial production, the flow of the charge pump is expanded in proportion according to the flow of the peristaltic pump, and the consumption of cyanide can be reduced effectively by applying the method of adding the chemical reagents continuously for cyanidation leaching copper-bearing gold ores by the peristaltic pump in the laboratory to industrial production, so that the cost is saved and the environmental pressure is reduced.

Owner:JILIN JIEN NICKEL IND +2

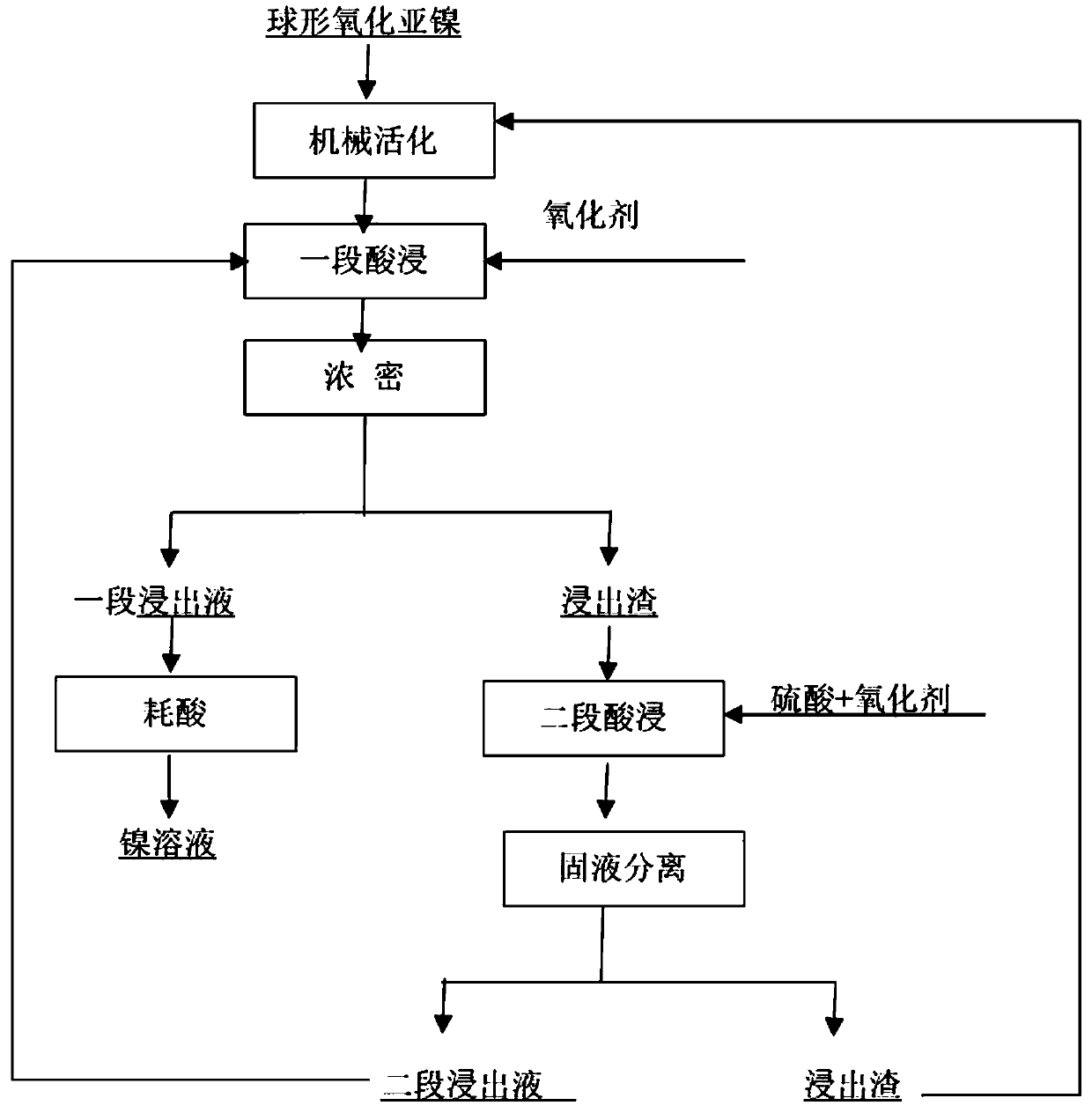

Spherical nickel protoxide segmented oxidation acid leaching treatment method

InactiveCN110607439AGuaranteed leaching ratePrevent crystallizationProcess efficiency improvementManganeseBiological activation

Owner:JINCHUAN GROUP LIMITED +1

Leaching equipment for producing potassium sulfate by using metallurgy dust mud

ActiveCN108640128AEasy to useAffect the leaching rateSulfate/bisulfate preparationEngineeringPotassium sulfate

The invention discloses leaching equipment for producing potassium sulfate by using metallurgy dust mud. The equipment comprises a base, a first supporting base and a second supporting base are fixedly arranged at the upper end of the base, and a leaching kettle is fixedly installed at the upper end of the first supporting base and comprises a first cylindrical structure at the upper end and a first spherical structure at the lower end; a feeding hopper is fixedly arranged on the side wall of the leaching kettle, a through hole is formed in the upper end of the leaching kettle, a sealing ballis movably arranged in the through hole, a buffer is fixedly connected to the upper end of the leaching kettle, and a supporting rack is fixedly connected to the outer side wall of the leaching kettle. According to the leaching equipment, a sulfuric acid solution can be controlled to flow into the leaching kettle intermittently, and the situation is avoided that a large amount of sulfuric acid isadded at a time, the local heat is too high, and accordingly the leaching rate of a potassium element is influenced; the leaching rate is guaranteed, sediment in the solution can be sufficiently filtered and adsorbed, the colors of other metal ions are eluted, it is guaranteed that potassium sulfate crystals which are prepared in the later period are better in color and luster, and the equipment is more convenient to use.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of electroplating sludge recycling process

InactiveCN104099474BReduce dosageGuaranteed leaching rateZinc sulatesSludge treatmentLiquid wasteSludge

The invention discloses an electroplating sludge recycling technology. The technology comprises the steps of acid dipping, iron removal, copper extraction, impurity removal, zinc extraction, nickel extraction, low acid leaching and high acid leaching, tailings are washed with water, the iron removal step is carried out through a sodium jarosite process, copper extraction adopts two stage extraction, two stage water washing, four stage back extraction, and second stage extraction is carried out after first stage extraction, precipitation, washing and acid dissolution. The technology has the advantages of technological period shortening, guarantee of the product purity through multiple stage extraction, effective use of the waste resource, and reduction of the emission of a waste liquid.

Owner:ZHENJIANG HUAKE ENVIRONMENTAL PROTECTION TECH

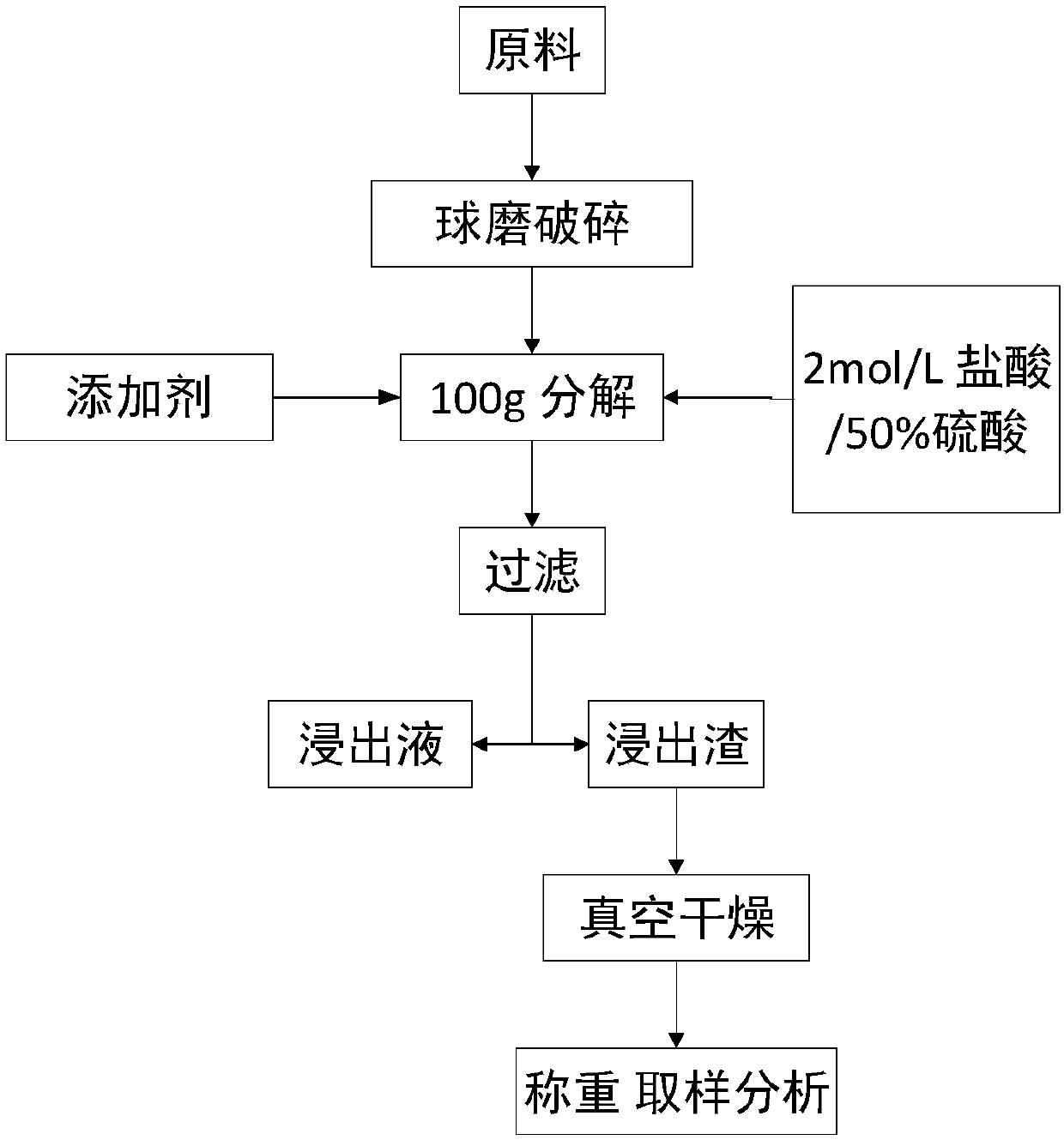

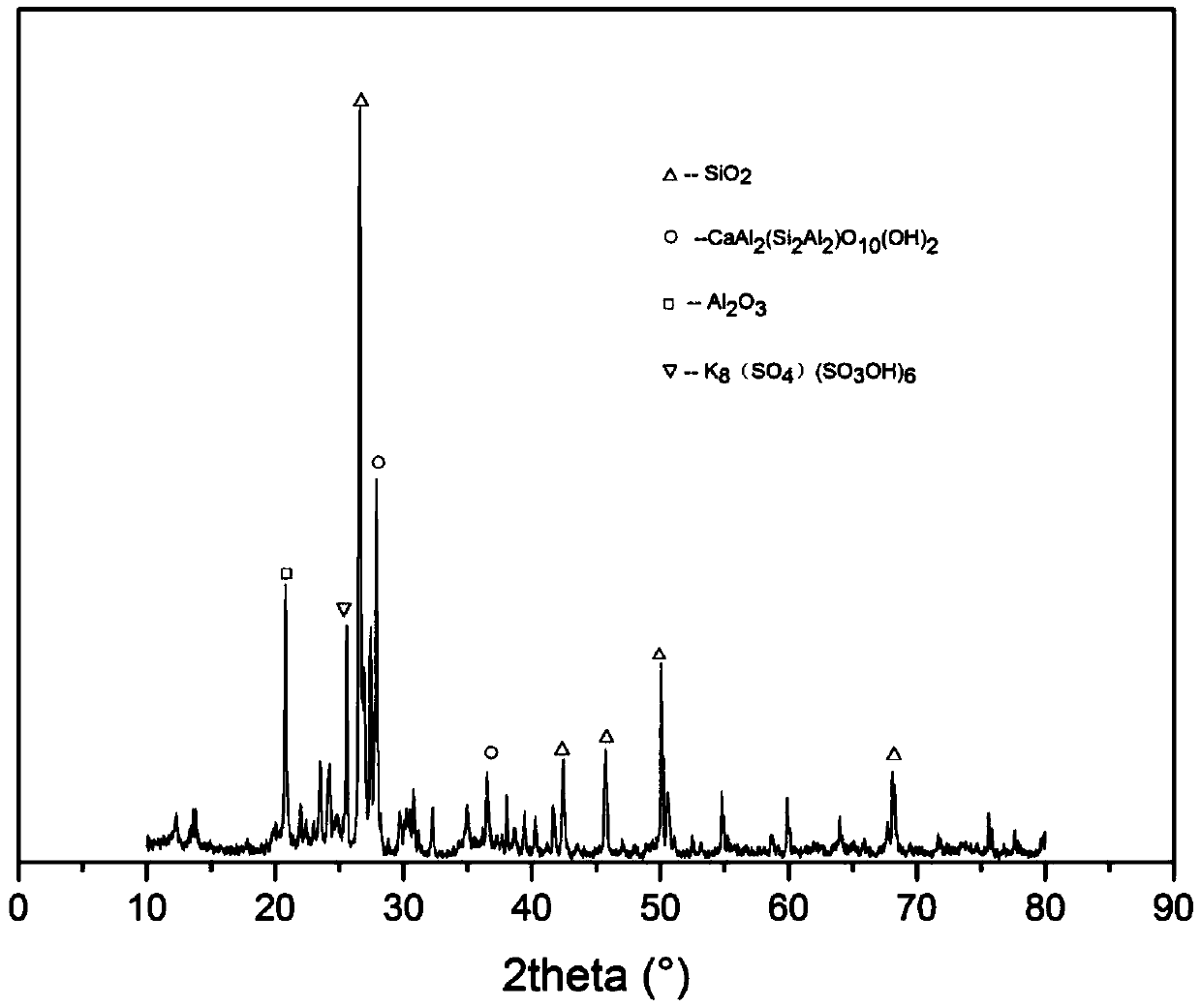

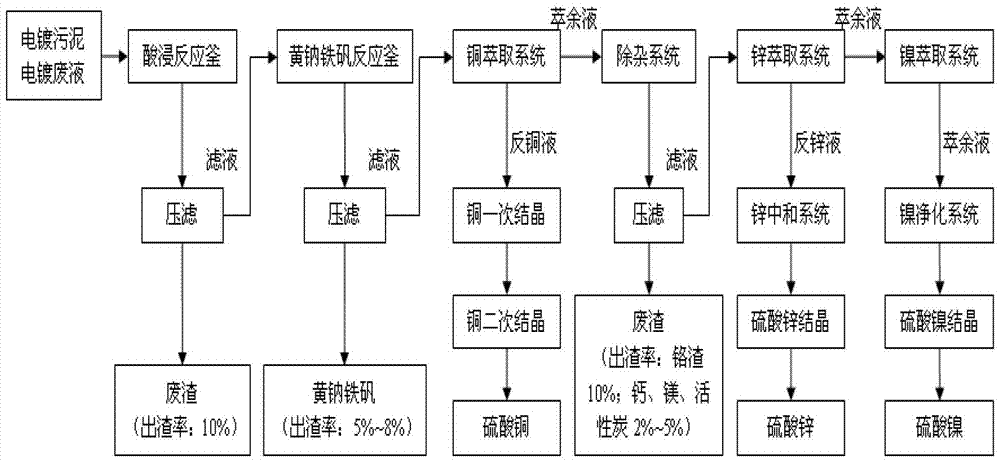

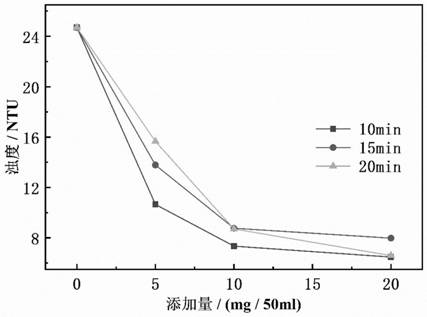

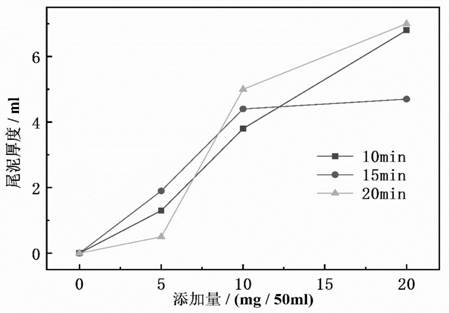

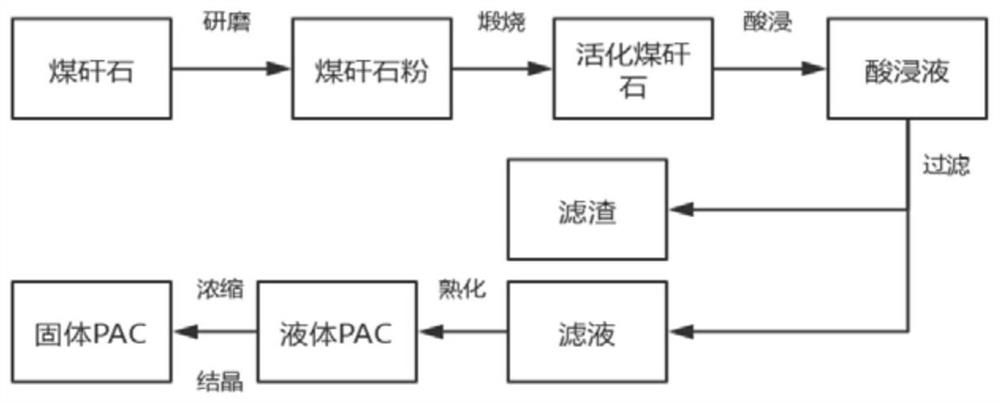

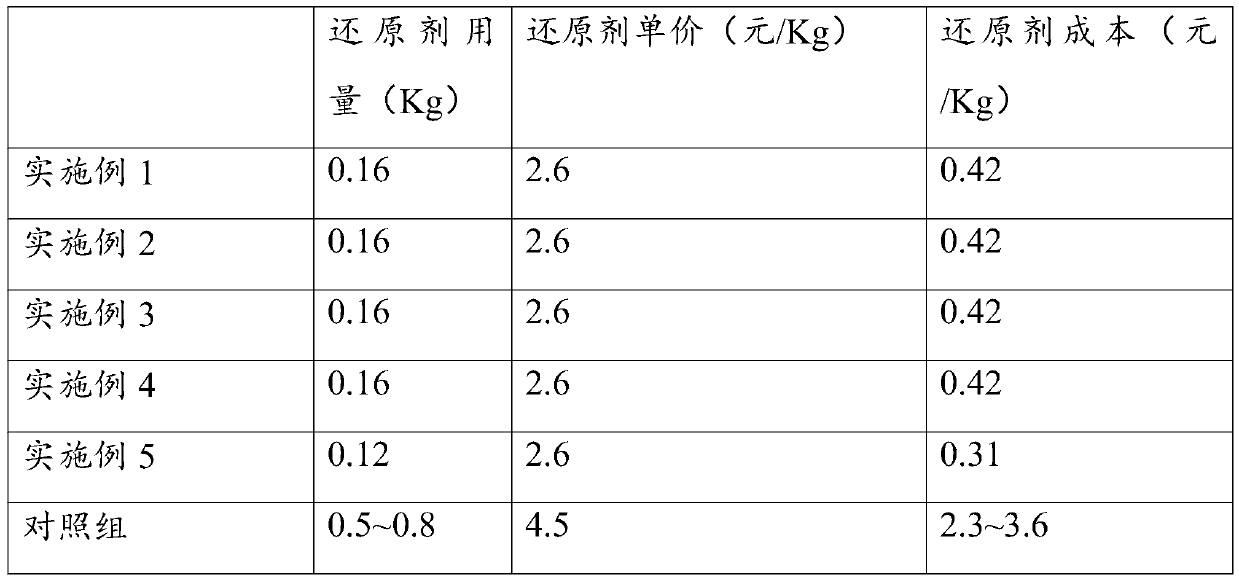

Polyaluminum chloride prepared from coal gangue by microwave hydrothermal method and method thereof

PendingCN112811453AEfficient flocculation effectGuaranteed leaching rateAluminium chloridesWater/sewage treatment by flocculation/precipitationPhysical chemistryEngineering

The invention relates to a method for preparing polyaluminum chloride from coal gangue by a microwave hydrothermal method. The raw materials consist of the following materials: 1-5g of coal gangue; 3-15 ml of 20% hydrochloric acid; the invention also discloses the preparation method which comprises the following steps: S1, crushing the coal gangue; s2, calcining and activating the coal gangue; s3, cooling; s4, mixing the materials; s5, microwave acid leaching; s6, filtering; s7, drying and weighing filter residues; s8, polymerizing and curing the filtrate; and S9, evaporating and crystallizing the sedimentation liquid. The method has the advantages that the polyaluminum chloride prepared from the coal gangue is easy in raw material obtaining and simple in process, the inorganic polymeric flocculant with high added value is prepared by properly processing the coal gangue, and compared with other acid leaching methods, the microwave method has the advantages that the acid leaching time is shortened from 1-3 h to 15 min, the solid-to-liquid ratio is reduced from 1: (3.5-7) to 1: 3, the cost is saved, the energy consumption is reduced, and the prepared product PAC can reduce the turbidity of domestic sewage of 24.740 NTU to 8.761 NTU, and the water purification effect is remarkable.

Owner:ANHUI UNIV OF SCI & TECH

Hingganite ore concentrate decomposition method

InactiveCN101492771BGuaranteed leaching rateImprove leaching rateProcess efficiency improvementNiobiumRare earth

A decomposition method of Xinganite ore concentrate comprises steps of mixing uniformly Xinganite ore concentrate, concentrated sulfuric acid and sulphate with weight ratio of 1:0.8-2.5:0.8-1.5, roasting at 180 DEG C to 400 DEG C for 0.5h to 8h, adding roasted material in water, at 20 DEG C to 80 DEG C, agitating for 0.5h to 3h, filtering and washing, thus lanthanon, beryllium, tantalum and niobium are contained in the solution. In the invention, the Xinganite ore concentrate, concentrated sulfuric acid and sulphate are roasted and composed, and lanthanon, beryllium, tantalum and niobium are leached out by water. In assurance of lanthanon leaching ratio, leaching ratios of beryllium, tantalum and niobium are improved. The lanthanon leaching ratio of the invention reaches 90% above, which prepares for next element separation.

Owner:GUANGDONG INST OF RARE METALS

A two-step method for the recovery of copper and gold from waste electronic materials

ActiveCN104073639BImprove the efficiency of leaching goldGuaranteed leaching rateProcess efficiency improvementChemical industryElectrolysis

The invention belongs to the fields of chemical industry and hydrometallurgy and in particular relates to a method for recycling copper and gold from a waste electronic material through a two-step method. The method comprises the following steps: firstly leaching ordinary metals out of the material in the presence of acidophilic microorganisms, recycling the copper from an acidophilic microorganism leaching solution by using an extraction electrolysis process; and subsequently leaching zero-valence gold out of residue in an acidic thiourea system and recycling thiourea gold by using active carbon or ion exchange resin method. The method has the advantages that the environment of the process for leaching copper out of the microorganisms is environment-friendly, pollution-free and low in cost; the materials can be recycled in a closed cycle mode; by virtue of the pretreatment materials of the microorganisms, higher gold-leaching efficiency of the acidic thiourea is achieved, a faster speed is achieved; reagents used in the gold-leaching system are non-toxic; and moreover, the copper-leaching efficiency can reach over 95% and the gold-leaching efficiency can reach over 90%.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Method for measuring gold in secondary utilization waste

PendingCN111579338AMeet needsAdapt to the development needs of green chemistryPreparing sample for investigationTesting metalsEnvironmental engineeringPotassium iodine

The invention relates to a method for measuring gold in secondary utilization waste, and belongs to the technical field of solid waste comprehensive utilization. The method comprises the steps of waste preparation, preparation of diluted hydrochloric acid extracting agent, stannous chloride and diluted hydrochloric acid are mixed to prepare a reducing agent; mixing the waste material with a diluted hydrochloric acid extracting agent and then carrying out leaching reaction; synchronously adding a stannous chloride solution reducing agent; the method comprises the following steps: taking gold-containing waste leachate, heating in a water bath, mixing the gold-containing waste leachate with a cyanide-free agent or an environment-friendly agent or an iodine-potassium iodide gold leaching solution, carrying out a leaching reaction, synchronously introducing micro-nano bubbles in the cyanide-free or environment-friendly leaching reaction to obtain gold-free waste leachate subjected to the leaching reaction, and calculating the leaching rate of gold according to a test result. The method has the advantages that the natural solubility of jarosite and stannate is brought into full play, andthe recovery rate of gold minerals is increased; a small amount of stannous chloride mixed solution is added as a reducing agent, the reaction is more sufficient and thorough through water bath heating, the leaching rate of gold minerals is ensured, and the gold recovery rate is high.

Owner:CHANGCHUN GOLD RES INST

Method for leaching manganese from electrolytic manganese anode residues through sulfuric acid curing

ActiveCN110846512AImprove leaching rateAchieve leaching separationProcess efficiency improvementClinker (waste)Manganese

The invention discloses a method for leaching manganese from electrolytic manganese anode residues through sulfuric acid curing. The method specifically includes the following steps that the electrolytic manganese anode residues, sulfur powder and concentrated sulfuric acid are weighed according to requirements and used for standby application; the sulfur powder and the concentrated sulfuric acidare added in the electrolytic manganese anode residues and evenly mixed, and clinker is obtained through the curing reaction; and water is added in the clinker to conduct leaching, and a manganese-contained leaching solution and leaching residues are obtained after liquid-solid separation. The method has the advantages that the source of reducing agents is wide, the price is low, the process is simple, the manganese leaching rate is high, the operation cost is low and no secondary waste residue pollution or waste gas pollution is caused, and the problems that in the prior art, the manganese leaching cost is high and secondary pollution is generated in the leaching process can be effectively solved.

Owner:JISHOU UNIVERSITY

A nitric acid selective leaching method for low-nickel high-iron alloy powder

ActiveCN107338357BReduce consumptionSelective leaching achievedProcess efficiency improvementSlagFiltration

The invention discloses a method for leaching low-nickel high-iron alloy powder selectively through nitric acid. The method comprises the steps that firstly, primary leaching is conducted on the low-nickel high-iron alloy powder through the concentrated nitric acid; when total immersion is ended, magnetic separation is conducted; magnetic separation concentrate is returned for further leaching, so that after remaining ore pulp is filtered, leaching residues and a leaching solution are obtained, and the leaching solution enters a neutralization-for-iron-removal procedure; the low-nickel high-iron alloy powder is added to the leaching solution, so that neutralization for iron removal is conducted; after a neutralization-for-iron-removal reaction is ended, magnetic separation is conducted; magnetic separation concentrate is returned to the primary total immersion procedure, so that after ore pulp is filtered, neutralization iron slag and a separation and immersion solution are obtained; and the neutralization iron slag obtained after filtration is subjected to washing, drying and calcinations, so that an iron ore concentrate product with the iron content ranging from 60% to 65% is obtained. By means of the method, nickel and cobalt leaching and iron removal are completed through one step, and selective leaching of nickel, cobalt and iron is achieved; the nickel and the cobalt enter the solution, and the iron is inhibited in the slag, so that the nickel and the cobalt are effectively separated from the iron; and the leaching rate of the nickel and the cobalt is greater than 98%; the nickel content of the leaching residues is less than 0.5%, the iron content of the leaching residues is less than 10%, and the cobalt content of the leaching residues is less than 0.02%; the iron content of the neutralization iron slag is greater than 50%, and the nickel content o the neutralization iron slag is less than 0.1%; and the iron content of the separation and immersion solution is less than 3 g / L.

Owner:JINCHUAN GROUP LIMITED

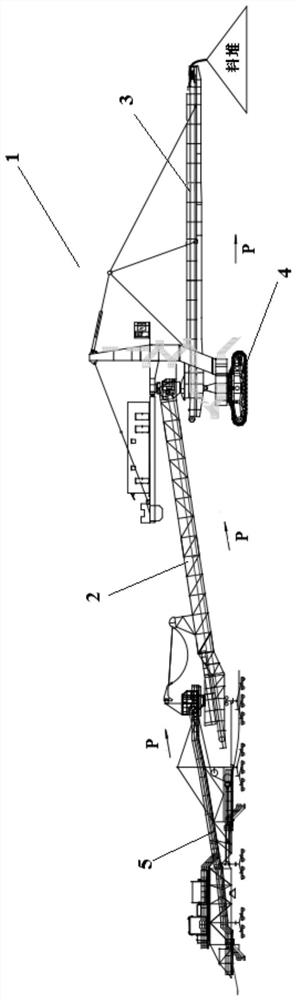

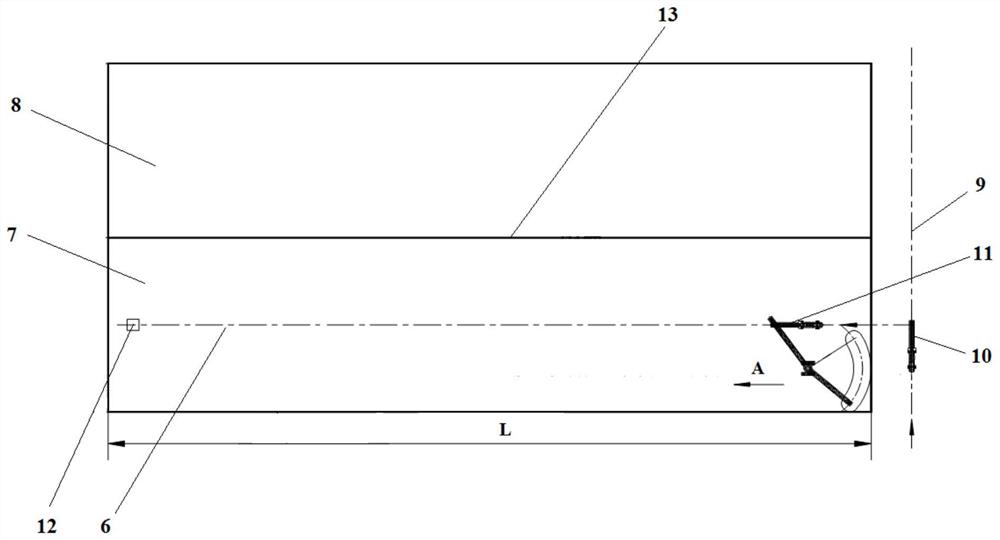

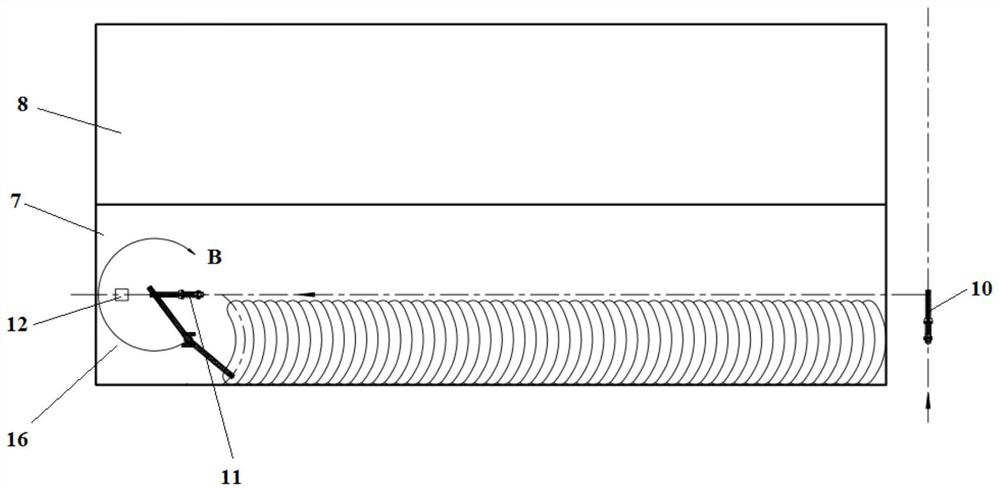

Heaping method using dumping plough for mine dump leaching field

ActiveCN111961846AReduce the frequency of relocationIncrease usageProcess efficiency improvementDump leachingHeap leaching

The invention discloses a heaping method using a dumping plough for a mine dump leaching field. The heaping method comprises the following steps of S1, firstly, a double-side heaping step is executedby using the dumping plough, specifically, heaping is carried out continuously on two sides of a first moving sealing-tape machine by using the dumping plough to form a first dump leaching unit, wherein the first heap leaching unit comprises two parallel material piles formed by stacking materials, and a safe distance is reserved between the two parallel material piles so as to form a valley bottom part clamped between the two parallel material piles; S2, a moving step is executed, specifically, the dumping plough and the first moving sealing-tape machine are moved out of the two ends of the valley bottom part correspondingly, and then the dumping plough and the first moving sealing-tape machine are moved to a site where another second heap leaching unit is formed; and S3, the double-sideheaping step S1 and the moving step S2 are repeatedly executed. According to the method, heaping is conducted through the dumping plough with a crawler belt, double-side heaping can be moved at a time, and the moving frequency is reduced.

Owner:TAIYUAN HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com