Processing device for edible oil preparation

A processing device and edible oil technology, which are applied in the fields of edible oil/fat, application, food science, etc., can solve the problems of reducing the quality and work efficiency of soybean oil leaching, complicated soybean oil extraction procedures, and thick soybean billet material layer, etc. To achieve the effect of eliminating the need for filtering bean dregs, improving the leaching effect and increasing the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

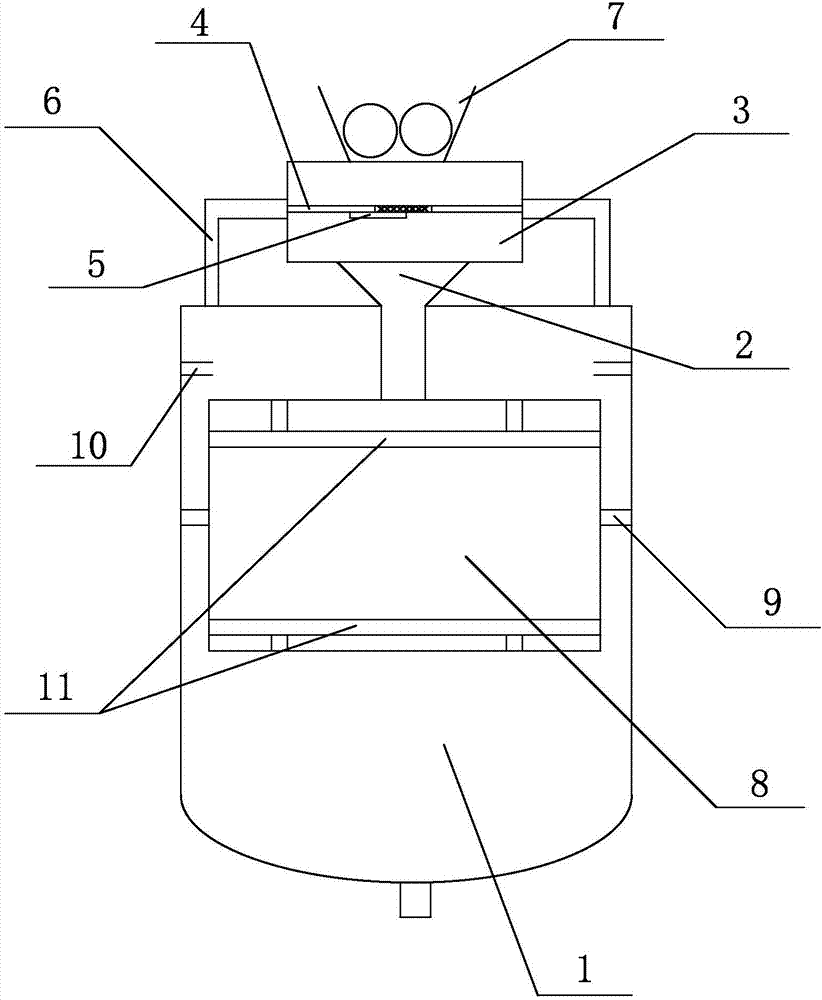

[0022] Such as figure 1 As shown, the processing device for edible oil preparation of the present invention includes a leaching kettle body 1, a feed inlet 2 is provided above the leaching kettle body 1, a liquid outlet 10 is provided below, and a sieve is provided above the feed inlet 2 Material box 3, the screen material box 3 is provided with a partition 4, the center of the partition 4 is provided with an opening, the opening is provided with a filter screen, the bottom of the partition 4 is slidably connected with a horizontally moving closing plate 5, closed The size of the plate 5 is larger than the size of the filter screen. A hopper 7 is arranged above the sieve box 3, and a crushing roller is arranged in the hopper. The hopper 7 communicates with the sieve box 3 through a valve arranged on the top of the sieve box 3. A rotating rod 6 is connected to the material box 3, and the rotating rod drives the sieve material box 3 to rotate around its own axis. The leaching ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com