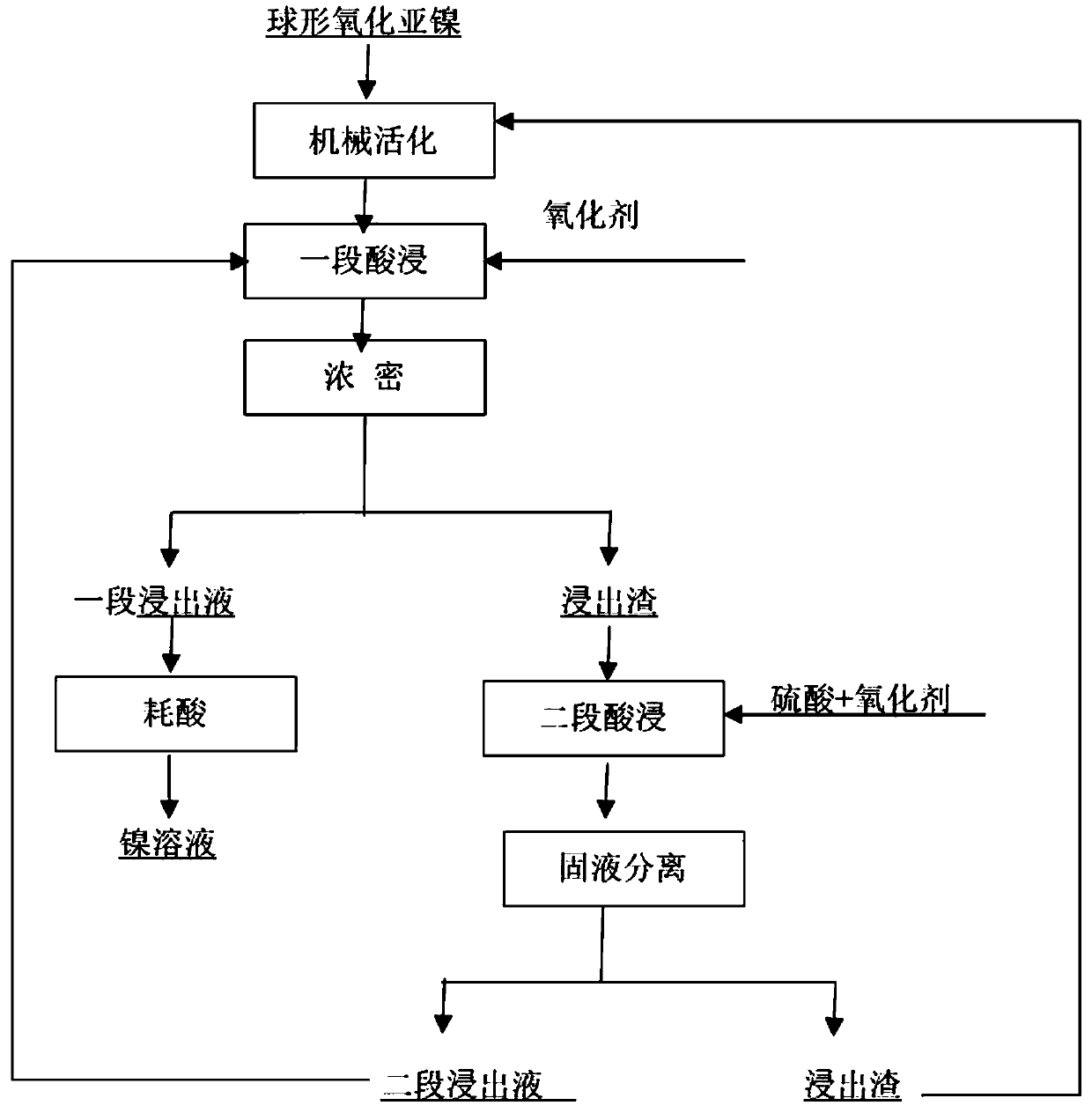

Spherical nickel protoxide segmented oxidation acid leaching treatment method

A technology of nickelous oxide and a treatment method, applied in the chemical industry, can solve the problems of difficulty in utilizing large-particle nickelous oxide and high processing cost, and achieve the effects of significant economic and social benefits, short technological process, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A segmented oxidative acid leaching treatment method for spherical nickelous oxide, using a ball mill to mechanically activate the spherical granular nickelous oxide raw material to a material particle size of about 20 μm, 10m 3 There are two stages of leaching in the reaction kettle, among which 4.5mol / L sulfuric acid is used in the second stage reaction kettle, 2.0mol / L sulfuric acid is added in the first stage, and the temperature is raised to 100°C, and mechanically activated nickelous oxide is added in the first stage reaction kettle, and the flow rate is 2.3t / h, secondary acid addition, sulfuric acid flow rate 1.62m 3 / h, pure water flow 4.92m 3 / h, no acid is added at the first stage, only water is added, and the water flow rate is 8.2m 3 / h, keeping the acidity of the leaching solution unchanged, leaching for 0.5h, adding sodium persulfate in the two stages of leaching, and the flow rate of 20% sodium persulfate is 1.1m 3 / h, after the first-stage leaching is...

Embodiment 2

[0031] A segmented oxidative acid leaching treatment method for spherical nickelous oxide, using a ball mill to mechanically activate spherical granular nickelous oxide raw materials until the particle size of the material is about 30 μm, 10m 3 Two-stage leaching of the reaction kettle, wherein, the second-stage reaction kettle is 3.5mol / L sulfuric acid, the first-stage reaction kettle is added with 2.5mol / L sulfuric acid, and the temperature is raised to 90°C, and the first-stage reaction kettle is added with mechanically activated nickelous oxide, and the flow rate is 0.72 t / h, secondary acid addition, sulfuric acid flow rate 0.51m 3 / h, pure water flow 1.87m 3 / h, no acid is added at the first level, only water is added, and the water flow is 1.87m 3 / h, to maintain the acidity of the leaching solution, leaching for 2h, adding hydrogen peroxide in the two stages of leaching, and the flow rate of 30% sodium persulfate is 0.35m 3 / h, add mechanically activated nickelous oxid...

Embodiment 3

[0033] A segmented oxidative acid leaching treatment method for spherical nickelous oxide, using a ball mill to mechanically activate the spherical granular nickelous oxide raw material to a material particle size of about 50 μm, 10m 3 There are two stages of leaching in the reaction kettle, among which 4.5mol / L sulfuric acid is used in the second stage reaction kettle, 3.5mol / L sulfuric acid is added in the first stage, and the temperature is raised to 85°C, and mechanically activated nickelous oxide is added in the first stage reaction kettle, and the flow rate is 0.67t / h, secondary acid addition, sulfuric acid flow rate 0.48m 3 / h, pure water flow 1.44m 3 / h, no acid is added at the first stage, only water is added, and the water flow rate is 0.59m 3 / h, to maintain the acidity of the leaching solution, add hydrogen peroxide during the two-stage leaching process, and the flow rate of 30% sodium persulfate is 0.67m 3 / h, leaching for 3h. After thickening with a thickener,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com