Leaching equipment for producing potassium sulfate by using metallurgy dust mud

A technology of metallurgical dust and potassium sulfate, applied in the field of metallurgical dust, can solve the problems of high local heat affecting the leaching rate of potassium element, incomplete adsorption and decolorization, and affecting use, so as to ensure the leaching rate, promote the leaching of potassium ions, and improve the color Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

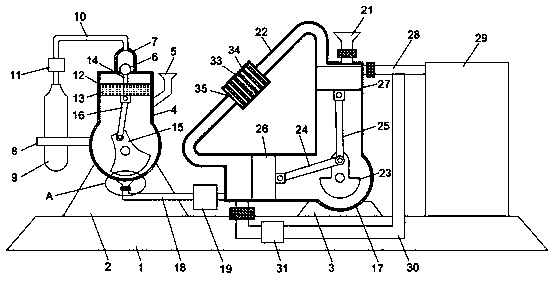

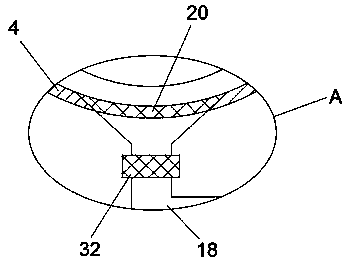

[0020] refer to Figure 1-2 , a leaching device for producing potassium sulfate by using metallurgical dust and mud, comprising a base 1, a first support base 2 and a second support base 3 are fixedly installed on the upper end of the base 1, a leaching kettle 4 is fixedly installed on the upper end of the first support base 2, and the leaching The kettle 4 includes a first cylindrical structure at the upper end and a first spherical structure at the lower end, and the first cylindrical structure communicates with the first spherical structure. The side wall of the leaching kettle 4 is fixed with a feed hopper 5, and the upper end of the leaching kettle 4 is provided with a There is a through hole, a closed ball 6 is movable inside the through hole, a buffer 7 is fixedly connected to the upper end of the leaching kettle 4, and the closed ball 6 is located inside the buffer 7, and the closed ball 6 is made of a shot ball center wrapped with a layer of glass material. The extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com