Polyaluminum chloride prepared from coal gangue by microwave hydrothermal method and method thereof

A technology of microwave hydrothermal method and polyaluminum chloride is applied in the application field of coal gangue, which can solve the problems of increasing reaction time, long preparation period, long activation time, etc., so as to reduce the amount of acid, shorten the production period, and shorten the reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

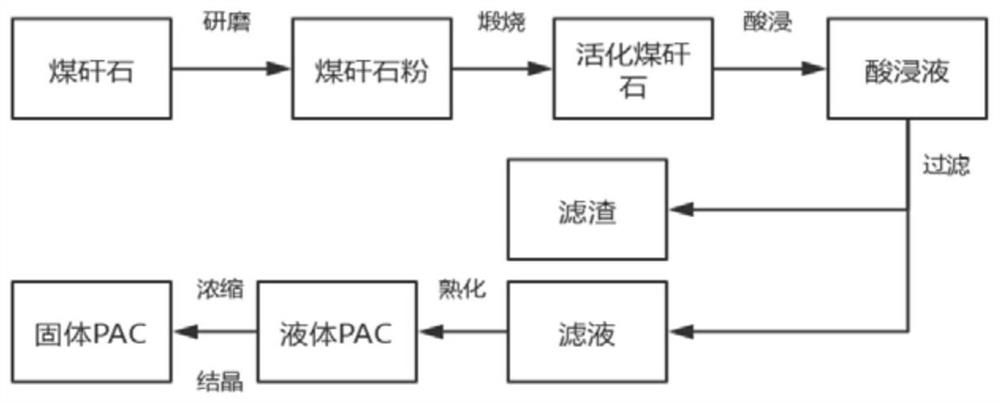

Embodiment 1

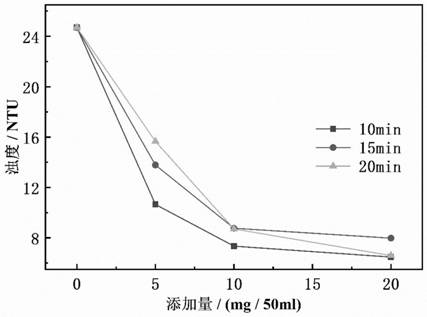

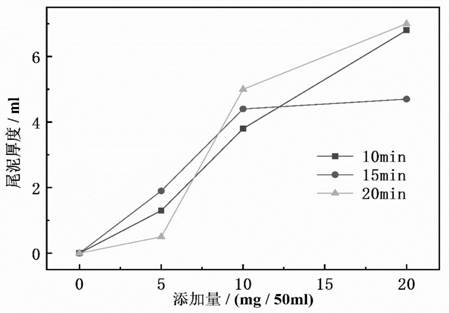

[0040] Get 2.5g of coal gangue mixed with 7.5ml of hydrochloric acid, put it into a microwave digestion tank, process it in a microwave oven for 5 minutes, take it out, filter after cooling, wash the filter residue with deionized water when filtering, control the amount of deionized water, and ensure the filtrate. The amount is 37.5ml, then the filter residue is dried and weighed in a constant temperature box, and the data is recorded. The filtrate is placed in a constant temperature water bath at 100°C, stirred and polymerized with a stirrer for 1.5h, and then continued to mature for 1.5h. Evaporate and crystallize at 95°C. After all the water is evaporated to dryness, lower the temperature to 75°C and continue drying for 30 minutes to obtain solid polyaluminum chloride.

[0041] After weighing, 0.849 g of polyaluminum chloride was obtained, and the extraction rate of alumina in coal gangue was 31.4%. 50ml of domestic sewage was treated with 10mg of polyaluminum chloride, and...

Embodiment 2

[0043] Get 2.5g of coal gangue mixed with 7.5ml of hydrochloric acid, put it into a microwave digestion tank, process it in a microwave oven for 10min, take it out, filter after cooling, wash the filter residue with deionized water during filtration, control the amount of deionized water, and ensure the filtrate The amount is 37.5ml, then the filter residue is dried and weighed in a constant temperature box, and the data is recorded. The filtrate is placed in a constant temperature water bath at 100°C, stirred and polymerized with a stirrer for 1.5h, and then continued to mature for 1.5h. Evaporate and crystallize at 95°C. After all the water is evaporated to dryness, lower the temperature to 75°C and continue drying for 30 minutes to obtain solid polyaluminum chloride.

[0044] After weighing, 1.492 g of polyaluminum chloride was obtained, and the extraction rate of alumina in coal gangue was 64.0%. 50ml of domestic sewage was treated with 10mg of polyaluminum chloride, and the...

Embodiment 3

[0046] Get 2.5g of coal gangue mixed with 7.5ml of hydrochloric acid, put it into a microwave digestion tank, process it in a microwave oven for 15min, take it out, filter after cooling, wash the filter residue with deionized water when filtering, control the amount of deionized water, and ensure the filtrate. The amount is 37.5ml, then the filter residue is dried and weighed in a constant temperature box, and the data is recorded. The filtrate is placed in a constant temperature water bath at 100°C, stirred and polymerized with a stirrer for 1.5h, and then continued to mature for 1.5h. Evaporate and crystallize at 95°C. After all the water is evaporated to dryness, lower the temperature to 75°C and continue drying for 30 minutes to obtain solid polyaluminum chloride.

[0047] After weighing, 1.816 grams of polyaluminum chloride was obtained, and the extraction rate of alumina in coal gangue was 80.8%. 50ml of domestic sewage was treated with 10mg of polyaluminum chloride, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com