Method for producing polyaluminum sulfate by using aluminum ash

A technology for polymerizing aluminum sulfate and aluminum ash, which is applied in the direction of aluminum sulfate, aluminum sulfur compounds, chemical instruments and methods, etc., can solve problems such as unsatisfactory flocculation effect, poor product stability, complicated preparation process, etc., and achieve improved flocculation effect, adsorption Improved performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

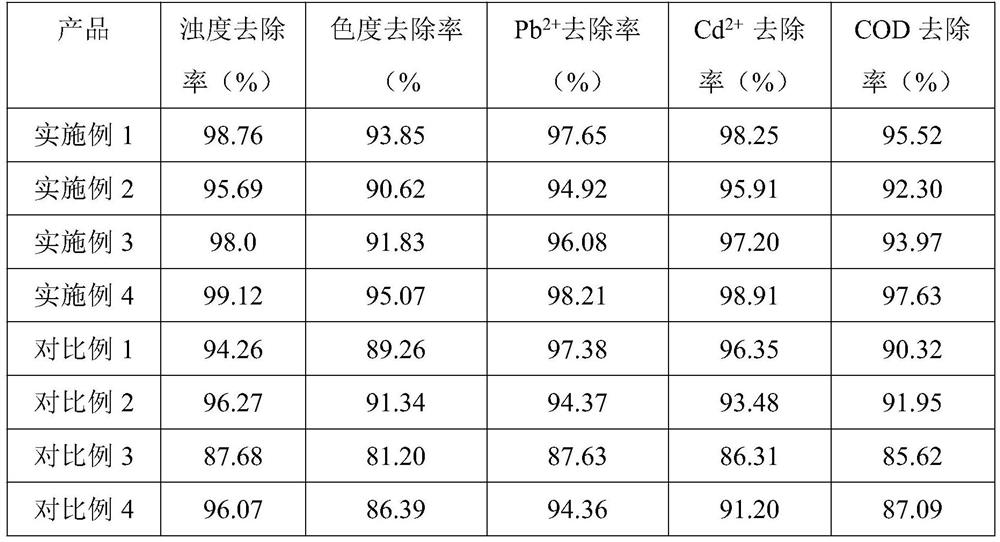

Examples

Embodiment 1

[0026] A kind of method utilizing aluminum ash to produce polyaluminum sulfate, comprises the steps:

[0027] S1: After the aluminum ash is ground, add water that is 4 times the weight of the aluminum ash and stir and mix to obtain an aluminum ash suspension, add calcium chloride and 1.8% calcium acetate that are 3.5% of the quality of the aluminum ash to the suspension, and After denitrification and fluorine removal at 50°C for 45 minutes, solid-liquid separation is carried out, and the separated solid is harmless aluminum ash;

[0028] S2: Add 1.3 tons of harmless aluminum ash, 1.8 tons of concentrated sulfuric acid and 8 tons of water into the reactor, react at a temperature of 100°C for 3 hours, cool down to 60°C, and then add 8kg of stabilizer, 12kg of polyethylene glycol and sixteen Alkyltrimethylammonium bromide 4.5kg, described stabilizing agent is made up of sodium metaaluminate, phytic acid and ammonium dihydrogen phosphate that mass ratio is 5:2:3, stirs 1h, gets al...

Embodiment 2

[0032] A kind of method utilizing aluminum ash to produce polyaluminum sulfate, comprises the steps:

[0033] S1: After the aluminum ash is ground, add water that is 5 times the weight of the aluminum ash and stir and mix to obtain an aluminum ash suspension, add calcium chloride and 1.3% calcium acetate that are 4.2% of the quality of the aluminum ash in the suspension, and Reaction at 60°C for 40 minutes to remove nitrogen and fluorine, and then conduct solid-liquid separation, the separated solid is harmless aluminum ash;

[0034] S2: Add 1.15 tons of harmless aluminum ash, 1.6 tons of concentrated sulfuric acid and 6 tons of water into the reactor, react at a temperature of 100°C for 2.5 hours, cool down to 70°C, and then add 7kg of stabilizer, 10kg of polyethylene glycol and ten Hexaalkyltrimethylammonium bromide 3kg, described stabilizing agent is made up of sodium metaaluminate, phytic acid and ammonium dihydrogen phosphate that mass ratio is 7:2:5, stirs 1.5h, gets alu...

Embodiment 3

[0038] A kind of method utilizing aluminum ash to produce polyaluminum sulfate, comprises the steps:

[0039] S1: After the aluminum ash is ground, add water that is 4.5 times the weight of the aluminum ash and stir and mix to obtain an aluminum ash suspension, add calcium chloride and 1.8% calcium acetate that are 3.8% of the aluminum ash quality in the suspension, and After denitrification and fluorine removal at 50°C for 60 minutes, solid-liquid separation is carried out, and the separated solid is harmless aluminum ash;

[0040] S2: Add 1.5 tons of harmless aluminum ash, 2.0 tons of concentrated sulfuric acid and 8 tons of water into the reactor, react at a temperature of 120°C for 3 hours, cool down to 80°C, and then add 5kg of stabilizer, 12kg of polyethylene glycol and sixteen Alkyltrimethylammonium bromide 4kg, described stabilizing agent is made up of sodium metaaluminate, phytic acid and ammonium dihydrogen phosphate that mass ratio is 5:2:5, stirs 1h, gets aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com