Novel technology for roasting cobalt sulfide copper ore through sulfating

A technology of sulfate roasting and acid roasting, which is applied in the roasting field of cobalt-copper sulfide ore, which can solve the problems of difficult filtration, poor effect, and many copper ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

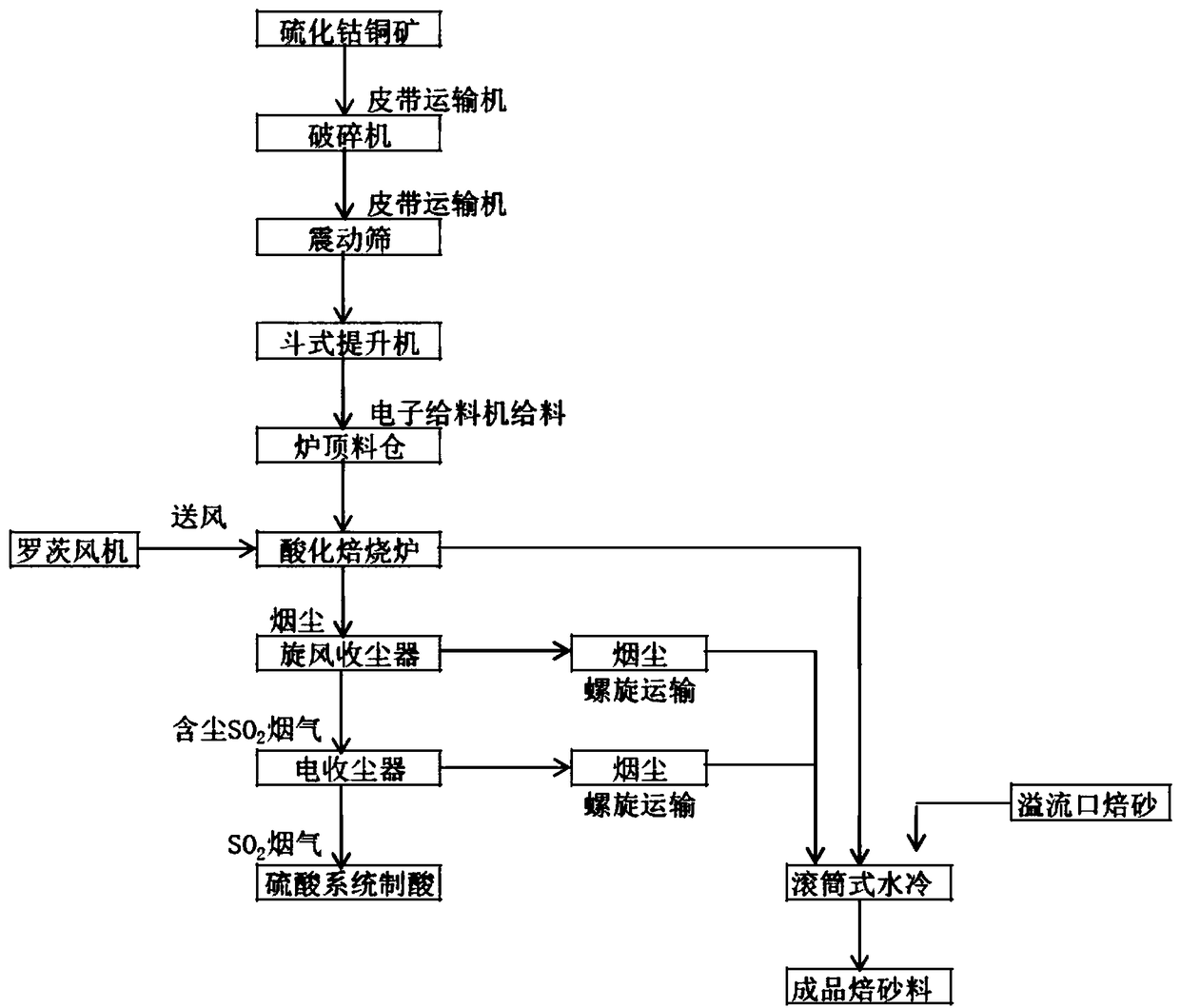

Image

Examples

Embodiment 1

[0028] The content of the main components of a certain batch of cobalt-copper sulfide ore is as follows:

[0029] analysis element

co

Cu

mn

Mg

Fe

Al

Cd

Cr

Ca

Zn

Ni

Pb

Cl

S

content(%)

5.39

22.92

0.0076

0.84

20.87

0.21

0.001

0.005

1.02

0.021

0.19

0.0097

0.001

22

[0030] Because the sulfur content in cobalt copper sulfide ore is high, sulfur combustion releases a lot of heat when roasting in the furnace, and the temperature in the furnace needs to be controlled at 640°C ± 50°C to maintain acidified roasting conditions, so heat exchange tubes are installed in the furnace. Take away part of the heat to maintain a stable temperature in the furnace. When the acidizing furnace is in normal production, the pressure in the furnace should be stabilized to ensure that the pressure in the furnace is 2100-2400 mm water column, and the oxygen concentration of the flue gas at th...

Embodiment 2

[0042] The content of the main components of a certain batch of cobalt-copper sulfide ore is as follows:

[0043] analysis element

co

Cu

mn

Mg

Fe

Al

Cd

Cr

Ca

Zn

Ni

Pb

Cl

S

content(%)

5.42

23.1

0.008

0.91

20.21

0.2

0.001

0.004

1.00

0.020

0.18

0.0099

0.001

22.1

[0044]Because the sulfur content in cobalt copper sulfide ore is high, sulfur combustion releases a lot of heat when roasting in the furnace, and the temperature in the furnace needs to be controlled at 640°C ± 50°C to maintain acidified roasting conditions, so heat exchange tubes are installed in the furnace. Take away part of the heat to maintain a stable temperature in the furnace. When the acidizing furnace is in normal production, the pressure in the furnace should be stabilized to ensure that the pressure in the furnace is 2100-2400 mm water column, and the oxygen concentration of the flue gas at the ...

Embodiment 3

[0056] The content of the main components of a certain batch of cobalt-copper sulfide ore is as follows:

[0057] analysis element

co

Cu

mn

Mg

Fe

Al

Cd

Cr

Ca

Zn

Ni

Pb

Cl

S

content(%)

5.22

22.84

0.0070

0.81

20.89

0.22

0.001

0.006

1.03

0.022

0.18

0.01

0.001

22.2

[0058] Because the sulfur content in cobalt copper sulfide ore is high, sulfur combustion releases a lot of heat when roasting in the furnace, and the temperature in the furnace needs to be controlled at 640°C ± 50°C to maintain acidified roasting conditions, so heat exchange tubes are installed in the furnace. Take away part of the heat to maintain a stable temperature in the furnace. When the acidizing furnace is in normal production, the pressure in the furnace should be stabilized to ensure that the pressure in the furnace is 2100-2400 mm water column, and the oxygen concentration of the flue gas at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com