Lithium battery waste recycling method and application thereof

A lithium battery and waste technology, applied in the field of lithium battery waste recycling, can solve problems such as high requirements and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

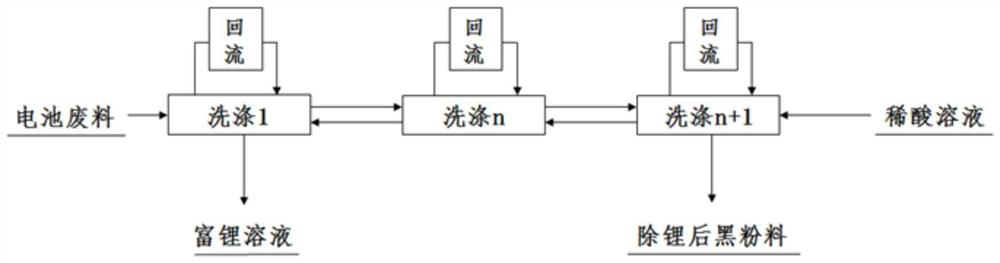

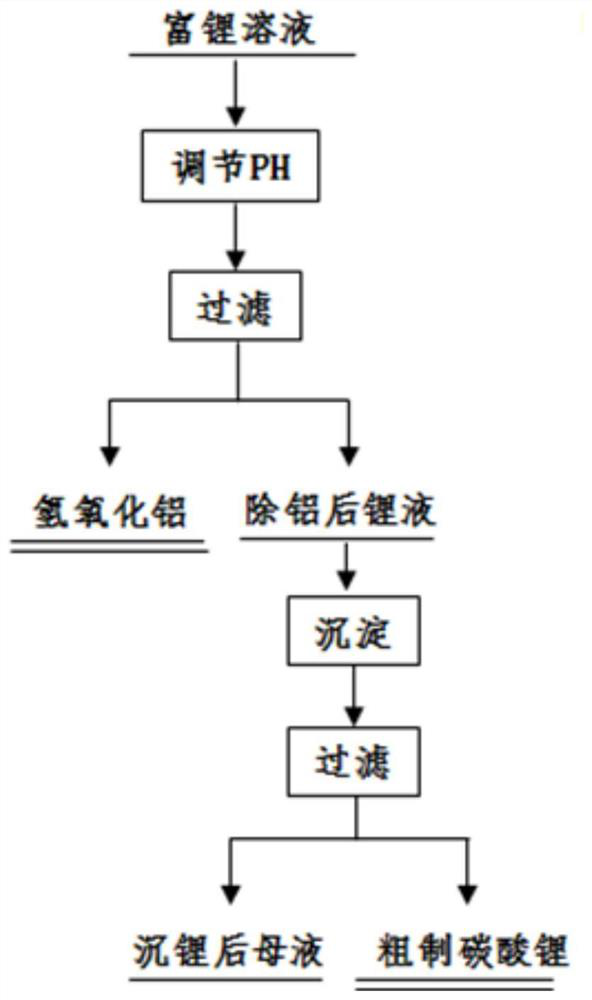

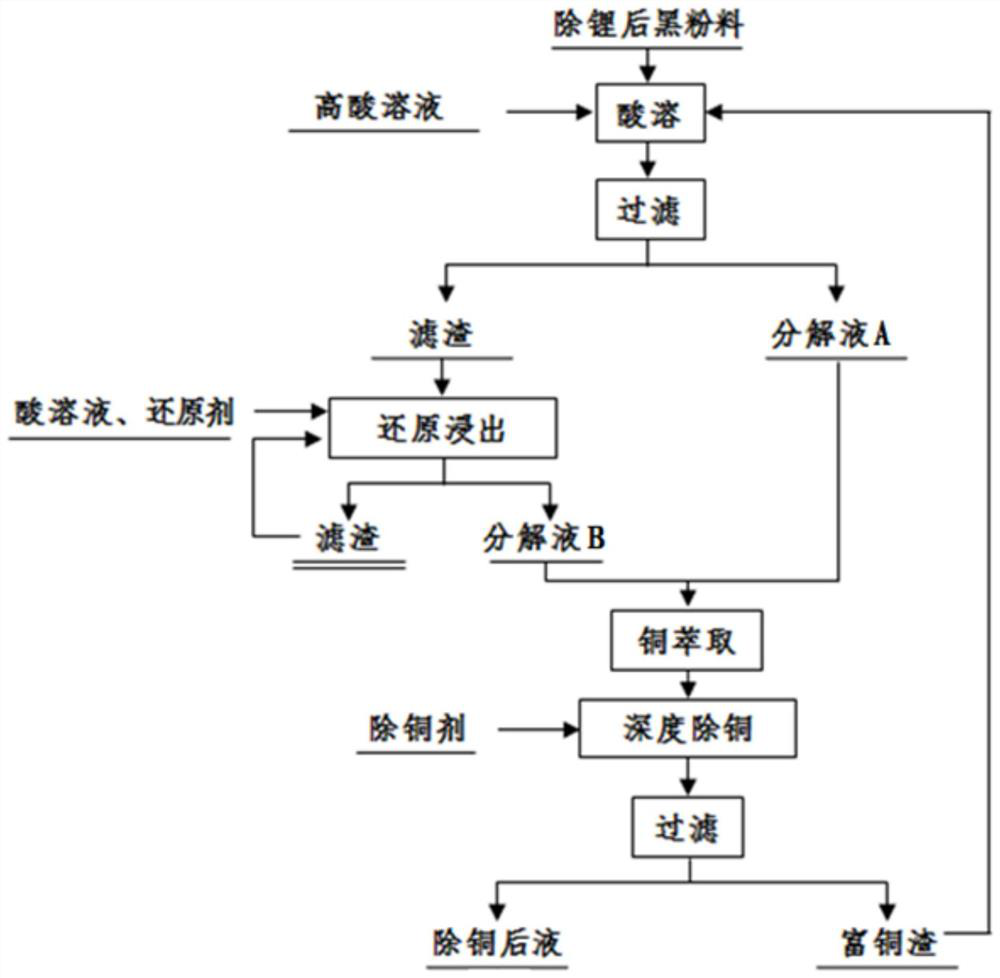

[0112] Such as Figure 1~4 Shown: figure 1 It is a schematic diagram of the technological process of performing multi-stage countercurrent washing on the reduced and calcined battery waste to obtain the lithium-rich solution and the black powder after lithium removal in this embodiment; figure 2 The schematic diagram of the technological process that the present embodiment utilizes the lithium-rich solution to reclaim aluminum hydroxide and crude lithium carbonate; image 3 It is a schematic diagram of the technological process of sequentially performing acid leaching, reduction leaching and copper ion removal on the black powder after lithium removal in this embodiment; Figure 4 It is a schematic diagram of the process flow for magnesium removal and cobalt-nickel-manganese mixed salt crystallization in this embodiment.

[0113] A method for recycling lithium battery waste, said method comprising the following steps:

[0114] (1) After the lithium battery waste is obtaine...

Embodiment 2

[0141] A method for recycling lithium battery waste, said method comprising the following steps:

[0142] (1) After the lithium battery waste is obtained, it is discharged and crushed into particles with a particle size of 180 μm; then hydrogen or natural gas is introduced at 700 ° C for reduction and calcination for 6 hours, and the ventilation rate is 5 m 3 / h. After calcining, the material is crushed and sieved to obtain particles with a particle size of 120 μm;

[0143] Using the countercurrent washing method to carry out multi-stage counter-current washing on the battery waste after the reduction and calcination treatment, using 4-stage washing, the initial solution is a weakly acidic pH=6 sulfuric acid solution, and the end point is pH=10 after multi-stage washing. The solid-to-liquid ratio is controlled by the pH value to 1:3 (the aqueous solutions at all levels are set to reflux to prevent the high impurity content caused by pH fluctuations). The leaching rate of lit...

Embodiment 3

[0169] A method for recycling lithium battery waste, said method comprising the following steps:

[0170] (1) After the lithium battery waste is obtained, it is discharged and crushed into particles with a particle size of 180 μm; then hydrogen or natural gas is introduced at 500°C for reduction and calcination for 4 hours, and the ventilation rate is 15m 3 / h. After calcining, the material is crushed and sieved to obtain particles with a particle size of 150 μm;

[0171] Using the countercurrent washing method to carry out multi-stage counter-current washing on the battery waste after the reduction and calcination treatment, using 4-stage washing, the initial solution is a weakly acidic pH=8 sulfuric acid solution, and the end point is pH=12 after multi-stage washing. The solid-to-liquid ratio is controlled by the pH value to 1:5 (the aqueous solutions at all levels are set to reflux to prevent the high impurity content caused by pH fluctuations). The leaching rate of lithi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com