Method for safely leaching waste batteries and application

A waste battery and leaching technology, which is applied in battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of excessive aluminum content, unsafe hydrogen gas, and inability to remove aluminum, so as to reduce the adhesion performance and improve safety , the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

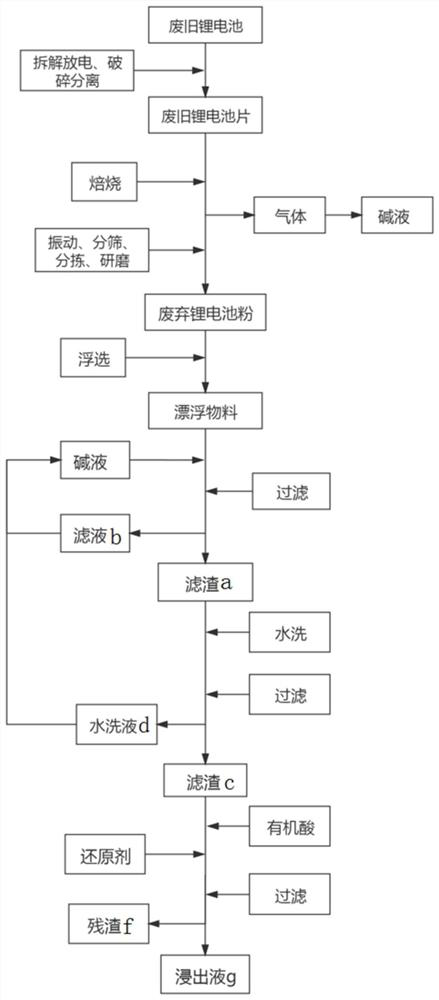

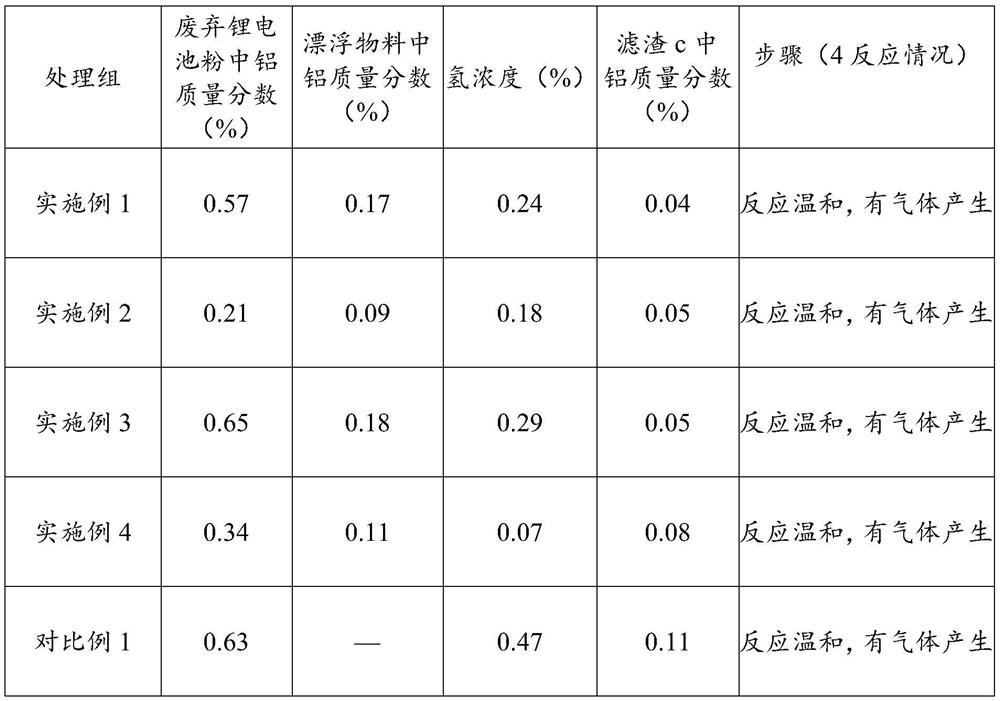

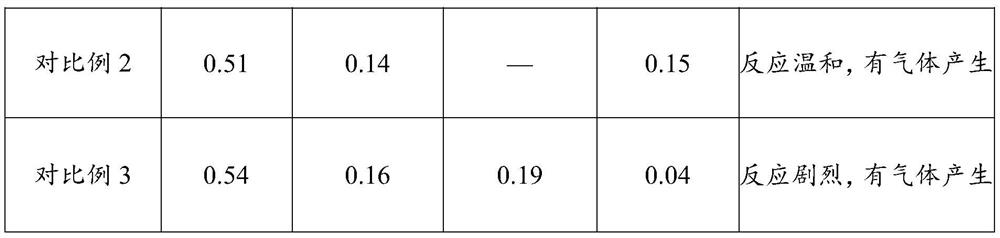

[0044] The method for the safe leaching of waste batteries of the present embodiment comprises the following specific steps:

[0045] (1) The recovered lithium iron phosphate battery is disassembled and discharged, and after being roughly crushed mechanically, the broken waste lithium battery is placed in a sintering kiln for roasting, the roasting temperature is controlled at 350°C, and the roasting is stable for 4.8 hours, and the heating rate during the period is controlled At about 15°C / min, the gas generated by roasting is collected with 0.01mol / L sodium hydroxide lye, and the waste lithium batteries after roasting are vibrated and screened, and the color sorter sorts aluminum foil and copper foil, and then the sorting The finished waste lithium battery powder is ground by a ball mill;

[0046] (2) Add waste lithium battery powder after ball milling into pure water, the solid-to-liquid ratio of waste lithium battery powder:water is 1:1.5g / ml, stir and remove floating impu...

Embodiment 2

[0051] The method for the safe leaching of waste batteries of the present embodiment comprises the following specific steps:

[0052] (1) The recovered lithium iron phosphate battery is disassembled and discharged, and after being roughly crushed mechanically, the broken waste lithium battery is placed in a sintering kiln for roasting. The roasting temperature is controlled at 580°C, and the roasting is stable for 2.4 hours. During the period, the heating rate is controlled. At 23°C / min, the gas generated by roasting is collected with 0.04mol / L sodium hydroxide lye, and the waste lithium batteries after roasting are vibrated and screened. The color sorter sorts aluminum foil and copper foil, and then the sorting is completed. The waste lithium battery powder is ground by a ball mill;

[0053] (2) Add waste lithium battery powder after ball milling into pure water, the solid-to-liquid ratio of waste lithium battery powder:water is 1:2.5g / ml, stir and remove floating impurities,...

Embodiment 3

[0057] The method for the safe leaching of waste batteries of the present embodiment comprises the following specific steps:

[0058] (1) The recovered lithium iron phosphate battery is disassembled and discharged, and after being coarsely crushed by machinery, the broken waste lithium battery is placed in a sintering kiln for roasting. The roasting temperature is controlled at 420°C, and the roasting is stable for 3.5 hours. During the period, the heating rate is controlled. At 18°C / min, the gas generated by roasting is collected with 0.09mol / L sodium hydroxide lye, and the waste lithium batteries after roasting are vibrated and screened. The color sorter sorts aluminum foil and copper foil, and then the sorting is completed The waste lithium battery powder is ground by a ball mill;

[0059] (2) Add waste lithium battery powder after ball milling into pure water, the solid-to-liquid ratio of waste lithium battery powder:water is 1:2.5g / ml, stir and remove floating impurities,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com