Sulfur fixation method of roasting low-grade molybdenite concentrate through lime method

A molybdenum concentrate, low-grade technology, applied in the field of molybdenum metallurgy, can solve problems such as poor sulfur fixation effect, and achieve the effects of reducing dosage, improving sulfur fixation efficiency, and inhibiting molybdenum grade depletion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

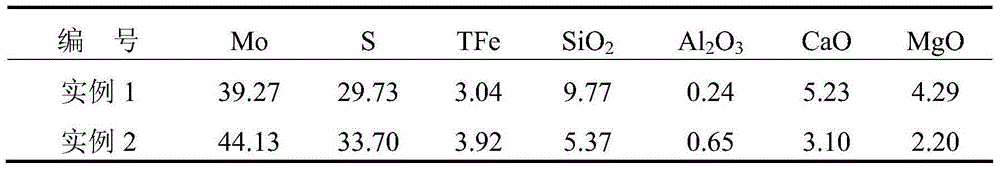

[0026] For the molybdenum concentrate with a molybdenum grade of 39.27wt% and a sulfur content of 29.73wt% (the chemical composition of raw materials is shown in Table 1), the molybdenum concentrate is divided into two parts according to the mass ratio of 4:6; 200ml 4N-HCl , Quicklime with a particle size of 100% less than 0.074mm, the molar ratio of Ca / S in the mixture is 1:1, and the mass fraction of the mixture is 4% MnO 2 ;Add 300ml of activity to the second part of molybdenum concentrate 4N-HCl , 100% of particle size is less than quicklime of 0.074mm, make the molar ratio of Ca / S in the mixture be 1.5:1, and add NaOH accounting for 2% of the mixture mass fraction; put the first part of the mixture in the disc pelletizer Prepare a 6mm spherical core, and then add the spherical core to the second disc pelletizer, and perform secondary pelletizing together with the second part of the mixture to obtain core-shell structure molybdenum concentrate pellets; molybdenum concentr...

Embodiment 2

[0029]For the molybdenum concentrate with a molybdenum grade of 44.13wt% and a sulfur content of 33.70wt% (the chemical composition of raw materials is shown in Table 1), the molybdenum concentrate is divided into two parts according to the mass ratio of 6:4; 250ml 4N-HCl , Quicklime with a particle size of 100% less than 0.074mm, the molar ratio of Ca / S in the mixture is 0.5:1, and the mass fraction of the mixture is 2% MnO 2 ; Add activity to the second part of molybdenum concentrate is 330ml 4N-HCl 100% quicklime with a particle size of less than 0.074mm, the molar ratio of Ca / S in the mixture is 2:1, and the addition of 5% Na 2 CO 3 ;Prepare the first part of the mixture into a 4mm ball core in the disc pelletizer, then add the ball core to the second disc pelletizer, and carry out secondary pelletizing together with the second part of the mixture to obtain the core Shell structure molybdenum concentrate pellets; the molybdenum concentrate pellets are distributed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com