System and method for stacking or dumping waste ore through large self-moving bridge type distributing machine

A spreader, self-moving technology used in conveyors, loading/unloading, transport and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

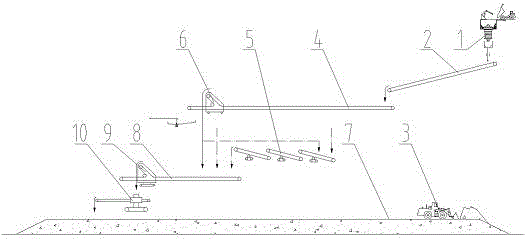

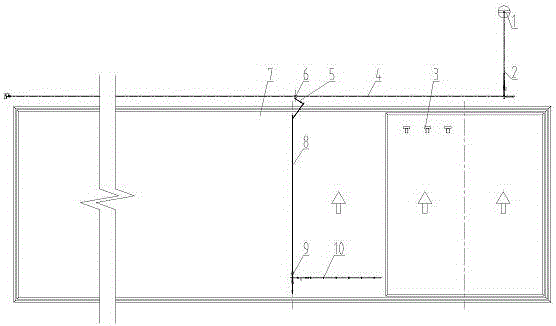

[0017] A system that adopts a large self-moving bridge-type distributing machine for pile building or waste rock disposal. Its main components include: crusher 1, fixed belt conveyor 2, bulldozer 3, fixed belt conveyor with unloading vehicle Machine 4, portable belt conveyor 5, track-type unloading vehicle 6, heap leaching site or waste rock yard 7, displacement belt conveyor 8, crawler-type unloading vehicle 9, self-moving bridge-type distributing machine 10. The conveying system after material crushing is composed of fixed belt conveyor 2, fixed belt conveyor 4 with unloading vehicle, portable belt conveyor 5, displacement belt conveyor 8 and self-moving bridge distributing machine 10. Material is conveyed by belt conveyor. The discharge equipment at the end of the system, that is, the self-moving bridge-type distributing machine 10 can perform backward or forward discharge in the heap leaching field or waste rock field 7 by self-propelling. When the self-moving bridge-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com