A flame-retardant impregnating glue and its application in the preparation of flame-retardant decorative panels

A flame-retardant, impregnated glue technology, applied in the direction of adhesives, lamination devices, adhesive types, etc., can solve the problems of poor compatibility of flame retardants with resins, unsatisfactory depth, and influence on curing time, etc., to achieve flame retardant Obvious effect, not easy to foam, good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

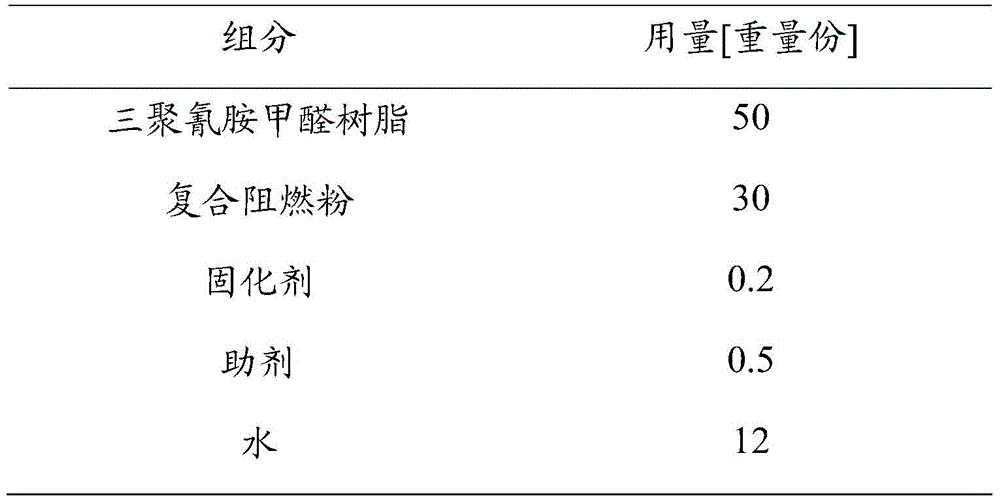

[0030] A flame-retardant impregnating glue prepared by parts by weight from the components described in Table 1:

[0031] Table 1

[0032]

[0033] Among them, melamine-formaldehyde resin is generally weakly alkaline, and as the amount of free formaldehyde increases, the curing time will be accelerated. In this implementation, the mass fraction of formaldehyde in the melamine formaldehyde resin is 4%. The solid content and viscosity of the melamine formaldehyde resin will affect the system stability of the impregnating glue and the permeability of the functional components. In this embodiment, the solid content of the formaldehyde resin is 56%, and the viscosity is 17 seconds.

[0034] Wherein, the composite flame retardant powder is made of 25 parts by weight of ammonium polyphosphate, 5 parts by weight of small particle urea, 40 parts by weight of Al(OH) 3 and 30 parts by weight of Mg(OH) 2 Mix well.

[0035] Among them, the curing agent is prepared by dissolving 20 p...

Embodiment 2

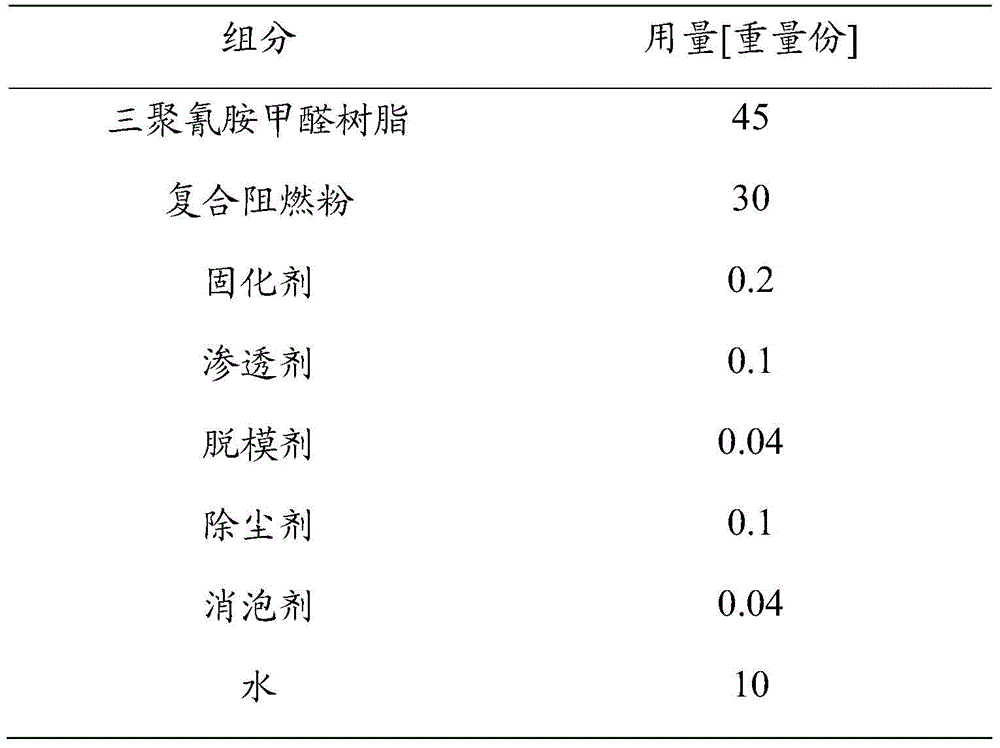

[0038] A flame-retardant impregnating glue, which is uniformly mixed by stirring and mixing the components shown in Table 2 in parts by weight:

[0039] Table 2

[0040]

[0041] Wherein, the solid content of the melamine formaldehyde resin is 55%, the viscosity is 17 seconds, and the mass fraction of free formaldehyde is 2%;

[0042] The composite flame retardant powder is mixed evenly by 22 parts by weight of ammonium polyphosphate and 8 parts by weight of small particle urea, and then added 35 parts by weight of Al(OH) 3 and 35 parts by weight of Mg(OH) 2 production. Small granular urea is urea with a nitrogen content of 46.4% and a particle size of 0.85-2.80 mm.

[0043] Wherein the penetrating agent is selected from alkylate penetrating agents, the release agent is selected from silicone release agents, the defoamer is selected from silicone defoamers, and the dust remover is selected from stearic acid amide dust removers.

[0044] The curing agent is prepared by d...

Embodiment 3

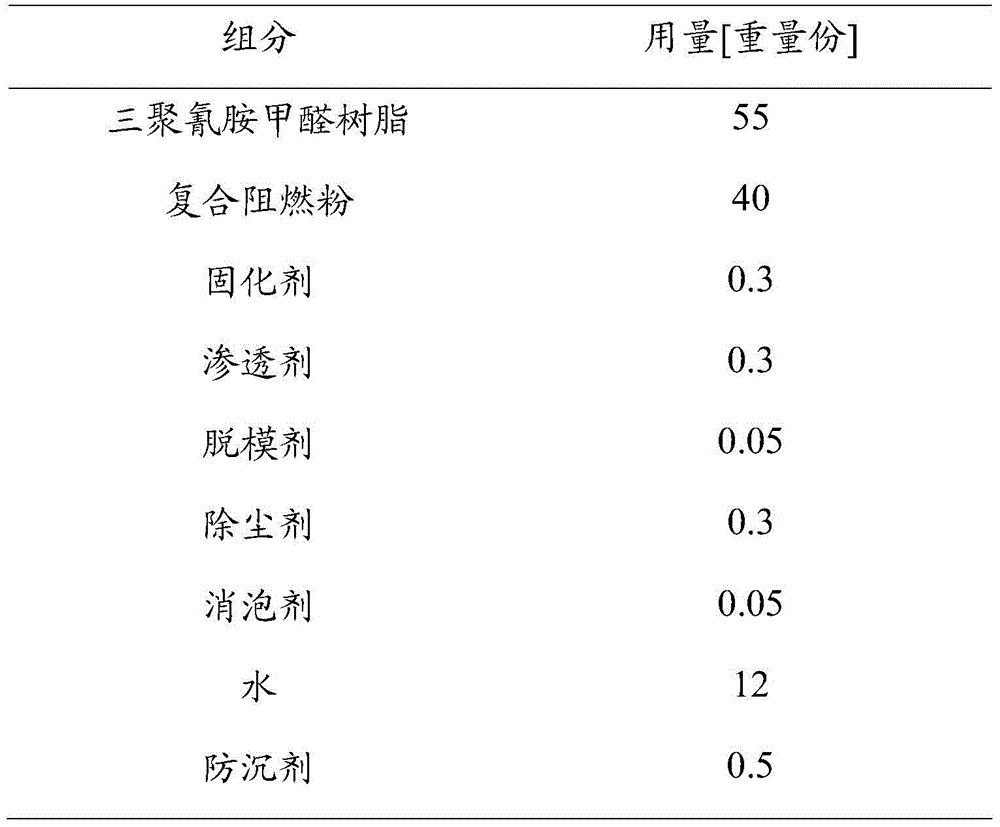

[0046] A flame-retardant impregnating glue, which is formed by stirring and mixing the components shown in Table 3 in parts by weight:

[0047] table 3

[0048]

[0049]During the mixing process, first take 40 parts of composite flame retardant, add 12 parts by weight of water to mix and dissolve, mix with 55 parts by weight of melamine formaldehyde resin, add 0.3 parts by weight of penetrating agent, 0.05 parts by weight of release agent, 0.03 parts by weight of Part of dust remover, 0.05 part by weight of defoamer, and then add 0.5 part by weight of polyamide wax water-based anti-settling agent as anti-settling agent, stir and mix evenly to obtain flame-retardant adhesive.

[0050] The polyamide wax water-based anti-settling agent model Disparon 5501.

[0051] Wherein, the solid content of the melamine formaldehyde resin is 52%, the viscosity is 15 seconds, and the mass fraction of free formaldehyde is 5%.

[0052] Wherein, the composite flame retardant powder is made b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com