Acid dump leaching technology of atacamite

A technology of heap leaching of chlorotacamite, which is applied in the direction of photographic process, photographic auxiliary process, process efficiency improvement, etc., can solve the problems of low recovery rate, fine ore slime interference, low economic benefit, difficult solid-liquid separation, etc., and achieve Improve the level of comprehensive utilization, improve economic benefits, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

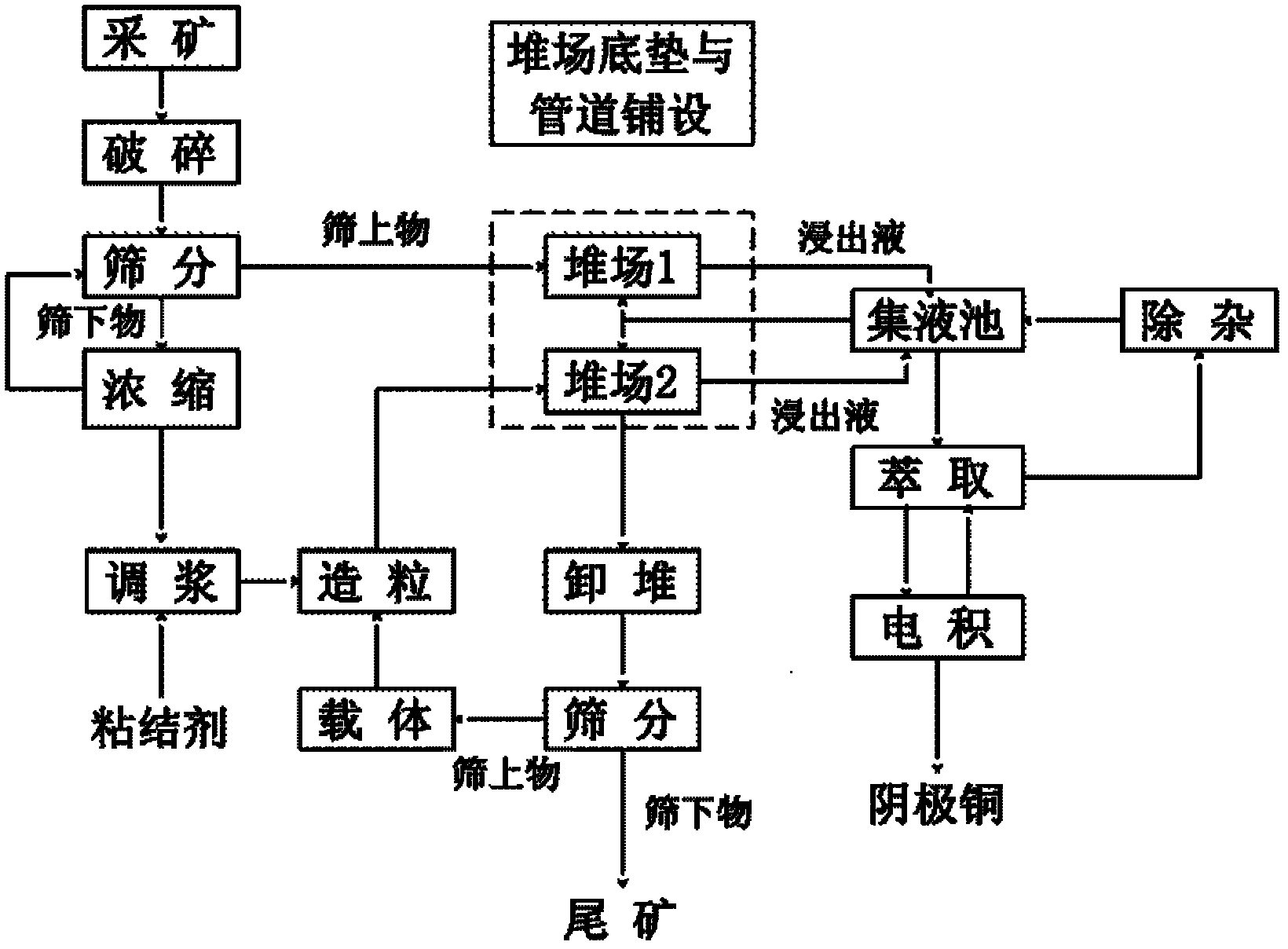

Method used

Image

Examples

Embodiment 1

[0038] In China, the Tuwu Copper Oxide Mine in Xinjiang is located in the Gobi Desert in the west. It is a copper chloride ore deposit. ore, pyrite, sphalerite, galena and chalcocite, etc. Gangue minerals are mainly quartz, sericite / muscovite, plagioclase, epidote, biotite, potassium feldspar, gypsum, etc. Beneficial metal element copper exists in the form of copper oxide dominated by chlorotacamite and malachite, with a small amount of bornite, copper blue and chalcopyrite. Mineral composition in the ore: 1wt% of chloratackite and malachite, 8wt% of limonite, 20wt% of clay minerals, and 42wt% of quartz.

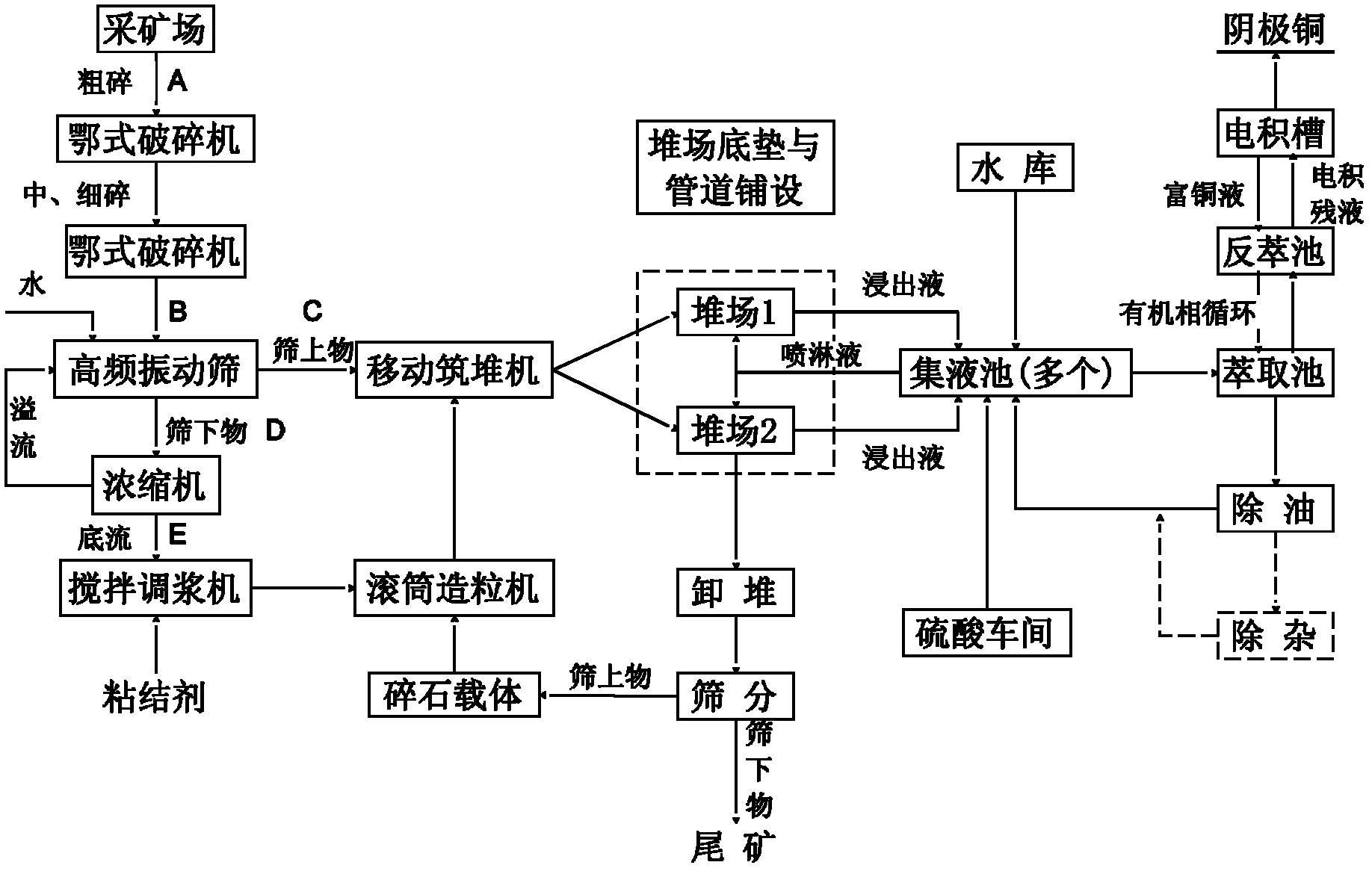

[0039] Because there are many clay-like muddy minerals in the ore and the content of iron minerals is large, no matter whether the flotation process or the gravity separation process is used, the separation effect of copper is poor, and it is difficult to obtain good technical indicators. In this example, using figure 2 The ore is processed by the method shown in the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com