Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

199results about "Sedimentation regulating devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

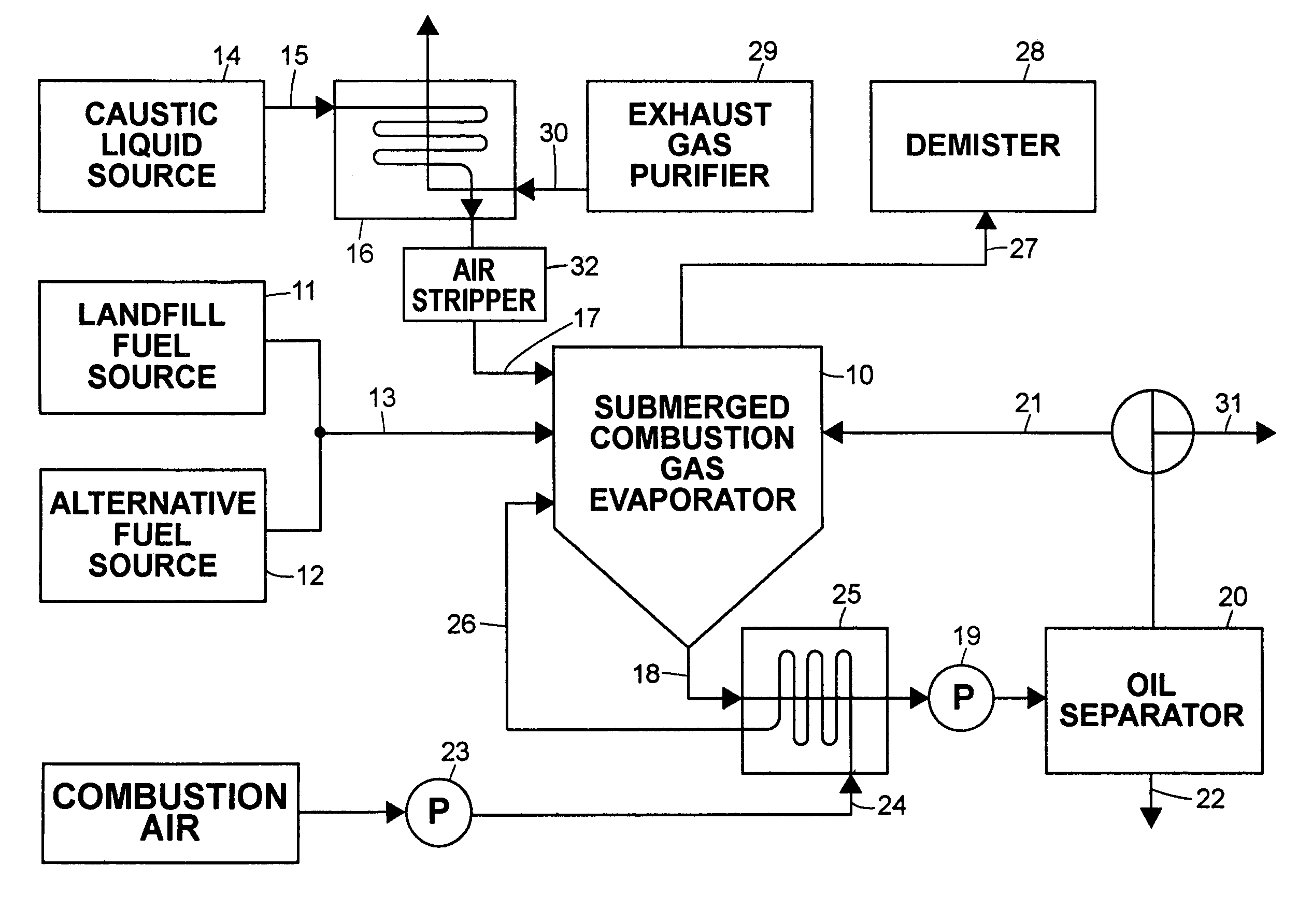

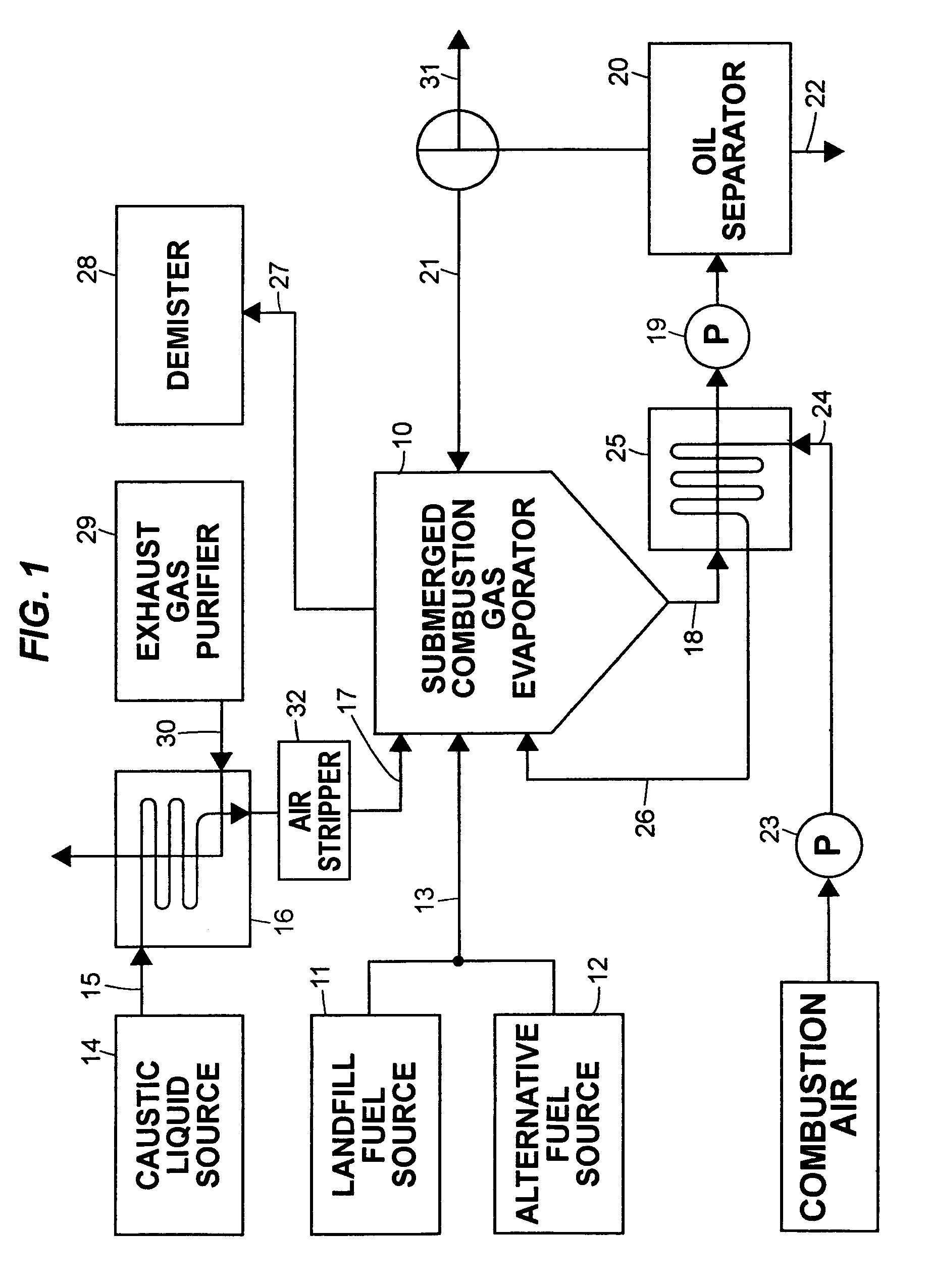

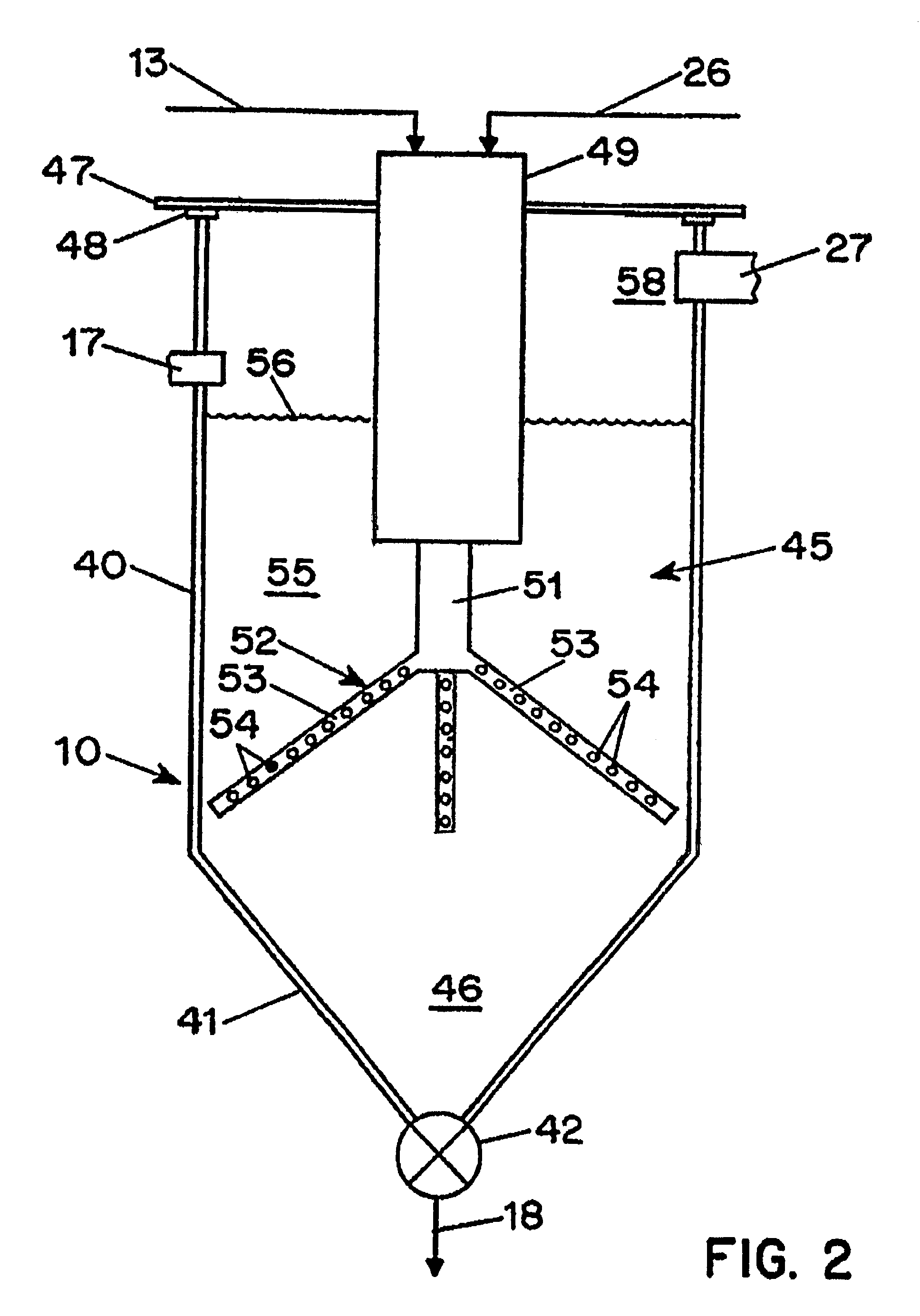

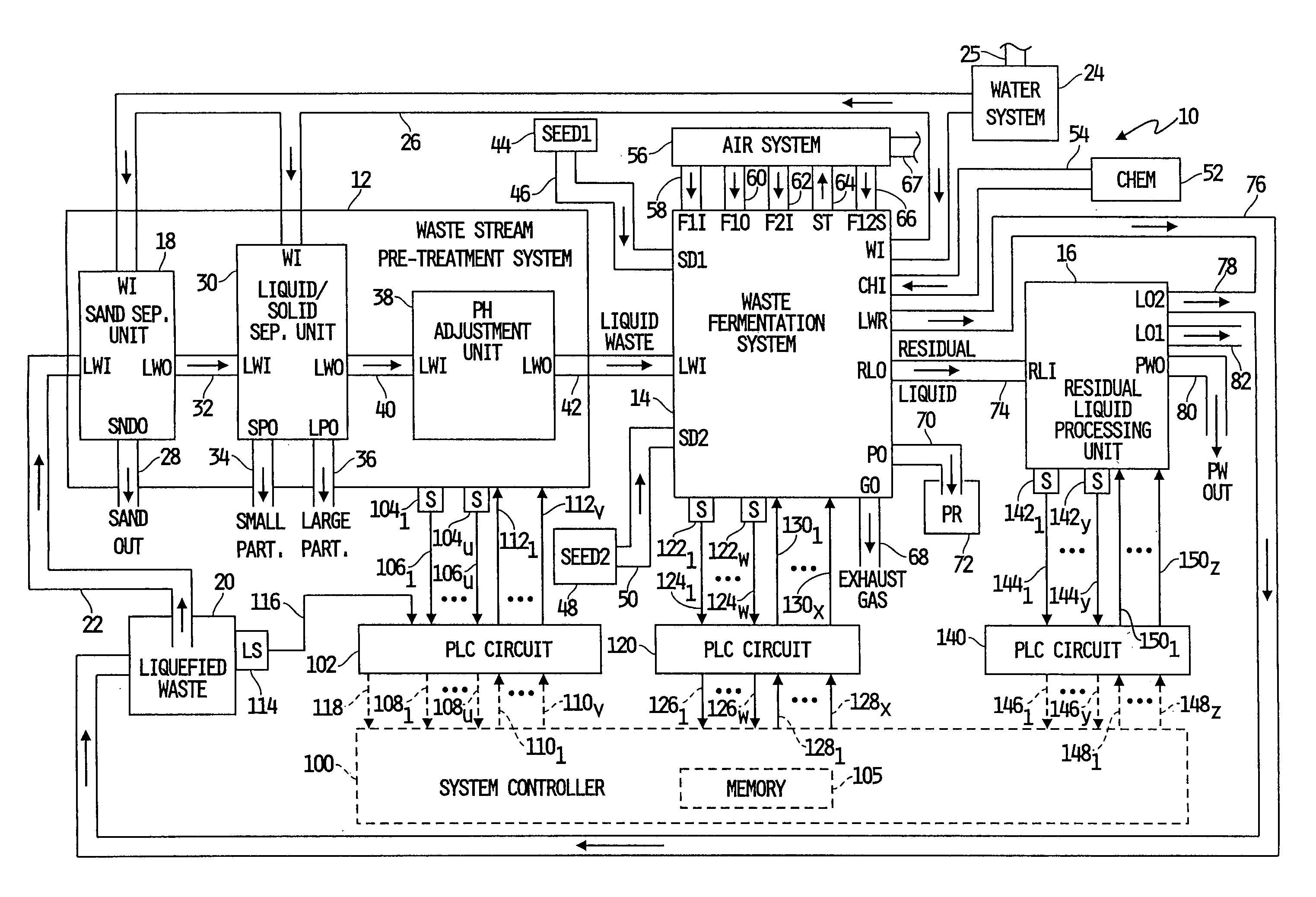

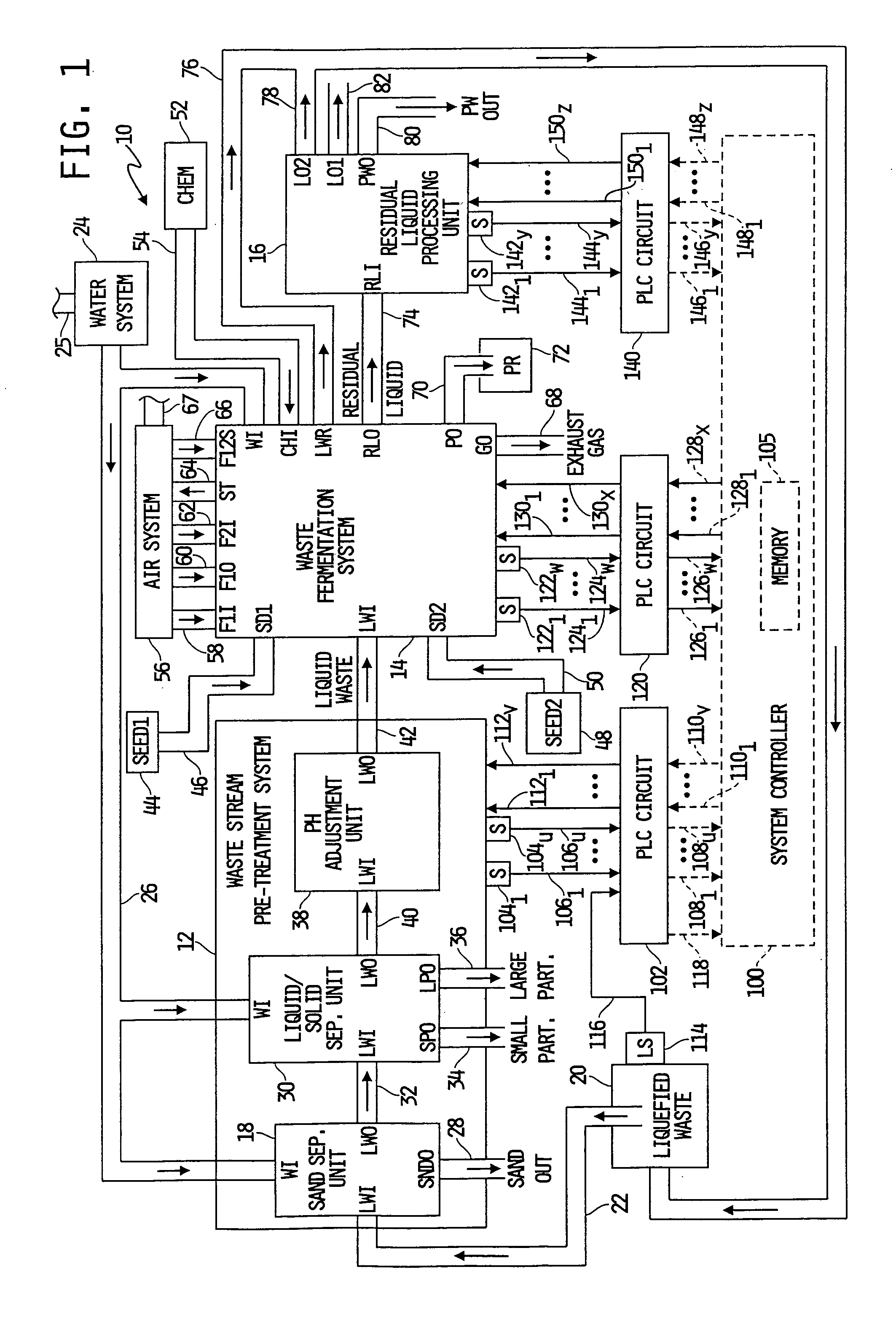

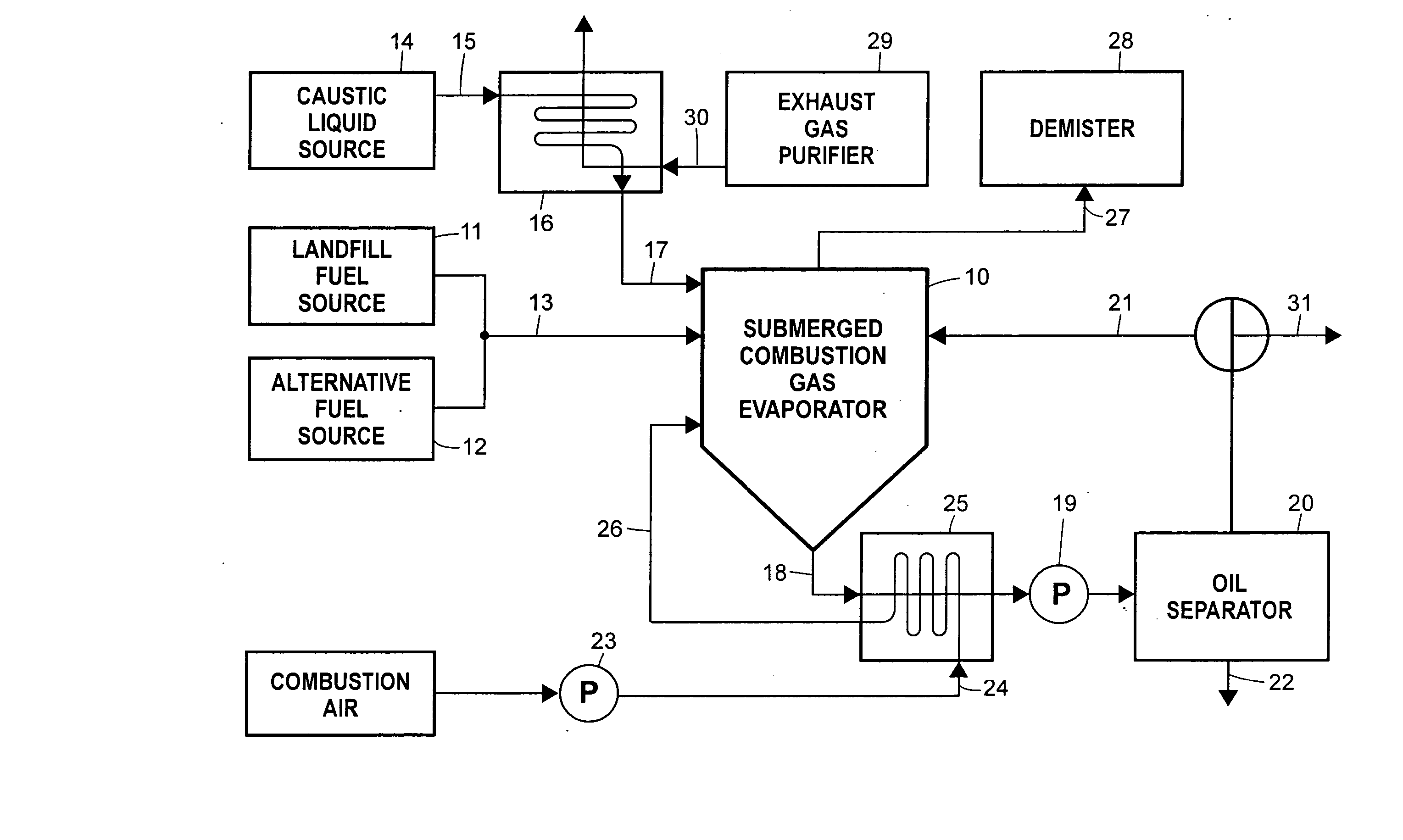

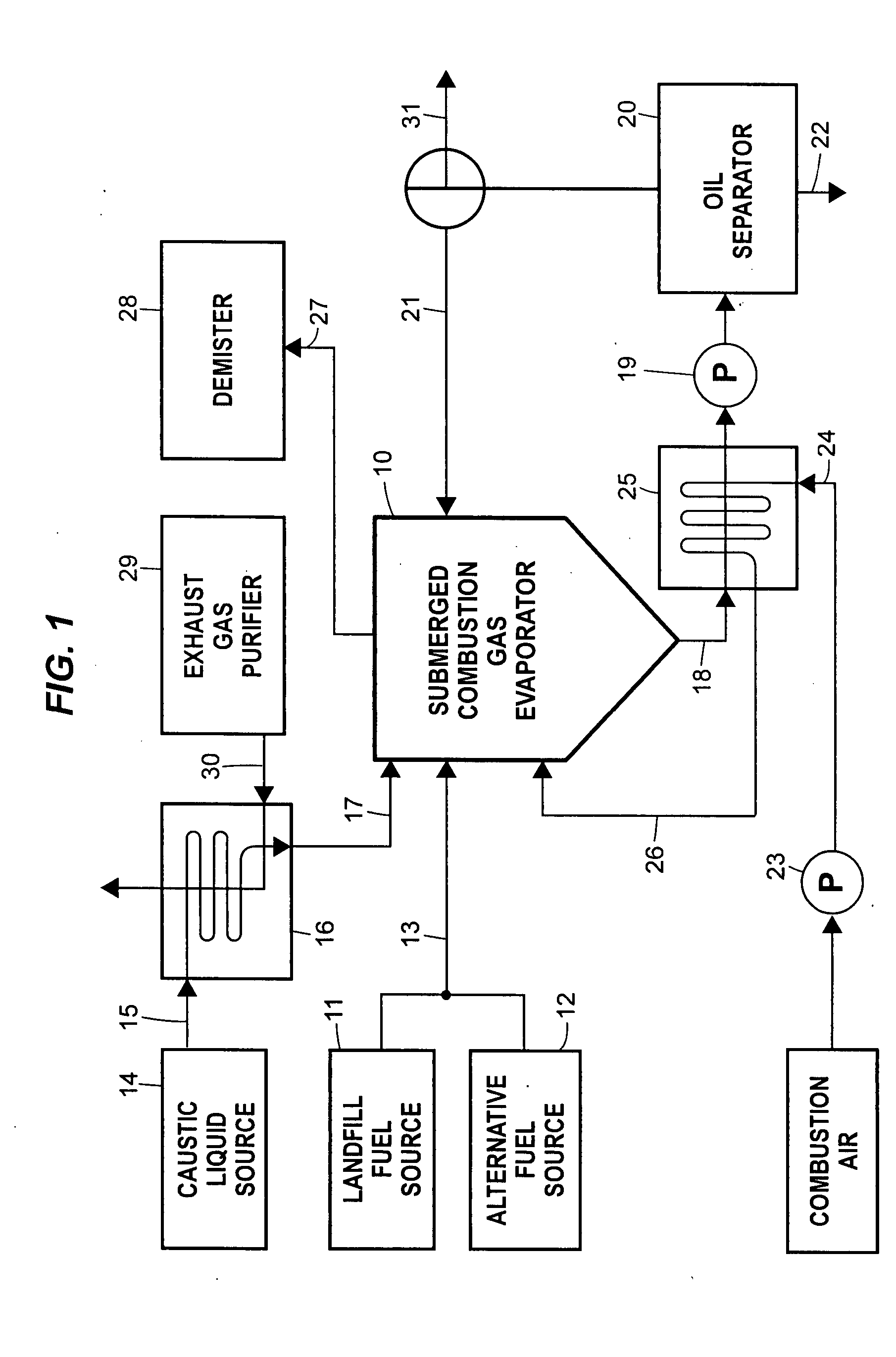

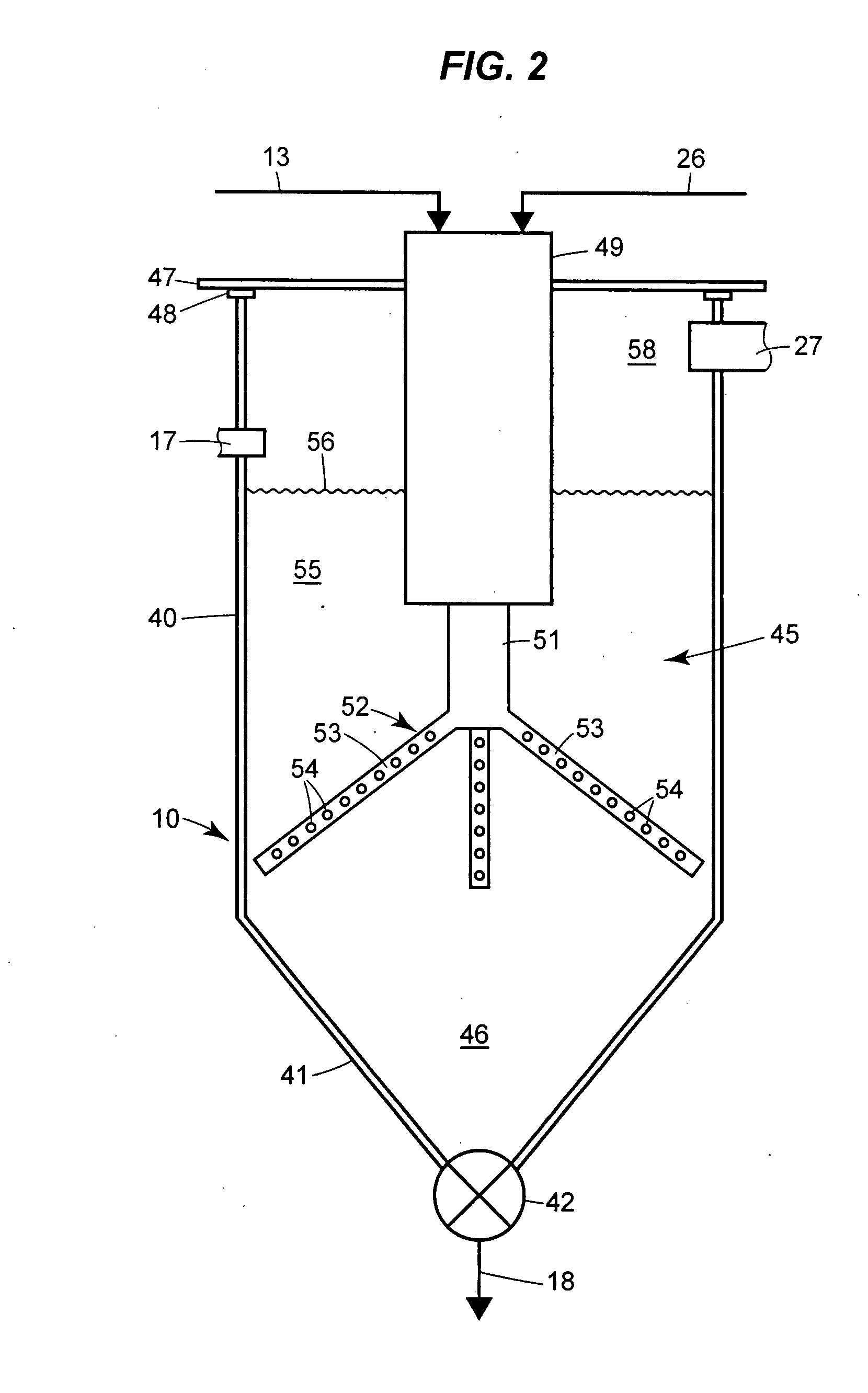

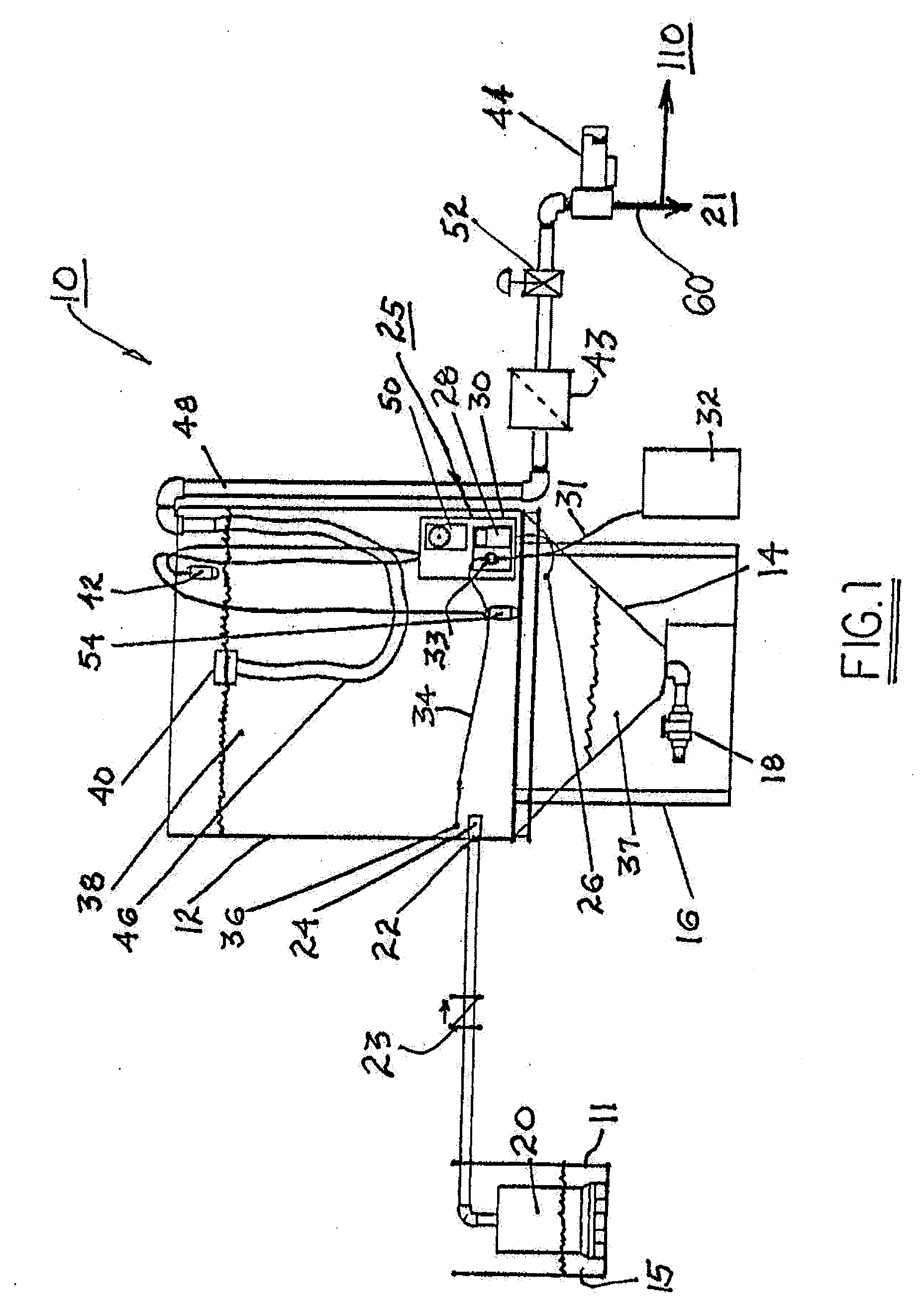

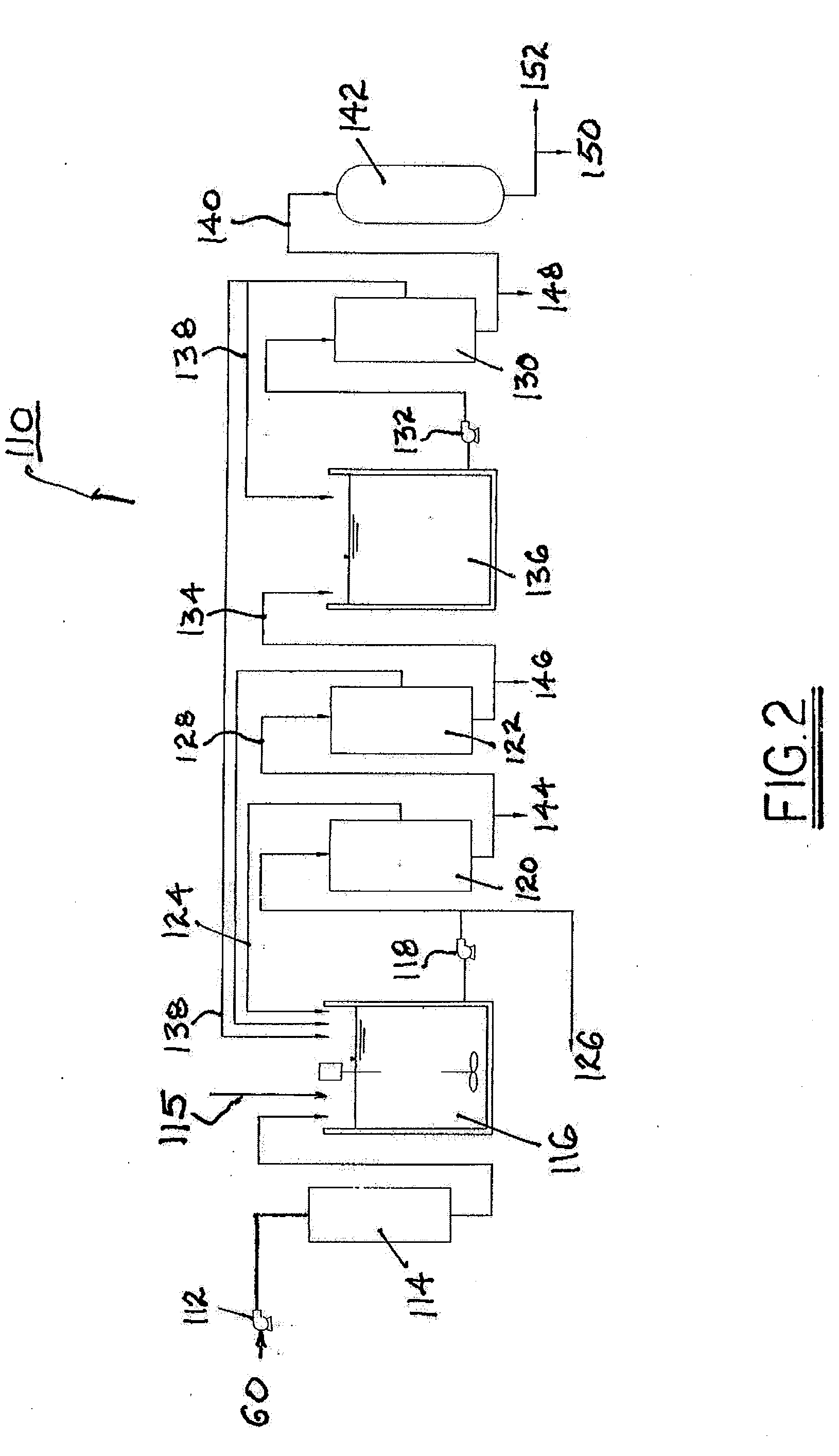

Treatment of spent caustic refinery effluents

InactiveUS7214290B2Avoid spreadingDrying using combination processesLiquid degasificationLiquid wasteCombustion

In the methods for treatment of caustic effluents described in the specification, a spent caustic refinery effluent is supplied to a submerged combustion gas evaporator in which hot combustion gas containing carbon dioxide is injected into the caustic liquid to concentrate the liquid and convert a hydroxide constituent to a carbonate. Where the caustic effluent is from a petroleum refinery, oil in the waste liquid is separated from the aqueous constituent before, during or after concentration.

Owner:GEI LIQUID SOLUTIONS +1

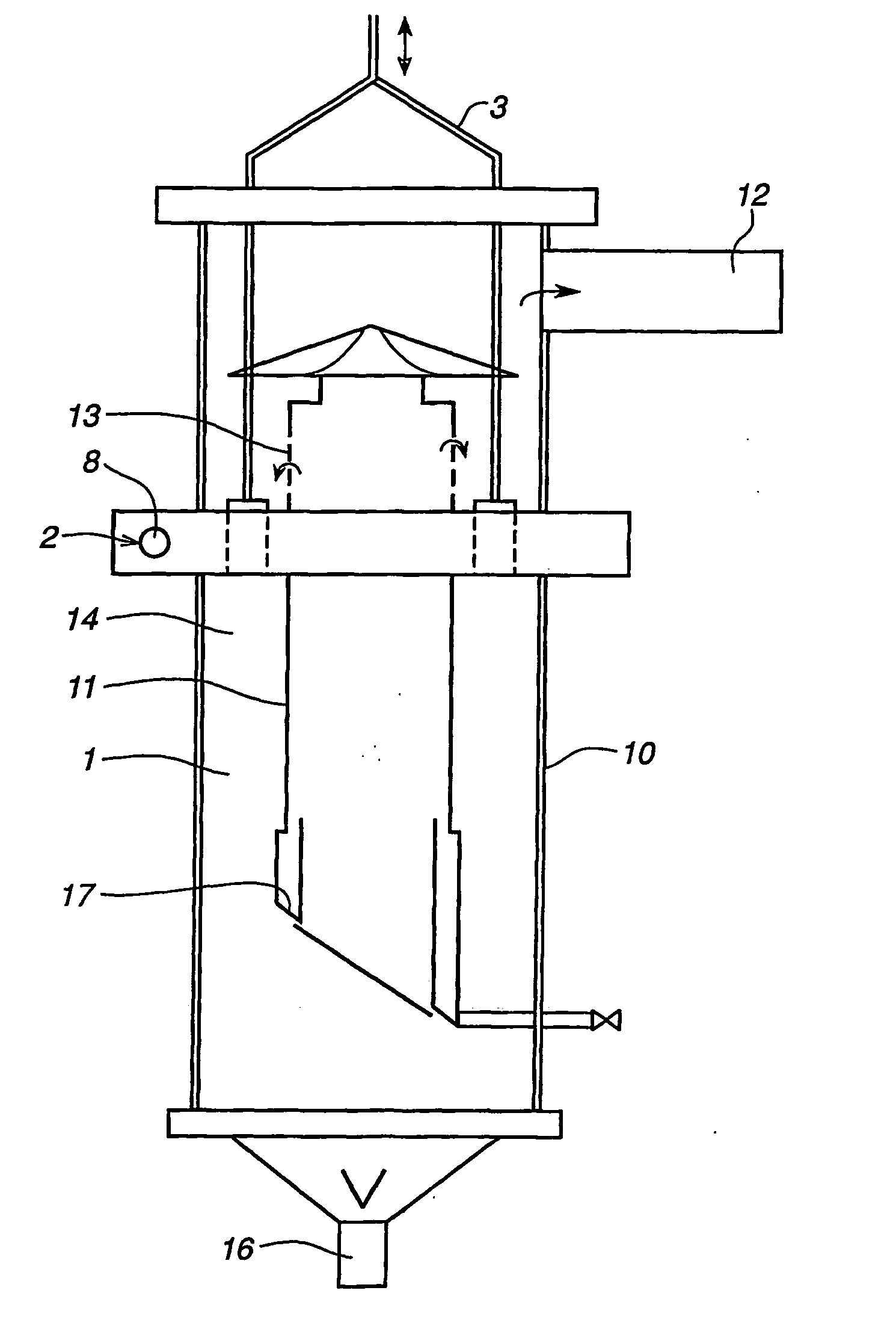

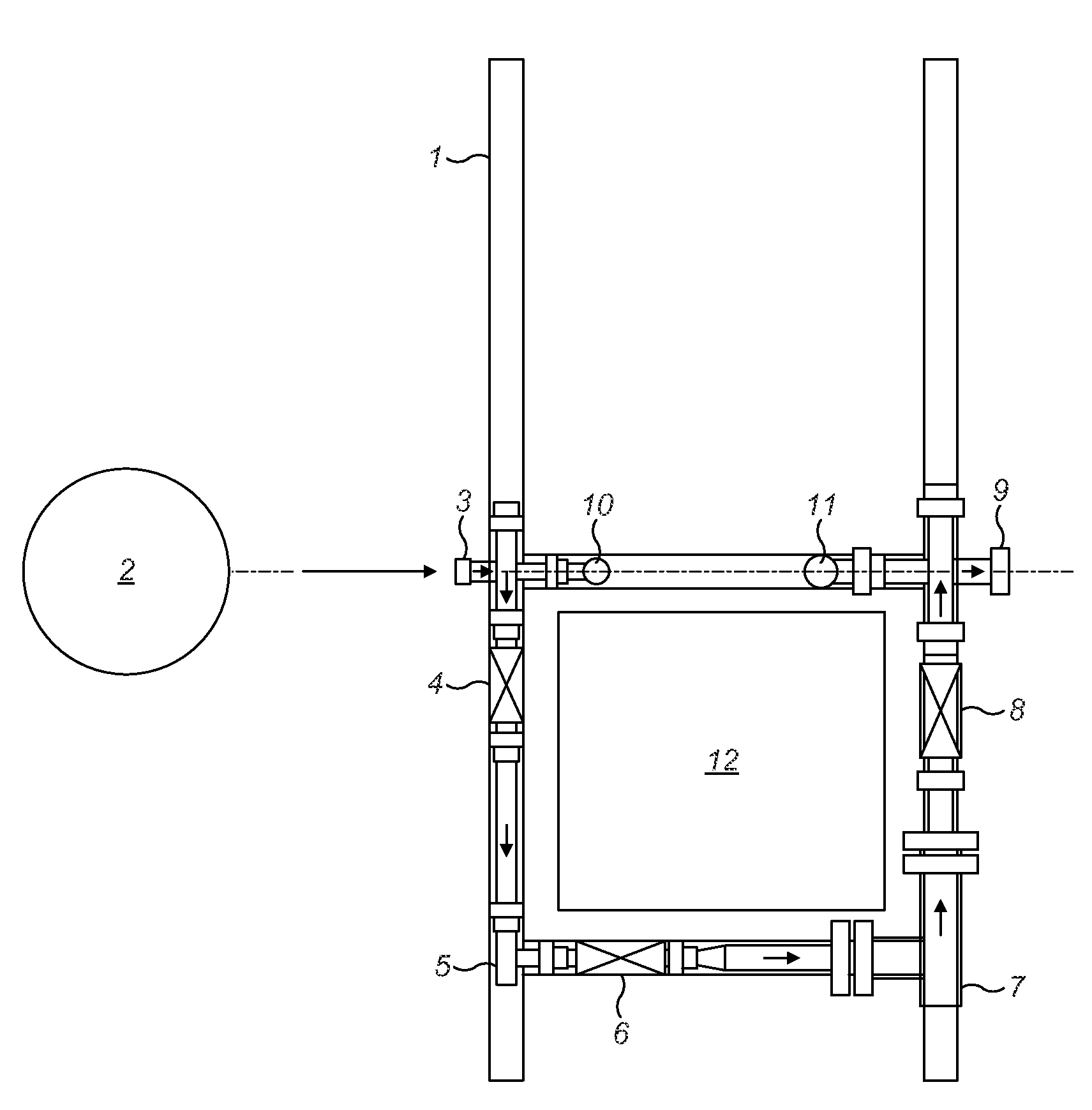

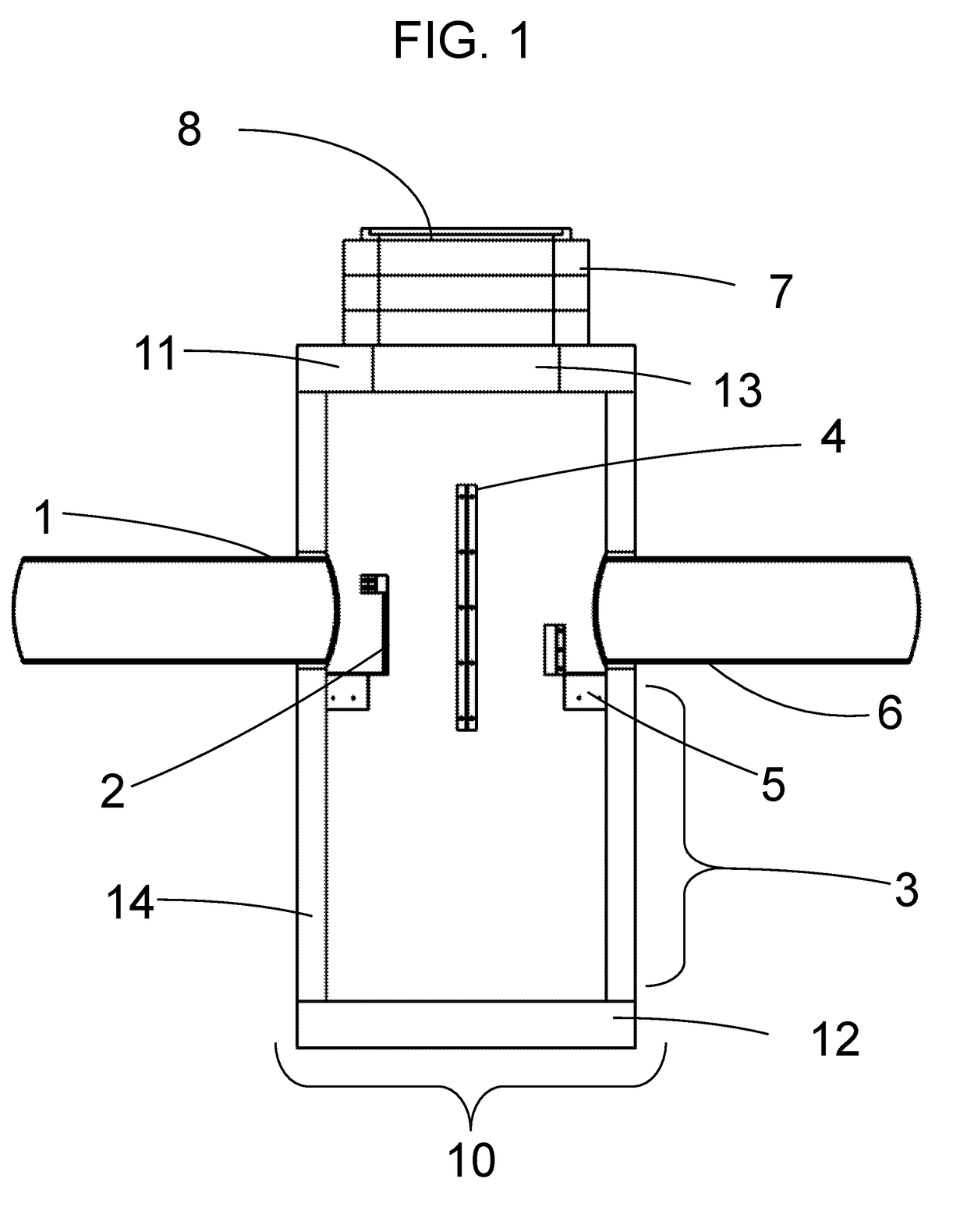

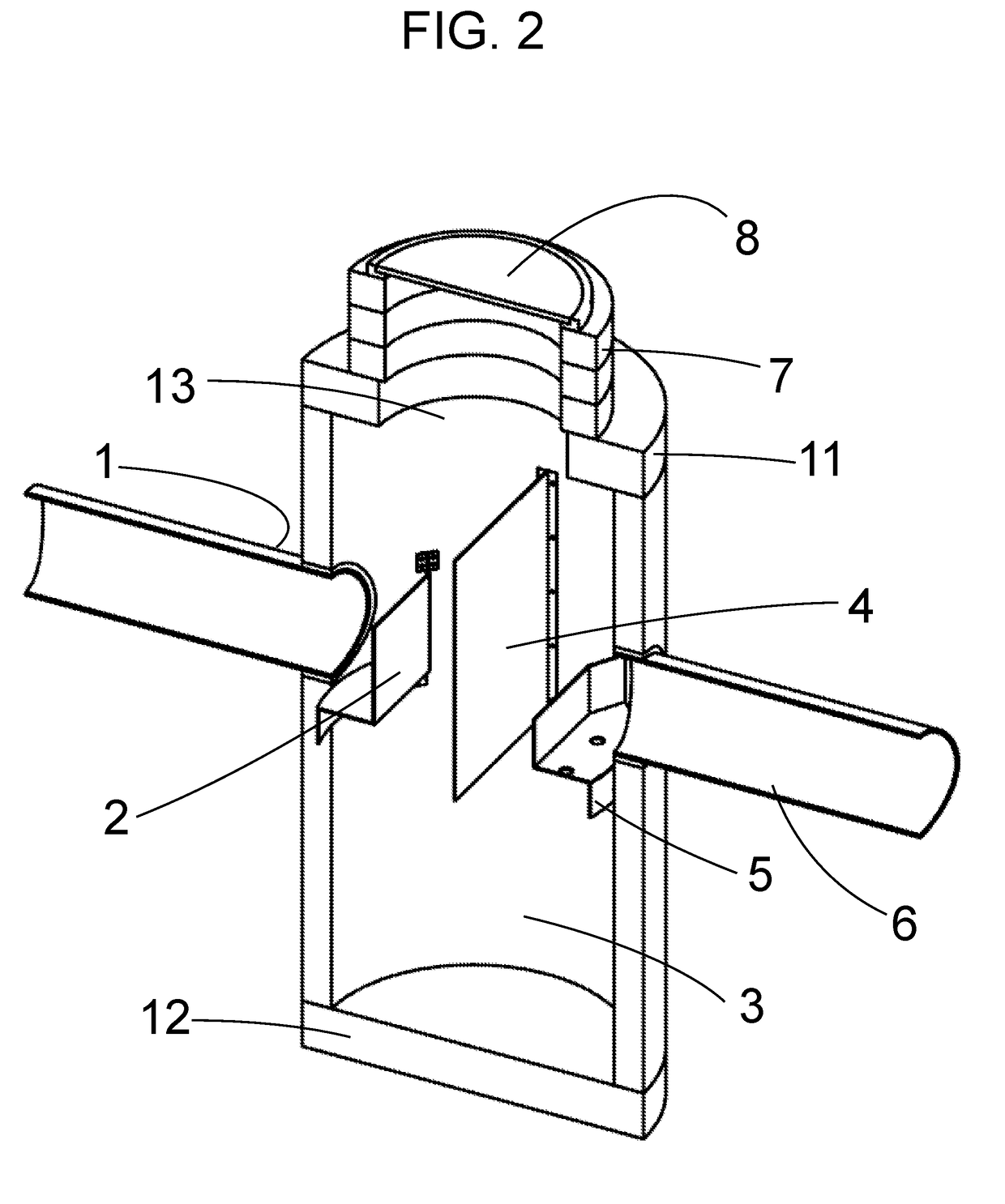

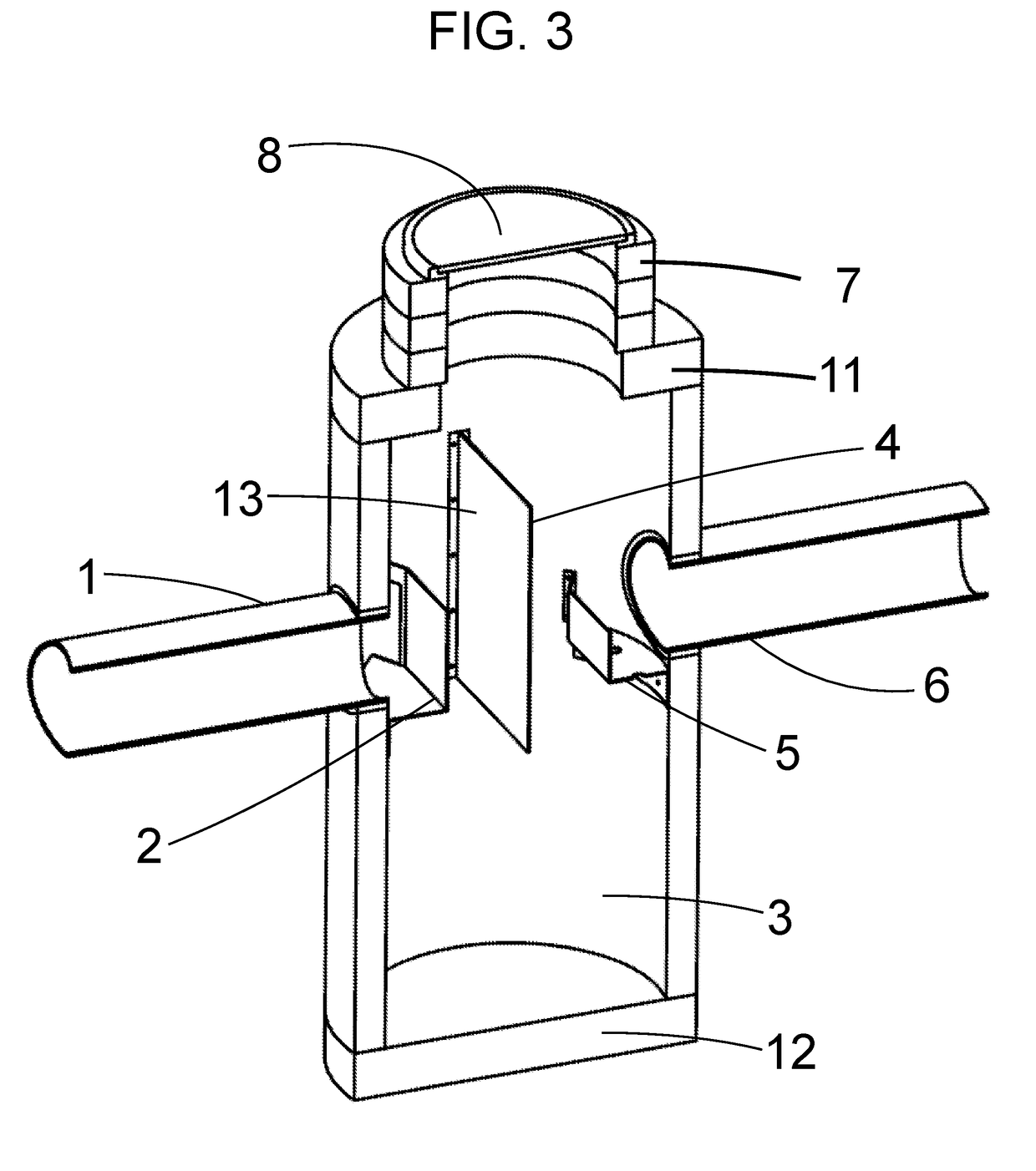

Inlet device and a method of controlling the introduction of a fluid into a separator

InactiveUS20070095032A1Easy to carryEasy to installAuxillary pretreatmentLiquid degasificationEngineeringPartial closure

An inlet device to a separator including a generally tubular outer wall and a generally tubular inner wall. The walls define at least a part of a first annular path between them. An inlet opening provides for the passage of a fluid through the outer wall into the first annular path. At least one communication channel provides for the passage of a fluid from the first annular path into the second annular path. At least one movable closing element provides for at least partial closure of the fluid passage from the first path into the second path. The communication channel(s) is / are arranged to extend along the outside of the inner wall downwards from the first path into the second path, wherein the second path is arranged below the first path.

Owner:SULZER MANAGEMENT AG

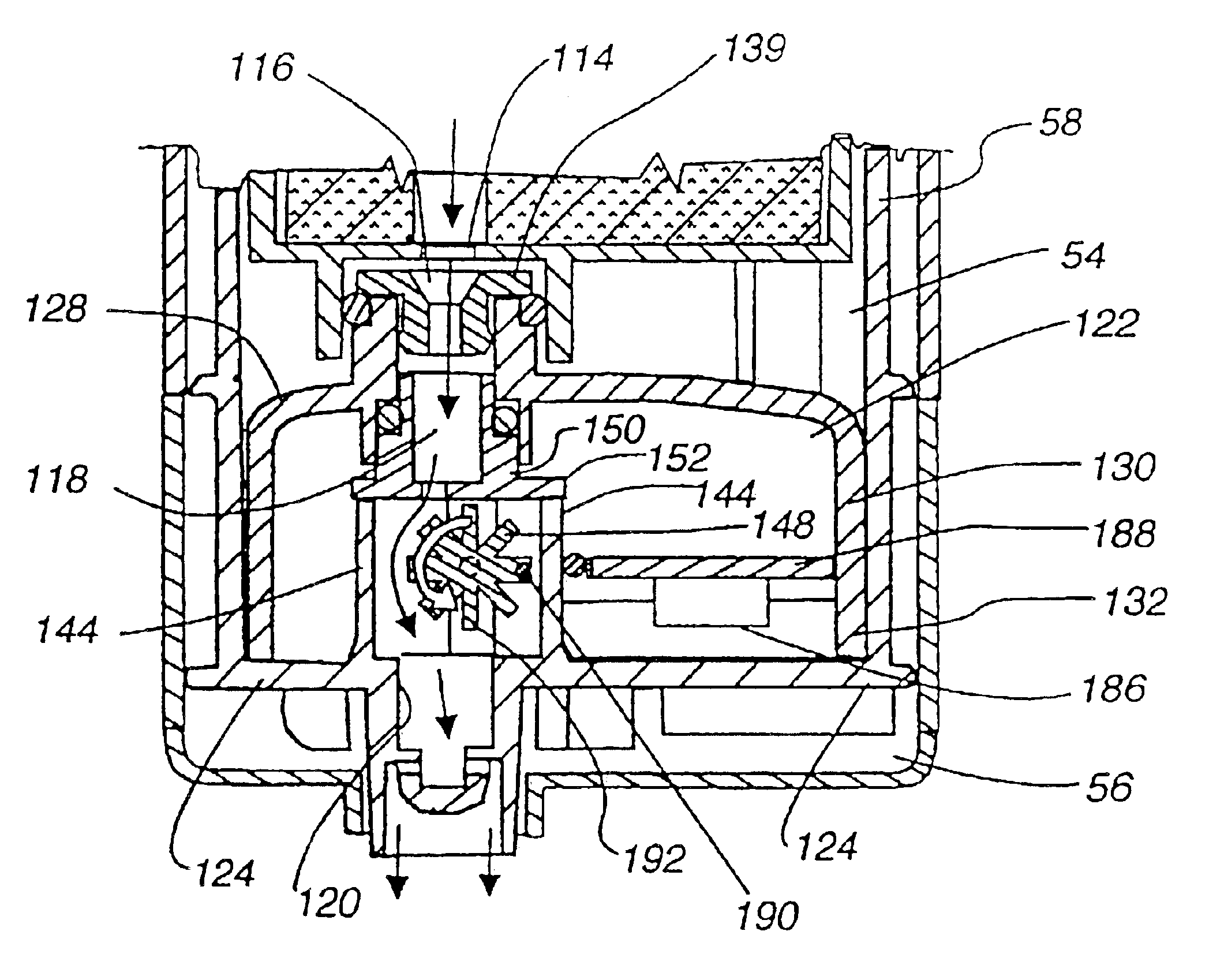

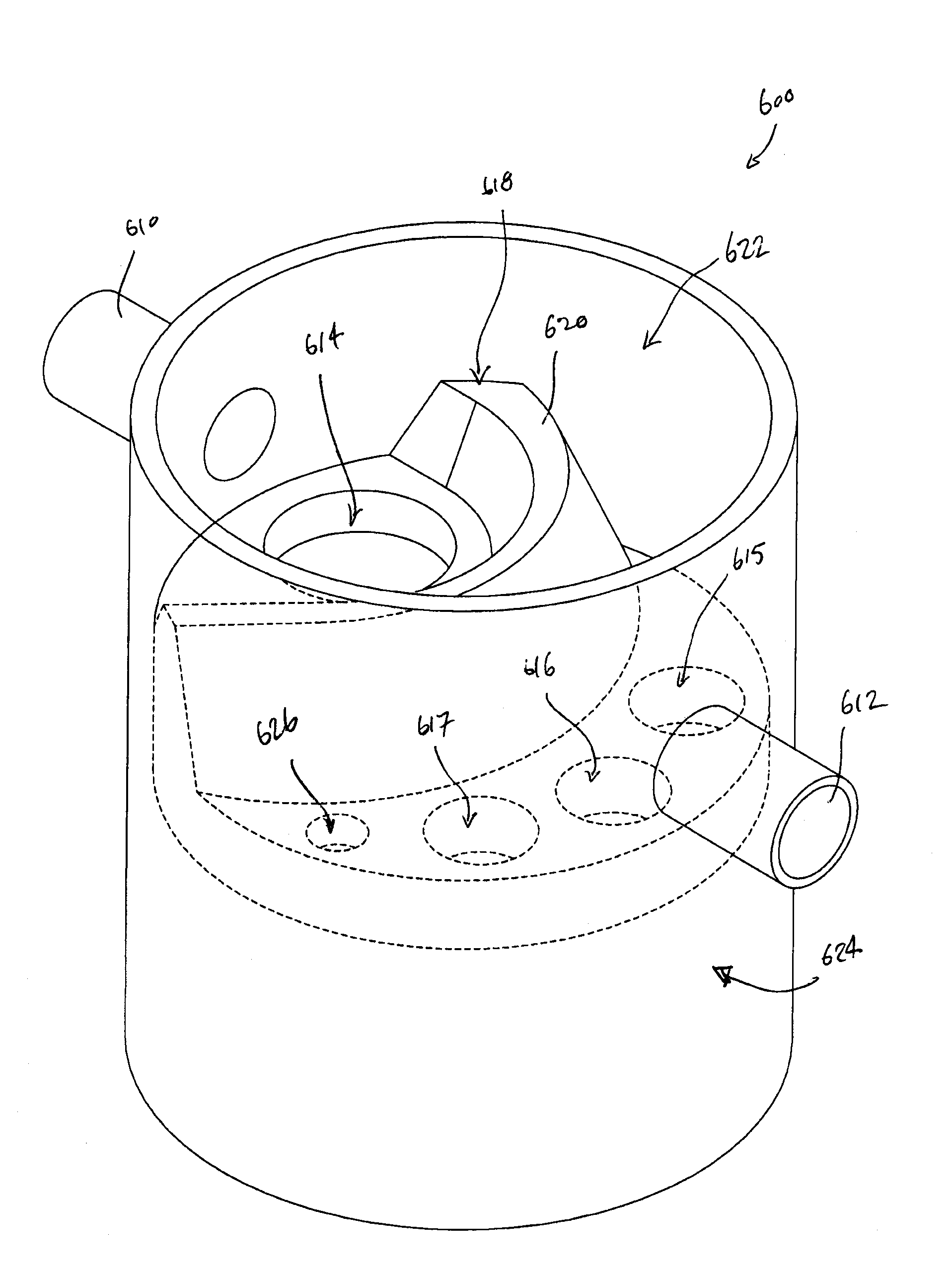

Dual stage centrifugal liquid-solids separator

InactiveUS7025890B2Reduce cavitationEasy to disassembleWater/sewage treatment by centrifugal separationLiquid degasificationDual stageSpins

Disclosed is a vortex-based centrifugal separator for removing solids from a liquid / solids fluid stream in two stages. A fluid stream under pressure is introduced at the top of the cylindrical separator at a tangential angle forming helical downward flow. The first stage uses a centrally-located spin plate for reversing the cleaner interior flow of the vortex back upward, while the heavier solids settle at the bottom of the chamber for periodic removal. In the second stage, a plurality of louvered slots in an upper discharge pipe remove finer solids from the exiting upward fluid flow prior to discharge.

Owner:GRISWOLD CONTROLS LLC

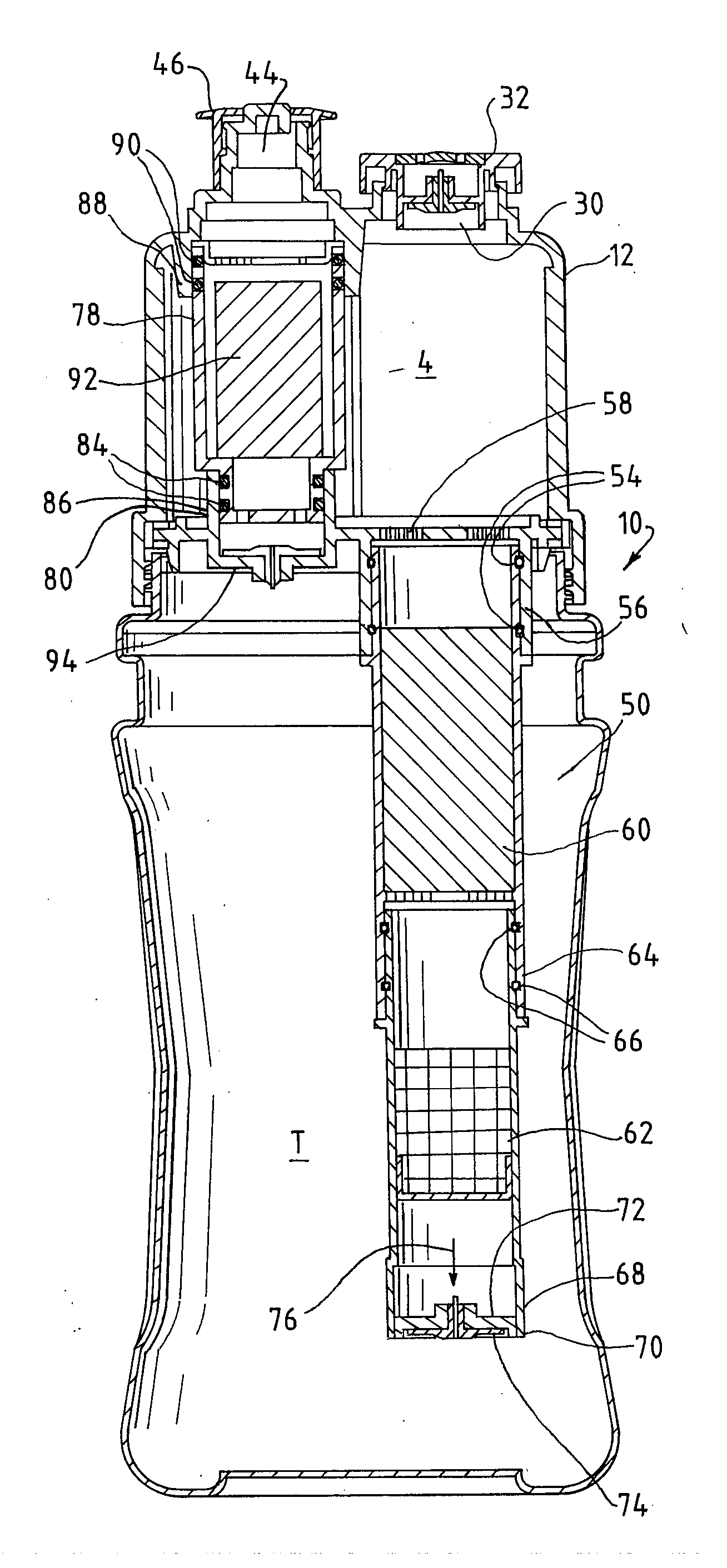

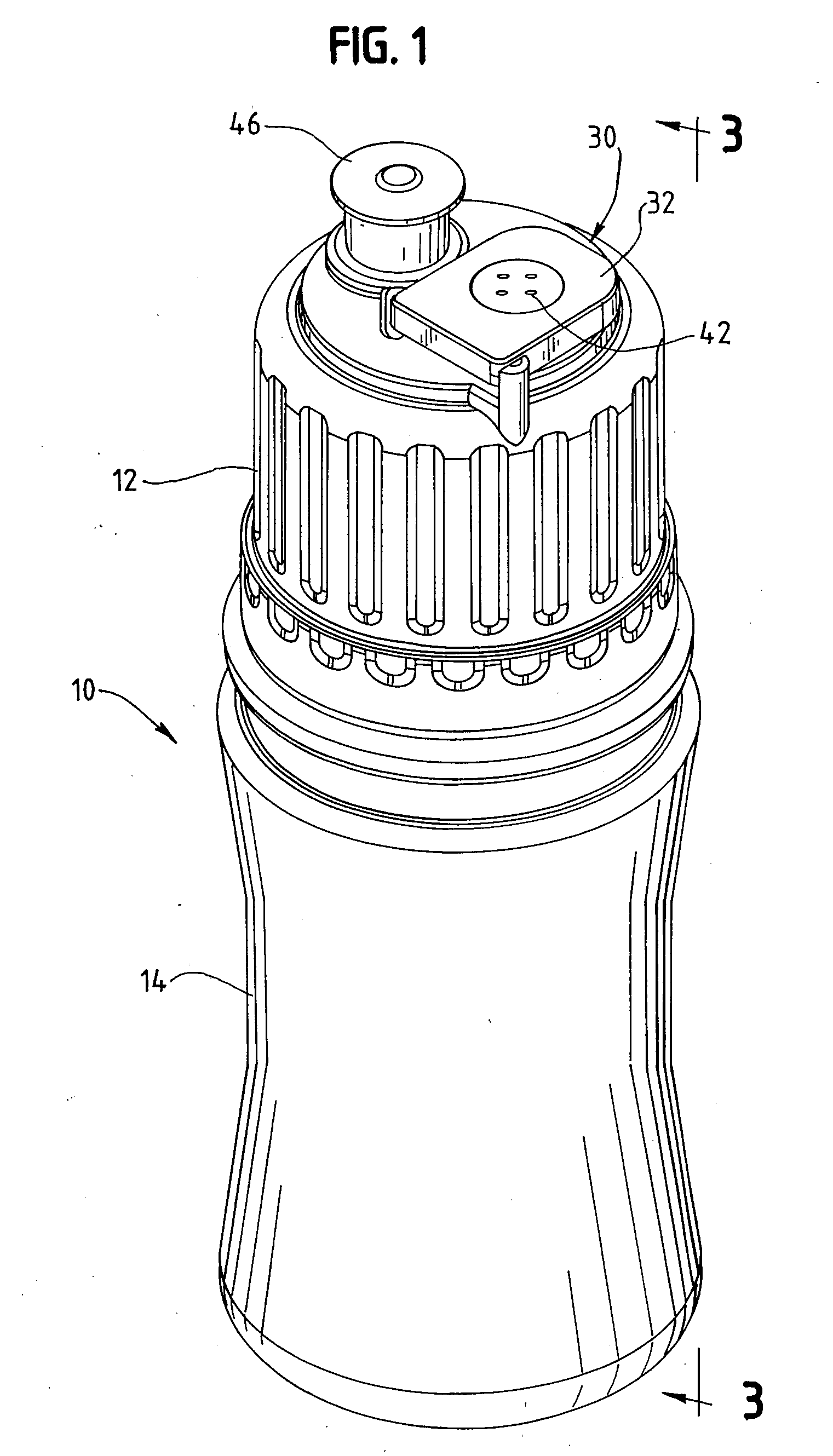

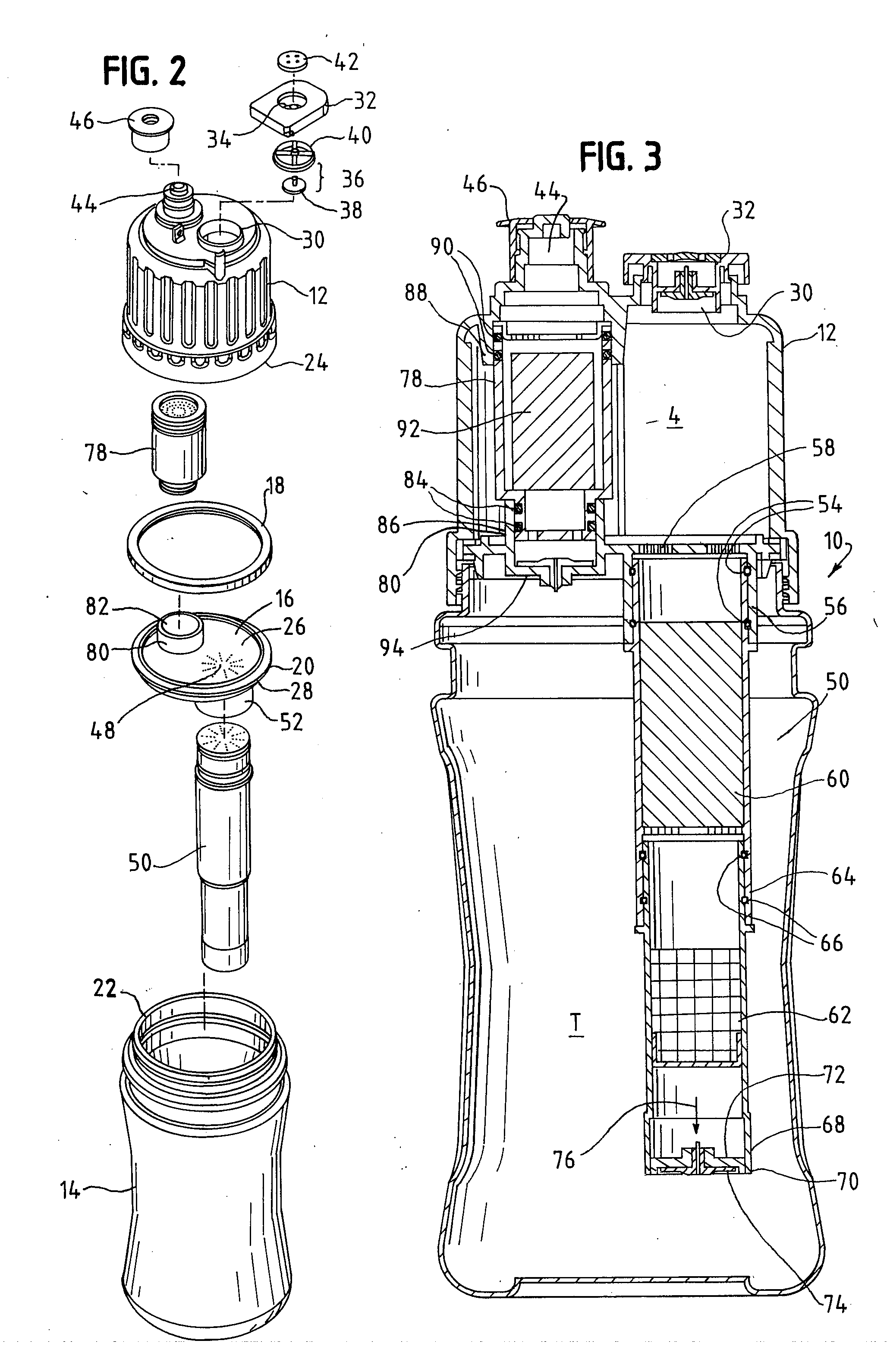

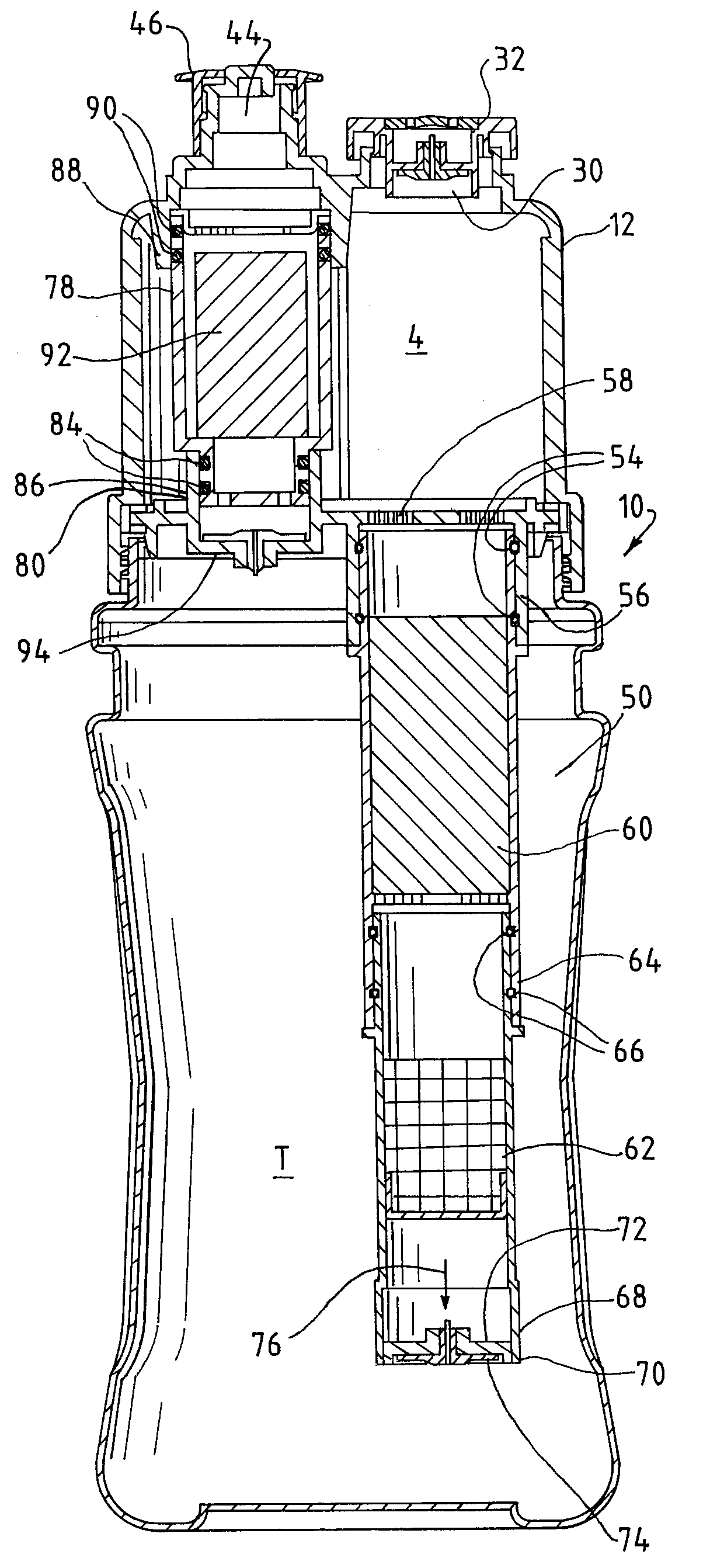

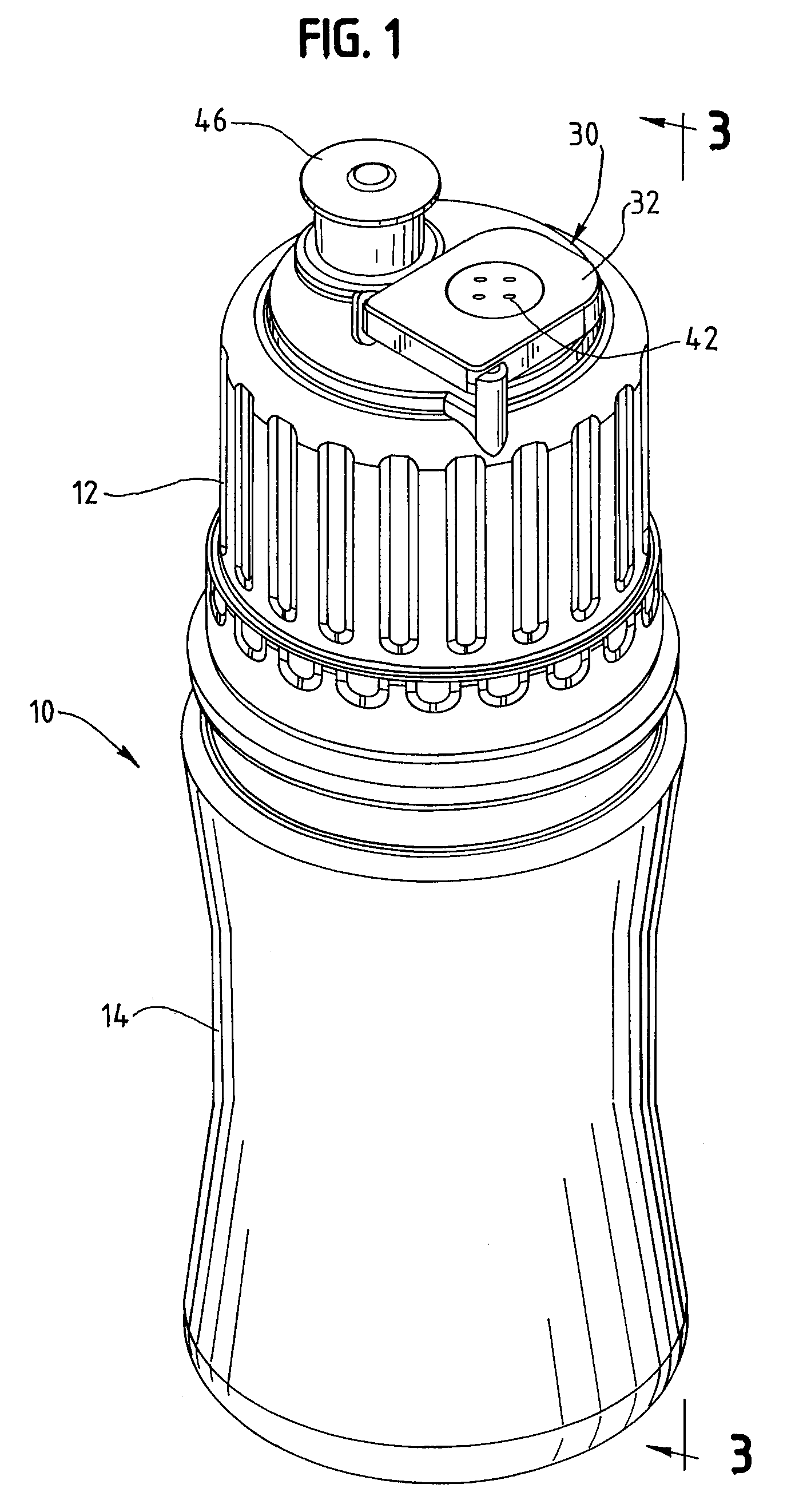

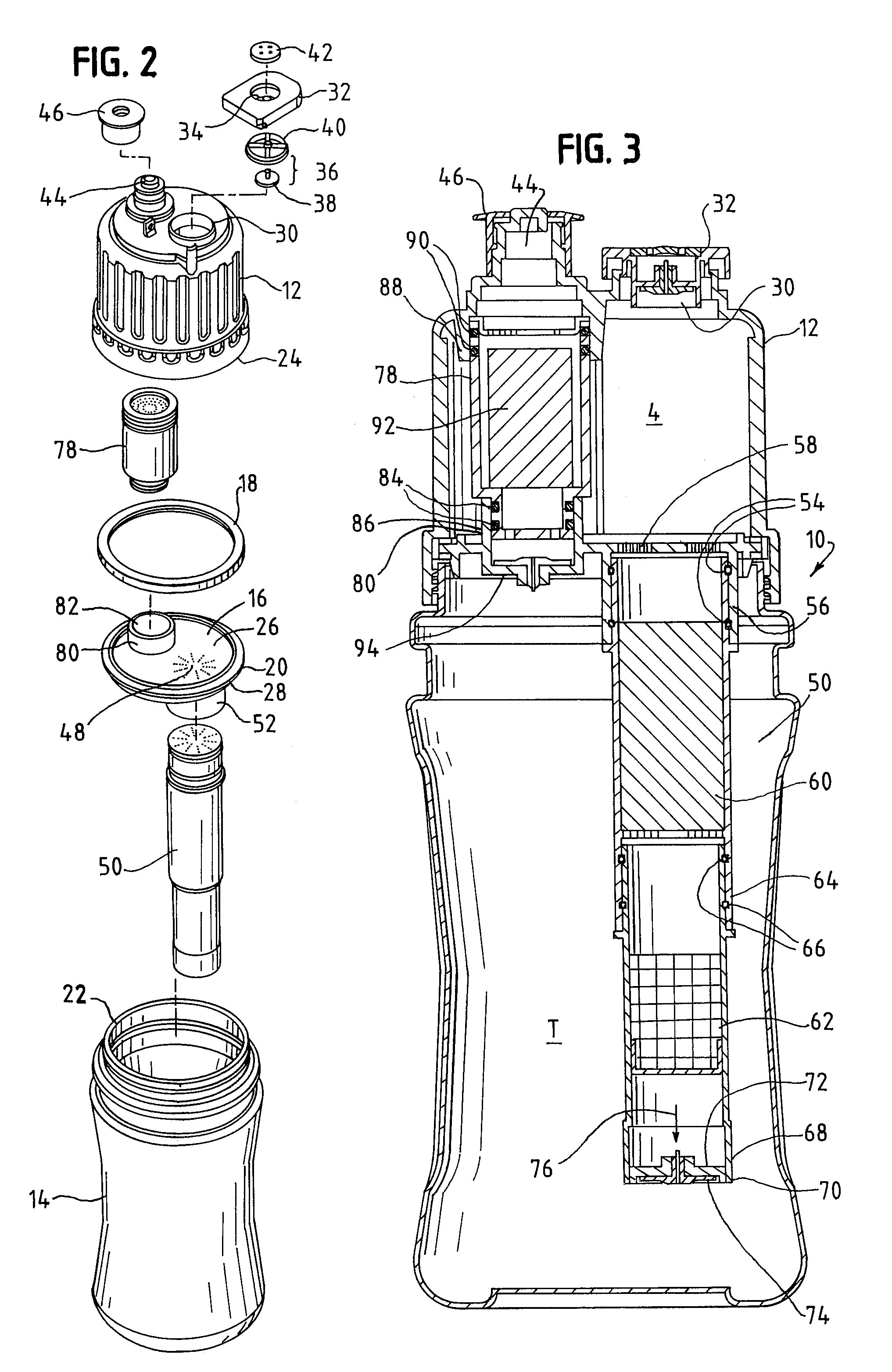

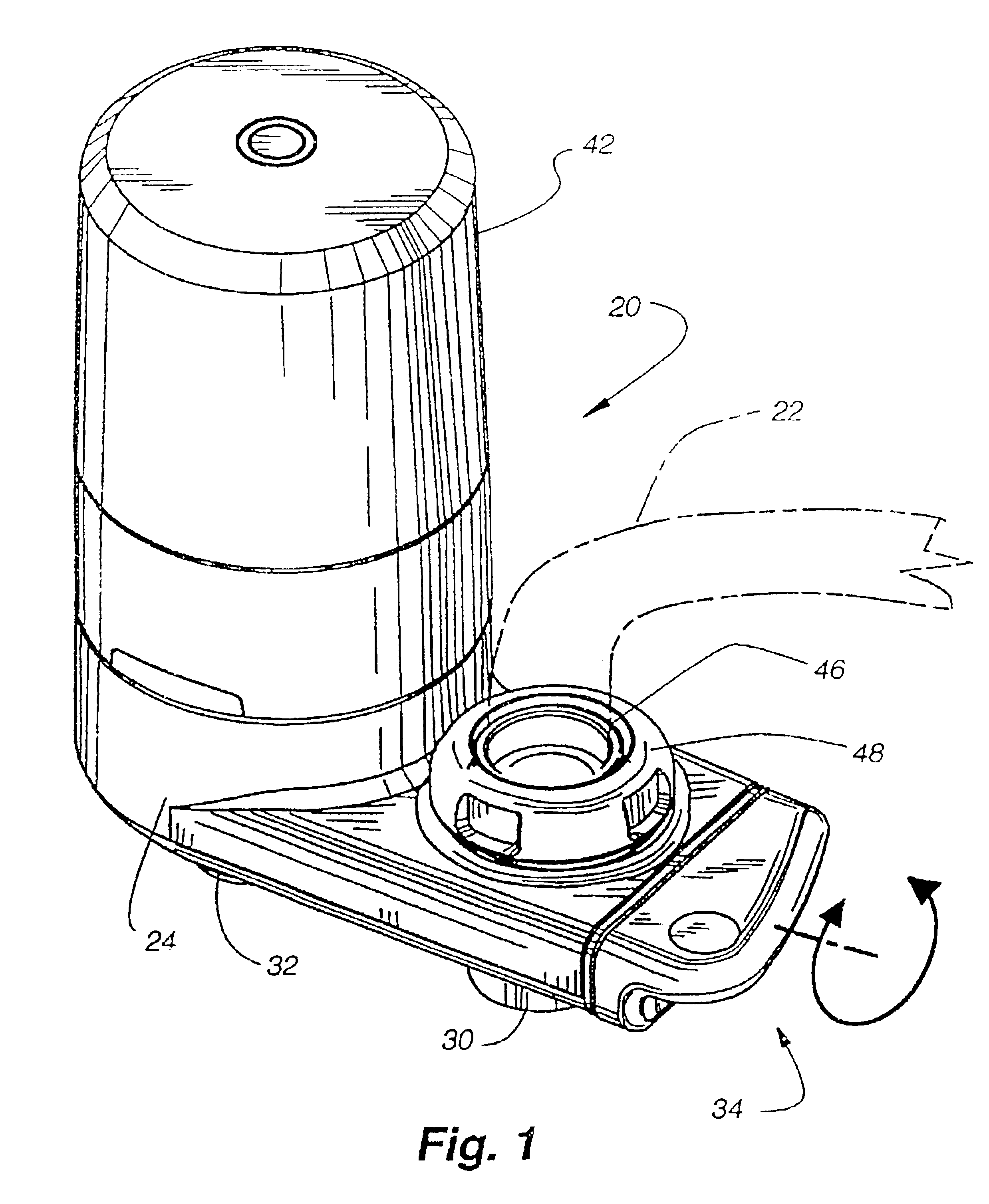

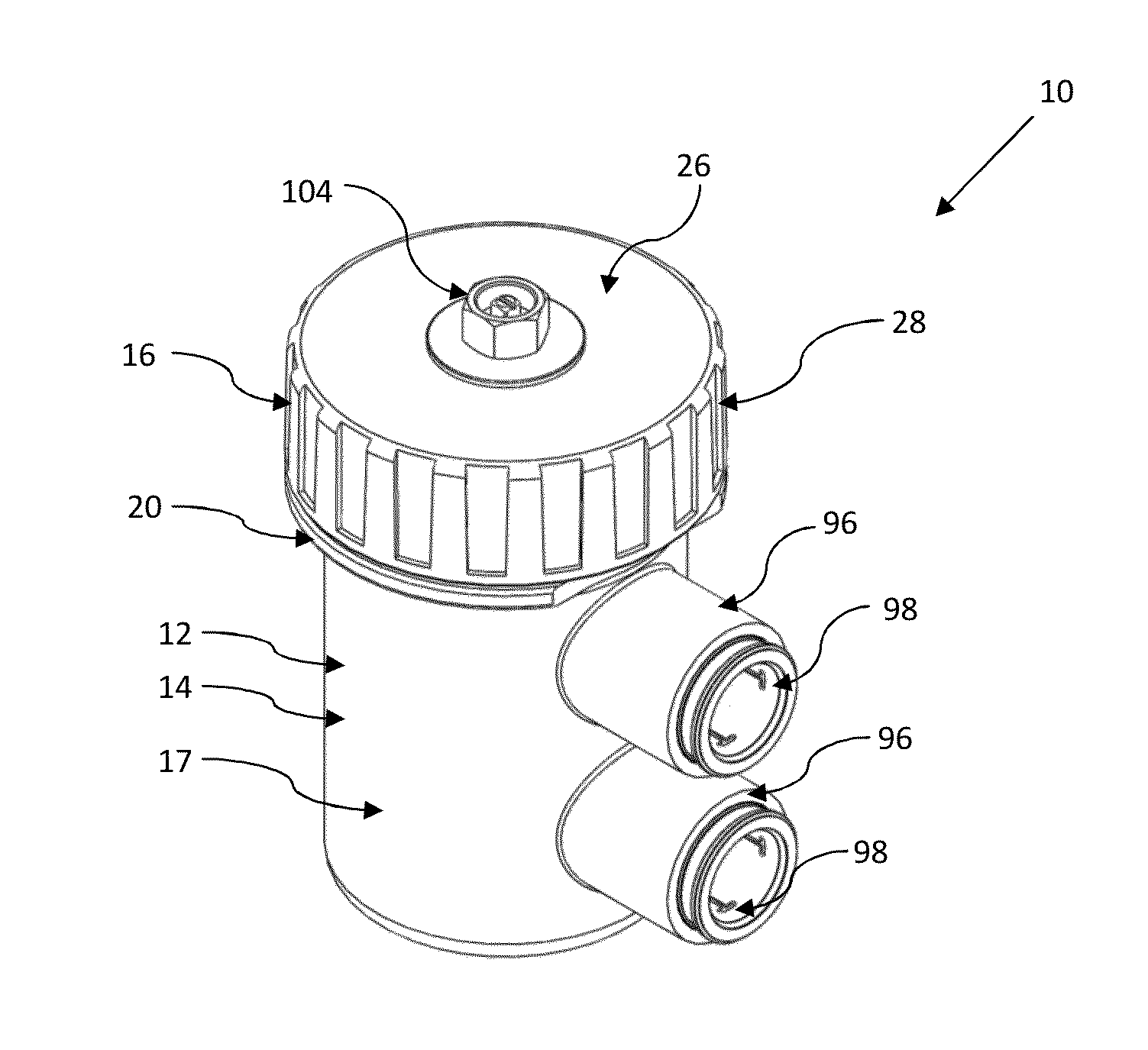

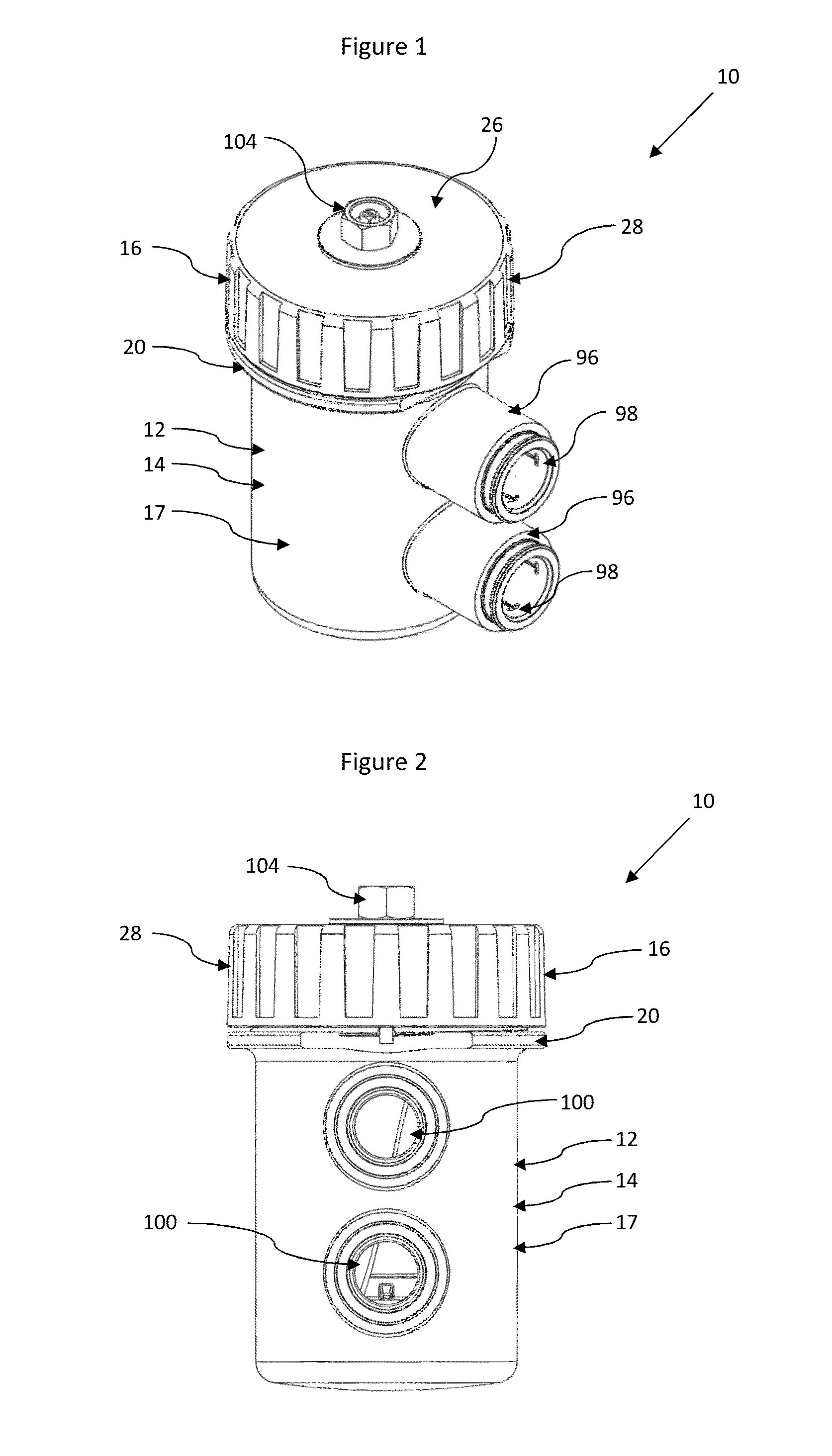

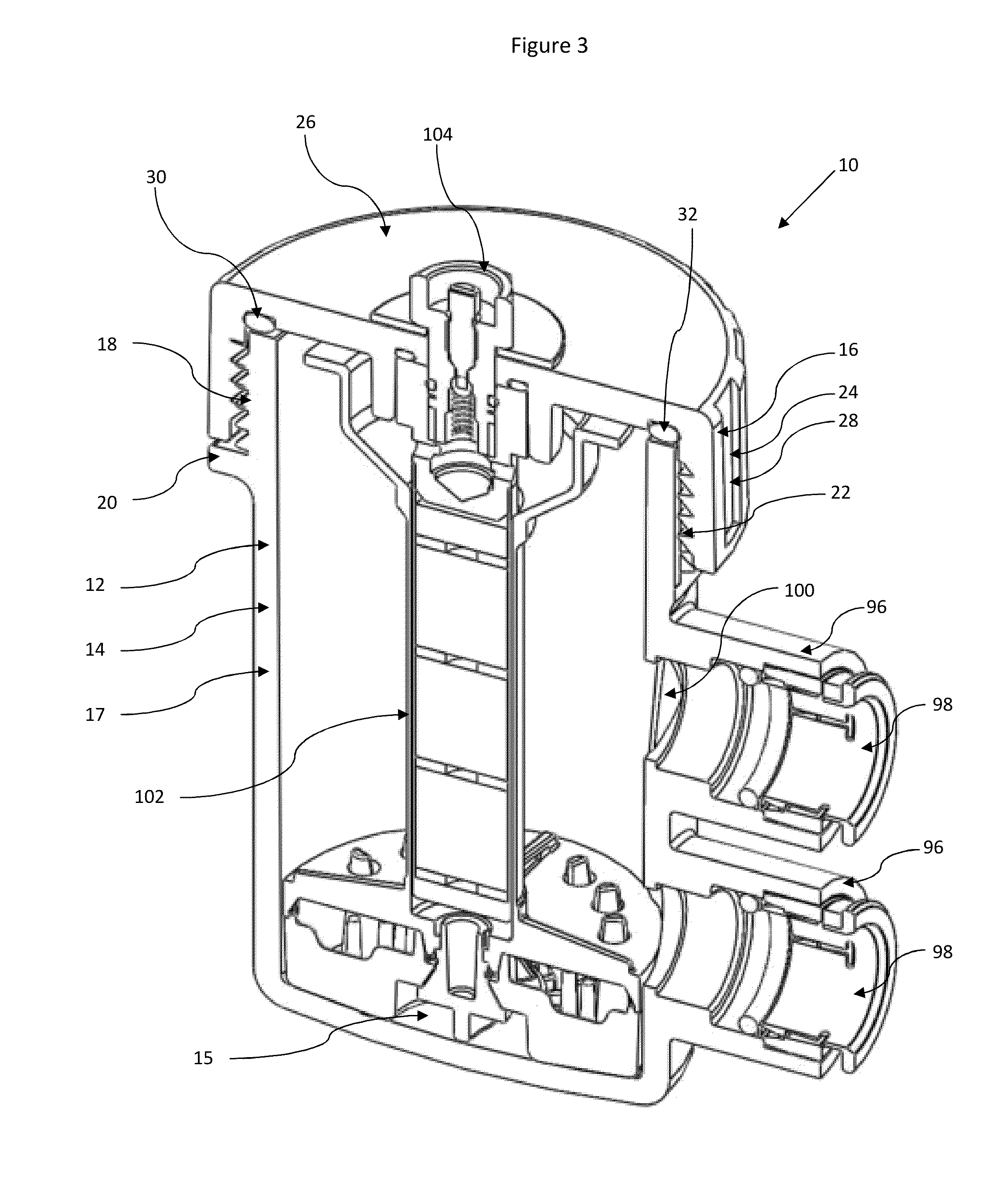

Multi-stage water purification device

InactiveUS20070102332A1Lower the volumeOther chemical processesSedimentation regulating devicesWater flowEnvironmental engineering

A multi-stage water purification device includes an untreated water compartment having an untreated water inlet and a treated water compartment formed from a resilient material. The compartments are segregated from one another. An outlet is in flow communication with the treated water compartment. A first unidirectional valve is disposed between the treated water compartment and the outlet and is configure to permit flow out of the treated water compartment only. A filter is disposed between the untreated water compartment and the treated water compartment. The untreated water flows through the filter to produce treated water. A second unidirectional flow valve is positioned at the discharge of the filter and is configured to permit flow out of the filter and into the treated water compartment only. Water is introduced into the untreated water compartment and the treated water compartment is deformed to reduce the volume therein. As the treated water compartment returns to its initial volume it provides a negative pressure to draw the water through the filter into the treated water compartment.

Owner:MARMON WATER SINGAPORE

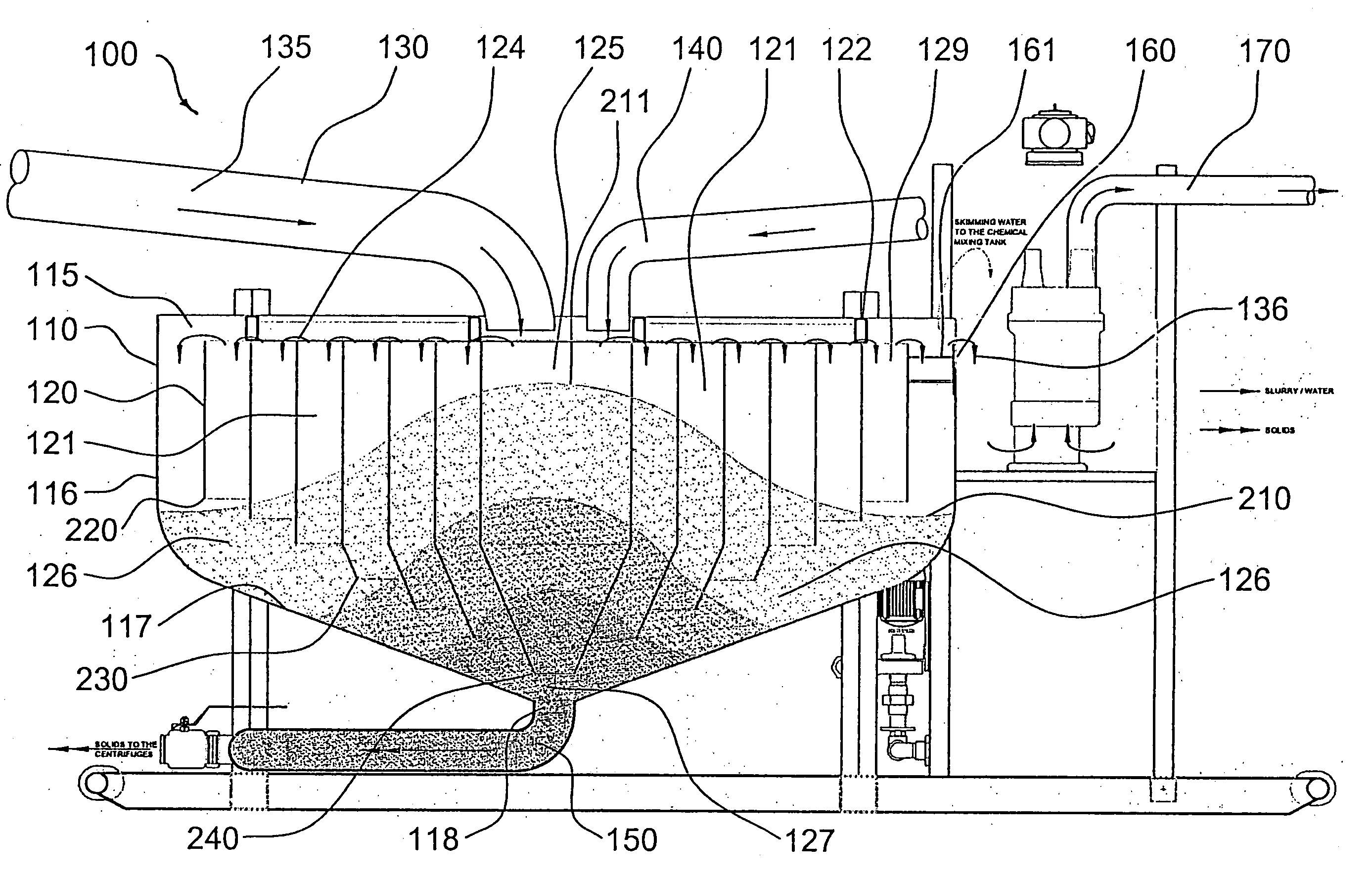

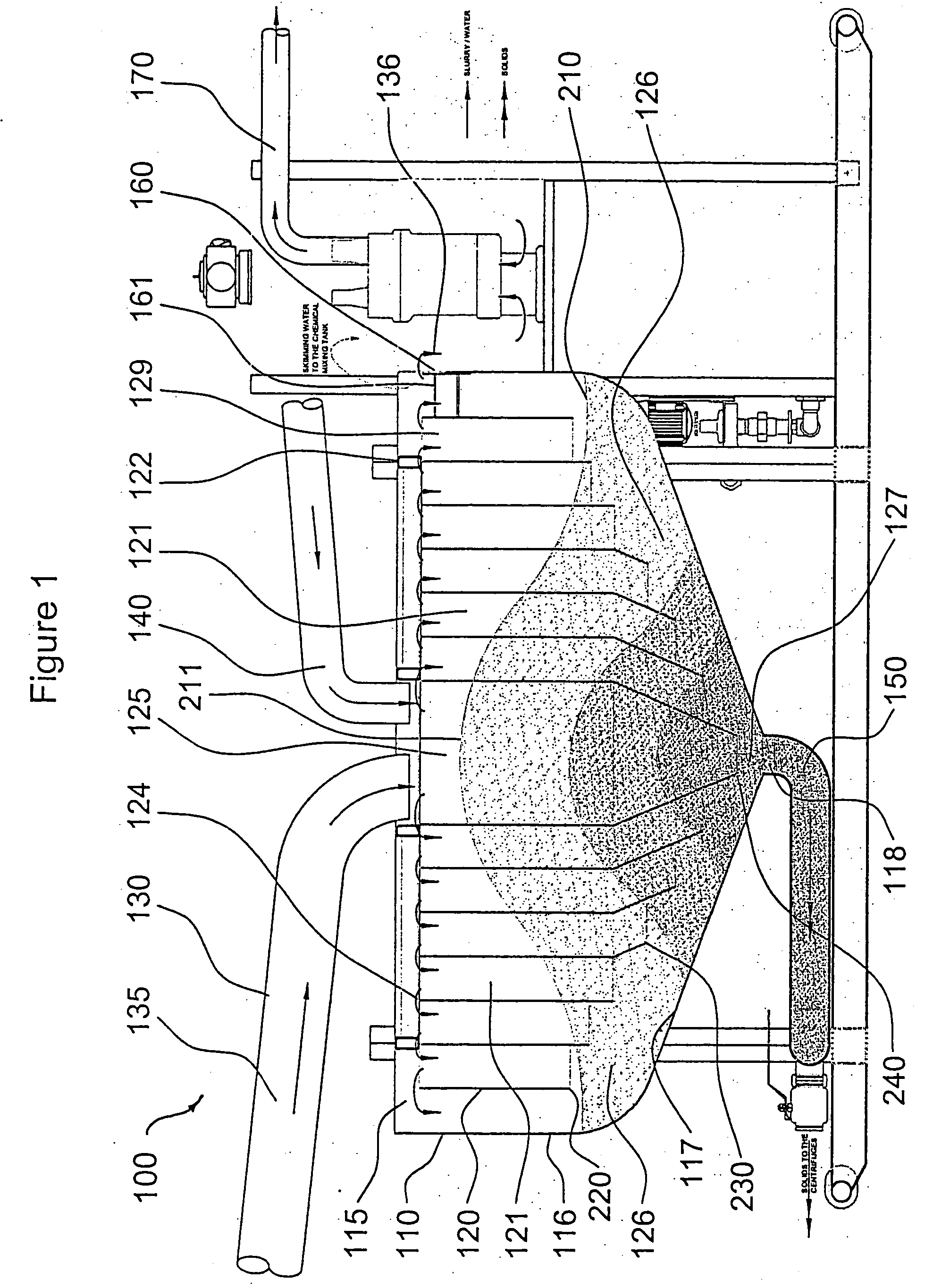

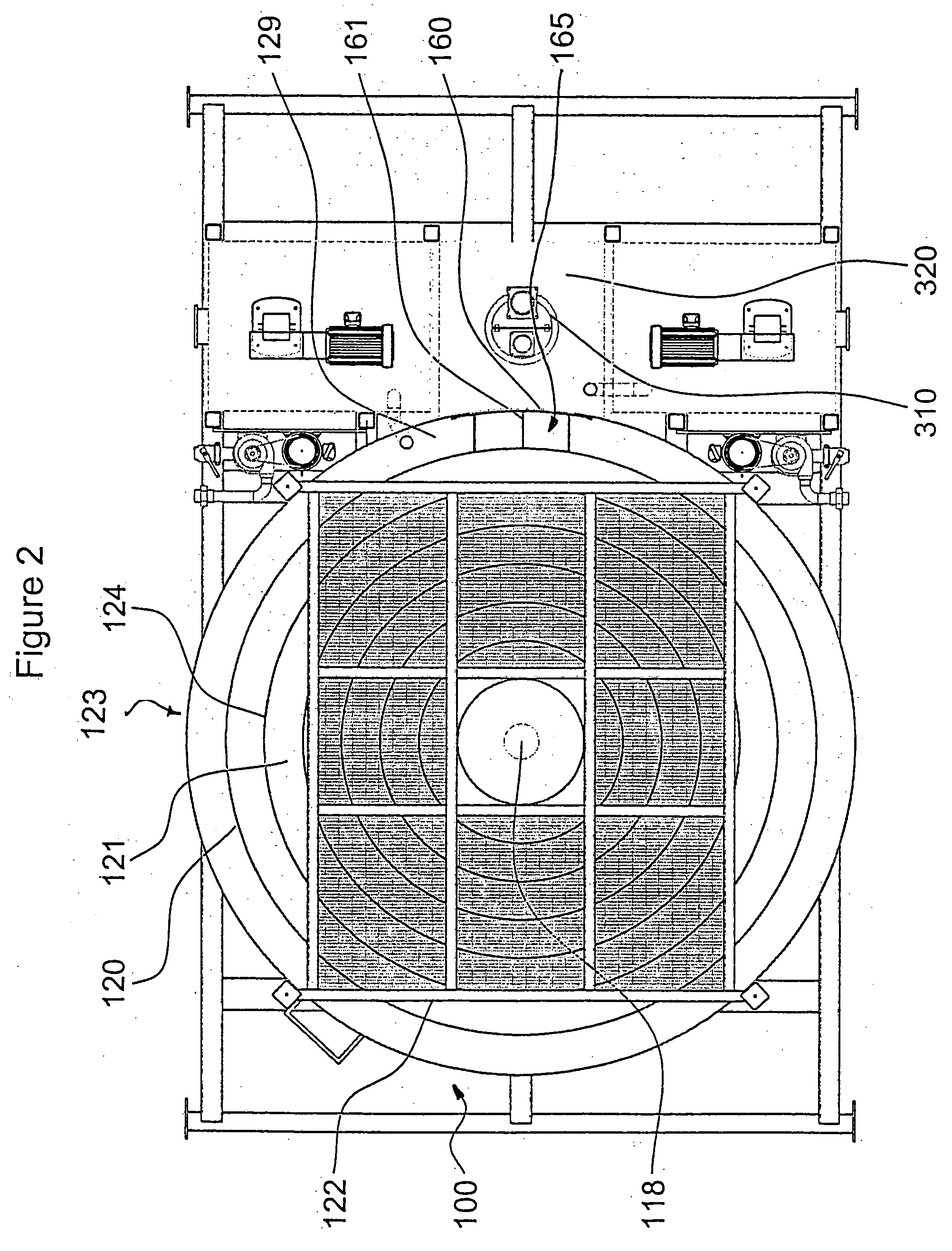

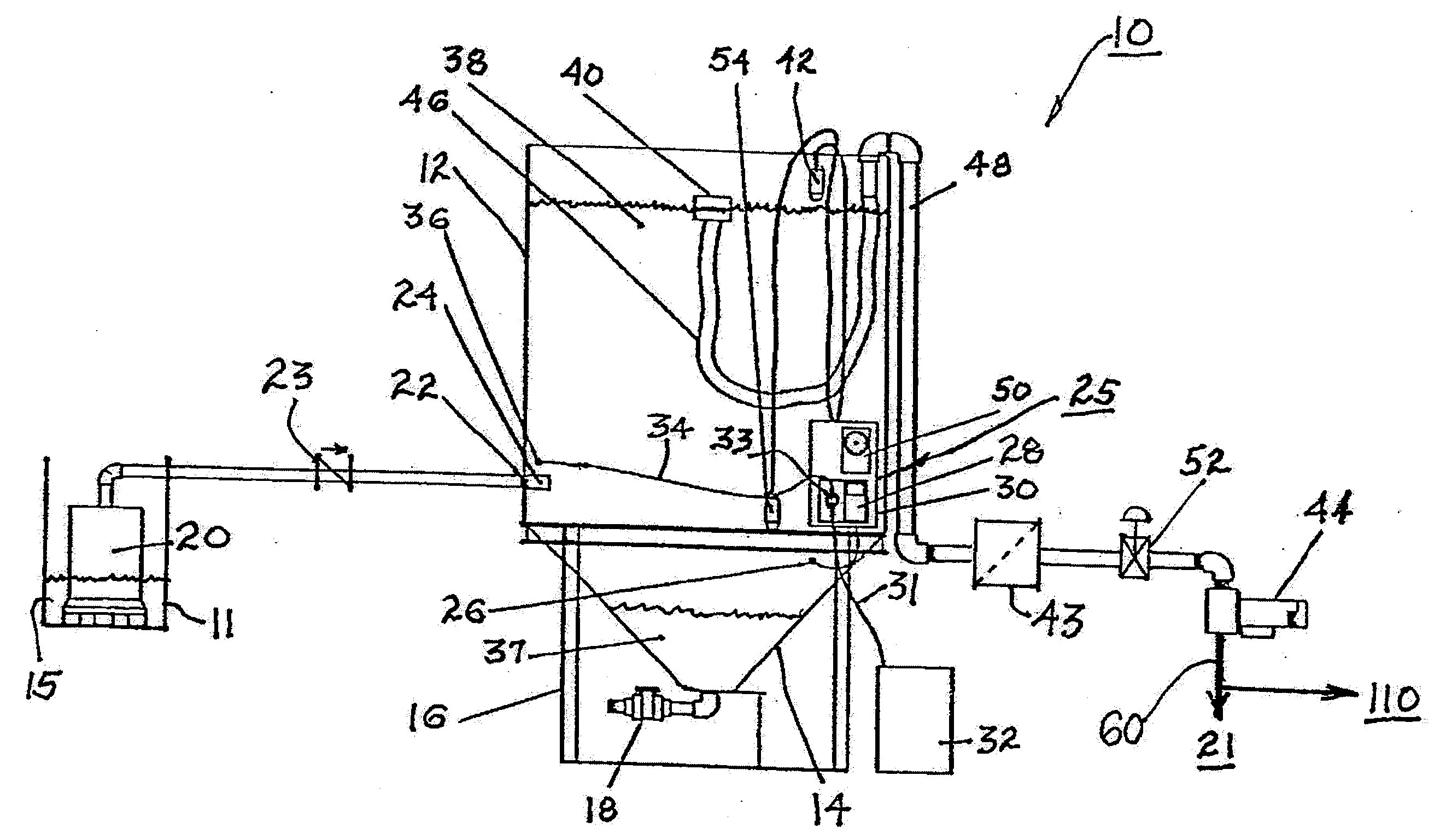

Method, system and apparatus for separating solids from drilling slurry

InactiveUS20050194322A1Minimize water escapingImprove concentrationIon-exchanger regenerationLiquid displacementSlurryCentrifuge

An apparatus to separate solids from drilling slurry, having an inlet positioned over an outlet of a concentration tank to displace water that would otherwise enter the down-stream centrifuges. Baffles are provided to direct solids to the outlet and minimize the time that solids spend in the concentration tank. Fluids having solids removed therefrom are removed from the apparatus at a location remote from the outlet.

Owner:PALMER ROBERT M

Multi-stage water purification device

InactiveUS7585409B2Lower the volumeSolid sorbent liquid separationLoose filtering material filtersWater flowEnvironmental engineering

A multi-stage water purification device includes an untreated water compartment having an untreated water inlet and a treated water compartment formed from a resilient material. The compartments are segregated from one another. An outlet is in flow communication with the treated water compartment. A first unidirectional valve is disposed between the treated water compartment and the outlet and is configure to permit flow out of the treated water compartment only. A filter is disposed between the untreated water compartment and the treated water compartment. The untreated water flows through the filter to produce treated water. A second unidirectional flow valve is positioned at the discharge of the filter and is configured to permit flow out of the filter and into the treated water compartment only. Water is introduced into the untreated water compartment and the treated water compartment is deformed to reduce the volume therein. As the treated water compartment returns to its initial volume it provides a negative pressure to draw the water through the filter into the treated water compartment.

Owner:MARMON WATER SINGAPORE

System For Removing Solids From Aqueous Solutions

InactiveUS20070199903A1Water treatment parameter controlSedimentation regulating devicesAqueous solutionPrecipitation

Processes, apparatus, and compositions are described for removing solids, including dissolved and undissolved solids, from aqueous solutions by crystallization, precipitation, aggregation, absorption, and / or adsorption.

Owner:BIOMASS PROCESSING TECH

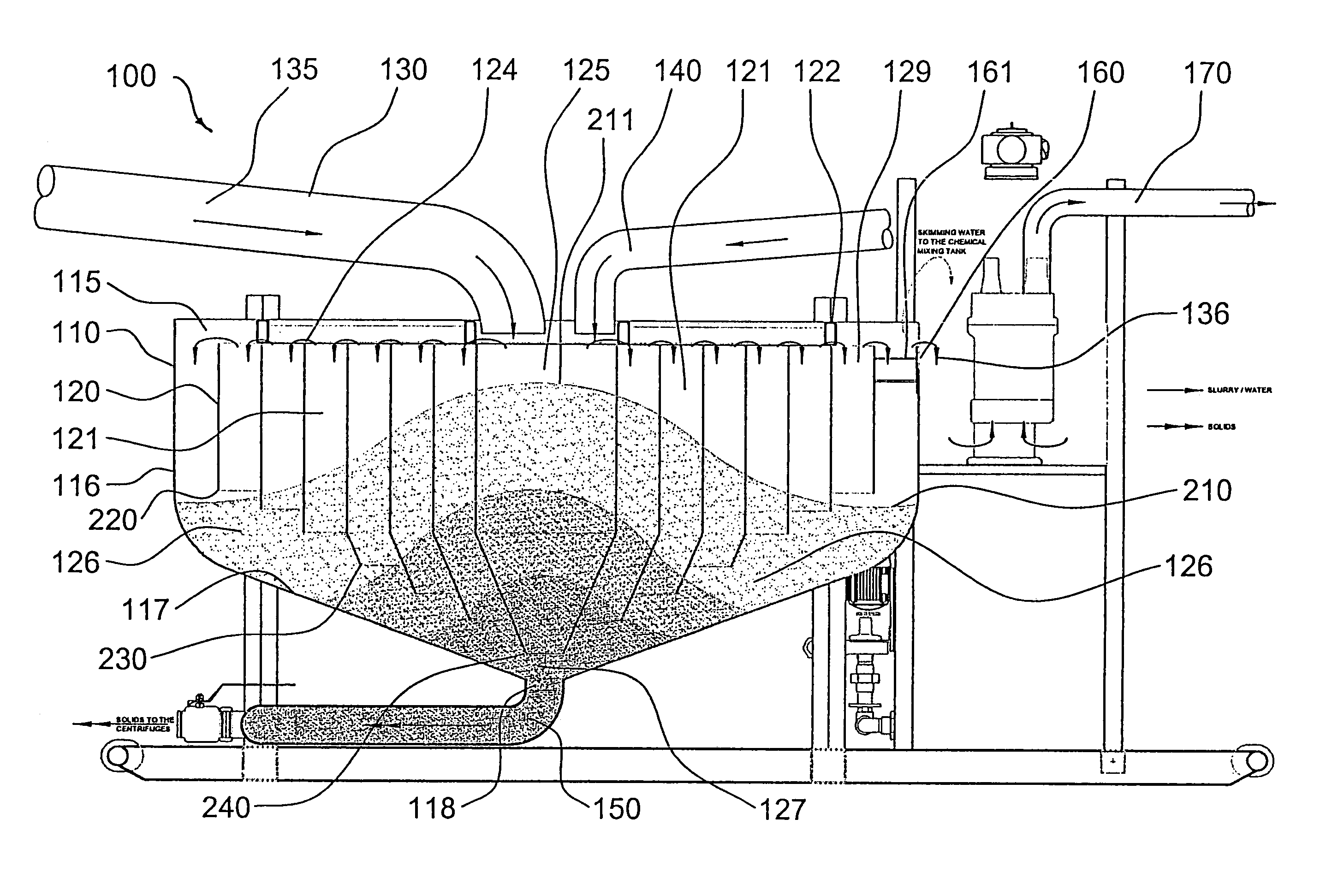

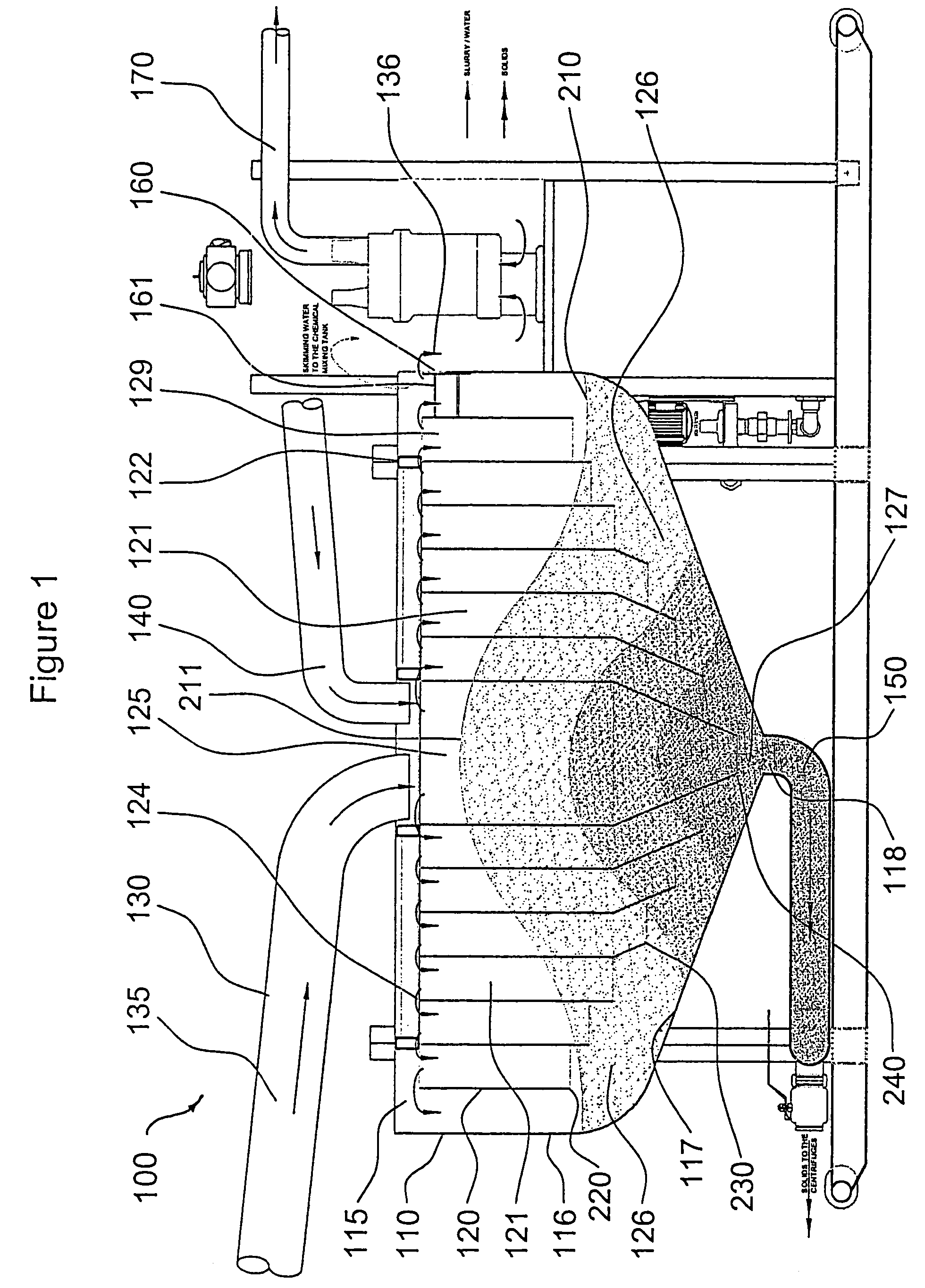

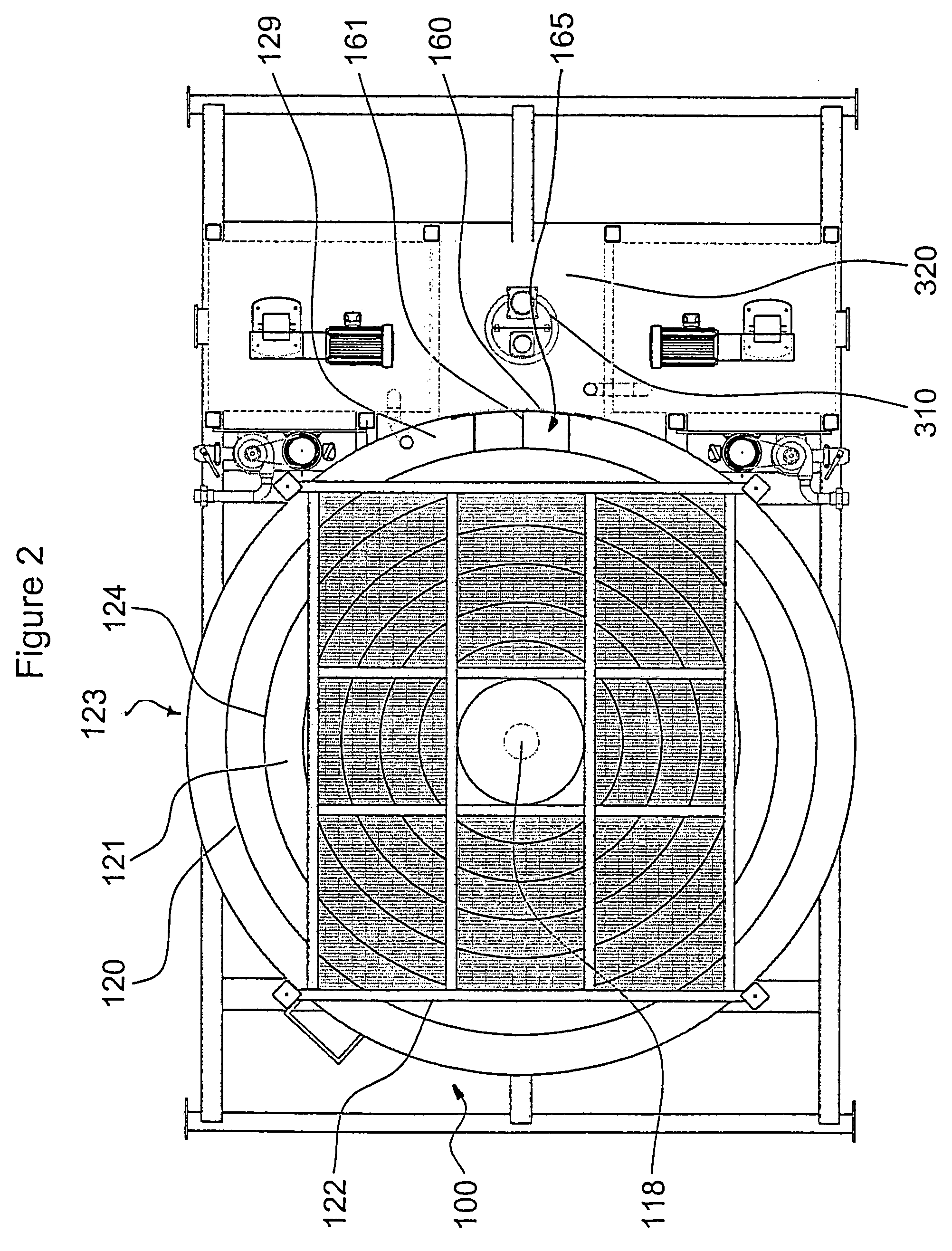

Apparatus and system for concentrating slurry solids

InactiveUS7135107B2Minimize water escapingImprove concentrationIon-exchanger regenerationLiquid displacementSlurryCentrifuge

An apparatus to separate solids from drilling slurry, having an inlet positioned over an outlet of a concentration tank to displace water that would otherwise enter the down-stream centrifuges. Baffles are provided to direct solids to the outlet and minimize the time that solids spend in the concentration tank. Fluids having solids removed therefrom are removed from the apparatus at a location remote from the outlet.

Owner:PALMER ROBERT M

Treatment of spent caustic refinery effluents

InactiveUS20070251650A1Avoid spreadingDrying using combination processesLiquid degasificationCombustionSpent caustic

Owner:DUESEL BERNARD F JR +2

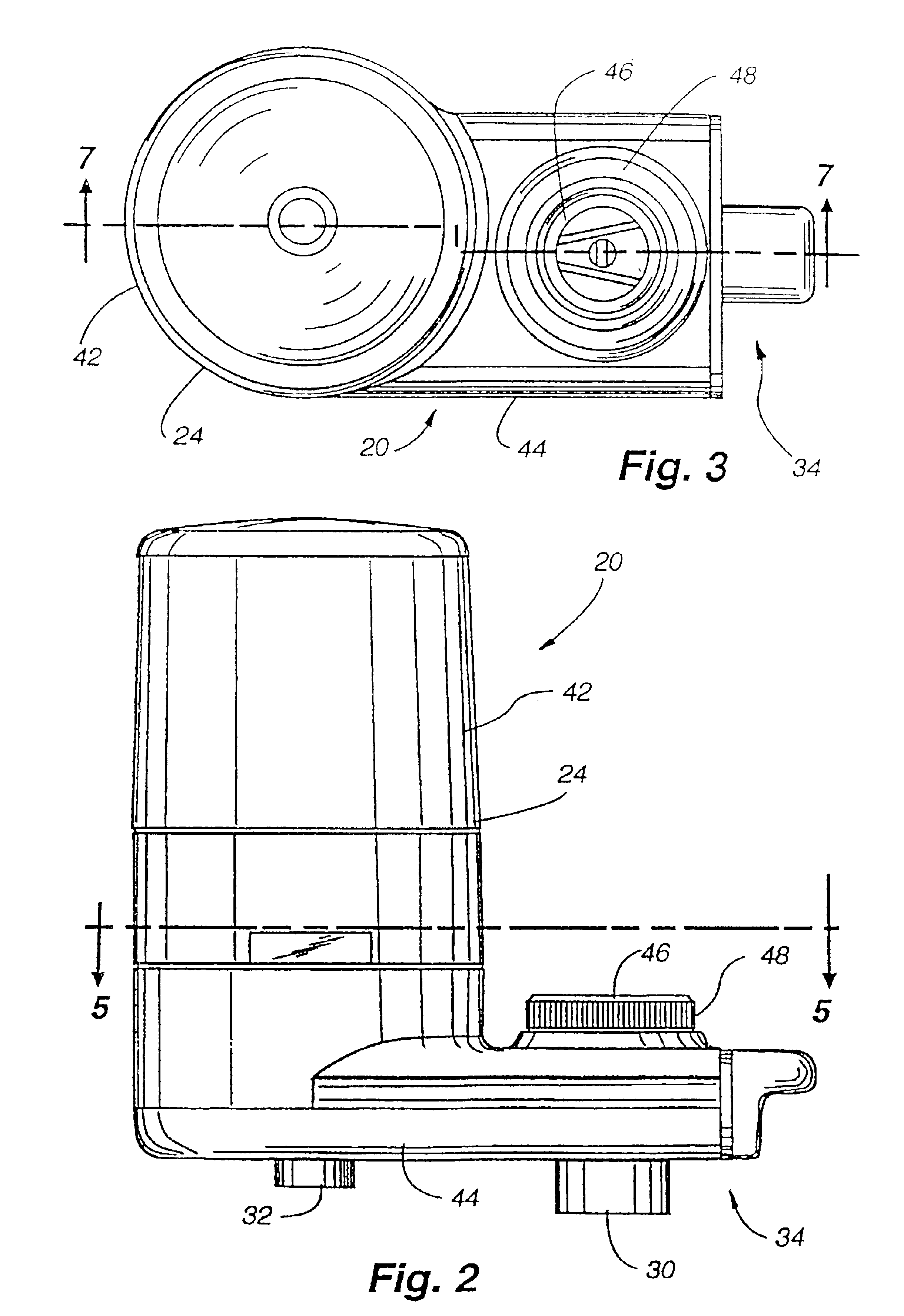

Water treatment device with volumetric and time monitoring features

InactiveUS6926821B2Less palatableEnhanced flushingTreatment involving filtrationCartridge filtersMicrocontrollerOutput device

A totalization meter system for a water treatment device, the device having an inlet aperture and an outlet aperture, and a channel for channeling water between the inlet and outlet apertures. A flow reactive device is positioned in the channel and is exposed to the flowing water, and a signal generating member is positioned on the flow reactive device. A switch is positioned proximately to the flow reactive device, and is sensitive to the proximity of the signal generating member. The switch is able to communicate electric signals indicative of the motion of the signal generating member. A resettable processor having a performance threshold programmed therein and an output device is included. The microcontroller is in electrical communication with the switch for receiving electrical signals from the switch. The switch is capable of sensing the characteristics of the flow reactive device and communicates electrical signals representative of the characteristics to the microcontroller. The microcontroller interprets the signals as a first performance data. The microcontroller compares the first performance data against the respective performance threshold in the microcontroller to determine if the performance threshold has been surpassed, and if surpassed actuates the output device.

Owner:INSTAPURE BRANDS

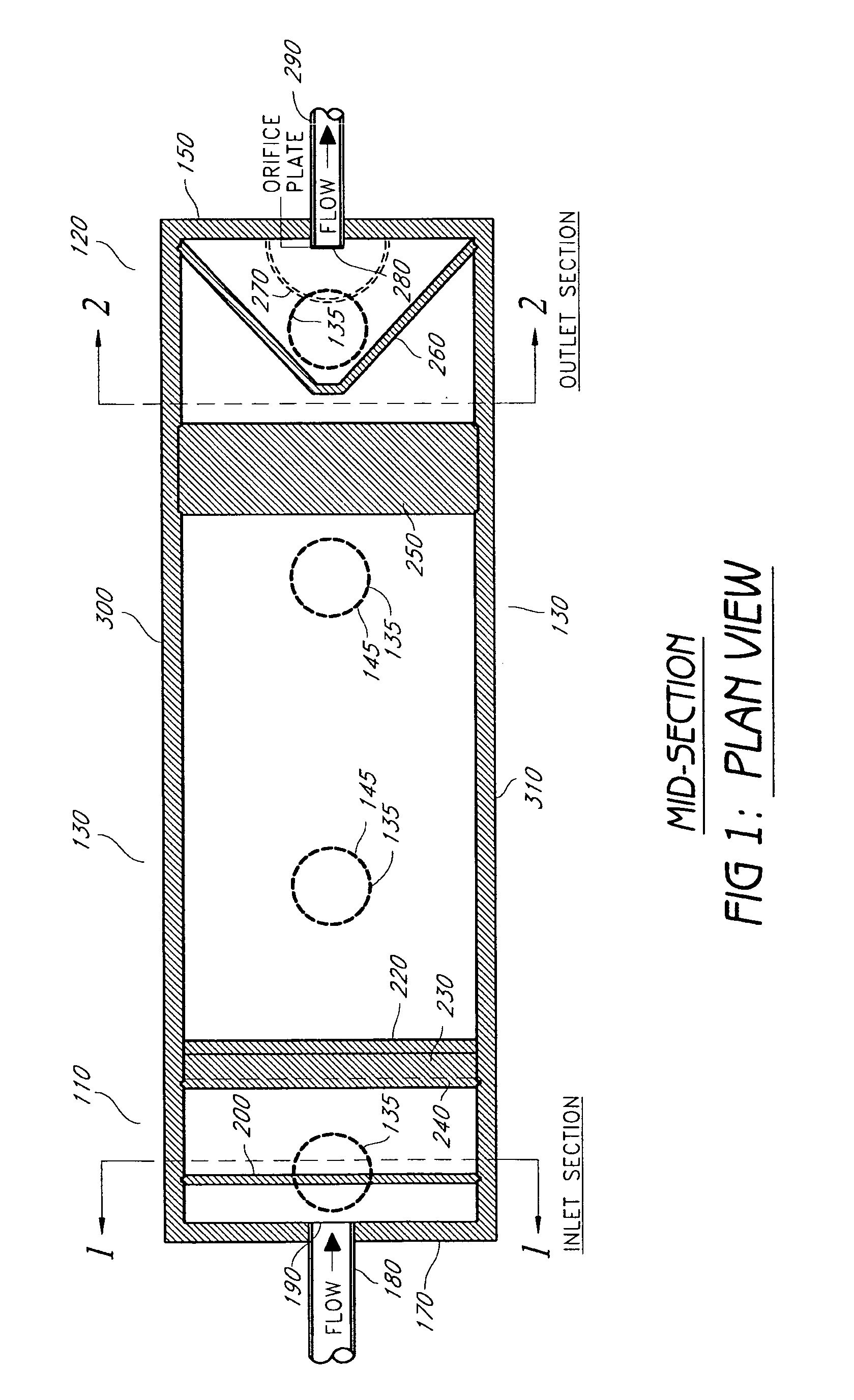

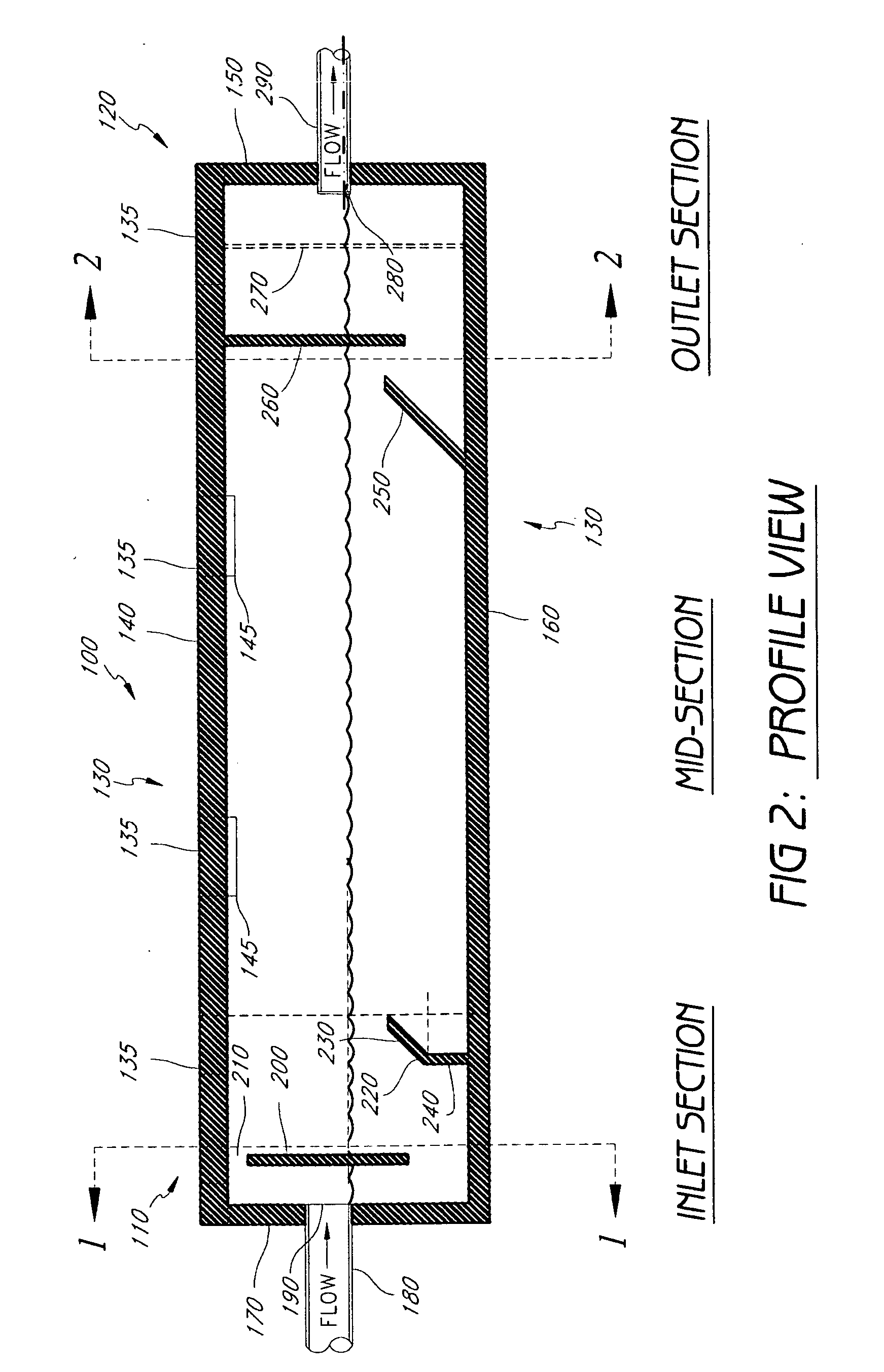

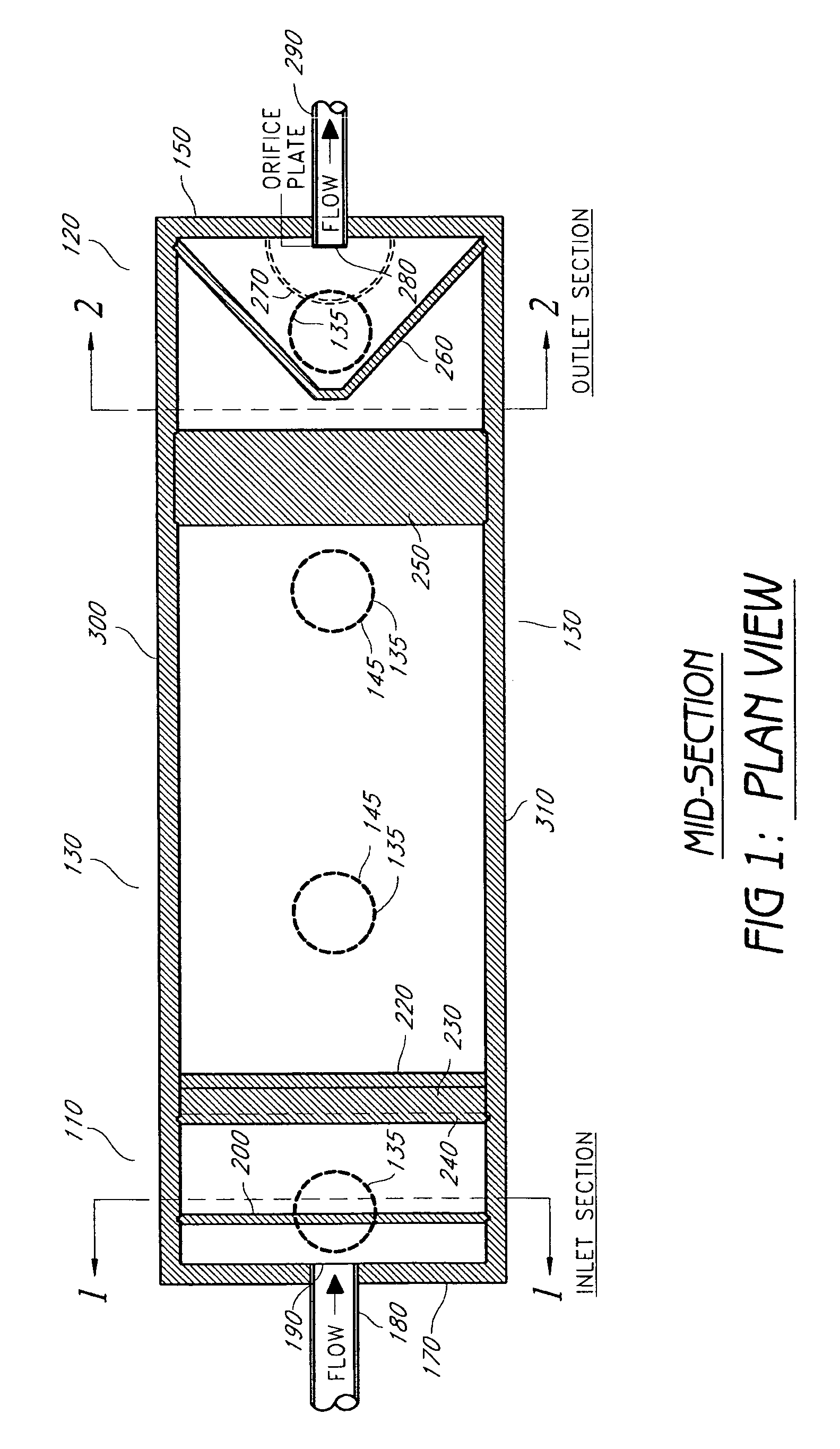

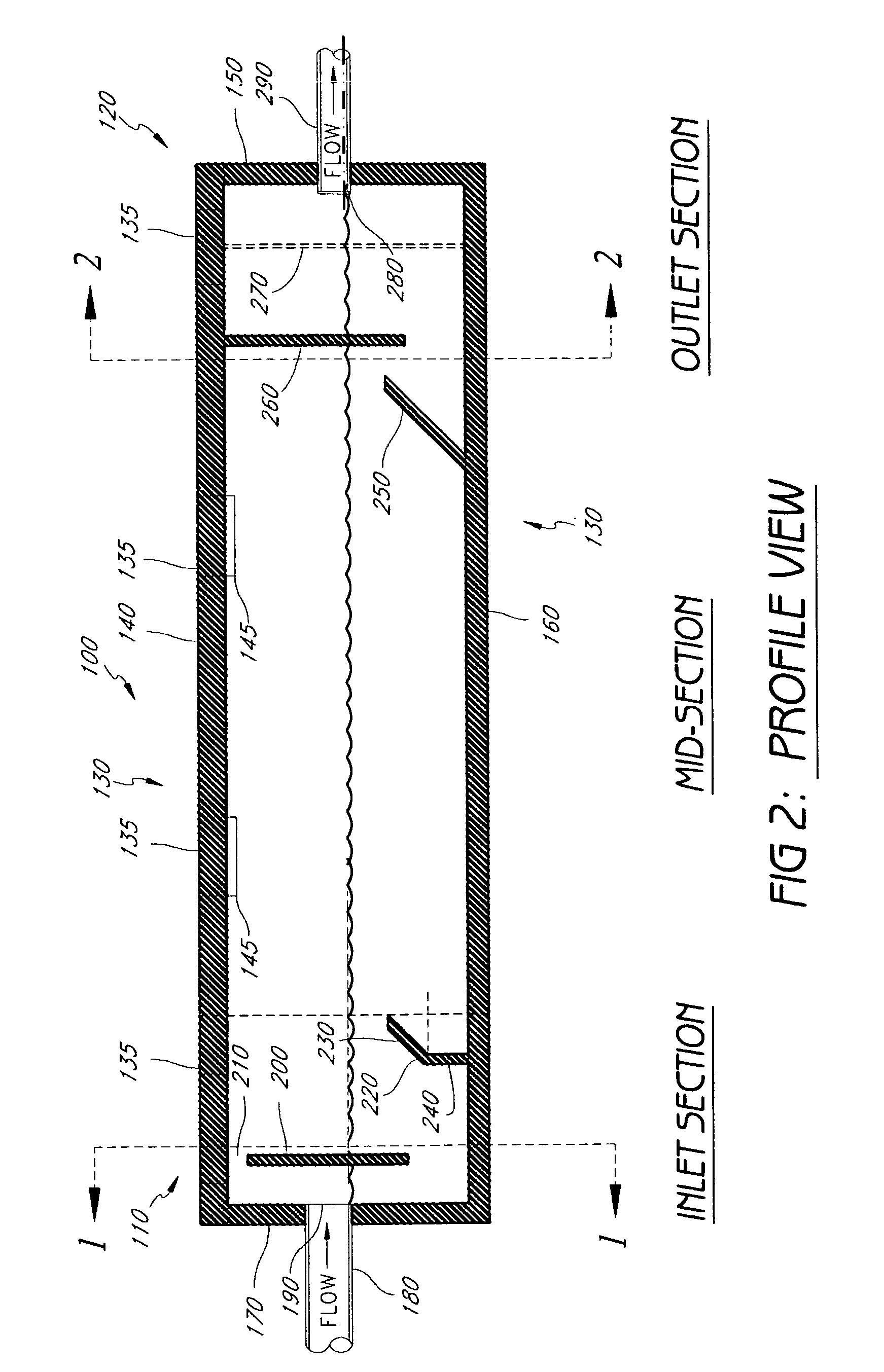

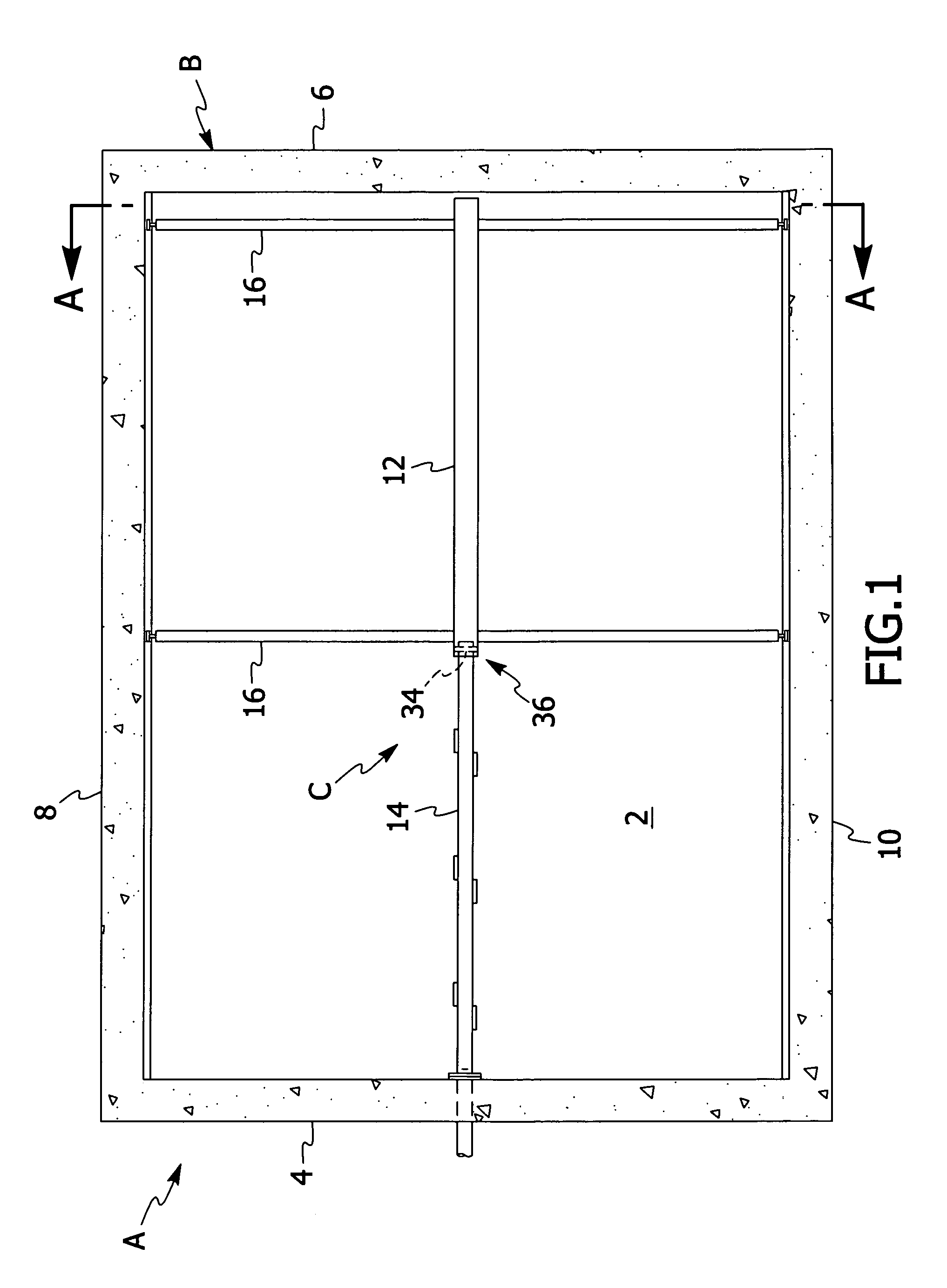

Stormwater treatment apparatus and method

InactiveUS20070068878A1Compact footprint areaCompact plan areaGeneral water supply conservationTreatment involving filtrationWater volumeWater flow

A liquid purification and separation apparatus for separation of pollutants in stormwater runoff is disclosed. This apparatus utilizes gravitational separation and tortuosity, resulting from a plurality of baffles both perpendicular to and oblique to the primary water flow direction, to trap substances less-dense and more-dense than water. The apparatus features improved resistance to pollutant remobilization through treatment of water volume rather than flow rates, using vertically stacked water columns of varying depths to settle small particles. An overflow structure diverts excessive liquid without interfering with purification and separation, and can be placed integrally within or external to the apparatus receptacle.

Owner:JENSEN PRECAST

Stormwater treatment apparatus and method

InactiveUS7638065B2Reduce flow rateReduced and eliminated relative flow velocityGeneral water supply conservationTreatment involving filtrationWater volumeWater flow

A liquid purification and separation apparatus for separation of pollutants in stormwater runoff is disclosed. This apparatus utilizes gravitational separation and tortuosity, resulting from a plurality of baffles both perpendicular to and oblique to the primary water flow direction, to trap substances less-dense and more-dense than water. The apparatus features improved resistance to pollutant remobilization through treatment of water volume rather than flow rates, using vertically stacked water columns of varying depths to settle small particles. An overflow structure diverts excessive liquid without interfering with purification and separation, and can be placed integrally within or external to the apparatus receptacle.

Owner:JENSEN PRECAST

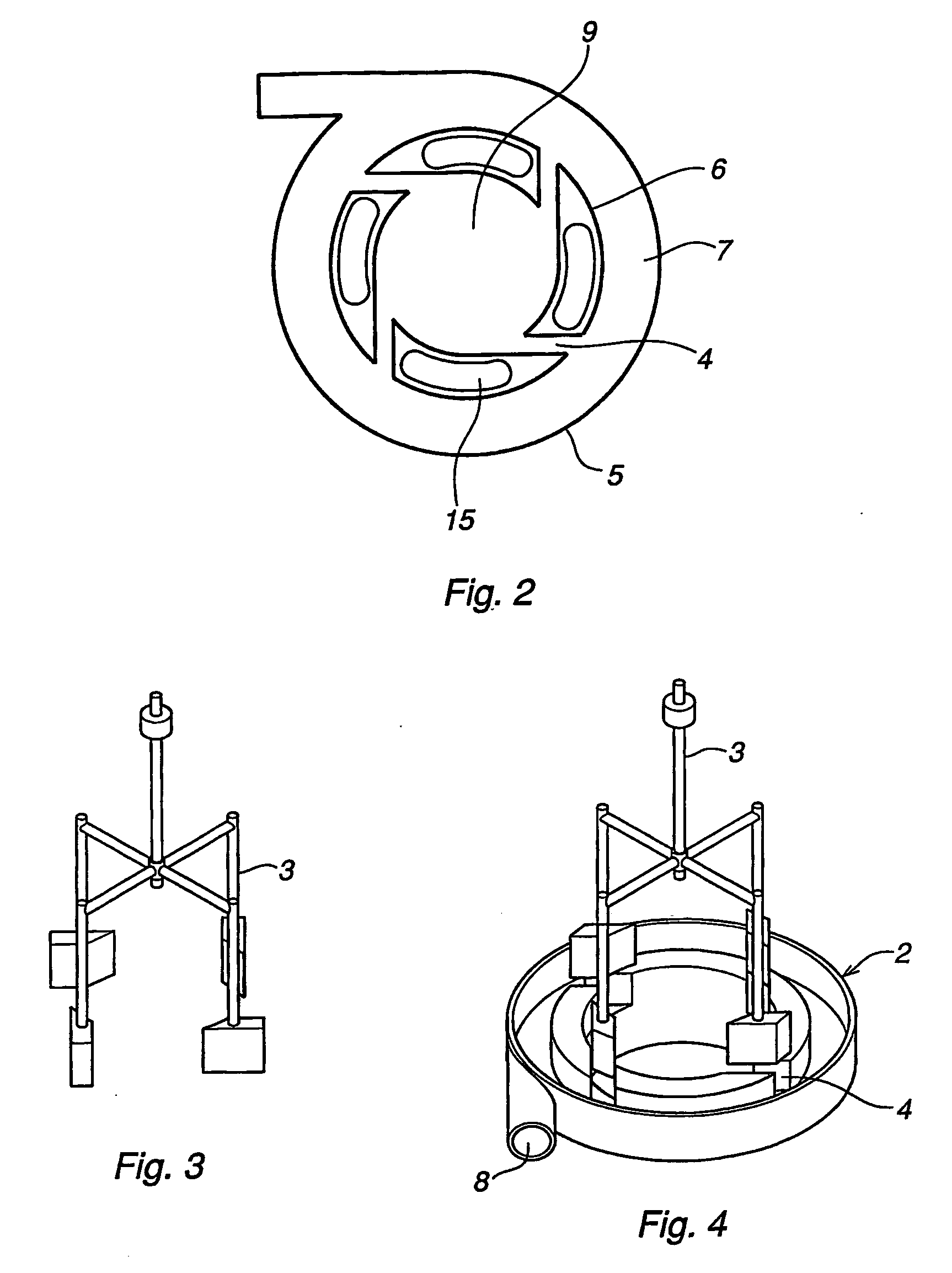

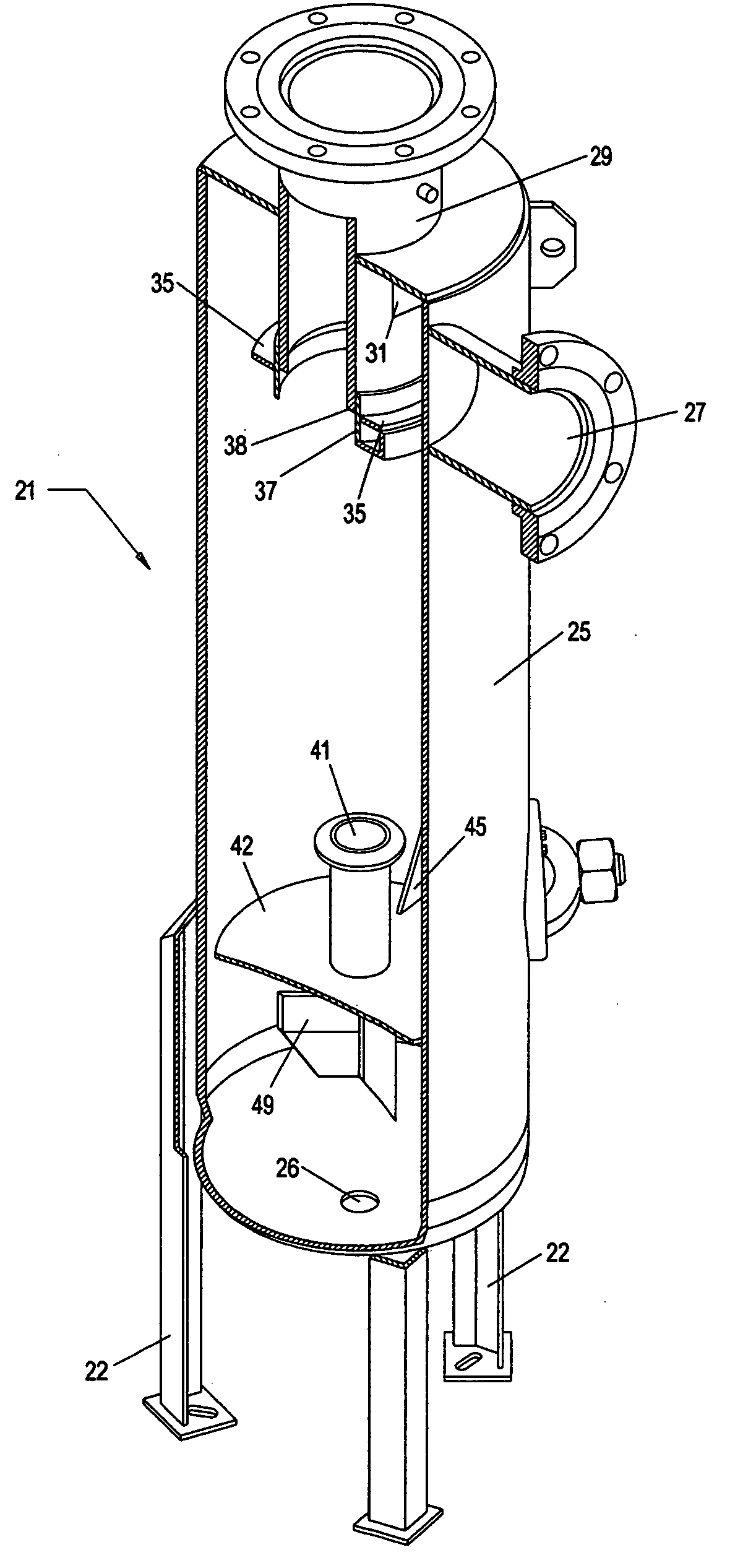

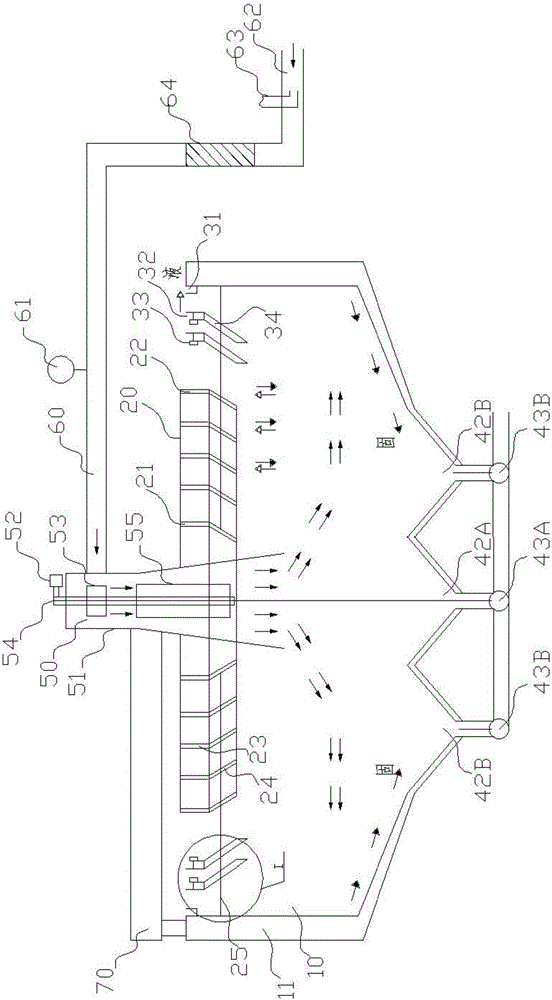

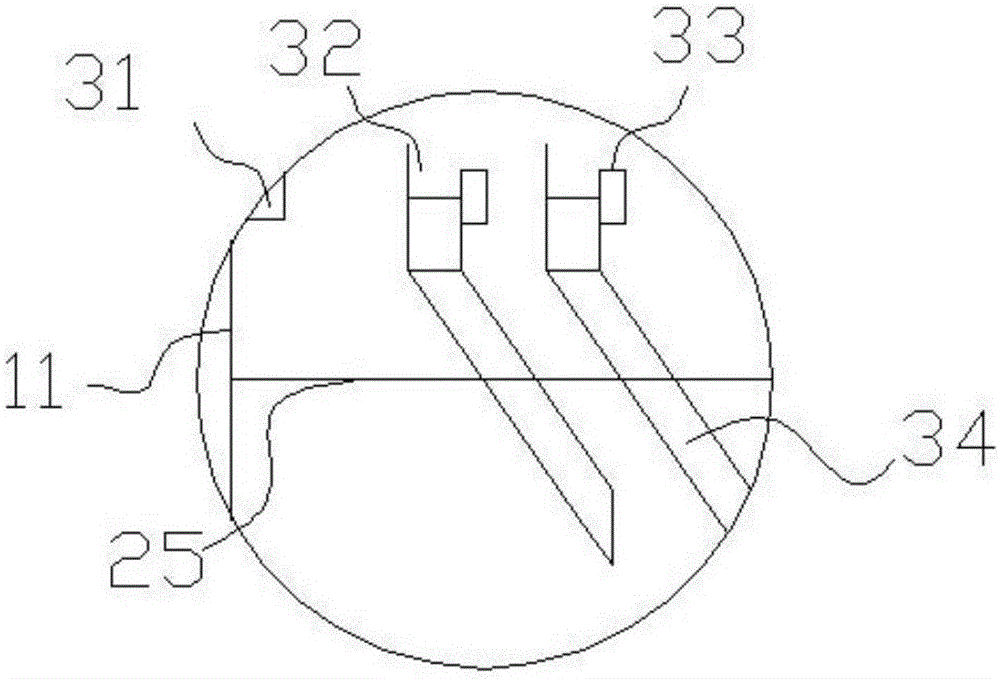

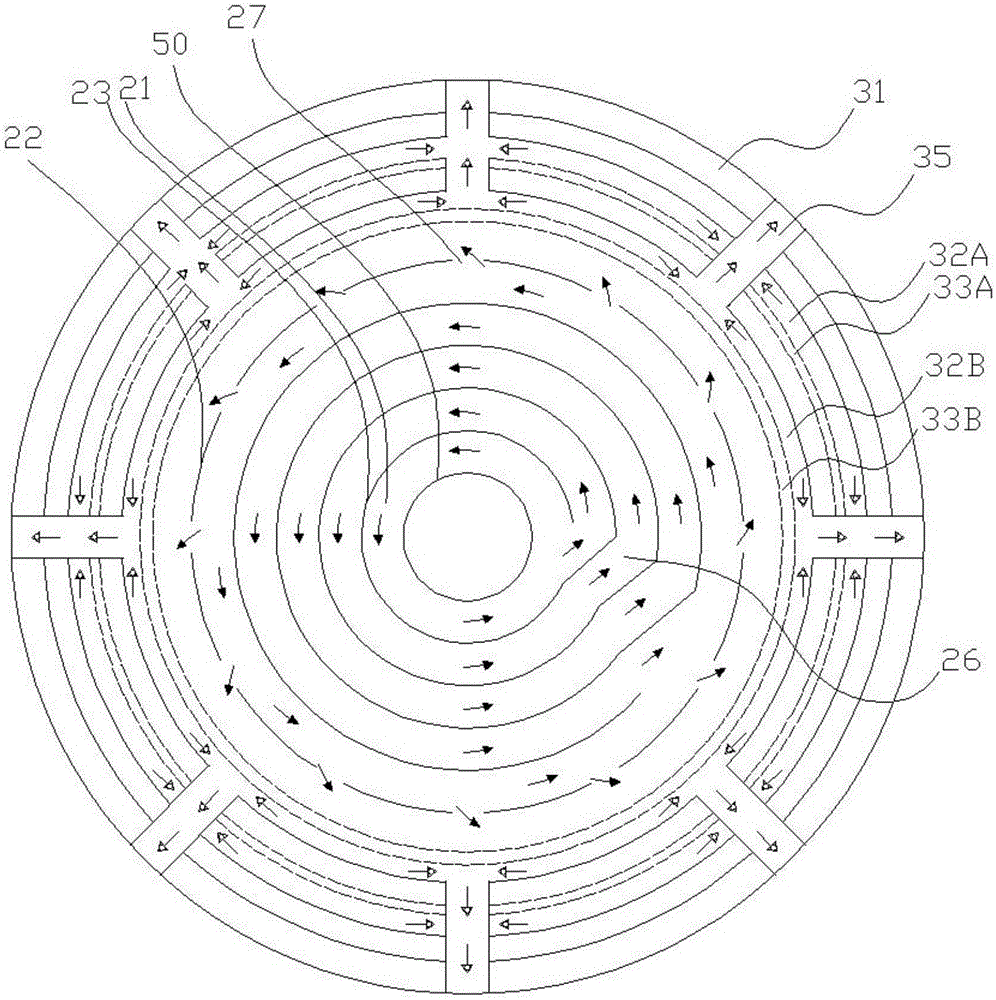

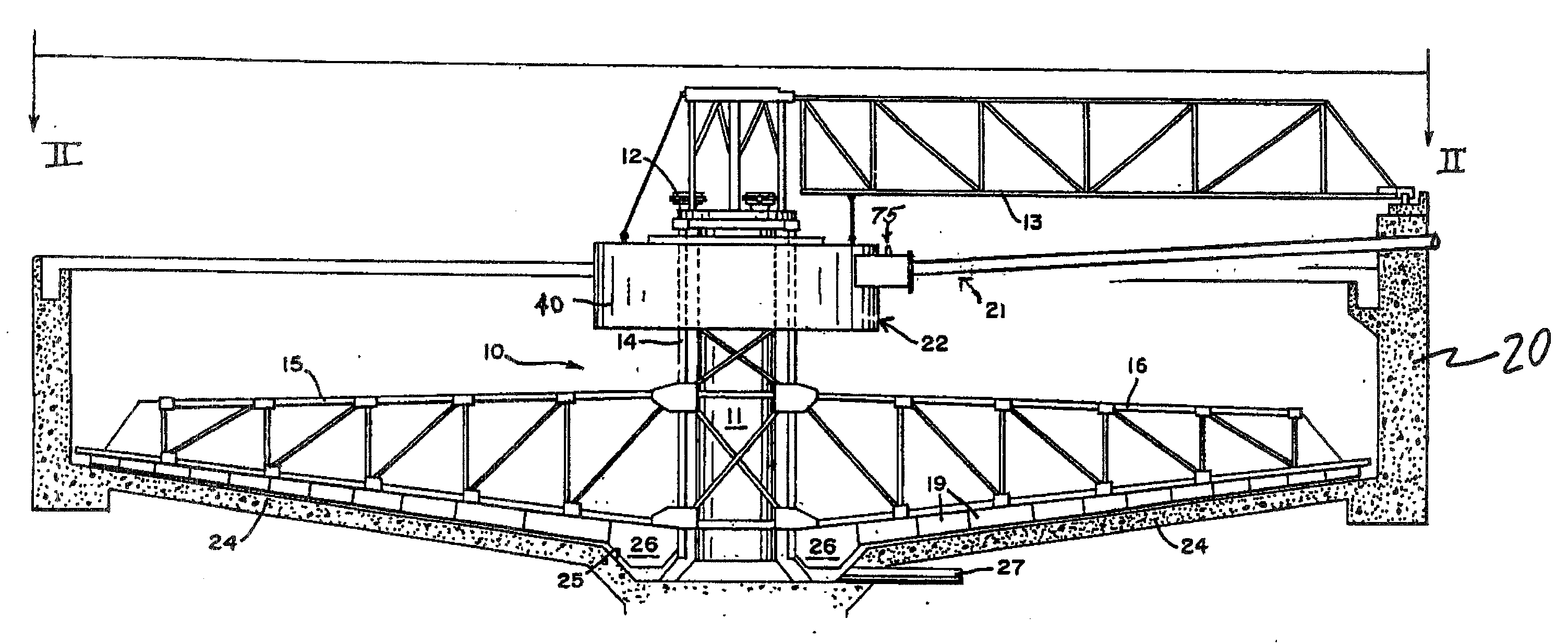

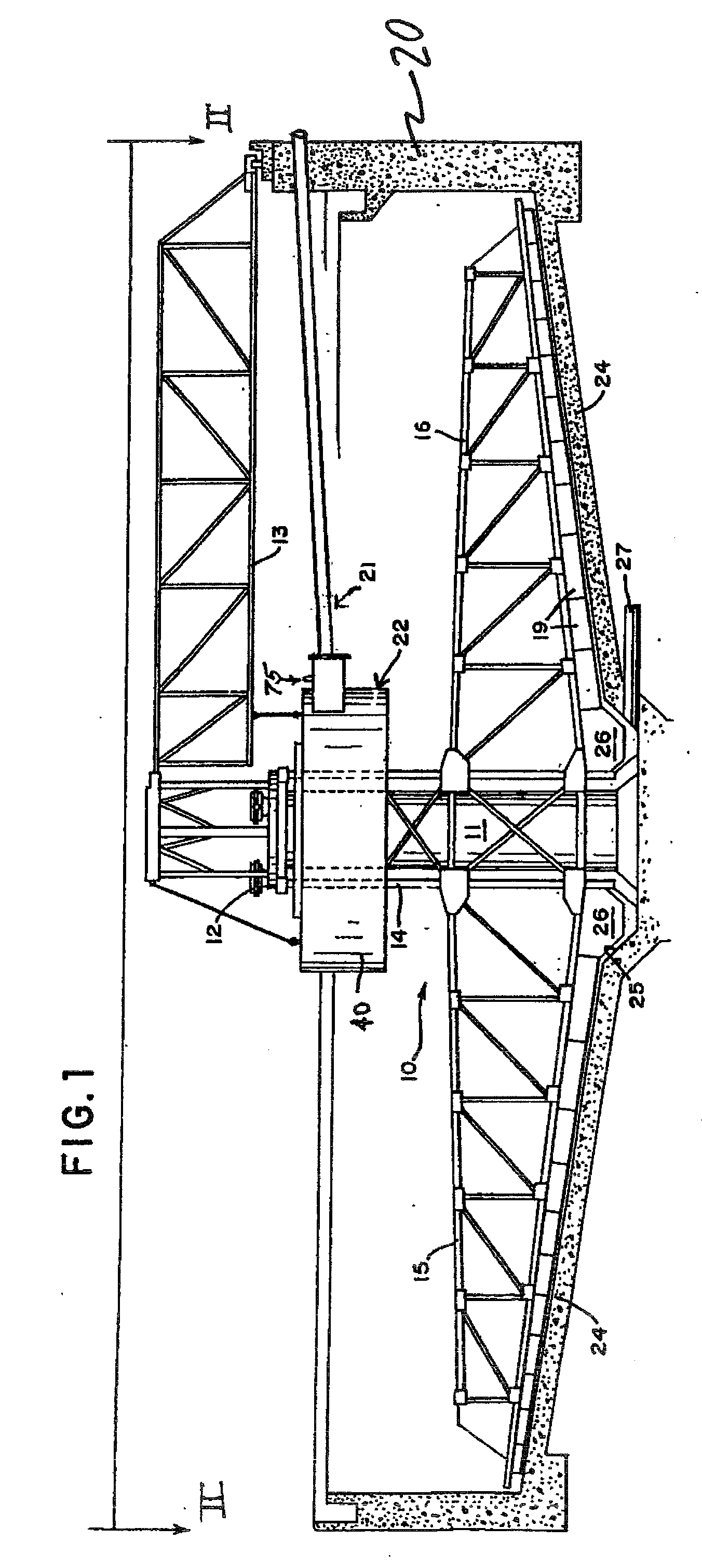

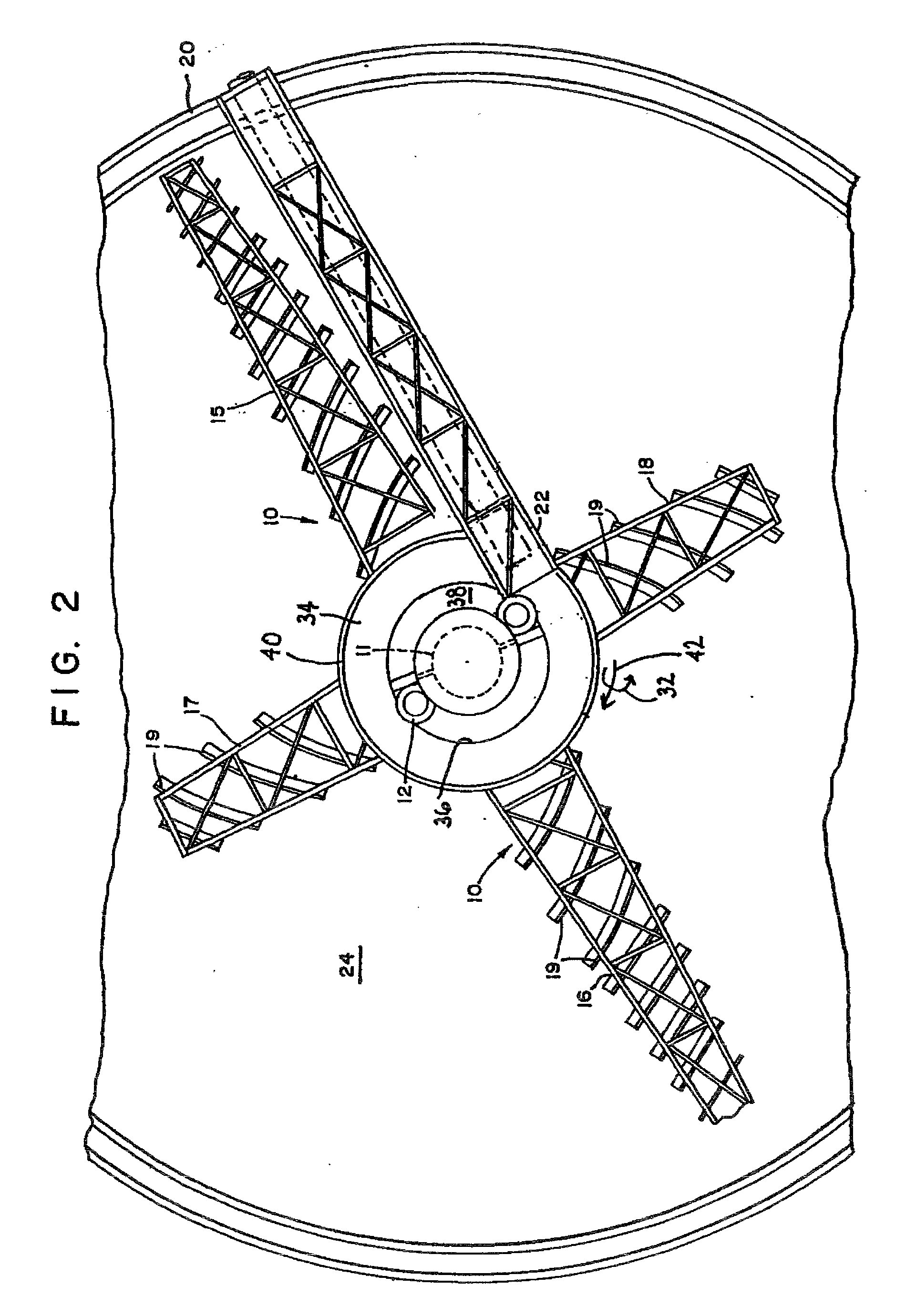

Rake-free thickener with rotary annular channels

ActiveCN105944407AEnsure stabilityImprove settlement performanceSedimentation regulating devicesSettling tanks feed/dischargeWater concentrationEngineering

The invention relates to the field of slime water concentration and clarification, in particular to a rake-free thickener with rotary annular channels. The rake-free thickener at least comprises a thickener body, and further comprises rotary annular channels, wherein the rotary annular channels are used for constraining upper-layer ore pulp inside the thickener to do reciprocatory motion; the rotary annular channels consist of a plurality groups of annular channels of which the diameters are increased gradually; adjacent annular channels are mutually communicated through connecting channels; each group of the annular channels comprises an upper annular partitioning plate and a lower inclined settlement plate; overflowing ore pulp is discharged out from overflow weirs; the overflow weirs comprise annular overflow weirs and composite overflow weirs; settled granules are fed into a bottom flow discharge system; the bottom flow discharge system consist of bottom flow collecting cabins, bottom flow holes and corresponding bottom flow pumps; the rake-free thickener further comprises a feeding pipeline and a driving stirring mechanism; a stirring machine is driven by residual power of the feeding pipeline conveying the ore pulp to rotate so as to uniformly mix the ore pulp with medicines. The rake-free thickener has the characteristics of being low in energy consumption, low in repairing workload, low in medicine consumption and free of rake.

Owner:ANHUI UNIV OF SCI & TECH

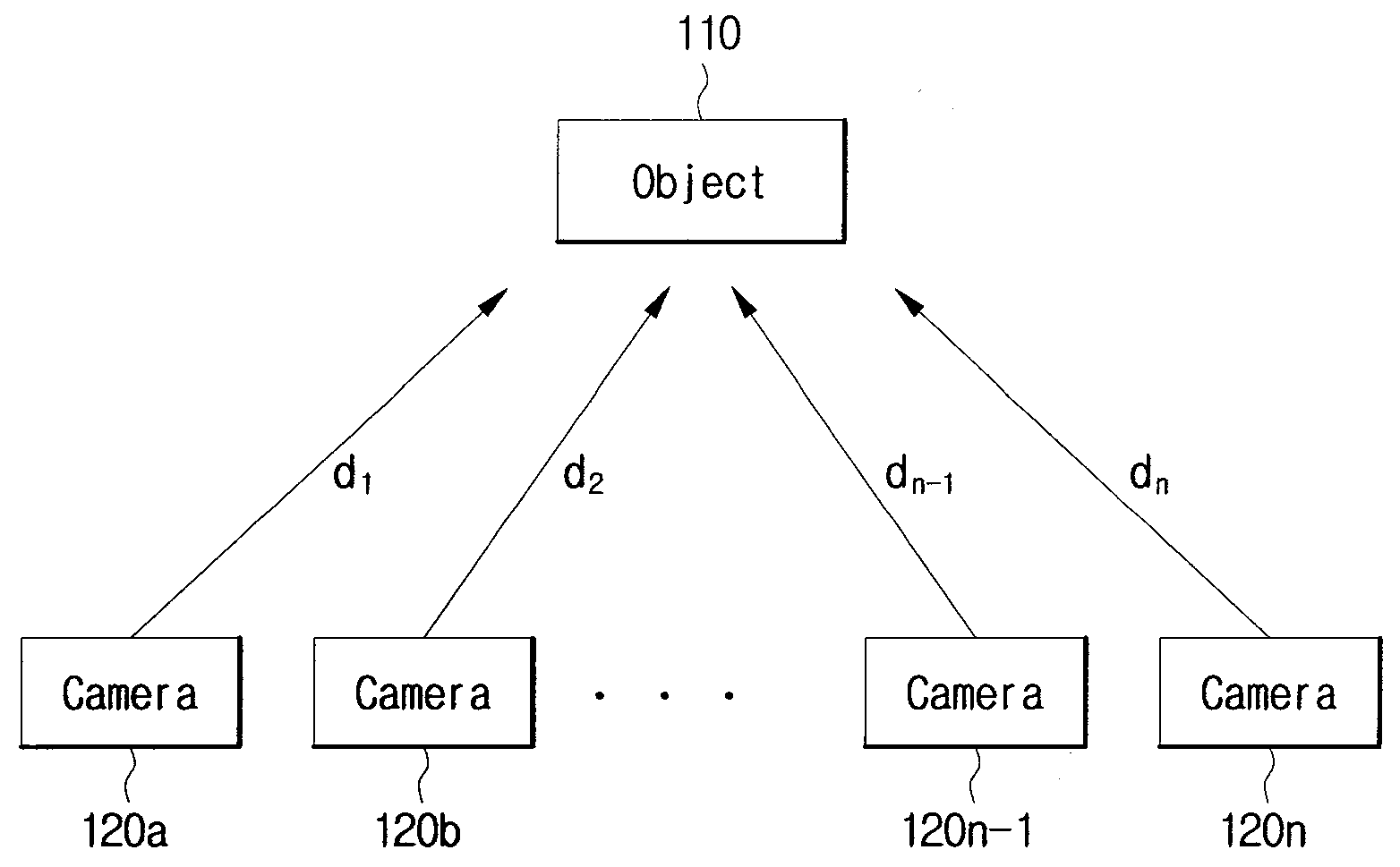

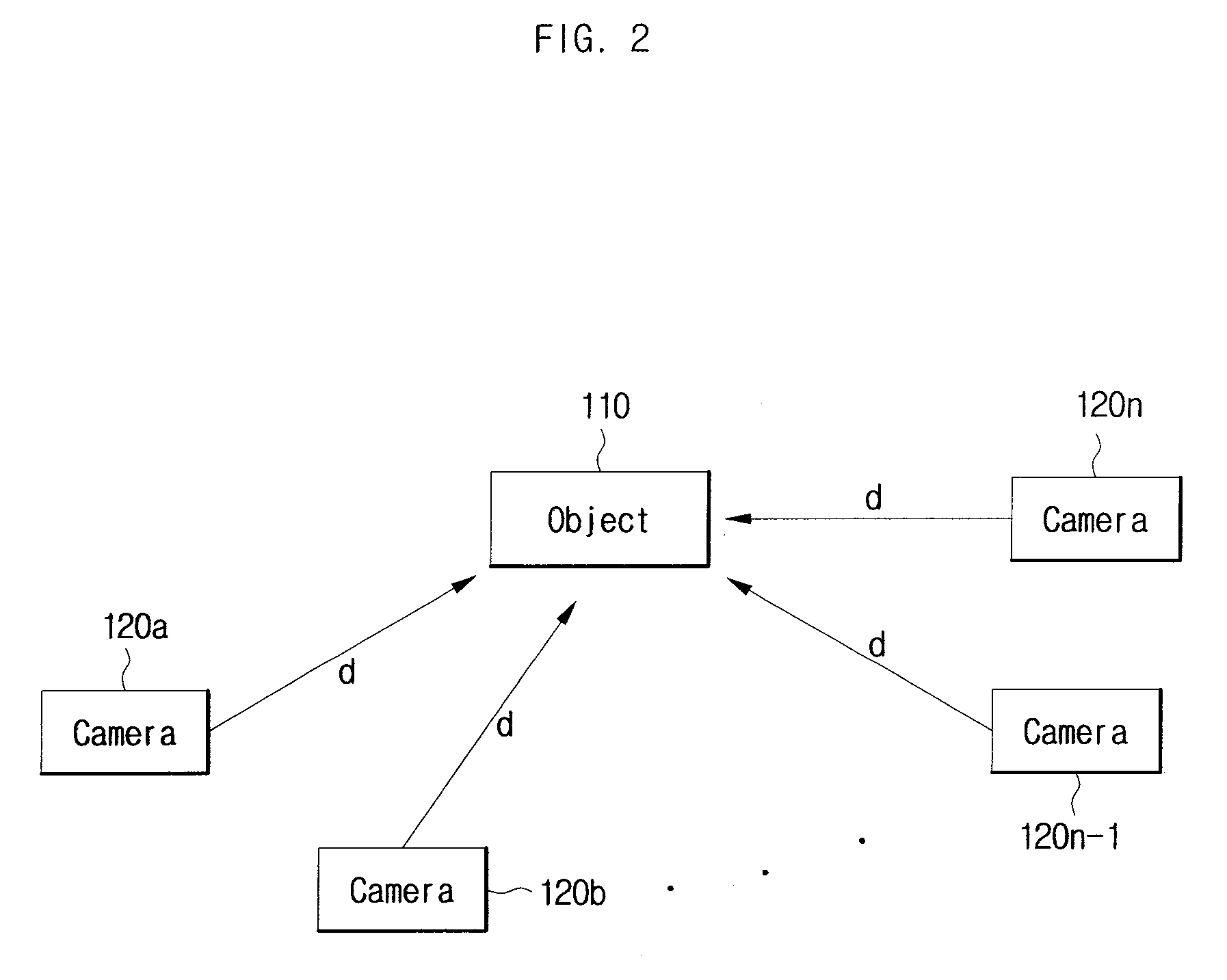

Reference Frame Ordering For Multi-View Coding

InactiveUS20080130738A1Improve picture qualityAvoid delayPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningThree dimensionalityComputer science

A method for setting the order of reference frames for multi-view coding and a recorded medium recording the method are disclosed. The method of setting the order of reference frames, in accordance with an embodiment of the present invention, comprises the steps of selecting the n (integer) number of frames of the same kind that have a same-view relation with said current frame and are encoded or decoded prior to said current frame as a first reference frame, selecting the m (integer) number of frames of the same kind that have a same-view relation with said current frame and have an inter-view relation with a frame of the same kind, which is encoded or decoded immediately before, as a second reference frame, wherein the frame of the same kind has a same-view relation with said current frame, and encoding or decoding said current frame by making reference to the frames of the same kind included in said first reference frame and said second reference frame. With the present invention, an improved picture quality and three-dimensionality can be provided, and the delay in processing time can be prevented when using the reference frame.

Owner:HUMAX CO LTD

Apparatus and method for removing materials from a material collection container

ActiveUS9067727B2Easy to installEasy to operateSedimentation regulating devicesSettling tanks feed/dischargeMaterial removalSludge

An apparatus for removing material collected in a material collection container having a floor and at least one substantially vertically extending wall. The apparatus includes a material removal assembly for removing material collected in the material collection container. The material removal assembly includes a first conduit and a second conduit. The first conduit is in telescoping relationship with the second conduit to permit the first conduit to move relative to the second conduit. The first conduit and the second conduit each have a longitudinal axis. The material removal assembly further includes at least one material removal header configured to receive material accumulating on the floor of the material collection container. The material removal assembly is preferably configured to enhance numerous aspects of the sludge removal process.

Owner:ROBERTS MARKETING DE

Pollutant Trap

A system for removing pollutants from a liquid. The system has a tank with a bypass chamber, a treatment chamber, inlet and outlet ports. A dividing wall is located within the tank and defines the bypass chamber and the treatment chamber. The dividing wall has an inlet opening, one or more outlet openings, retaining rods forming a retention space at least partially below the inlet opening, and a vertically-extending weir between the inlet opening and the outlet opening(s). The inlet opening receives polluted liquid from the inlet port and the one or more outlet openings output a cleaned liquid to the outlet port. A float in the treatment chamber is adapted to float in a retention space formed by the retaining rods. The float is adapted to rise against the inlet opening when a fluid level in the treatment chamber reaches a predetermined level to substantially block the inlet opening.

Owner:IMBRIUM SYST

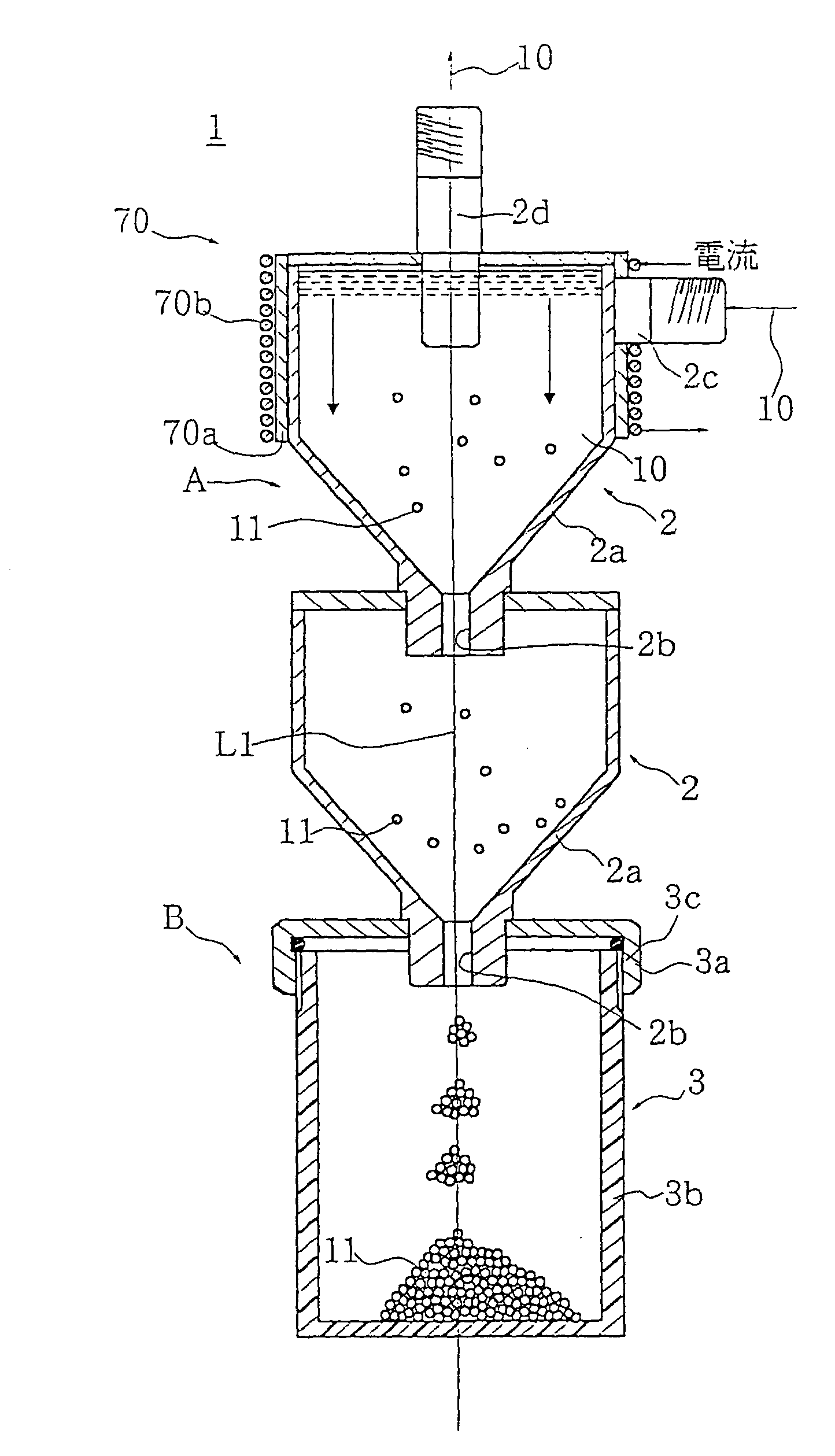

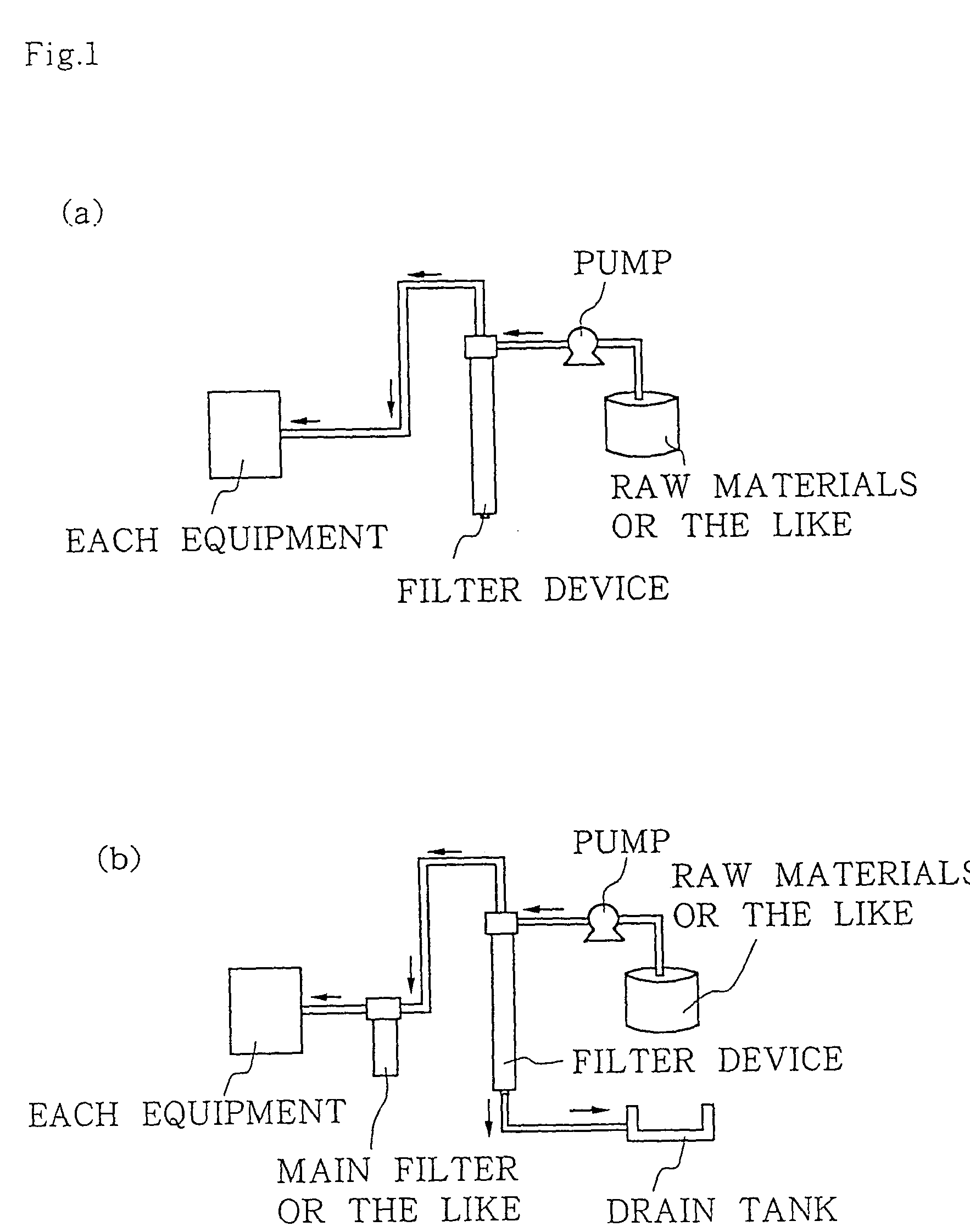

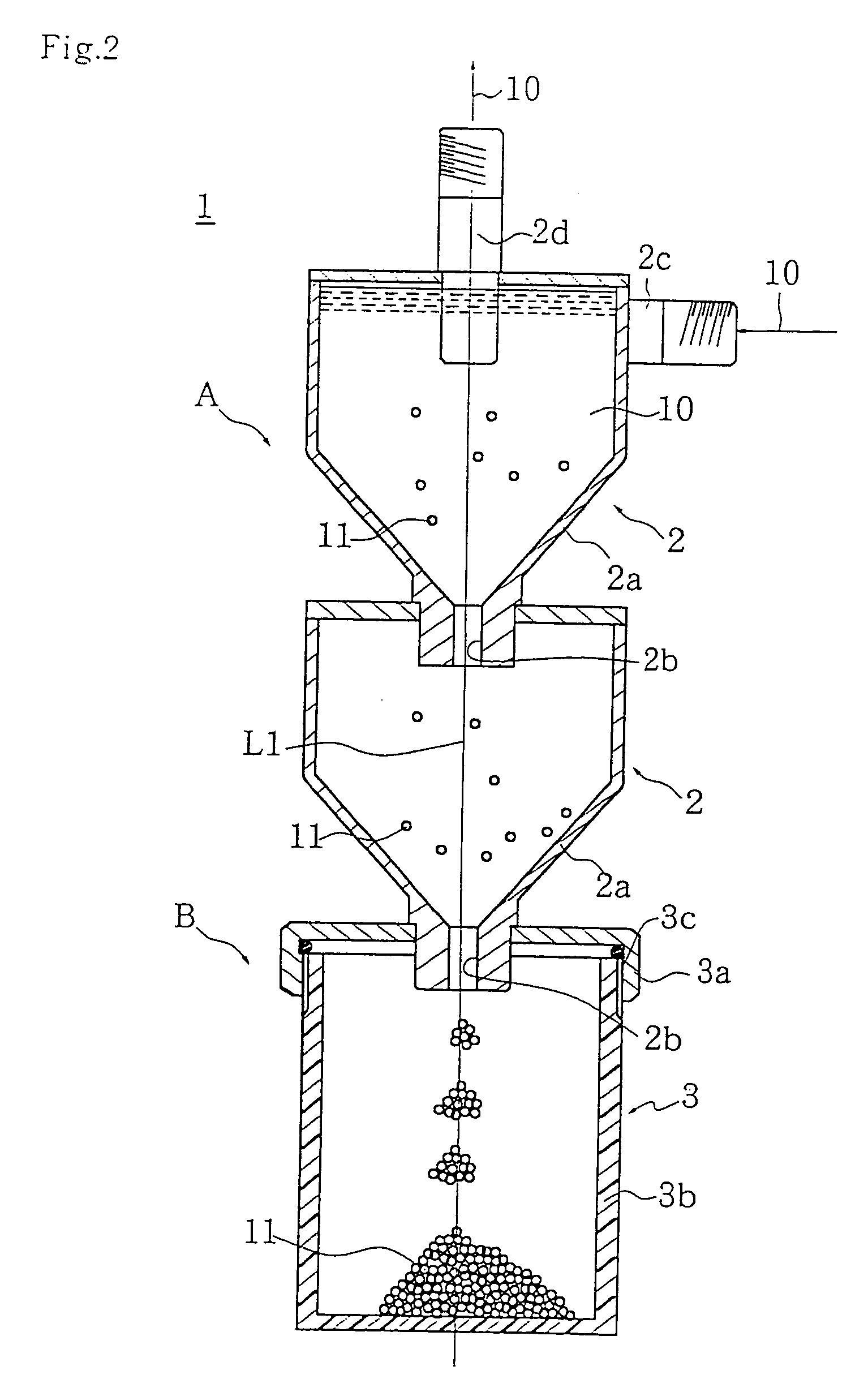

Filter device

InactiveUS7909990B2Reliable removalLow costLiquid separation auxillary apparatusReversed direction vortexEngineeringCentrifugal force

A filter device is made up of: a filter portion having a fluid outlet at its axis, and a fluid inlet in a position away from the axis, in which a fluid containing particles is supplied at a predetermined flow speed from the fluid inlet to cause a swirling, particles are moved outward in a centrifugal state and the fluid from which the particles are separated is discharged from the fluid outlet, and the particles separated by slowing down the swirling are allowed to sink; and a settlement portion in which the particles that settle in the filter portion are allowed to settle. Thus, a fluid containing particles is supplied at a predetermined flow speed to cause swirling, the particles are separated by a centrifugal force caused by the swirling and allowed to sink and settle, and the fluid from which the particles are separated is discharged. A large amount of particles can be allowed to settle and be reliably removed in a short time with this small-sized and simple device. The filter device does not clog, does not need washing and exchanging work and keeps the costs low.

Owner:INDUSTRIA CO LTD

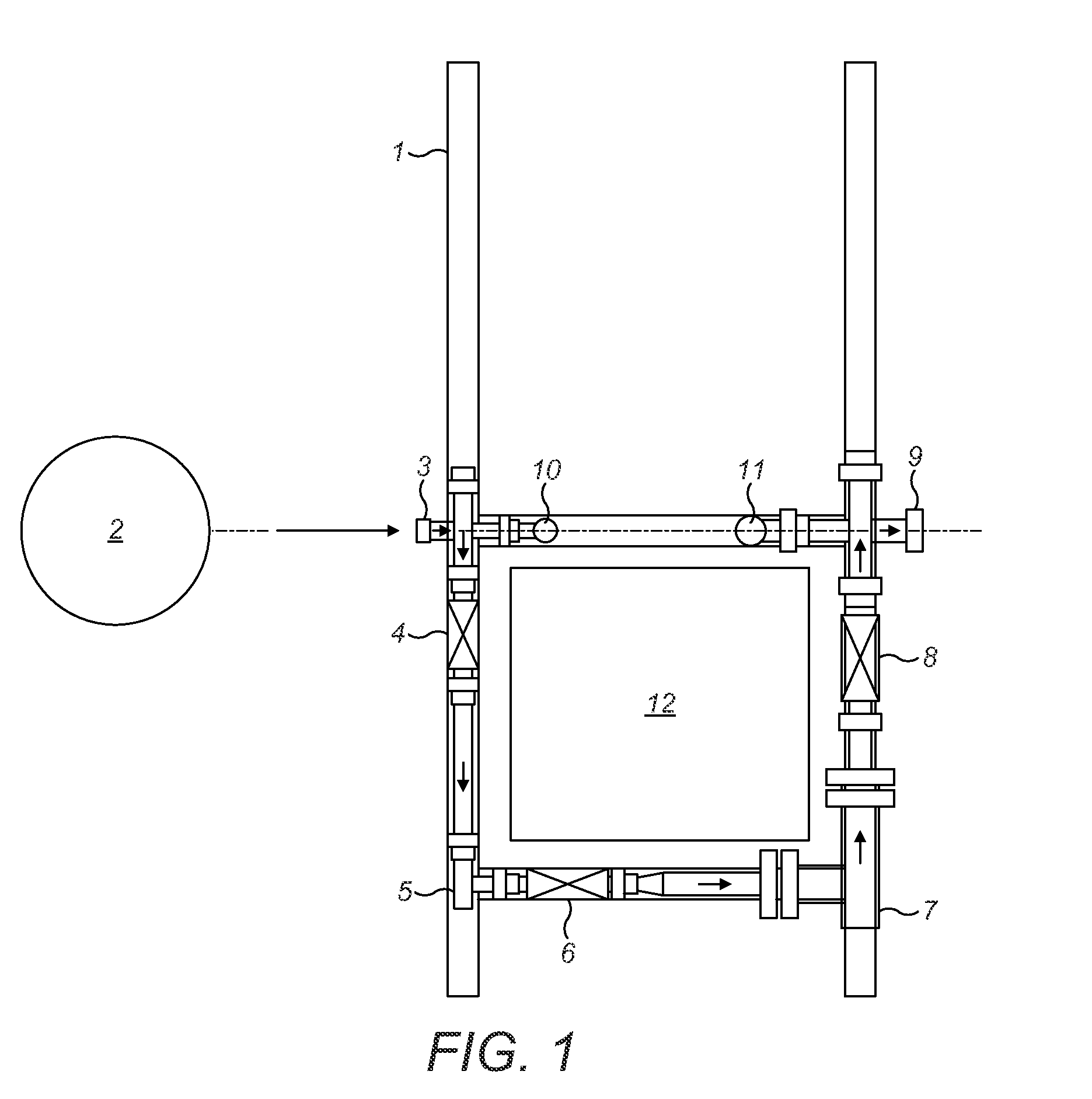

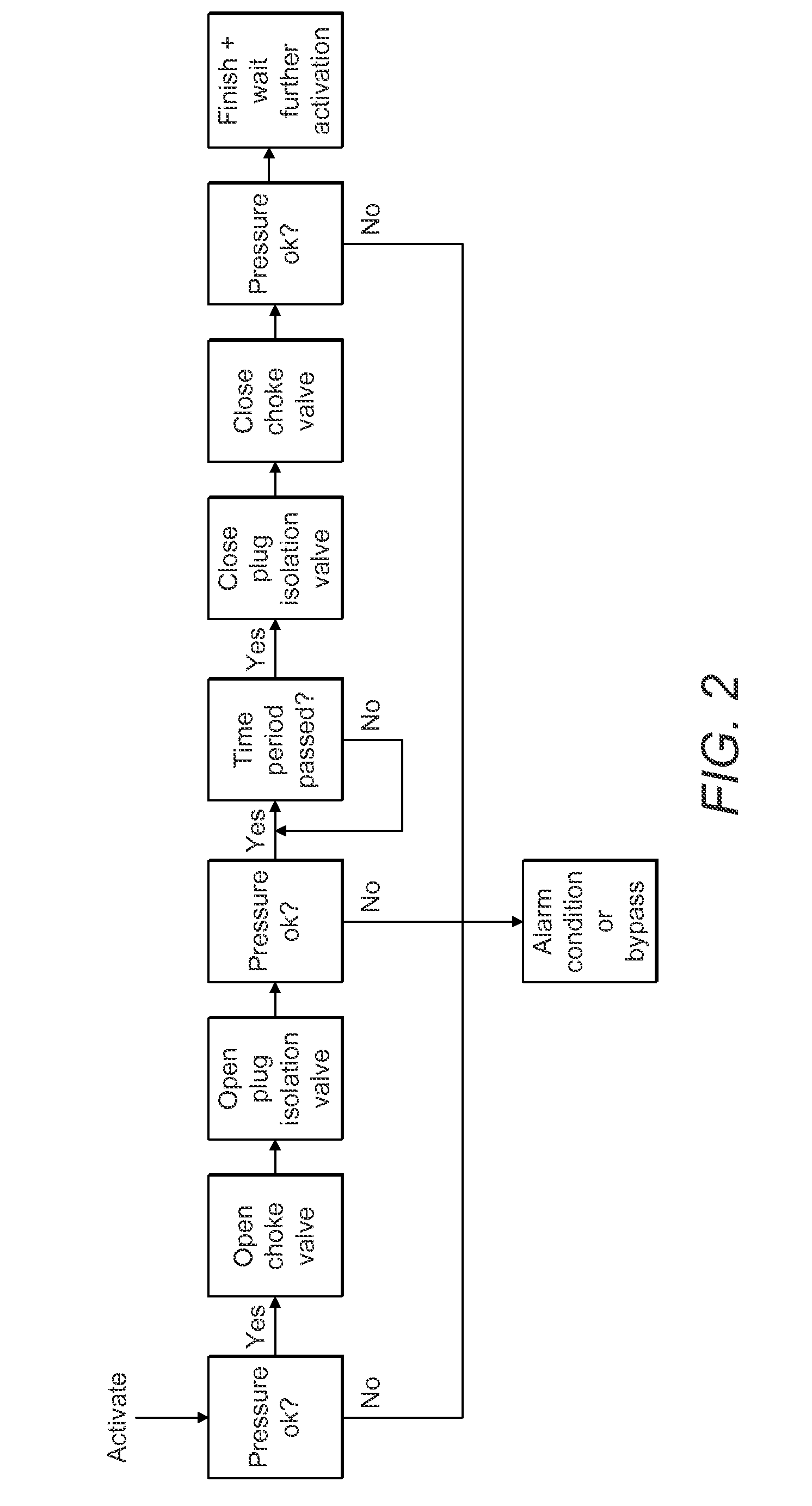

Automated dump system for solid separator

InactiveUS20140345727A1Prevent overuseReduce maintenanceOperating means/releasing devices for valvesConstructionsSolid massOil and natural gas

An automated dump system for use with a solid removal system is herewith described. The system is for use in the oil and gas industry. The dump system comprises a programmable controller and valve(s) such as a plug valve and a choke valve, whereby the controller operates the valves at selected timings and if desired in a predetermined sequence. The valves maybe provided in separately removable segments. Additional components in the dump system may include pressure monitoring elements and an alarm condition signal. The system maybe mounted on a skid for ease of movement.

Owner:NAT OILWELL VARCO LP

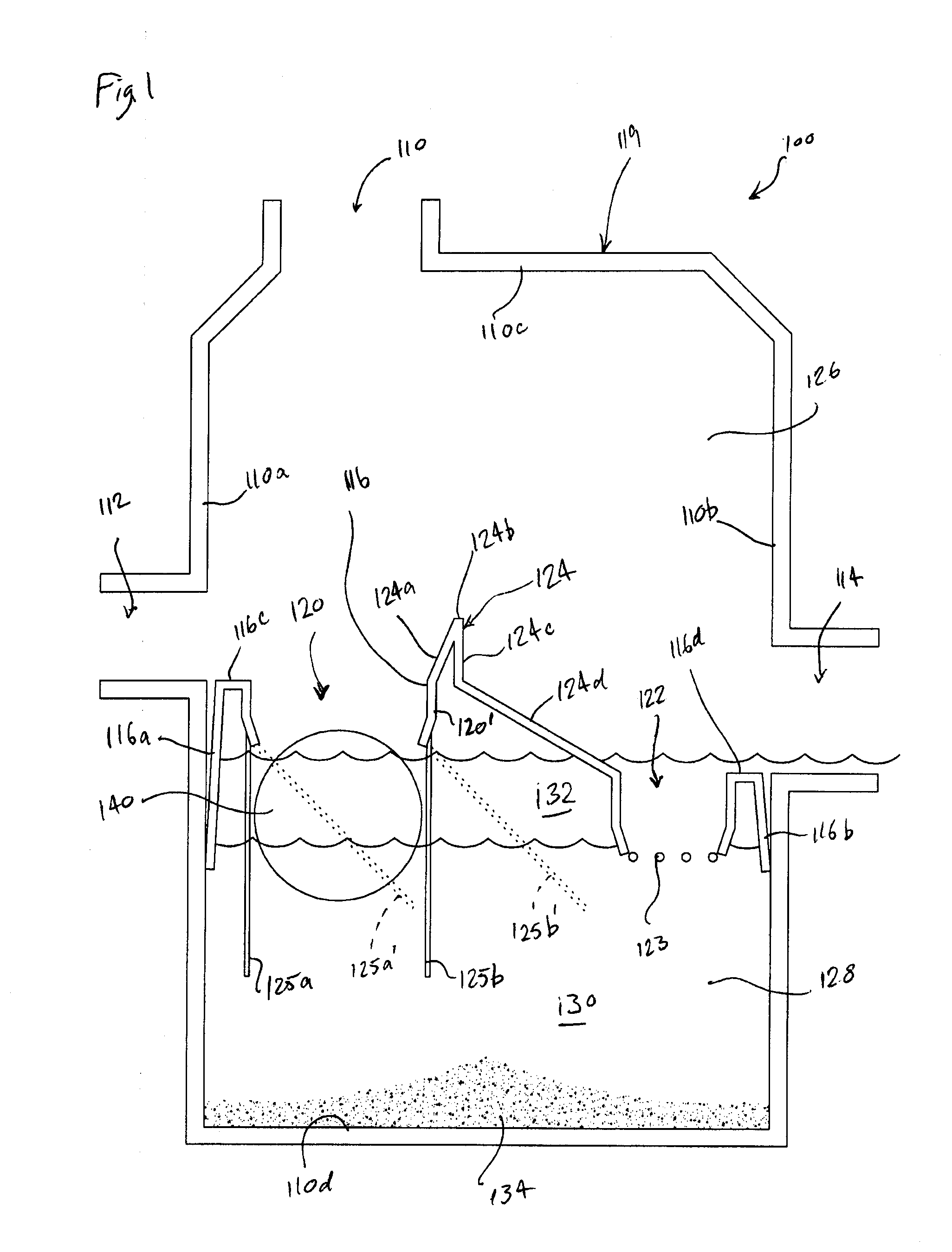

Method to Process Effluent Brine and Interface Rag from an Oil Dehydration/Desalting System

ActiveUS20130082005A1Water treatment parameter controlFatty/oily/floating substances removal devicesEmulsionInduced gas flotation

A method for processing interface emulsion, water, and solids contained within a separator vessel that comprises the steps of continually extracting those components from the vessel and then passing them through a gas flotation cell. The cell, which is preferably a vertical induced gas flotation cell, separates the oil and water contained in the interface emulsion and discharges recovered oil from an upper portion of the cell and treated water from a bottom portion of the cell. The recovered oil and treated water may be further processed and recycled to the vessel or sent elsewhere. The treated water may also be recycled to the cell or sent to a process sewer. Fuel gas residing in an upper portion of the cell may be cooled and passed through a splitter. All the steps of the method comprise a closed system with no air emissions.

Owner:CAMERSON INT CORP

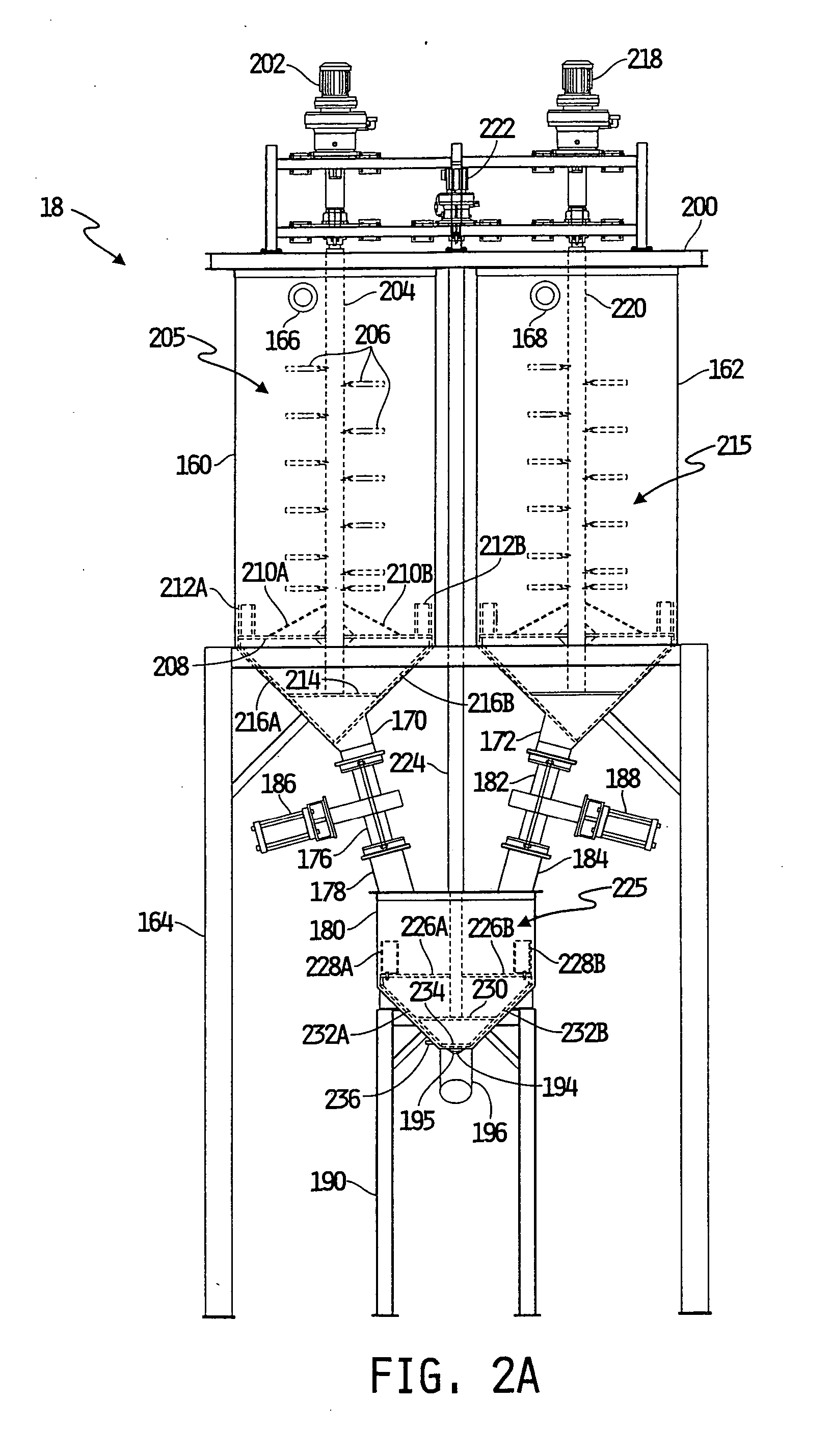

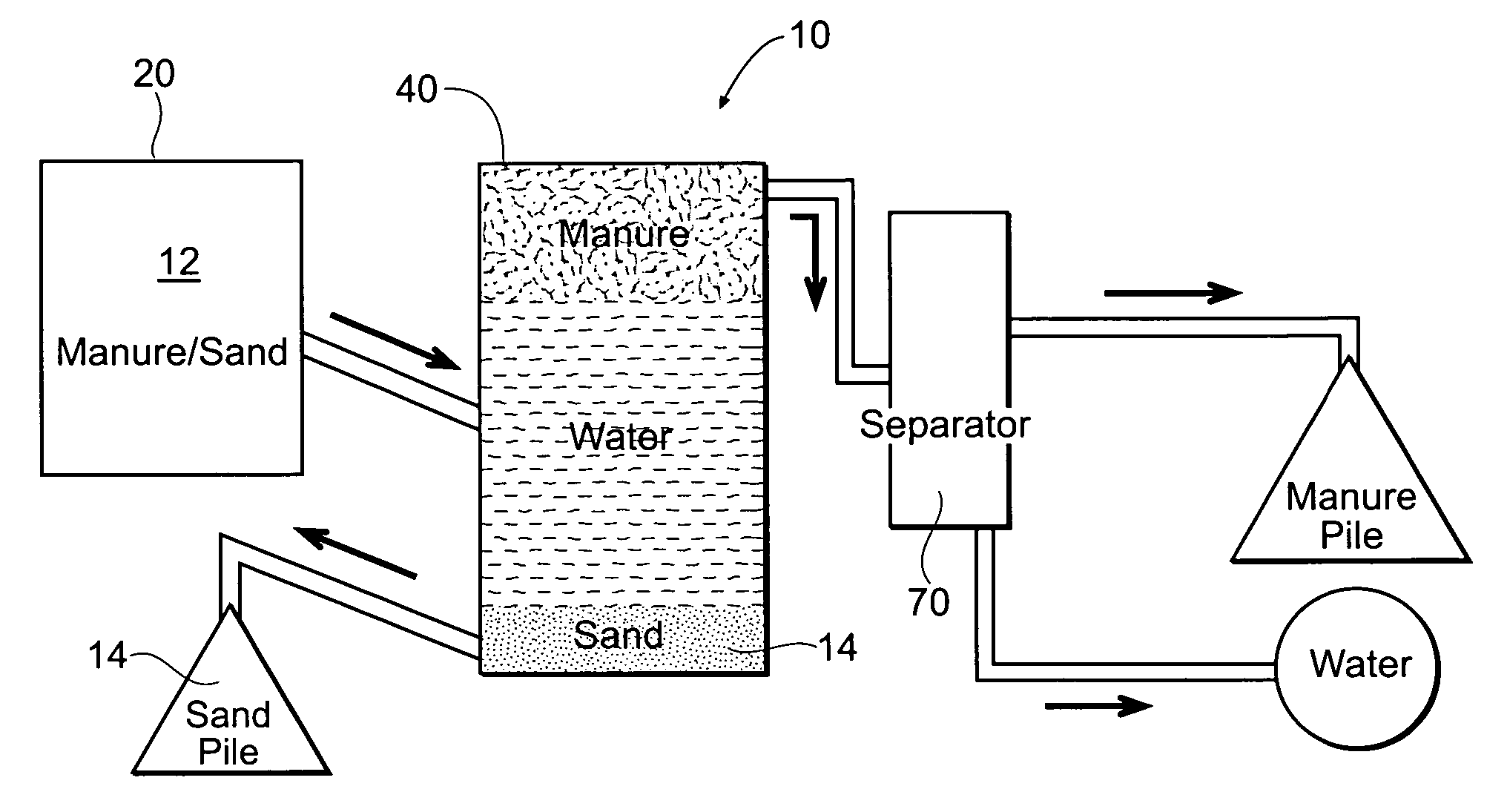

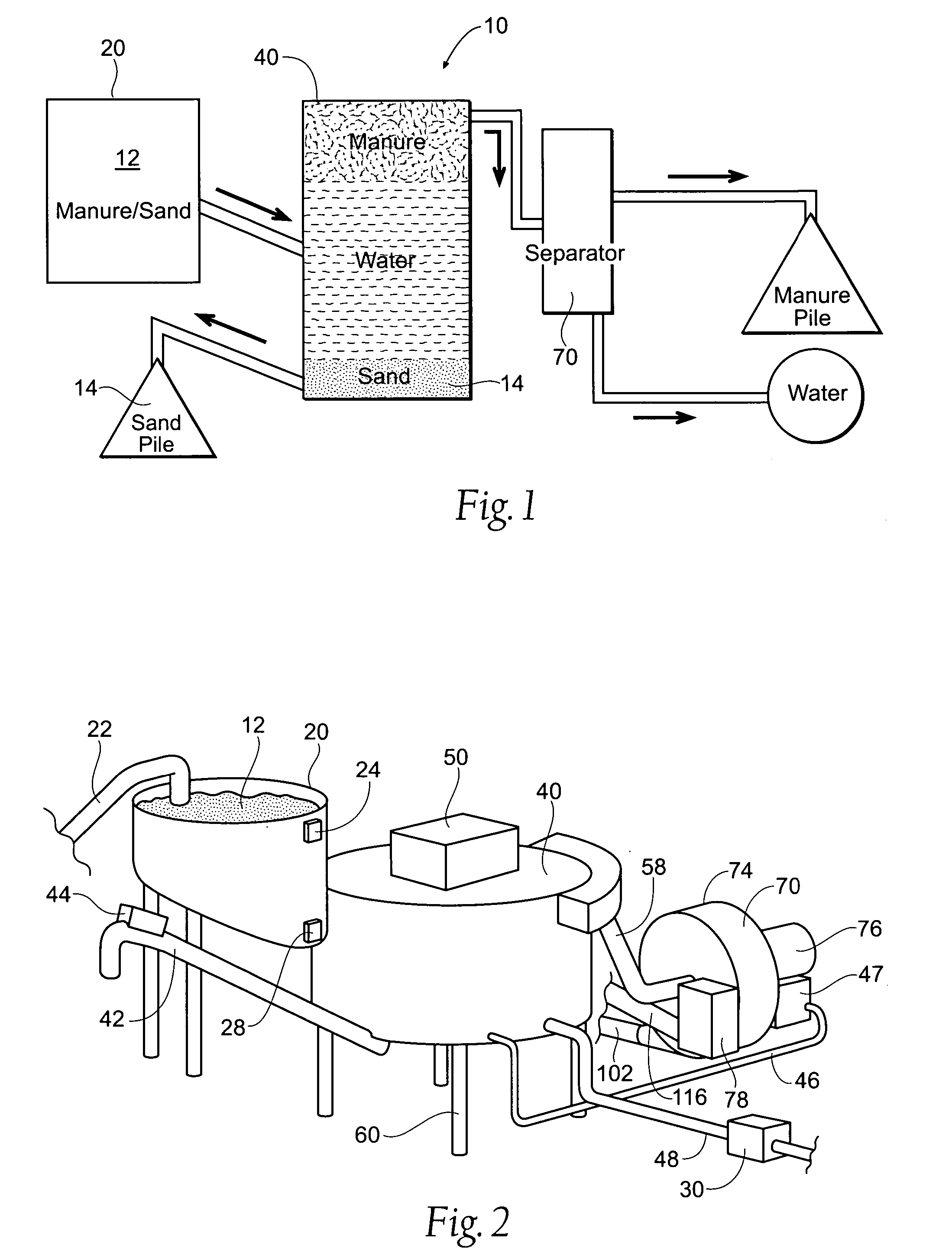

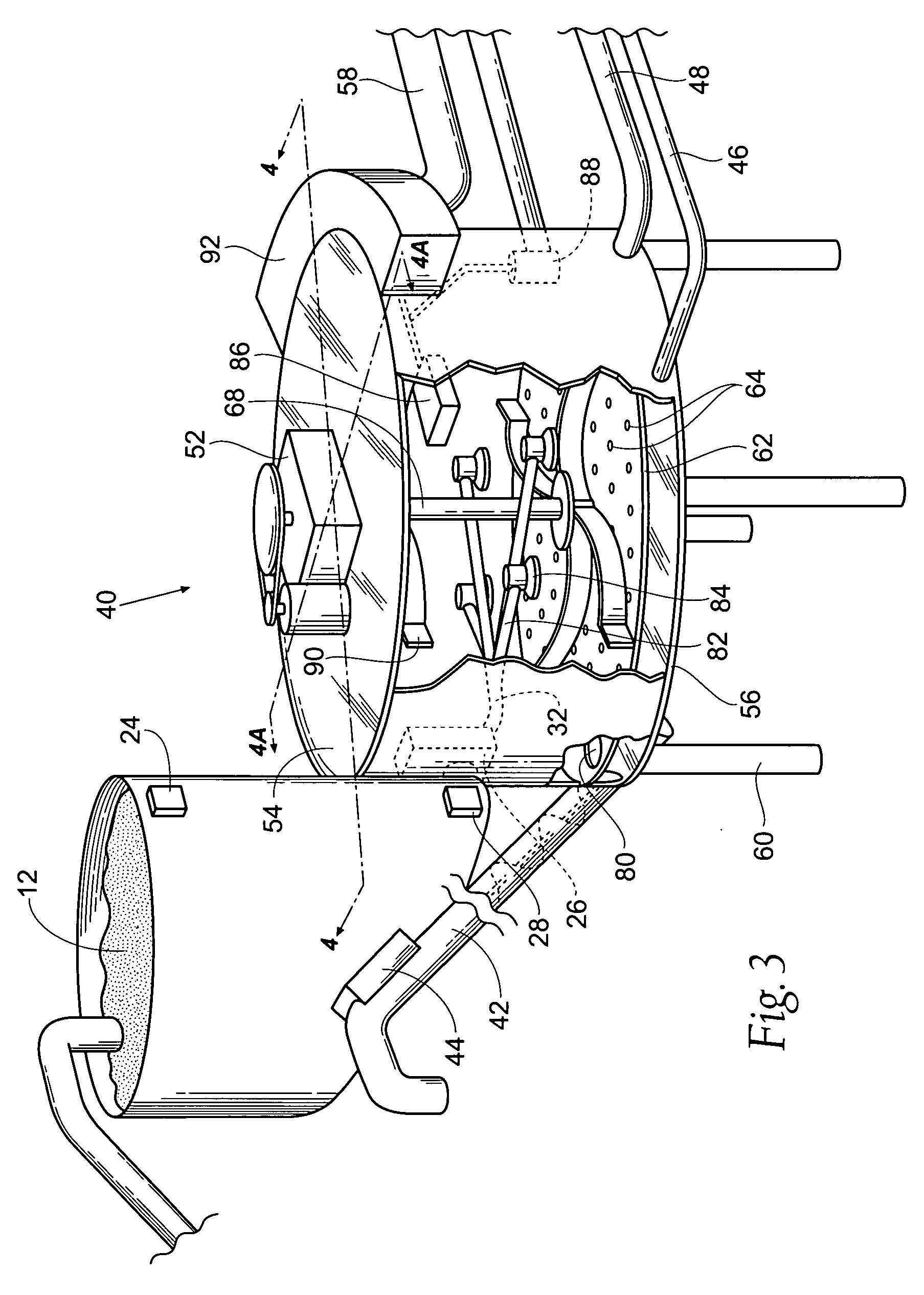

Manure separator

InactiveUS20060243677A1Efficiently breakEasy to haulExcrement fertilisersRotary centrifugesEnvironmental engineeringBedding

An apparatus and system for separating manure and sand in animal bedding is disclosed. The system separates the manure and sand by using a separator filled with water that agitates the sand / manure mixture with air and water. The manure removed from the separator is further processed to remove excess water from the manure. A spinning or centrifugal device is used to remove excess water from the manure.

Owner:SHEAHAN DONALD T

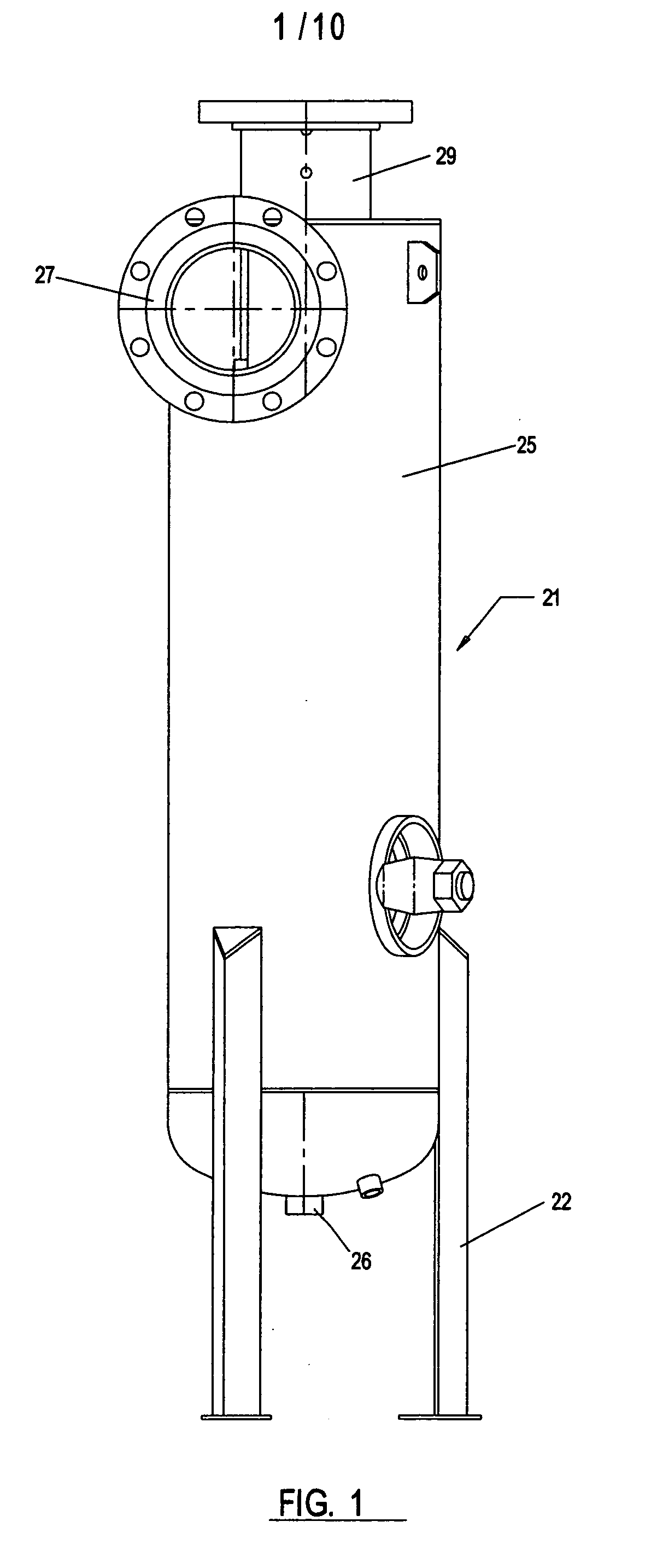

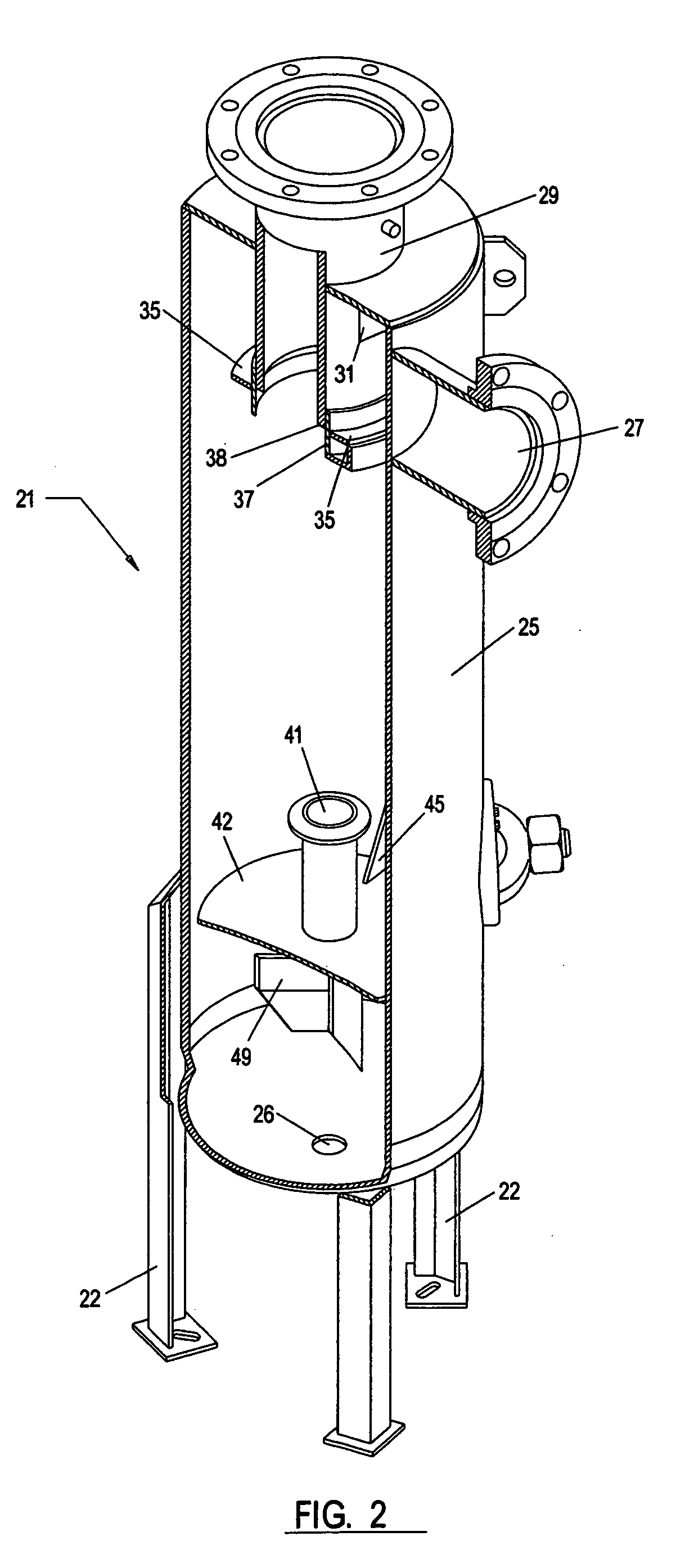

Separator Device

ActiveUS20150129491A1Efficient separationExtension of timeReversed direction vortexDispersed particle filtrationEngineeringSolid particle

A separator device is provided for removing particles from suspension in a fluid comprises a housing having first and second ports for ingress and egress of fluid into and out of the housing, the first and second ports being on the same vertical line; and at least one separation chamber for separating solid particles from the fluid.

Owner:ADEY HLDG

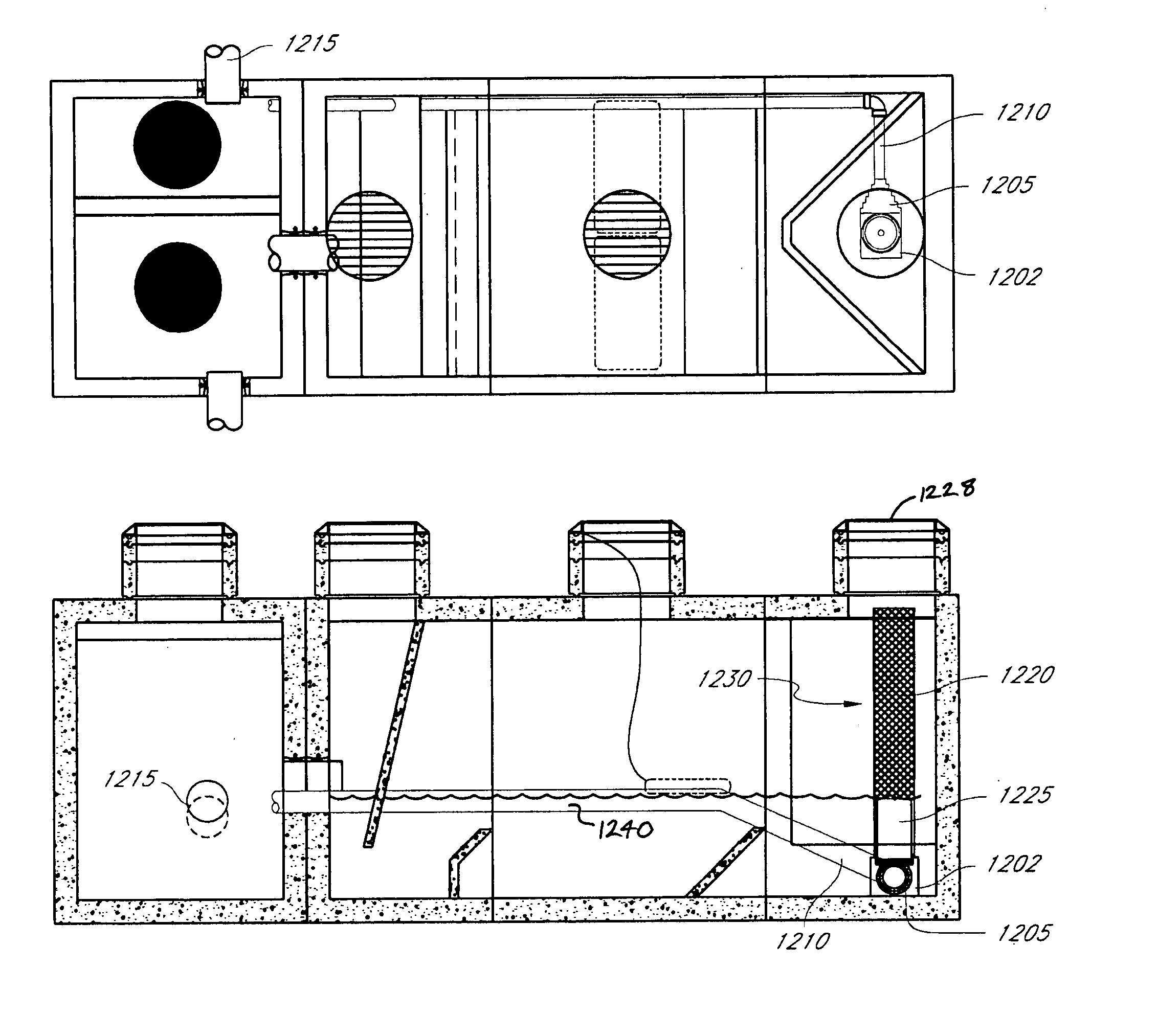

Open-channel feed dilution system for a thickener or settling tank

ActiveUS20130256243A1Accelerated dilutionReduce maintenanceSedimentation regulating devicesSettling tanks feed/dischargeSlurryClarifier

An open-channel infeed conduit of a feed dilution system of a thickener / clarifier settling tank is provided with orifices between its upstream inlet end and its outlet end. The orifices are positioned proximate to and in fluid communication with the clarified liquid phase in the tank to draw clarified liquid from the tank into the conduit responsive to or by virtue of momentum transfer between the flow of the liquid slurry feed stream in the conduit and the clarified liquid in the tank.

Owner:F L SMIDTH & CO AS

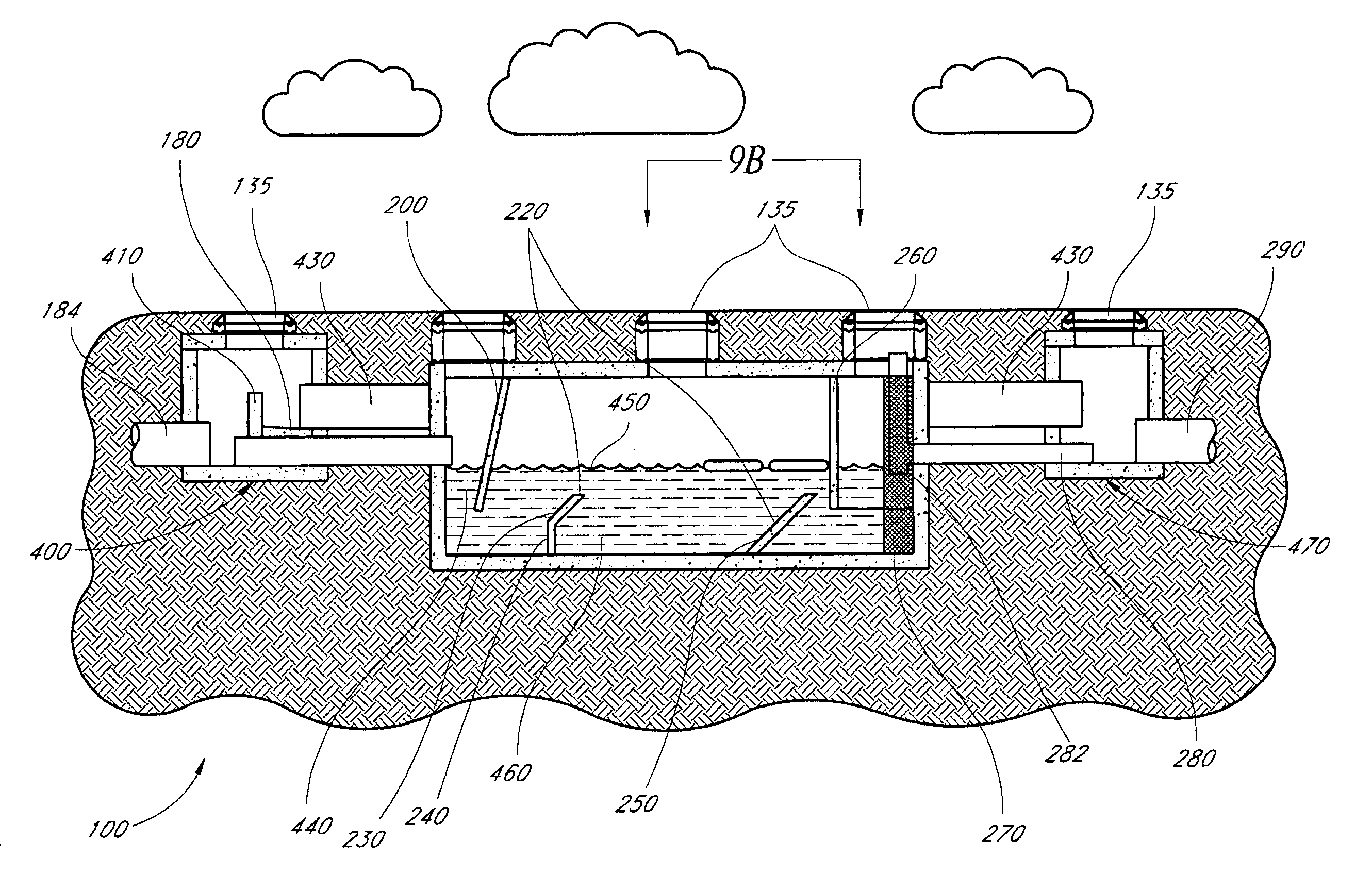

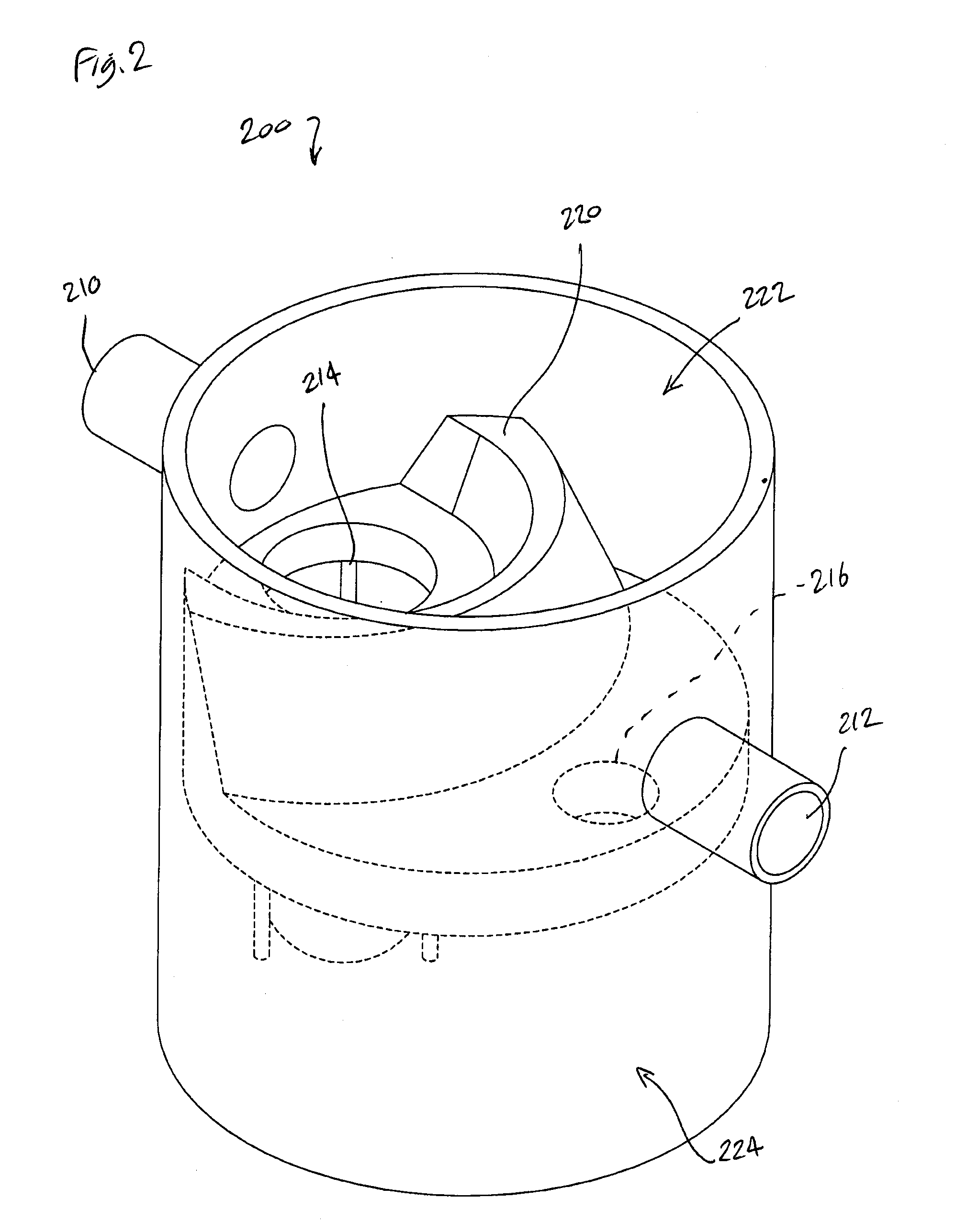

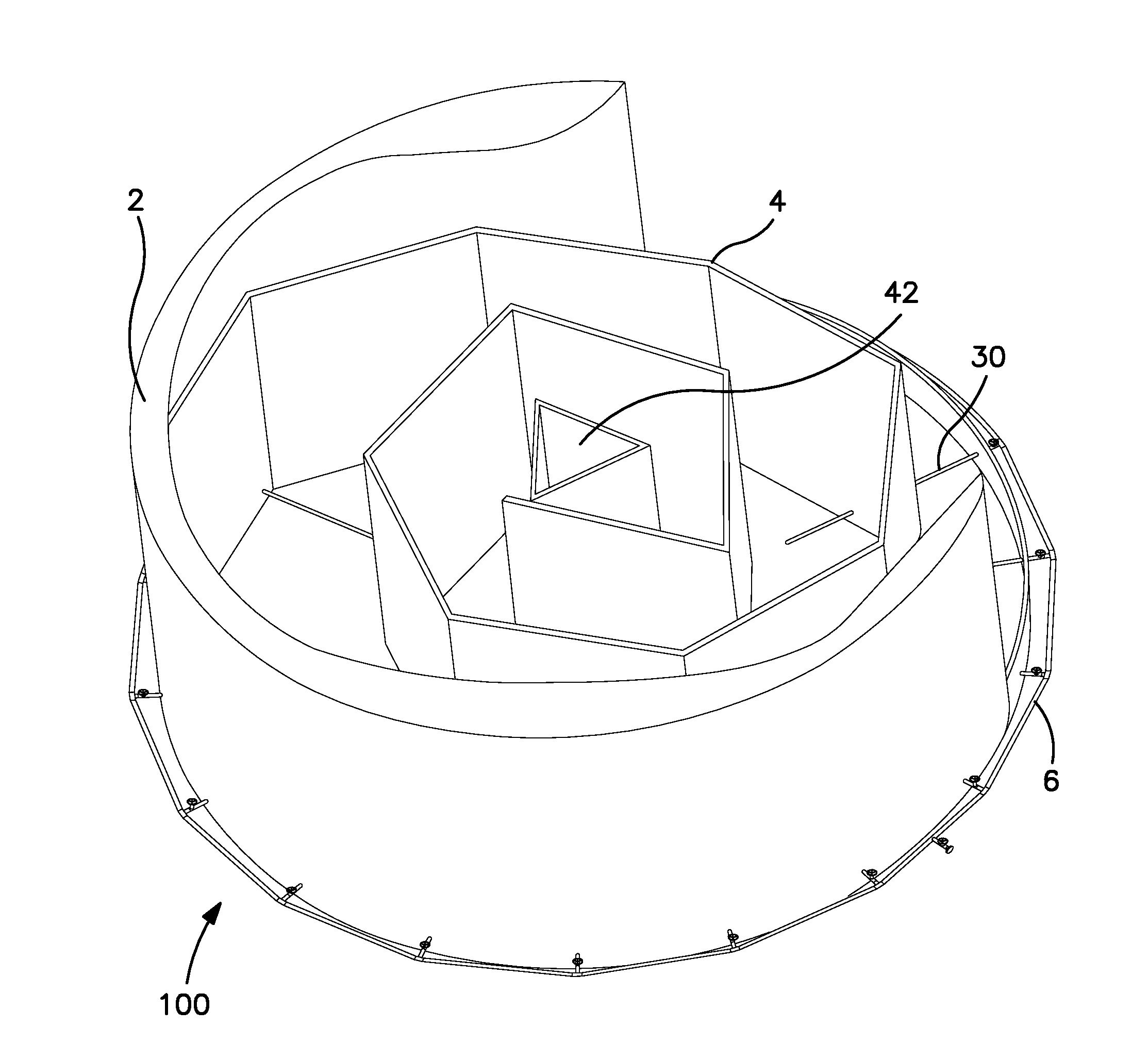

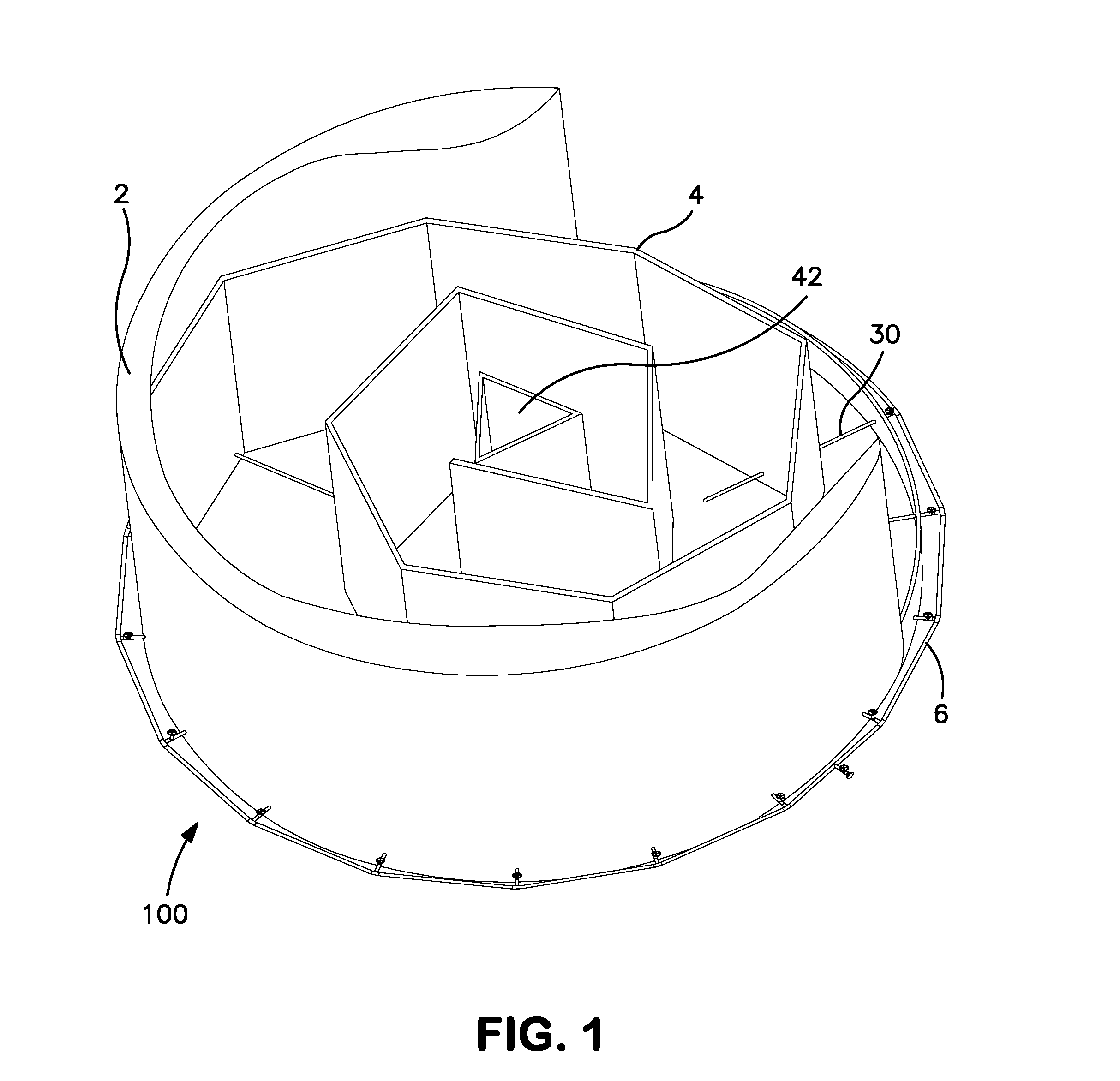

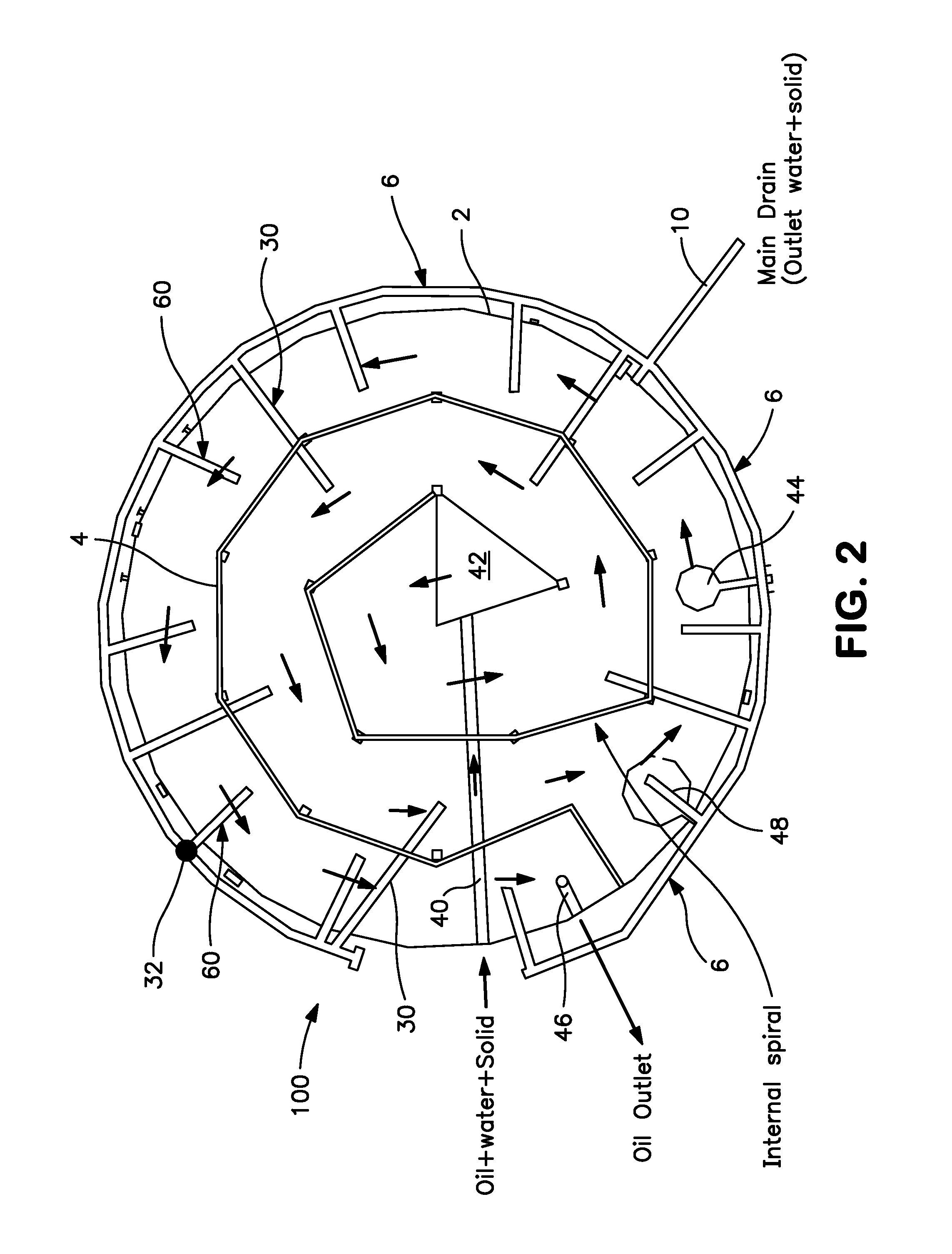

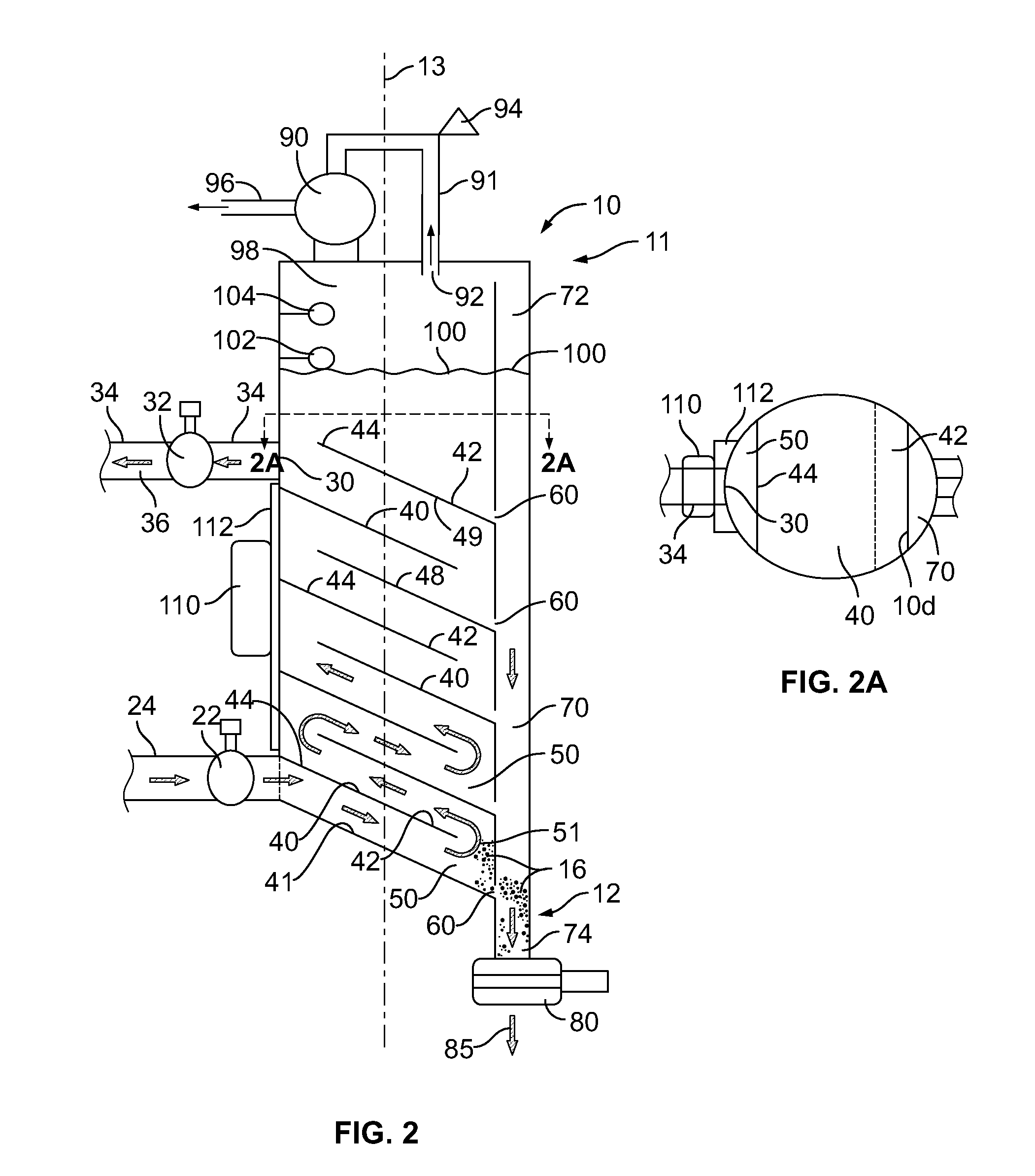

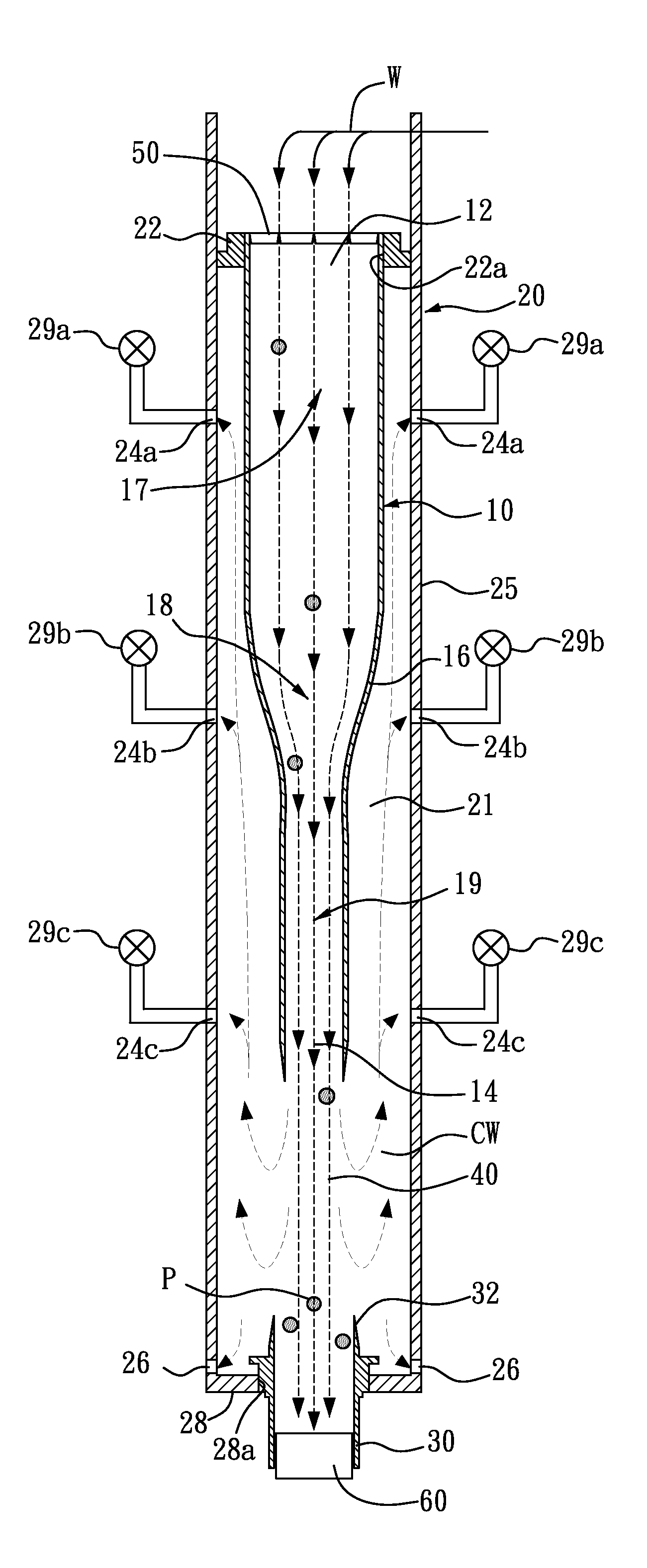

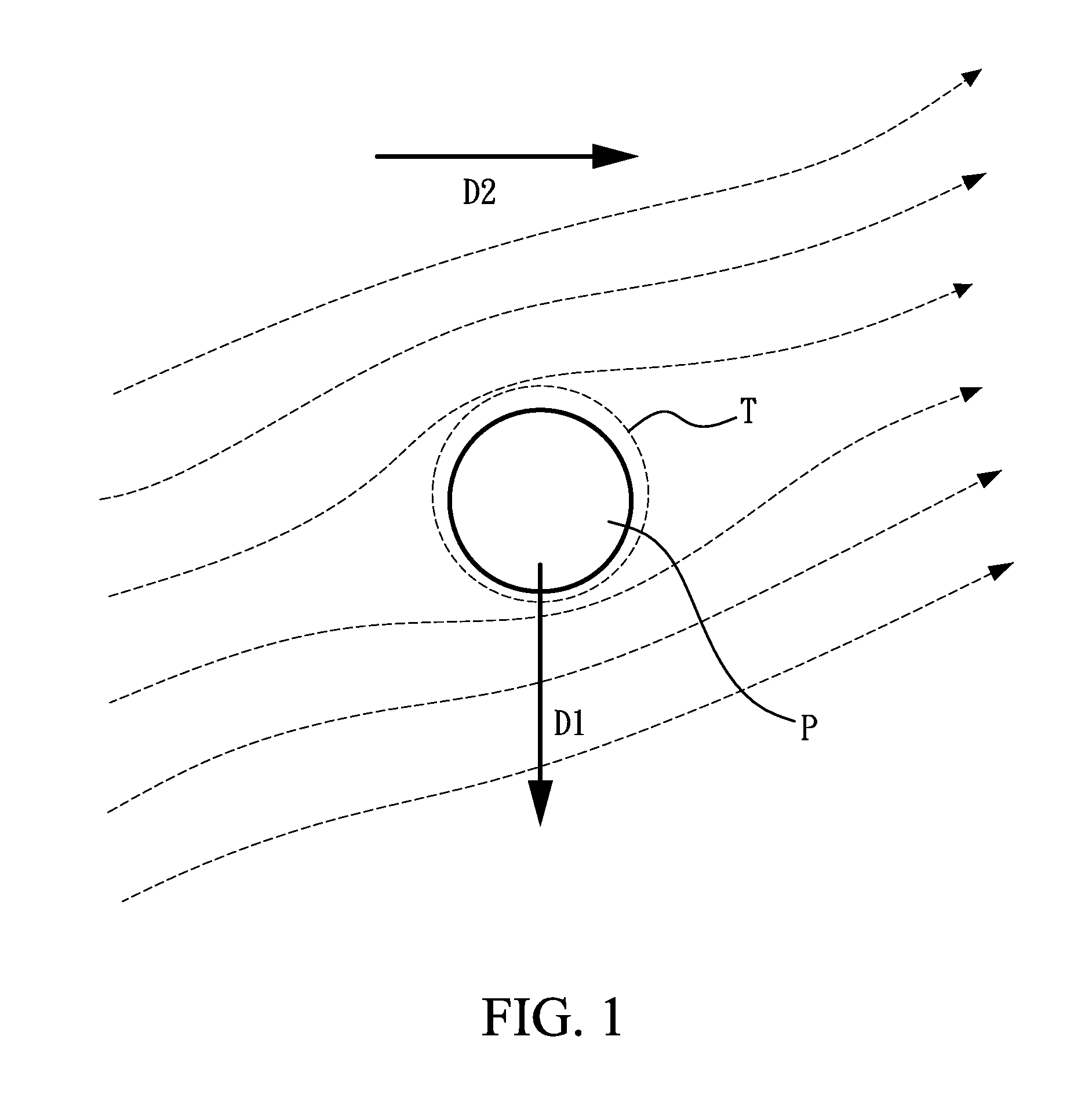

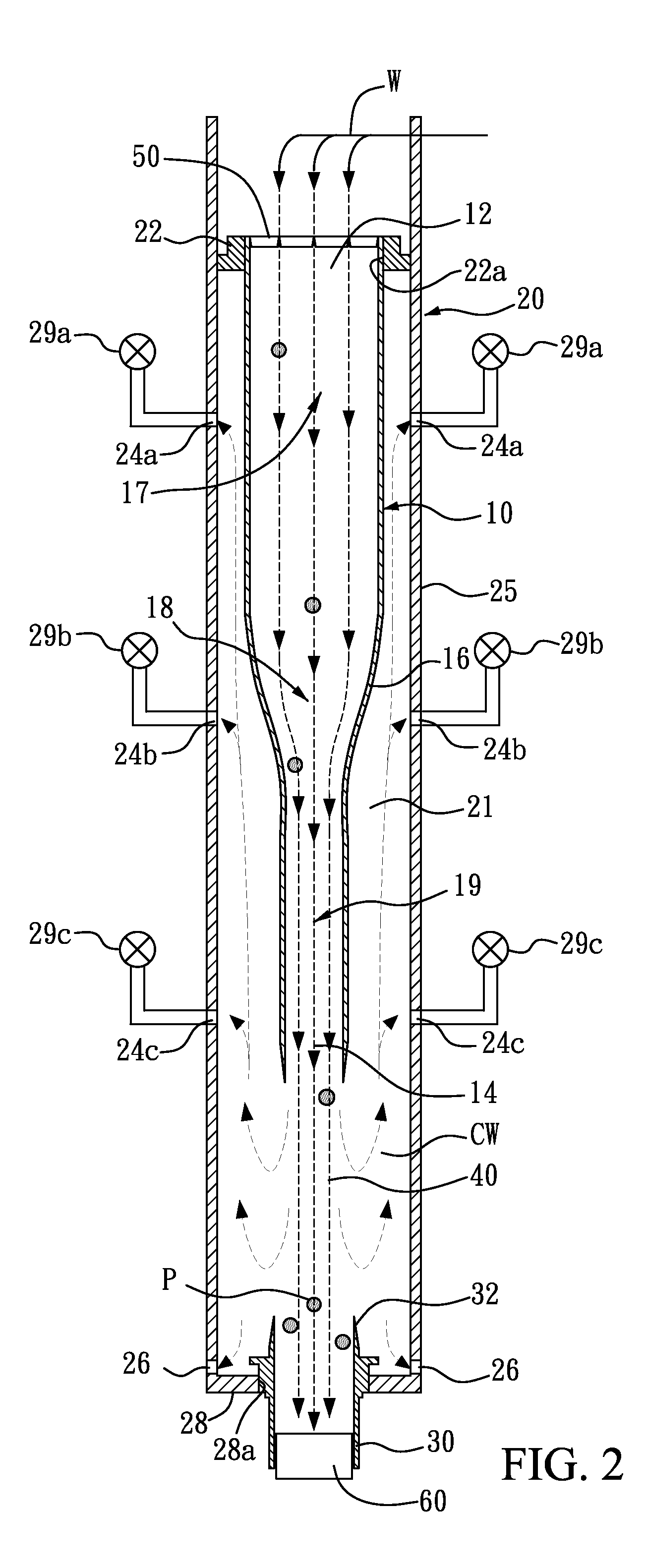

Hydrodynamic separator for stormwater treatment

ActiveUS10344466B2Minimizing velocityEfficient capture and retentionFatty/oily/floating substances removal devicesSewerage structuresStormwater treatmentEnvironmental engineering

A method, system, and apparatus directed to an innovative approach for the treatment of stormwater utilizing hydrodynamic separator assembly designed to maximize flow movement for more efficient sediment removal and maximize clearance space within assembly to facilitate cleaning and increase storage capacity of trash, debris, and sediment.

Owner:BIO CLEAN ENVIRONMENTAL SERVICES

Sediment removal tank and system

InactiveUS20130087515A1Quick and continuous and convenient and inexpensive removalSedimentation regulating devicesTreatment involving filtrationEngineeringSediment

This invention relates generally to the field of separation of heterogeneous mixtures and, more particularly to a solid-liquid separating tank and system.A settlement tank including: a tank wall defining a tank inner space; an internal wall structure in the inner space and defining a fluid flow path from a center of the inner space to a fluid outlet at the tank wall; and a plurality of drainage pipes having an open internal end and an outer end connected to a drainage manifold, wherein the open internal end is positioned at a bottom of the inner space to remove gravity decanted sediment and hydrostatically decanted water from the inner space.

Owner:INTREVEP SA

Solids removal system and method

The system and method is directed to improved separation or clarification of solids from a solids-laden liquid, including the removal of low gravity solids. A liquid to be treated is introduced into the inlet of a solid-liquid separator modified to include one or more sources of vibrational energy. The liquid is directed through a conduit within the separator. This conduit can be configured into a tortuous flow path to assist in the separation of solids from the liquid, the tortuous path being interconnected between two separation towers. Vibrational energy and gas sparging is applied to the flow path. As solids fall out of solution, they are collected. The clarified liquid is also collected. A vacuum can be applied to the system to assist in moving the solid-liquid mixture through the system and to provide vacuum clarification. Electrocoagulation electrodes can also be employed.

Owner:1612017 ALBERTA LTD

Particle-accelerating deposition and separation apparatus and method for turbid water

InactiveUS7547397B1Minimal maintenanceKeep for a long timeSedimentation regulating devicesSeparation devicesFiltrationTurbid water

A pretreatment particle-accelerating deposition and separation apparatus and method for purifying turbid raw water, which based on the theories of laminar flow requirement, particle-accelerating vertical deposition and water horizontal movement, separates water molecules from turbidity particles in a laminar flow region (with a Reynolds number lower than 1,000). By accelerating the velocity of high-turbidity raw water and the turbidity particles, the particles settle vertically because of inertia. Thus, the turbidity particles can be removed physically from the raw water and clean water can be collected at different heights of the apparatus while concentrated turbid water can be released to a nearby body of water after appropriate treatments. Thereby, turbid water can be purified for the subsequent coagulation, sedimentation and filtration processes in traditional water treatment plants.

Owner:LIU SHI PING

System for processing food process waste water including purification and optional recycling of purified waste water

InactiveUS20160288021A1Easy to disassembleFiner treatment levelUltrafiltrationTreatment involving filtrationFiltrationWastewater

An apparatus and method for treatment of food process waste water, comprising a tank for receiving a food process waste water influent via an influent pump and discharging a treated food process waste water effluent via an effluent pump; a floating decanter disposed in the tank; a valved outlet formed in the bottom of the tank; an upper level float switch operationally connected to the floating decanter; a lower level float switch operationally connected to the floating decanter and to the effluent pump; and a timer operationally connected to the floating decanter and the effluent pump. Solids are settled from the waste water and drawn off through the tank bottom after a supernatant fluid is drawn off through the floating decanter. The supernatant fluid is passed through a filtration and membrane water purification apparatus to generate purified water.

Owner:CLEARCOVE SYST

Hydrodynamic separator for stormwater treatment

ActiveUS20190078310A1Minimizing velocityEfficient capture and retentionFatty/oily/floating substances removal devicesSewerage structuresStormwater treatmentEnvironmental engineering

A method, system, and apparatus directed to an innovative approach for the treatment of stormwater utilizing hydrodynamic separator assembly designed to maximize flow movement for more efficient sediment removal and maximize clearance space within assembly to facilitate cleaning and increase storage capacity of trash, debris, and sediment.

Owner:BIO CLEAN ENVIRONMENTAL SERVICES

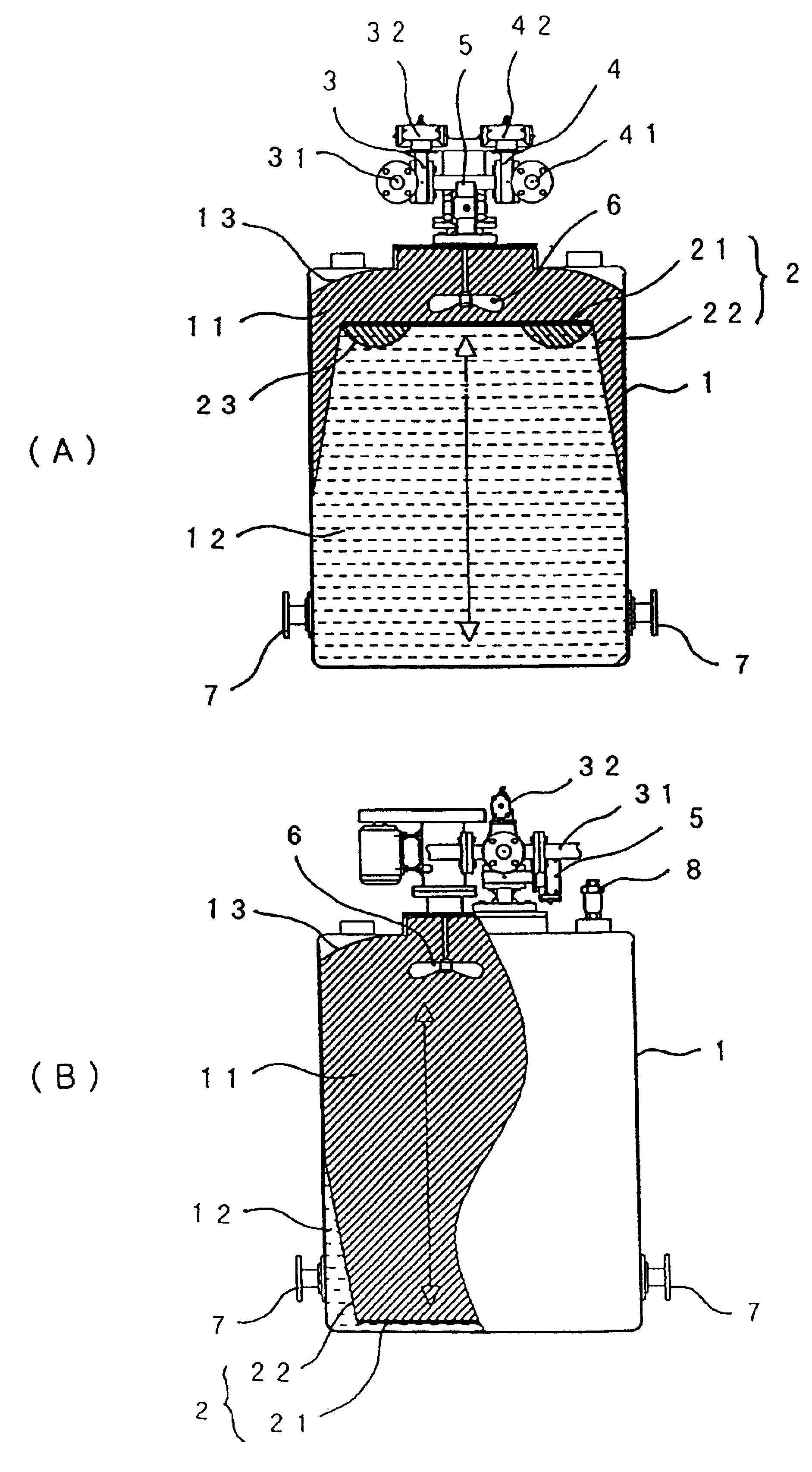

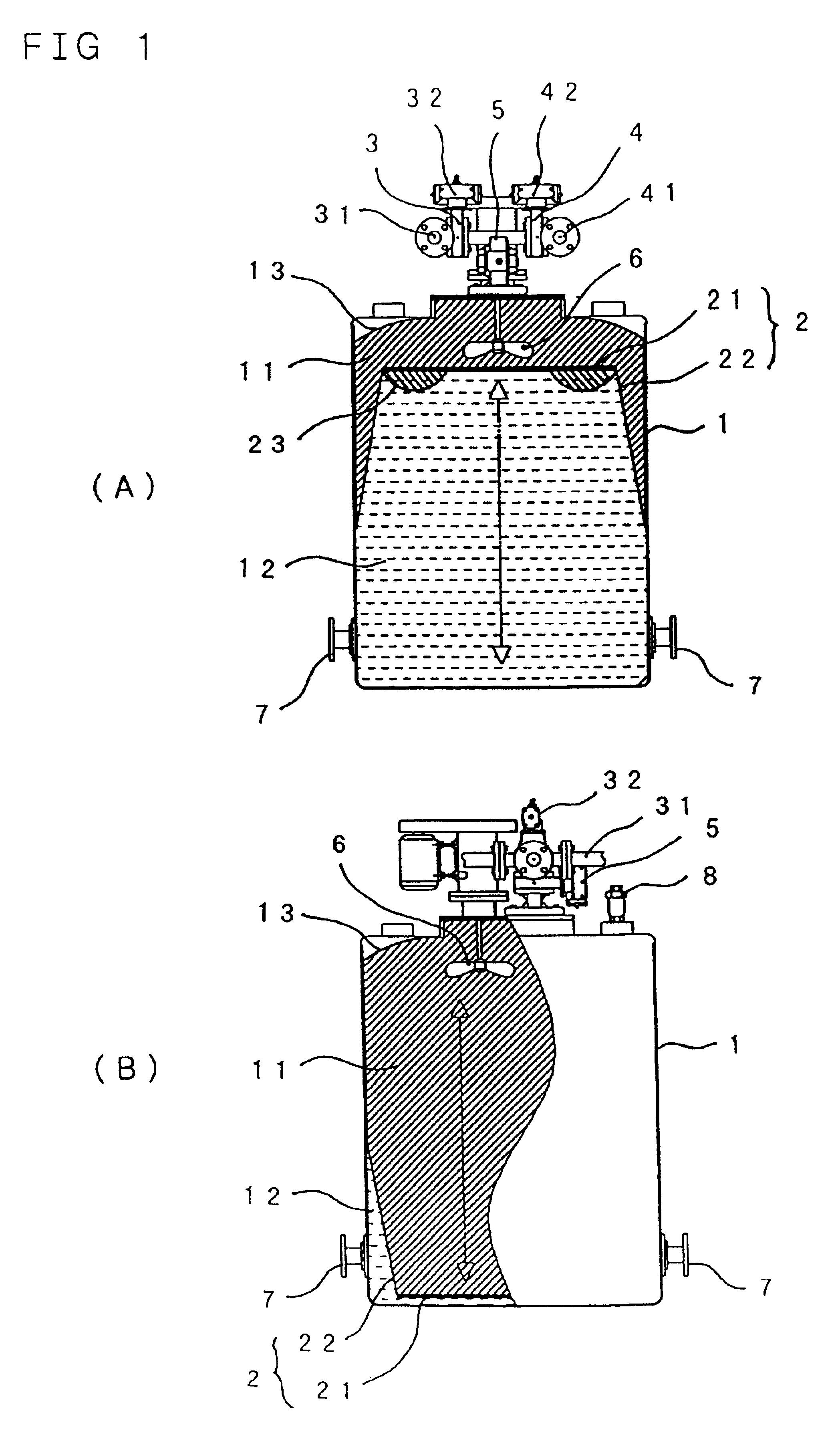

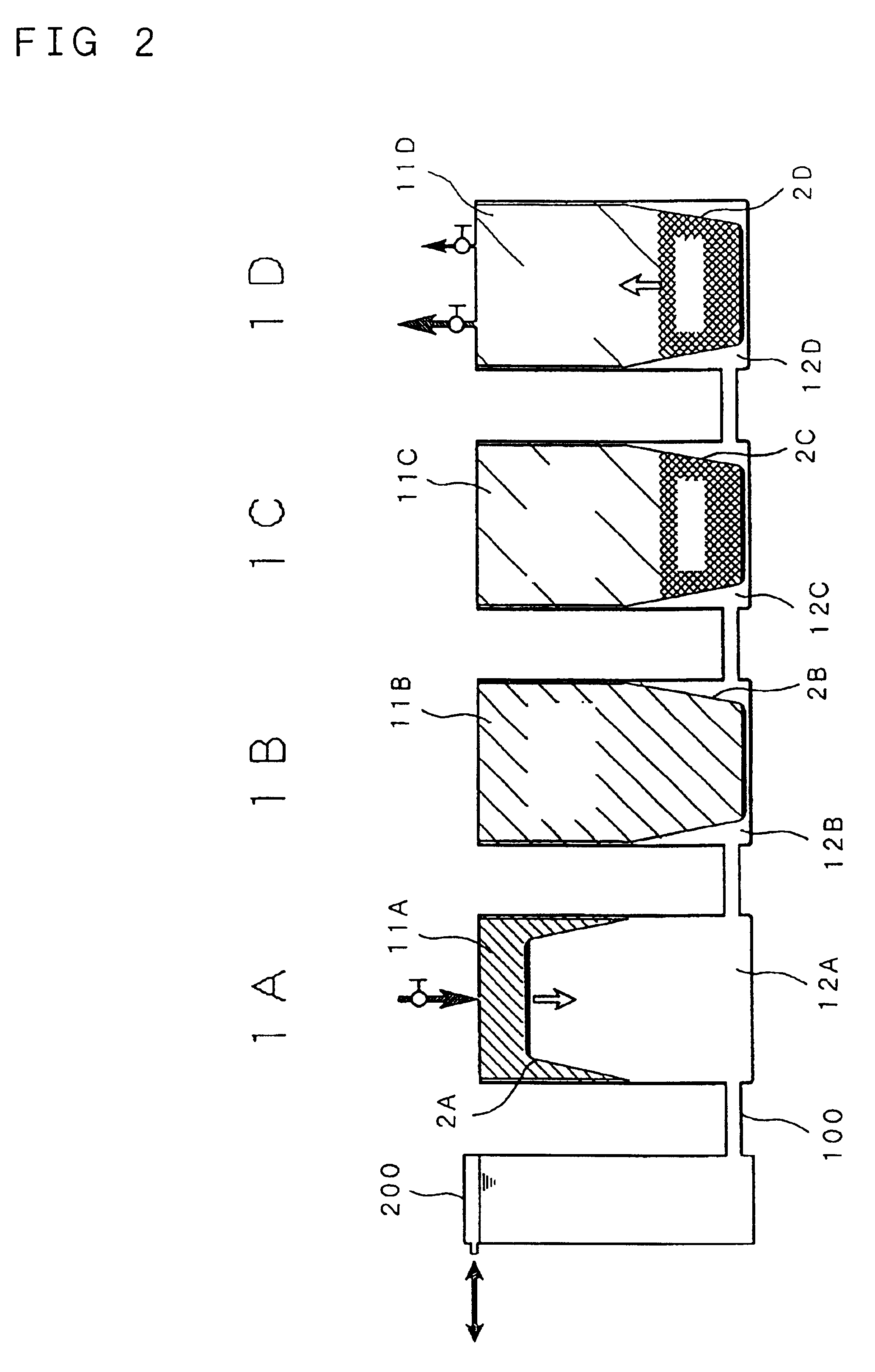

Water treatment apparatus

InactiveUS6837994B2Easy to processEasy to assembleMixing methodsSolid sorbent liquid separationWater levelTreated water

The special features of the water treatment apparatus in the present invention are that a tank fitted with a raw water inlet and a treated water outlet on the upper part, has within said tank an upper chamber and lower chamber which divide said tank into two sections, upper and lower, and is fitted with a separating wall which can be raised and lowered to adjust the water level in said upper and lower chamber, the upper chamber above said separating wall and the lower chamber below said separating wall both being filled with water. By use of this apparatus, a novel water treatment apparatus is provided which can be extremely easily assembled into a water treatment facility.

Owner:HIGUCHI SHINYA

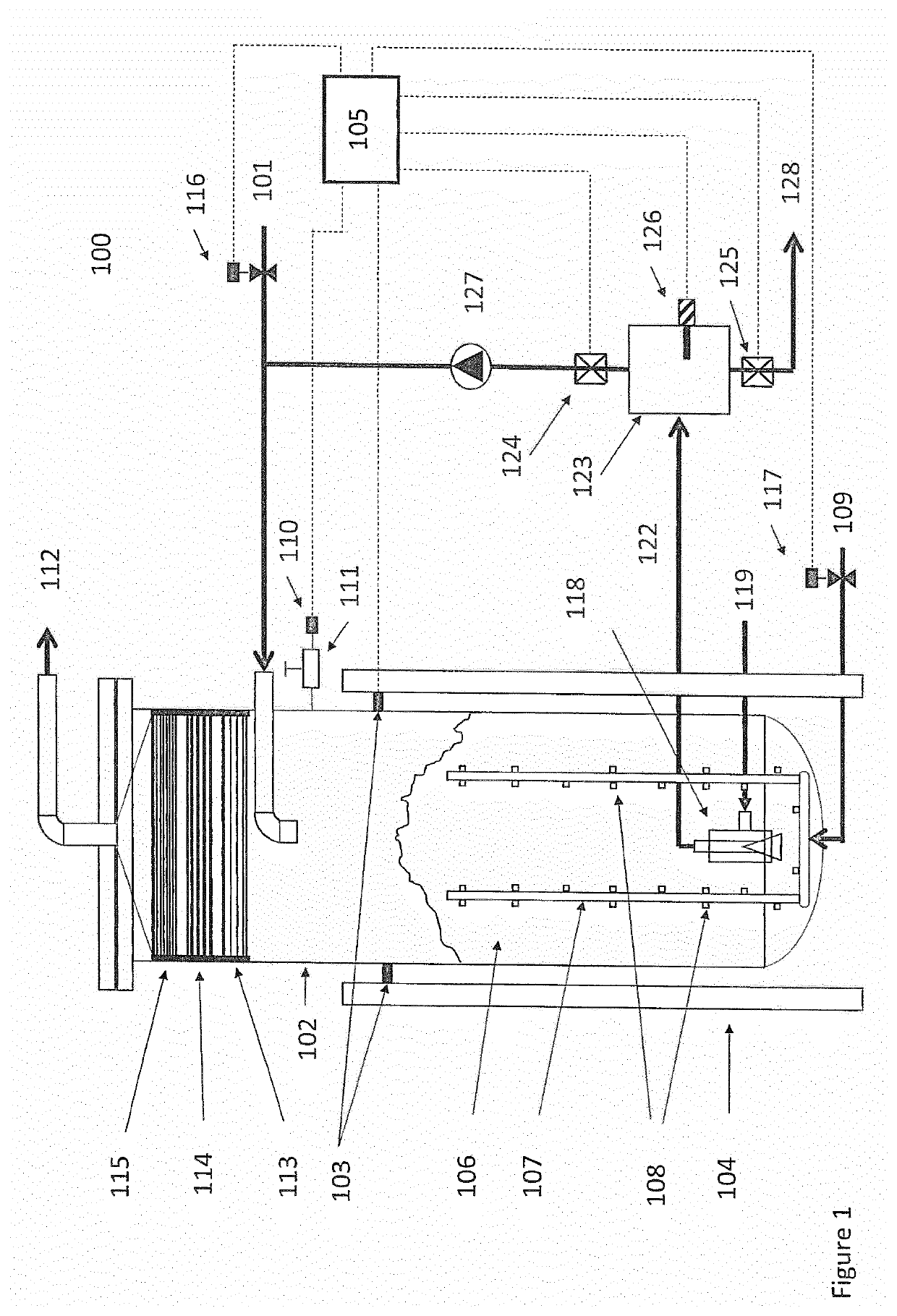

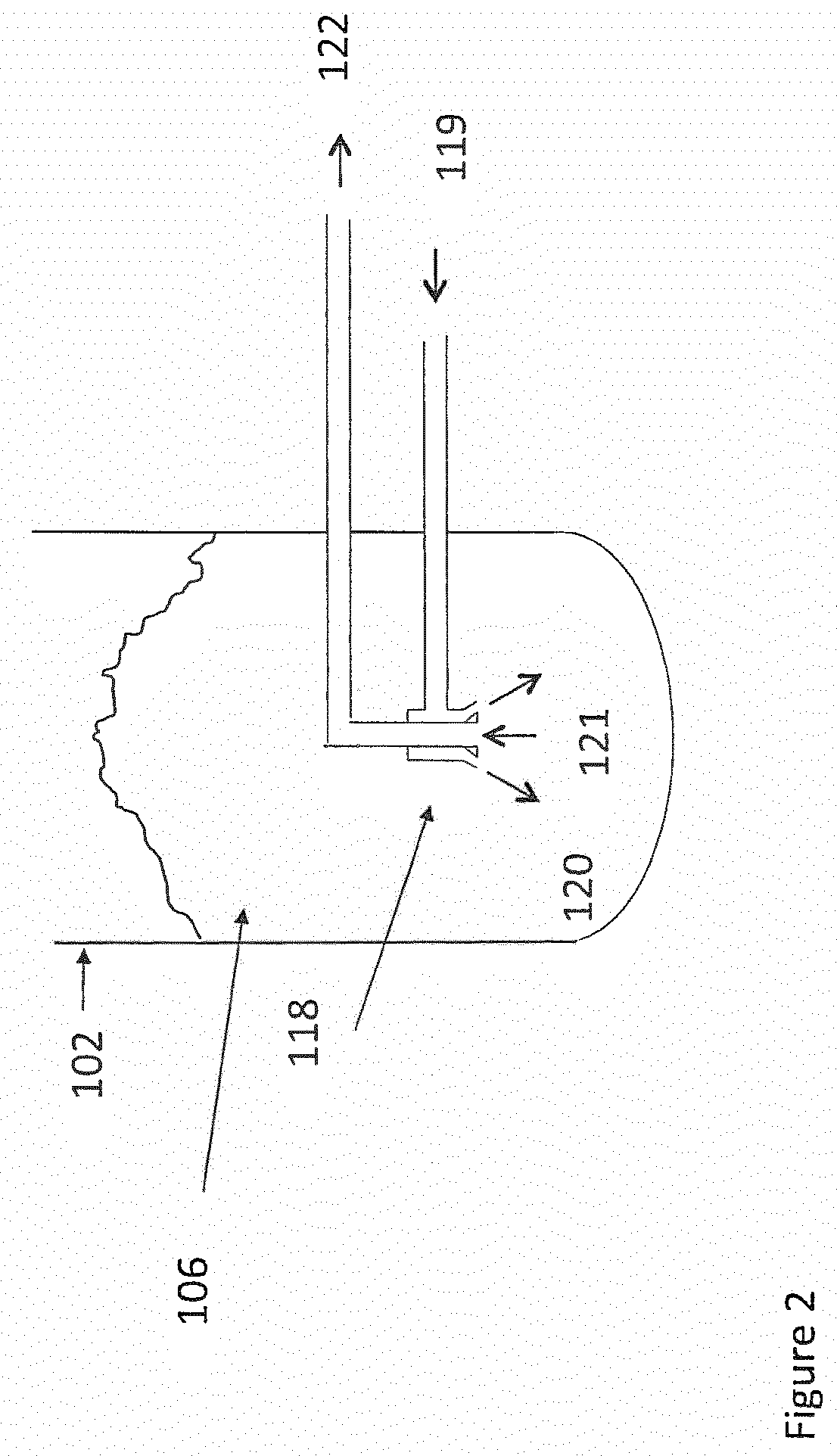

Solids washing in oil and/or gas production

ActiveUS20200324323A1Safe disposalSedimentation regulating devicesSolid separationThermodynamicsSolid particle

An apparatus for washing solid particles removed from a hydrocarbon-containing fluid produced from an oil and gas production facility using a company automated unit. The apparatus comprises an inlet that carries a mixture of solids particles and water flushed from a de-sander.

Owner:FOURPHASE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com