Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69 results about "Spent caustic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spent caustic is a waste industrial caustic solution that has become exhausted and is no longer useful (or spent). Spent caustics are made of sodium hydroxide or potassium hydroxide, water, and contaminants. The contaminants have consumed the majority of the sodium (or potassium) hydroxide and thus the caustic liquor is spent, for example, in one common application H₂S (gas) is scrubbed by the NaOH (aqueous) to form NaHS (aq) and H₂O (l), thus consuming the caustic.

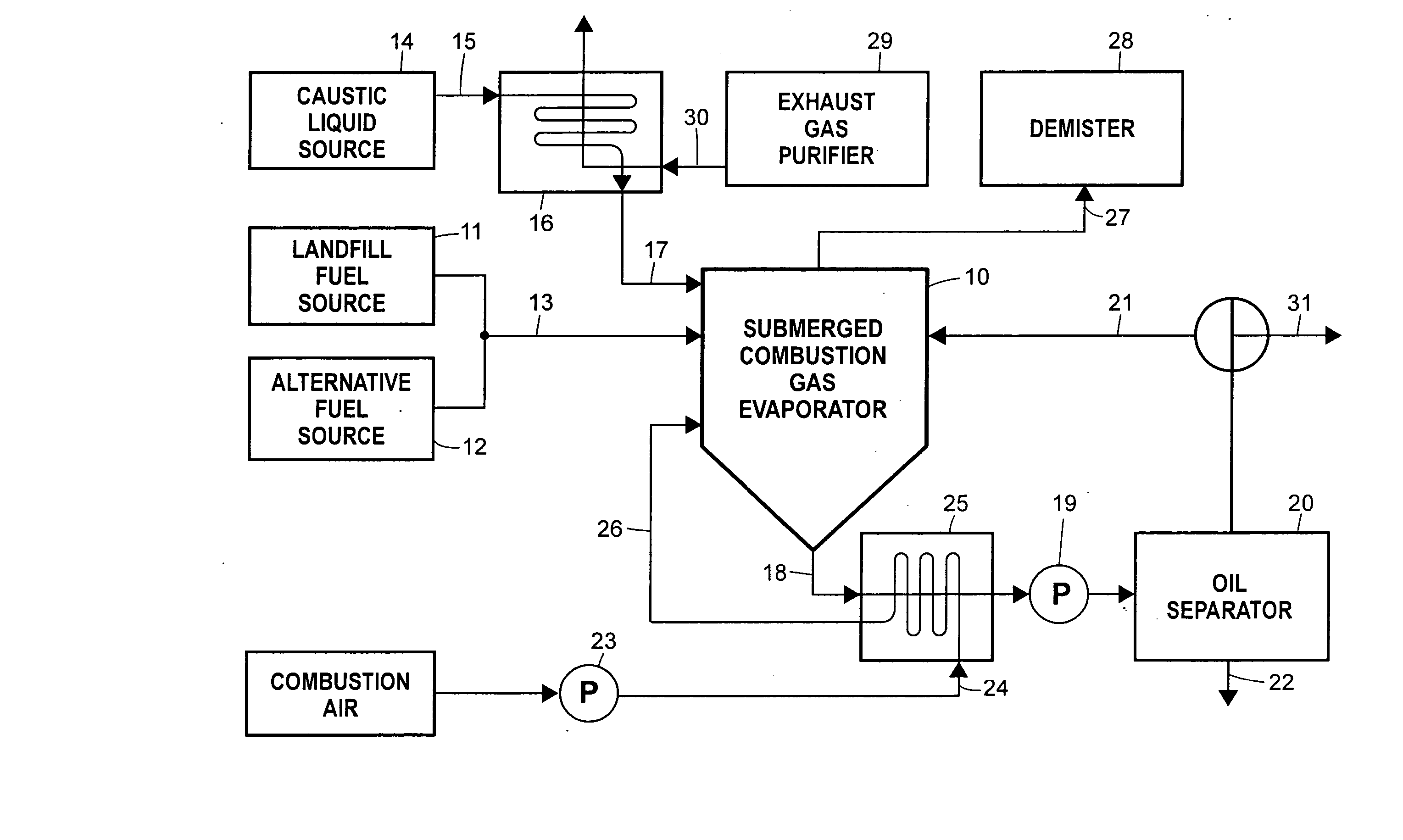

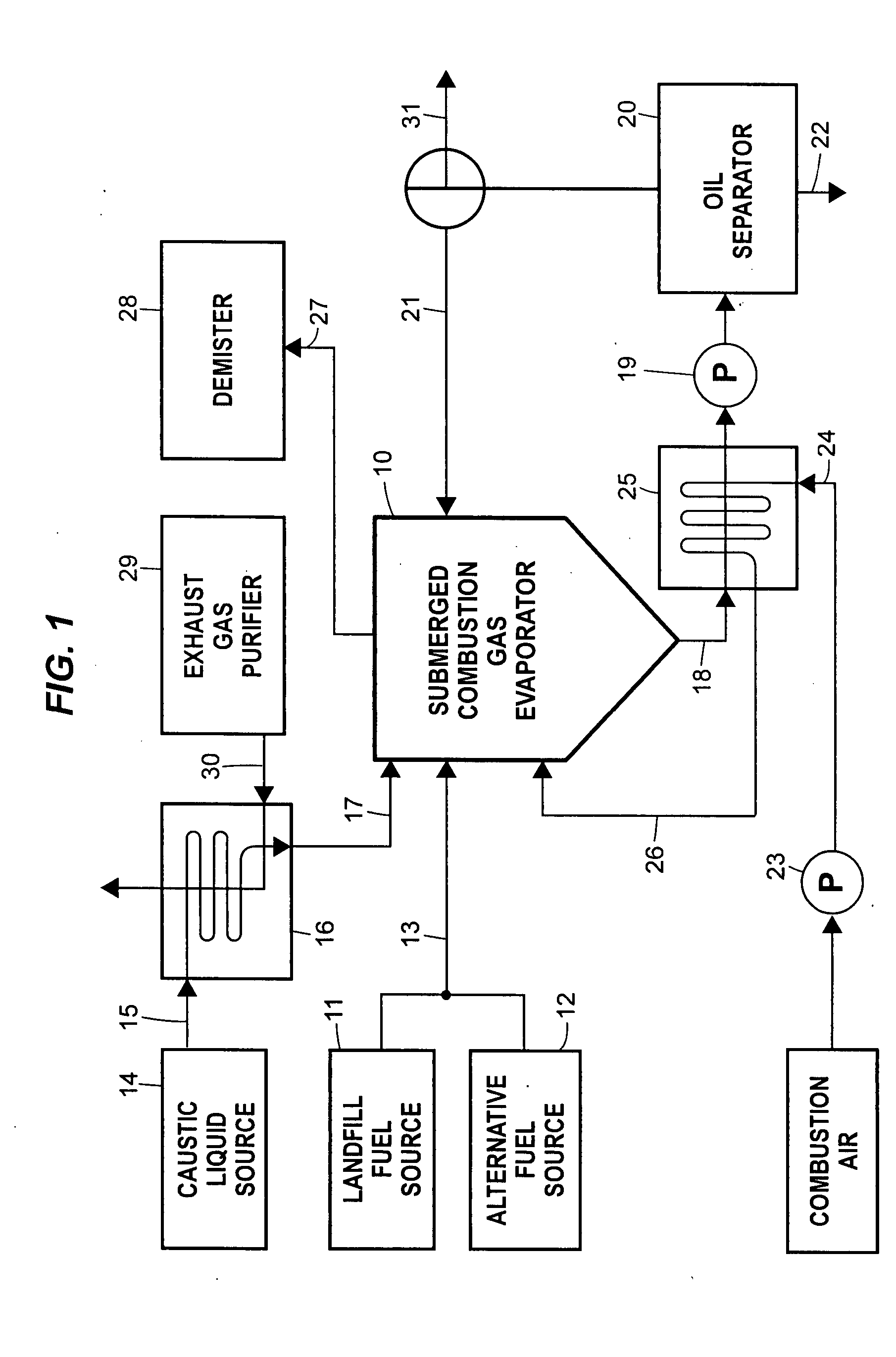

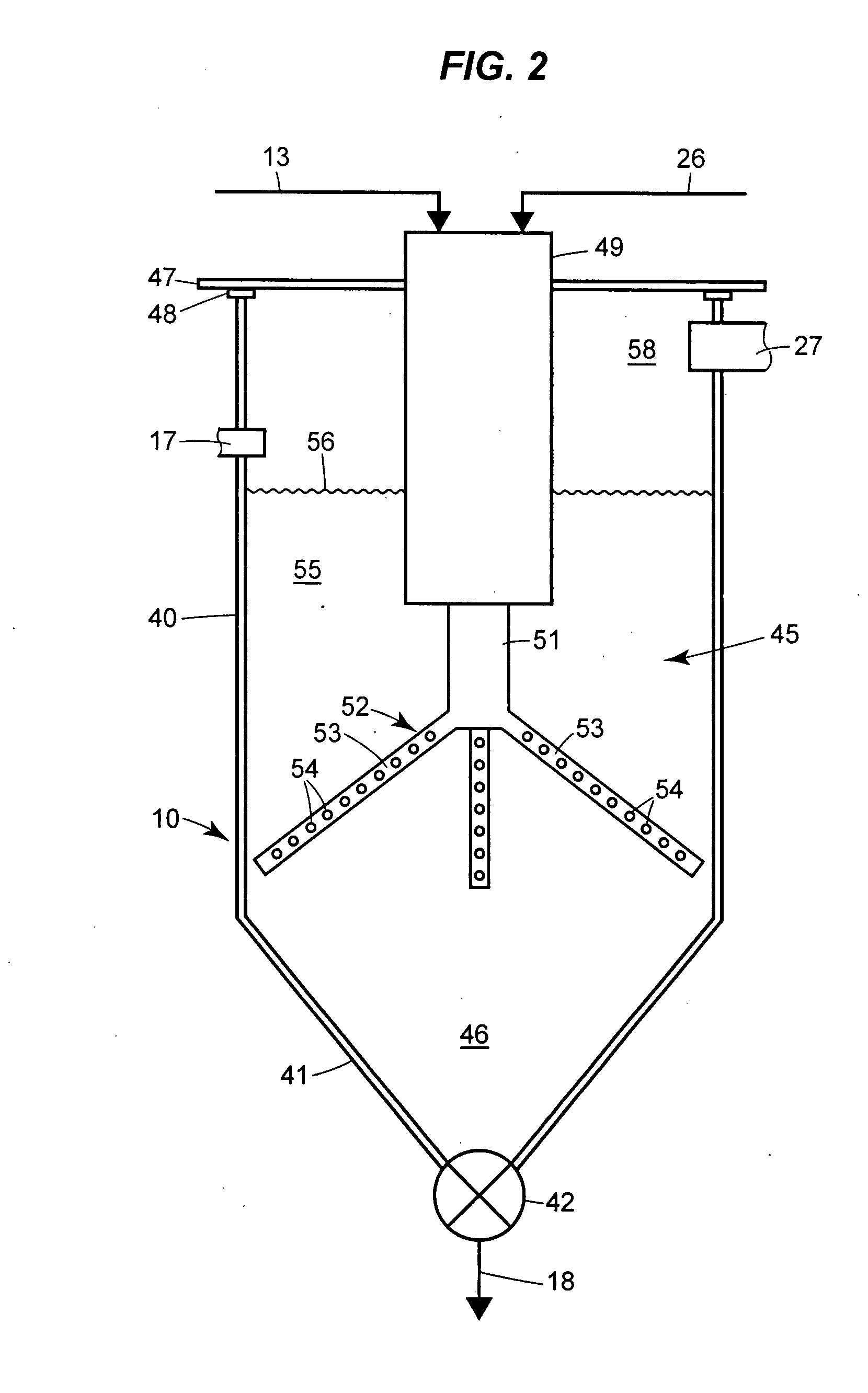

Treatment of spent caustic refinery effluents

InactiveUS7214290B2Avoid spreadingDrying using combination processesLiquid degasificationLiquid wasteCombustion

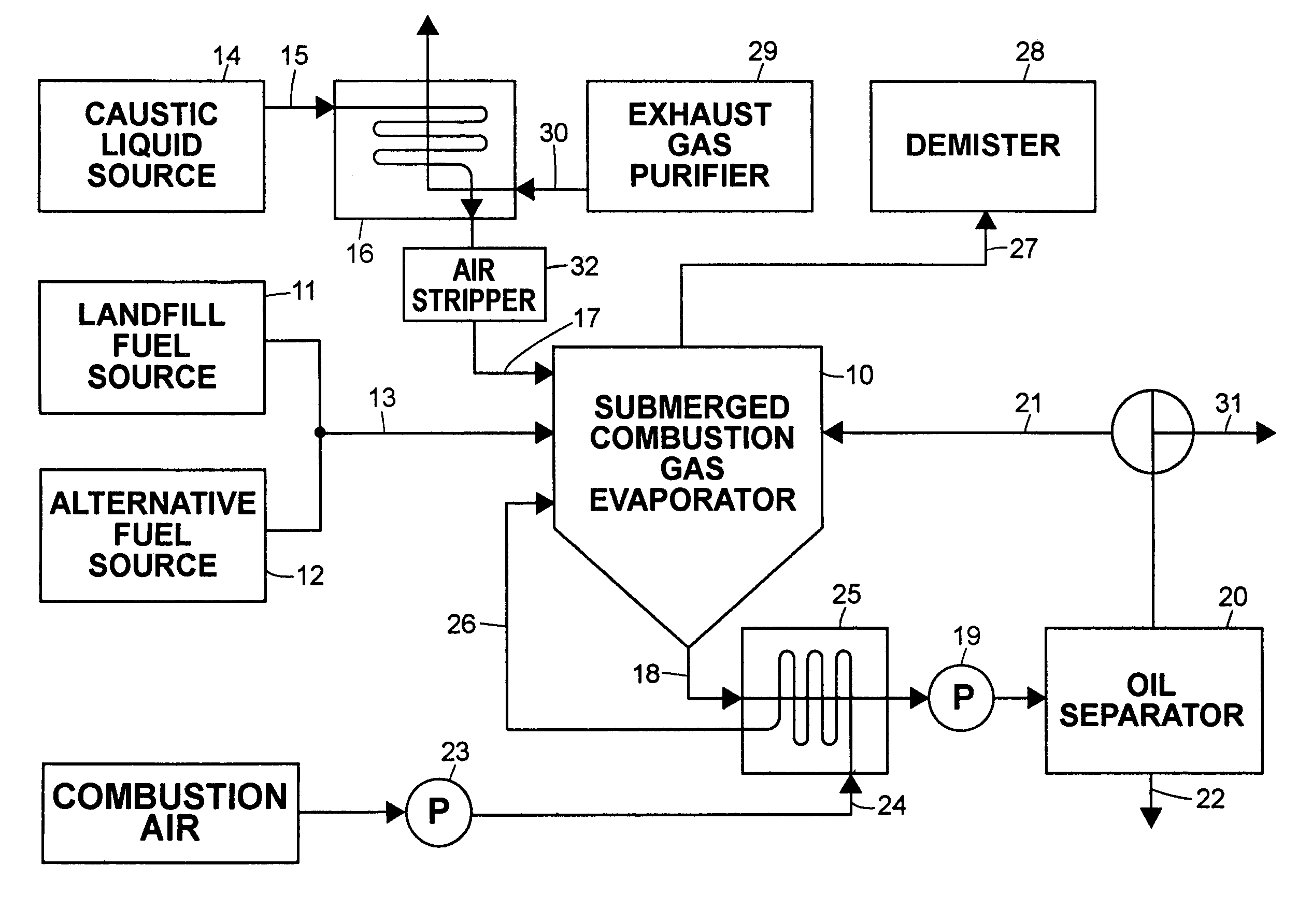

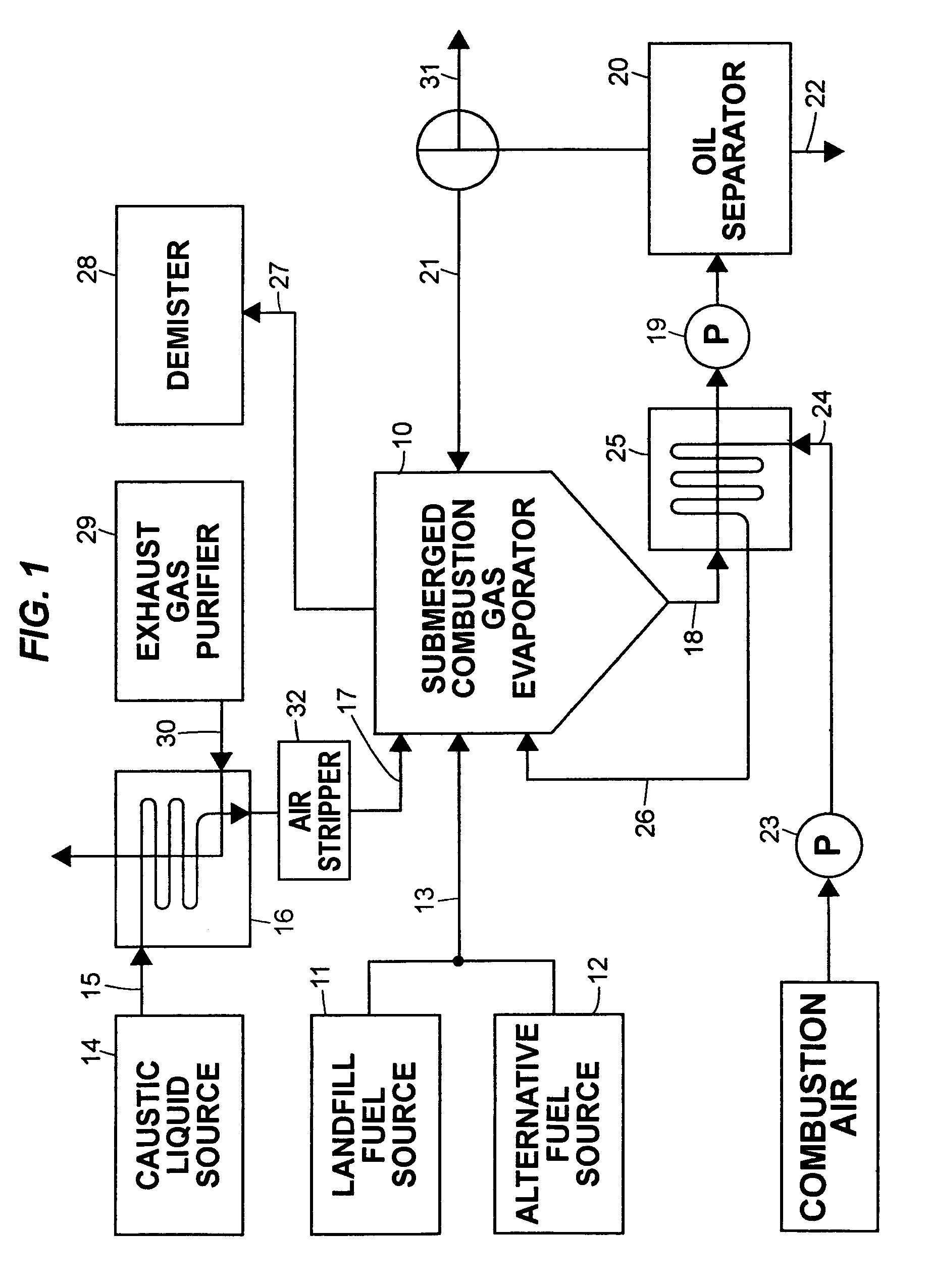

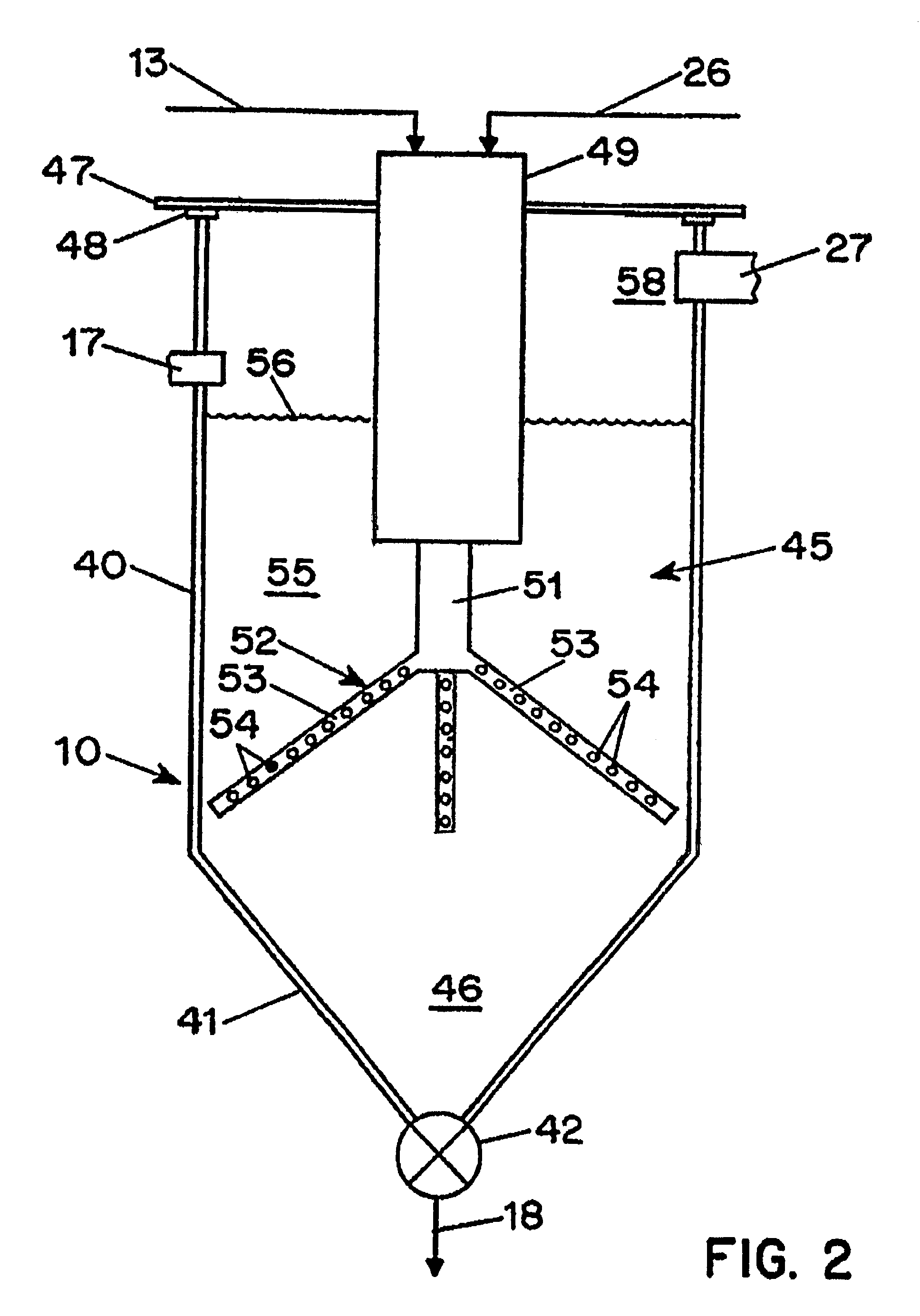

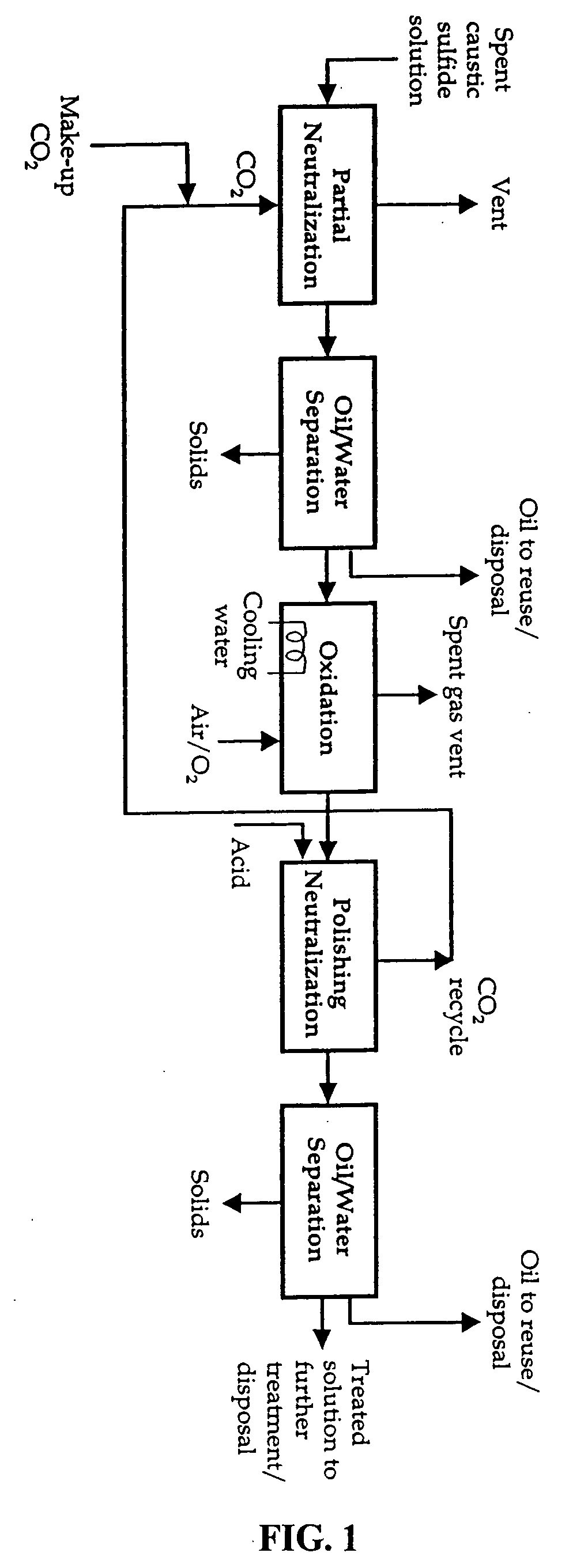

In the methods for treatment of caustic effluents described in the specification, a spent caustic refinery effluent is supplied to a submerged combustion gas evaporator in which hot combustion gas containing carbon dioxide is injected into the caustic liquid to concentrate the liquid and convert a hydroxide constituent to a carbonate. Where the caustic effluent is from a petroleum refinery, oil in the waste liquid is separated from the aqueous constituent before, during or after concentration.

Owner:GEI LIQUID SOLUTIONS +1

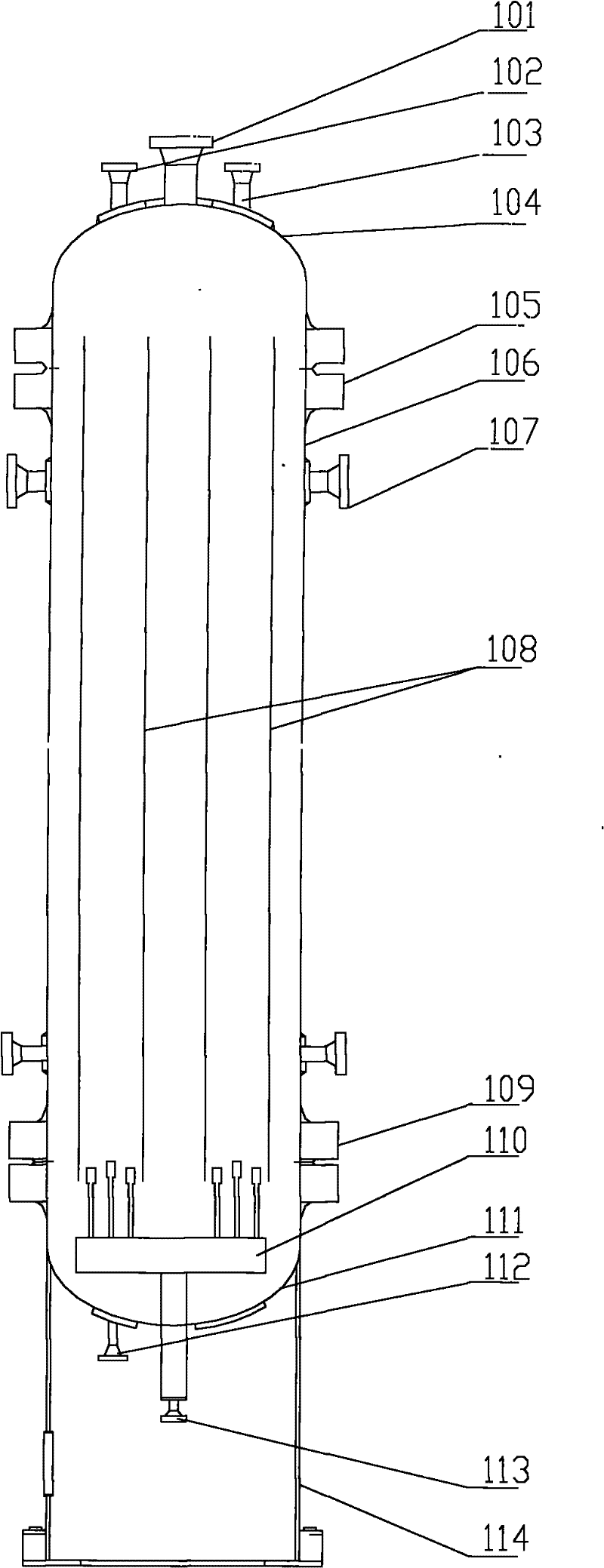

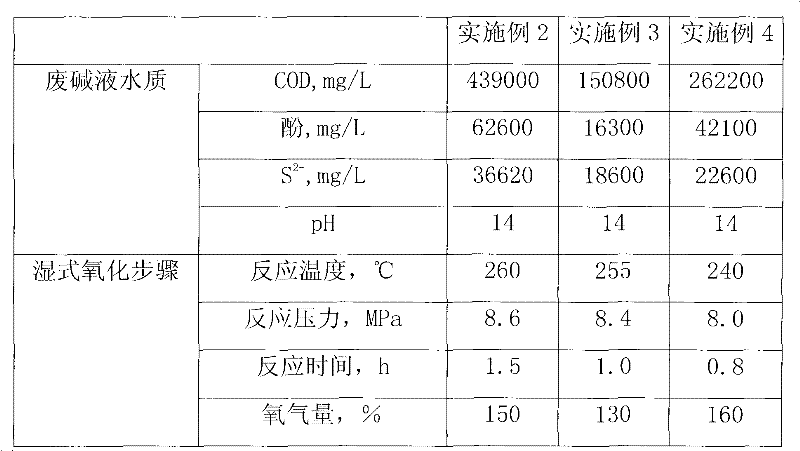

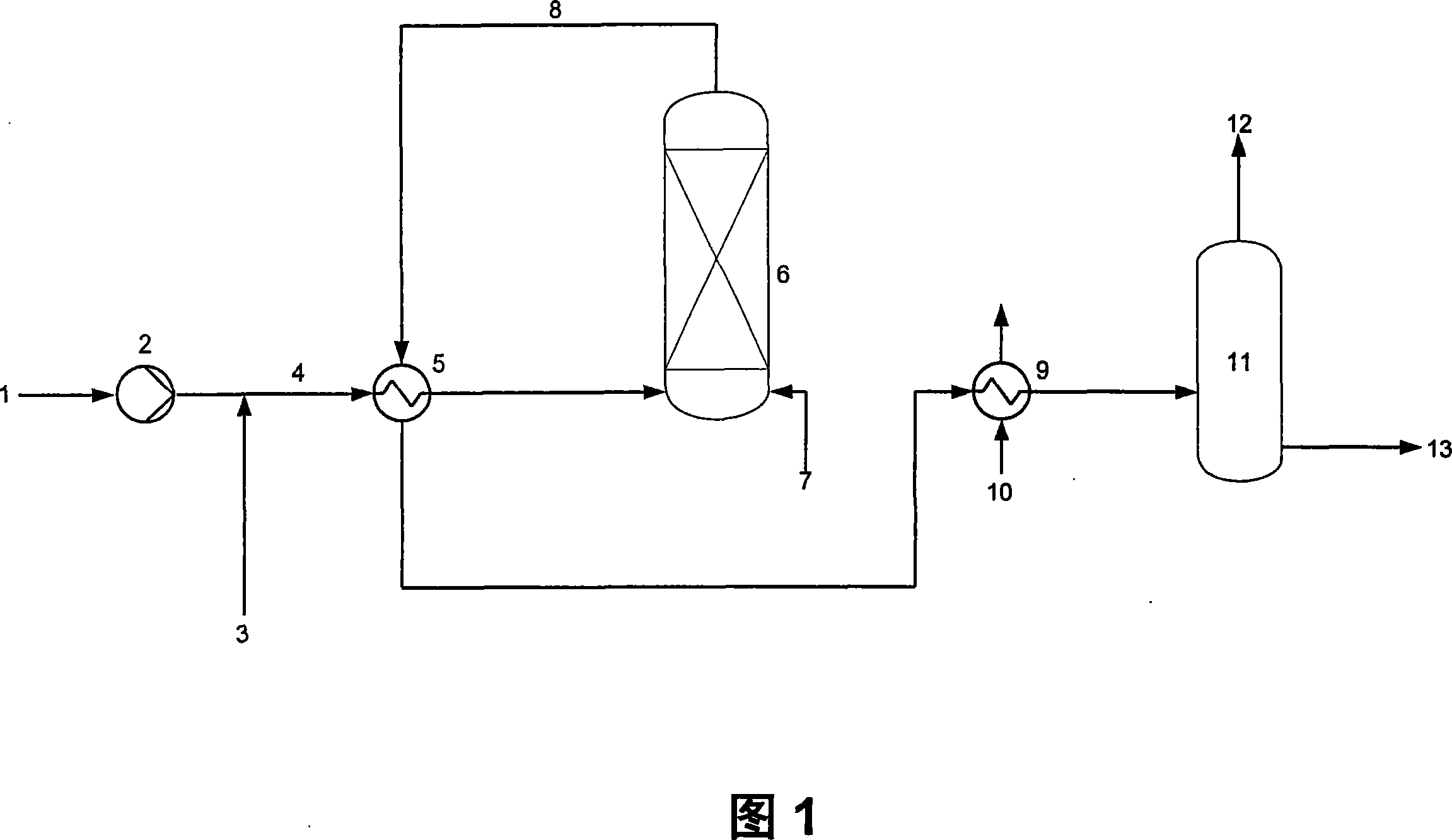

A high-temperature wet oxidation method for treating waste caustic soda

InactiveCN102285729ANo impactNo secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by oxidationHigh concentrationGas phase

The invention discloses a method for treating waste lye by high-temperature wet oxidation. At 220°C to 260°C and under the pressure of keeping the waste lye in liquid phase, the waste lye is contacted with air exceeding the theoretical oxygen demand, and the waste lye is used The oxygen in the air oxidizes the inorganic sulfide and organic matter in the waste caustic so that the sulfur in it is converted into sulfate, and the organic matter is oxidized and decomposed into water and carbon dioxide; the reacted material discharged from the wet liquid phase oxidation reactor enters the high-pressure gas-liquid separator , The oxidized spent lye after gas-liquid separation and the waste lye feed are exchanged for heat, and the oxidized spent lye after heat exchange and the gas phase separated from gas and liquid enter the cooling and washing tower. Compared with the prior art, the method of the present invention has low energy consumption, the removal rate of S2- can reach 100%, the removal rate of COD can reach 75%-85%, and the waste lye after treatment can be directly discharged into the sewage treatment system, effectively alleviating the The pressure brought by the high concentration of wastewater in sewage treatment plants.

Owner:CHINA PETROLEUM & CHEM CORP +1

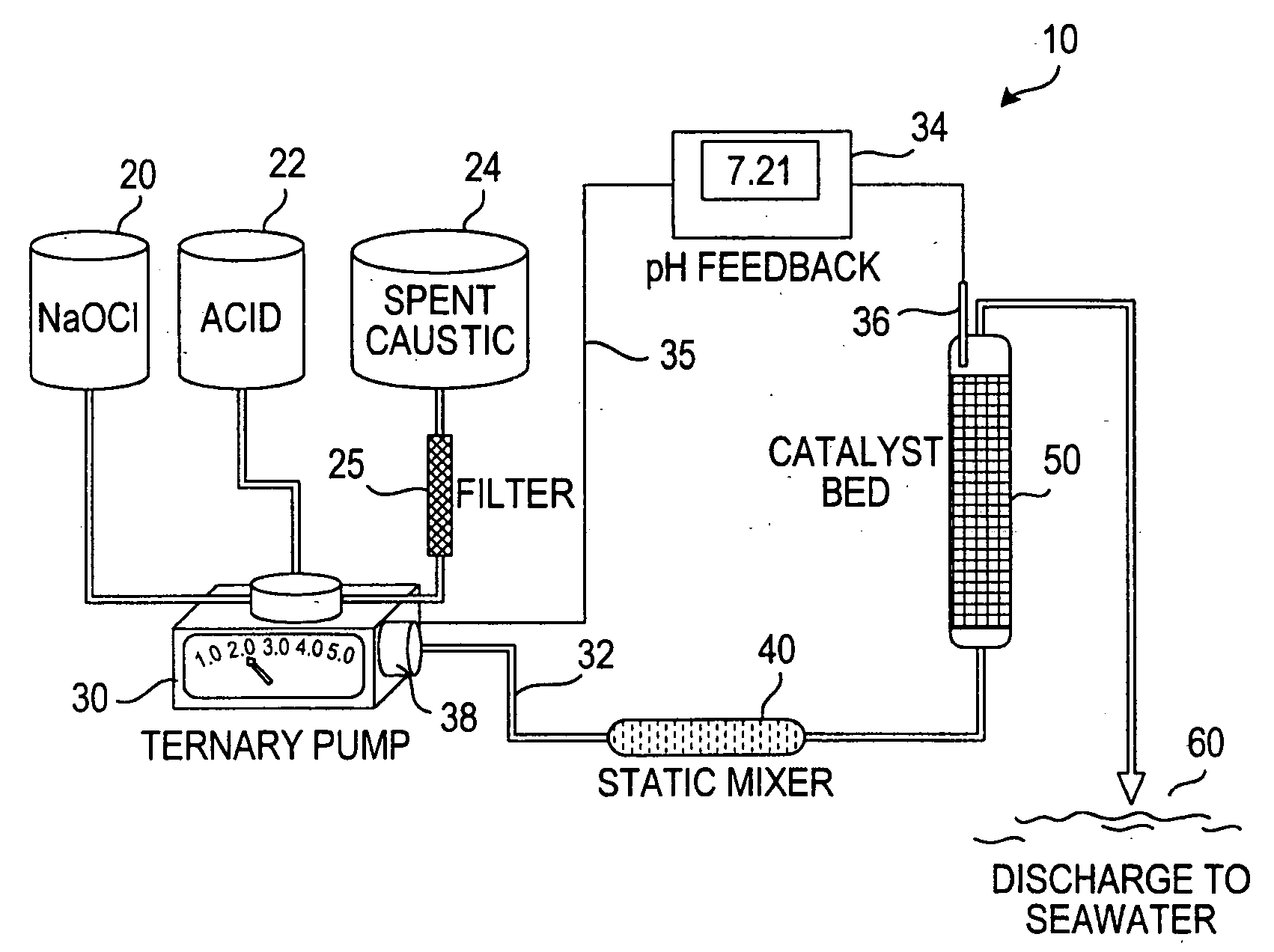

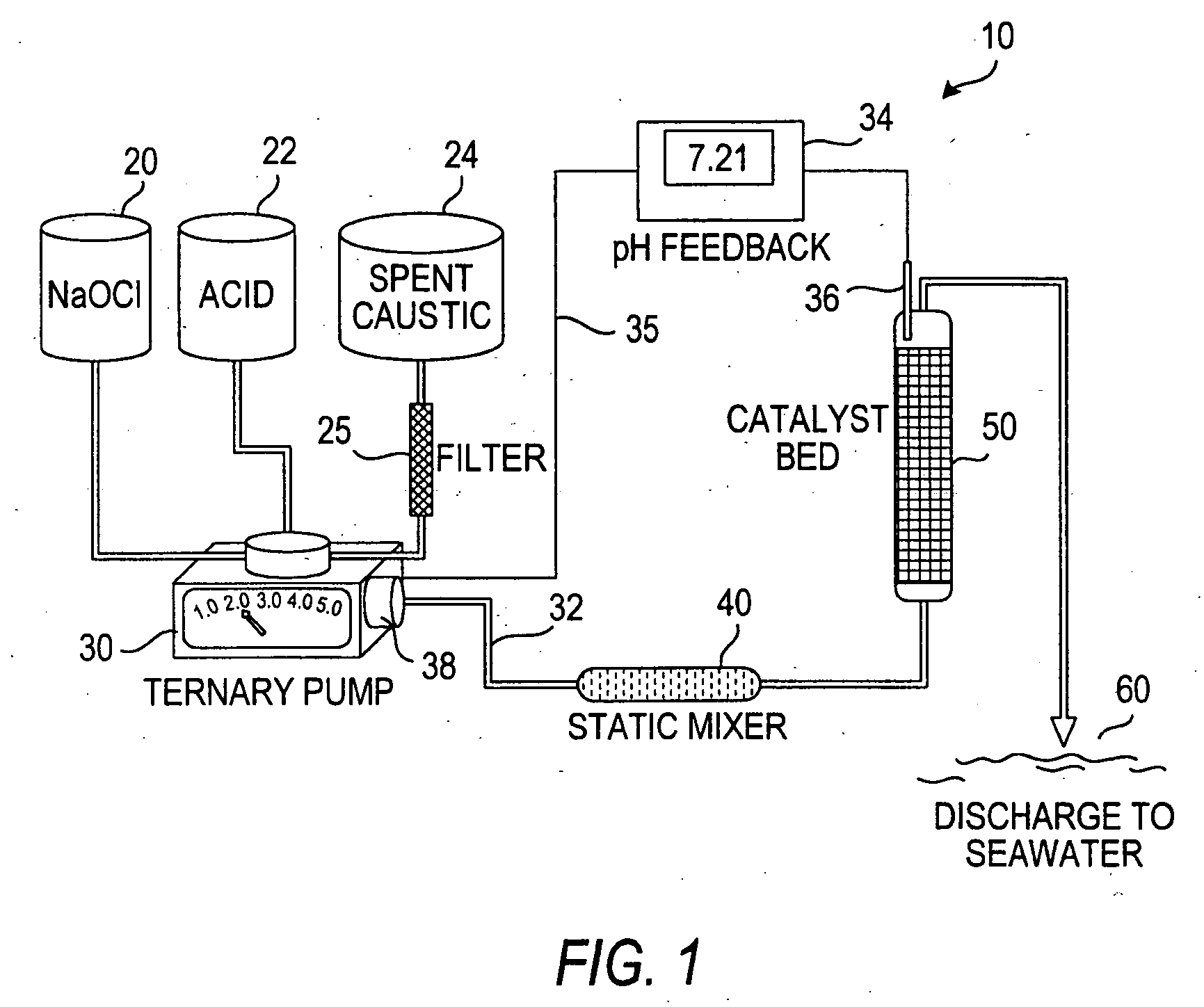

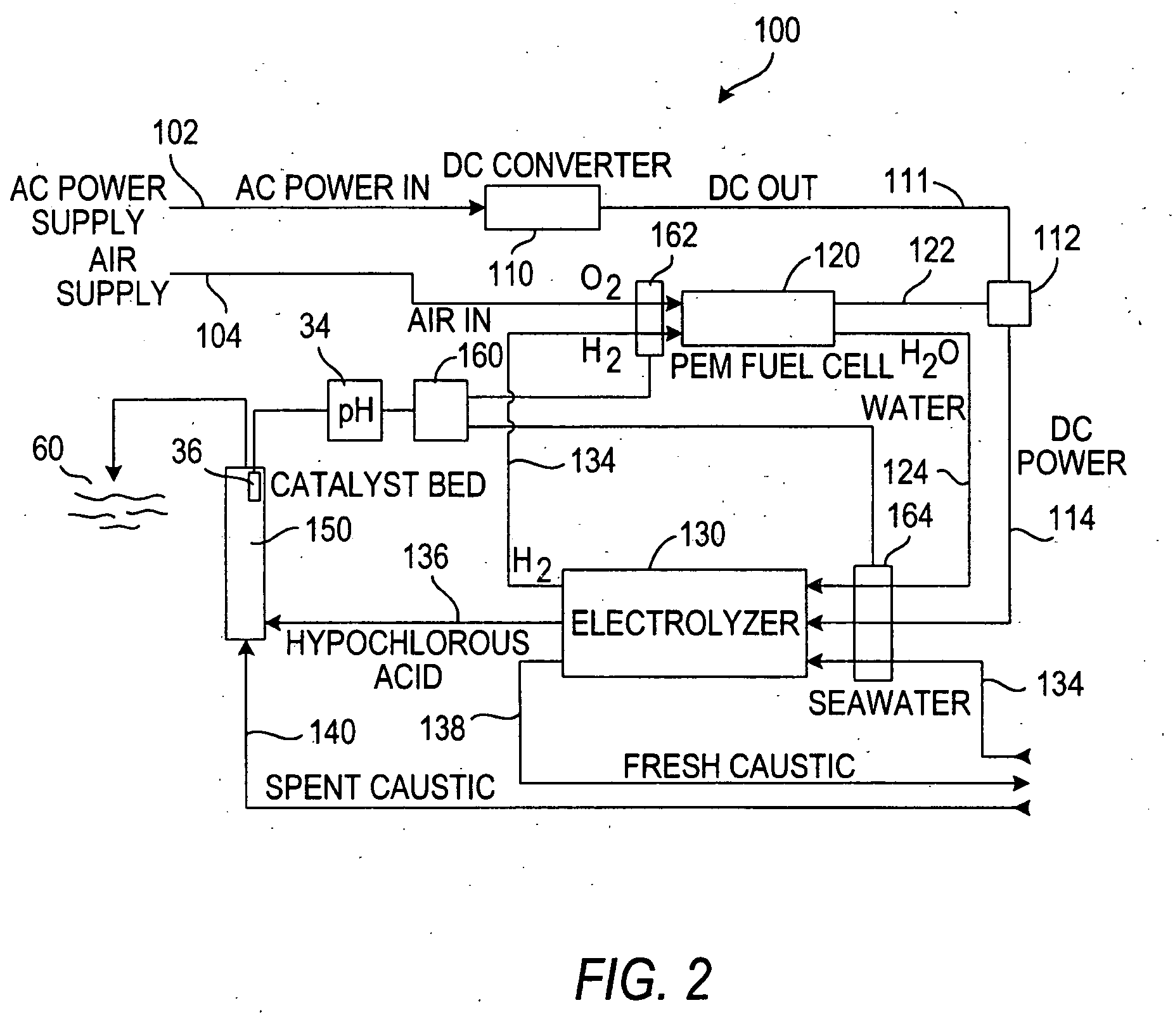

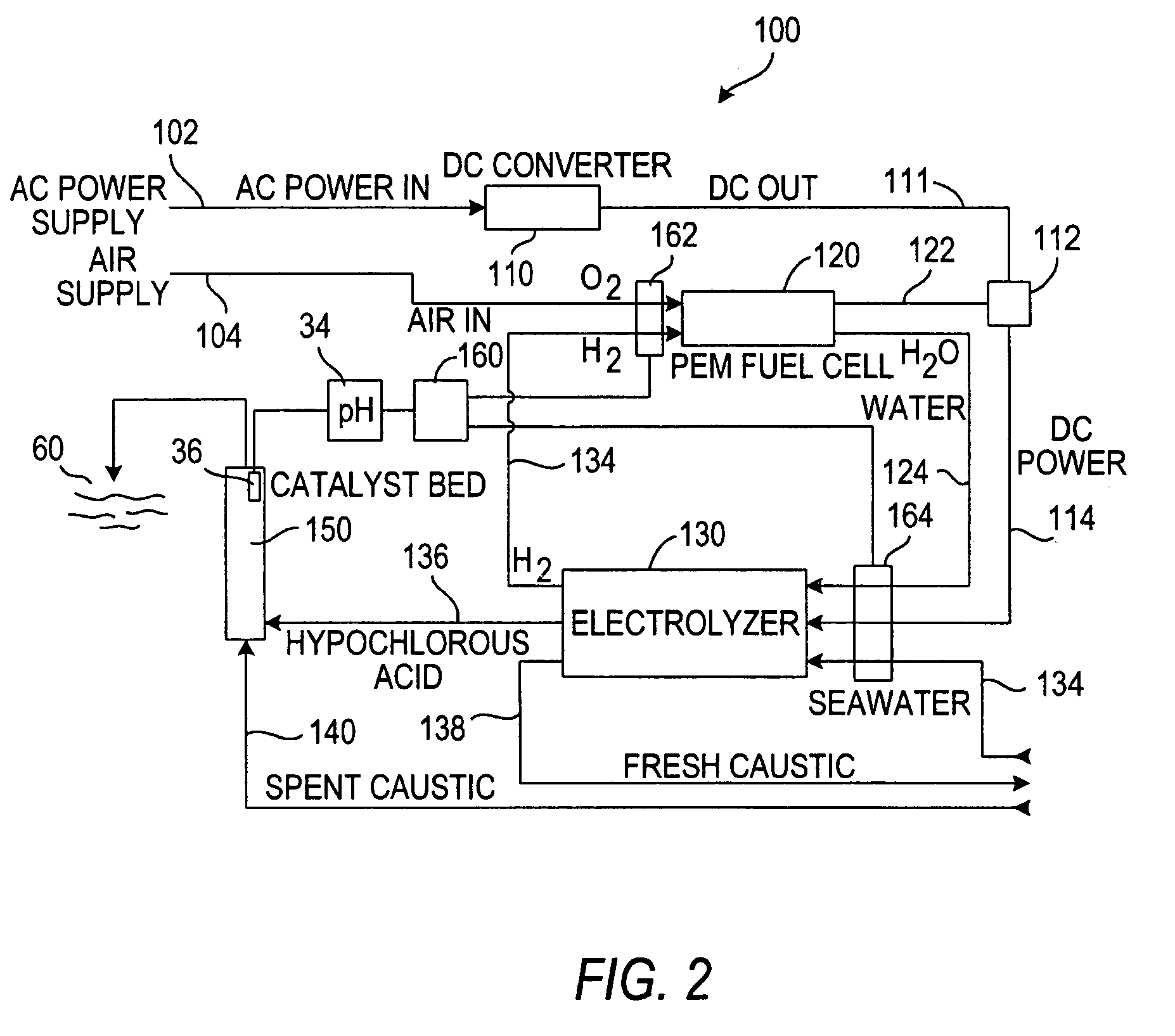

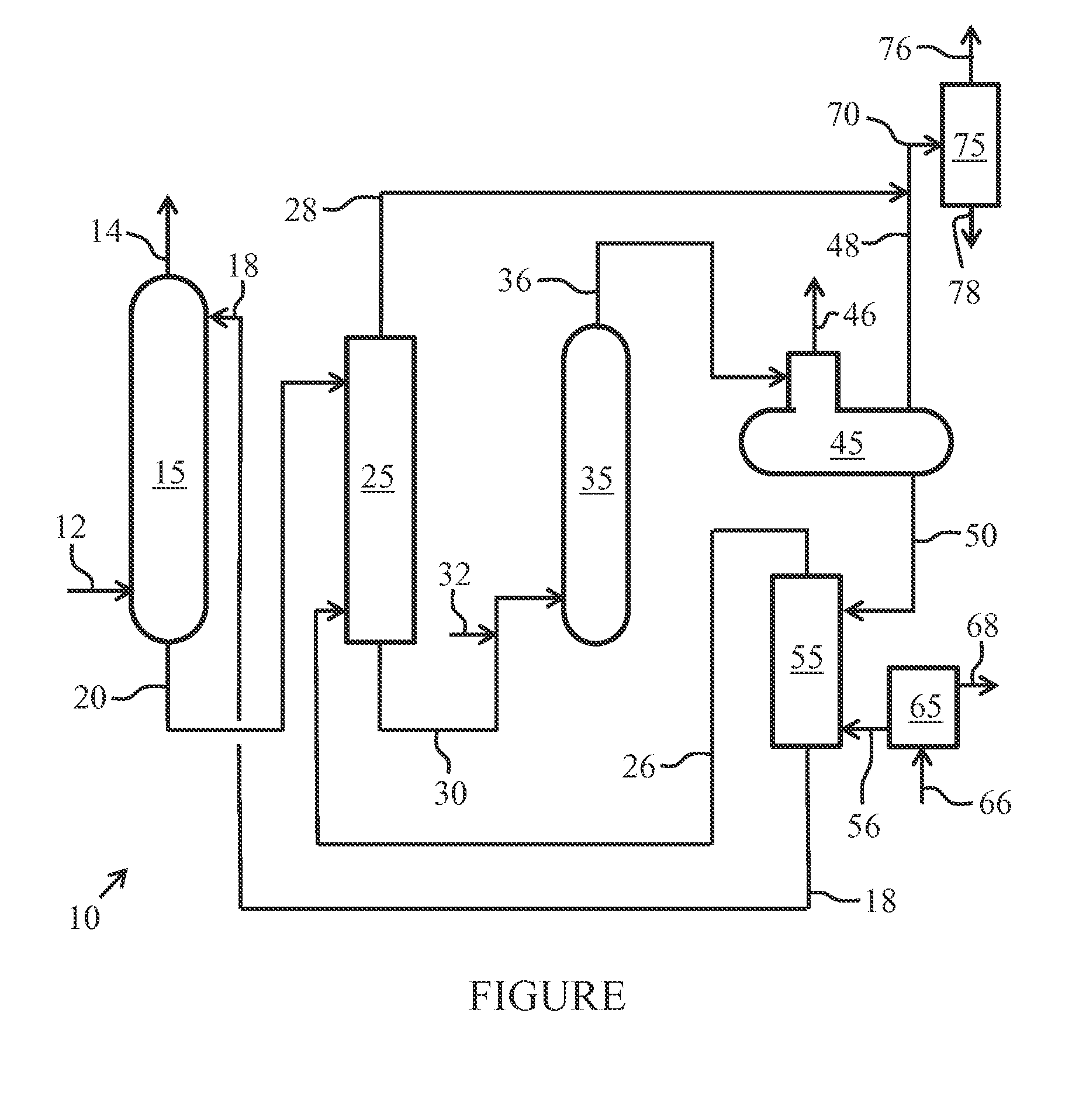

Process for treating a sulfur-containing spent caustic refinery stream using a membrane electrolyzer powered by a fuel cell

ActiveUS20060254930A1Simple and inexpensive and effectiveReduce investmentPhotography auxillary processesElectrolysis componentsSodium sulfateSulfur containing

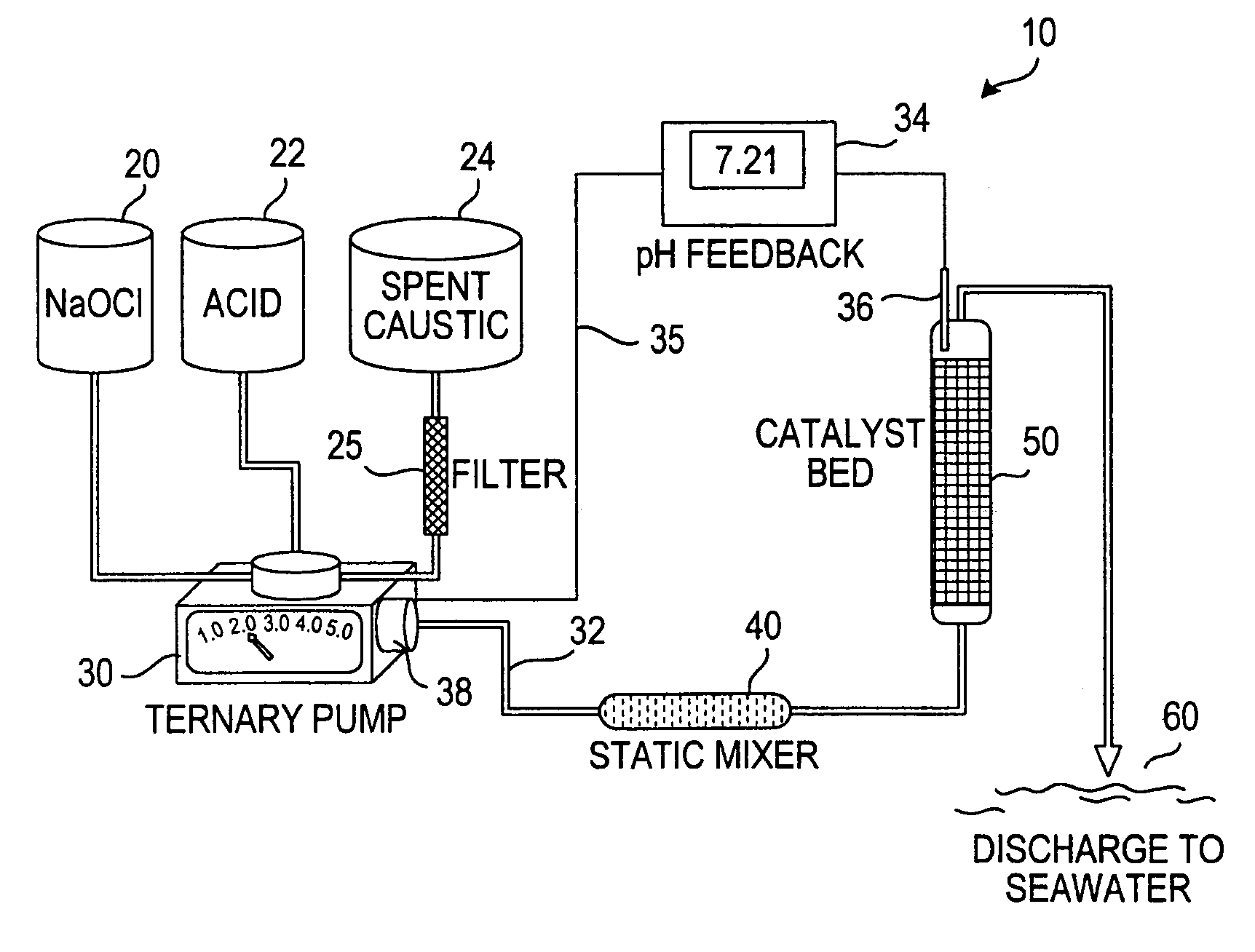

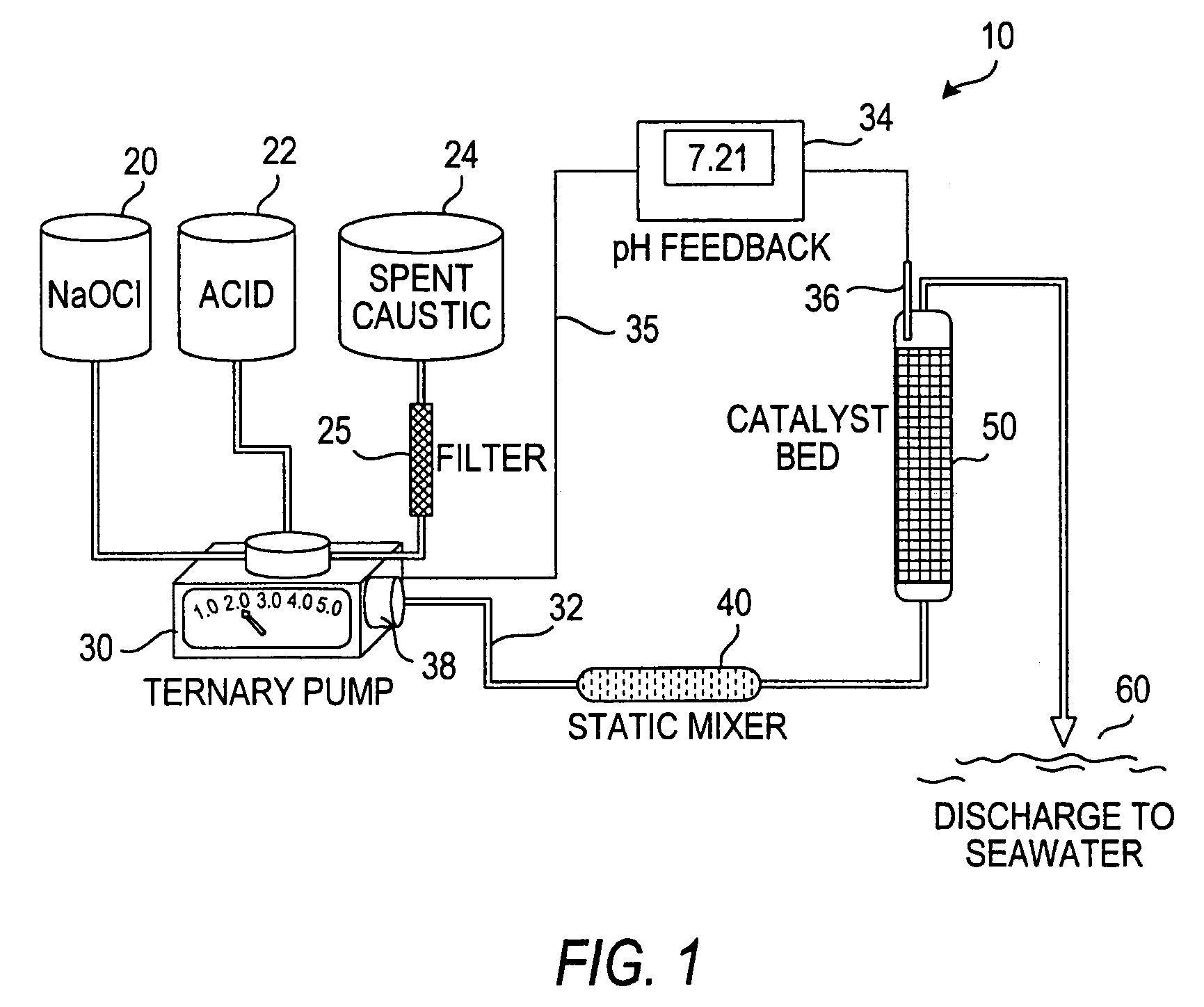

A continuous method for the treatment of a spent aqueous caustic stream used to scrub a hydrocarbon process stream to remove oxidizable sulfur-containing compounds includes: a. mixing an oxidizing hypochlorous acid stream produced from an aqueous brine solution with the aqueous caustic stream to form a reactive mixed feedstream; b. contacting the reactive mixed feedstream with at least one catalyst to promote the oxidation of the sulfur-containing compounds and the neutralization of the sodium hydroxide; and c. recovering a neutral treated product stream comprising aqueous sodium sulfate, sodium carbonate and sodium chloride that is odorless, non-toxic and environmentally acceptable for discharge into the sea or into a conventional sewage treatment system. Preferably, the hypochlorous acid is produced by an electrolyzer that also produces a (1) hydrogen stream that is directed to a PEM fuel cell to generate at least a portion of the electrical power requirement of the electrolyzer, and (2) water that is combined with fresh sodium hydroxide from the electrolyzer to form a fresh caustic stream for use in scrubbing the hydrocarbon process stream.

Owner:SAUDI ARABIAN OIL CO

Treatment of spent caustic refinery effluents

InactiveUS20070251650A1Avoid spreadingDrying using combination processesLiquid degasificationCombustionSpent caustic

Owner:DUESEL BERNARD F JR +2

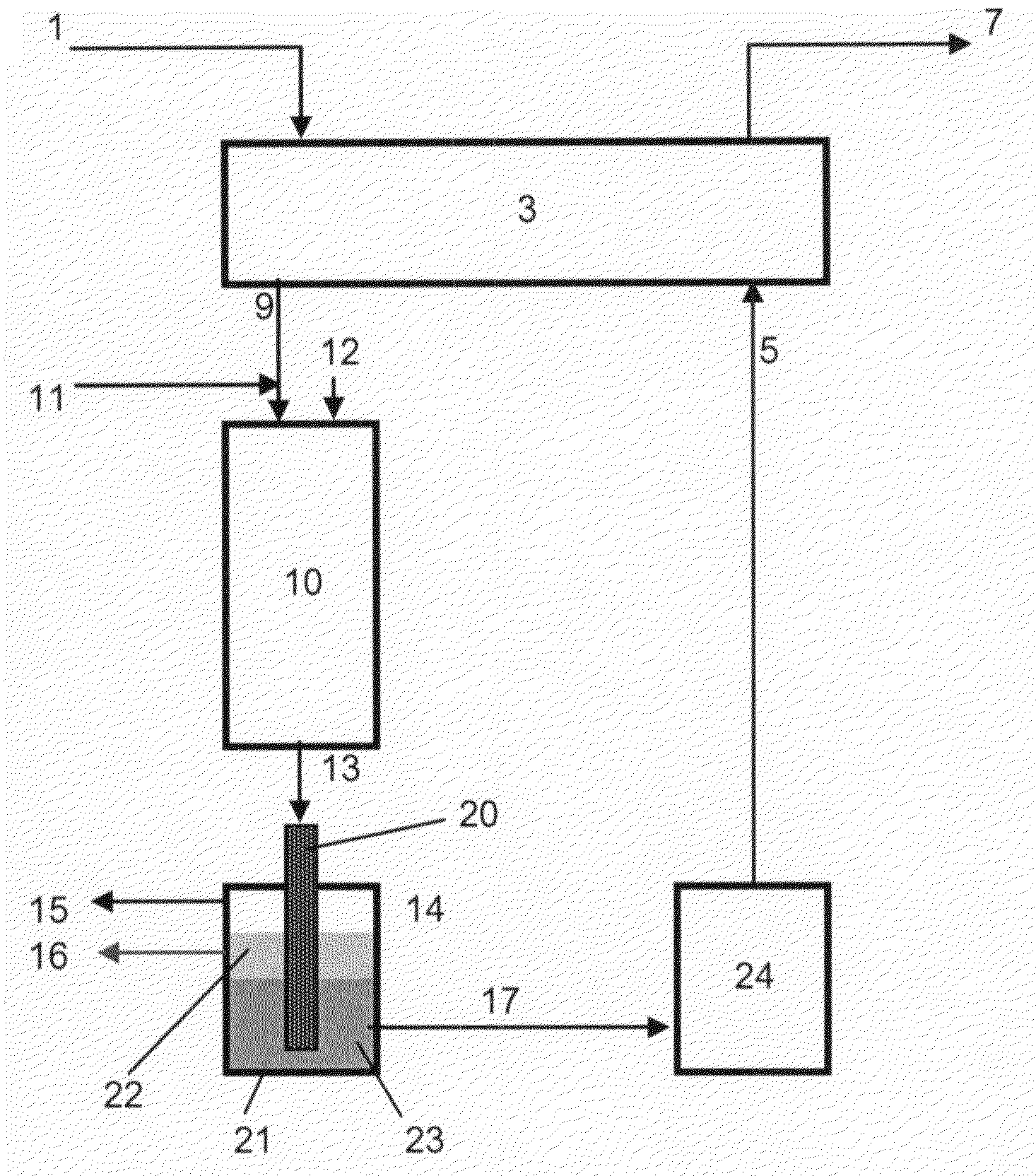

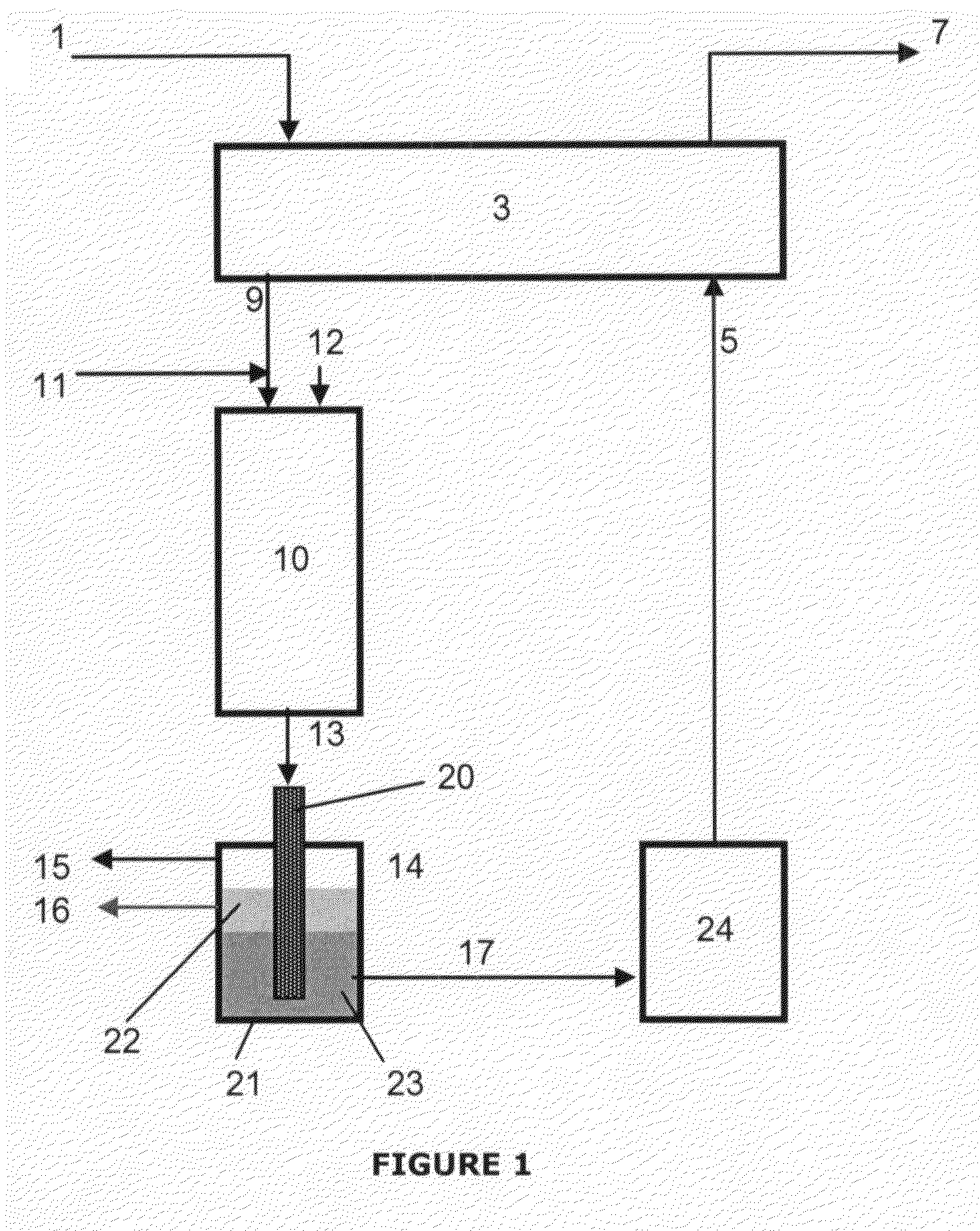

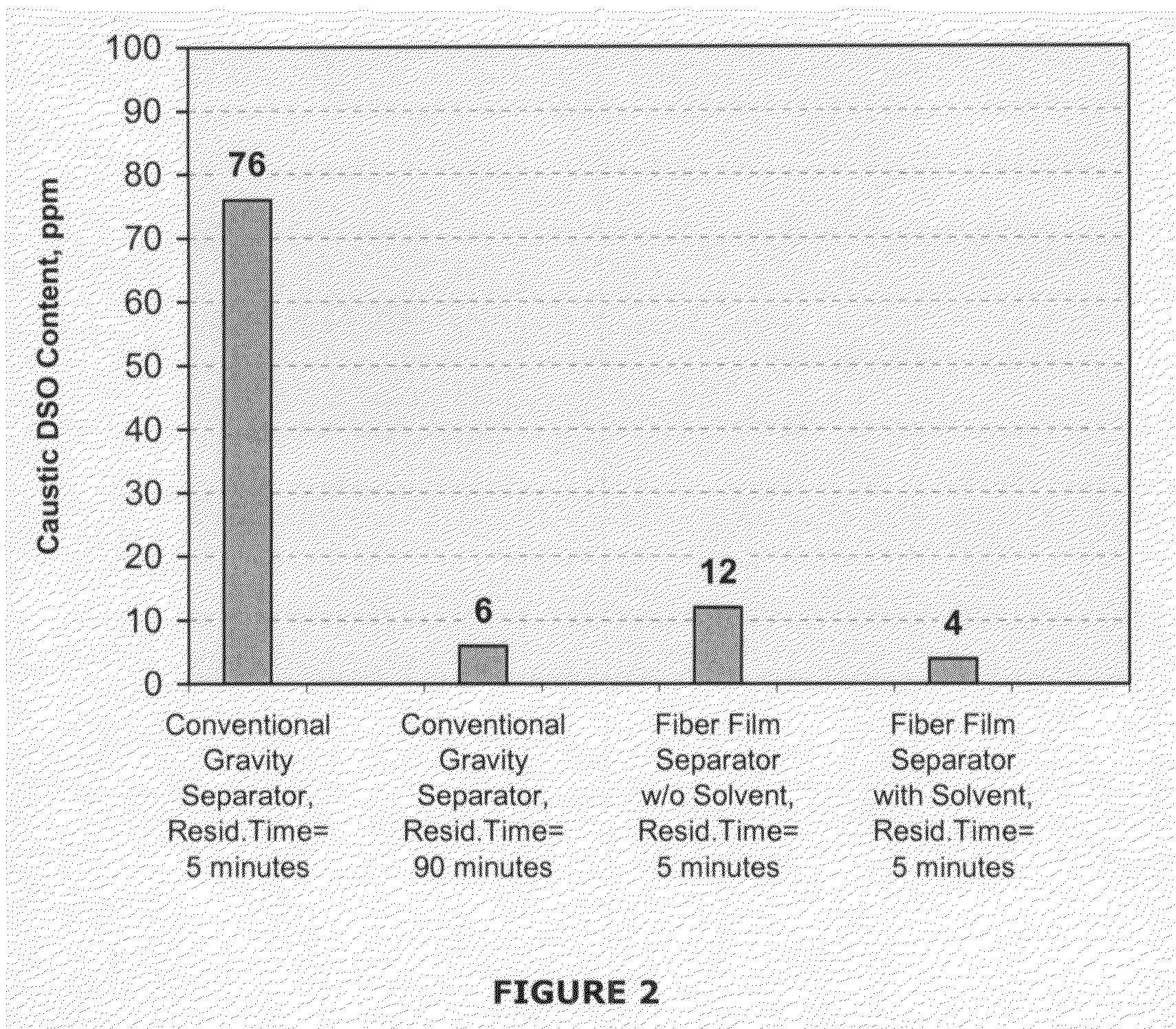

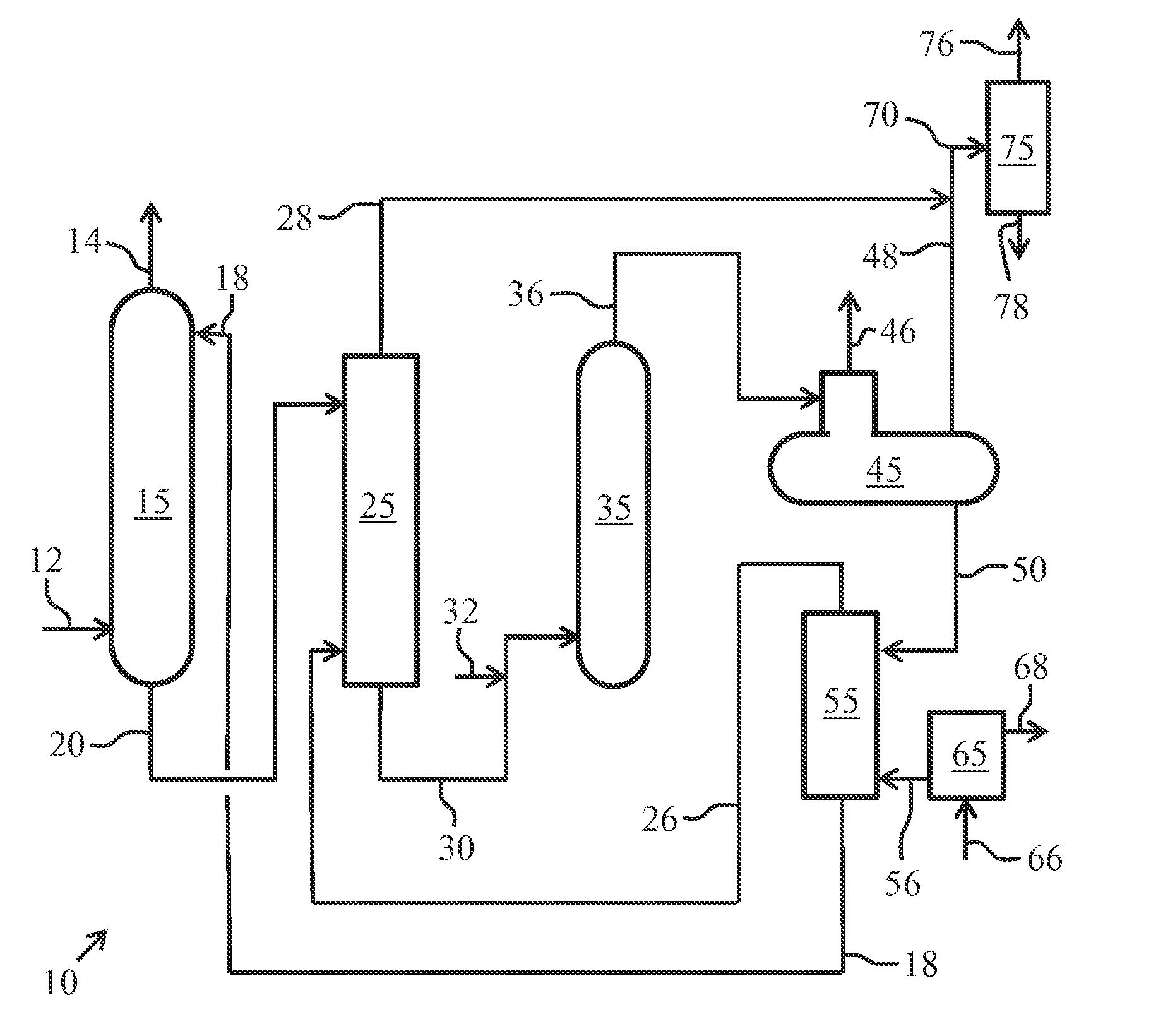

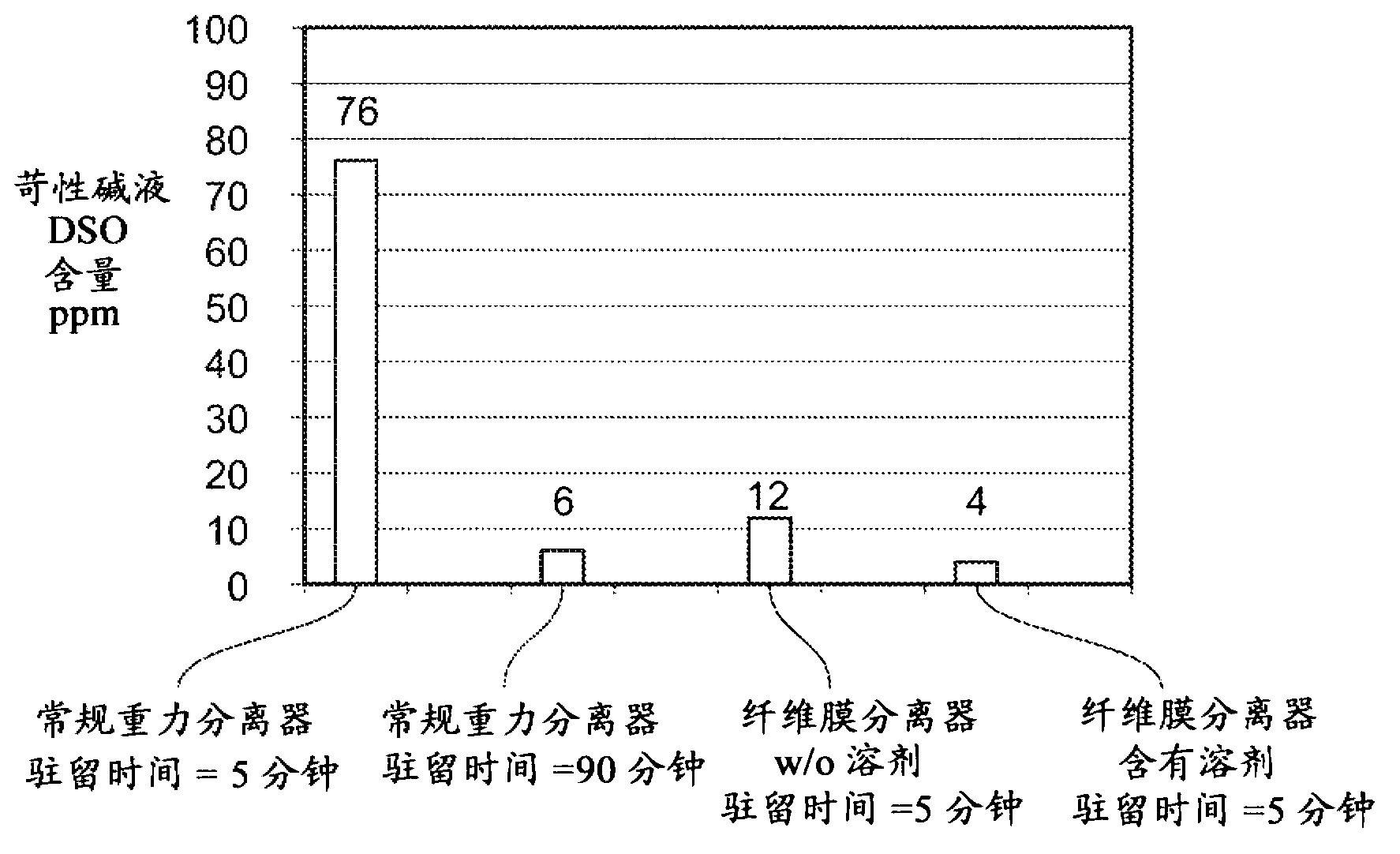

Separation process

ActiveUS20080308503A1Separation in timeEasy to separateDewatering/demulsification with mechanical meansLiquid suspension thickening by filtrationFiberSulfur

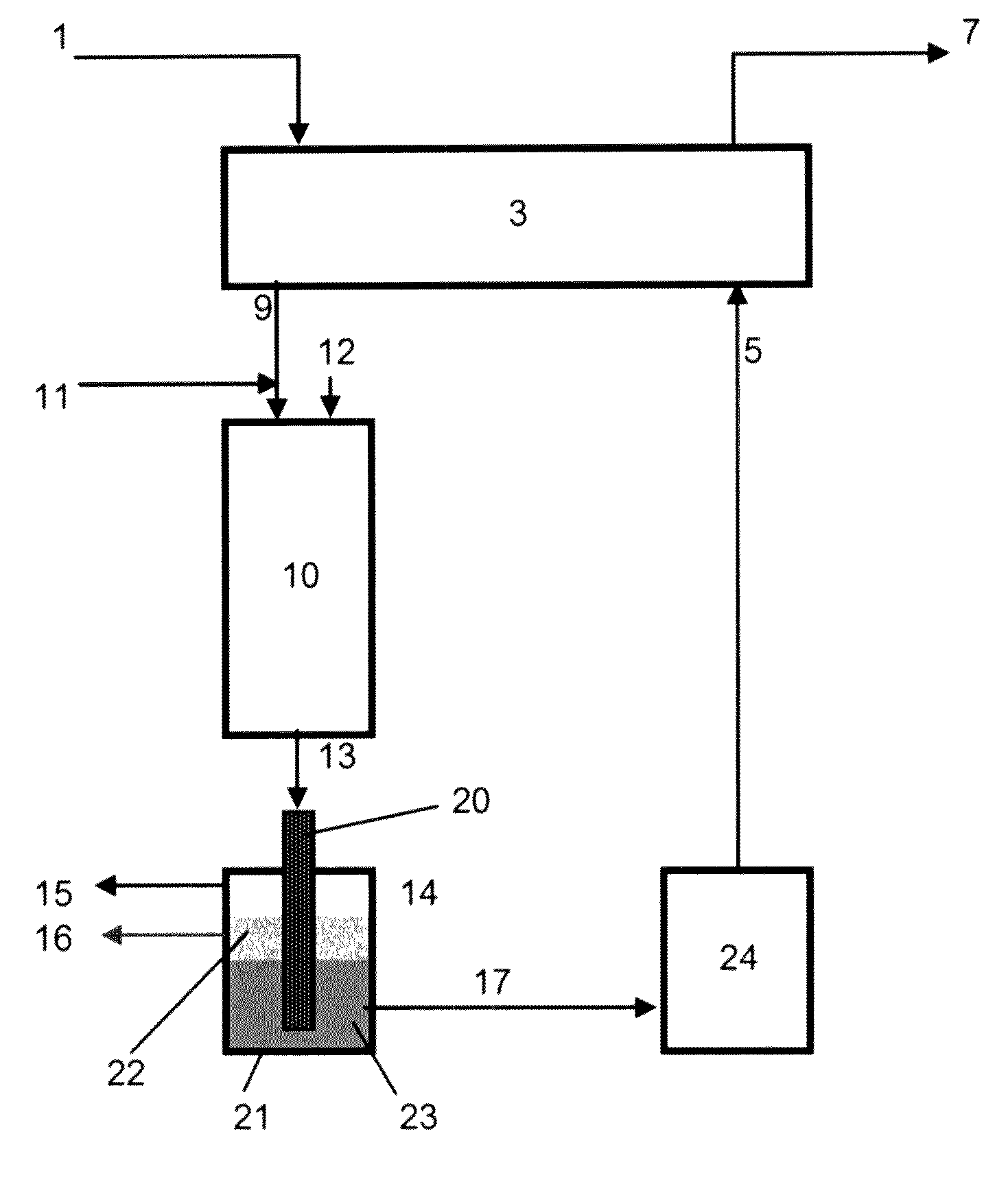

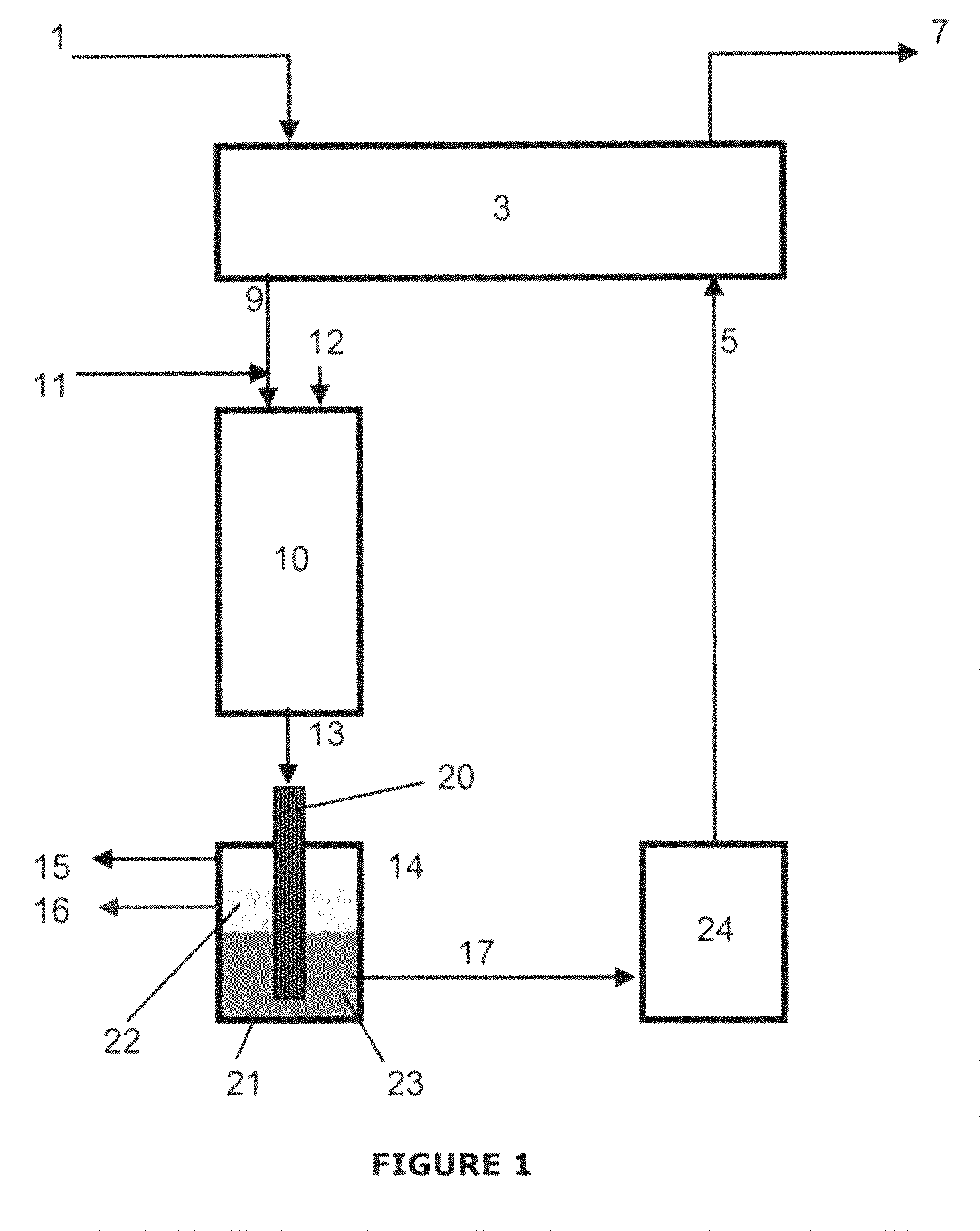

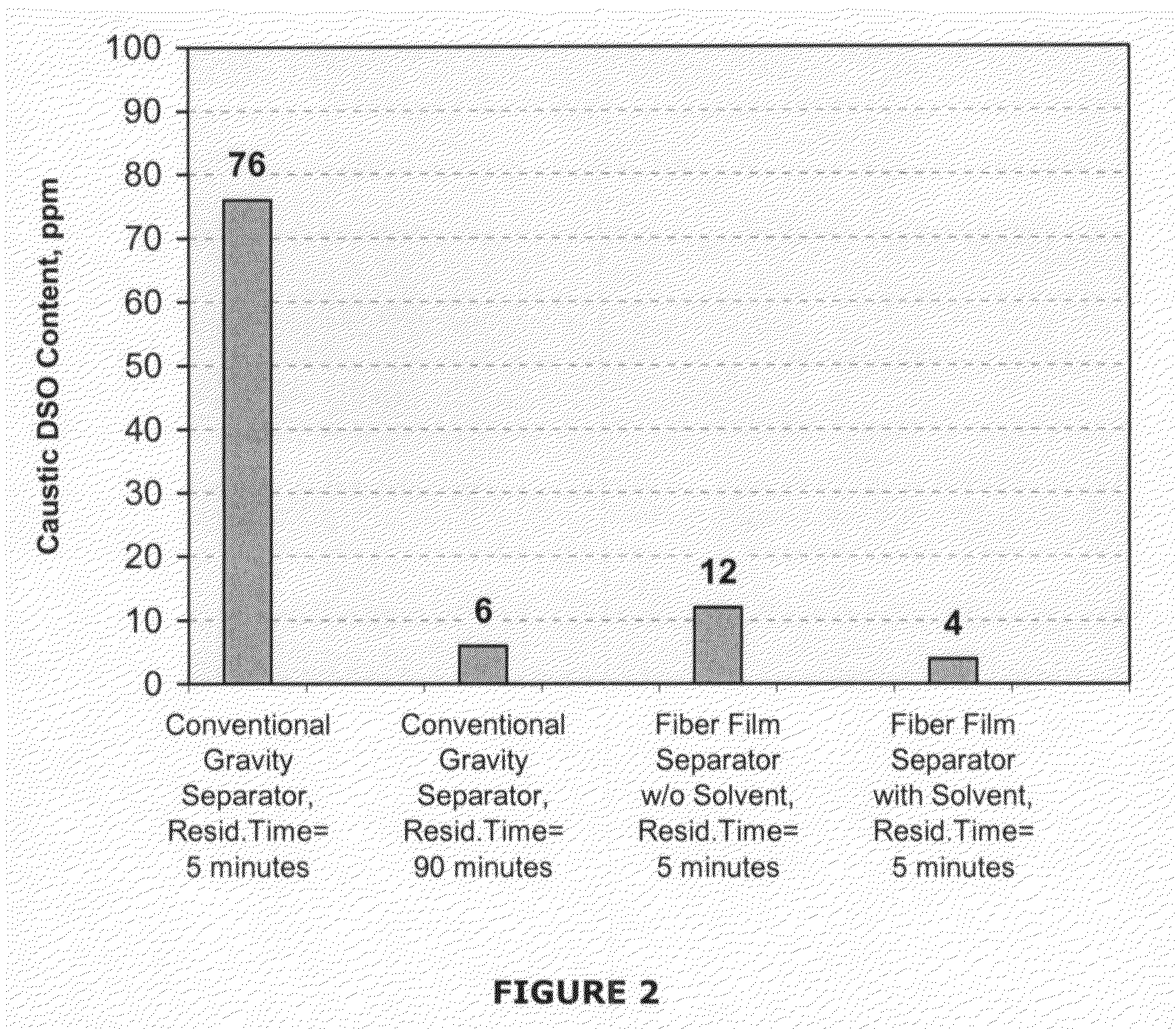

A separation process for separating two or more immiscible liquids using fiber-film technology is disclosed. This separation process is especially useful in the separation of disulfide oil formed during the oxidation of spent caustic solution that was used to remove sulfur contaminates from light hydrocarbons.

Owner:MERICHEM CO

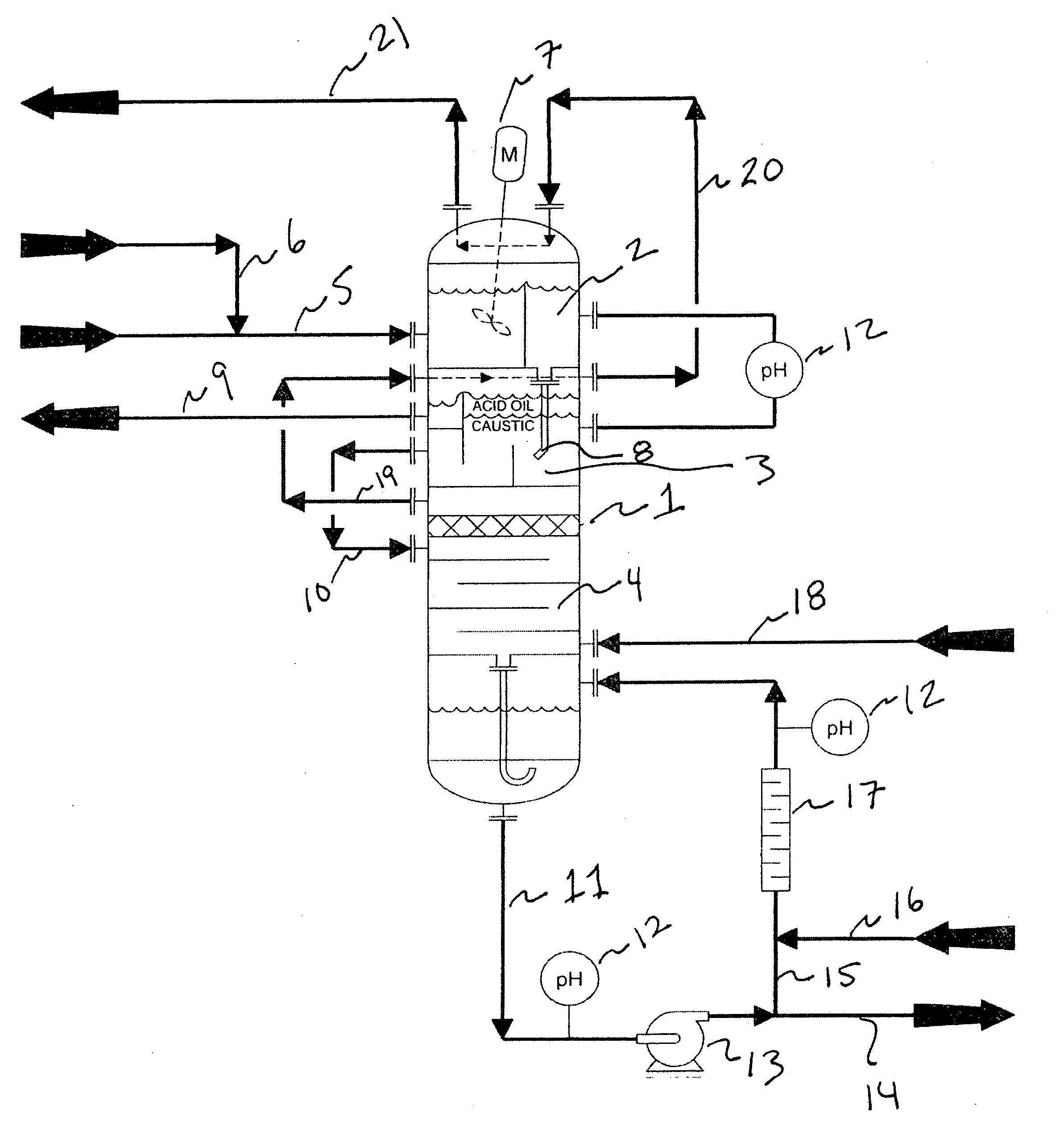

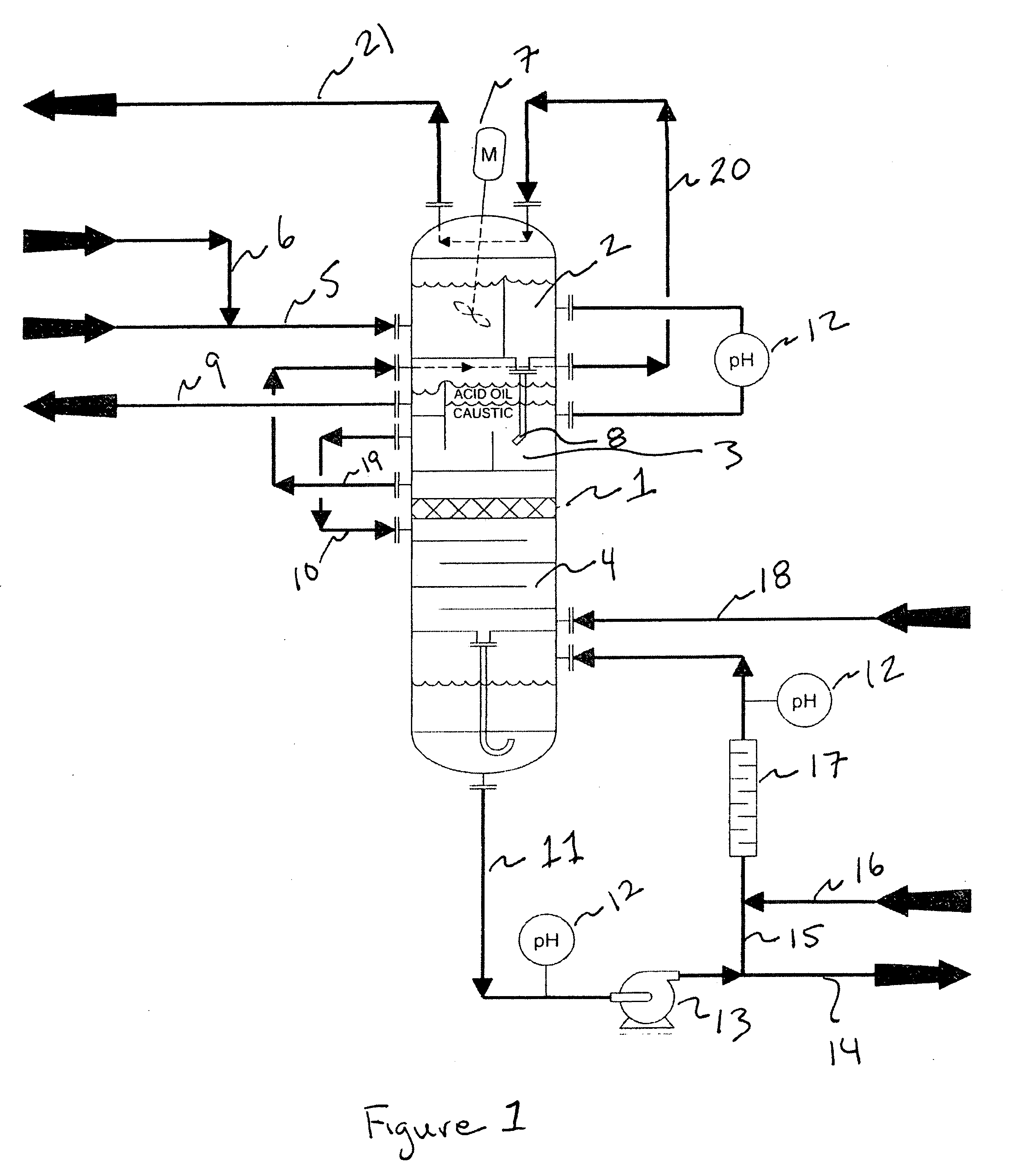

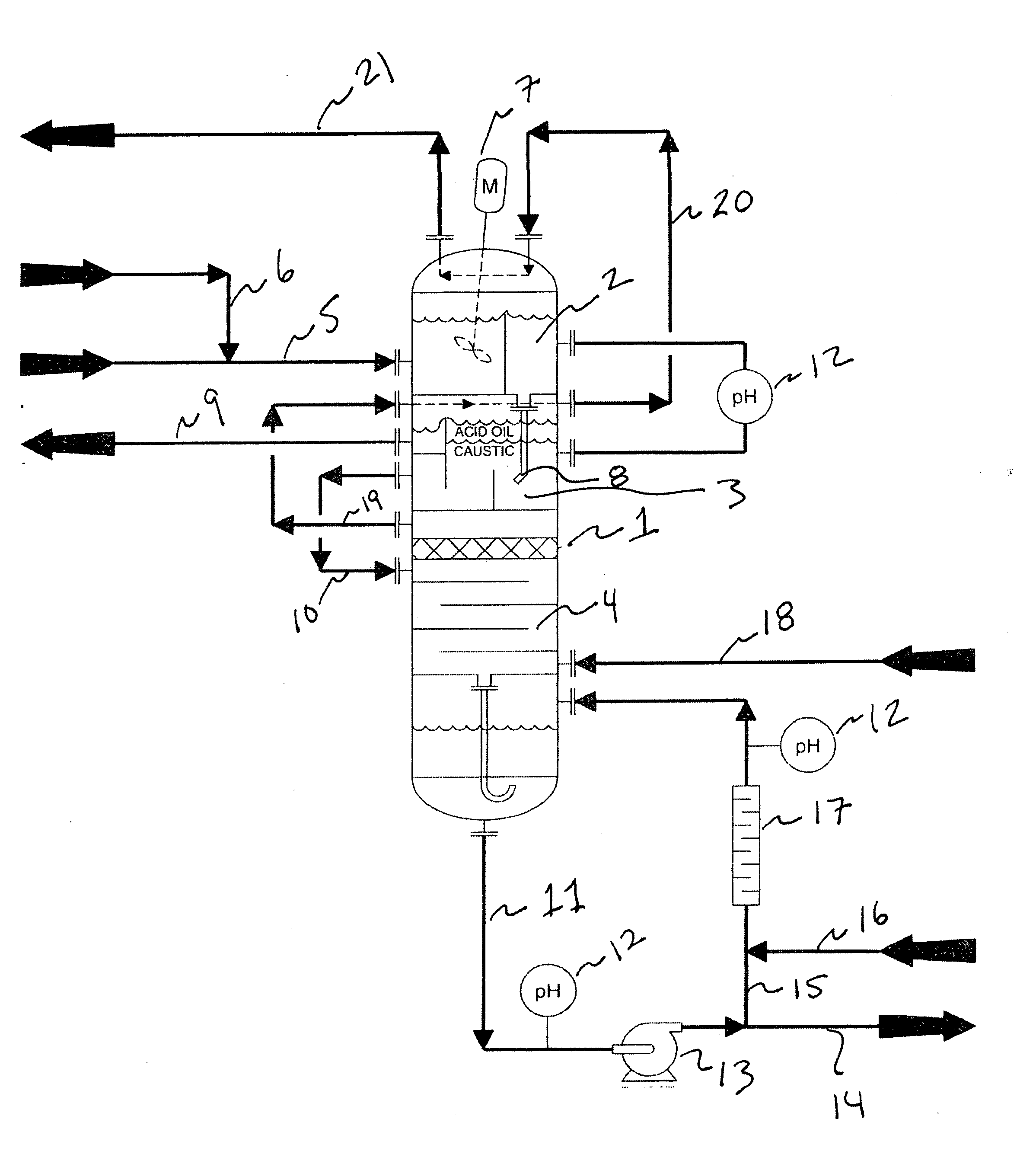

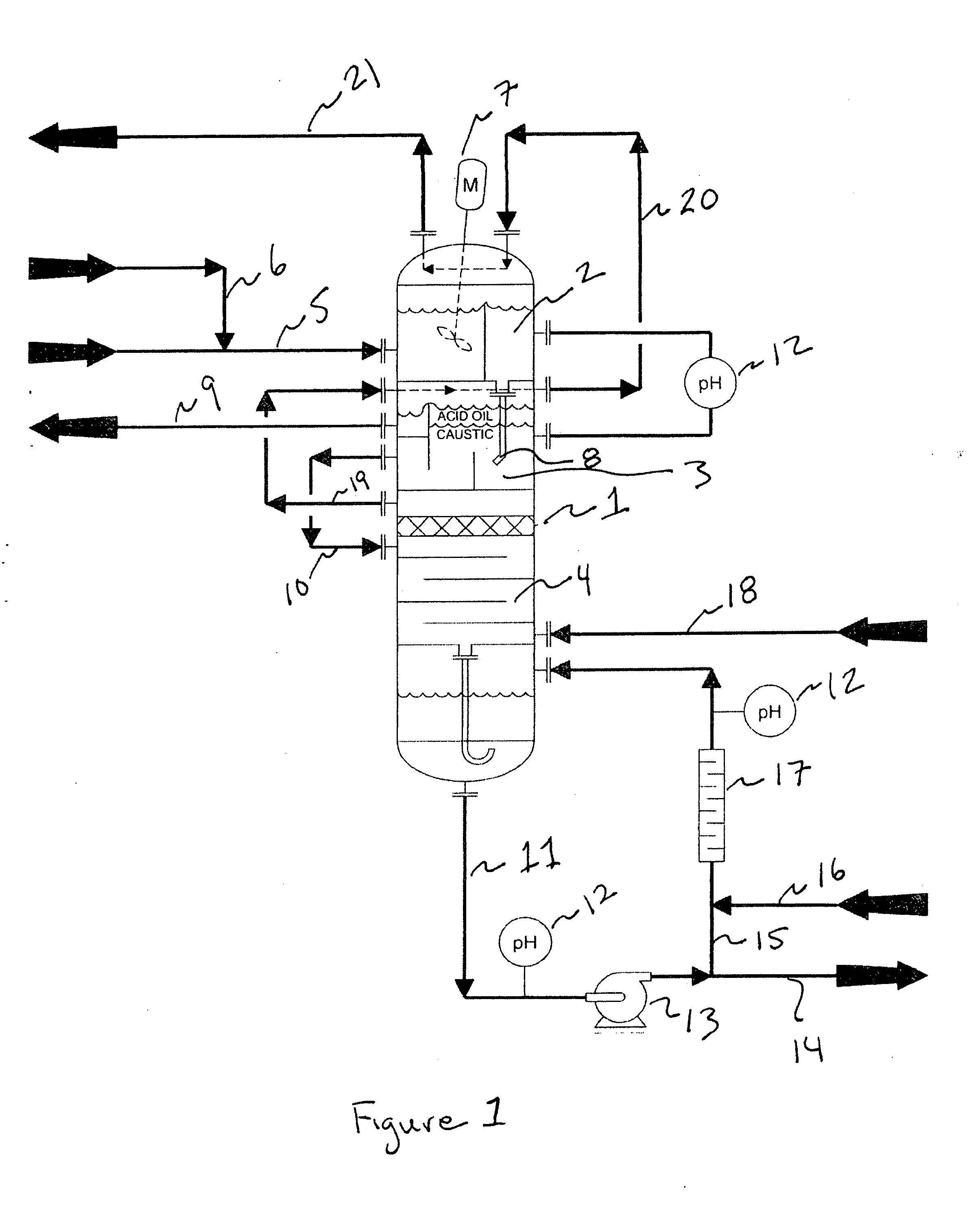

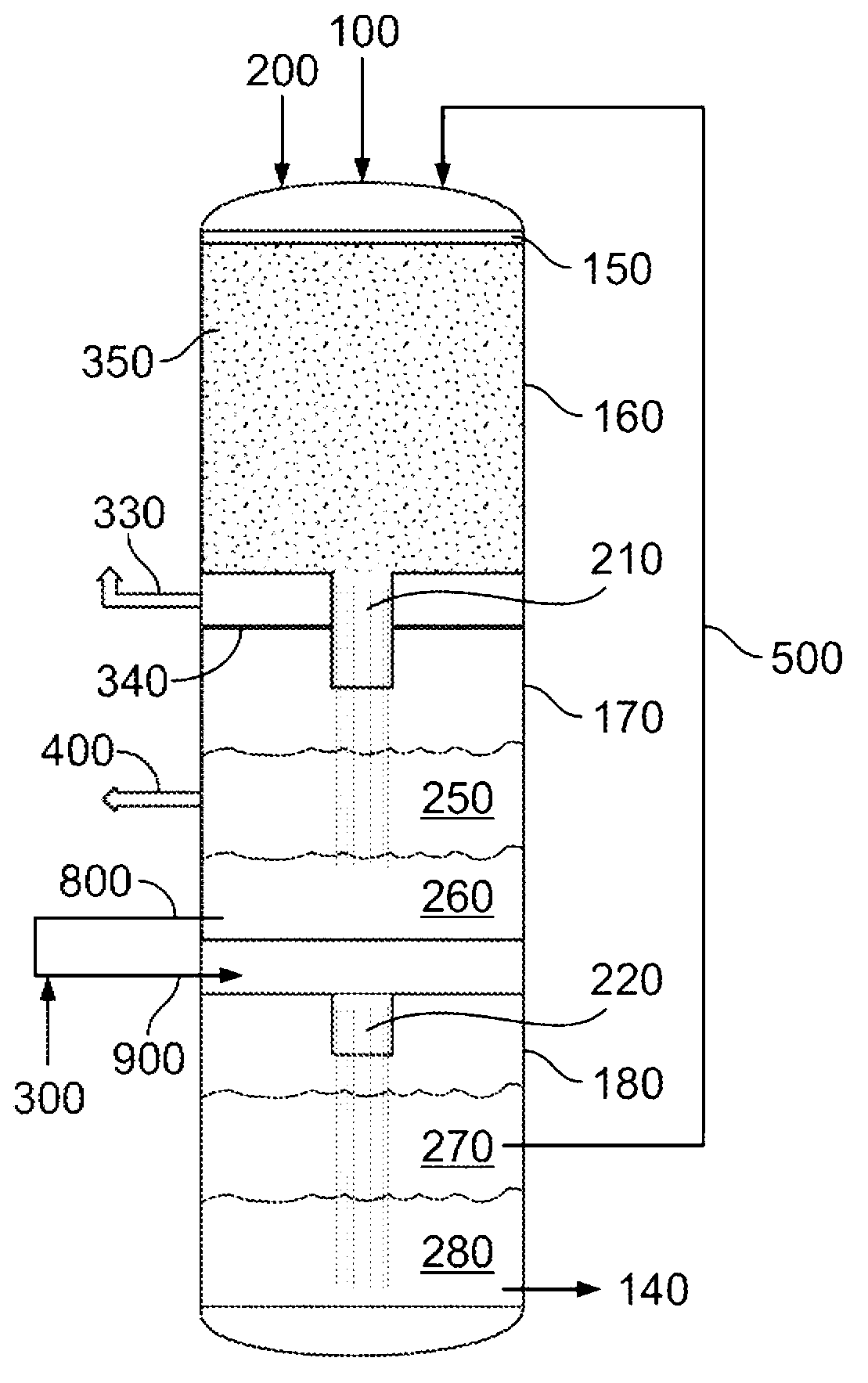

Apparatus for treating a waste stream

ActiveUS20100122950A1Lower cost of capitalLiquid degasificationIon-exchanger regenerationWaste streamUnit operation

Owner:MERICHEM CO

Apparatus for treating a waste stream

ActiveUS20100200477A1Lower cost of capitalLiquid degasificationIon-exchanger regenerationWaste streamUnit operation

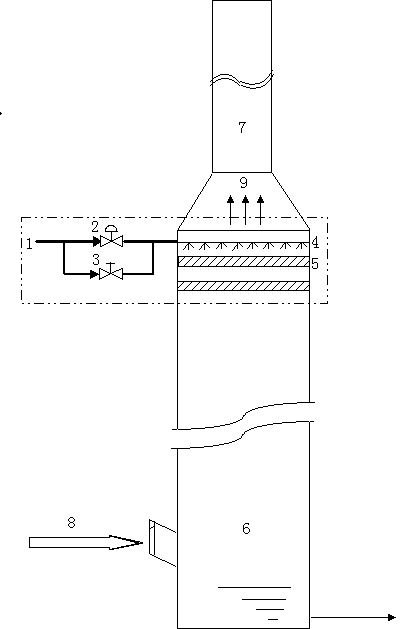

An integrated unit operations for the treatment of a waste stream, such as spent caustic, is provided in a single vertical vessel having at least three separate zones: a mixing, a settling, and a mass transfer zone.

Owner:MERICHEM CO

Treatment of spent caustic waste

Owner:LUMMUS TECH LLC

Process for treating a sulfur-containing spent caustic refinery stream using a membrane electrolyzer powered by a fuel cell

ActiveUS7713399B2Simple and inexpensive and effectiveReduce investmentPhotography auxillary processesElectrolysis componentsSulfur containingSodium sulfate

A continuous method for the treatment of a spent aqueous caustic stream used to scrub a hydrocarbon process stream to remove oxidizable sulfur-containing compounds includes:a. mixing an oxidizing hypochlorous acid stream produced from an aqueous brine solution with the aqueous caustic stream to form a reactive mixed feedstream;b. contacting the reactive mixed feedstream with at least one catalyst to promote the oxidation of the sulfur-containing compounds and the neutralization of the sodium hydroxide; andc. recovering a neutral treated product stream comprising aqueous sodium sulfate, sodium carbonate and sodium chloride that is odorless, non-toxic and environmentally acceptable for discharge into the sea or into a conventional sewage treatment system.Preferably, the hypochlorous acid is produced by an electrolyzer that also produces a (1) hydrogen stream that is directed to a PEM fuel cell to generate at least a portion of the electrical power requirement of the electrolyzer, and (2) water that is combined with fresh sodium hydroxide from the electrolyzer to form a fresh caustic stream for use in scrubbing the hydrocarbon process stream.

Owner:SAUDI ARABIAN OIL CO

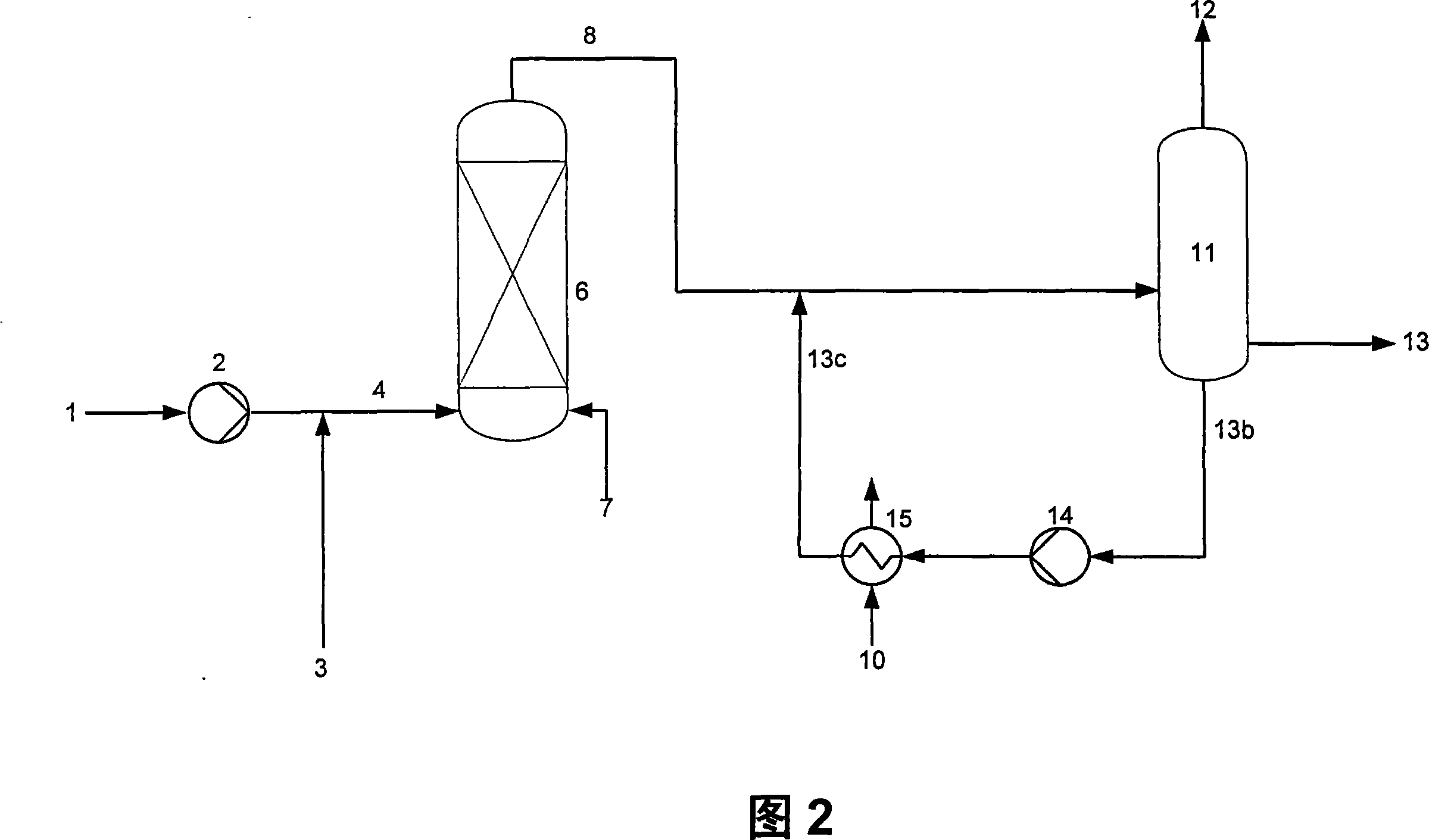

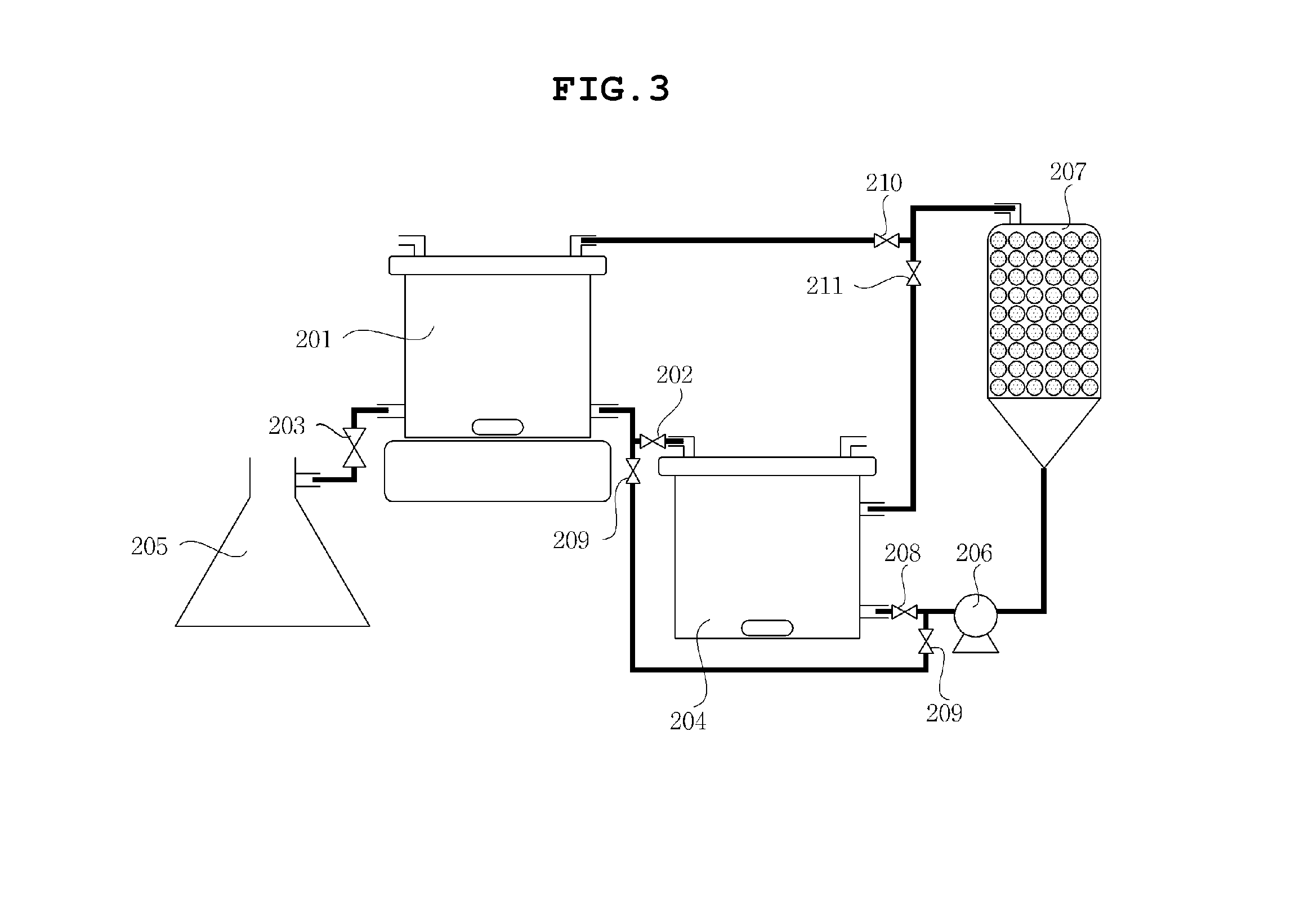

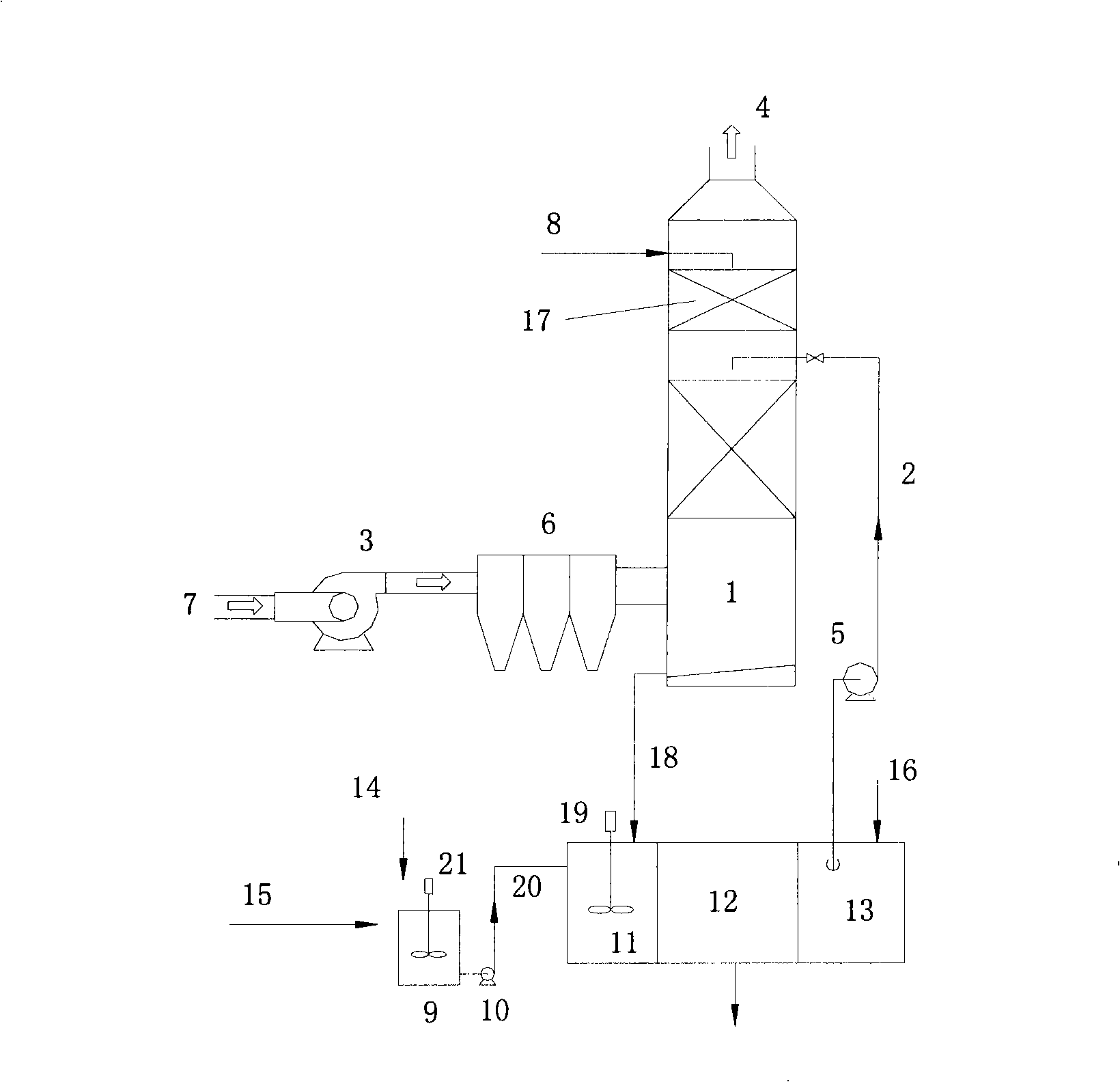

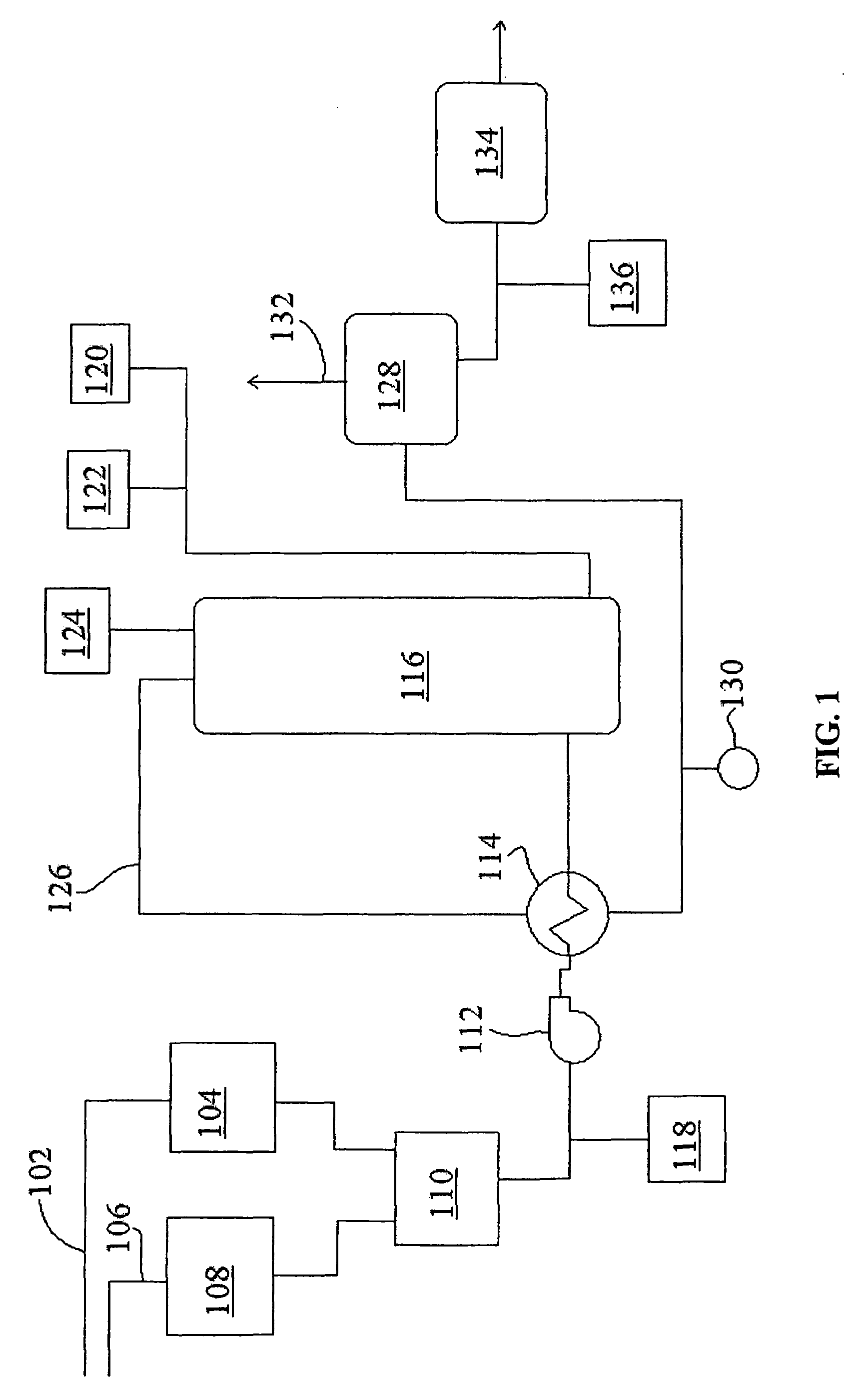

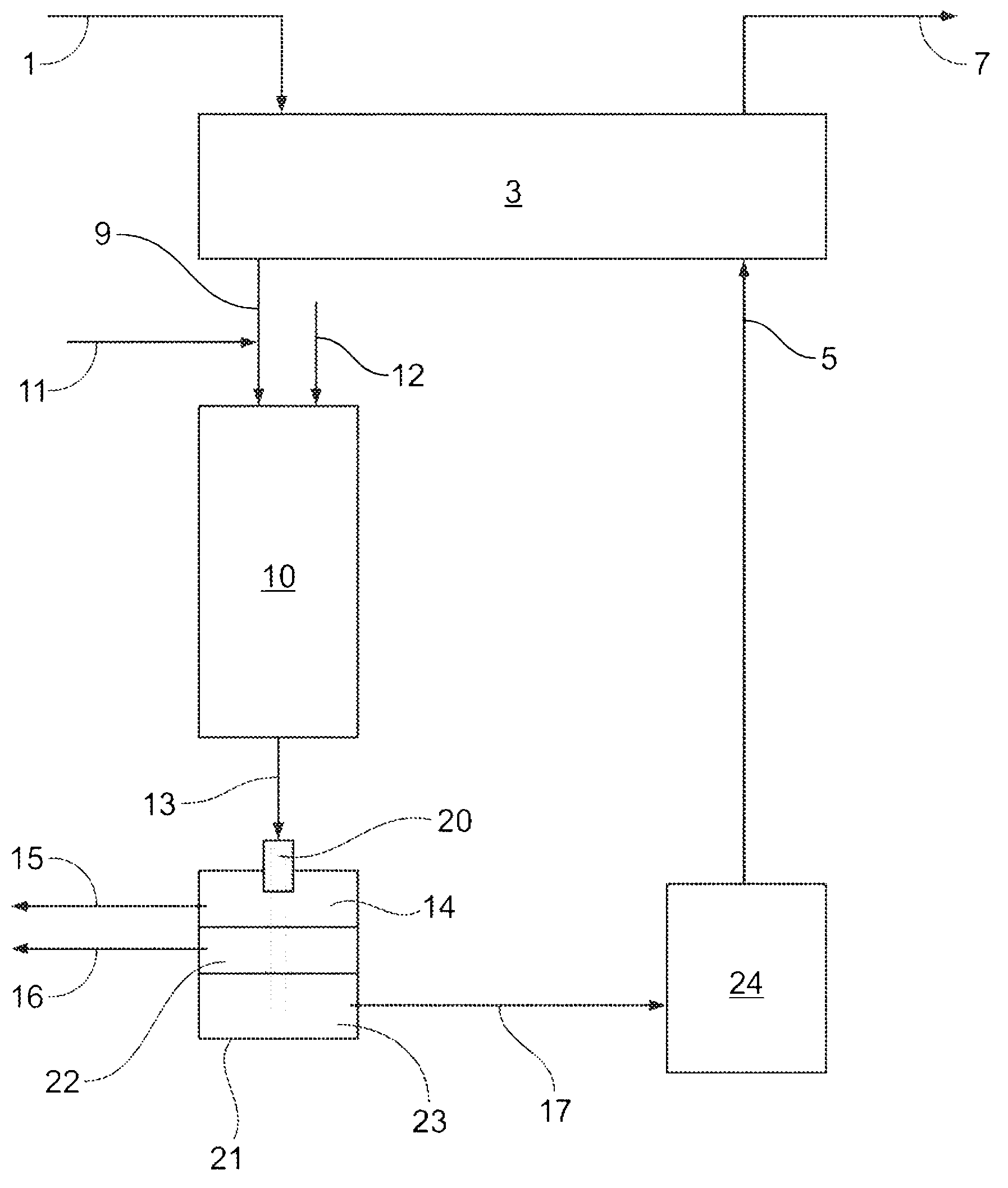

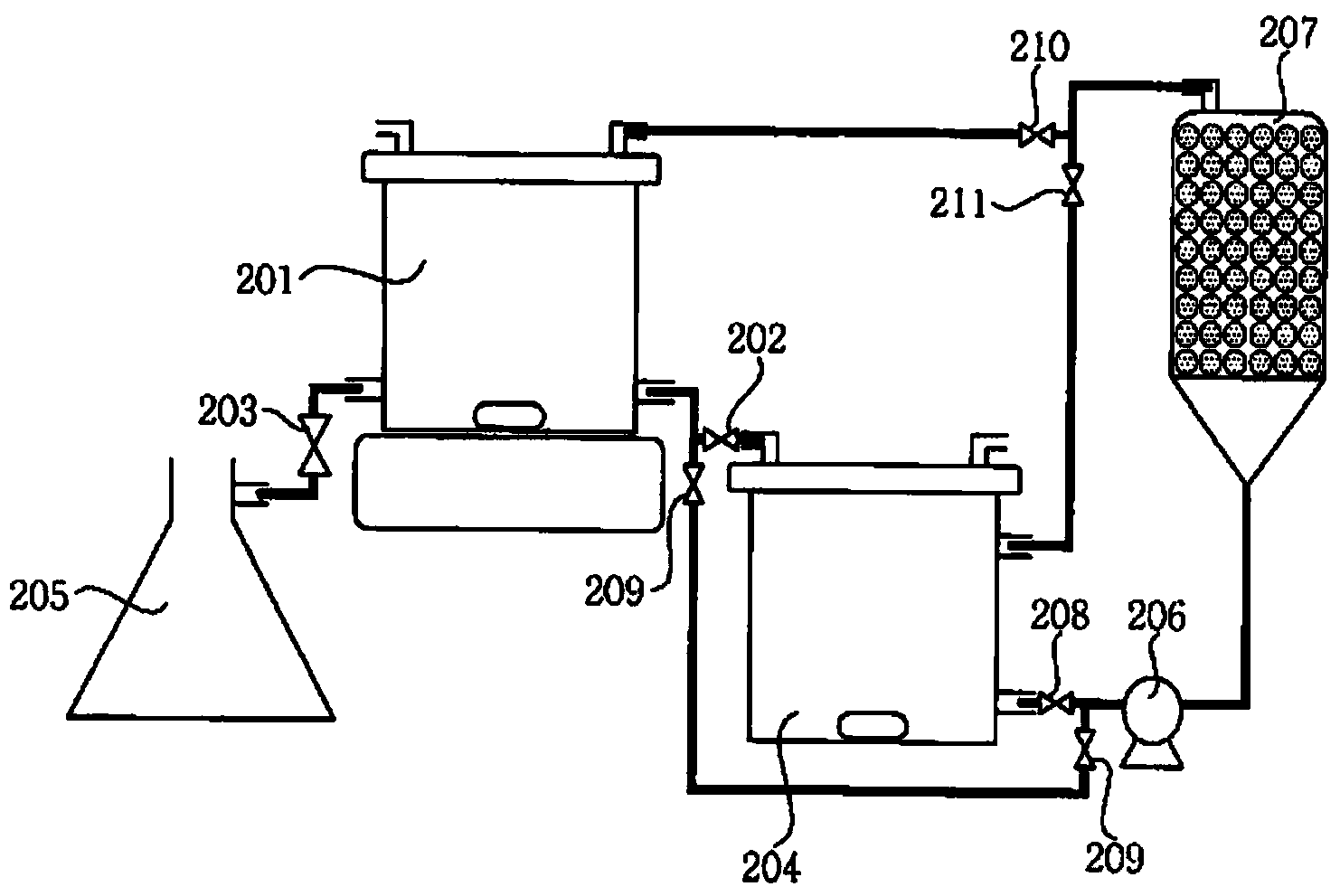

Oxidation method and equipment for spent caustic in petrochemistry equipment

InactiveCN101164913ALow investment costInvestment costs are minimizedSludge treatment by oxidationNature of treatment waterEngineeringPetrochemical

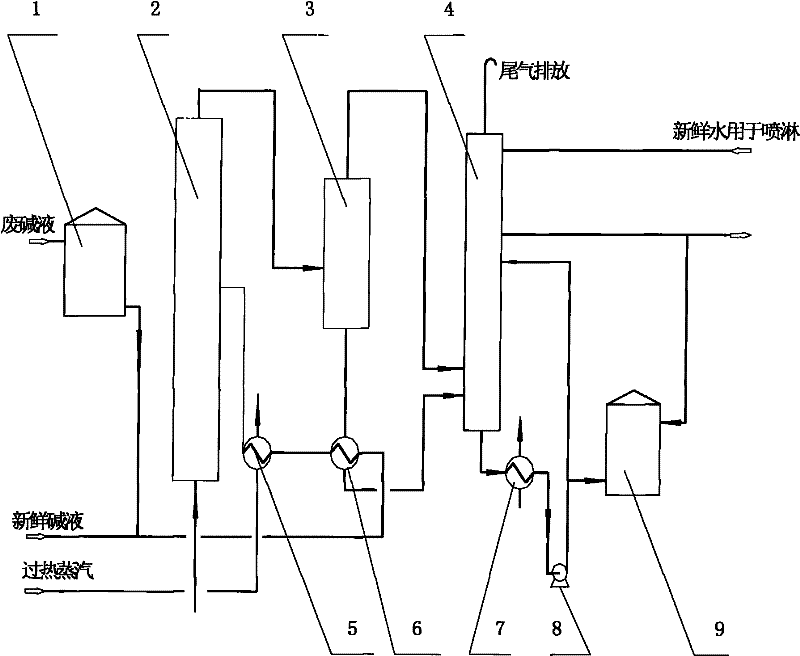

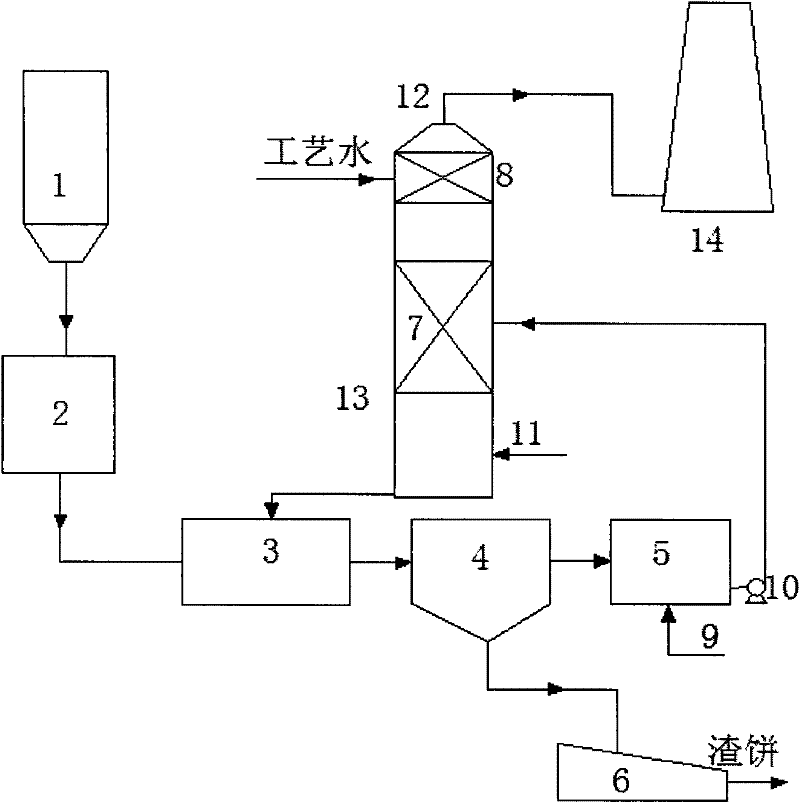

The invention discloses a method for wet oxidizing waste alkali liquor, as well as a device for a petrochemical device. The waste alkali liquor (1) is transported through a high voltage pump (2). A liquid-gas mixture (4) is produced by leading into air or oxygen (3) and then is directly put into a reactor (6) for oxidization. The temperature inside the reactor is adjusted by leading into hot steam (7). The generated liquid-gas mixture (8) consisting of oxidized alkali liquor and waste gas is mixed with the oxidized cold alkali liquor (13c) from a separator (11) due to the temperature and the pressure inside the reactor, and then is further put into the separator to be separated into waste gas (12) and oxidized alkali liquor (13). Partial oxidized alkali liquor (13b) is brought back as refrigeration cycle through a pump (14) and a thermal exchanger (15).

Owner:LINDE AG

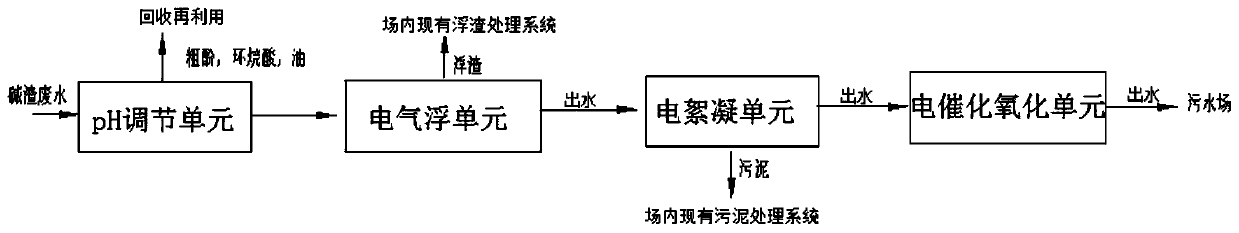

System and method for treating high-salinity spent caustic wastewater

InactiveCN110563221AReduce CODLow toxicityWater treatment parameter controlWater contaminantsElectricityFlocculation

The invention discloses a treatment system for high-salinity spent caustic wastewater. The treatment system comprises a pH adjusting unit, an electric flotation unit, an electric flocculation unit andan electrocatalytic oxidation unit which are arranged in sequence, wherein the electric flotation unit comprises an electric flotation device; the electric flocculation unit comprises electric flocculation equipment and solid-liquid separation equipment; and the electrocatalytic oxidation unit comprises electrocatalytic oxidation equipment. In addition, the invention also discloses a treatment method for the high-salinity spent caustic wastewater. The method comprises the following steps: 1) regulating the pH value of the high-salinity spent caustic wastewater to 5-8, and carrying out standing for layering; 2) carrying out electric flotation treatment on the lower-layer wastewater obtained in the step 1); 3) performing electric flocculation treatment on the effluent of electric flotation,and performing solid-liquid separation on the effluent generated by the electric flocculation treatment; and 4) performing electrocatalytic oxidation treatment on the liquid-phase effluent obtained in the step 3). By utilizing the treatment system and method disclosed by the invention, high-efficiency, economic and environment-friendly treatment of the high-salinity spent caustic wastewater an berealized at normal temperature and normal pressure.

Owner:BEIJING DILI WEIYE TECH DEV

Bio-Assisted Process for the treatment and regeneration of spent caustic

The present invention relates to a bio-assisted method for treatment of spent caustic by treating with haloalkaliphilic consortium of bacteria capable of reducing or transforming sulphides, thiols, mercaptants and other sulphur containing compounds, phenols, hydrocarbons, naphthenic acids and their derivatives in spent caustic.

Owner:INDIAN OIL CORPORATION

Separation process

ActiveUS7833499B2Separation in timeEasy to separateDewatering/demulsification with mechanical meansLiquid suspension thickening by filtrationFiberSulfur

A separation process for separating two or more immiscible liquids using fiber-film technology is disclosed. This separation process is especially useful in the separation of disulfide oil formed during the oxidation of spent caustic solution that was used to remove sulfur contaminates from light hydrocarbons.

Owner:MERICHEM CO

Demister washing technology for ethylene spent caustic flue gas desulfurization and demister washing device thereof

InactiveCN103624022AReduce in quantityReduce maintenance workloadDispersed particle separationCleaning using liquidsThermodynamicsRinse water

The invention discloses a demister washing technology for ethylene spent caustic flue gas desulfurization. A demister washing spraying system is arranged below a chimney inside a desulfurizing tower so that dynamic washing spraying can be conducted on a demister. The demister washing spraying system and a main water charging system of a gas desulfurization system are in joint debugging and joint control. When the main water charging system of the desulfurizing tower is insufficient in capacity or breaks down, dynamic washing spraying is controlled to be conducted on the demister, meanwhile, water balance of the whole gas desulfurization system can be maintained in an auxiliary mode, and the liquid level at the bottom of the desulfurizing tower is controlled to be stabilized within a set height range. The invention further provides a demister washing device which is composed of a demister washing water spraying layer, a washing water main pipe and a control switch. By means of the demister washing technology for ethylene spent caustic flue gas desulfurization and the demister washing device thereof, the defects that the demister washing water spraying layers are numerous, and valves and nozzles are also numerous in a traditional desulfurization mode are overcome, the maintenance workload is small, water resources are saved, the demister washing system for ethylene spent caustic flue gas desulfurization is simpler and more practical, the long-period efficient operating requirement is met, and maintaining is more convenient.

Owner:SHANGHAI UNIV

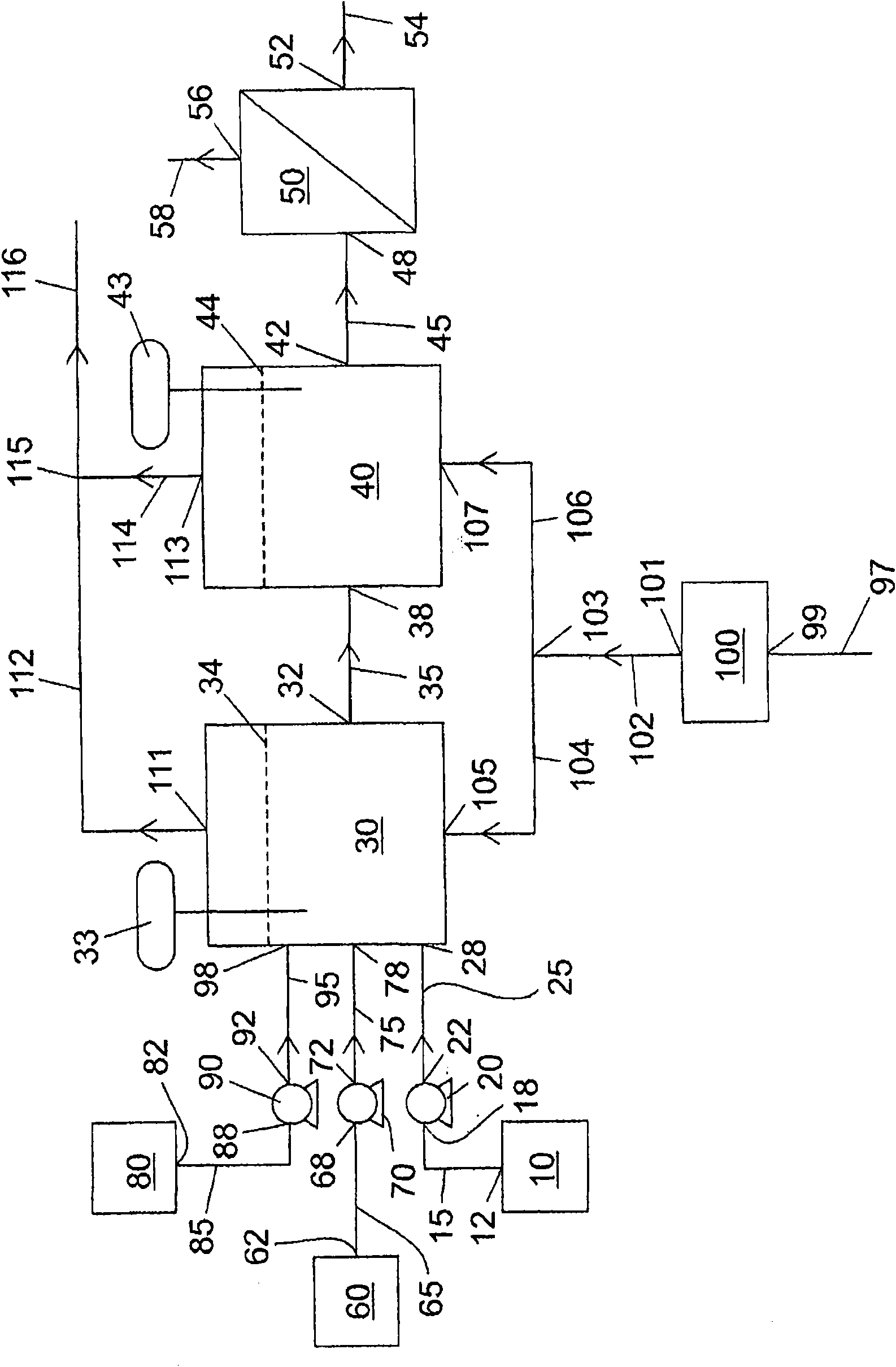

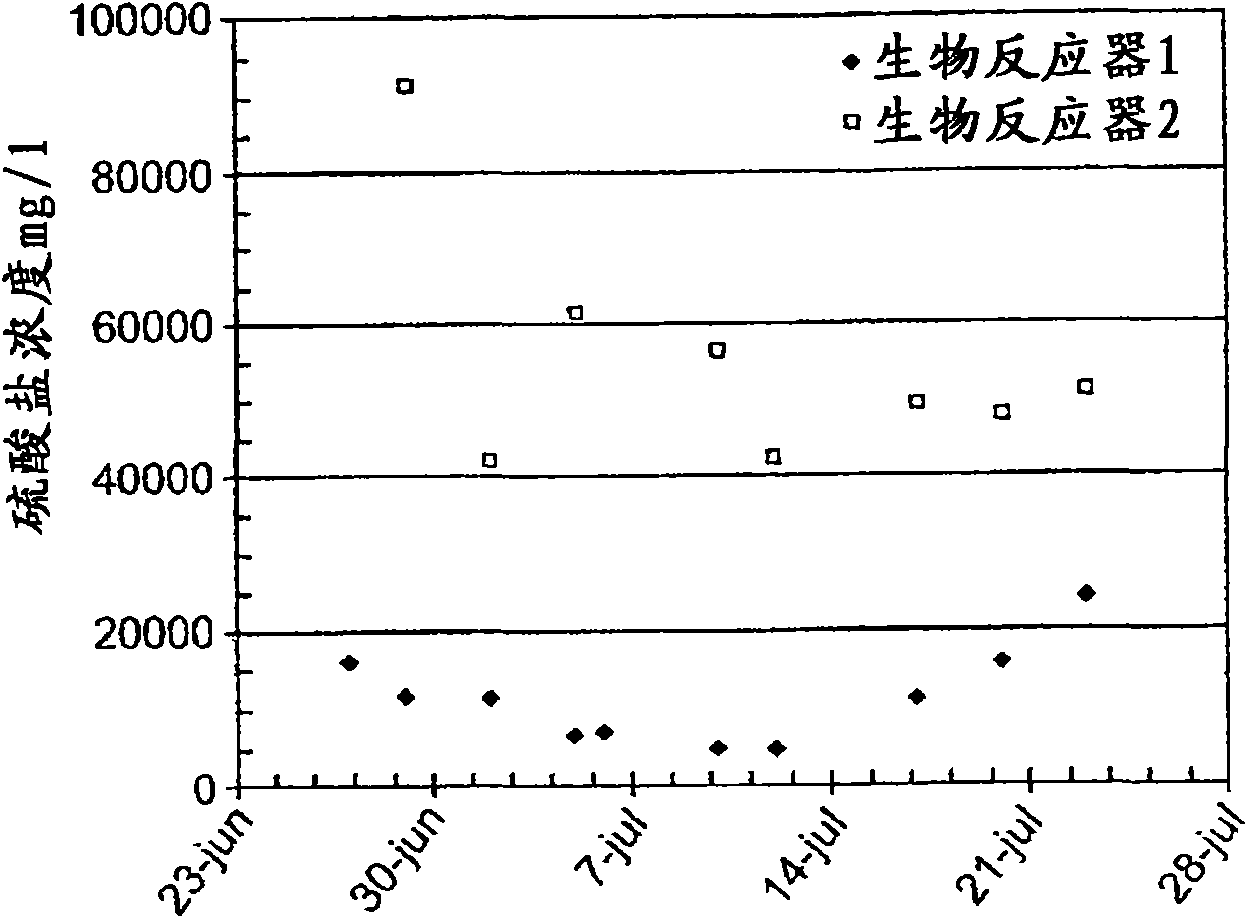

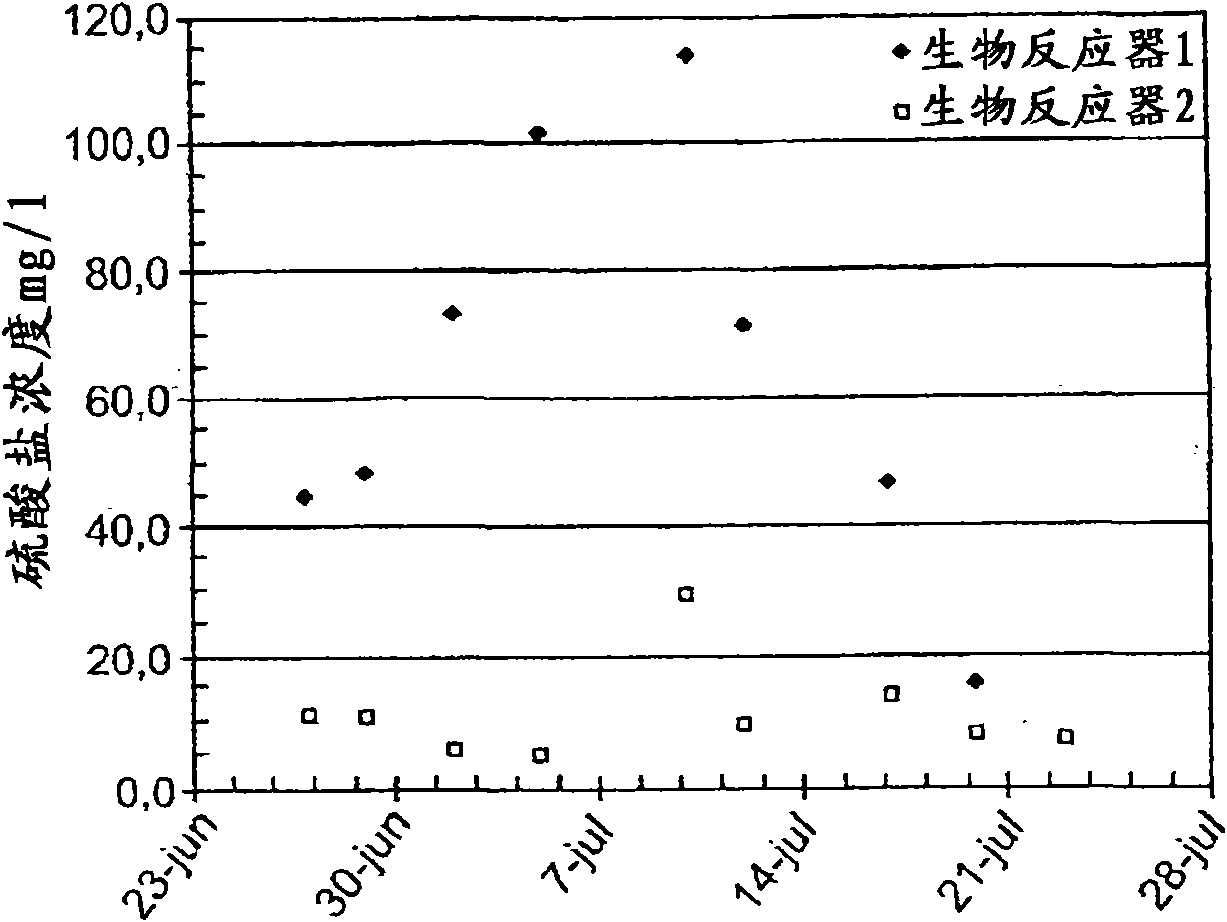

Method and apparatus for biological treatment of spent caustic

The invention provides a method and apparatus for biologically treating a spent caustic to provide a treated spent caustic, said method comprising the steps of : (a) passing a spent caustic stream (25) comprising water, alkali metal hydroxide and sulphide to a first bioreactor (30); (b) biologically oxidising sulphide in the first bioreactor (30) with sulphide-oxidising bacteria to form sulphur (S0) and sulphate to provide a partially oxidised spent caustic comprising sulphur (S0) and sulphate; (c) passing the partially oxidised spent caustic to a second bioreactor (40) where at least a portion of the partially oxidised spent caustic is further oxidised with sulphide-oxidising bacteria to generate sulphate from sulphur (S0) to provide a treated spent caustic comprising sulphate.

Owner:SHELL INT RES MAATSCHAPPIJ BV

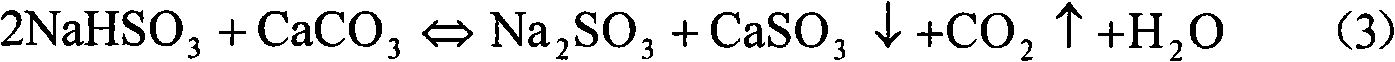

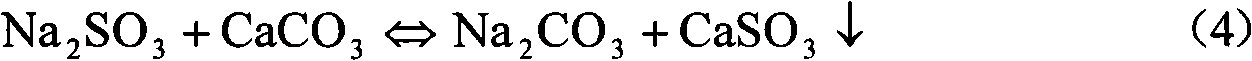

Regeneration method of spent caustic from ethylene

InactiveCN106315904ALess alkali consumptionHigh desulfurization rateMultistage water/sewage treatmentNature of treatment waterSpent causticPollution

The invention relates to a regeneration method of spent caustic from ethylene. The method comprises the steps of desulphurization, causticization, desulfurizer regeneration and causticization agent regeneration. The method realizes desulphurization regeneration of spent caustic from ethylene under normal temperature and normal pressure, the regenerated spent caustic can be recycled, and a purpose for resource processing of the spent caustic can be realized, secondary pollution problem of the volatile organic compounds in the tail gas by a wet-type oxidation technology can be avoided; the desulfurizer is regenerated by the wet-type oxidation technology, the cycle utilization of the desulfurizer is realized, the secondary pollution generation is not generated during a desulfurizer regeneration process, compared with the prior art, the desulphurization effect is increased, the desulphurization regeneration reaction time is shortened, and the desulfurizer regeneration reaction time is shortened.

Owner:PETROCHINA CO LTD

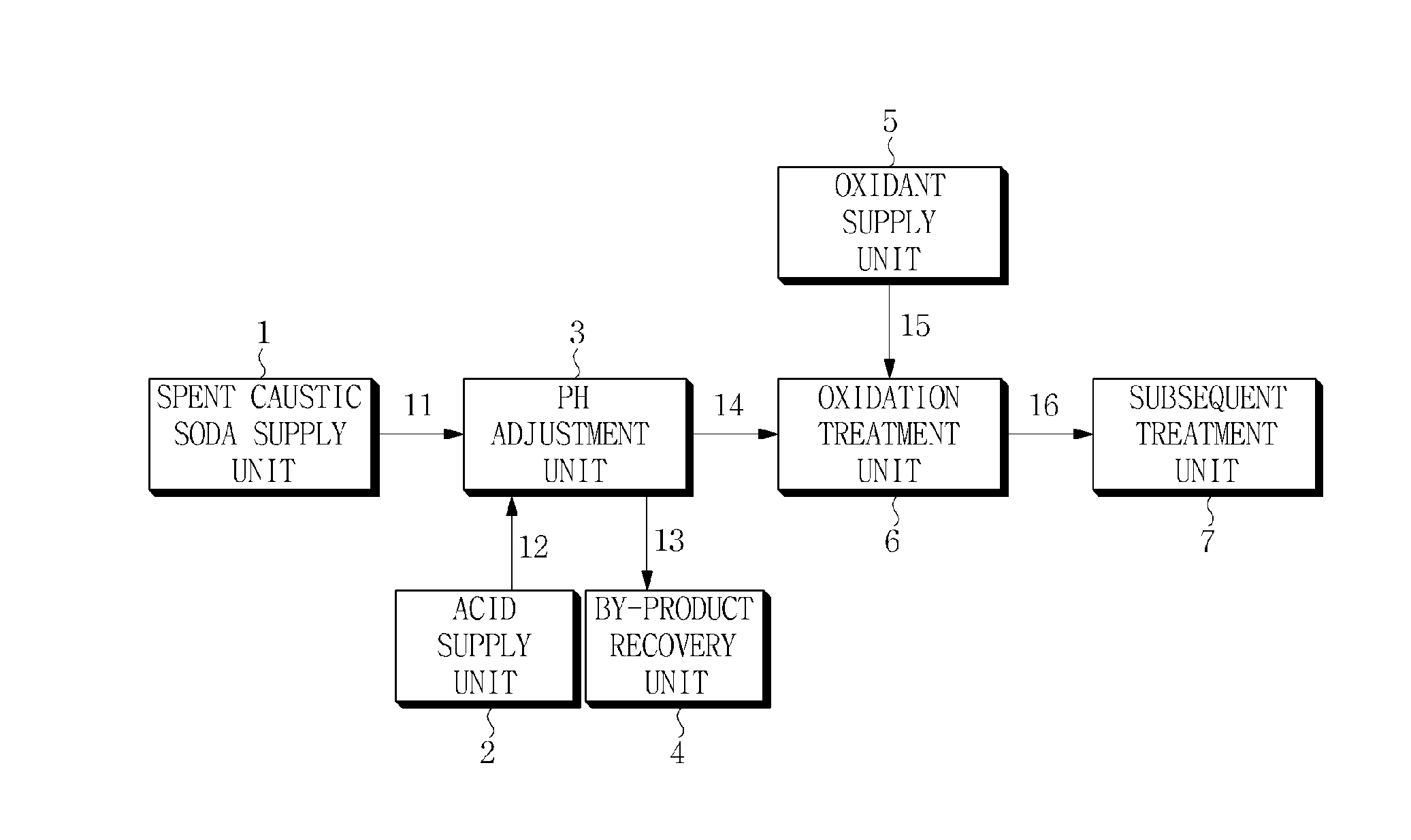

Treatment method for spent caustic soda

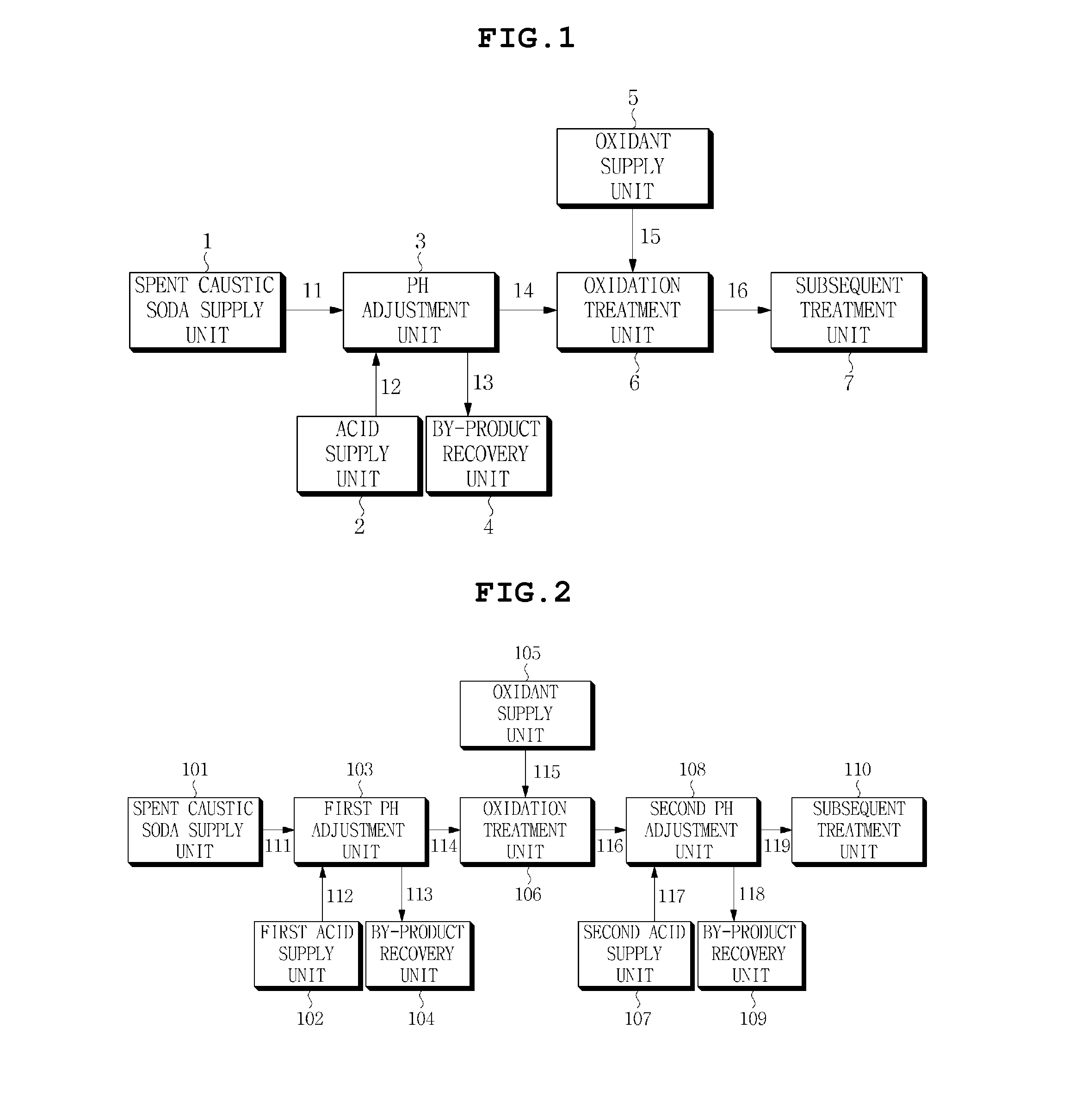

InactiveUS20140140906A1Effective treatmentMultistage water/sewage treatmentWater/sewage treatment by neutralisationPetrochemicalHigh pressure

An embodiment of the present invention relates to a method for treating spent caustic soda generated from an oil refinery process, a petrochemical process, etc. through a process in which a series of treatment steps are integrated, wherein the method can constitute a process under mild conditions excluding high temperature and / or high pressure conditions and can be advantageous to a post treatment process since the amount of by-products is small.

Owner:SK ENERGY CO LTD (KR)

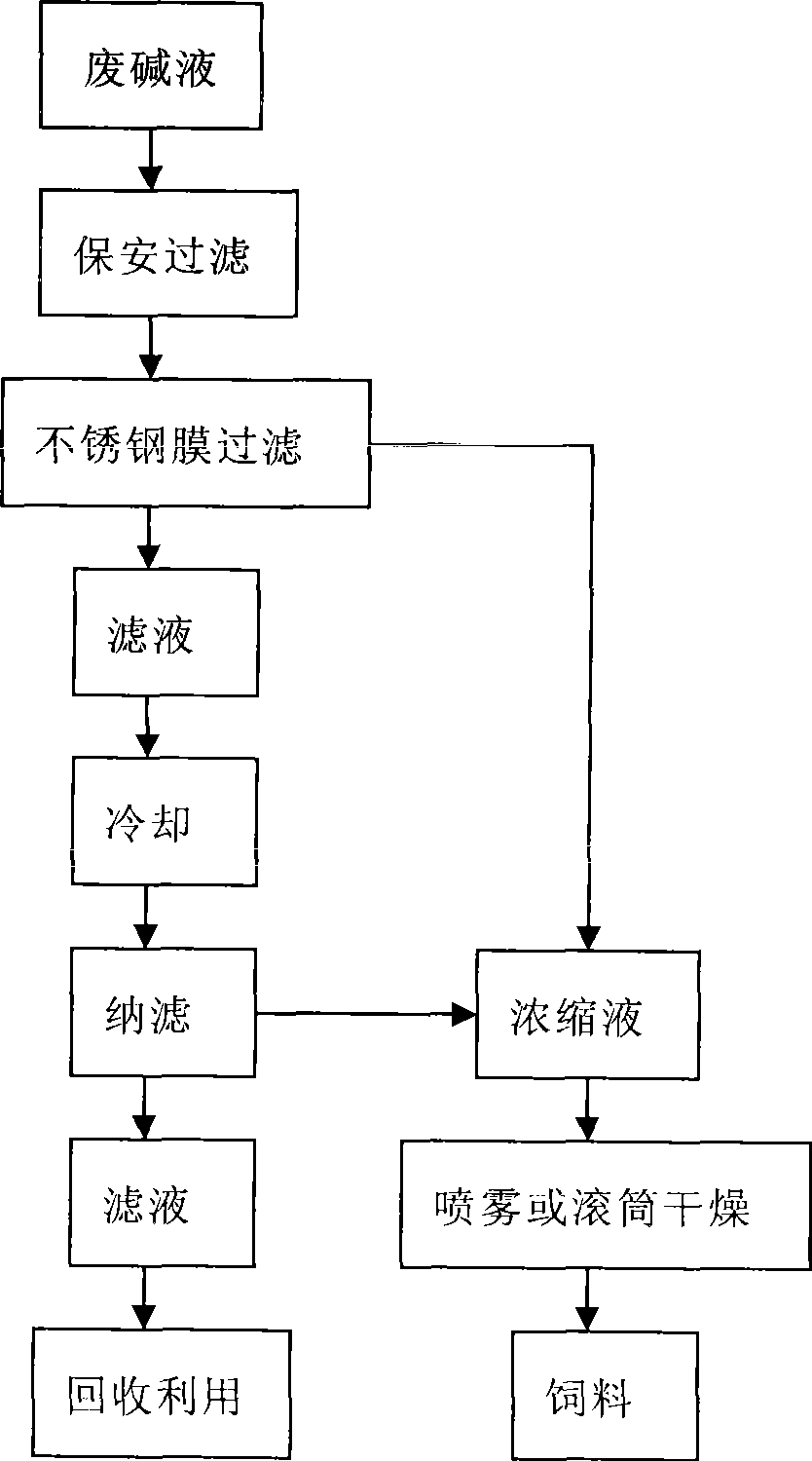

Method for recycling spent caustic liquid during chitin production process

ActiveCN101423307ASolve pollutionHigh purityAnimal feeding stuffAccessory food factorsHigh concentrationFiltration

The invention discloses a method for recycling alkali waste liquid generated during the production of chitin and relates to the technical field of treatment and comprehensive use of wastewater generated during food processing. The method comprises the following steps: alkali waste liquid generated in a deproteinization process during the production of chitin is used as a raw material and subjected to stainless steel membrane filtration and nanofiltration to obtain clean alkali liquid to be reused; and concentrated solutions obtained after the stainless steel membrane filtration and nanofiltration are mixed, neutralized and subjected to spray drying and roller drying to obtain high-protein feed additives. Compared with the prior method for treating waste liquid, the method realizes recycling of alkali liquid, comprehensive use of active ingredients, and prevention of discharge of alkali liquid into environment, adopts a separation and purification process which is simple, reasonable, short in process, convenient in operation, high in yield and quality of alkali, and combines a stainless steel membrane filtration separation system and a nanofiltration separation system which have advantages of low operation cost, high filtration precision, high concentration factor, high concentration of the concentrated solutions and so on, contributes to production of high-protein feed additives through solidification of concentrated solutions and avoids secondary pollution.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

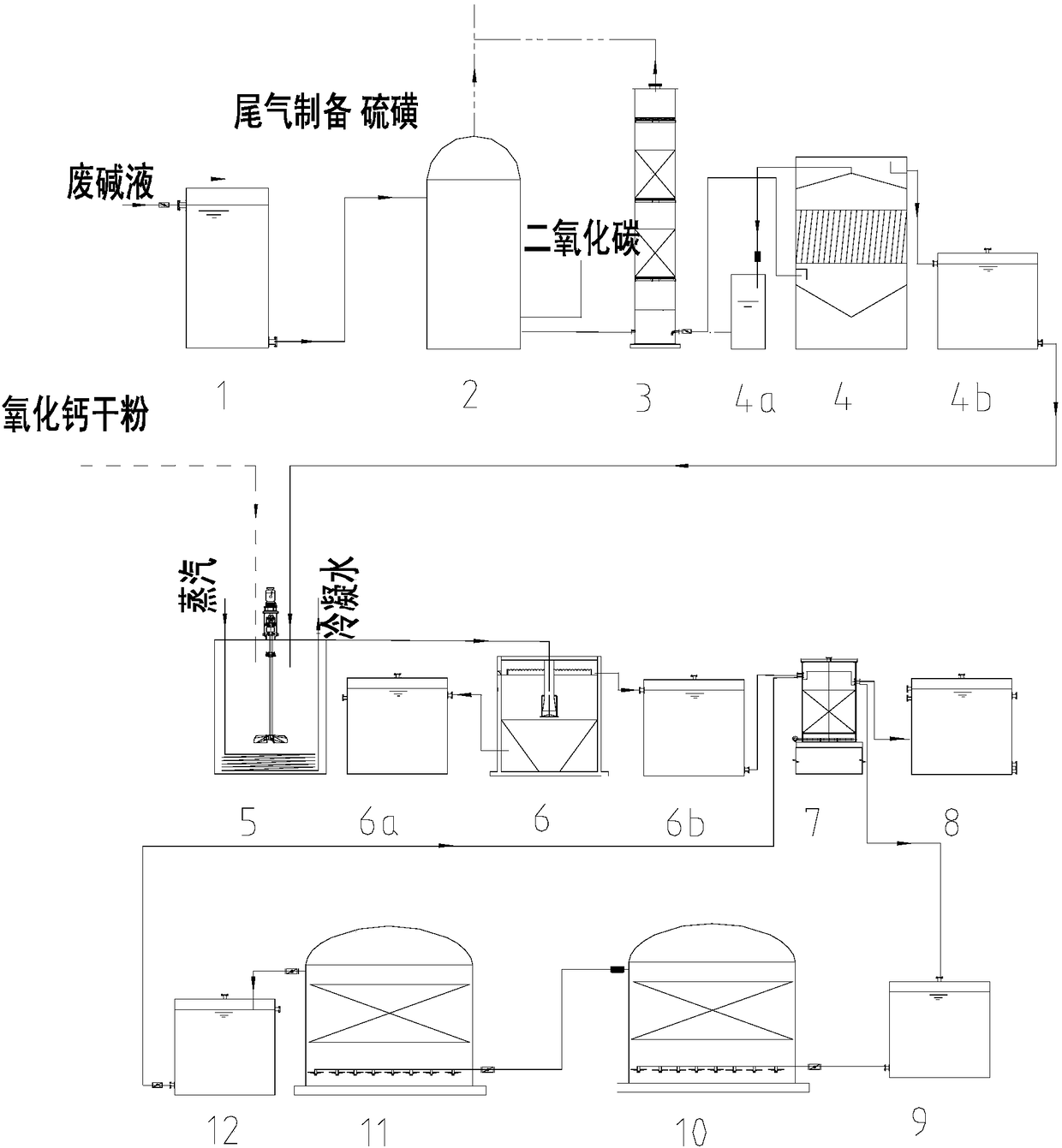

Recycling device for spent caustic residues from ethylene

InactiveCN108147628AAchieve reductionHarmlessFatty/oily/floating substances removal devicesSpecific water treatment objectivesSodium bicarbonateWater storage tank

The invention provides a recycling device for spent caustic residues from ethylene, and belongs to the technical field of environmental protection. Under the action of carbon dioxide, sodium sulfide is converted into a mixed solution of sodium carbonate and sodium bicarbonate, at the same time, hydrogen sulfide is generated, and air stripping is performed; a causticizing system comprises a causticizing tower, a causticizing liquid precipitation separation tank and a causticizing mud storage tank, calcium hydroxide reacts with sodium carbonate to generate calcium carbonate precipitation, the sodium carbonate is converted into sodium hydroxide, calcium carbonate which is generated through the reaction is dewatered and dried, and powdery lime is prepared and fed into dry-method desulfurationequipment to be recycled; a refining system comprises an adsorption refining reaction tank, a to-be-treated regenerated liquid storage tank, an anaerobic VTBR efficient reactor, an aerobiotic VTBR efficient reactor, a regenerated liquid clear water storage tank and a recovered alkali liquor storage tank, performs refining on causticizing liquid to remove a large amount of chroma and organic matter, reserves alkalinity and achieves recovery of the sodium hydroxide. The device can efficiently recycle spent caustic, effectively utilize side product in the whole process, and achieve zero dischargeof spent caustic and waste.

Owner:大连理工环境工程设计研究院有限公司

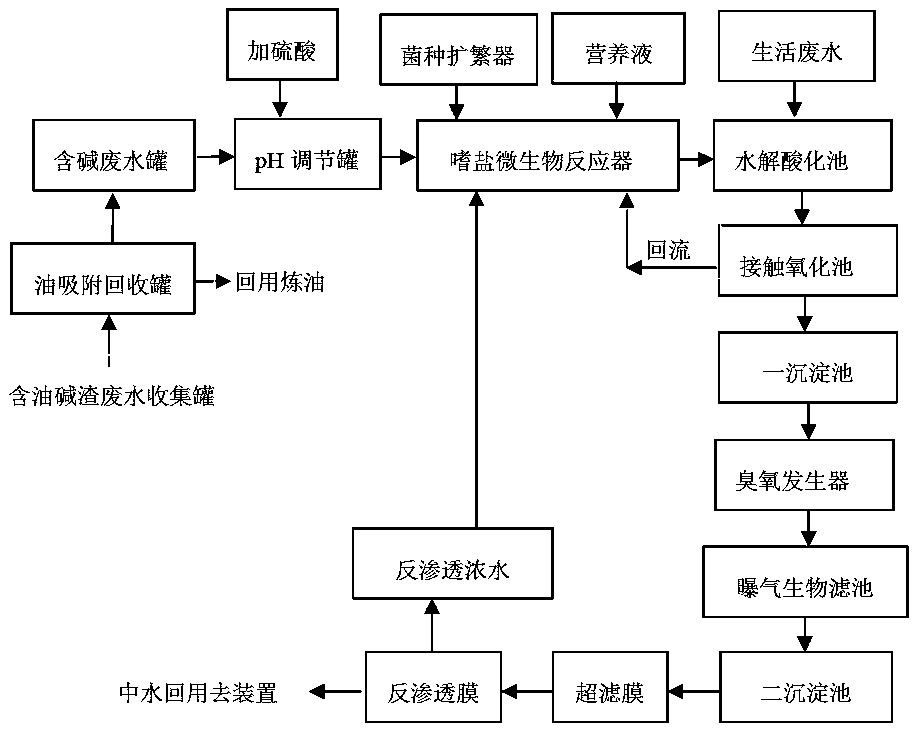

Method for treating spent caustic wastewater by utilizing halophilic microorganism

InactiveCN107739127AAchieve recyclingSave energyTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentUltrafiltrationEconomic benefits

The invention provides a method for treating spent caustic wastewater by utilizing halophilic microorganism. The method comprises the steps that the spent caustic wastewater is adsorbed by polyurethane sponge adsorption particles, then subjected to treatment through a halophilic microorganism reactor, and spent caustic wastewater treatment can be achieved after the spent caustic wastewater is treated through a hydrolysis acidification pool, a contact oxidation tank, a primary settling pond, an ozonator, a biological aerated filter, a second settling pond, an ultrafiltration membrane and a reverse osmosis membrane, meanwhile, recycling of oil is achieved, the energy is saved, the cost is lowered, and the purposes of economic benefits and environmental benefits are achieved at the same time.

Owner:浙江海牛环境科技股份有限公司

Flue gas desulfurization technique using dual alkali method with white slime as recycling agent

InactiveCN101347707AIncrease profitRealize the purpose of circular economyDispersed particle separationSocial benefitsFlue gas

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Caustic solution treatment process

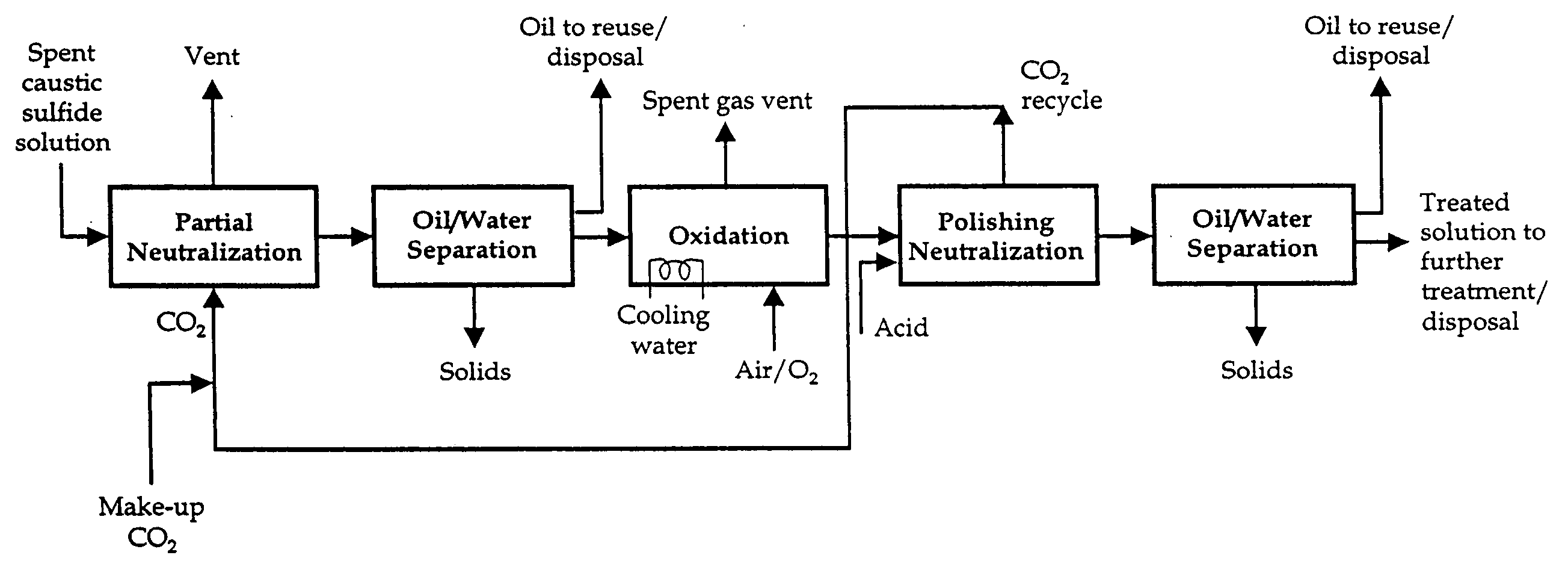

InactiveUS20060283812A1Reduce BODReduce CODWater treatment parameter controlWaste water treatment from gaseous effluentsSolution treatmentSpent caustic

A method for treating a spent caustic solution having a pH greater than about 10.5 includes the steps of (a) lowering the pH of the caustic solution into the range of between about 10 to 10.5 to produce a pH-modified caustic solution; (b) oxidizing the pH-modified caustic solution until the solution to produce a non-sulfide reactive oxidized solution; and (c) lowering the pH of the oxidized solution to a pH less than 9.

Owner:TRC ENVIRONMENTAL CORP

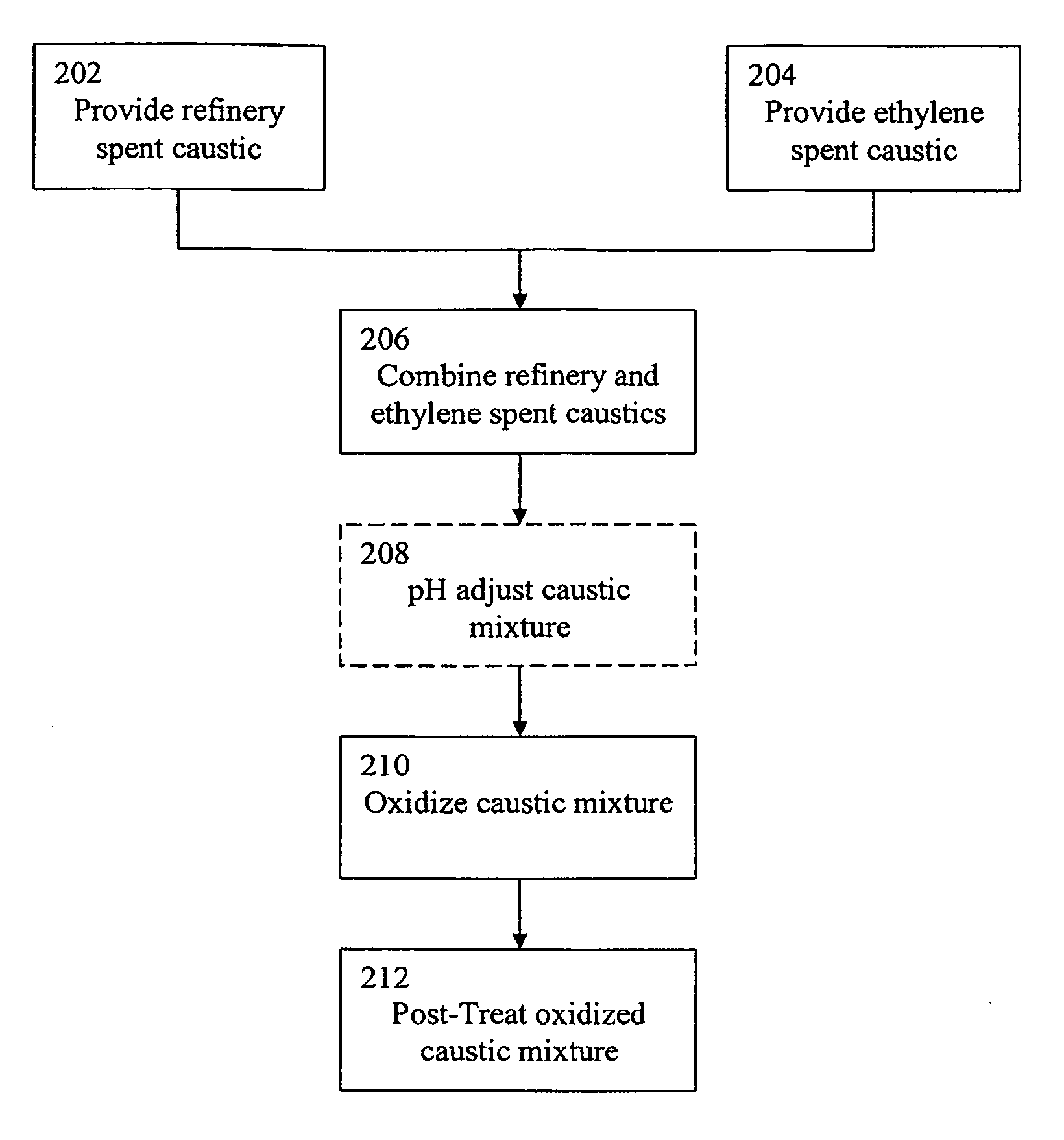

Treatment of spent caustic waste

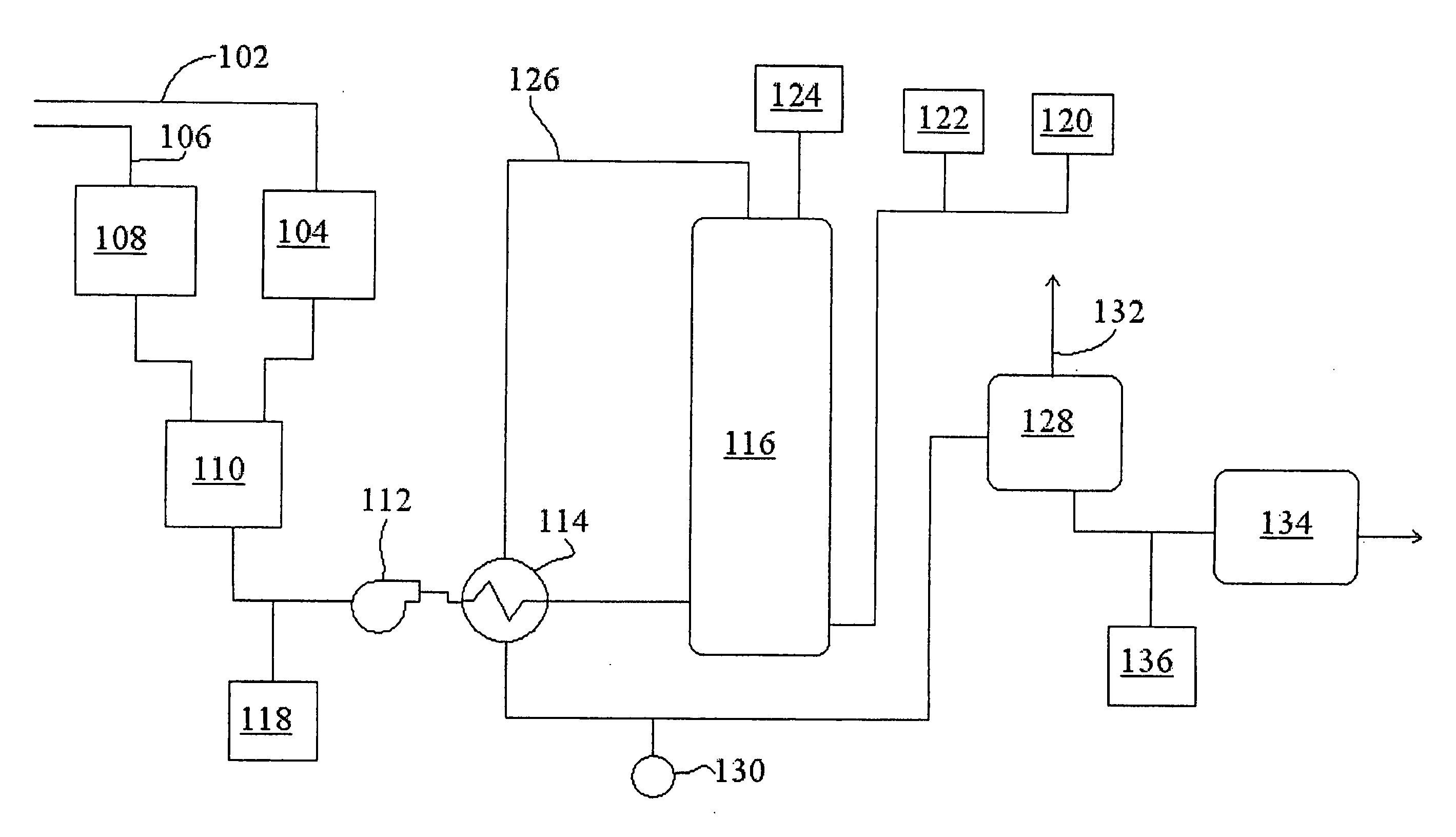

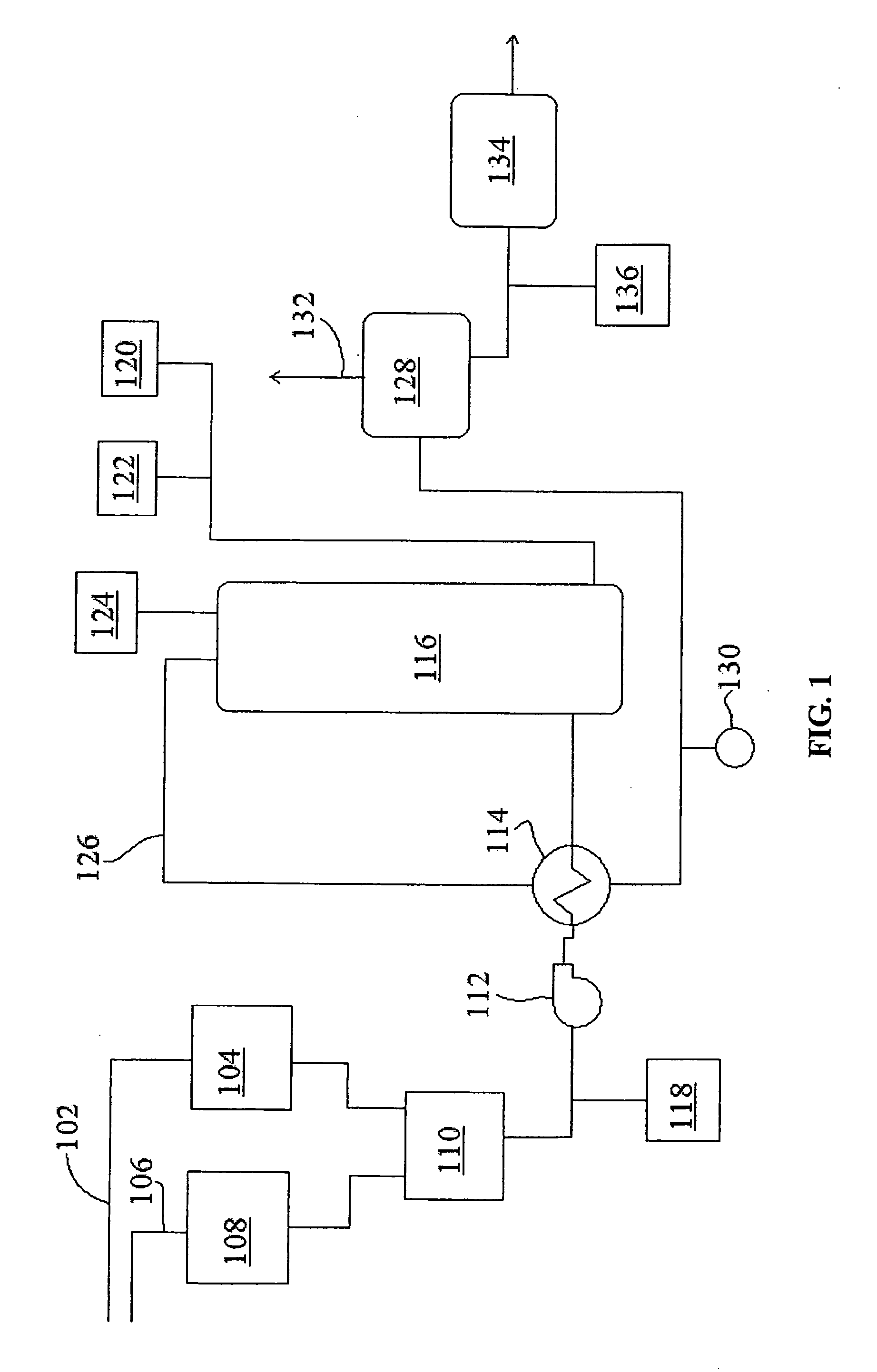

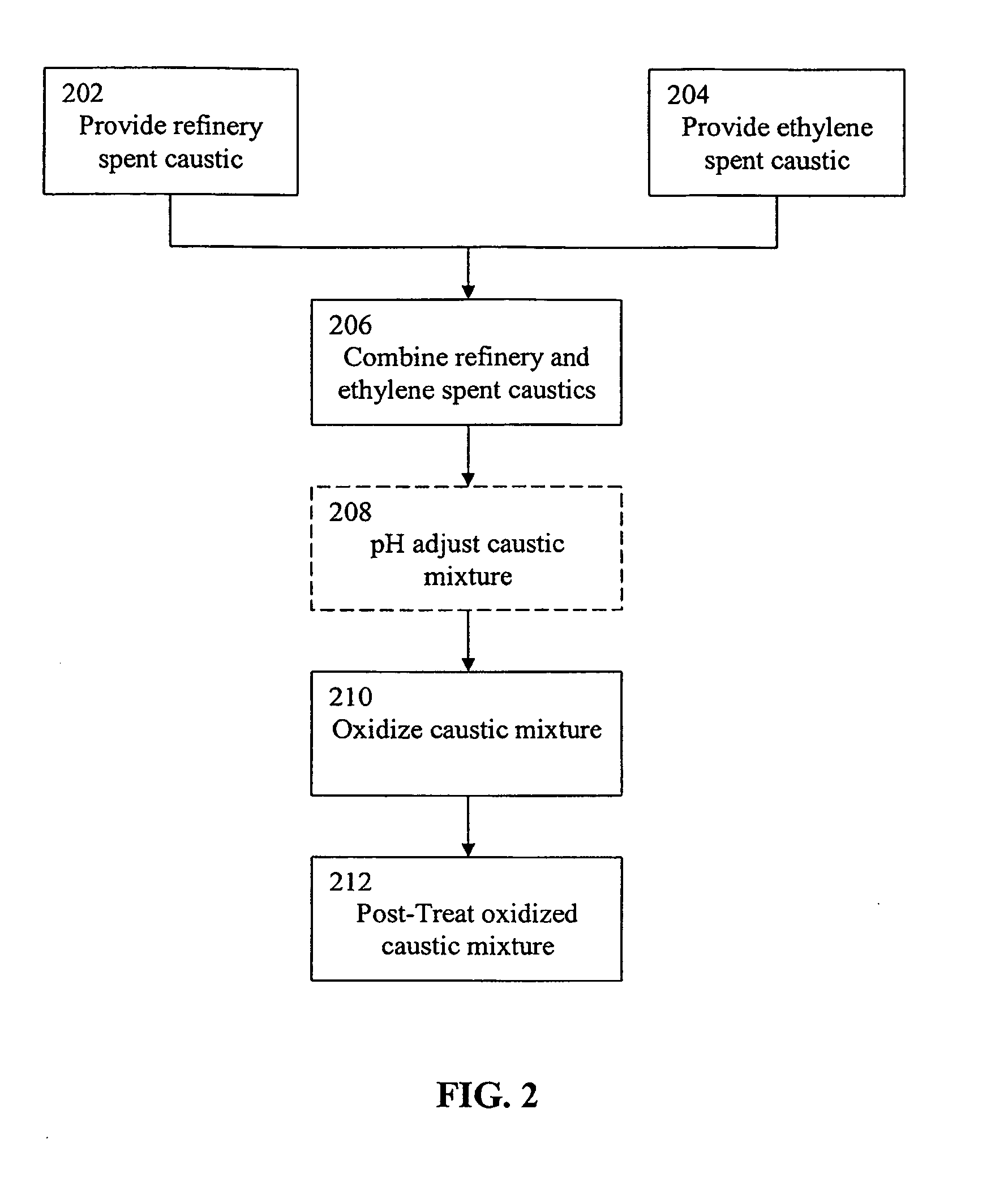

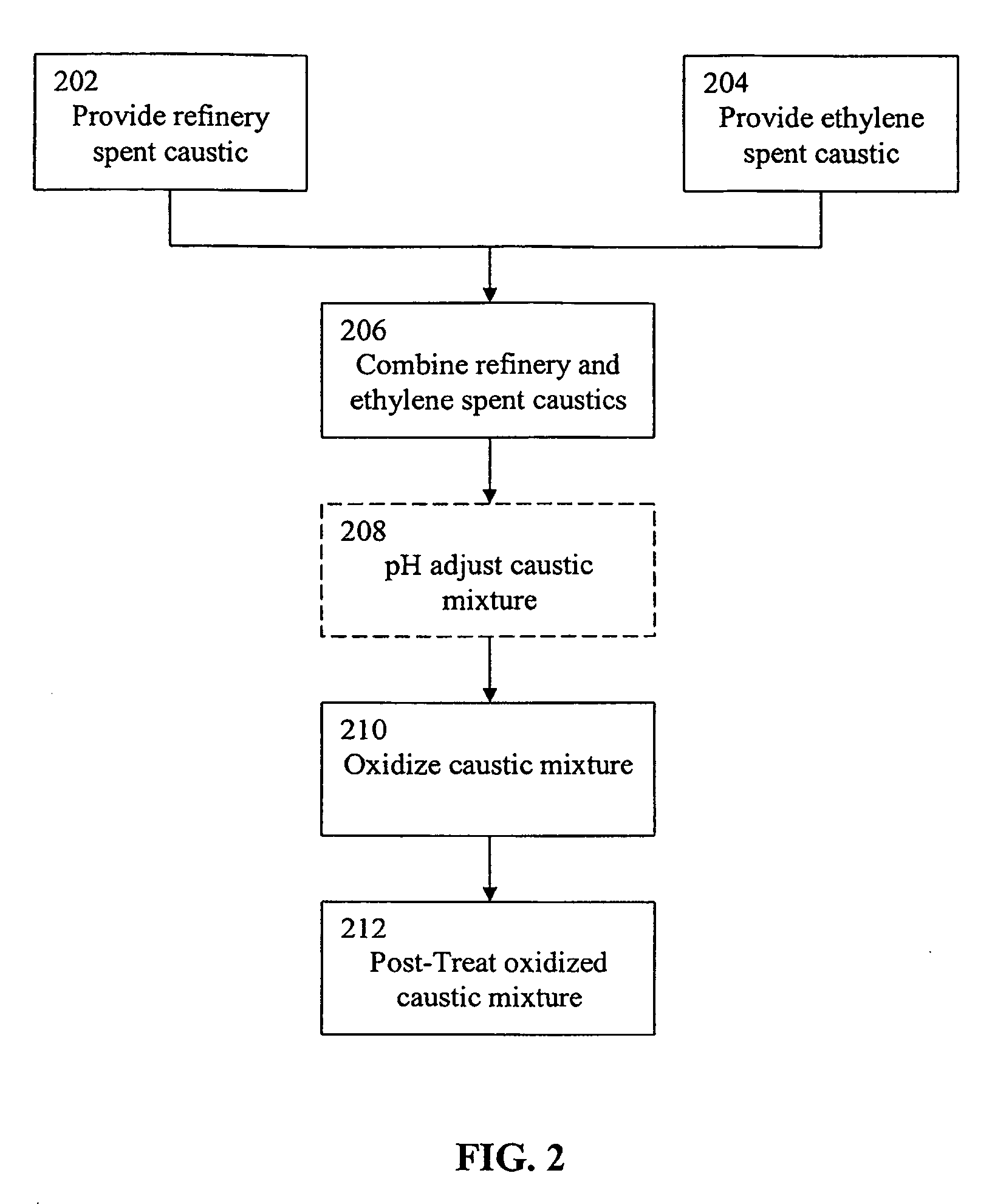

Systems and methods are provided for the treatment of caustic wastewater. Specifically, systems and methods are provided for combining refinery spent caustic and ethylene spent caustic solutions and treating the combined spent caustic mixture using a wet air oxidation process.

Owner:LUMMUS TECH LLC

Slag-sodium alkali dual-alkali wet type flue gas desulfurization process

InactiveCN102225306ALower pHPromote absorptionSolid waste disposalDispersed particle separationWater useSlag

The invention discloses a novel wet flue gas desulfurization process in which a slag is used as a regenerating agent while a calcined soda, caustic soda or spent caustic is used as an absorbing agent. The novel wet flue gas desulfurization process is mainly used for sulfur dioxide desulfurization for an electric plant, an industrial coal-fired boiler and other flue gas containing sulfur dioxide. The novel wet flue gas desulfurization process is characterized in that the slag from a steel plant is directly used as a desulfurization regenerating agent without being broken, namely the energy consumption is zero; no scaling and blocking problem exists in the whole running process; the desulfurization efficiency is high; an effect of processing flue gas by using a limestone / gypsum method can be achieved; the water used for desulfurization is reused in a sealing manner in the whole running process; the dosage of fresh water is greatly reduced; and the 'zero emission' of desulfurization waste water is realized. The novel wet flue gas desulfurization process has the advantages that investment of the adopted process is small, running and management costs are low, once investment of the novel wet flue gas desulfurization process is less than the investment of the limestone / gypsum method, and the total annual cost of running management is low. The regenerating agent, slag, is low in cost and is easily acquired, a desulfurization device is flexibly arranged and an occupied area is small, so that the novel wet flue gas desulfurization process has excellent cost performance and wide market prospect.

Owner:CHENGDU UNIV OF INFORMATION TECH

Processes and apparatuses for removing mercaptans from a feed stream

InactiveUS20150034529A1Hydrocarbon oil dewatering/demulsificationRefining with aqueous alkaline solutionsThiolOxygen

Processes and apparatuses for removing mercaptans from feed streams are provided. In one embodiment, a process for removing mercaptans from a feed stream includes extracting mercaptans and a polymeric precursor from the feed stream with a caustic solvent to form a polymeric precursor rich spent caustic solvent. The polymeric precursor rich spent caustic solvent is contacted with a polymeric precursor-deficient hydrocarbon stream in a multistage vessel and the polymeric precursor is extracted from the polymeric precursor rich spent caustic solvent to form a treated spent caustic solvent. The process contacts the treated spent caustic solvent with oxygen and oxidizes the mercaptans to disulfides to form an oxidized caustic solvent stream. The process includes separating the oxidized caustic solvent stream into an offgas stream, a disulfide stream, and a caustic solvent stream.

Owner:UOP LLC

Separation process

ActiveCN103189117ASave real estateDewatering/demulsification with mechanical meansLiquid suspension thickening by filtrationFiberPhysical chemistry

A separation process for separating two or more immiscible liquids using contactors utilizing high surface area vertical hanging fibers is disclosed. This separation process is especially useful in the separation of disulfide oil formed during the oxidation of spent caustic solution that was used to remove sulfur contaminates from light hydrocarbons.

Owner:MERICHEM CO

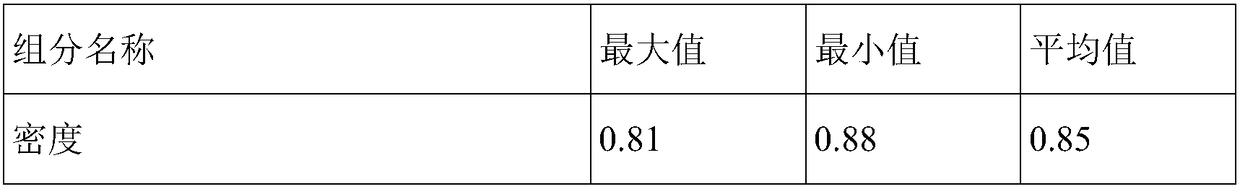

Method for incinerating petrochemical industry waste liquid based on mixed fuel of gas and oily liquid

ActiveCN108870413AReduce incineration costsAvoid pollution and even stalled parking problemsIncinerator apparatusCombined combustion mitigationLiquid wasteEngineering

The invention discloses a method for incinerating petrochemical industry waste liquid based on mixed fuel of gas and oily liquid. The method comprises the steps of spraying the petrochemical industrywaste liquid into a combustion area of a spent caustic incinerator in an atomized manner, using fuel gas and oily liquid as combustion-supporting fuel, and carrying out combustion on the condition ofblowing in gas with oxygen while controlling the temperature of the combustion area to range from 800 DEG C to 1, 200 DEG C, wherein the material input of petrochemical industry waste liquid, and thematerial input of the fuel gas and the oily liquid simultaneously meet the requirements that the ratio of petrochemical industry waste liquid quantity per hour to spent caustic incinerator combustionarea hearth cross sectional area ranges from 0.7 to 1.0 t / h.m2, the ratio of fuel gas quantity per hour to spent caustic incinerator combustion area hearth cross sectional area ranges from 0.05 to 0.09 t / h.m2, and the ratio of oily liquid quantity per hour to spent caustic incinerator combustion area hearth cross sectional area ranges from 0.03 to 0.08 t / h.m2. With the method for incinerating petrochemical industry waste liquid based on mixed fuel of gas and oily liquid, it can be achieved that the combustion load is reasonable, the processing cost is reduced, damage caused by overhigh combustion load to a device is reduced, and it is beneficial for a waste liquid incineration technology to be promoted and applied to industries.

Owner:CHINA PETROLEUM & CHEM CORP +1

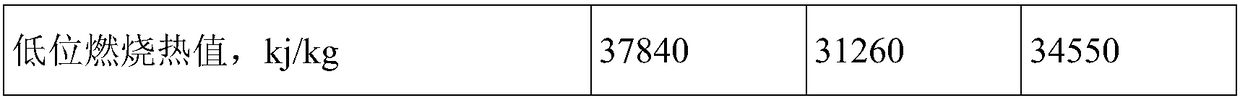

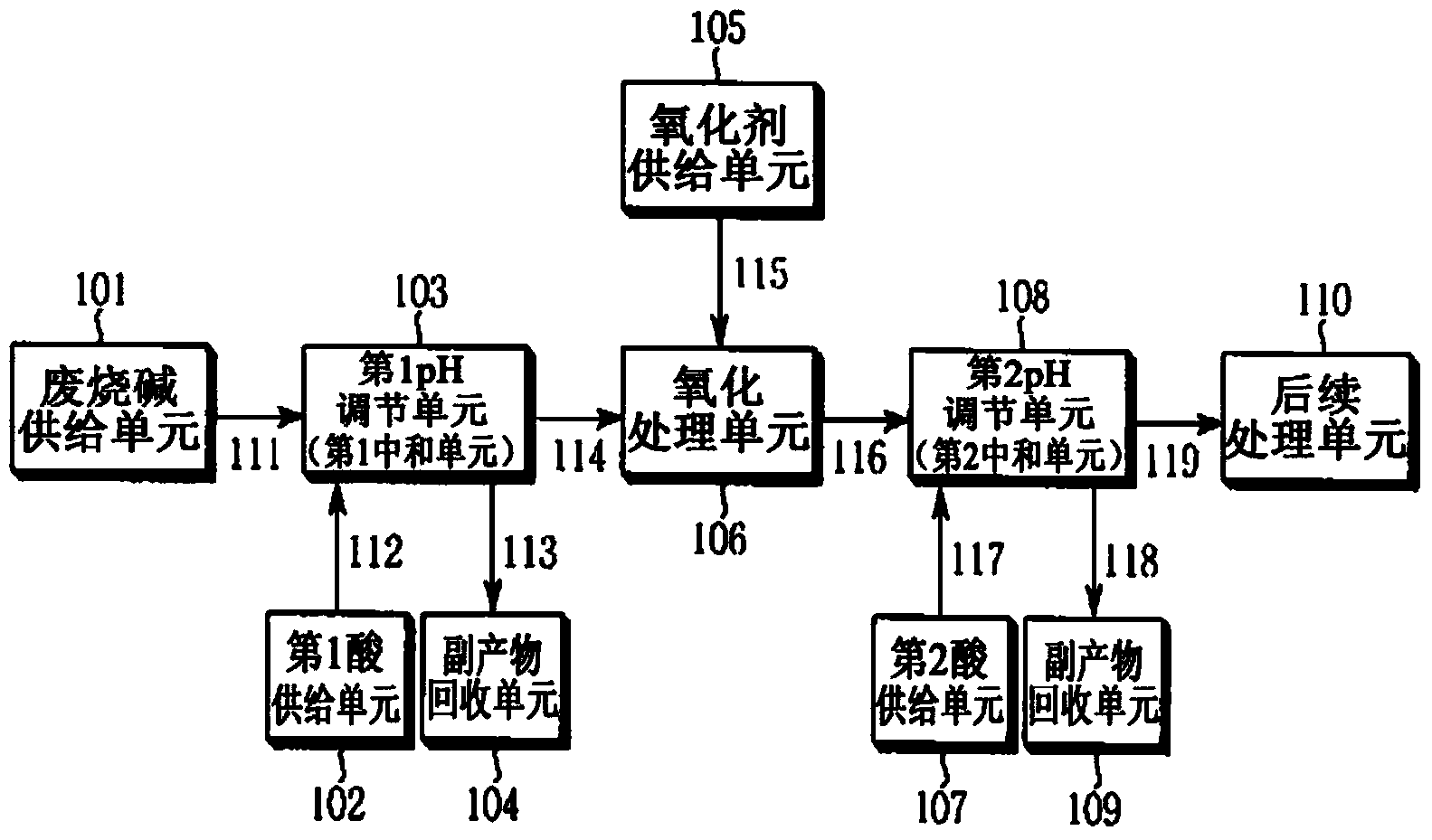

Treatment method for spent caustic soda

InactiveCN103842302AEasy to handleGuaranteed flexibilitySolid waste disposalMultistage water/sewage treatmentPetrochemicalEngineering

An embodiment of the present invention relates to a method for treating spent caustic soda generated from an oil refinery process, a petrochemical process, etc. through a process in which a series of treatment steps are integrated, wherein the method can constitute a process under a mild condition excluding high temperature and / or high pressure conditions and can be advantageous to a post treatment process since the amount of by-products is small.

Owner:SK ENERGY CO LTD (KR)

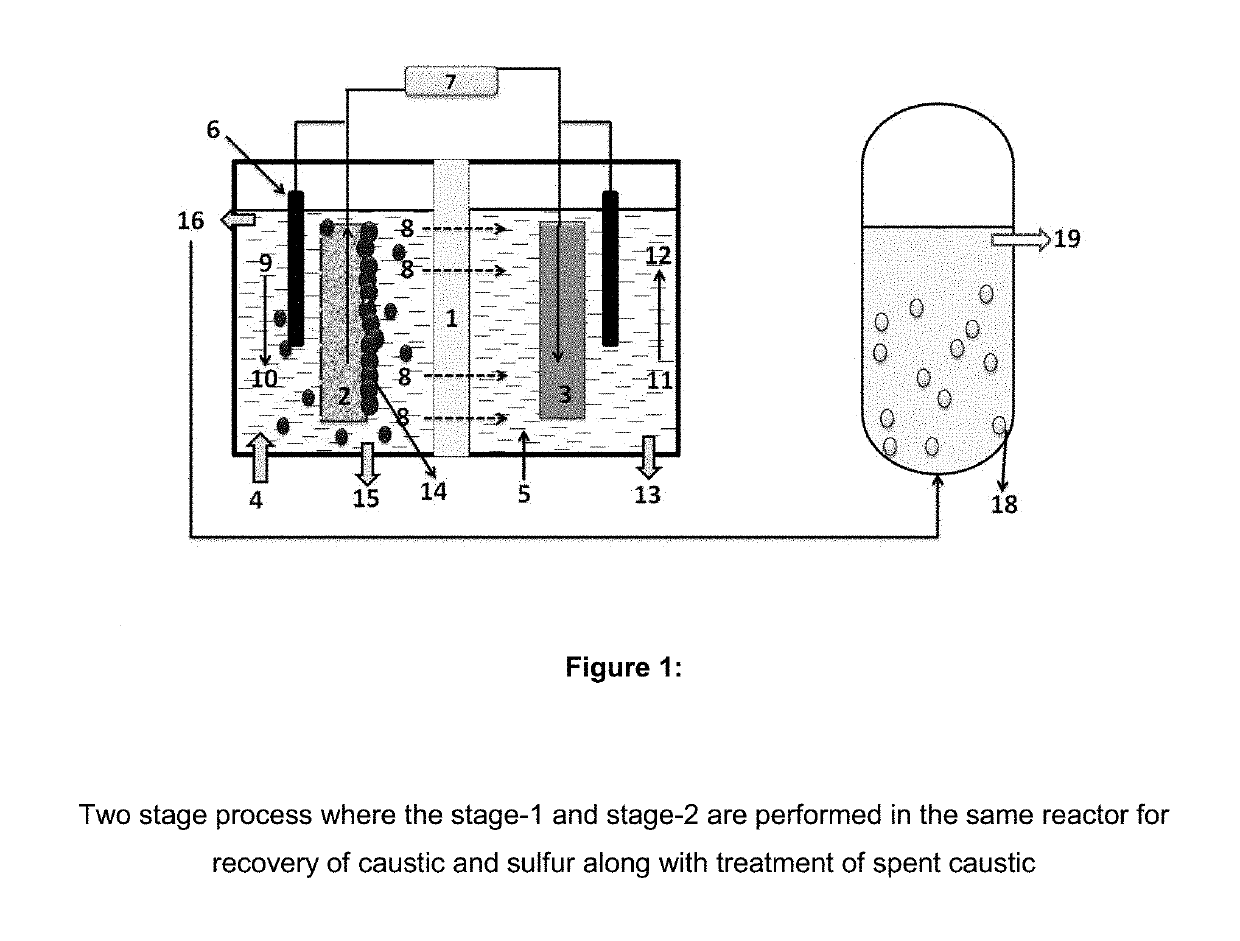

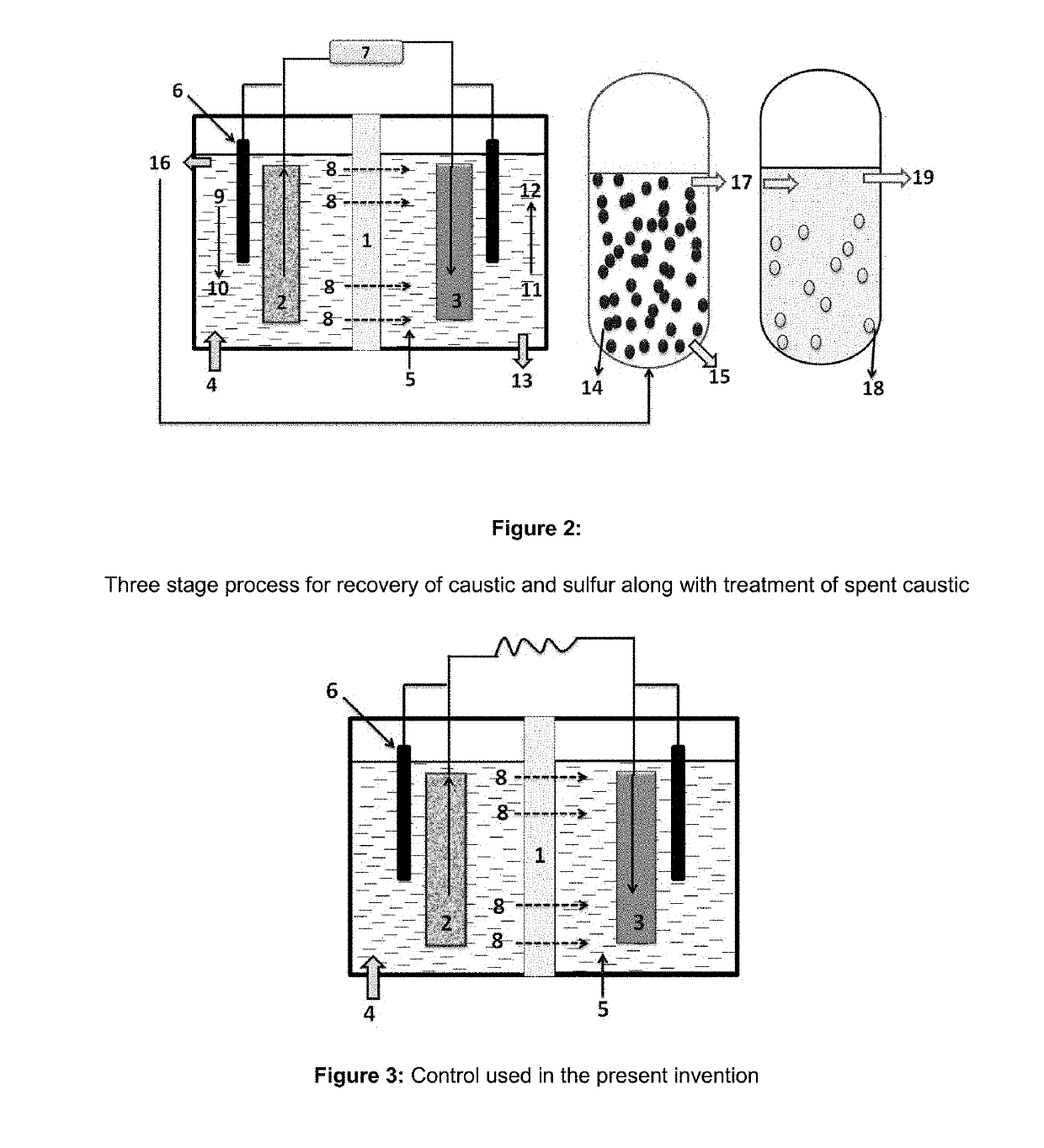

Treatment and recovery of caustic from spent caustic through bioelectrochemical process

The present invention relates to an apparatus and method for bio-assisted treatment of spent caustic obtained from hydrocarbon and gas processing installations. The present invention also relates to method for recovery of caustic and recovery of sulfur from spent caustic. According to present invention, the sulfide removal is about 96% and the sulphur formation and deposition on the electrode lies in range of 72±8%.

Owner:INDIAN OIL CORPORATION

Decoloring method and recycling method for spinning finishing colored waste alkali

InactiveCN107337291AReduce chromaTreatment involving filtrationMultistage water/sewage treatmentParticulatesRecovery method

The invention provides a decolorization method and a recovery method of colored waste caustic soda in textile finishing. The present invention sequentially performs primary filtration, air flotation treatment, and ultrafiltration membrane decolorization on the colored waste caustic soda after textile finishing, and successively removes particulate matter, colored suspended matter such as larger fluff and fine fluff, and residual pulp dyes in the colored waste caustic soda after textile finishing, effectively Reduced the chromaticity of waste lye. In the present invention, the decolorized spent caustic soda obtained by the above decolorized method is evaporated and concentrated, and the obtained concentrated lye has low chroma, which can be directly reused for textile finishing; the obtained hot water can also be directly used in the production steps. Experimental results show that after textile finishing colored waste caustic soda is treated by the decolorization method and recovery method provided by the present invention, the content of suspended solids is reduced from 1320 mg / L to 444 mg / L, the chromaticity is reduced from 600 to 400, and the Baume degree is increased by 4°Bé To 17 ~ 25 ° Bé, can be directly used for textile finishing.

Owner:韶关市北纺智造科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com