Flue gas desulfurization technique using dual alkali method with white slime as recycling agent

A desulfurization process and dual-alkali process technology, applied in the field of air pollution control, can solve problems such as endangering waterways, dust pollution, and land resources occupied by white mud, and achieve the effects of inhibiting oxidation, reducing operating costs, and improving utilization rates.

Inactive Publication Date: 2009-01-21

ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since it cannot be properly treated, the white mud can only be piled up naturally, or directly discharged into the sea

Long-term stacking of white mud occupies a large amount of land resources, and its s

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

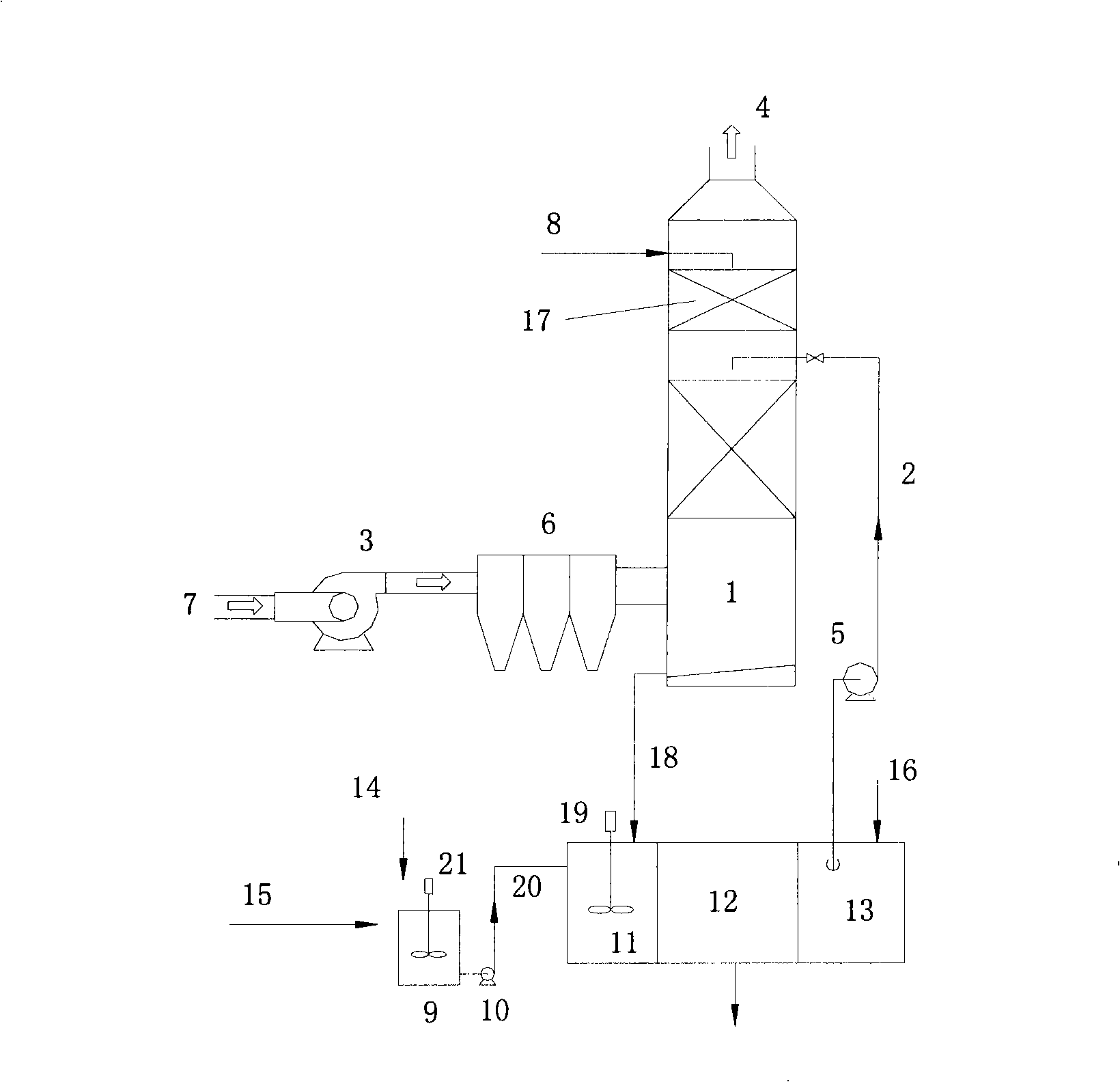

The invention discloses a double alkali flue gas desulfurization technology adopting white slime for regeneration; calcined soda and caustic soda or spent caustic and other alkali liquors are taken as absorbing agent and white slime is taken as regenerant for flue gas desulfurization, absorption liquid is sent into an absorber by a pump and is subject to contact reaction with the flue gas after dust removal and after defogging the desulfurated flue gas is discharged to a chimney; after reaction, the absorption liquid flows into a regeneration pool and reacts with added white slime slurry for regeneration, the regenerated absorption liquid is precipitated, and then supernatant fluid is sent to the absorber for recycling. The desulfurization efficiency of the invention can reach over 90%; by adopting white slime as regenerant, the technology of the invention not only can reduce running cost, but also can embody the development modes of using waste to treat waste, energy conservation and emission reduction, thus having significant environmental, economic and social benefits.

Description

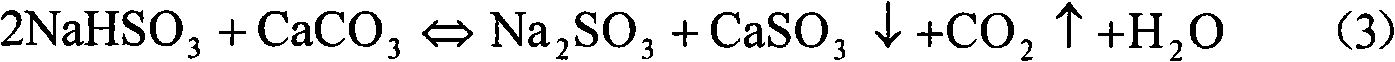

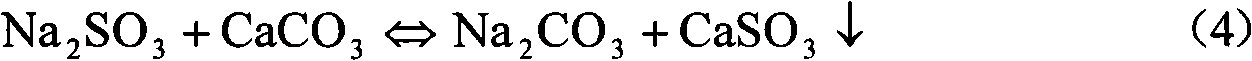

technical field [0001] The invention relates to the technical field of air pollution control, in particular to a double-alkali flue gas desulfurization process in which soda ash, caustic soda or spent caustic soda is used as an absorbent and white mud slurry is used as a regenerant in flue gas purification. Background technique [0002] Flue gas desulfurization (FGD) is the only large-scale commercial desulfurization technology in the world. As long as FGD technology uses absorbent or adsorbent to remove SO in flue gas 2 , and transform it into a more stable sulfur compound. There are many types of FGD technologies, but only a dozen are truly industrialized. FGD technology can be divided into wet method, dry method and semi-dry (semi-wet) method according to the dry and wet state of absorbent and desulfurized product in the desulfurization process. Among them, the wet flue gas desulfurization technology accounts for about 85% of the entire industrialized desulfurization e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/50B01D53/78B01D53/96

Inventor 吴忠标程常杰莫建松

Owner ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com