Treatment method for spent caustic soda

A technology of spent caustic soda and caustic soda, applied in the field of spent caustic soda, can solve problems such as large inorganic sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

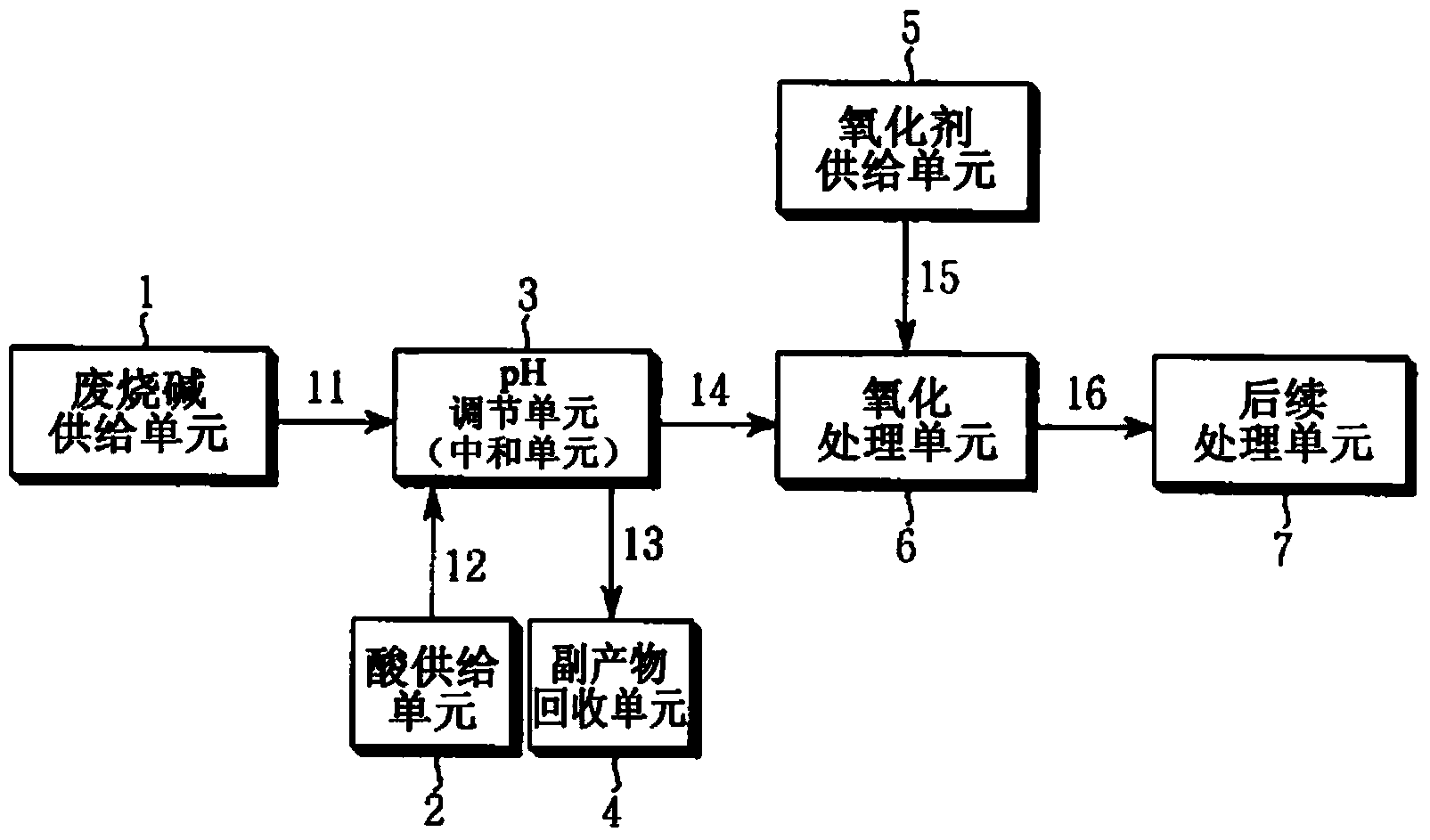

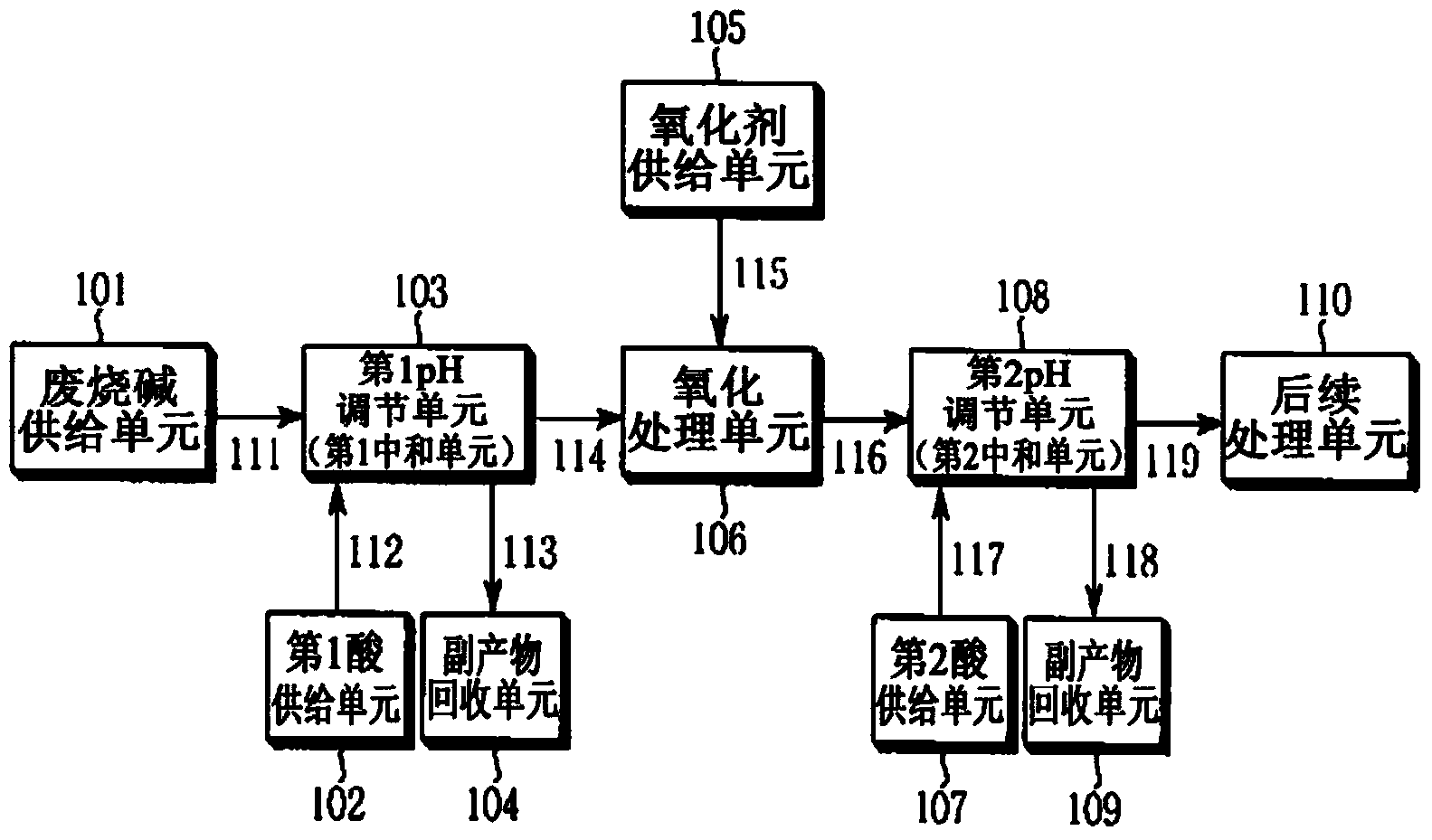

Method used

Image

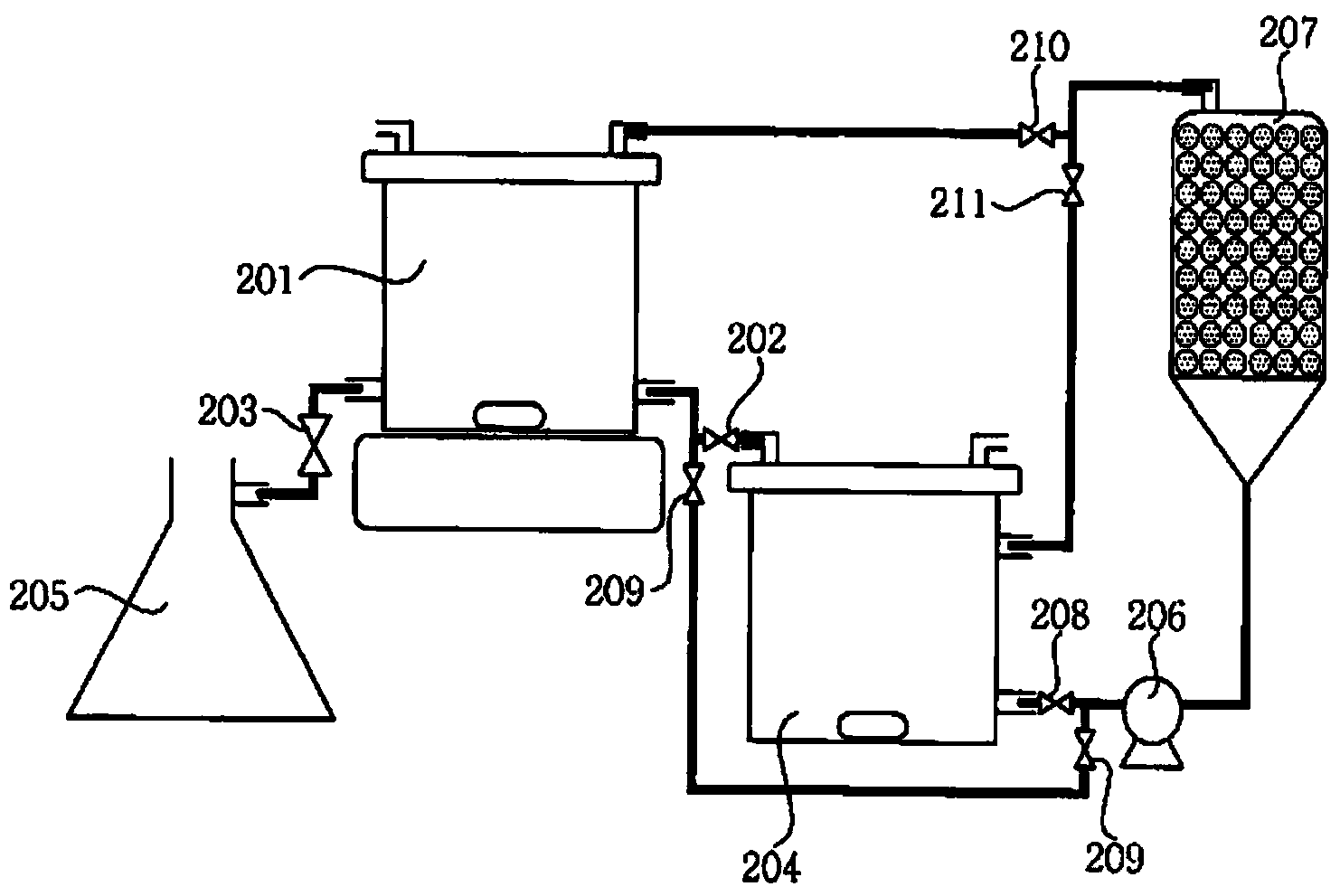

Examples

Embodiment 1

[0143] (1) Physical properties of caustic soda

[0144] Two types of spent caustic soda were used in this example, the spent caustic soda produced by the KMX (Kero Merox) process licensed by Merichem Corporation and UOP Corporation respectively. Its physical properties are shown in Tables 3 and 4 below.

[0145] [table 3]

[0146]

[0147] [Table 4]

[0148]

[0149] (2) The substances used in this example are as follows:

[0150] 1) Sulfuric acid (Aldrich Corp, concentration 98wt%)

[0151] 2) Sodium hydroxide (Aldrich company, dilute sodium hydroxide with distilled water to prepare a solution containing 50wt% sodium hydroxide)

[0152] 3) Hydrogen peroxide (Aldrich company, solution containing 33wt% hydrogen peroxide)

[0153] 4) As an oxidation catalyst, a commercially available spherical catalyst having a particle size of about 1 mm was prepared, which contained iron (III) oxide (main component), about 20 to about 30 wt % potassium based on the weight of iron ox...

Embodiment 2

[0189] Effect of phenol concentration on oxidation reaction temperature and hydrogen peroxide injection dose.

[0190] The spent caustic soda was treated in the same manner as in Test 1 in Example 1, except that the treatment was carried out while changing the oxidation reaction temperature and hydrogen peroxide injection concentration. The reaction temperature before the oxidation reaction was set as the manipulated variable, and the others were set as independent variables. The concentration of phenol was measured with the water analysis kit from HUMAS. When the concentration of phenol is above about 2,000 mg / L, distilled water is added. When the concentration of phenol is below about 2,000 mg / L, the phenol solution is added. Thereby, the content of phenol in the spent caustic soda adjusted by pH is controlled at about 2,000 mg / L. The content of phenol in the finally treated spent caustic soda is shown in Tables 9 and 10 below (average of 10 times).

[0191] [Table 9]

...

Embodiment 3

[0200] Influence of Hydrogen Peroxide Injection Dose on COD

[0201] Treat spent caustic soda with the same method as test 1 and 2 in embodiment 1, difference is to change the injection dose of hydrogen peroxide (aqueous solution), and described hydrogen peroxide is the oxidizing agent used in oxidation treatment reaction, and test result is as follows shown in Tables 11 and 12.

[0202] [Table 11]

[0203] Hydrogen Peroxide Injection Dosage

10

15

20

25

30

35

40

45

COD(mg / L)

3317

3134

2653

2167

2256

2890

3420

4590

[0204] As shown in Table 11, it can be determined that based on about 700 mL of spent caustic soda, the optimal injection dose of the oxidizing agent (hydrogen peroxide) is about 25 mL. In this case, the ratio of oxidant:COD (by weight) is about 2:1. In particular, it was confirmed that when more than 25 mL of hydrogen peroxide was injected, residual unreacted hydrogen peroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com