Demister washing technology for ethylene spent caustic flue gas desulfurization and demister washing device thereof

A technology of ethylene waste lye and flushing device, which is applied in the direction of liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, and can solve the unrealized advantages of saving water resources, reducing energy consumption and facilitating equipment maintenance. and other issues to achieve the effect of meeting long-term efficient operation, reducing leakage points and failure points, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

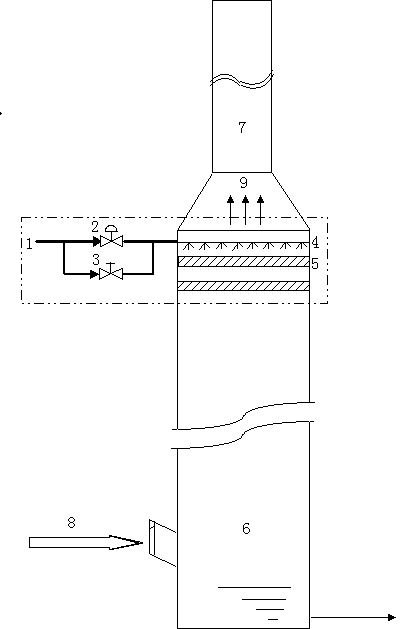

[0020] In this example, see figure 1 , a demister flushing device implementing a demister flushing process for desulfurization of ethylene waste caustic soda, consisting of a demister flushing water spray layer 4, a flushing water main pipe 1 and a flushing control switch, the demister The flushing water spraying pipeline of the flushing water spraying layer 4 is arranged above the uppermost demister 5, and the demister flushing water spraying layer 4 consists of a series of demister rinsing nozzles arranged in a single plane at the same height. On the layer spraying surface, the flushing control switch is independently controlled by the parallel connection of the remote control switch valve 2 and the bypass manual valve 3, wherein the remote control switch valve 2 is a pneumatic or electric switch valve, and the flushing water of the demister is sprayed by controlling the flushing control switch Layer 4 performs dynamic flushing and spraying on the demister 5, and the demiste...

Embodiment 2

[0031] This embodiment is basically the same as Embodiment 1, and the special feature is: the spray angle of each fan-shaped nozzle of the demister flushing water spray layer 4 is 60°, and the water pressure and While ensuring the spraying coverage and uniformity of spraying with a suitable number of nozzles, the structure is simplified, and the number of nozzles is less than that used in Liyiyi. At the same time, it can ensure the dynamic flushing and spraying of the demister and assist in maintaining the entire desulfurization system. The water balance and the need to control the liquid level at the bottom of the desulfurization tower to be stable within the set height range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com