Method for recycling spent caustic liquid during chitin production process

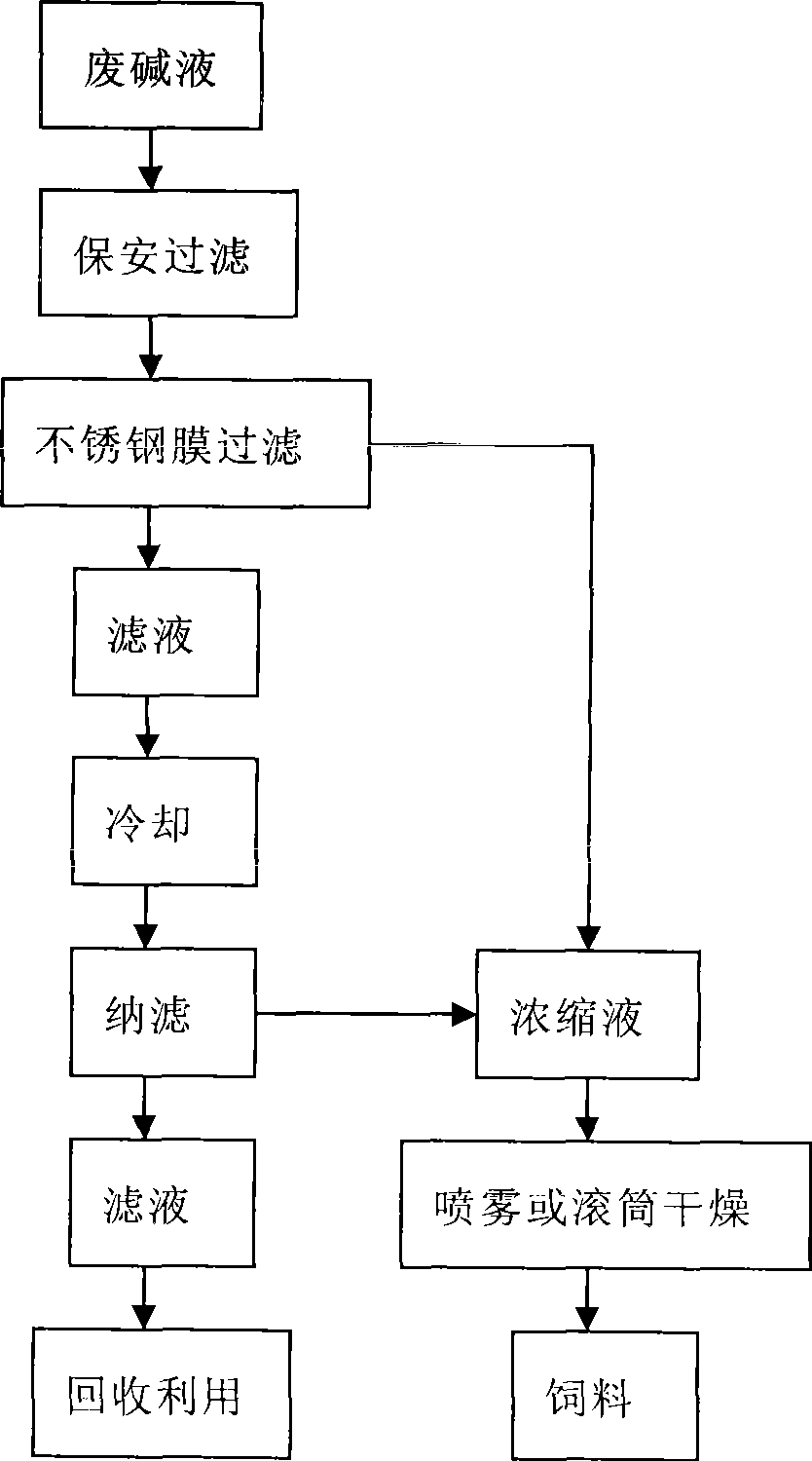

A production process and waste lye technology, applied in the directions of chemical instruments and methods, applications, additional food elements, etc., can solve the problems of extensive waste lye water treatment methods, unsatisfactory discharge, and increase production costs, and achieve the goal of being conducive to resource utilization. The effect of utilization, high concentration ratio and lye cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using the waste lye produced in the deproteinization process during the production of chitin as raw material, the mass concentration of sodium hydroxide in the waste lye is 1%-8%, the mass concentration of protein is 0.3%-5%, and the mass concentration of total solids is 2%. -12%. The waste caustic liquor is filtered through a 60-180 mesh security filter and then enters the stainless steel membrane element. The temperature of the feed liquid is 60-70°C, the operating pressure is 0.3-0.4MPa, the flow velocity on the membrane surface is 3-5.5m / s, and the average flux of the membrane is 300Lm -2 h -1 , end after 5 times of concentration. The filtrate is cooled to 50-55°C, pumped into the nanofiltration system, the operating pressure is 2.5-3MPa, the membrane surface flow rate is 2.2-3.0m / s, the concentration is 80 times, and the average flux of the membrane is 20Lm -2 h -1 . The total filtration yield is 94-96%, the amount of filtrate is 0.94 times of the original was...

Embodiment 2

[0028] The waste lye produced in the deproteinization process during the production of chitin is used as raw material, the mass concentration of sodium hydroxide in the waste lye is 1%-8%, the mass concentration of protein is 0.3%-5%, and the mass concentration of total solids is 2-5%. 12%. The waste lye is filtered through a 60-180 mesh security filter and enters the stainless steel membrane element. The temperature of the feed liquid is 80-90°C, the operating pressure is 0.7-0.8MPa, the membrane surface flow rate is 8-10m / s, and the average flux of the membrane is 600Lm -2 h -1 , end after 1-fold concentration. The filtrate is cooled to 50-60°C, pumped into the nanofiltration system, the operating pressure is 3-4MPa, the membrane surface flow rate is 8-10m / s, the concentration is 50 times, and the average flux of the membrane is 25Lm -2 h -1 . The total filtration yield is 94-96%, the amount of filtrate is 0.96 times of the original waste liquid, and the amount of concen...

Embodiment 3

[0031] The waste lye produced in the deproteinization process during the production of chitin is used as raw material, the mass concentration of sodium hydroxide in the waste lye is 1%-8%, the mass concentration of protein is 0.3%-5%, and the mass concentration of total solids is 2-5%. 12%. The spent caustic liquor is filtered through a 60-180 mesh security filter and then enters the stainless steel membrane element. The temperature of the feed liquid is 10-20°C, the operating pressure is 0.05-0.15MPa, the flow velocity on the membrane surface is 1-1.5m / s, and the average flux of the membrane is 10Lm -2 h -1 , end after 60 times of concentration. The filtrate is pumped into the nanofiltration system, the operating pressure is 0.1-0.2MPa, the membrane surface flow rate is 0.5-1.0m / s, the concentration is doubled, and the average flux of the membrane is 50Lm -2 h -1 . The total filtration yield is 50%, the amount of filtrate is 0.5 times of the original waste liquid, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com