System and method for treating high-salinity spent caustic wastewater

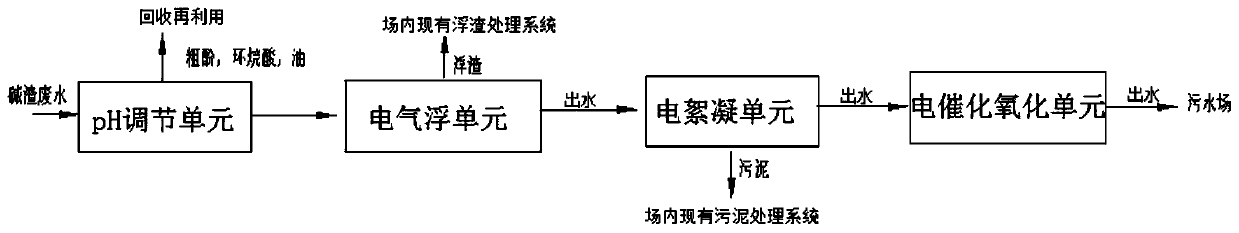

A treatment system and treatment method technology, which is applied in the petrochemical industry sewage treatment field, can solve the problems of high saline-alkali residue wastewater investment and high operating costs, and achieve the effects of reducing COD and toxicity, good application prospects, and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Utilize the processing system and method as described above of the present invention to process 1.0m 3 / h Catalytic gasoline high-salt-alkali slag wastewater from a refinery, in the wastewater, COD49800mg / L, sulfide 8540mg / L, volatile phenol 8600mg / L. The whole process includes:

[0035] 1) The high-salt-alkali slag wastewater enters the pH adjustment tank, and at the same time, sulfuric acid is added to the adjustment tank to adjust the pH value of the wastewater to 7 and stand for 8 hours until the demulsification and stratification of the wastewater occurs, and the upper layer of crude phenol, cyclo Alkanoic acid and oil, the lower layer of wastewater enters the electric floating device;

[0036] 2) In the electric floatation equipment, the wastewater is pre-oxidized to break the gel and demulsify under the action of electricity, and the organic sulfur in the wastewater is converted into inorganic sulfur, and the phenol molecules are degraded and decolorized at the ...

Embodiment 2

[0041] Utilize the above-mentioned treatment system and method of the present invention to process certain ethylene high salinity slag waste water 1.0m 3 / h, of which, COD in wastewater is 25000mg / L, sulfide is 10000mg / L, and volatile phenol is 8000mg / L. The entire processing process is similar to Embodiment 1, and will not be repeated here. After the above-mentioned treatment of ethylene high-salt-alkali residue wastewater, the effluent has COD550mg / L, BOD200mg / L, B / C=0.36, sulfide 12mg / L, and volatile phenol 18mg / L. The effluent is clear, has good biodegradability, and has no Notable smell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com