Method for treating spent caustic wastewater by utilizing halophilic microorganism

A technology for halophilic microorganisms and alkali slag wastewater, which is applied in biological water/sewage treatment, sedimentation treatment, water/sewage treatment, etc., can solve the problems of high investment cost, low treatment efficiency, complex operation process, etc., and achieve energy saving, Reduce costs, achieve economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

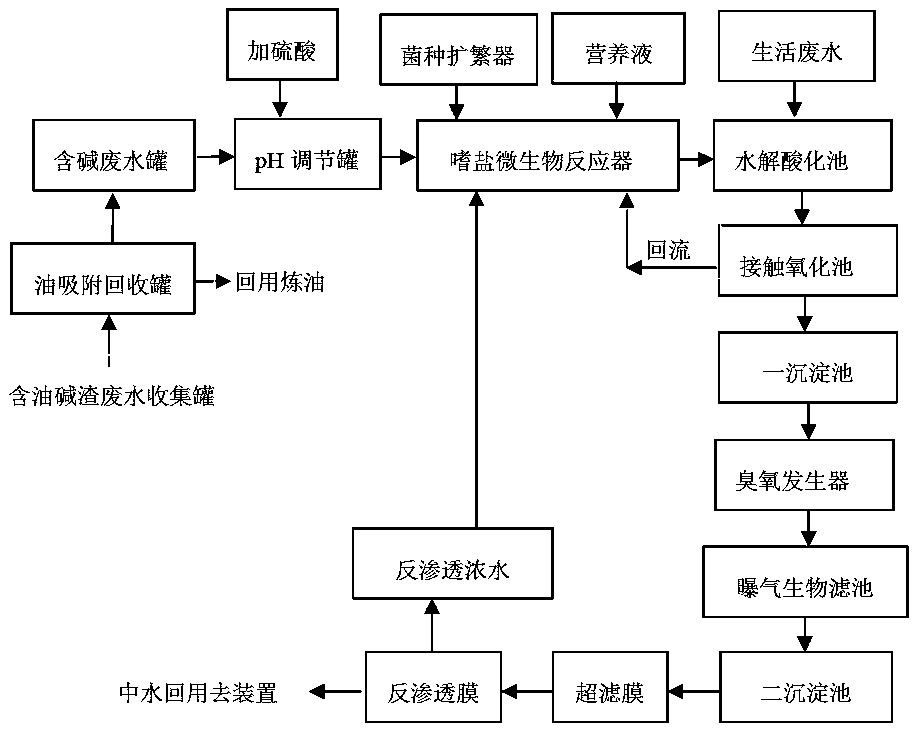

Image

Examples

Embodiment Construction

[0019] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following cases .

[0020] Case 1

[0021] A refining and chemical company produces 600 cubic meters of alkali slag wastewater every year in the process of sweetening liquefied gas. This type of alkali slag contains sulfides, volatile phenols and other substances, which are highly toxic, high-concentrated, and difficult to degrade. General biochemical Law is basically impossible to deal with. Currently using CO 2 After neutralization, it is sent to the sewage treatment plant for treatment. Since the sulfide and volatile phenol in the alkali slag are highly irritating, this process has a great impact on the surrounding environment. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com