Recycling device for spent caustic residues from ethylene

A waste alkali residue, ethylene technology, applied in the direction of grease/oily substance/float removal device, special treatment target, multi-stage water treatment, etc. Convenience, meet production and environmental protection requirements, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

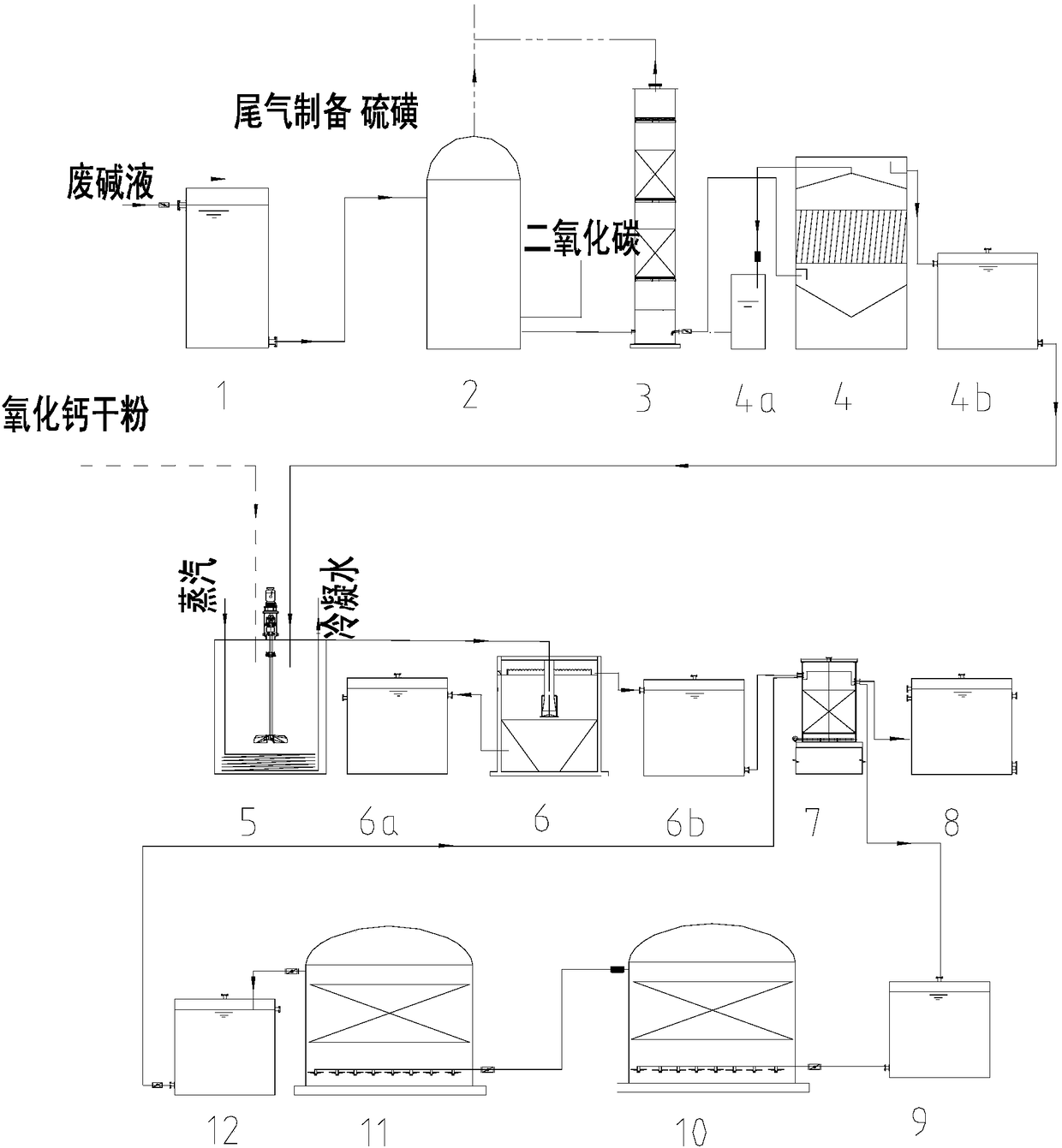

[0016] A device for recycling waste ethylene slag, the device for recycling ethylene waste slag includes a carbonization system, a causticizing system and a refining system;

[0017] Described carbonization system comprises waste lye storage tank 1, carbonization tower 2, tail gas stripping tower 3, carbonized liquid grease trap 4, oil residue tank 4a and carbonized liquid storage tank 4b; The lift pump A1 is connected to the water inlet at the upper end of the carbonization tower 2, the water outlet at the lower end of the carbonization tower 2 is connected to the water inlet at the lower end of the tail gas stripping tower 3 through the second lift pump A2, and the water outlet at the upper end of the tail gas stripping tower 3 passes through the third The lift pump A3 is connected to the carbonized liquid oil trap 4, and the carbonized liquid oil trap 4 is respectively connected to the oil residue tank 4a and the carbonized liquid storage tank 4b, and both the carbonization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com