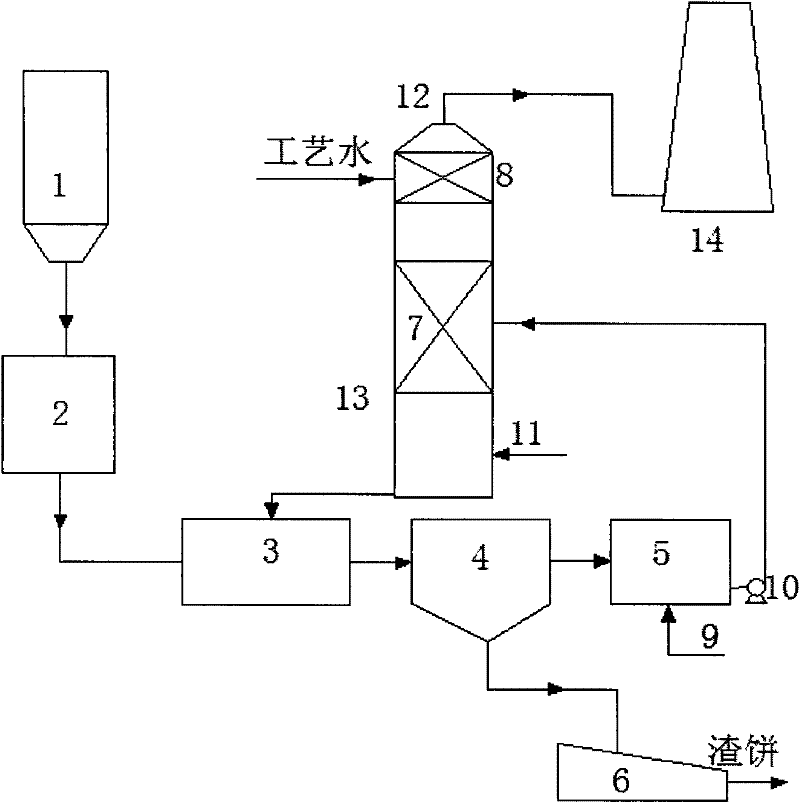

Slag-sodium alkali dual-alkali wet type flue gas desulfurization process

A dual-alkali method and steel slag technology, applied in separation methods, chemical instruments and methods, solid waste removal, etc., can solve problems such as affecting desulfurization rate and slow dissolution of alkaline substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Referring to the accompanying drawings, the steel slag transported from the steel mill is directly poured into the steel slag dissolving tank 2 from the steel slag storage bin 1, and at the same time, tap water is filled to fill the dissolving tank 2, and continuously stirred with a stirrer to promote the dissolving of the steel slag, the slag in the steel slag can be The dissolved components enter the regeneration tank through the pipe network through the gravity flow along with the solution. Sodium alkali 9 is added to the adjustment tank 5, and the pH value of the slurry in the adjustment tank 5 is adjusted to 8-9. The slurry with adjusted pH value is pumped into the desulfurization tower 13 by the circulation pump 10, and absorbs and desulfurizes the flue gas entering from the flue gas inlet 11 in the desulfurization zone 7, and the purified flue gas passes through the demister 8 from the desulfurization tower 13 The top 12 is discharged into the chimney 14, absorbi...

Embodiment 2

[0026] According to the technological process described in embodiment 1, carry out the supporting flue gas desulfurization of 170t / h boiler, boiler outlet SO 2 The concentration is 1800mg / Nm 3 , the temperature is 152°C, the liquid-gas ratio is 5.0L / m 3 , all the other conditions are the same as Example 1, and the desulfurization rate is 94.2%.

Embodiment 3

[0028] The coal quality used in Example 2 is adjusted according to the process described in Example 1, and part of sulfur is added to increase the boiler flue gas outlet SO 2 The concentration is 9000mg / Nm 3 , the steel slag / water ratio is 350kg / m 3 , the liquid-gas ratio is 10.0L / m 3 , all the other conditions are the same as in Example 2, and the desulfurization rate is 92.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com