Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Increase solid solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permanent ferrite magnetic tile and preparation method thereof

InactiveCN101202138AIncrease solid solutionImprove performancePermanent magnetsInorganic material magnetismFiberSilicon oxide

The invention relates to a permanent ferrite magnetic arc and the manufacturing method thereof, belonging to a manufacturing field of a motor permanent ferrite. Weight proportions of main material components and additive components are as the following: main materials: 8.7 to 9.0 percent of strontium oxide; 86 to 87 percent of iron oxide red; additives: 0.6 to 1.0 percent of calcium carbonate; 0.6 to 1.0 percent of aluminum oxide; 0.4 to 0.8 percent of chrome oxide; 0.3 to 0.6 percent of boric acid; 0.3 to 0.5 percent of silicon oxide; 0.2 to 0.4 percent of cobalt oxide; 0.2 to 0.4 percent of lanthanum oxide and 0.1 to 0.3 percent of silicate fiber. The invention is provided with high surplus magnetic induction strength and high intrinsic coercivity so as to enhance a mechanical strength of the magnetic arc.

Owner:CHANGZHOU DIER MAGIC MATERIALS

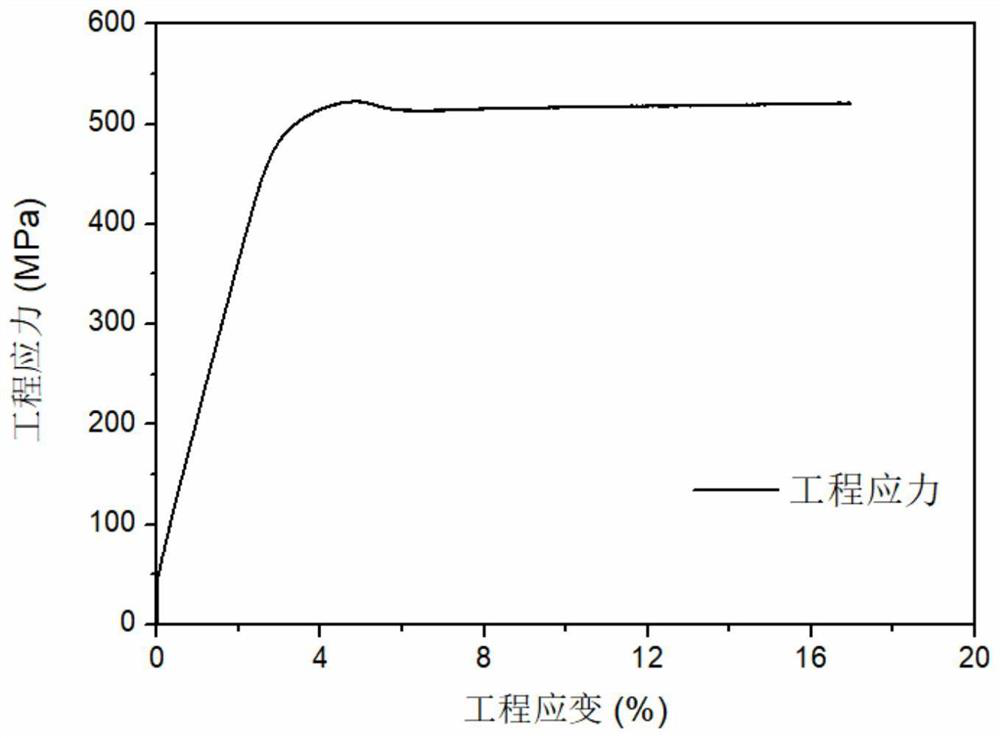

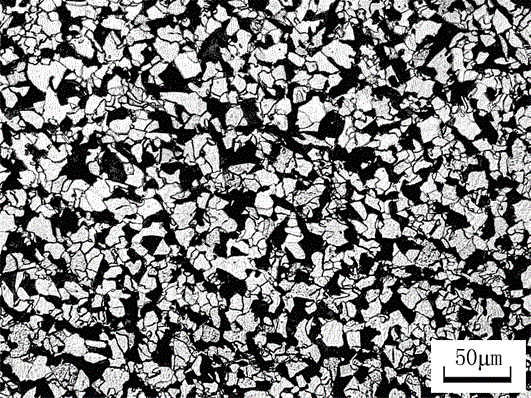

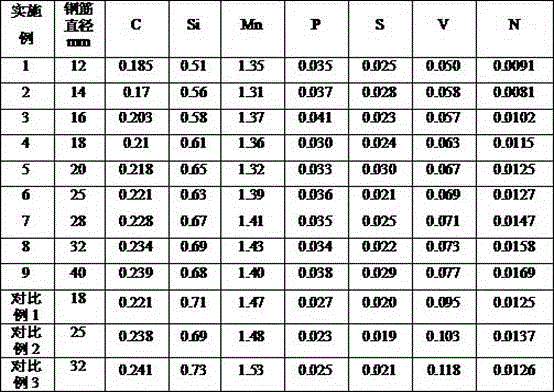

Hot-rolled ribbed steel bar having strength-to-yield ratio of 1.25 or more, and production method thereof

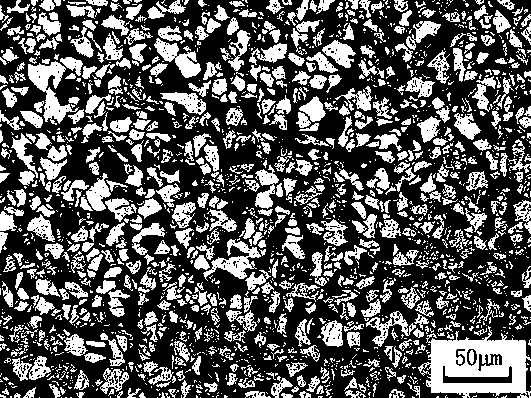

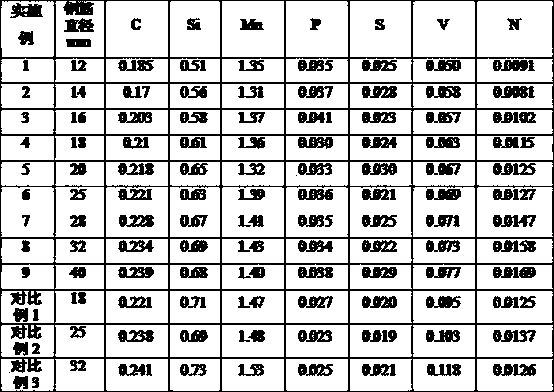

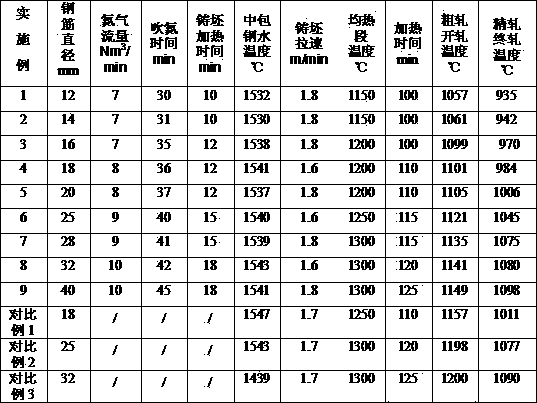

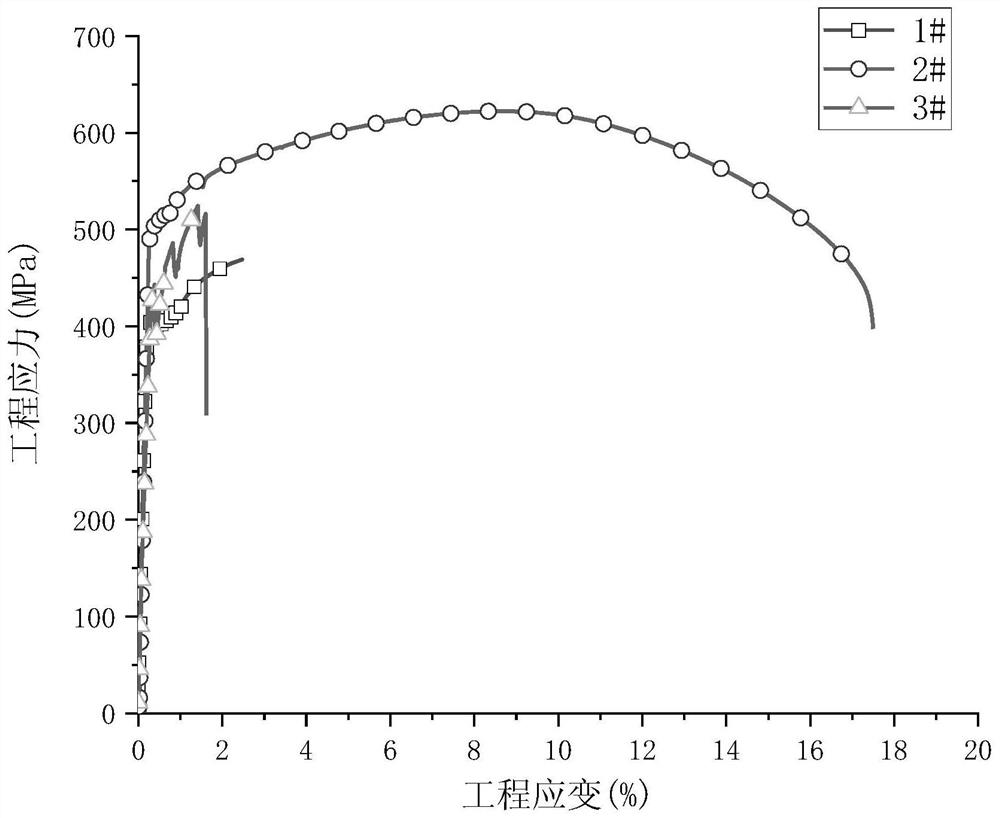

A hot-rolled ribbed steel bar having a strength-to-yield ratio of 1.25 or more comprises 0.17-0.25wt% of C, 0.4-0.8wt% of Si, 1.2-1.5wt% of Mn, 0.045wt% or less of P, 0.045wt% or less of S, 0.05-0.08wt% of V, 0.006-0.018wt% of N, and the balance of Fe and impurity elements, and has a specification diameter of 12-40mm. A production method of the hot-rolled ribbed steel bar comprises the following steps: desulfurizing molten iron; carrying out top-bottom blowing of a converter; carrying out component fine-adjustment at an argon station, and blowing in nitrogen; refining an LF furnace, and blowing nitrogen into the LF furnace; continuously casting; carrying out stacking cooling; heating casted blanks; carrying out rough rolling and finish rolling; and naturally cooling to room temperature. Nitrogen is blown to realize greatly reduced cost, greatly reduced vanadium alloy consumption, increased V (C,N) amount and dispersity with the increase of the content of N in steel, substantial reinforcement effect and stable mechanical performances on the premise that mechanical performances comprising a hot-rolled yield strength of above 530MPa, a strength-to-yield ratio of 1.25-1.30, an A value of 18% or more and an Agt value of 10 or more are guaranteed.

Owner:武汉钢铁有限公司

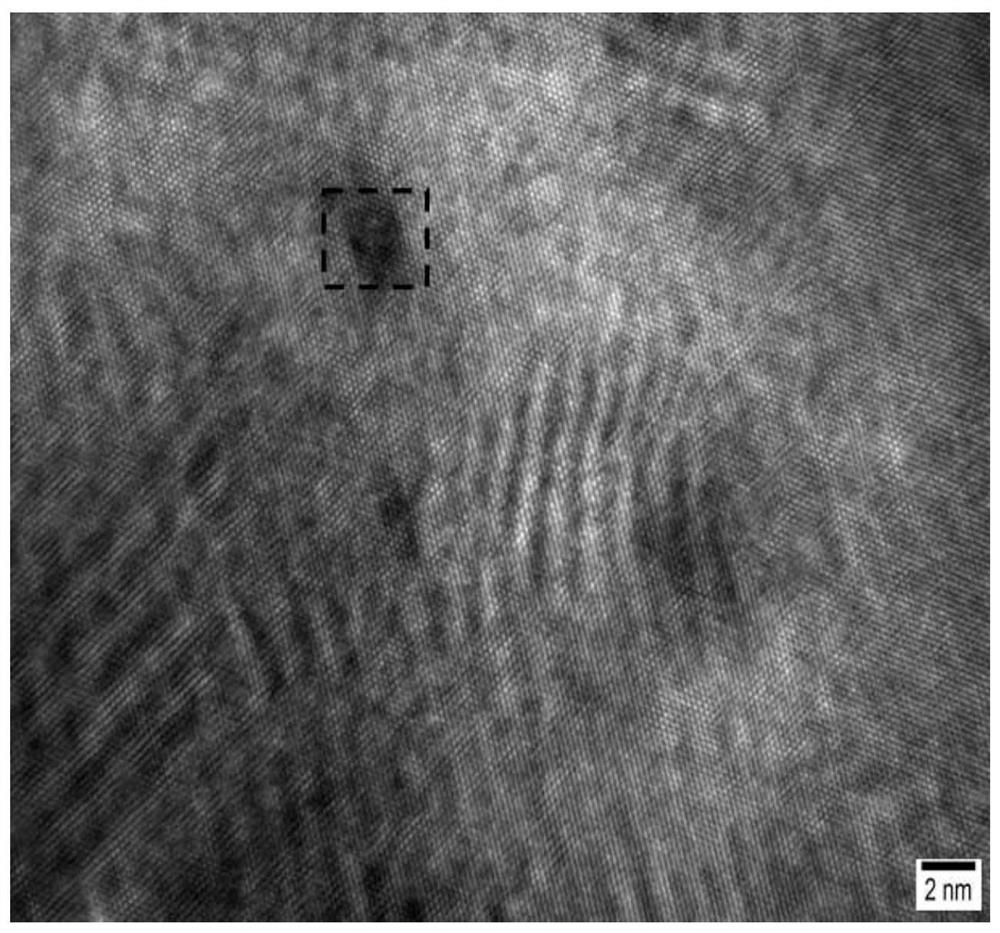

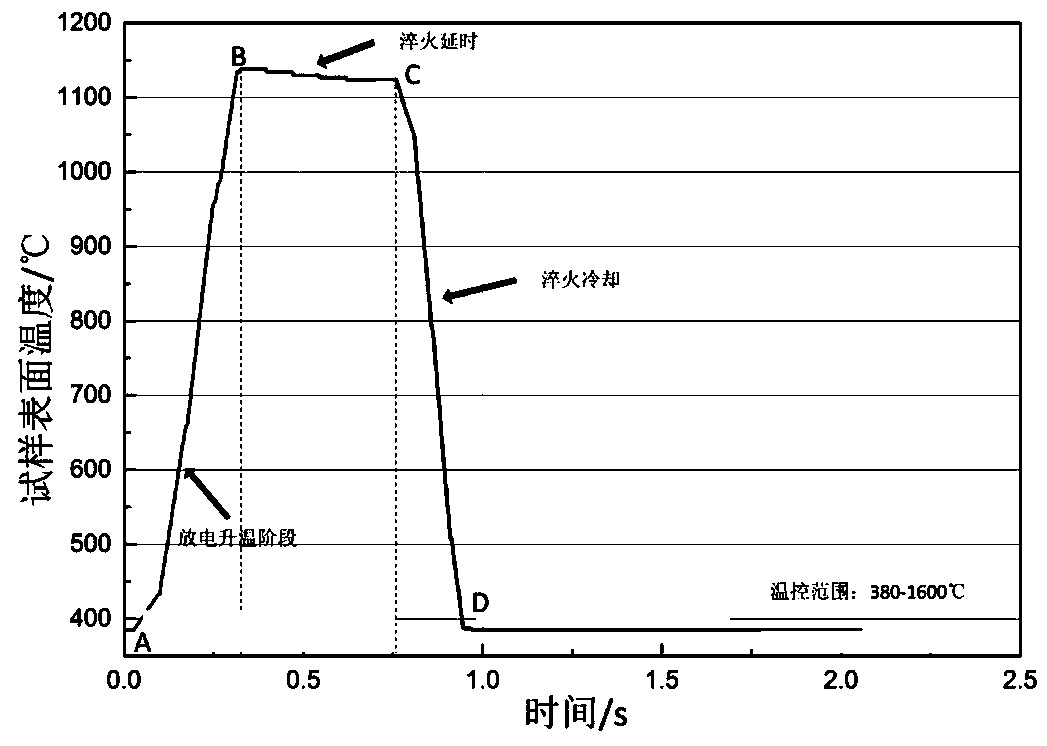

Method for preparing high-solid-solubility ultrafine grain high-speed steel through electric pulses

ActiveCN109825689AHigh hardnessImprove toughnessHeat treatment process controlAustenite grainCarbide

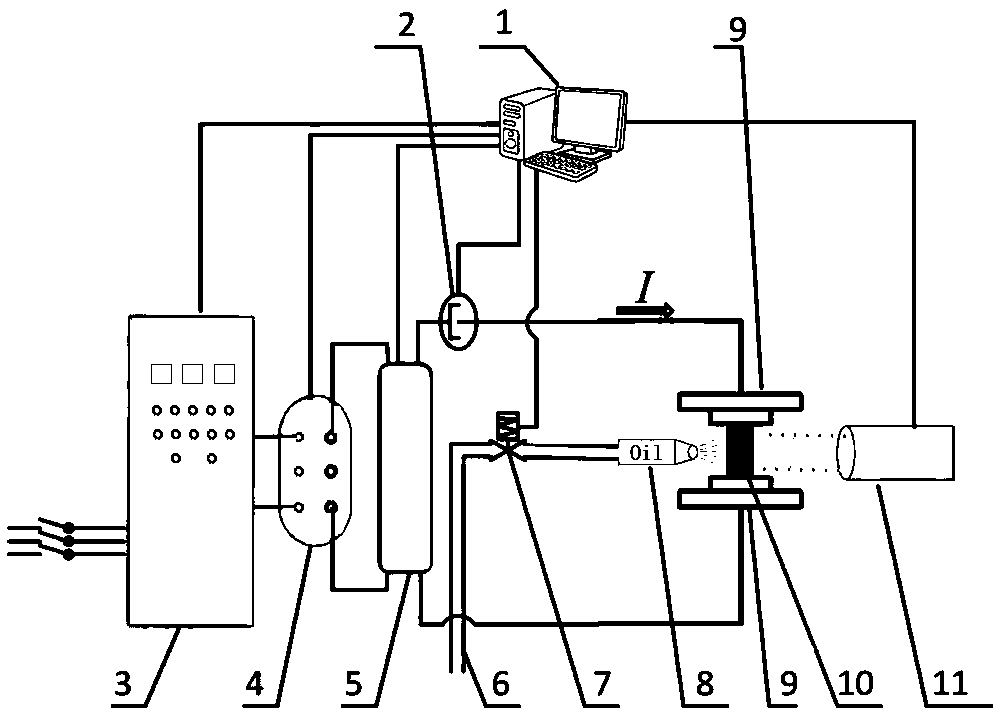

The invention discloses a method for preparing high-solid-solubility ultrafine grain high-speed steel through electric pulses. The method includes the steps that high-speed steel is subjected to conventional austenitizing and then quenched and tempered; then the two ends of the steel are clamped between electrodes of electric pulse equipment, the high-speed steel is discharged in the air environment, the temperature of the material rises to the austenitizing temperature region through pulse currents, austenite grains are ultrafine, and dissolution of carbide is promoted; after electric pulse discharge is completed, quenching is completed through an automatic quenching device; and finally the high-solid-solubility ultrafine grain high-speed steel in a quenched state through electric pulse treatment is tempered three times, and the high-speed steel with excellent comprehensive mechanical performance is obtained. By means of the method, the technical bottleneck that in the traditional heat treatment process, high-speed steel grain refinement and carbide dissolution promotion cannot be taken into account is solved, and the double effects that the high-speed steel austenite grains are ultrafine, and the dissolution quantity of the carbide is increased are achieved. The method is short in technological process, energy saving and high efficiency are achieved, and the hardness and thetoughness of the high-speed steel can be simultaneously improved.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

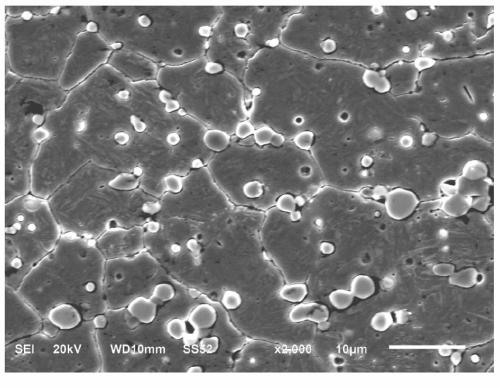

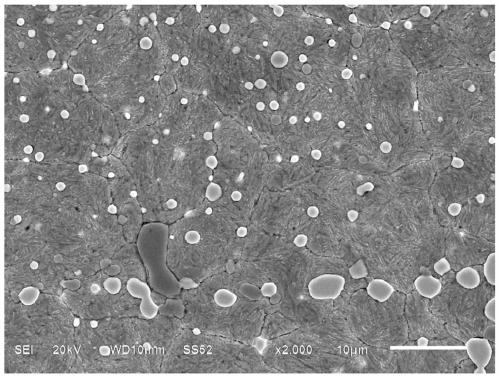

High-strength and high-conductivity Cu-Cr-Nb alloy with double-peak grain size and double-scale nano-phase reinforcing function

ActiveCN112391556AHigh plastic conductivityImprove conductivityAdditive manufacturing apparatusTransportation and packagingElectrically conductiveCopper matrix

The invention provides a high-strength and high-conductivity Cu-Cr-Nb alloy with a double-peak grain size and a double-scale nano-phase reinforcing function, and belongs to the field of additive manufacturing and high-strength and high-conductivity copper alloys. In the designed alloy, the contents of Cr and Nb are 2.0-2.8 at% and 1-1.3 at% correspondingly, the atomic ratio of Cr to Nb is controlled to be slightly greater than 2:1, and a copper matrix is reinforced by nanophases such as a Cr2Nb phase and a Cr phase. According to the alloy, the high-performance Cu-Cr-Nb alloy with the double-peak grain size and the double-scale nano-phase reinforcing function is prepared through the cooperation of selective laser melting and a special heat treatment process. The tensile strength of the prepared Cu-Cr-Nb alloy at room temperature is larger than 800 MPa, the yield strength of the Cu-Cr-Nb alloy is larger than 710 MPa, the microhardness of the Cu-Cr-Nb alloy is not lower than 256 HV, the elongation of the Cu-Cr-Nb alloy is not lower than 25%, and the conductivity of the Cu-Cr-Nb alloy is not lower than 70% IACS. The tensile strength at 700 DEG C is 145-155 MPa.

Owner:CENT SOUTH UNIV

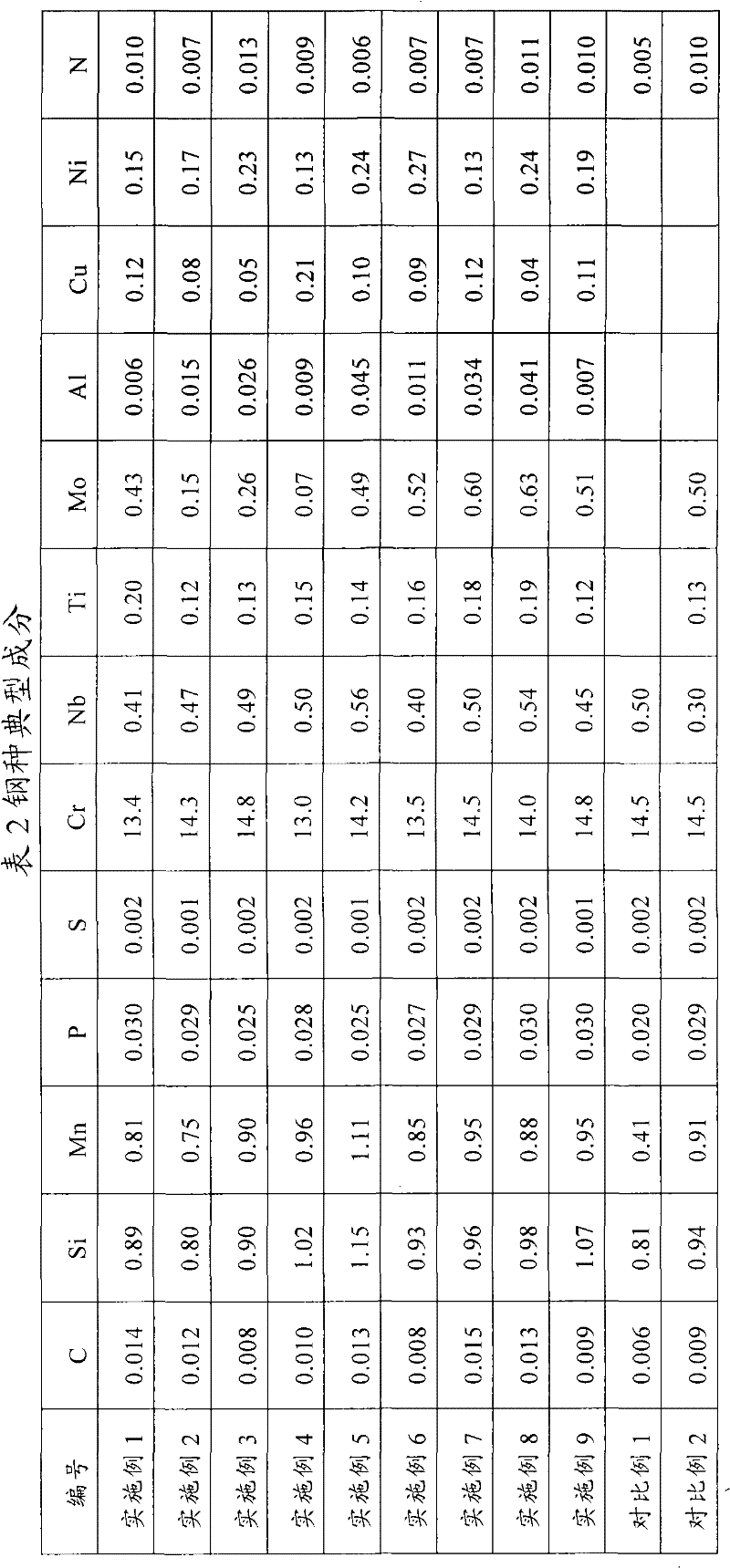

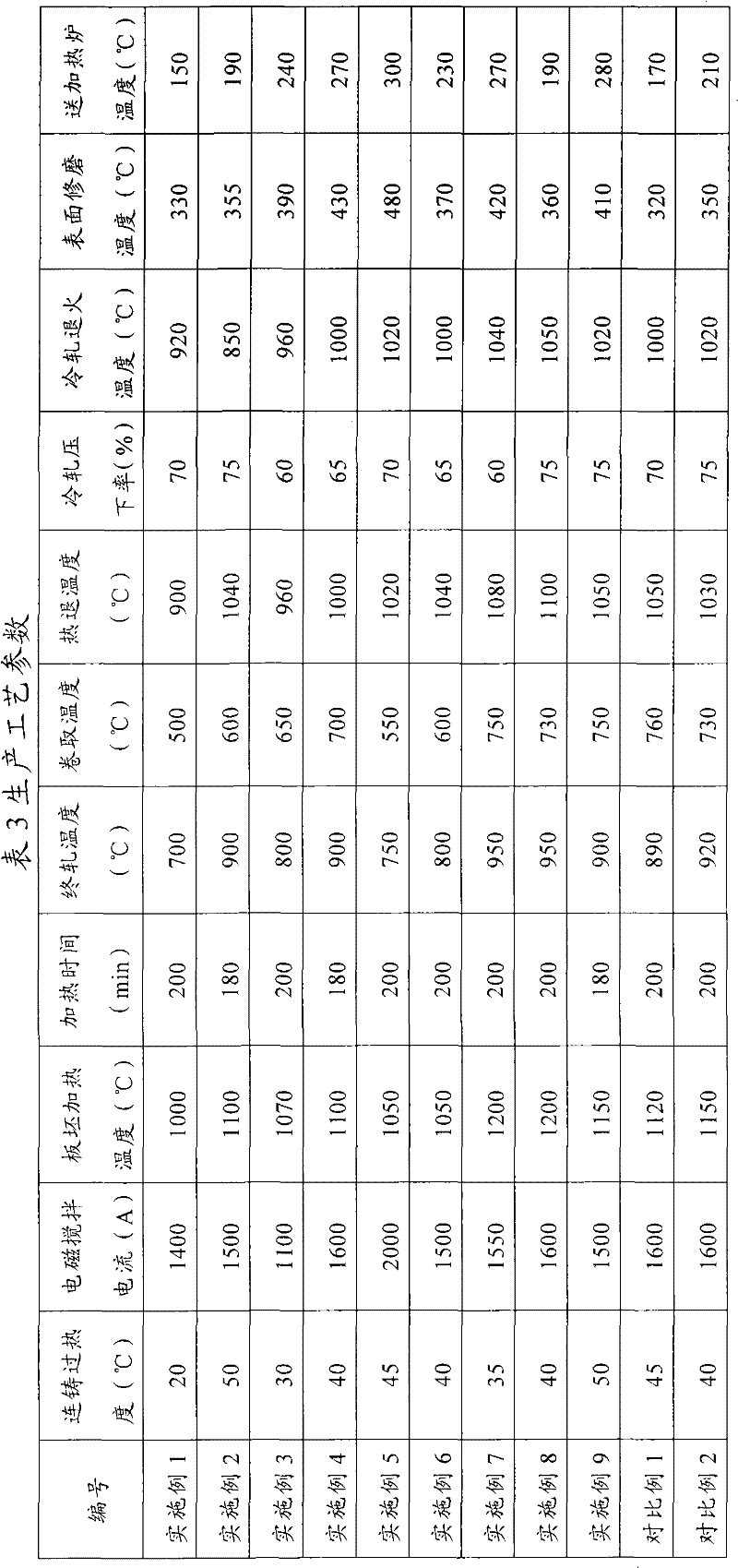

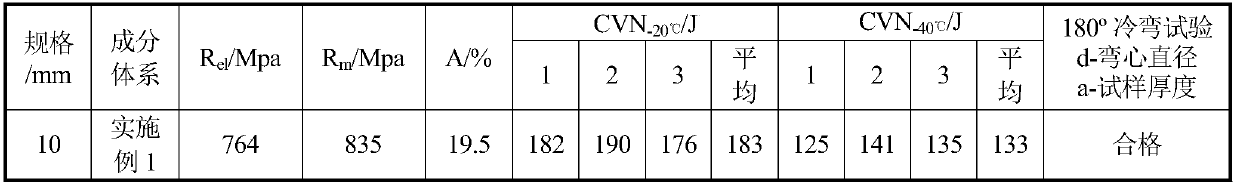

Ferrite stainless steel and manufacturing method of ferrite stainless steel cold-rolled sheet made therefrom

ActiveCN102234740AIncrease solid solutionReduce quality problemsTemperature control deviceMetal rolling arrangementsMetallurgy

The invention provides ferrite stainless steel which comprises the following chemical components by weight percent: 0.008-0.020% of C, 0.80-1.20% of Si, 0.70-1.20% of Mn, less than or equal to 0.70% of Mo, 13.0-16.0% of Cr, less than or equal to 0.03% of P, less than or equal to 0.003% of S, [4*(C+N)+0.30]-0.60% of Nb, [6*(C+N)]-0.2% of Ti, 0.005-0.05% of Al, [0.15+10*(C+N)]-0.2% of Ti, 0.005-0.05% of Al, more than or equal to [0.15+10*(C+N)]% and less than or equal to 0.50% of [Ti+0.5Nb], less than or equal to 0.015% of N, less than or equal to 0.030% of C+N, less than or equal to 0.3% of Ni, less than or equal to 0.3% of Cu and the balance of Fe and inevitable impurities, wherein the total amount of impurities is less than 0.05%. The ferrite stainless steel cold-rolled sheet made from the steel has the advantage of good high-temperature property, and is extremely suitable for being used in a manifold component of an automobile exhaust system.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

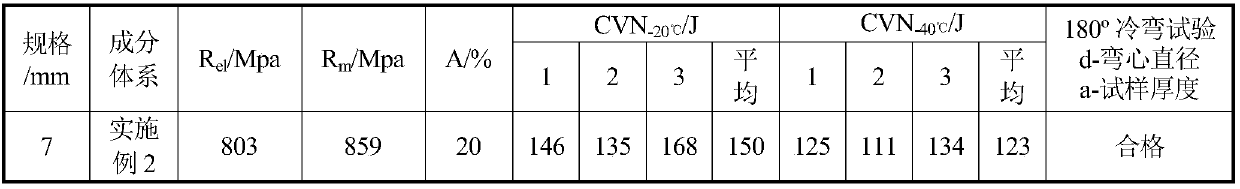

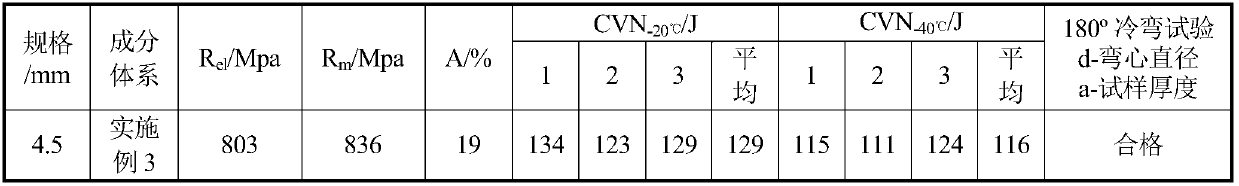

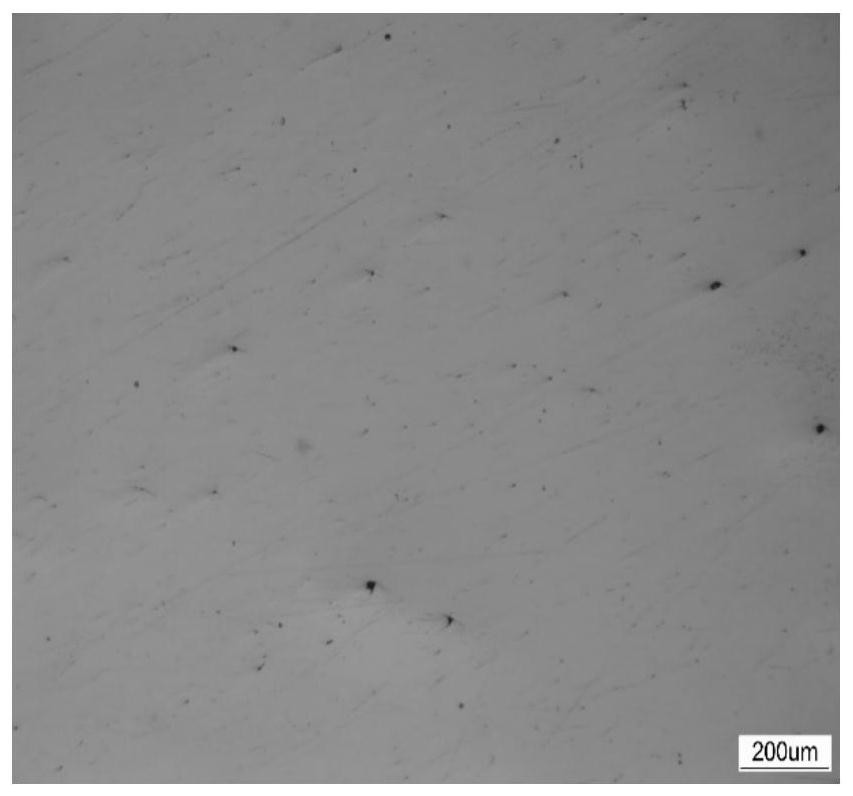

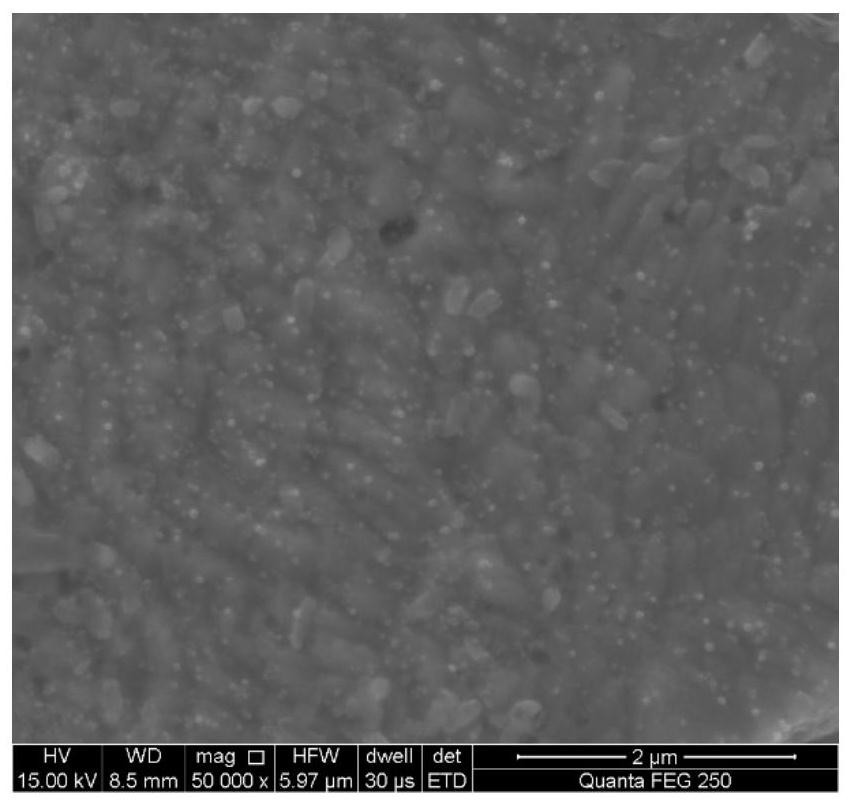

Economical high-toughness 800MPa-level automobile beam steel and production method thereof

The invention provides economical high-toughness 800MPa-level automobile beam steel. The economical high-toughness 800MPa-level automobile beam steel is prepared from the following components in percentage by weight: 0.07-0.11% of C, 1.55-1.80% of Mn, 0.05-0.20% of Si, less than or equal to 0.015% of P, less than or equal to 0.008% of S, 0.020-0.040% of Nb, 0.10-0.20% of Mo, 0.03-0.06% of Al, 0.09-0.13% of Ti, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The invention further provides a production method for the economical high-toughness 800MPa-level automobile beam steel, and the production method comprises the following steps: a top and bottom re-blowing converter process, LF refining, slag continuous casting, 1780mm mill rolling, and front-sectioncooling. The automobile beam steel has high strength, high toughness and low production cost. While used as an automobile structure part, the automobile beam steel can avoid occurrence of a cracking phenomenon in use in processes such as shearing, stamping, bending and welding.

Owner:ANYANG IRON & STEEL

Method for improving strength and conductivity of Cu-Cr-Nb alloy

ActiveCN112317755AIncrease solid solutionInhibit growthAdditive manufacturing apparatusConductive materialHydrogen contentElectro conductivity

The invention provides a method for improving strength and conductivity of a Cu-Cr-Nb alloy. According to the method, Cu-Cr-Nb alloy powder with high sphericity degree and less satellite powder is prepared through argon atomization, nitrogen low-temperature winnowing powder screening is adopted, and packaging is conducted in the reducing atmosphere; SLM forming is conducted in the atmosphere withthe hydrogen content being 1-3% and the balance of argon gas, so that oxygen content in the alloy is effectively reduced, and conductivity of the alloy is improved; and finally, a formed part is placed in a reducing atmosphere to be subjected to two-stage aging treatment, and the Cu-Cr-Nb alloy with high strength, high plasticity and high conductivity is obtained. The room-temperature tensile strength of the Cu-Cr-Nb alloy prepared through the method is not lower than 623 MPa, the elongation is not lower than 27%, the microhardness is not lower than 217 HV, the electric conductivity reaches 84% IACS, and the 700 DEG C high-temperature tensile strength is not lower than 140 MPa. The method has important application value in the field of high-strength and high-conductivity copper alloys.

Owner:CENT SOUTH UNIV

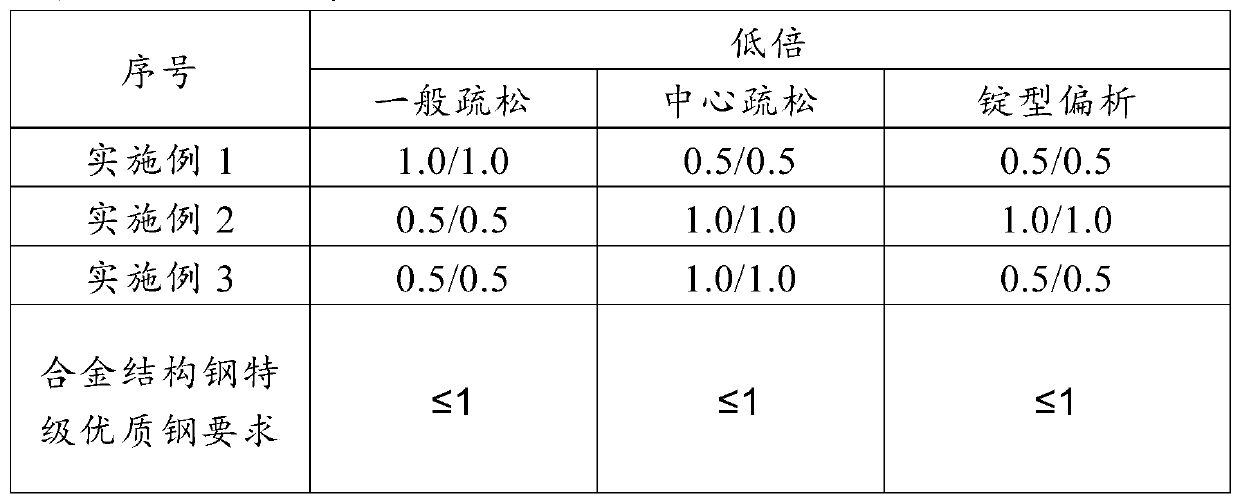

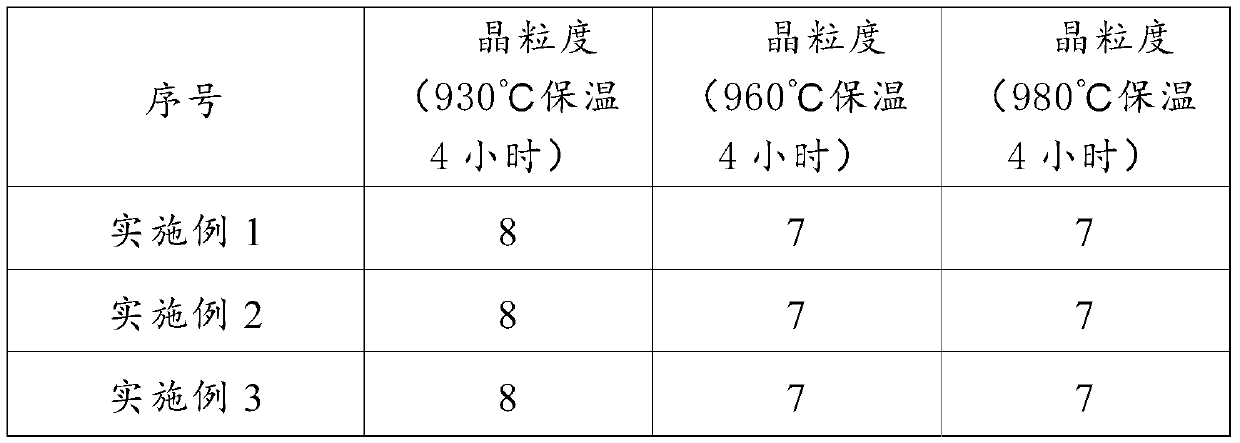

Narrow-hardenability high-temperature fine grain MnCr gear steel and preparation method thereof

InactiveCN110952022ANarrow hardenability bandwidthReduce distortionTemperature control deviceMetal rolling arrangementsFine grainHardenability

The invention discloses narrow-hardenability high-temperature fine grain MnCr gear steel. The narrow-hardenability high-temperature fine grained MnCr gear steel comprises the following components in percentage by weight: 0.19%-0.21% of C, 1.25%-1.35% of Mn, 0.20-0.30% of Si, 1.20%-1.30% of Cr, less than or equal to 0.020% of P, 0.010%-0.025% of S, 0.013%-0.02% of N, 0.034-0.050% of Al, less than or equal to 0.0015% of [O], less than or equal to 0.0002% of [H], and the balance iron and inevitable impurity elements. The invention further discloses a preparation method for the gear steel. The gear steel has the advantages of low cost, high-temperature fine grains, high purity, narrow hardenability, stable performance, and can ensure that the hardenability bandwidth of the steel is narrow, quality of the rolled surface of the steel is good, and the grains are small.

Owner:宝钢特钢长材有限公司

Gadolinium zirconate ceramic for curing TRPO simulated waste, and preparation method thereof

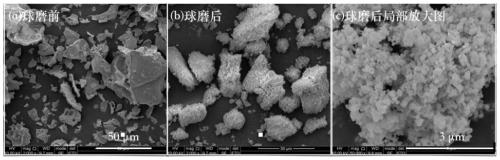

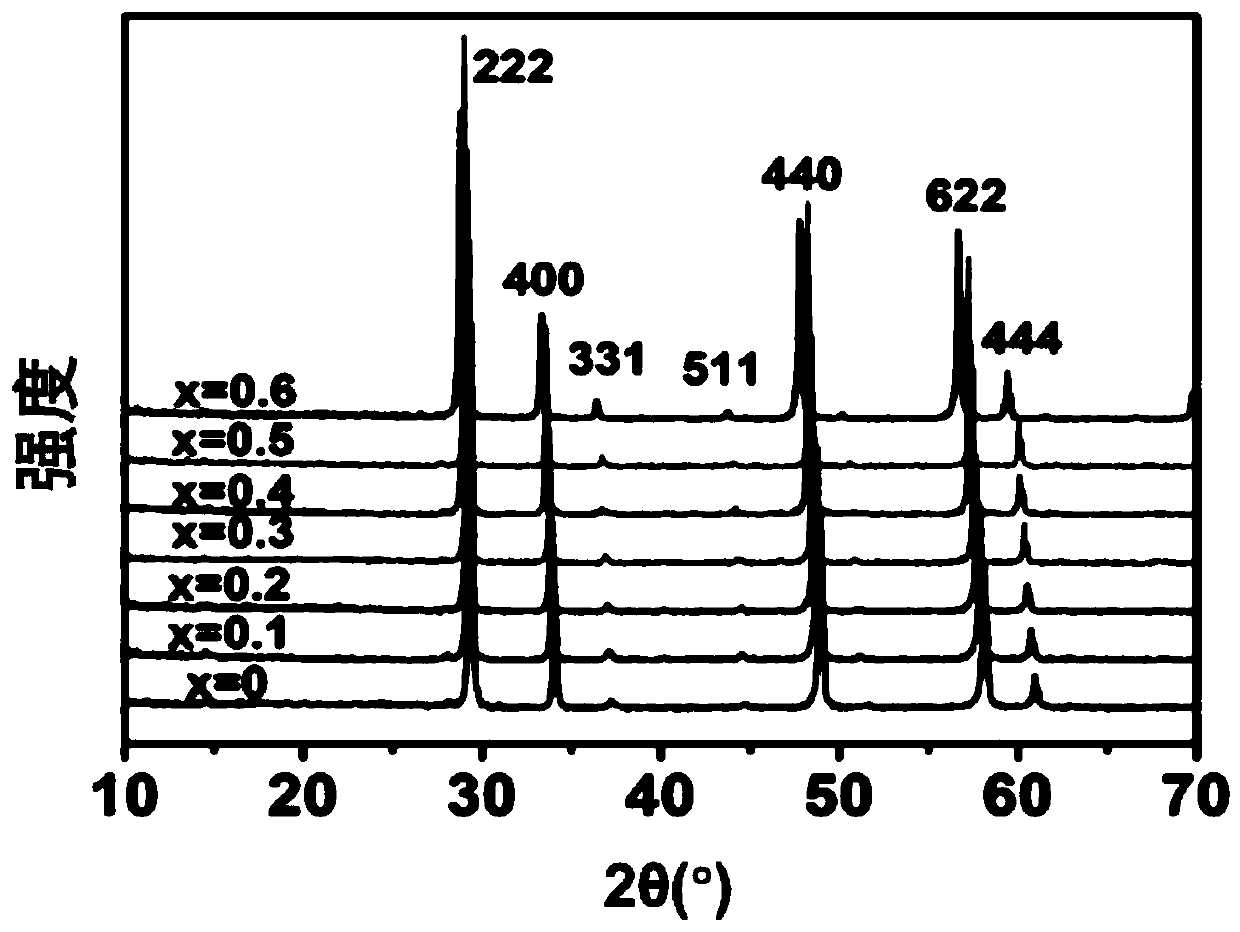

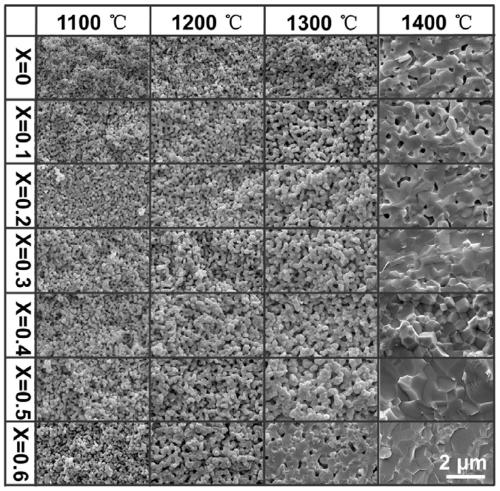

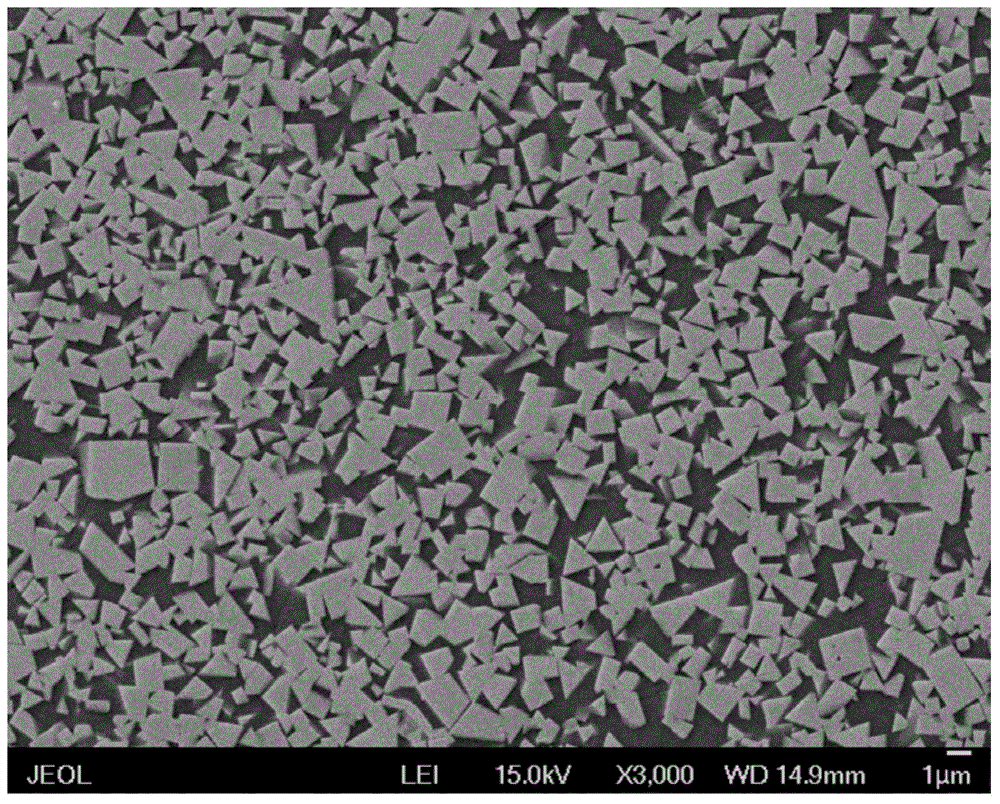

ActiveCN111039674AEasy to handleGood dispersionCeramic shaping apparatusRadioactive decontaminationZirconateGadolinium

The invention discloses a gadolinium zirconate ceramic for curing TRPO simulated waste, and a preparation method thereof. The preparation method comprises the following steps: (1) preparing precursorpowder by solid solution of radioactive elements in a liquid manner; (2) preparing a biscuit from the precursor powder obtained in step (1) by adopting dry pressing; and (3) preparing the gadolinium zirconate ceramic for curing the TRPO simulated waste by adopting a microwave sintering method. The prepared gadolinium zirconate ceramic for curing the TRPO waste has the advantages of no block cracking, high compactness and high hardness, and still keeps a single fluorite structure when the solid solution content reaches 60%. The preparation method provides a basic reference scheme for treating high-level radioactive waste liquids, especially curing actinide nuclides with long service life.

Owner:SICHUAN UNIV

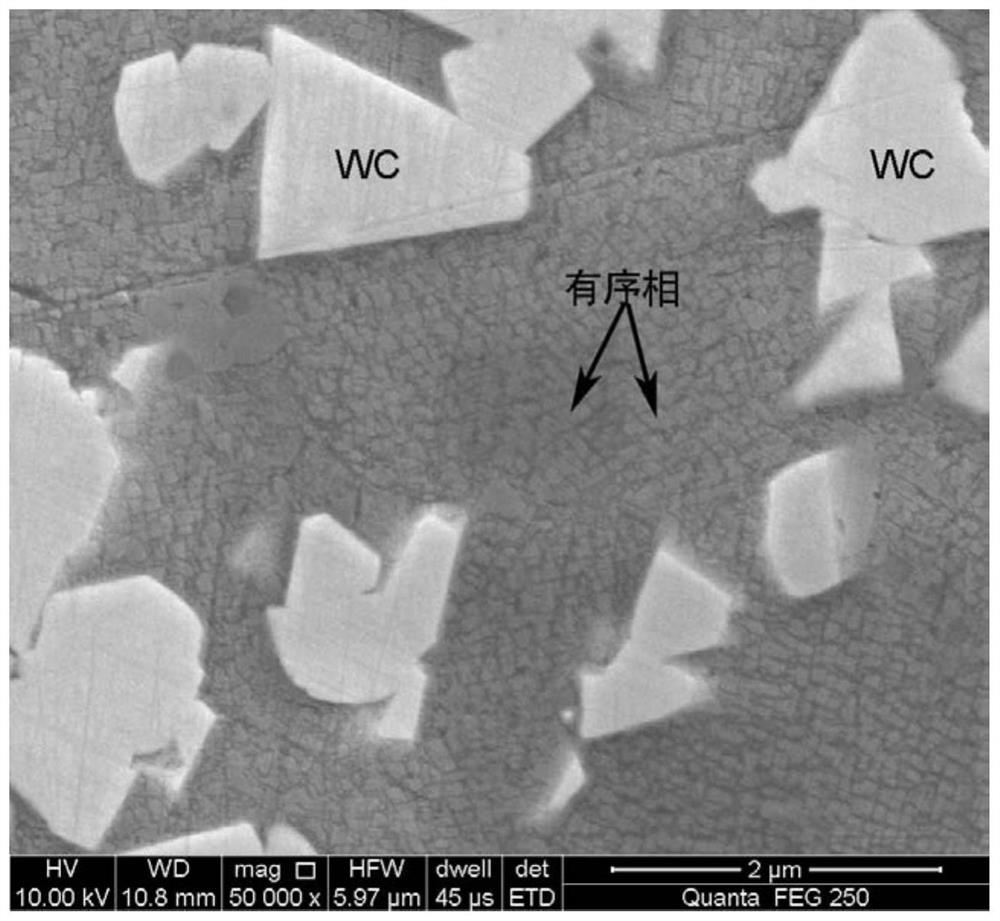

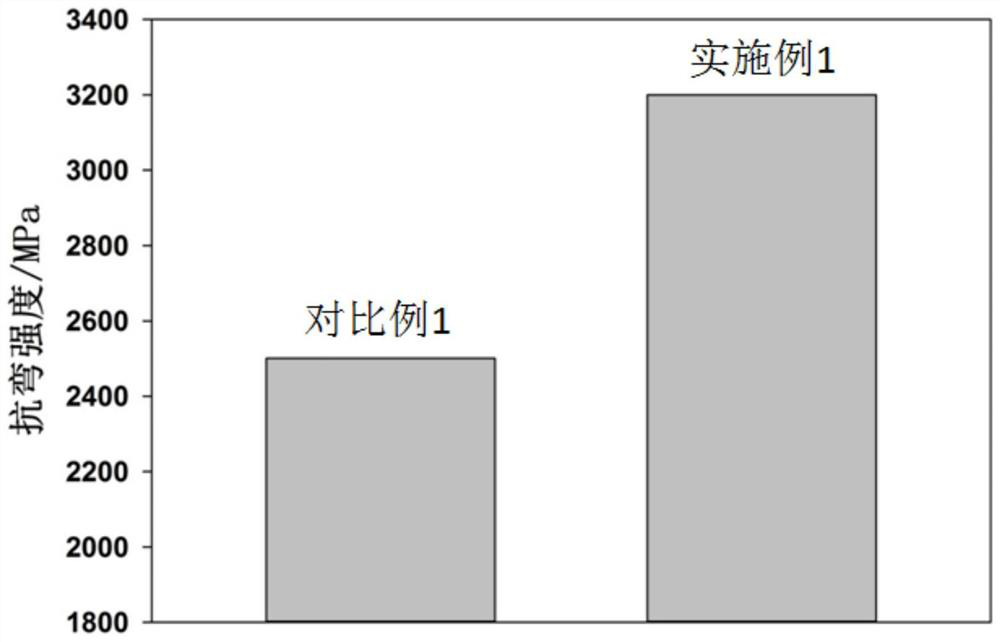

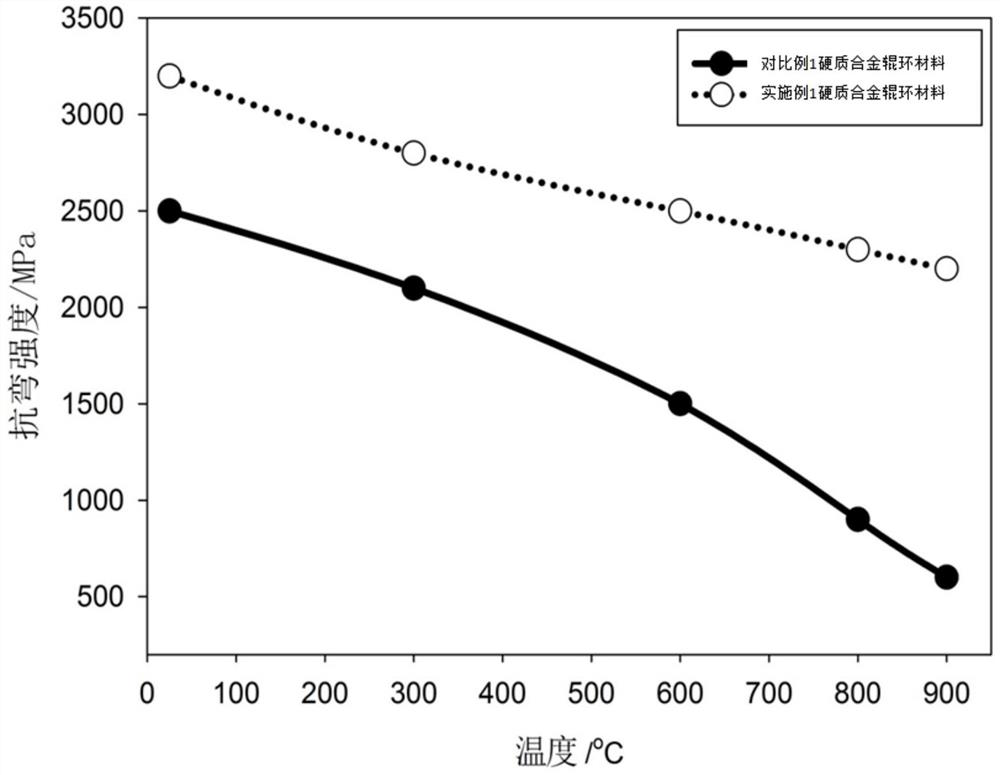

Hard alloy for cold heading mold and preparation method thereof

The invention discloses a hard alloy for a cold heading mold and a preparation method thereof. The preparation method comprises the following steps: mixing the following materials in percentage by weight: 22-28% of Co, 70.5-77.5% of WC and the balance of Cr3C2, wherein the Fsss particle size of WC is 1.0-6.0 mu m; and then, performing wet grinding, drying, performing pressure molding, sintering, quenching, and tempering. For a hard phase of the hard alloy prepared by the method disclosed by the invention, the average grain size is 1.2-2.0 mu m, the hardness is 84.0-86.0HRA, the bending strength is above 3100 MPa, and the alpha-Co content is high; the toughness and corrosion resistance of the alloy are favorable; Cr3C2 is almost completely dissolved in the Co phase, thus further strengthening the Co phase and reinforcing the stability of the alpha-Co phase; and transition of alpha-Co to epsilon-Co is inhibited in the use process, thus greatly increasing the comprehensive properties and service life of the hard alloy.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Low-precipitation super ferrite cast stainless steel and preparation method thereof

The invention relates to low-precipitation super ferrite cast stainless steel and a preparation method thereof. The stainless steel comprises components of 25%-30% of Cr, 1-4% of Mo, 0.03%-0.05% of Al, 0.03%-0.08% of Ce, less than or equal to 0.0020% of C, less than or equal to 0.0031% of N, less than or equal to 0.0020% of S, less than or equal to 0.0090% of P, and the balance of Fe. During preparation, stainless steel ingots with corresponding content are taken, corresponding amounts of Al and Ce are added successively after smelting, refining is completed, and low-precipitation super ferrite stainless steel castings are prepared. By reducing the oxygen content of a matrix and adding rare earth Ce for microalloying treatment, the precipitation tendency of sigma phase of the stainless steel is obviously reduced, and the elongation and corrosion resistance of the super ferrite cast stainless steel castings are greatly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

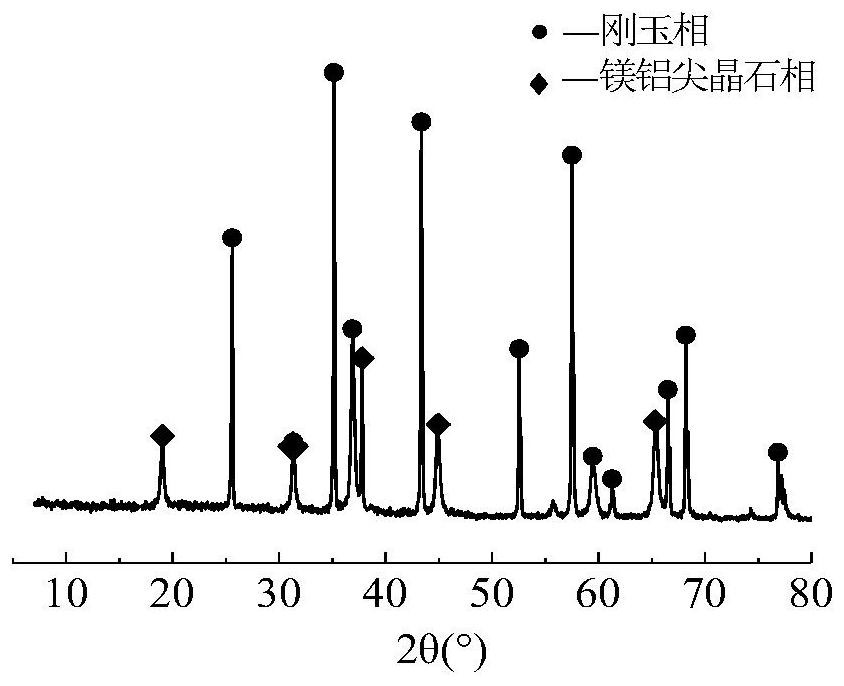

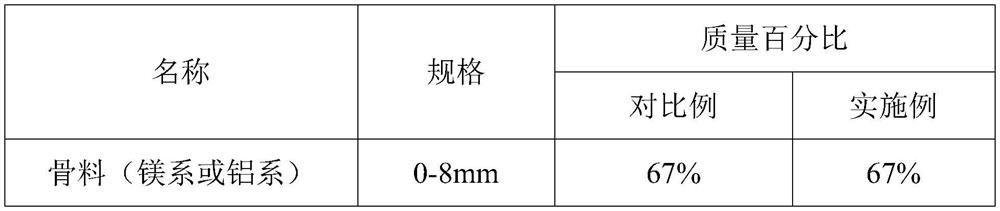

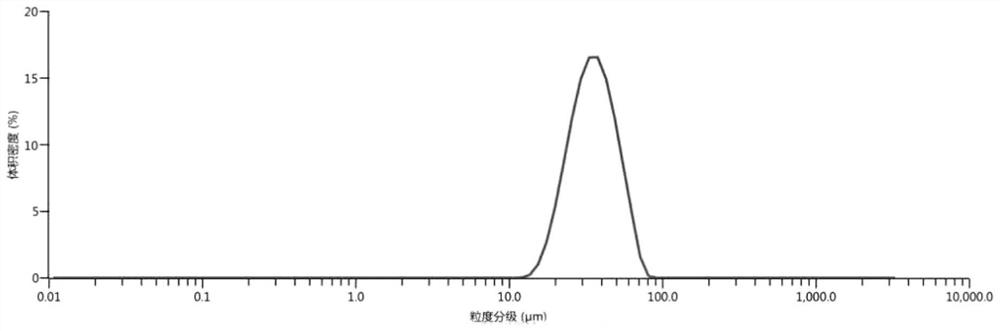

Method for synthesizing aluminum-rich spinel through low-temperature solid-phase reaction

The invention belongs to the field of refractory materials, and particularly relates to a method for synthesizing aluminum-rich spinel through a low-temperature solid-phase reaction. The method specifically comprises the following steps: firstly, mixing 80-90 parts by weight of an aluminum oxide raw material, 10-20 parts by weight of a magnesium oxide raw material, 0.5-2 part by weight of magnesium aluminate spinel micro powder and 0.5-3 part by weight of an additive, and co-grinding the materials until the particle size of the raw materials is in a range of 5-20 microns; transferring the co-ground powder into a high-temperature kiln, heating to 1000-1500 DEG C, and calcining; and finally, keeping for 3-12 hours at the calcining temperature, and implementing naturally cooling or quickly air-cooling to room temperature to obtain the aluminum-rich spinel. A low-temperature synthesis process is adopted, the aluminum-rich spinel synthesized through low-temperature calcination is fine in grain and high in lattice defect degree, and meanwhile the prepared aluminum-rich spinel powder is high in activity. The prepared aluminum-rich spinel does not contain beta aluminum oxide or impurity phases such as free magnesium oxide, and the content of aluminum oxide in the aluminum-rich spinel reaches 80-90%. When the prepared aluminum-rich spinel powder is used in a corundum spinel castable, the aluminum-rich spinel powder has the advantages of high sintering strength and strong slag penetration resistance.

Owner:湖北斯曼新材料股份有限公司

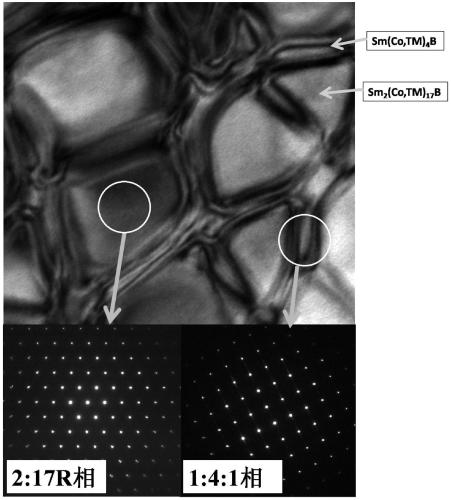

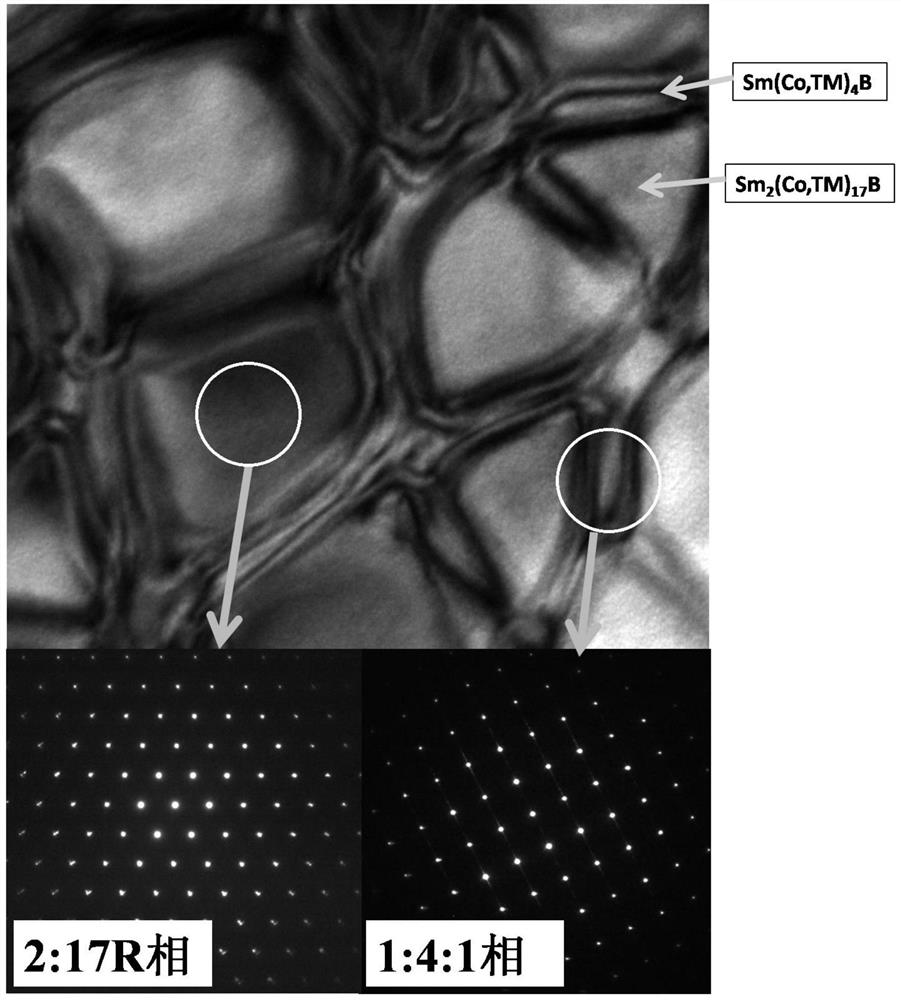

(2:17)-type SmCoCuFeZrB sintered permanent magnet and preparation method thereof

ActiveCN111180157AImprove magnetic propertiesOptimize high temperature comprehensive magnetic propertiesIncreasing energy efficiencyInductances/transformers/magnets manufactureCrystal structureSamarium

The invention discloses a (2:17)-type SmCoCuFeZrB sintered permanent magnet. The element composition formula of the sintered permanent magnet is Smx(Co1-a-b-c-dFeaCubZrcBd)z, wherein the symbols x, a,b, c, d and z in the formula represent composition ranges of limited elements, and the atomic number ratio of x to a to b to c to d to z is 1:(0.01-0.4):(0-0.03):(0.01-0.05):(0.01-0.04):(6.8-8.4); the magnet has a cellular structure, a cell wall phase is an Sm(CoFeCu)4B phase with a 1:4:1 type crystal structure, and an intracellular main phase is an Sm2(CoFe)17B phase. The invention also discloses a preparation method of the sintered permanent magnet, and the density and orientation degree of the sintered permanent magnet prepared by adoption of the method are incomparable to those of nanocrystalline and amorphous magnets; a heat treatment process, an oxygen control process and the like are matched, uncontrolled decomposition of the phase of the magnet in the heat treatment process is effectively inhibited, effective regulation and control of the microstructure and phase composition are achieved, the adding amount of the Fe element in the sintered (2:17)-type samarium-cobalt magnet isincreased, the intrinsic coercive force of the magnet under the high Fe content is improved, and then the maximum magnetic energy product of the sintered (2:17)-type samarium-cobalt magnet is increased.

Owner:CHINA JILIANG UNIV +1

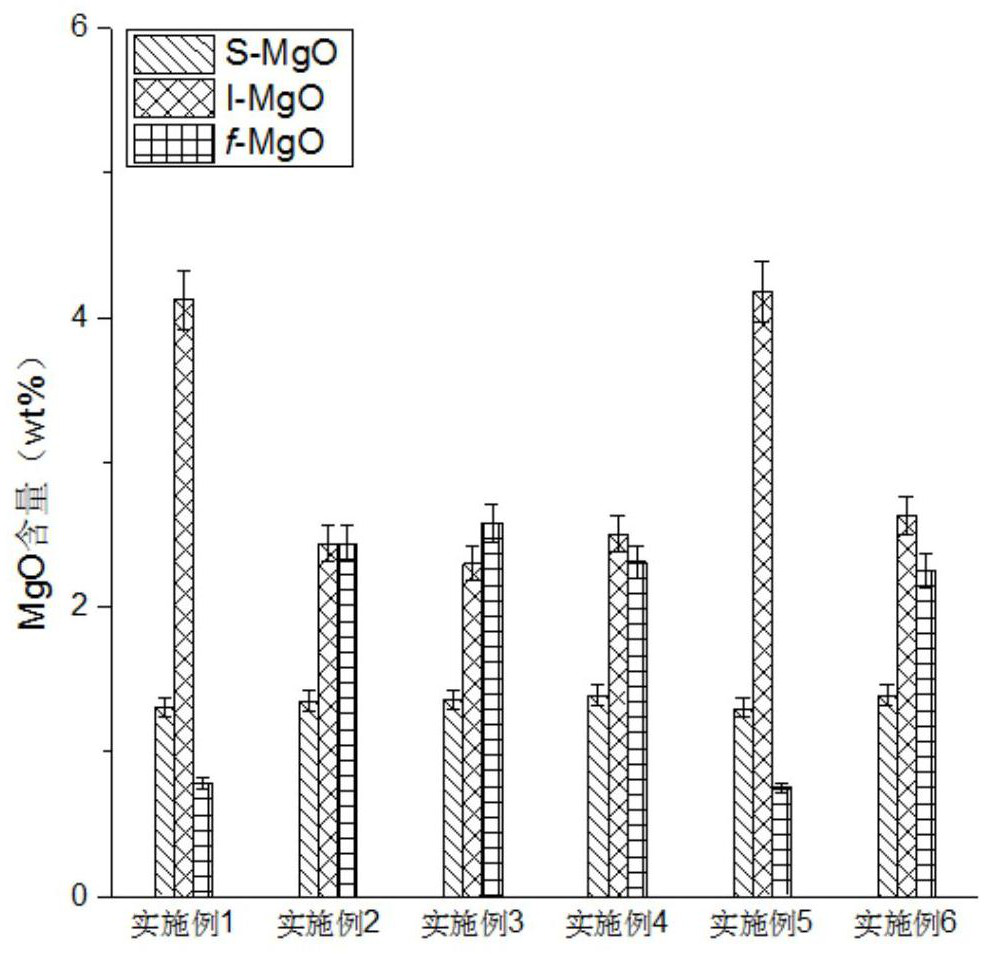

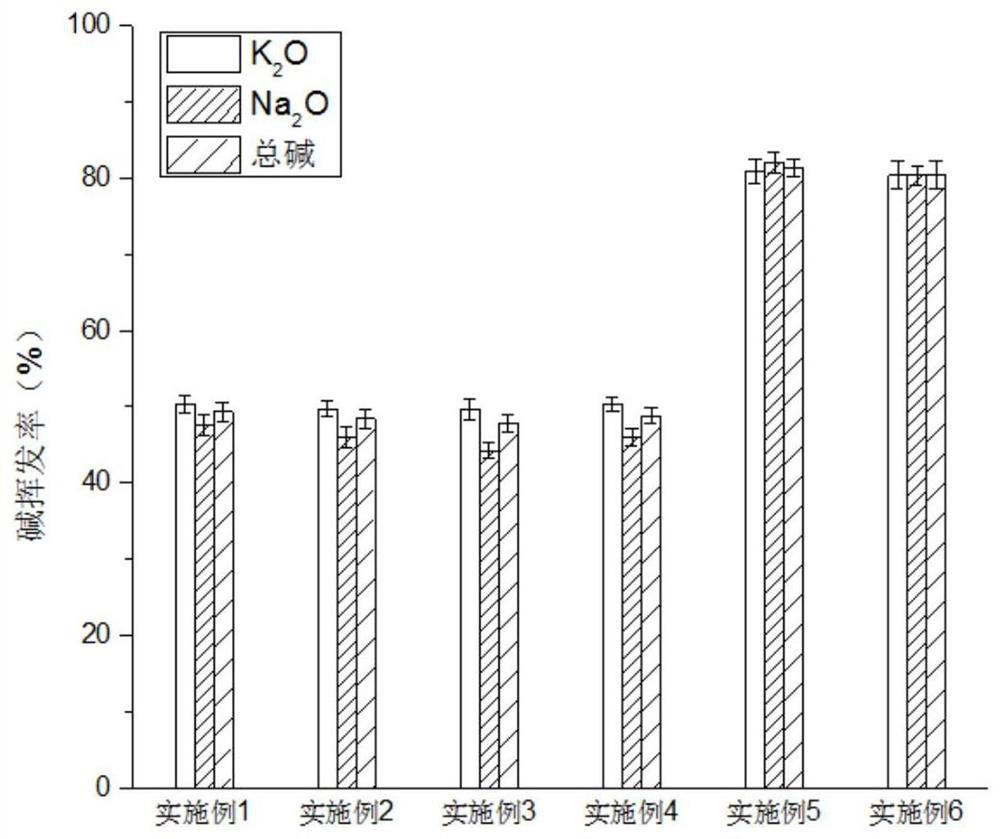

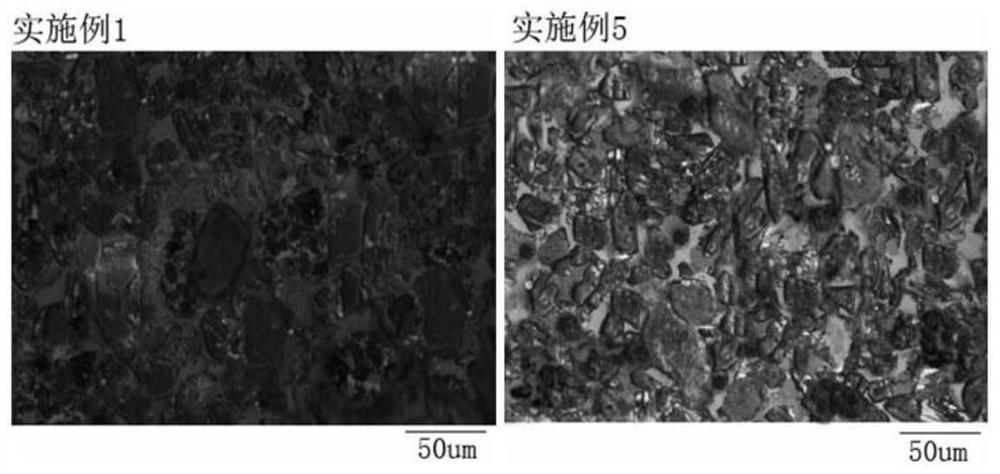

Method for preparing cement clinker by utilizing high-magnesium and high-alkali limestone

ActiveCN111943538AEnhancement and effectIncrease solid solutionCement productionSlagPhysical chemistry

The invention provides a method for preparing cement clinker from high-magnesium and high-alkali limestone, and belongs to the technical field of cement generation. The cement clinker is prepared fromthe following raw materials: high-magnesium and high-alkali limestone series, high-grade limestone, sandstone, slag and bituminous coal ash; in addition, a composite mineralizing agent, comprising afluorine-sulfur mineralizing agent and potassium humate, is also added. The method for preparing the cement clinker from the high-magnesium and high-alkali limestone has the advantages of high efficiency, environmental protection, low cost and high quality.

Owner:保定太行和益环保科技有限公司

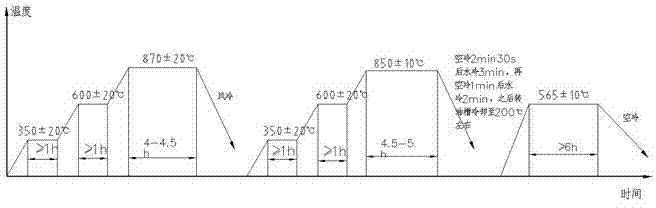

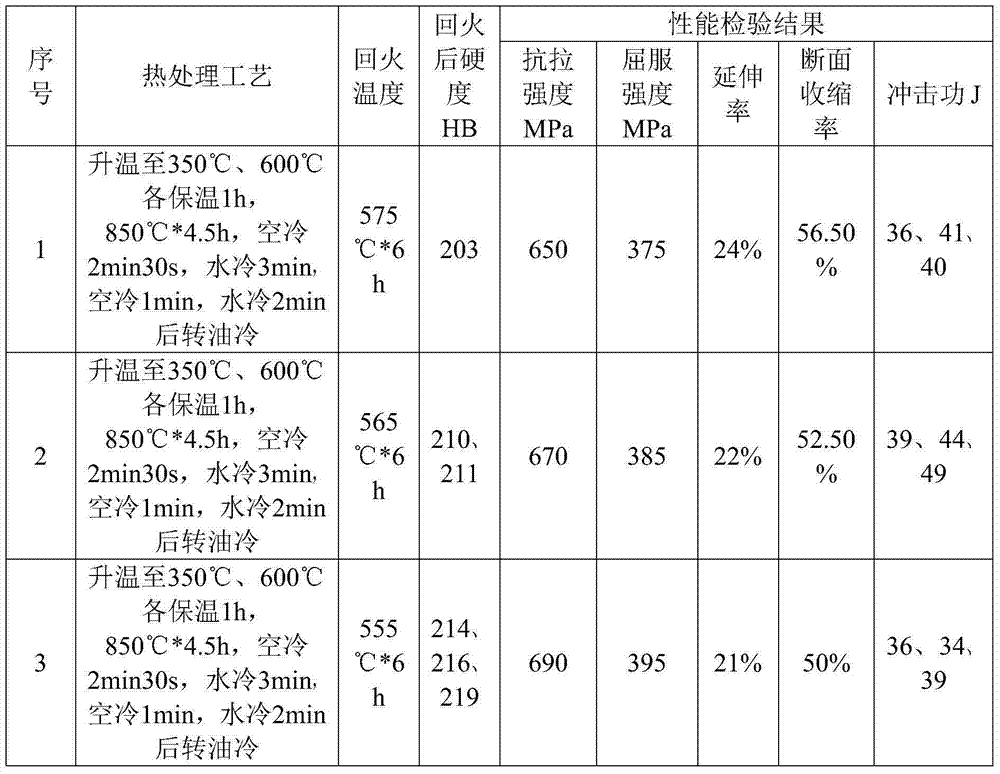

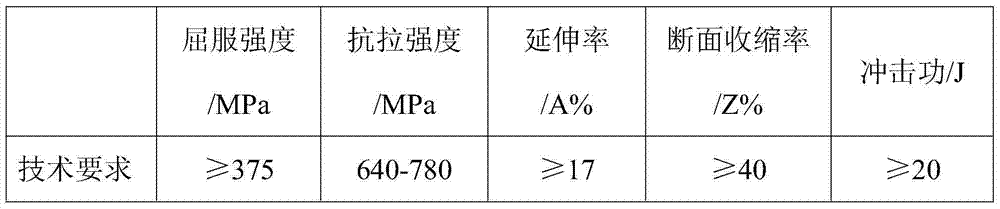

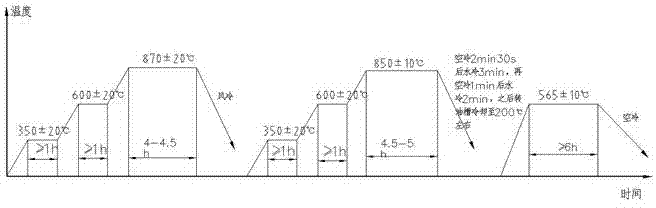

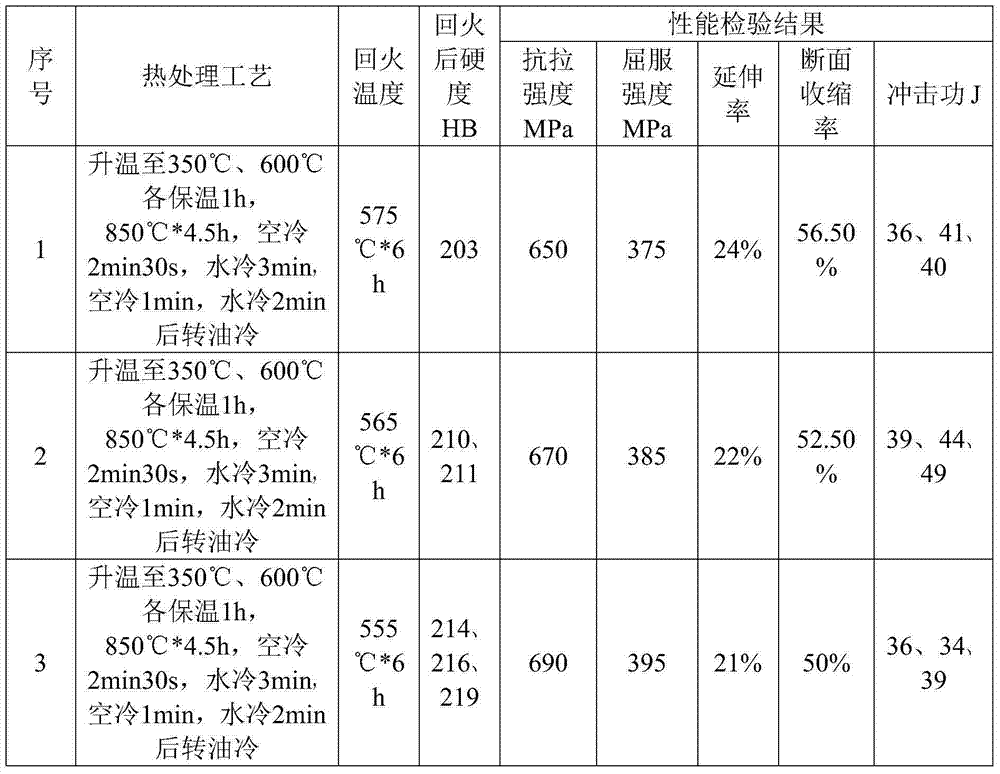

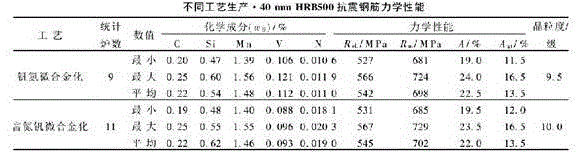

Medium-carbon steel large diesel engine output shaft hardening and tempering process

ActiveCN103614521AIncrease solid solutionImprove surface quenching hardnessFurnace typesHeat treatment furnacesQuenchingDiesel engine

The invention discloses a medium-carbon steel large diesel engine output shaft hardening and tempering process. The process comprises the following steps: (1) normalizing: filling an output shaft in a furnace, heating to the temperature of 350 + / -20 DEG C and 600+ / -20 DEG C in a staged way, preserving the heat, hanging out the output shaft, blowing cold air to cool the output shaft to room temperature by using a fan; (2) quenching for three times: filling the output shaft into the furnace again, heating to the temperature of 350 + / -20 DEG C, 600+ / -20 DEG C and 850+ / - 10 DEG C in a staged way; cooling by air and then cooling in a water tank, cooling by the air again and cooling by water again, and then cooling in an oil tank; (3) high-temperature tempering: tempering at the temperature of 565+ / - 10 DEG C, preserving the temperature and cooling by the air out of the furnace. By the process, the surface martensite transformation speed at the first stage of a large shaft forging is improved, and the surface quenching hardness of the large shaft forging is improved by adopting the reasonable quenching cooling mode of air cooling-water cooling-air cooling-water cooling-oil cooling. The difference between the inside temperature and the outside temperature of the large shaft forging is reduced by the air cooling adopted by the process, and the cracking tendency of the large shaft forging is effectively reduced.

Owner:CSSC MARINE POWER

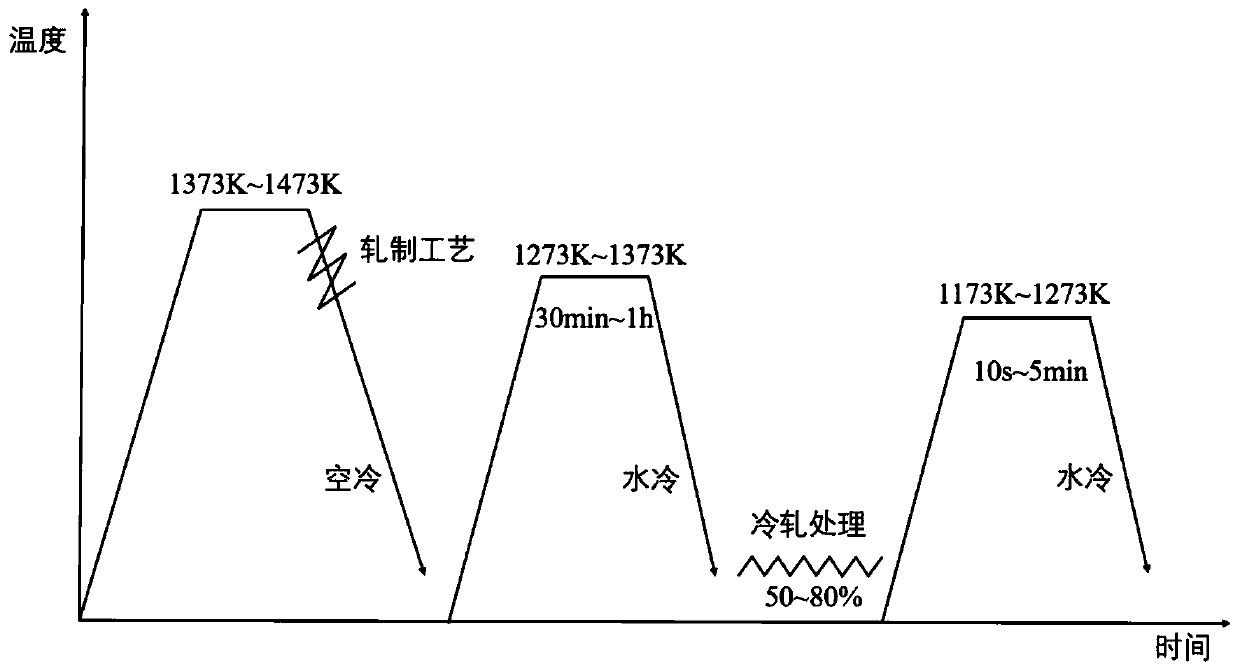

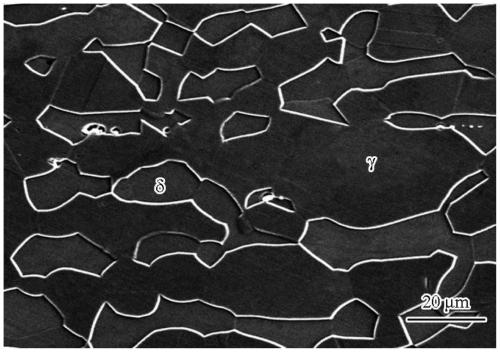

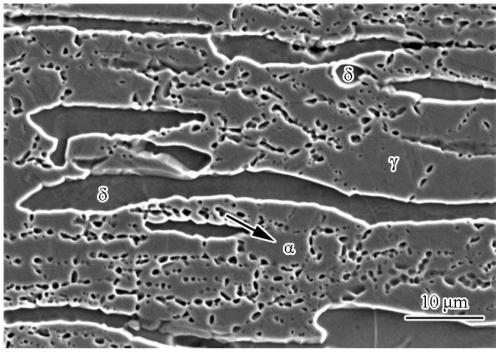

Heat treatment process for improving mechanical property of Fe-Mn-Al-C dual-phase steel by utilizing gamma-to-alpha allotropy transformation

ActiveCN109694997AImproved two-phase deformation coordinationIncrease solid solutionSteel platesDouble phase

The invention discloses a heat treatment process for improving the mechanical property of Fe-Mn-Al-C dual-phase steel by utilizing gamma-to-alpha allotropy transformation, and belongs to the technicalfield of automobile steel. The heat treatment process is characterized in that steel is heated to 1273-1373 K after undergoes hot rolling, the temperature is kept for 30 min-1 h, then water cooling is performed to enable to the temperature to reach the room temperature, then cold rolling treatment is performed, the cold deformation amount is 50-80%; the two-phase region temperature is selected for annealing treatment on a cold-rolled steel plate, the annealing temperature is not higher than the heat preservation temperature before cold rolling, and the annealing time is 10 s-5 min; a two-phase structure with transformation of gamma to alpha occurred at the austenite grain boundary is obtained through the heat treatment process, the gamma-phase orientation and the alpha-phase orientation meet the K-S relationship, meanwhile, the solid solution amount of the C in the austenite is increased, and the yield strength and the toughness of the steel are improved; the process is the heat treatment process for improving the strength and plasticity of the dual-phase steel at the same time, and the quality of the Fe-Mn-Al-C double-phase high-aluminum light steel is comprehensively optimized and improved.

Owner:SHANGHAI UNIV

A method for preparing high-solubility ultra-fine grain high-speed steel by using electric pulse

ActiveCN109825689BHigh hardnessImprove toughnessHeat treatment process controlAustenite grainCarbide

The invention discloses a method for preparing high-solid-solubility ultrafine grain high-speed steel through electric pulses. The method includes the steps that high-speed steel is subjected to conventional austenitizing and then quenched and tempered; then the two ends of the steel are clamped between electrodes of electric pulse equipment, the high-speed steel is discharged in the air environment, the temperature of the material rises to the austenitizing temperature region through pulse currents, austenite grains are ultrafine, and dissolution of carbide is promoted; after electric pulse discharge is completed, quenching is completed through an automatic quenching device; and finally the high-solid-solubility ultrafine grain high-speed steel in a quenched state through electric pulse treatment is tempered three times, and the high-speed steel with excellent comprehensive mechanical performance is obtained. By means of the method, the technical bottleneck that in the traditional heat treatment process, high-speed steel grain refinement and carbide dissolution promotion cannot be taken into account is solved, and the double effects that the high-speed steel austenite grains are ultrafine, and the dissolution quantity of the carbide is increased are achieved. The method is short in technological process, energy saving and high efficiency are achieved, and the hardness and thetoughness of the high-speed steel can be simultaneously improved.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

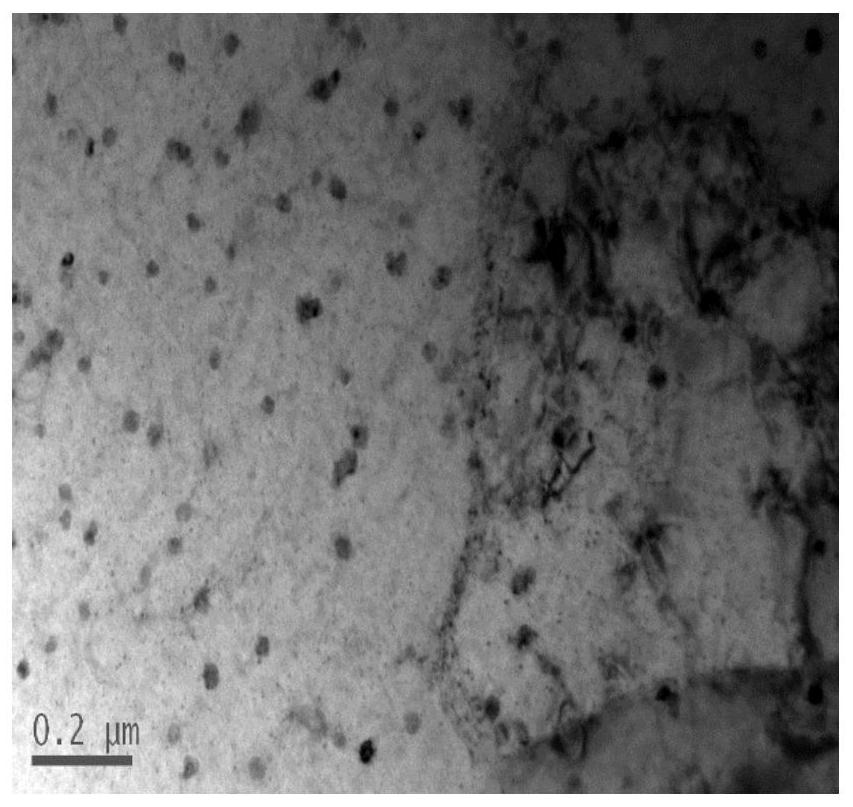

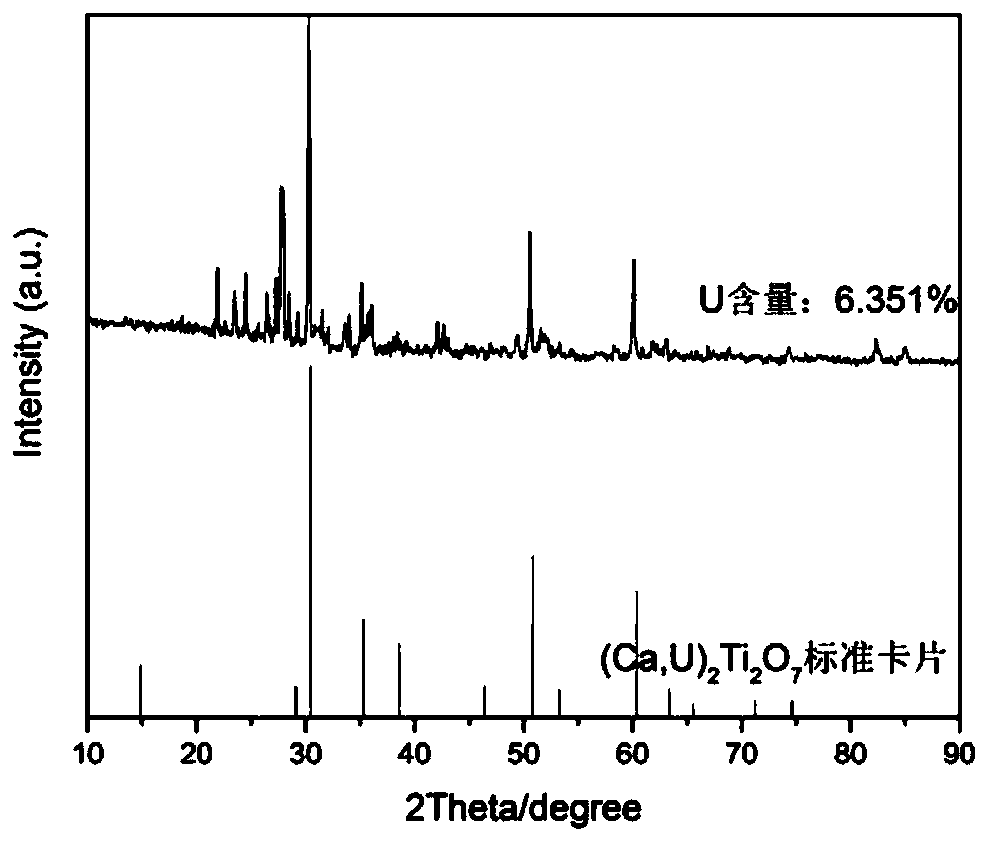

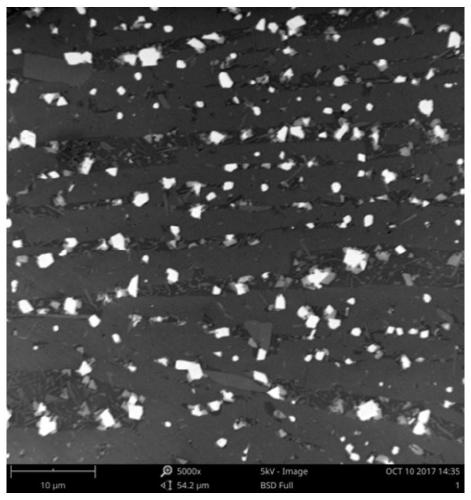

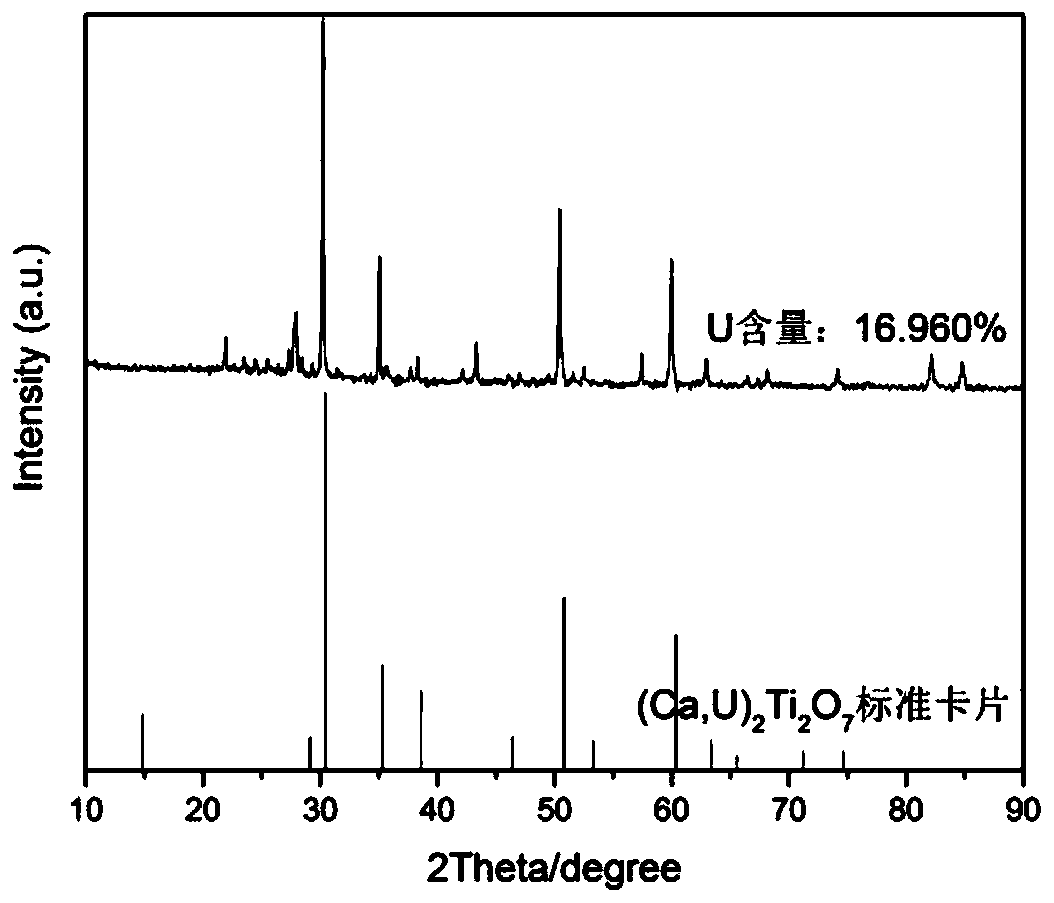

Preparation method of borosilicate glass ceramic solidified body containing uranpyrochlore

InactiveCN109761500AFew ingredientsReduce the amount of solid solutionRadioactive wasteHigh intensity

The invention relates to the technical field of radioactive waste treatment, in particular to a preparation method of a borosilicate glass ceramic solidified body containing uranpyrochlore. The preparation method comprises the following steps of respectively performing wet mixing drying and pre-sintering, gradual melting, sintering and quenching with SiO2, Al2O3, Na2CO3, B2O3, CaF2, CaO, U3O8 andTiO2 as raw materials to prepare the borosilicate glass ceramic solidified body. The preparation method has the advantages that the crystallization rate of the uranpyrochlore in glass can be regulatedand controlled; the ingredients remained by nuclide in the glass phase can be reduced; the accommodating capacity of nuclide U in the ceramic phase can be improved; the accommodating capacity of thenuclide U in the whole solidified body can be improved; the prepared borosilicate glass ceramic solidified body containing uranpyrochlore has the advantages of uniform crystal grain distribution, hightissue compactness and high intensity.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of cemented carbide for cold heading die and preparation method thereof

The invention discloses a hard alloy for a cold heading mold and a preparation method thereof. The preparation method comprises the following steps: mixing the following materials in percentage by weight: 22-28% of Co, 70.5-77.5% of WC and the balance of Cr3C2, wherein the Fsss particle size of WC is 1.0-6.0 mu m; and then, performing wet grinding, drying, performing pressure molding, sintering, quenching, and tempering. For a hard phase of the hard alloy prepared by the method disclosed by the invention, the average grain size is 1.2-2.0 mu m, the hardness is 84.0-86.0HRA, the bending strength is above 3100 MPa, and the alpha-Co content is high; the toughness and corrosion resistance of the alloy are favorable; Cr3C2 is almost completely dissolved in the Co phase, thus further strengthening the Co phase and reinforcing the stability of the alpha-Co phase; and transition of alpha-Co to epsilon-Co is inhibited in the use process, thus greatly increasing the comprehensive properties and service life of the hard alloy.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

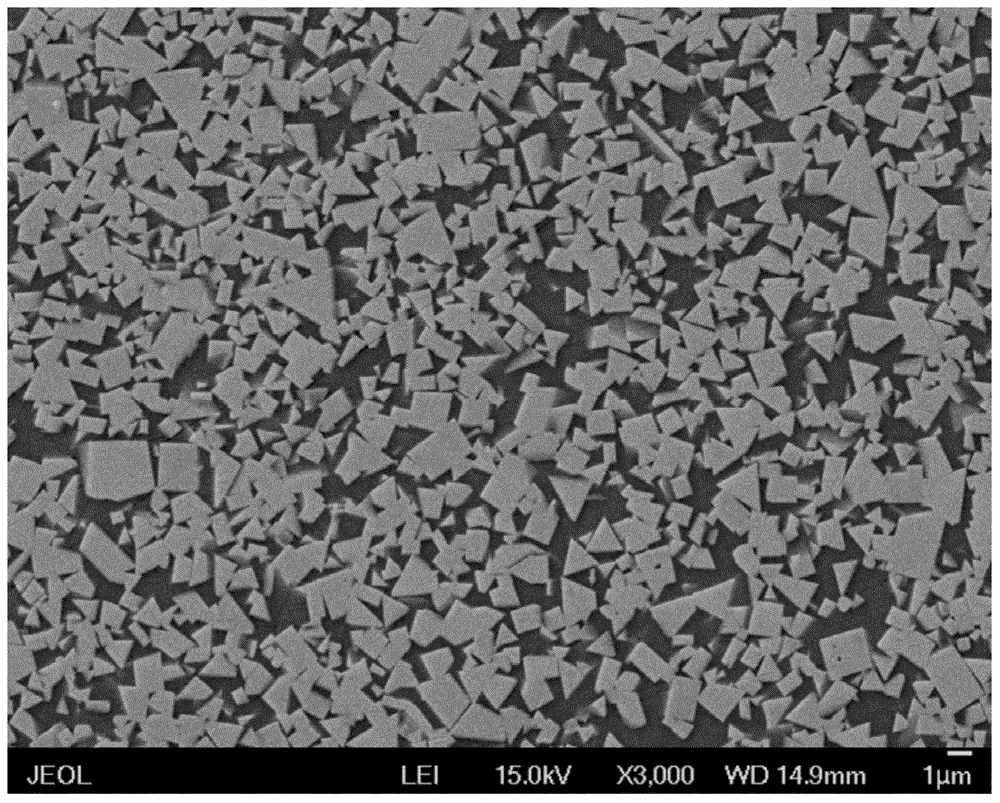

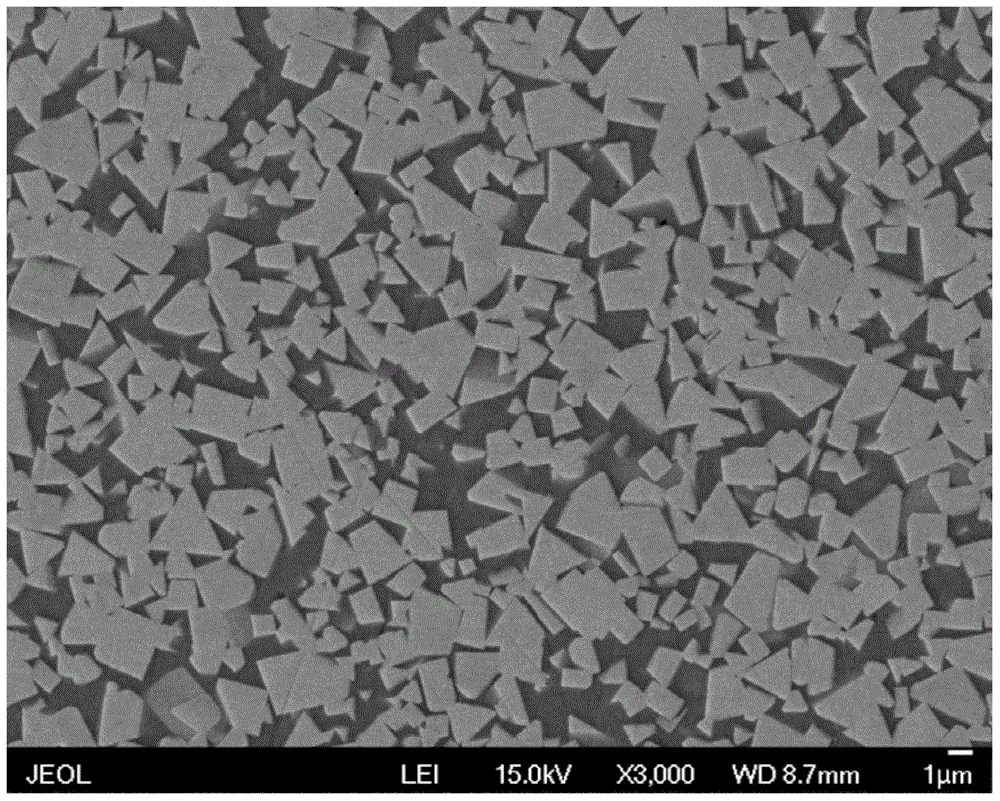

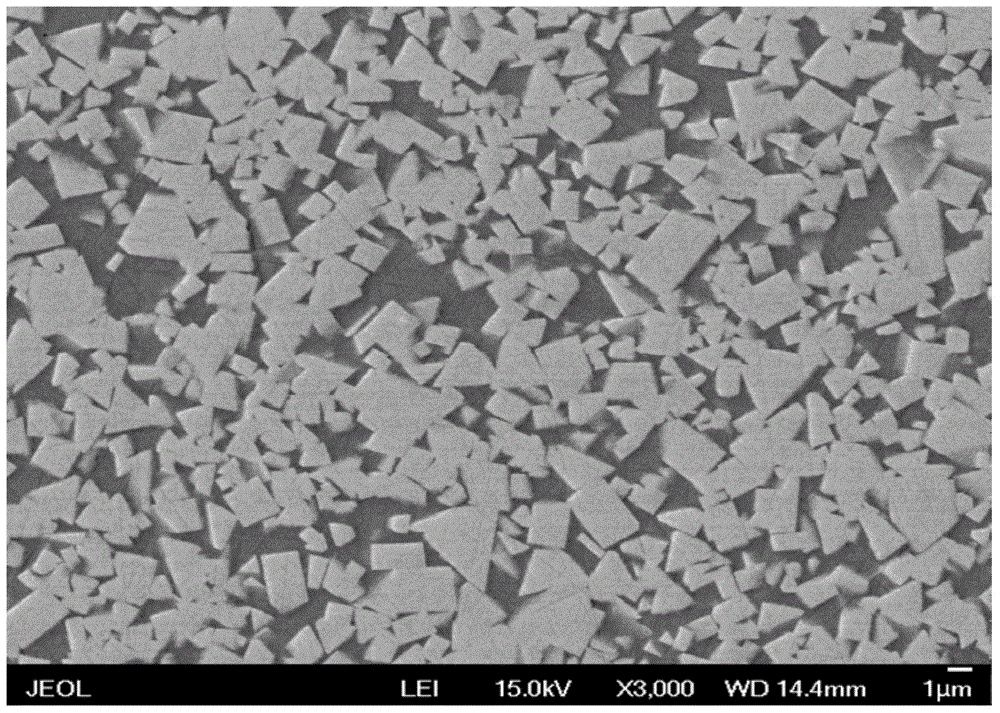

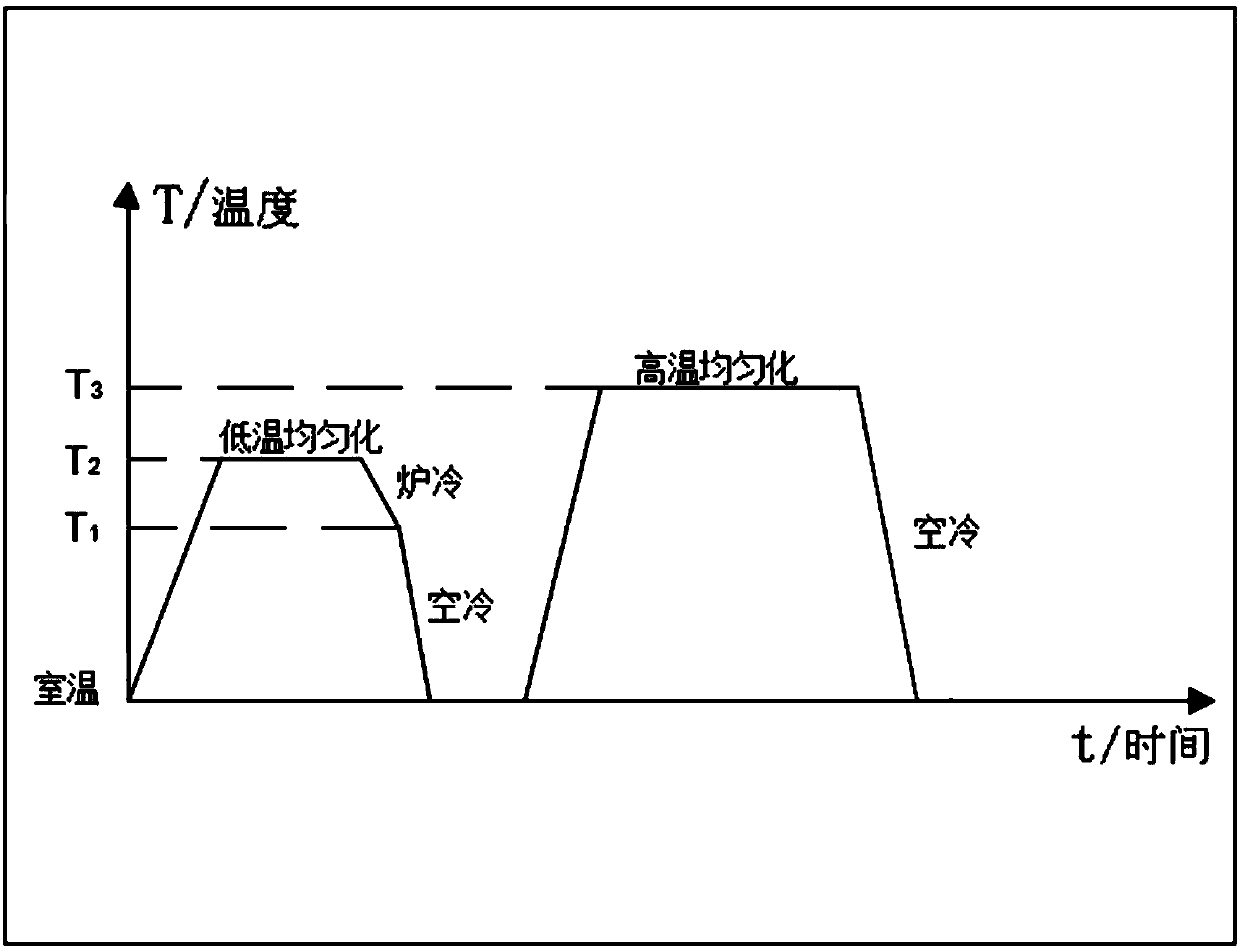

A Homogenization Heat Treatment Process for Eliminating Al-cu-mg-si-mn Alloy Casting Crystalline Phase

The invention provides a homogenizing heat treatment technology for eliminating the Al-Cu-Mg-Si-Mn alloy casting crystal phase. The homogenization technology comprises the steps that an Al-Cu-Mg-Si-Mn alloy ingot is placed into a furnace, is heated to 470-480 DEG C at the speed of 15-20 DEG C / min, is subjected to heat preservation for 8-12h, then is subjected to furnace cooling to 250-300 DEG C, and is subjected to air cooling to the room temperature; then the ingot is placed into a heat preservation furnace with the temperature being 510-520 DEG C and subjected to heat preservation for 18-24h; and finally, the ingot is subjected to air cooling to the room temperature. According to the homogenizing heat treatment technology, the homogenization problem that Al-Cu-Mg series alloy ingots containing a high amount of Si, Fe and Mn are high in melting point, so that a complex second phase is difficult to eliminate is solved, the technology is simple and convenient to operate, the feasible homogenizing heat treatment scheme is provided for the various Al-Cu-Mg series alloy ingots containing a high amount of Si, Fe and Mn, and industrial production is facilitated.

Owner:CENT SOUTH UNIV

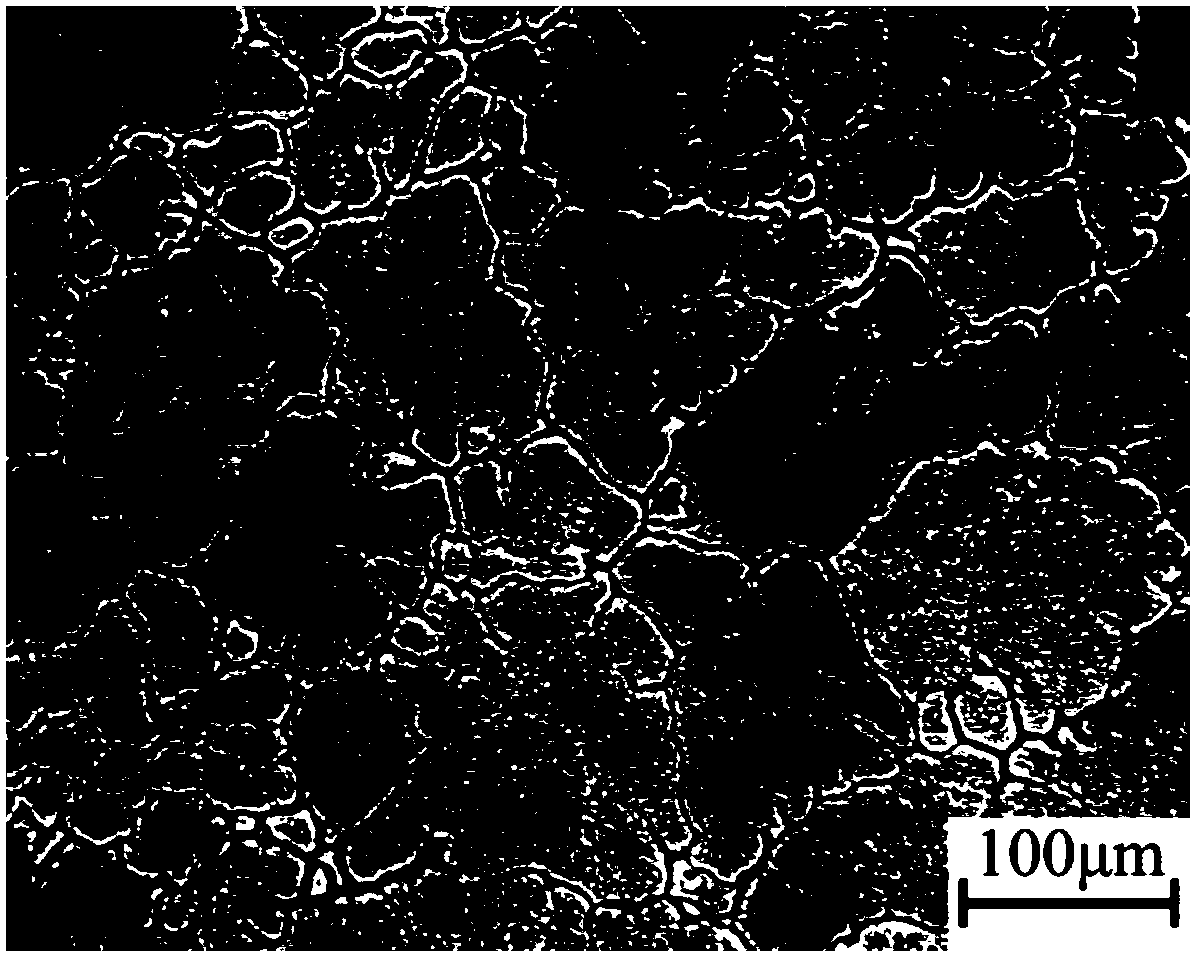

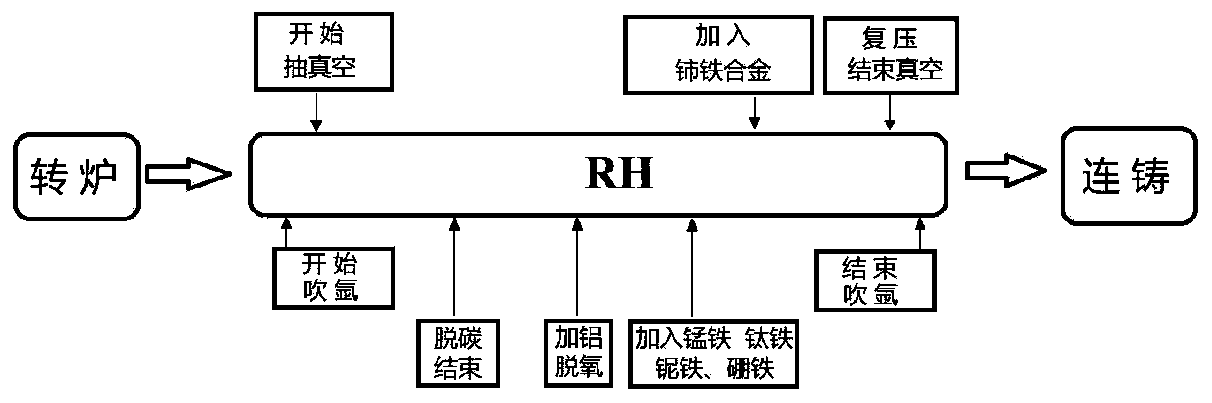

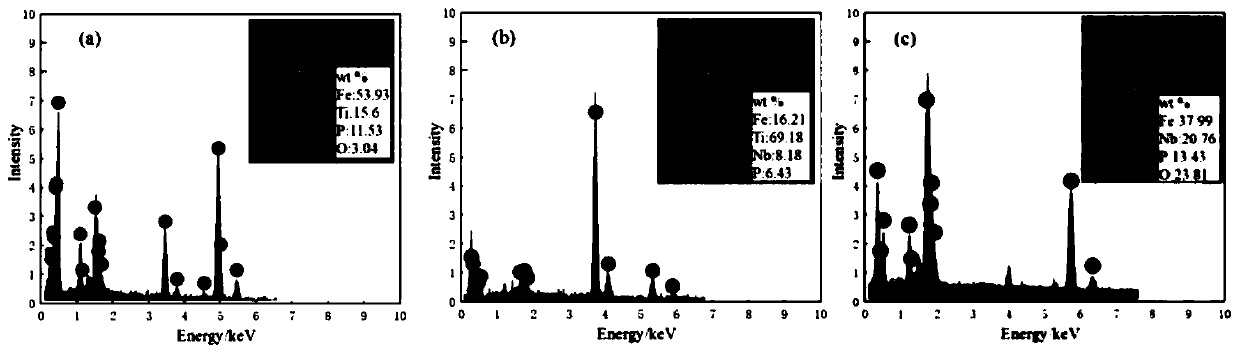

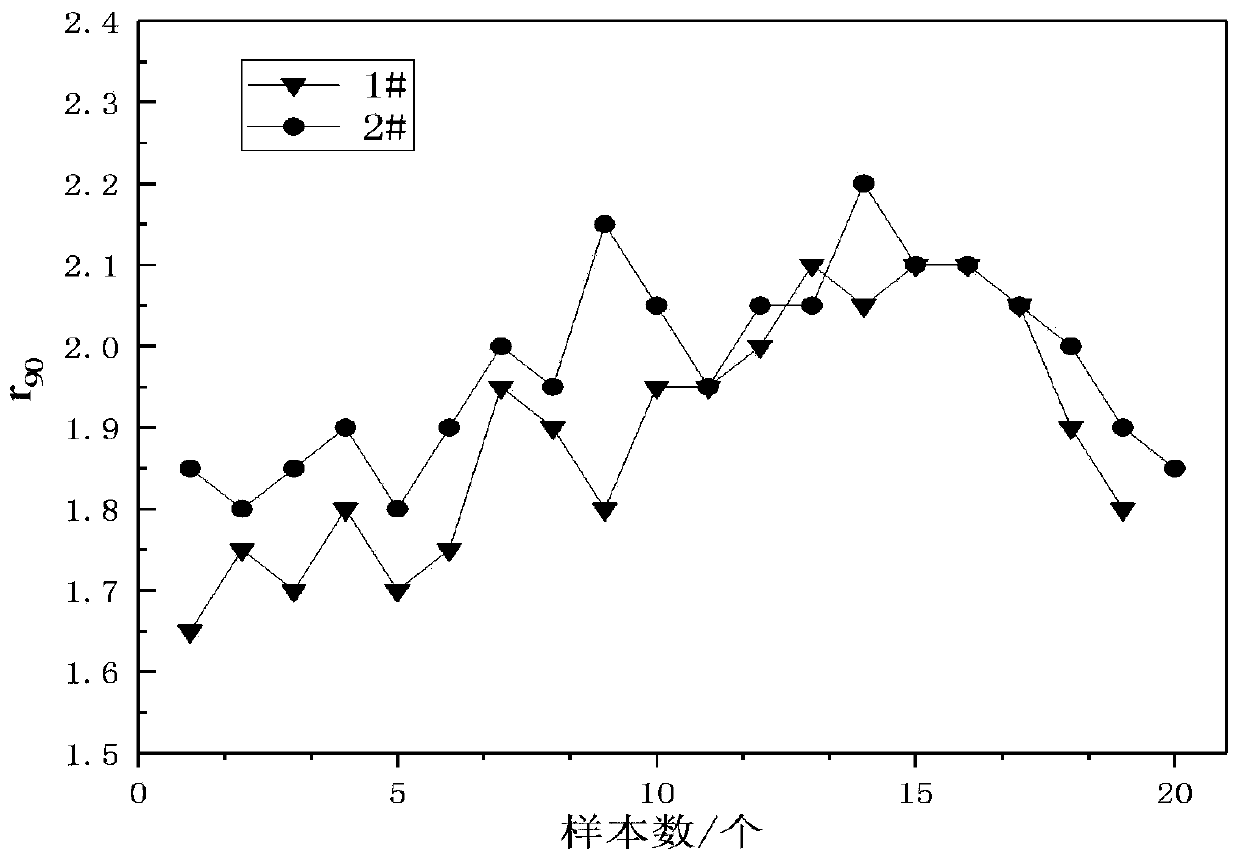

Method for improving solid solution quantity of P of phosphorus containing high-strength IF steel through rare earth treatment

InactiveCN111560497AIncrease solid solutionImprove the effect of solid solution strengtheningAluminateFree energies

The invention discloses a method for improving the solid solution quantity of P of phosphorus containing high-strength IF steel through rare earth treatment. The method is characterized by comprises the steps that at the treatment last stage of the RH refining procedure, an alloy is added in the RH vacuum treatment process, when circulating is carried out for 5 min after alloying is finished, a rare earth cerium-iron alloy is added, and the Ce content of molten steel reaches 18 ppm. By means of the method, rear earth Ce is added into steel, Ce and active O in steel are combined to have lower gibbs free energy, and CeAlO3, Ce2O2S, Ce2O3 and other rare earth oxide, rare earth aluminate and rare earth oxysulfide can be generated extremely easily; and the rear earth Ce suppresses precipitationof the P element and the Fe(Nb+Ti)P phase, the solid solution quantity of the P element in steel can be effectively increased, the solid solution enhancement effect of the P element in the high-strength IF steel can be improved easily, and therefore the r90 value of the forming performance index can be improved easily, and the phosphorus containing high-strength IF steel has better punching performance.

Owner:BAOTOU IRON & STEEL GRP

High-strength aluminum alloy powder, application of high-strength aluminum alloy powder in 3D printing and 3D printing method of high-strength aluminum alloy powder

ActiveCN114277285AImprove the effect of solid solution strengtheningInhibits the formation of cracksAdditive manufacturing apparatusTransportation and packagingSolid solution strengtheningAluminium alloy

The invention discloses high-strength aluminum alloy powder, which is prepared from the following components in percentage by mass: 4.2 to 6.0 weight percent of Mn, 1.2 to 3.0 weight percent of Mg, 0.6 to 1.0 weight percent of Sc, 0.05 to 0.6 weight percent of Zr, 0.01 to 0.2 weight percent of Si, 0.01 to 0.2 weight percent of Fe and the balance of Al. By optimizing the content of the alloy elements such as Mn, Mg, Fe and Si, the remarkable solution strengthening effect is achieved; by adding Sc and Zr, local formation of equiaxed grains is promoted, crack formation and expansion are inhibited, and meanwhile, an effective precipitation strengthening effect is achieved by means of dispersion particles generated in the aging process.

Owner:苏州倍丰智能科技有限公司

Permanent magnet ferrite tile

InactiveCN110739780AIncrease solid solutionImprove performanceInorganic material magnetismMagnetic circuit characterised by magnetic materialsFiberAluminum silicate

The invention discloses a permanent magnet ferrite tile. The permanent magnet ferrite tile comprises, by weight, 10 to 20 parts of iron oxide, 2 to 10 parts of cerium oxide, 4 to 6 parts of soda, 2 to6 parts of boric acid, 1 to 3 parts of lanthanum oxide, 6 to 10 parts of chromium oxide, 2 to 8 parts of aluminum silicate fiber,1 to 6 parts of zinc oxide, and 2 to 6 parts of talc powder. Accordingto the invention, the comprehensive performance of the magnetic tile can be improved.

Owner:南京美帮磁业有限公司

Novel binding phase hard alloy and preparation method thereof

The invention discloses a novel binding phase hard alloy and a preparation method thereof. The novel binding phase hard alloy is composed of the following components of, in percentage by mass, 10 wt%-15 wt% of cobalt, 10 wt%-15 wt% of nickel, 0.6 wt%-2.5 wt% of silicon carbide and the balance of tungsten carbide. According to the novel binding phase hard alloy, the Si-reinforced Co-Ni binding phase is adopted to reinforce the hard alloy, the ordered reinforcing phase of the hard alloy is dispersed and distributed into the binding phase, under equivalent conditions, compared with an existing Co-Ni binding phase hard alloy, the reinforced hard alloy with Co-Ni-Si as the binding phase has the advantages that the room-temperature and high-temperature bending strength can be improved by 20% or above, and moreover, the process is simple and controllable, and industrialization is facilitated.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Preparation method of 2:17 type SmCoCuFeZrB sintered permanent magnet

ActiveCN113020595AImprove magnetic propertiesOptimize high temperature comprehensive magnetic propertiesIncreasing energy efficiencyInductances/transformers/magnets manufactureSamariumMagnet

The invention discloses a preparation method of a 2:17 type SmCoCuFeZrB sintered permanent magnet. The preparation method is used for preparing the sintered permanent magnet Smx (Co1-a-b-c-dFeaCubZrcBd)z, the symbols x, a, b, c, d and z in the formula represent the composition range of limited elements, and the atomic number ratio of x to a to b to c to d to z is 1: (0.01-0.4): (0-0.03): (0.01-0.05): (0.01-0.04): (6.8-8.4); and the magnet has a cellular organization structure, and an intracellular main phase is an Sm2 (CoFe) 17B phase. The density and orientation degree of the sintered permanent magnet prepared by the method are incomparable to those of a nanocrystalline magnet and an amorphous magnet; and through cooperation of a heat treatment process, an oxygen control process and the like, uncontrolled phase decomposition of the magnet in the heat treatment process is effectively inhibited, effective regulation and control of a microstructure and phase composition are achieved, the addition amount of Fe elements in the sintered 2:17 type samarium-cobalt magnet is increased, the intrinsic coercive force of the magnet under the high Fe content is improved, and the maximum magnetic energy product of the sintered 2:17 type samarium-cobalt magnet is further improved.

Owner:CHINA JILIANG UNIV +1

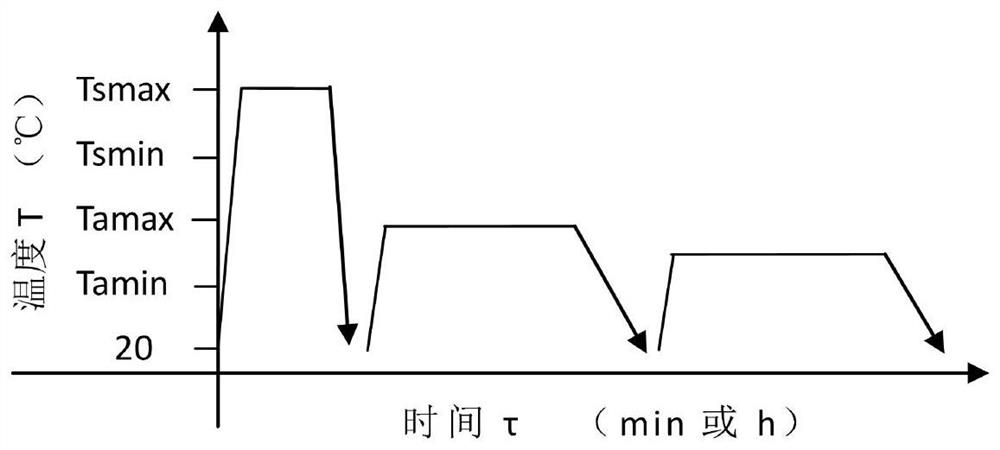

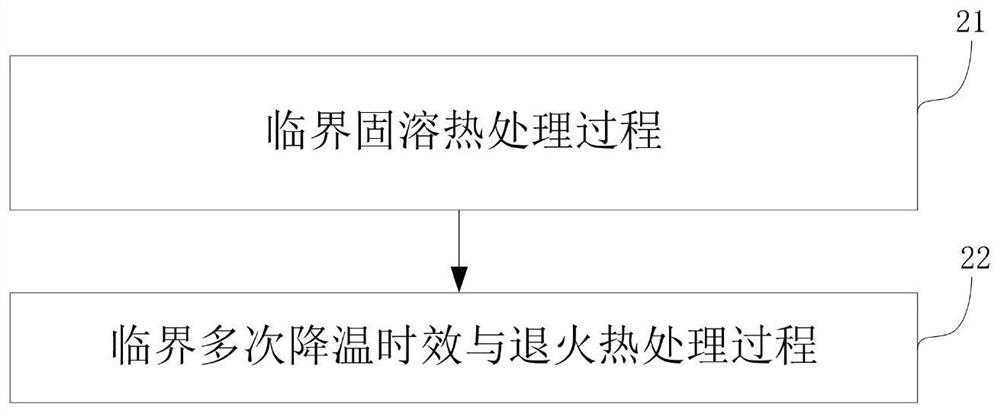

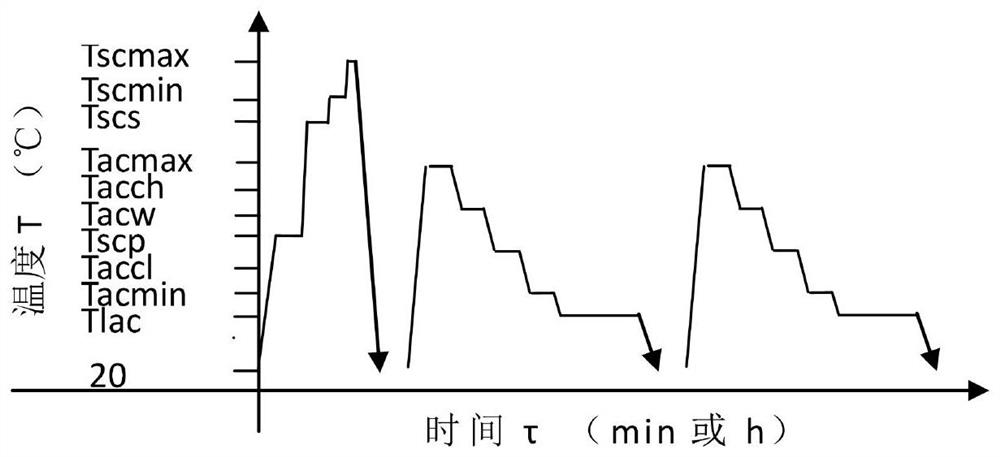

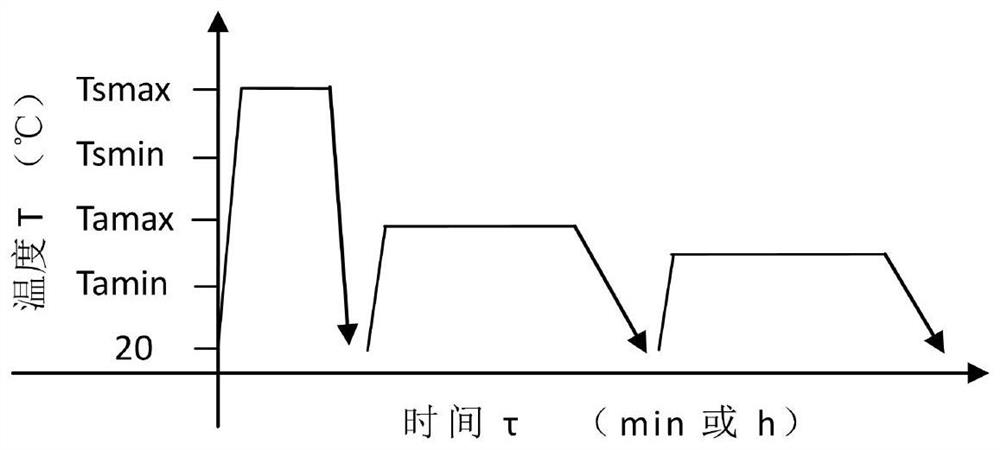

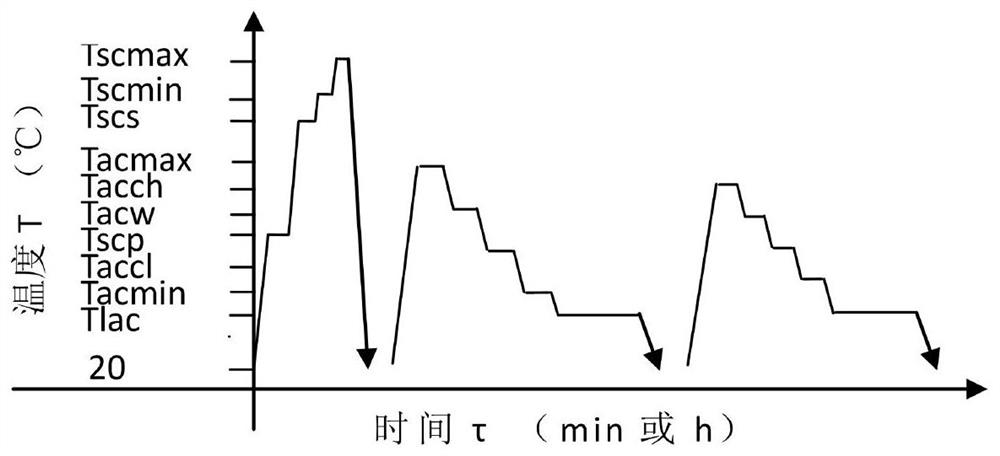

Critical solid solution and critical repeated cooling aging and annealing heat treatment method

The invention provides a critical solid solution and critical repeated cooling aging and annealing heat treatment method which comprises a critical solid solution heat treatment process and a critical repeated cooling aging and annealing heat treatment process. The scheme of the invention has technical feasibility, process adaptability, quality reliability, economic reasonability and use safety, can effectively enhance the advantages and avoid the disadvantages of a conventional mainstream heat treatment method of austenitic stainless steel, fundamentally solves the "one-long one-high four-poor five-low" special heat treatment technical difficult problems of "poor quality stability, low rate of qualified products, low hardness, low mechanical property, poor consistency, poor discoloration and rust corrosion resistance, long heating time, low efficiency, poor heating reliability of heat treatment equipment and low service life and high cost of a high-temperature component" of existing austenitic stainless steel heat treatment, and is particularly suitable for the technical field of heat working engineering such as smelting, steel rolling, forging, heat treatment and the like related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

Tempering process of medium-carbon steel large diesel engine output shaft hardening and

ActiveCN103614521BIncrease solid solutionImprove surface quenching hardnessFurnace typesHeat treatment furnacesDiesel engineQuenching

The invention discloses a medium-carbon steel large diesel engine output shaft hardening and tempering process. The process comprises the following steps: (1) normalizing: filling an output shaft in a furnace, heating to the temperature of 350 + / -20 DEG C and 600+ / -20 DEG C in a staged way, preserving the heat, hanging out the output shaft, blowing cold air to cool the output shaft to room temperature by using a fan; (2) quenching for three times: filling the output shaft into the furnace again, heating to the temperature of 350 + / -20 DEG C, 600+ / -20 DEG C and 850+ / - 10 DEG C in a staged way; cooling by air and then cooling in a water tank, cooling by the air again and cooling by water again, and then cooling in an oil tank; (3) high-temperature tempering: tempering at the temperature of 565+ / - 10 DEG C, preserving the temperature and cooling by the air out of the furnace. By the process, the surface martensite transformation speed at the first stage of a large shaft forging is improved, and the surface quenching hardness of the large shaft forging is improved by adopting the reasonable quenching cooling mode of air cooling-water cooling-air cooling-water cooling-oil cooling. The difference between the inside temperature and the outside temperature of the large shaft forging is reduced by the air cooling adopted by the process, and the cracking tendency of the large shaft forging is effectively reduced.

Owner:CSSC MARINE POWER

A hot-rolled ribbed steel bar with a strength-to-yield ratio ≥ 1.25 and its production method

A hot-rolled ribbed steel bar having a strength-to-yield ratio of 1.25 or more comprises 0.17-0.25wt% of C, 0.4-0.8wt% of Si, 1.2-1.5wt% of Mn, 0.045wt% or less of P, 0.045wt% or less of S, 0.05-0.08wt% of V, 0.006-0.018wt% of N, and the balance of Fe and impurity elements, and has a specification diameter of 12-40mm. A production method of the hot-rolled ribbed steel bar comprises the following steps: desulfurizing molten iron; carrying out top-bottom blowing of a converter; carrying out component fine-adjustment at an argon station, and blowing in nitrogen; refining an LF furnace, and blowing nitrogen into the LF furnace; continuously casting; carrying out stacking cooling; heating casted blanks; carrying out rough rolling and finish rolling; and naturally cooling to room temperature. Nitrogen is blown to realize greatly reduced cost, greatly reduced vanadium alloy consumption, increased V (C,N) amount and dispersity with the increase of the content of N in steel, substantial reinforcement effect and stable mechanical performances on the premise that mechanical performances comprising a hot-rolled yield strength of above 530MPa, a strength-to-yield ratio of 1.25-1.30, an A value of 18% or more and an Agt value of 10 or more are guaranteed.

Owner:武汉钢铁有限公司

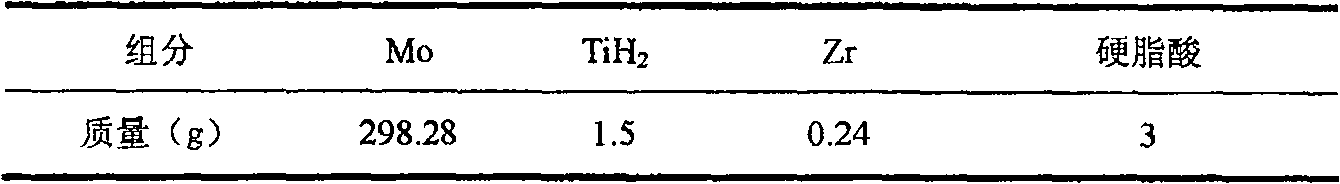

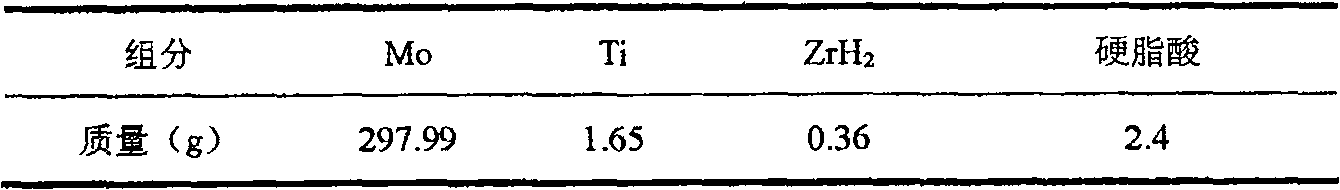

Method for manufacturing high performance sinter Mo-Ti-Zr molybdenum alloy

The invention relates to a method for preparing high-performance Mo-Ti-Zr(TZM) through utilizing powder metallurgy, which comprises the following steps: mechanically milling metal Mo powder, Ti(TiH2), Zr(ZrH2) powder and organic binder in a high energy ball mill, preparing pre-alloyed powder which is evenly mixed, pressing and forming mixed powder, presintering pressed compact in protective atmosphere, dehydrogenating, deoxidizing, wherein deoxidizing, controlling carbon and sintering in high temperature in high-temperature protective atmosphere, and finally, doing sintering later process for sintered compact. The mechanical property of TZM molybdenum alloy which is prepared by the method of the invention is better than that of alloy which is manufactured by a normal powder metallurgy process, wherein the highest tensile strength can reach570-600Mpa, and percentage of elongation reaches 19-25%.

Owner:CENT SOUTH UNIV

Critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method

The invention provides a critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method. The method comprises a critical solid solution heat treatment process and a critical multi-cooling variable-temperature aging and annealing heat treatment process. The scheme has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, and can effectively enhance the advantages and avoid the disadvantages of a traditional mainstream heat treatment method of austenitic stainless steel, so that the problems that the existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like are fundamentally solved. The critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com