Preparation method of 2:17 type SmCoCuFeZrB sintered permanent magnet

A technology of permanent magnets and magnets, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, manufacturing tools, etc., can solve the problem that the high residual magnetization cannot be effectively utilized, the intrinsic coercive force of the magnet decreases, and the Anisotropy and other problems, to achieve the effect of optimizing high-temperature comprehensive magnetic properties, optimizing magnetic properties, and increasing the maximum magnetic energy product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

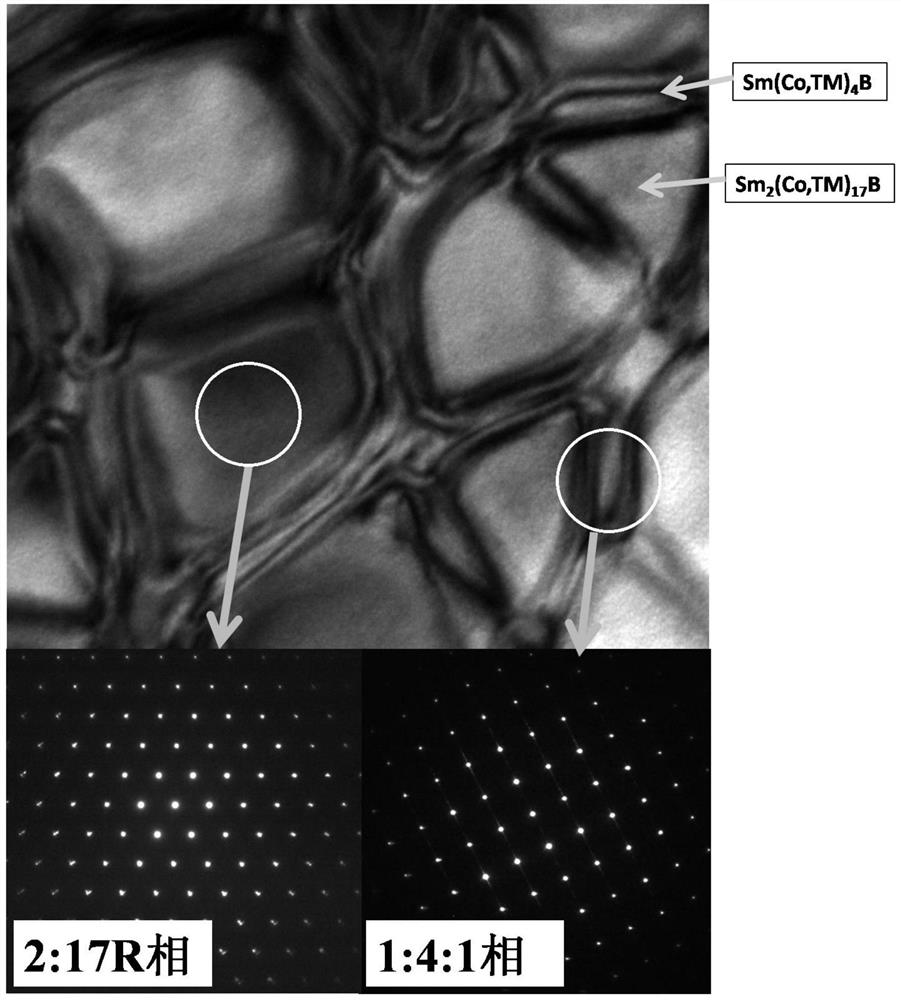

Image

Examples

Embodiment 1

[0028] (1) Ingredients: alloy molecular formula is: Sm(Co 0.59 Fe 0.35 Cu 0.01 Zr 0.03 B 0.02 ) 7.8 , according to the atomic number ratio of each element in the alloy molecular formula, calculate the mass percentage of each element, and weigh the required raw materials: Sm (purity is 99.9%), Co (purity is 99.9%), Cu (purity is 99.9%) , Zr (purity is 99.9%), Fe (purity is 99.9%), Fe-B alloy (wherein, the mass fraction of B is 18.9%);

[0029] (2) Prepare alloy ingots: adopt induction melting plus copper mold water cooling process to prepare alloy ingots;

[0030] Put the raw materials prepared in step (1) into the crucible of the vacuum induction melting furnace in turn, and first vacuumize the furnace body to 10 -1 ~10 -3 Pa, increase the power until the smelting is uniform, and cast it into a water-cooled copper mold to obtain an alloy ingot; in this step (2), both smelting and casting are carried out under the protection of argon.

[0031] (3) Preparation of magneti...

Embodiment 2

[0037] (1) Ingredients: alloy molecular formula is: Sm(Co 0.61 Fe 0.30 Cu 0.02 Zr 0.04 B 0.03 ) 7.6 Calculate the mass percent of each element according to the ratio of the number of atoms in the alloy molecular formula, and take the required raw materials by mass percent: Sm (purity is 99.9%), Co (purity is 99.9%), Cu (purity is 99.9%), Zr (purity is 99.9%), Fe (purity is 99.9%), Fe-B alloy (wherein, the mass fraction of B is 18.9%);

[0038] (2) Prepare alloy ingots: adopt induction smelting plus copper mold water cooling process to prepare alloy ingots; put the raw materials prepared in step (1) into the crucible of vacuum induction melting furnace in turn, and first vacuumize the furnace body to 10 -1 ~10 -3 Pa, increase the power until the smelting is uniform, and cast it into a water-cooled copper mold to obtain an alloy ingot; in this step (2), smelting and casting are all carried out under the protection of argon;

[0039] (3) Preparation of magnetic powder: use...

Embodiment 3

[0047] (1) Ingredients: alloy molecular formula is: Sm(Co 0.82 Fe 0.1 Cu 0.02 Zr 0.04 B 0.02 ) 7.1 ; According to the atomic number ratio of each element in the alloy molecular formula, the mass percentage of each element is calculated, and the required raw materials are taken by mass percentage: Sm (purity is 99.9%), Co (purity is 99.9%), Cu (purity is 99.9%) %), Zr (purity is 99.9%), Fe (purity is 99.9%), Fe-B alloy (mass fraction of B is 18.9%);

[0048] (2) Prepare alloy ingots: adopt induction smelting plus copper mold water cooling process to prepare alloy ingots; put the raw materials prepared in step (1) into the crucible of vacuum induction melting furnace in turn, and first vacuumize the furnace body to 10 -1 ~10 -3 Pa, increase the power until the smelting is uniform, and cast it into a water-cooled copper mold to obtain an alloy ingot; in this step (2), smelting and casting are all carried out under the protection of argon;

[0049] (3) Preparation of magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com