Annealing separating agent for grain oriented electrical steel sheet having uniform glass film and excellent magnetic properties and method of manufacturig the same

A technology of annealing separator and grain orientation, which is applied in solid-state chemical plating, coating, metal material coating process, etc. Satisfaction and other issues, to achieve excellent synergistic effect, inhibit other oxidation or nitrification, inhibit the effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

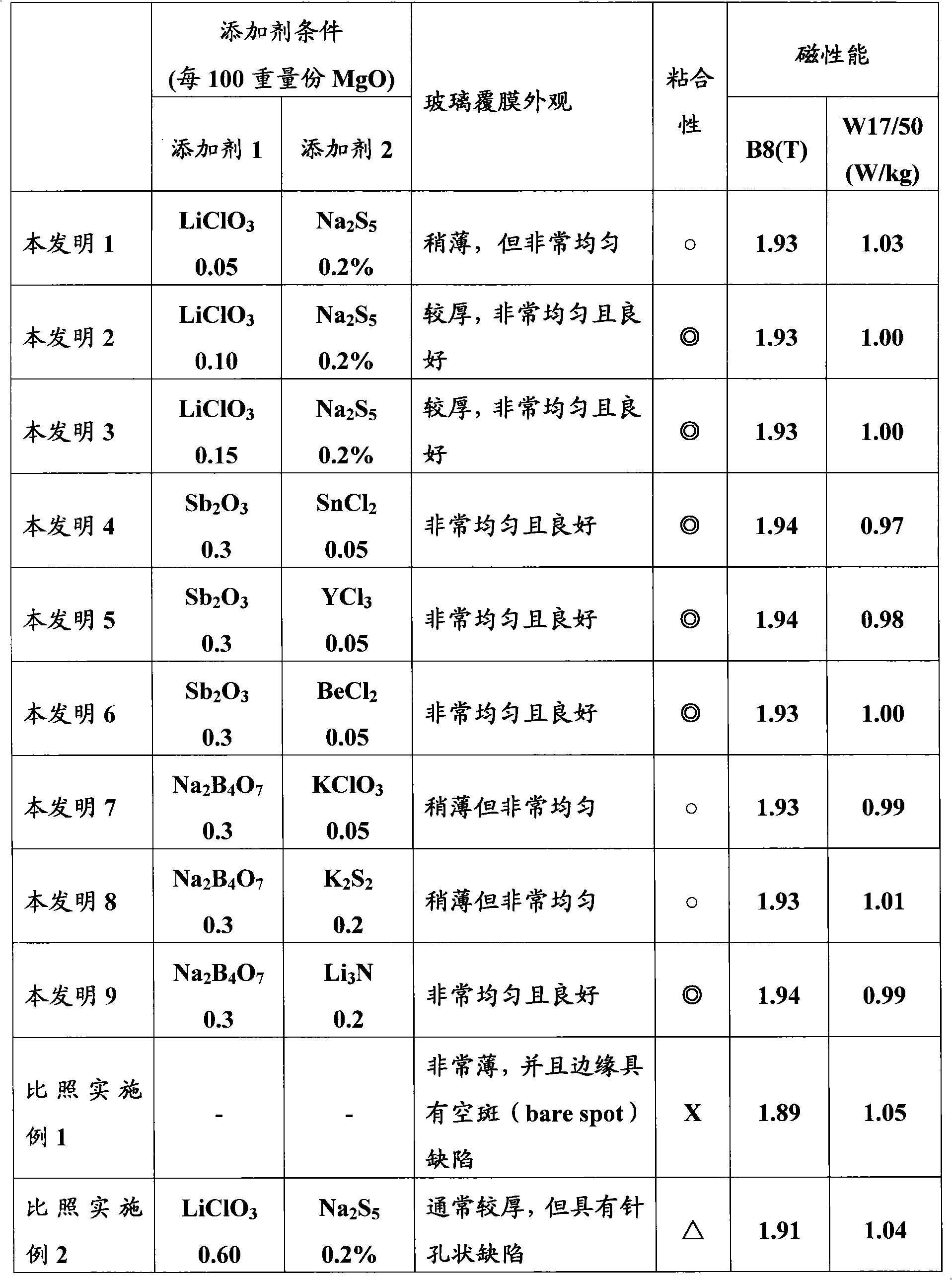

[0054] Orienting grains with high magnetic flux density containing 0.0078% C, 3.18% Si, 0.068% Mn, 0.024% S, 0.028% Al, 0.0080% N by weight %, and the balance being Fe and other unavoidable impurities The electromagnetic steel sheet material was hot-rolled, annealed and cold-rolled to obtain a final thickness of 0.30 mm. Then, the cold-rolled steel plate is put on the continuous annealing line in N 2 50%+H 2 Decarburization annealing was performed at 850° C. for 150 seconds in an atmosphere of 50% (63° C. DP). At this time, the oxygen content in the steel sheet was 750 ppm. Then, an alkaline composition was added by adding 5 parts by weight of TiO to 100 parts by weight of 40% MgO with a CAA value of 65 seconds 2 Obtained - and the slurry of the low-boiling point additive shown in the following table 1 is 6.5g (by dry weight) / m 2 The ratio of the surface of the steel plate is applied to the steel plate and allowed to dry. The resulting steel sheet was wound into a coil. ...

Embodiment 2

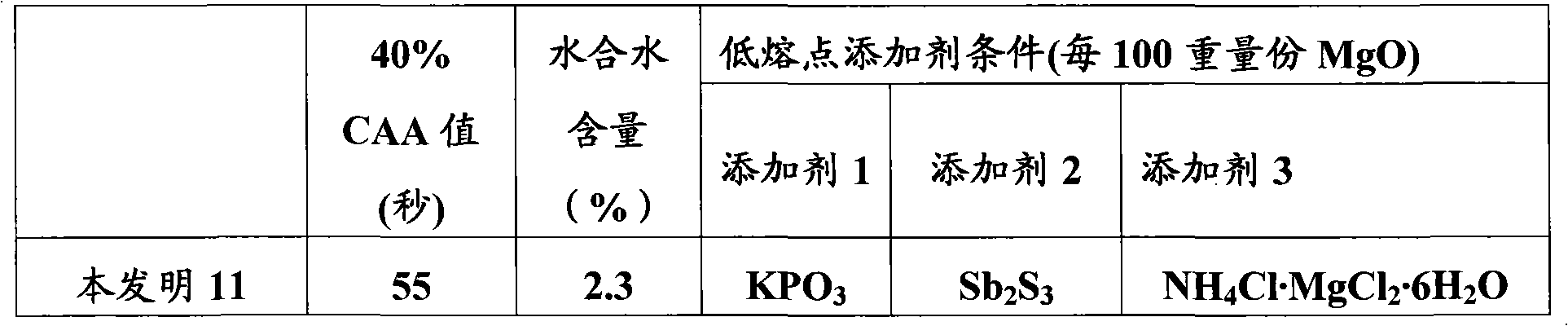

[0063] Hot-rolled and annealed grain-oriented electrical steel sheet material with high magnetic flux density containing 0.0060%C, 3.20%Si, 0.070%Mn, 0.029%Al by weight%, and the balance being Fe and other unavoidable impurities and cold rolling to obtain a final thickness of 0.23mm. Then, on the continuous annealing line at N 2 50%+H 2 Decarburization annealing was performed at 850°C for 130 seconds in an atmosphere of 50% (DP 62°C). Here, the oxygen content in the steel sheet was 730 ppm. Then, an alkaline composition was added by adding 5 parts by weight of TiO to 100 parts by weight of MgO with different 40% CAA values 2 Obtained - and the slurry of the low-melting point additive shown in the following table 2 is 6.0g (by dry weight) / m 2 The ratio of the surface of the steel plate is applied to the steel plate and allowed to dry. The resulting steel sheet was wound into a coil.

[0064] Then, according to the same method as in Example 1, the coil was subjected to a f...

Embodiment 3

[0076] The same raw material as used in Example 2 was rolled to a final thickness of 0.23 mm and subjected to decarburization annealing under the same conditions. The steel coil was then coated with an annealing release agent having the composition shown in Table 4 below and containing TiO 2 , V 2 o 5 , Nb 2 o 4 and / or MnO 2 Used as an additive to adjust the atmosphere between the steel plate surfaces. Then, the steel sheet coil was subjected to final annealing and insulation coating under the same conditions as in Examples 1 and 2, and its glass coating performance and magnetic performance were evaluated. Table 4 below shows the results obtained in this example.

[0077] 【Table 4】

[0078]

[0079]

[0080] As can be seen from the above table 4, in the present invention 32-39, 3-10 parts by weight are selected from TiO 2 , V 2 o 5 , Nb 2 o 4 and MnO 2 When one or more of them are added together with low melting point additives, good glass coating properties...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com