Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

206results about How to "Improve the effect of solid solution strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium alloy of high intensity and high yield ratio and preparation method thereof

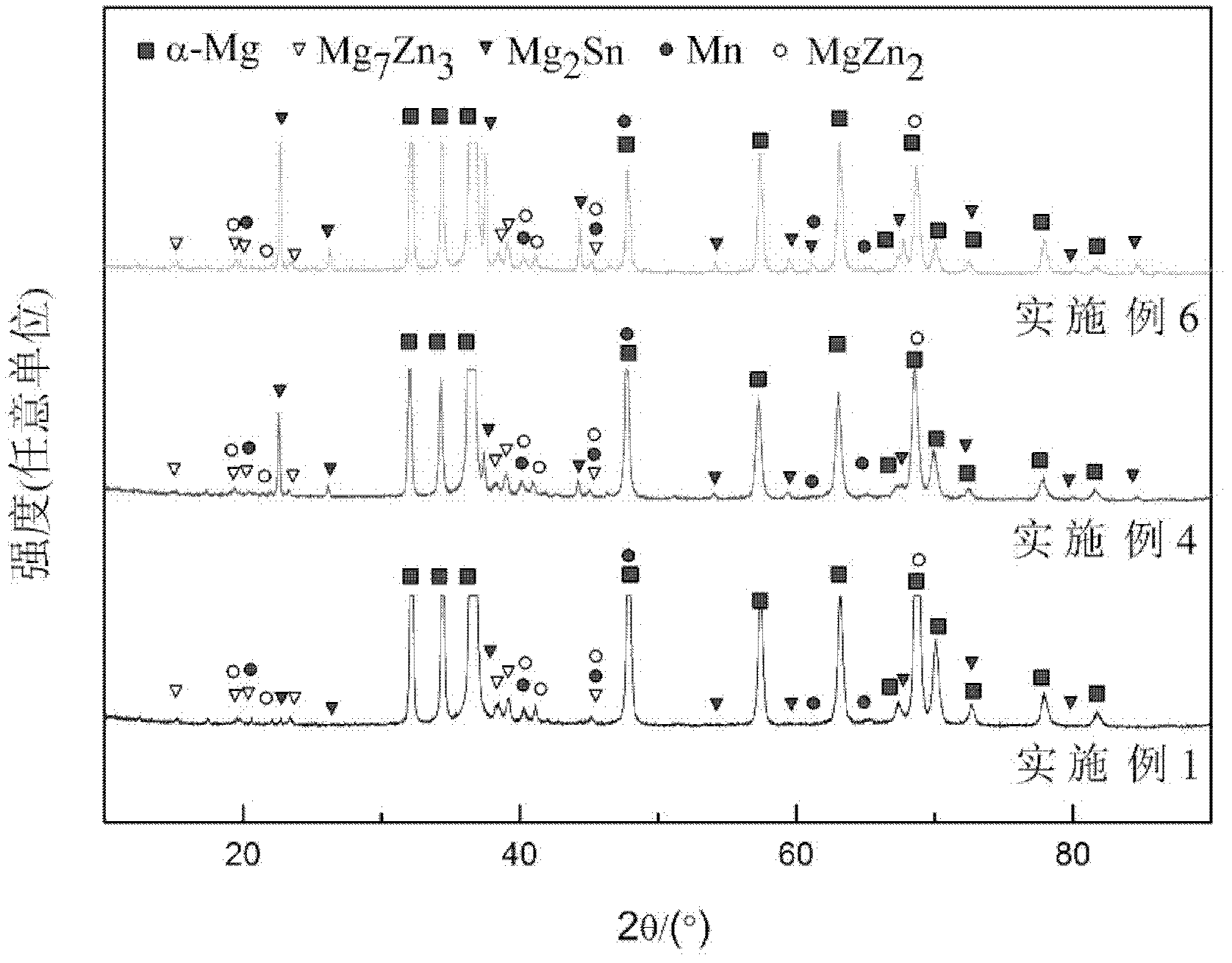

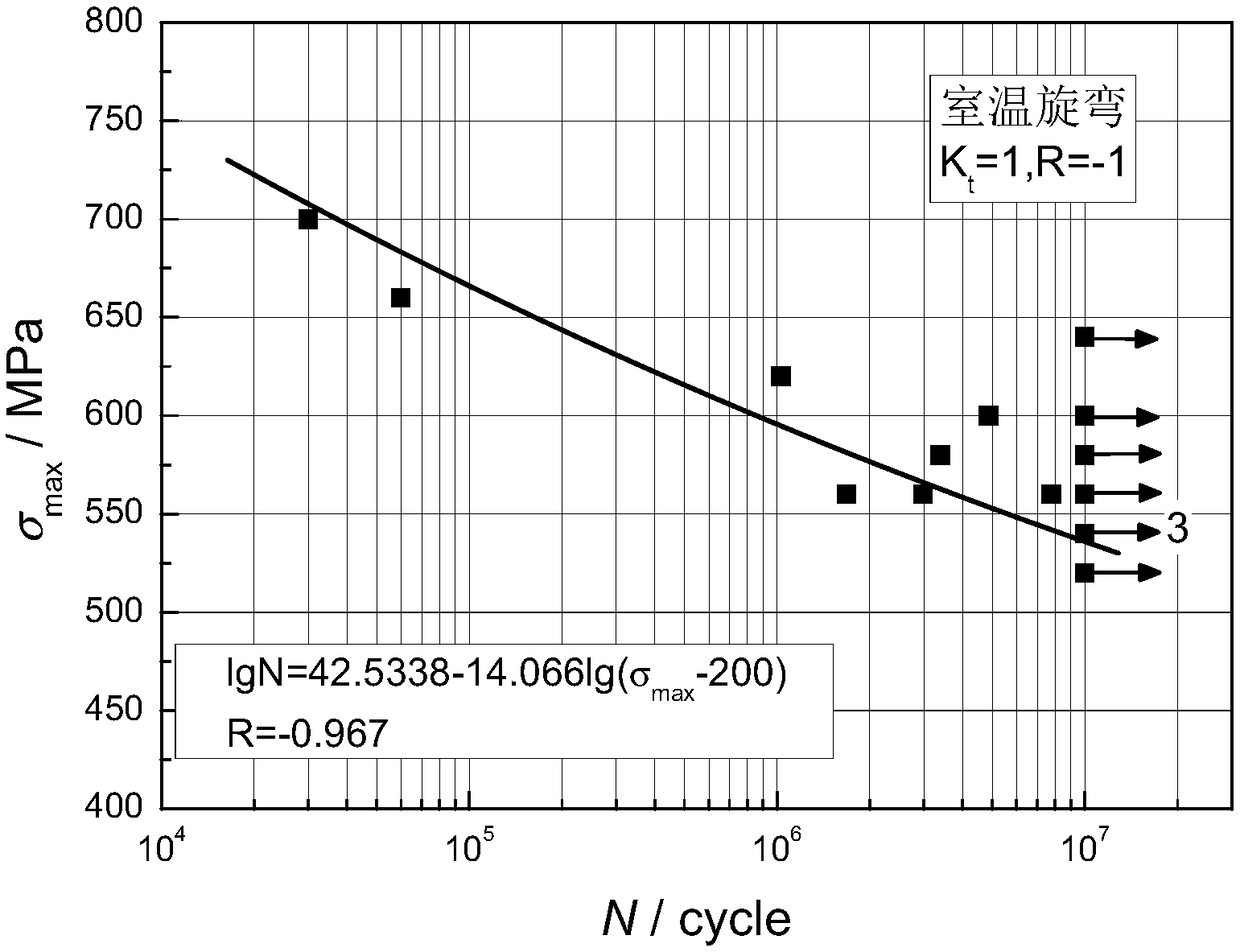

The invention provides a magnesium alloy material of high intensity and high yield ratio. The alloy comprises the following components by mass: 5.0-9.0% of Zn; 0.5-1.5% of Mn; 1-10% of Sn; less than 0.15% of inevitable impurities; and the balance magnesium. By means of plastic forming and a choice of reasonable technological conditions for heat treatment after forming, the magnesium alloy material of the invention can be of high intensity and high yield ratio, and is higher than the high-strength wrought magnesium alloy ZK60 in terms of yield strength and tensile strength. With low cost, good extrudability and formability at a low temperature, the magnesium alloy material provided in the invention boasts substantial application potential, thus being able to partly replace the magnesium alloy material ZK60.

Owner:QINGHAI SUNGLOW MAGNESIUM

TiAl alloy and preparation method thereof

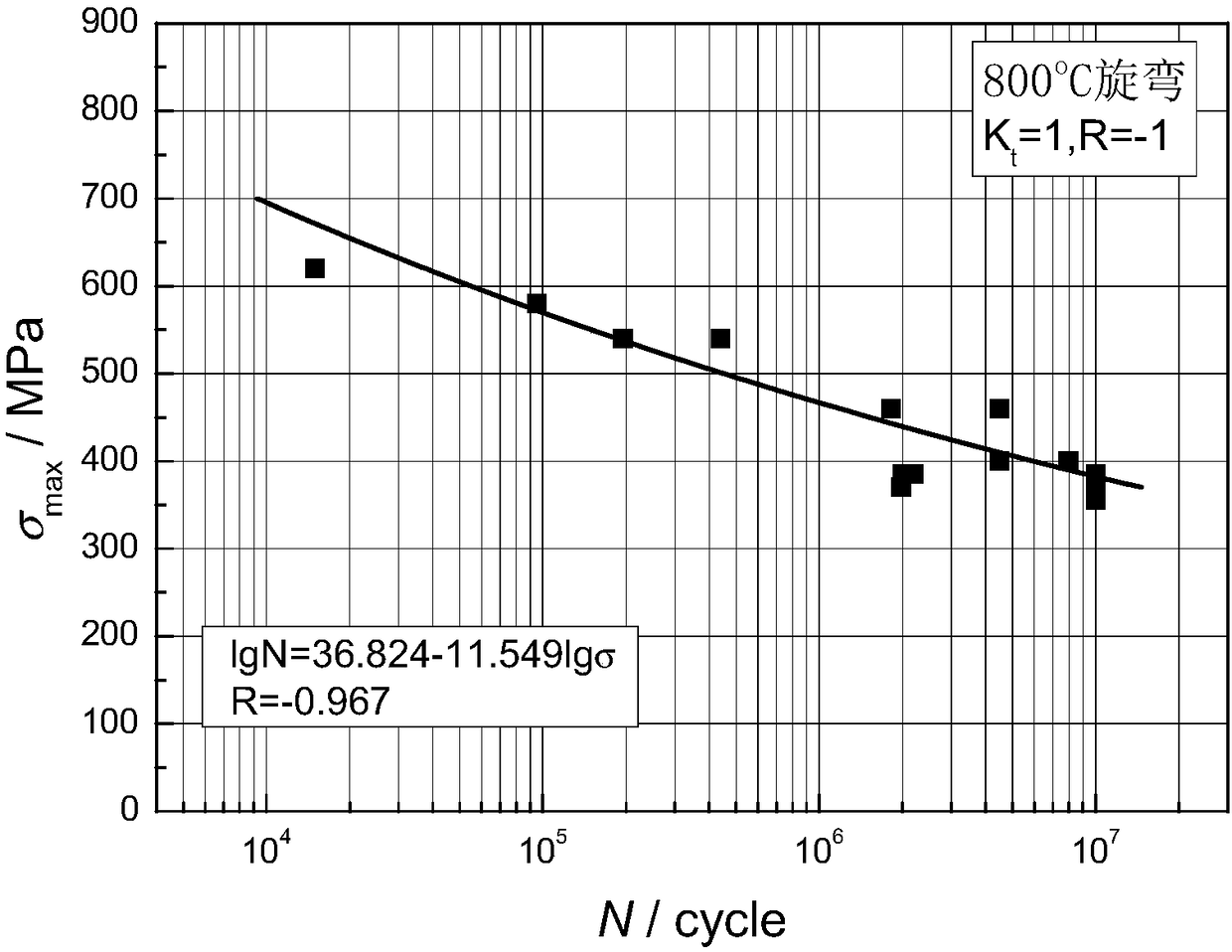

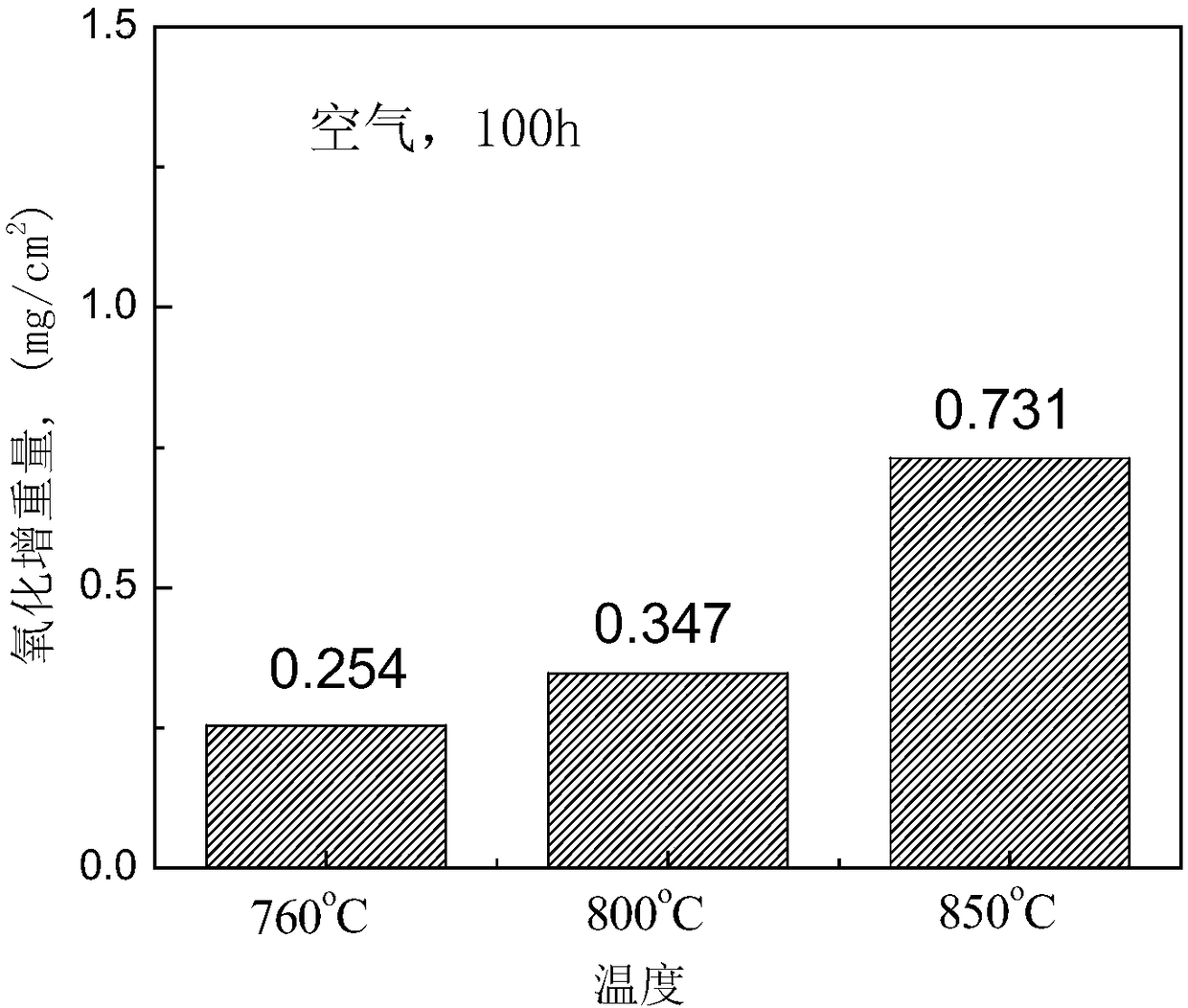

The invention belongs to the field of TiAl intermetallic compounds, and relates to forging TiAl alloy which is mainly applied to manufacturing of aero-engine blades, can be used for a long time at thetemperature being 700-800 DEG C, and is high in plasticity, high in strength, high-temperature-resistant and fatigue-resistant and a preparation method of the forging TiAl alloy. The TiAl alloy is added with beta stable elements such as Cr, Nb, Ta, W and Mo, and is further added with a small amount of interstitial elements such as B and Si. The forging TiAl alloy is characterized in that the TiAlalloy comprises the following components in percentages by atoms: 42-47% of Al, 3-6% of Nb, 1-2% of Cr, 0.1-0.5% of Ta, 0-0.2% of W, 0-0.2% of Mo, 0-0.2% of B, 0-0.2% of Si and the balance of Ti andinevitable impurities, wherein O content is less than or equal to 0.1 wt%, N content is less than or equal to 0.015 wt%, H content is less than or equal to 0.01 wt%, and Fe content is less than or equal to 0.08 wt%. After the various beta stable elements are combined and matched, the total adding amount is calculated according to a [Nb] equivalent formula and requires to be controlled between 6 and 11. The TiAl alloy can work at the temperature being 700-800 DEG C for a long time, can be used for manufacturing parts such as aero-engine compressor blades and low-pressure turbine blades, can also be used for manufacturing high-temperature-resistant structures such as supersonic aircrafts, and can be used for a short time at the temperature being 900-1000 DEG C.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

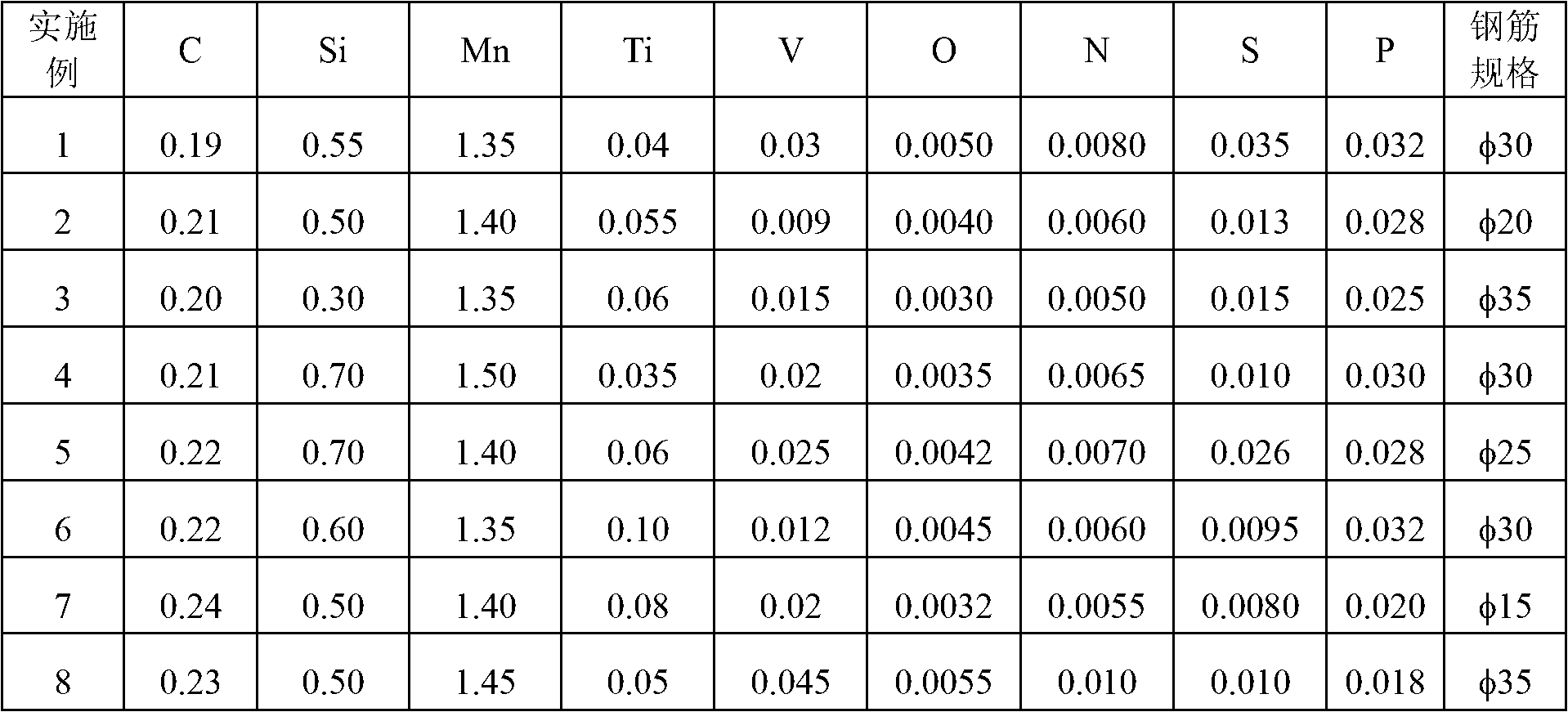

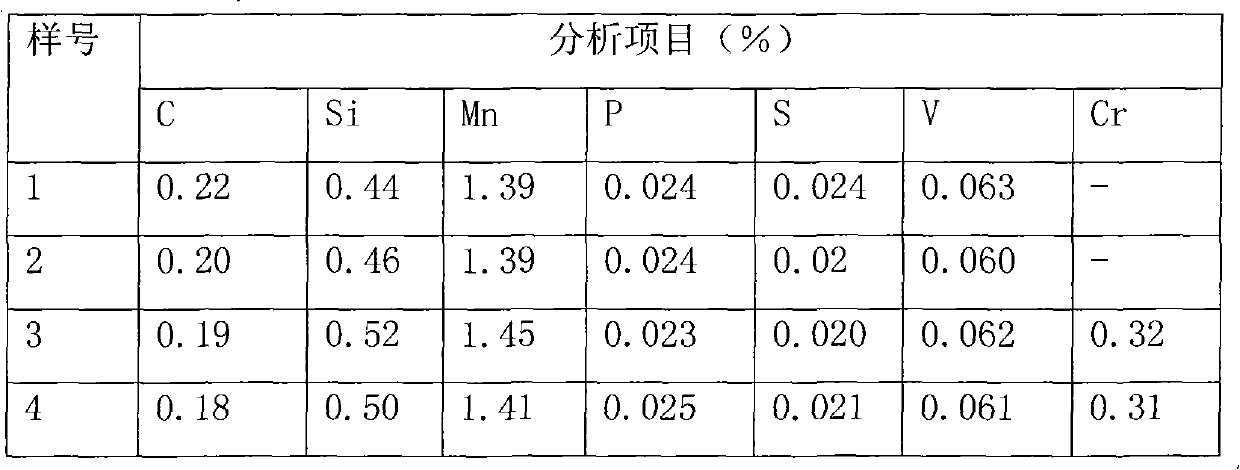

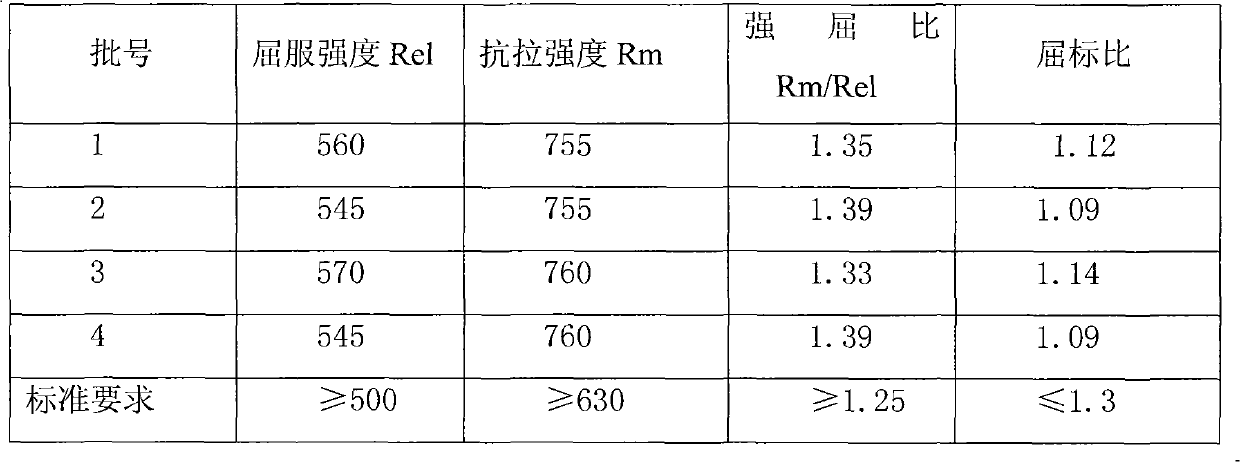

Vanadium and titanium compound microalloyed steel bar and production method thereof

The invention discloses a vanadium and titanium compound microalloyed steel bar and a production method thereof. The steel in the steel bar comprises the following chemical components in percentage by weight: 0.16 to 0.25 percent of C, 0.20 to 0.80 percent of Si, 1.20 to 1.50 percent of Mn, 0.001 to 0.12 percent of Ti, 0.001 to 0.10 percent of V, less than or equal to 0.01 percent of N, less than or equal to 0.045 percent of S, less than or equal to 0.045 percent of P, and the balance of Fe and inevitable impurities. The production method for the steel bar comprises the following steps of: a, smelting crude molten steel, tapping, deoxidizing and alloying; b, refining, trimming the components to make the components meet the component requirement of the steel bar, and casting; and c, performing hot rolling, wherein alloying vanadium and titanium after deoxidizing in the process of tapping, or in the process of refining. According to the vanadium and titanium compound microalloyed steel bar, the yield strength and the tensile strength of the steel are improved under the condition of not changing the ductility of the steel, and the performance requirements of the steel bars in 400 MPa or 500 MPa of grades are met.

Owner:PANZHIHUA GANGCHENG GROUP

Copper chromium zirconium alloy and preparing method thereof

A copper chromium zirconium alloy comprises, by weight, 0.7% to 2.0% of chromium, 0.05% to 0.3% of zirconium, 0.01% to 0.08% of magnesium, 0.01% to 0.1% of yttrium and the balance copper. The invention further provides a preparing method of the copper chromium zirconium alloy. The preparing method sequentially comprises the following steps that firstly, the copper, the chromium, the zirconium, the magnesium and the yttrium are prepared according to the proportion and are subject to vacuum purified smelting and flow dividing type casting, and a casting blank is prepared; secondly, the casting blank is subject to homogenization treatment and hot extrusion, and a sheared billet is prepared; thirdly, the sheared billet is subject to solid-solution treatment; fourthly, the sheared billet obtained after the solid-solution treatment is subject to cold deformation machining; and fifthly, a material obtained after cold deformation machining is subject to aging treatment, and the needed copper chromium zirconium alloy is obtained. The copper chromium zirconium alloy has the good comprehensive performance, the room temperature tensile strength of the copper chromium zirconium alloy is larger than 520 MPa, the room temperature elongation of the copper chromium zirconium alloy is larger than or equal to 22%, the room temperature electric conductivity of the copper chromium zirconium alloy is larger than or equal to 90%IACS, and the 350 DEG C high-temperature tensile strength of the copper chromium zirconium alloy is larger than 390 MPa.

Owner:SHANTOU HUAXING (RAOPING) COPPER IND CO LTD +1

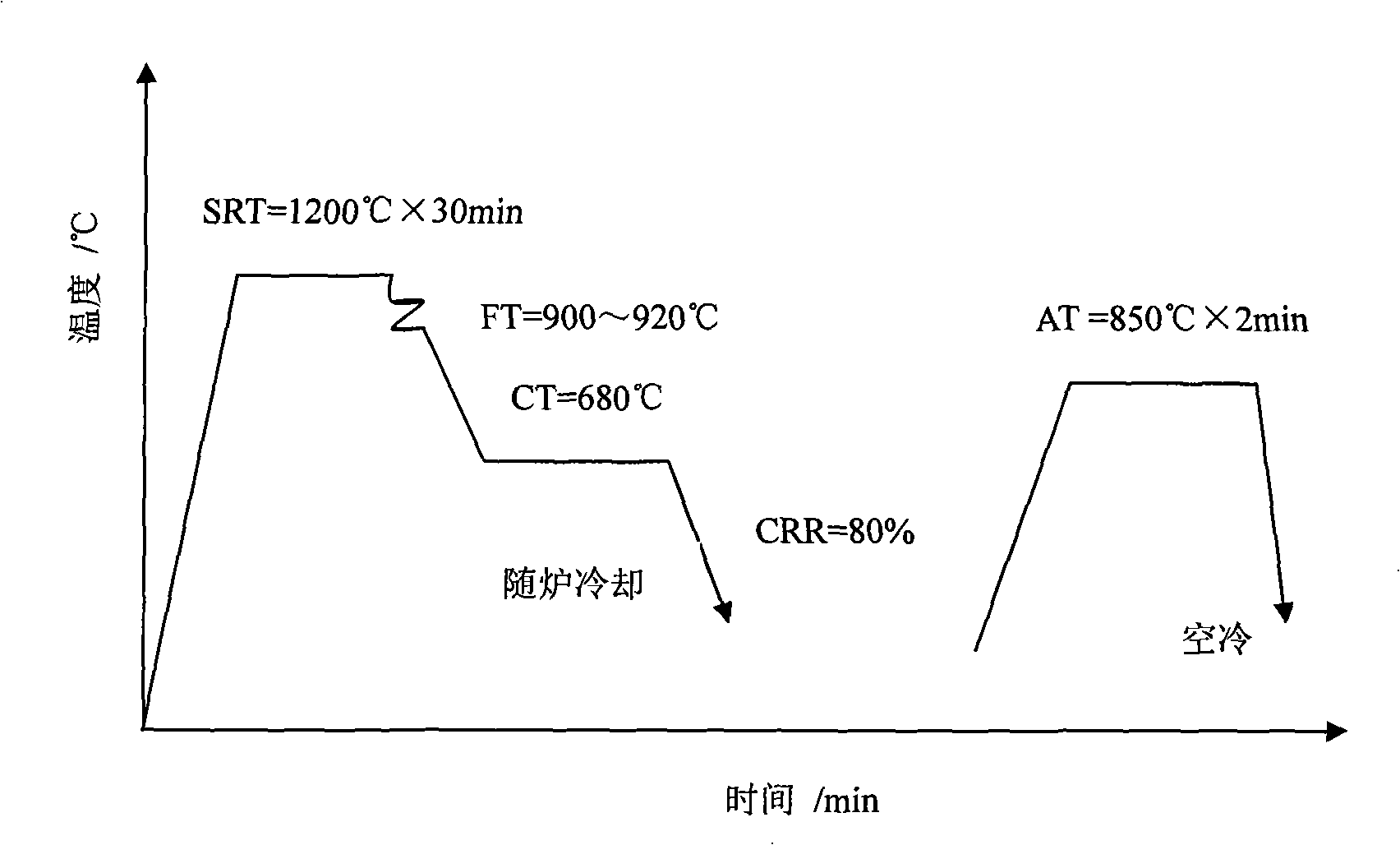

440MPa grade niobium-containing high-strength IF steel and manufacturing method thereof

InactiveCN101348884AImprove the effect of solid solution strengtheningRemarkable effect of fine grain strengtheningHigh intensityNiobium

The invention relates to a 440MPa niobium-bearing high-strength IF steel and a preparation method thereof, which belong to the high-strength automobile steel technical field. The chemical compositions in weight percent are 0.005 to 0.007 percent of carbon, 0.02 to 0.03 percent of silicon, 1.2 to 2.1 percent of manganese, less than 0.08 percent of phosphor, less than 0.006 percent of sulfur, less than or equal to 0.003 percent of nitrogen, 0.05 to 0.11 percent of niobium, 0.0005 to 0.002 percent of boron, 0.2 to 0.5 percent of chromium, 0.005 to 0.01 percent of titanium, 0.01 to 0.04 percent of aluminum, and the balance being iron and unavoidable impurities. The manufacturing technique is smelting, hot rolling, cold rolling and continuous annealing or hot galvanizing. The controlled technological parameters are as follows: the heating temperature of a hot-rolled slab is between 1,200 and 1,250 DEG C; the heat preservation time is between 0.5 and 1.5 hours; the finishing temperature is between 910 and 920 DEG C; the coiling temperature is between 640 and 680 DEG C; the cold rolling reduction is 80 percent; the annealing temperature is between 840 and 860 DEG C; and the annealing heat preservation time is between 100 and 120 seconds. The preparation method has the advantage of capability of obtaining the 440MPa high-strength IF steel with the strength more than or equal to 440MPa, an r value more than or equal to 1.5 and good deep drawability.

Owner:UNIV OF SCI & TECH BEIJING +1

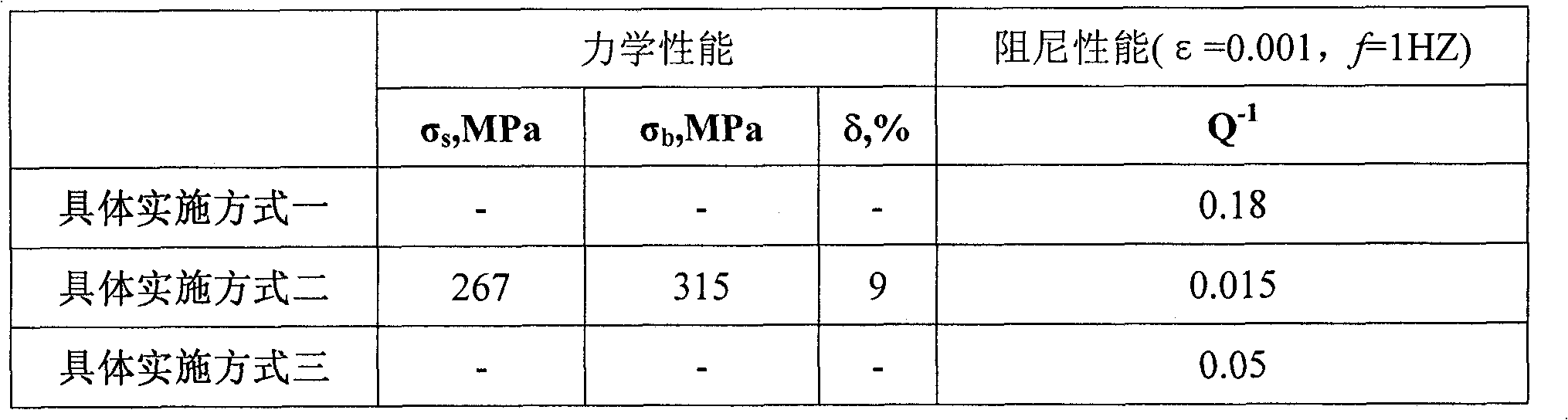

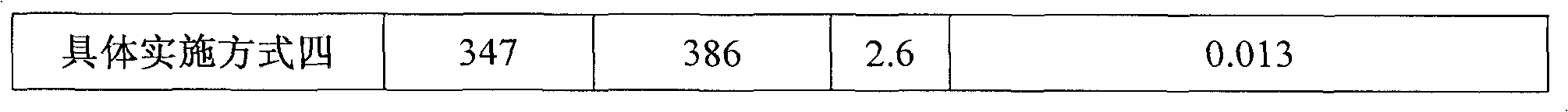

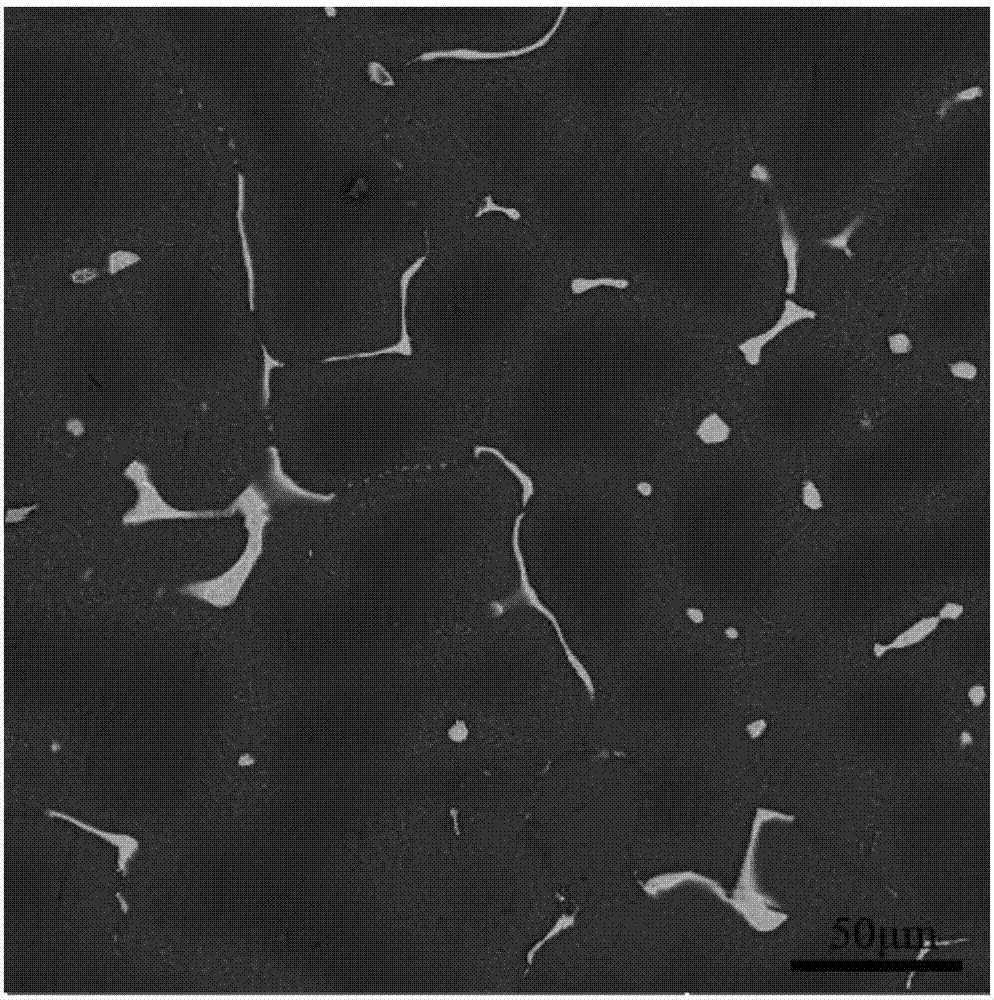

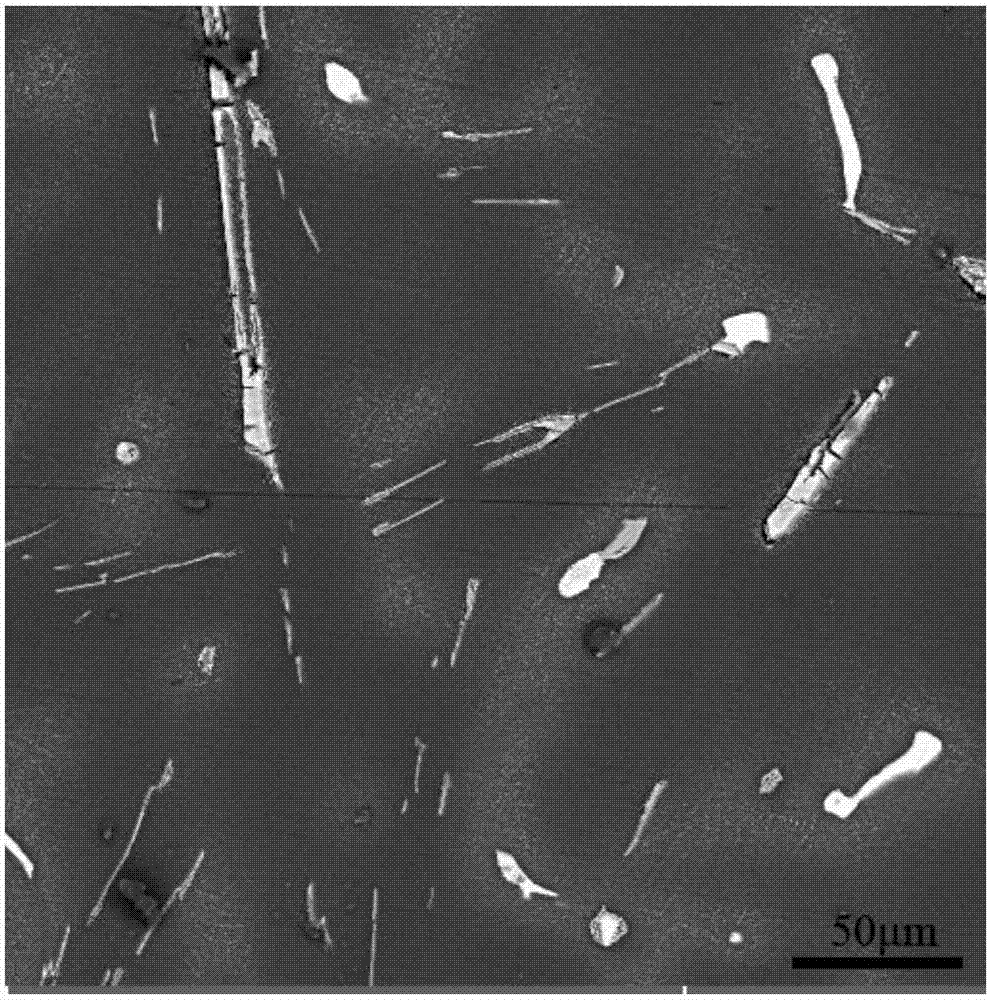

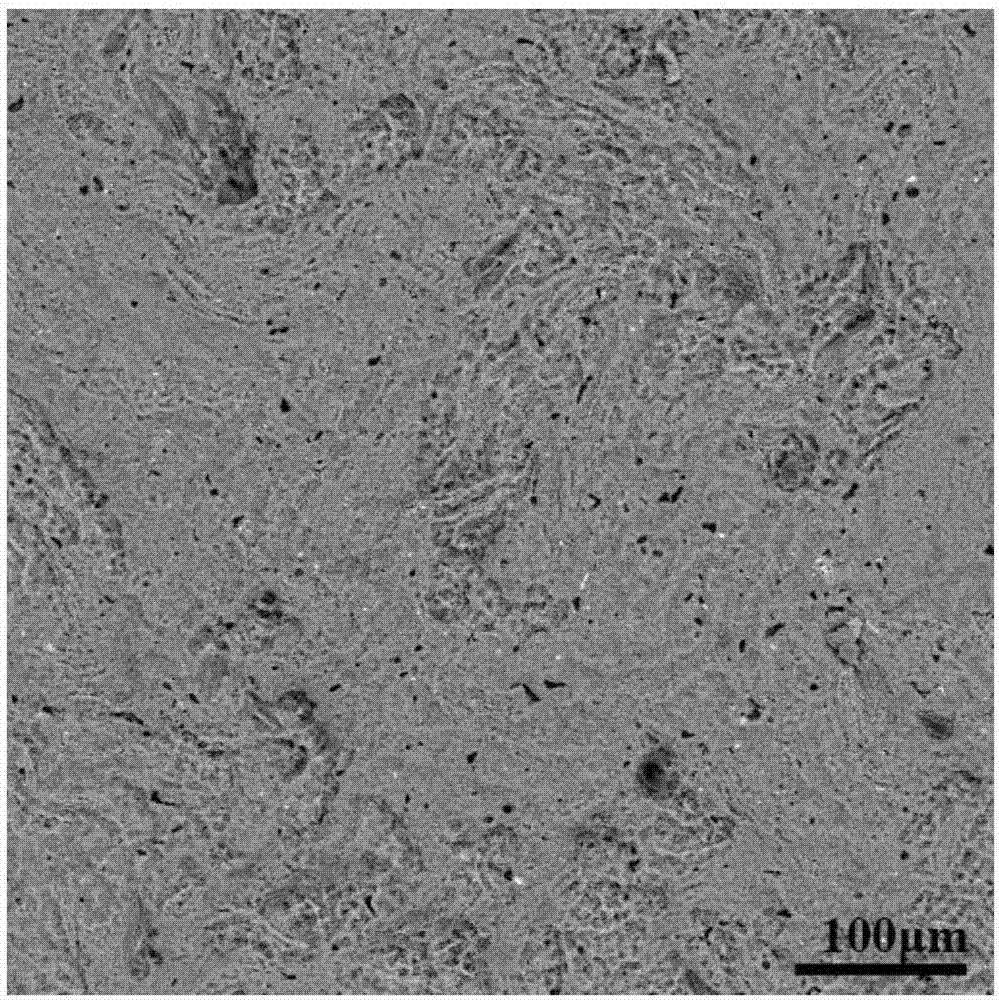

High-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and manufacturing method thereof

InactiveCN101805864ASolve the mechanical propertiesImprove mechanical propertiesQuasicrystalDislocation

The invention relates to high-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and a manufacturing method thereof. The high-damping and high-strength Mg-Cu-Mn-Zn-Y alloy is characterized by comprising the following alloying element components distributed in the alloy and the content value thereof in percent by weight: 1.0%-4.0% of Cu, 0.3%-1.5% of Mn, 0.3%-4.0% of Y, 1.0%-5.5% of Zn and the balance of magnesium. In order to solve the conflict of the damping property and the mechanical property of the magnesium alloy, the invention puts forward the fact that a Zn element and a Y element are added in the high-damping Mg-Cu-Mn alloy so that the Mg, the Zn and the Y form quasicrystals and / or long-prepared phases in the alloy, the quasicrystals or the long-prepared phases can introduce a great amount of new movable dislocations in a magnesium matrix, the damping property of the magnesium alloy is improved through movable dislocations newly increased in the magnesium matrix, and then the conventional heat extrusion is carried out on the alloy so that the mechanical property of the alloy is improved. The invention has the advantages of simple process, strong transportability, easy operation and lower cost and solves the problem that the Mg alloy has limited application due to high damping property and low mechanical property, and the used equipment is conventional and general equipment.

Owner:CHONGQING UNIV

Process for preparing nickel-base superalloy

ActiveCN102808113AElimination of lateral grain boundariesImprove organizationPolycrystalline material growthSingle crystal growth detailsSmelting processRoom temperature

The invention discloses a process for preparing nickel-base superalloy. The superalloy consists of the following components in percentage by weight: 22.5 to 24.5 percent of Cr, 7.0 to 8.0 percent of Co, 6.5 to 7.5 percent of W, 3.0 to 4.0 percent of Mo, 1.2 to 1.8 percent of Al, 1.5 to 2.5 percent of Ti, 2.0 to 3.0 percent of Nb, 1.0 to 2.0 percent of Mn, 2.0 to 4.0 percent of Fe, 0.02 to 0.08 percent of B, 0.5 to 1.5 percent of Ce, less than or equal to 0.1 percent of C, less than or equal to 0.2 percent of Si, less than or equal to 0.008 percent of P, less than or equal to 0.008 percent of S and the balance of Ni. The process for preparing the nickel-base superalloy comprises a smelting process and a heat treatment process, wherein the smelting process comprises the steps of: smelting master alloy by using a vacuum induction furnace, and performing directional solidification in a liquid metal directional furnace to prepare directional column crystal alloy, wherein the vacuum degree of the directional furnace is about (1-5)*10<-4>mmHg, the pouring temperature is 1,580 to 1,600 DEG C, the drawing speed is 4 to 8mm / min, the temperature gradient is 75 to 85 DEG C / cm, and the temperature of liquid tin is 250 to 350 DEG C; the heat treatment process comprises the following steps of: heating the column crystal alloy obtained through smelting to 1,240 to 1,260 DEG C, preserving heat for 3 to 5 hours, and performing air cooling to room temperature; heating to 1,150 to 1,170, preserving heat for 3 to 5 hours, and performing air cooling to room temperature; and heating to 930 to 950 again, preserving heat for 8 to 12 hours and performing air cooling to room temperature.

Owner:南通大地电气股份有限公司

Titanium microalloyed 500-MPa high-strength steel bar and production method thereof

The invention discloses a 500-MPa high-strength steel bar for reinforced concrete and a production method thereof, belonging to the technical field of microalloying in ferrous metallurgy. The steel in the steel bar comprises the following chemical components in percentage by weight: 0.18-0.25% of C, 0.20-0.80% of Si, 1.20-1.50% of Mn, 0.06-0.12% of Ti, at most 0.01% of N, at most 0.045% of S, at most 0.045% of P, and the balance of Fe and inevitable impurities. The preparation method of the steel bar comprises the following steps: a. crude smelting, tapping, deoxidizing and alloying; b. refining and composition fine adjustment, and casting after satisfying the steel bar composition requirement; and c. hot rolling; wherein the titanium is alloyed in the tapping process after deoxidizing or in the refining process. By using the principle that the titanium in steel reinforces the precipitation, the invention enhances the mechanical properties of the steel, and satisfies the performance requirements for 500-MPa high-strength steel bars and even anti-seismic steel bars.

Owner:PANZHIHUA GANGCHENG GROUP

Fire-resistant weather-proof steel plate for 690MPa-grade building structure and manufacturing method thereof

The invention relates to the technical field of fire-resistant weather-proof steel plates for building structures, in particular to a fire-resistant weather-proof steel plate for 690MPa-grade buildingstructure and a manufacturing method thereof. The steel plate consists of the following chemical components in percentage by weight: 0.05%-0.10% of C, 0.10%-0.40% of Si, 1.20%-1.80% of Mn, less thanor equal to 0.010% of P, less than or equal to 0.003% of S, 0.7%-1.1% of Ni, 0.65%-1.10% of Cu, 0.20%-0.60% of Mo, 0.07%-0.12% of Nb, 0.05%-0.075% of V, 0.02%-0.035% of Ti, less than or equal to 0.0025% of B, 0.01%-0.04% of Al, and the balance of iron and inevitable impurities. The fire-resistant weather-proof steel plate adopts a two-phase region once thermal treatment process to obtain a reversetransformed austenite structure which is proper in proportion and stable, so that a multi-phase structure which consists of tempered-state martensite, a nano precipitated phase and retained austeniteis finally obtained. A smelting and continuous-casting process scheme realizes low-phosphor low-carbon control. The product has high strength and toughness, high plasticity, a low yield ratio, and excellent fire resistance, weather resistance and lamellar tearing resistance.

Owner:ANGANG STEEL CO LTD

HRB500 anti-seismic reinforcing steel bar and production method

The invention discloses an HRB500 anti-seismic reinforcing steel bar and a production method, which belong to the technical field of iron and steel smelting and are used for improving the intensity, yield ratio and stable yield strength of the anti-seismic reinforcing steel bar. The anti-seismic reinforcing steel bar is characterized by comprising the following chemical components: 0.17 to 0.25 percent of C, 0.40 to 0.80 percent of Si, 1.20 to 1.60 percent of Mn, 0.05 to 0.30 percent of Cr, 0.05 to 0.09 percent of V, less than or equal to 0.035 percent of P, less than or equal to 0.035 percent of S and the balance of Fe. In the product of the invention, Cr and V are used as microalloying elements, the adding amount of the Cr is small, the solution strengthening effect of the V is enhanced, the precipitation strengthening and fine-grain strengthening effect of the V is reduced, the excessive refining of the steel grains is avoided, and the tensile strength is improved greatly at the same time of improving the yield strength; and the HRB500 anti-seismic reinforcing steel bar which meets the requirement on the performance can be produced by control over the technological parameters such as initial rolling temperature, finish rolling temperature, rolling speed and the like in the production process.

Owner:宣化钢铁集团有限责任公司 +1

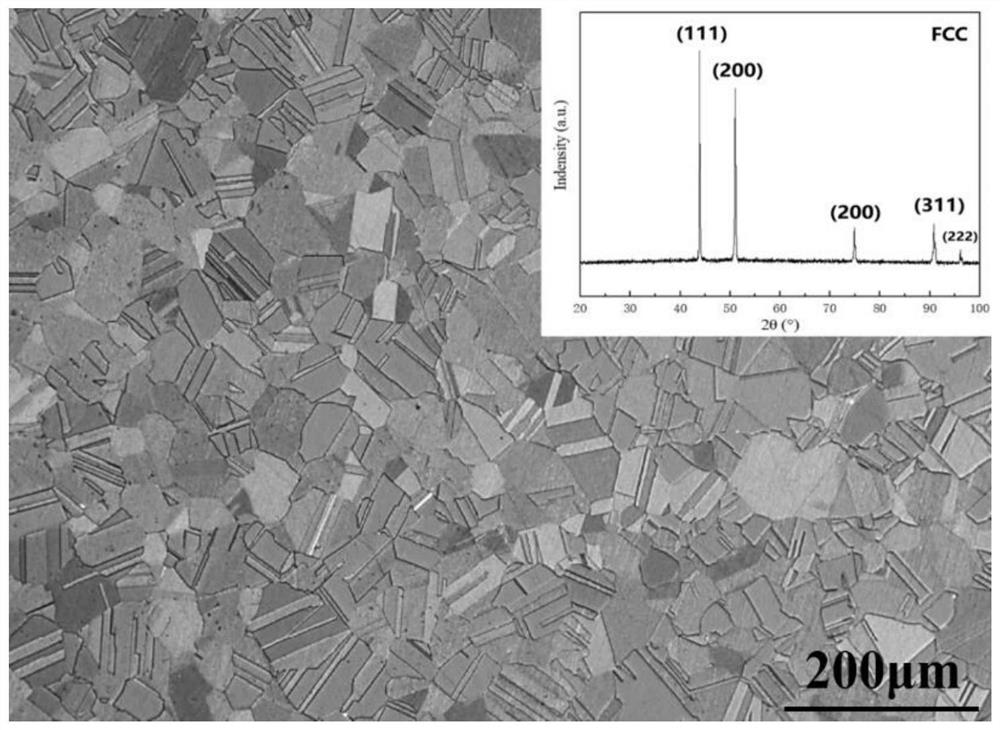

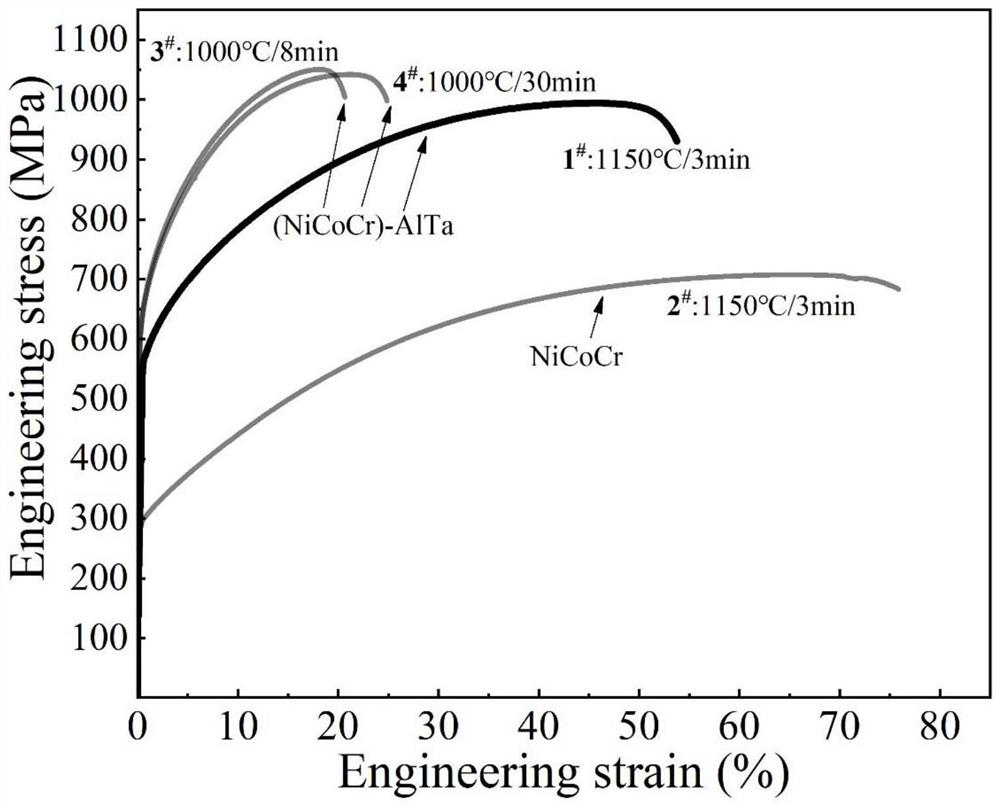

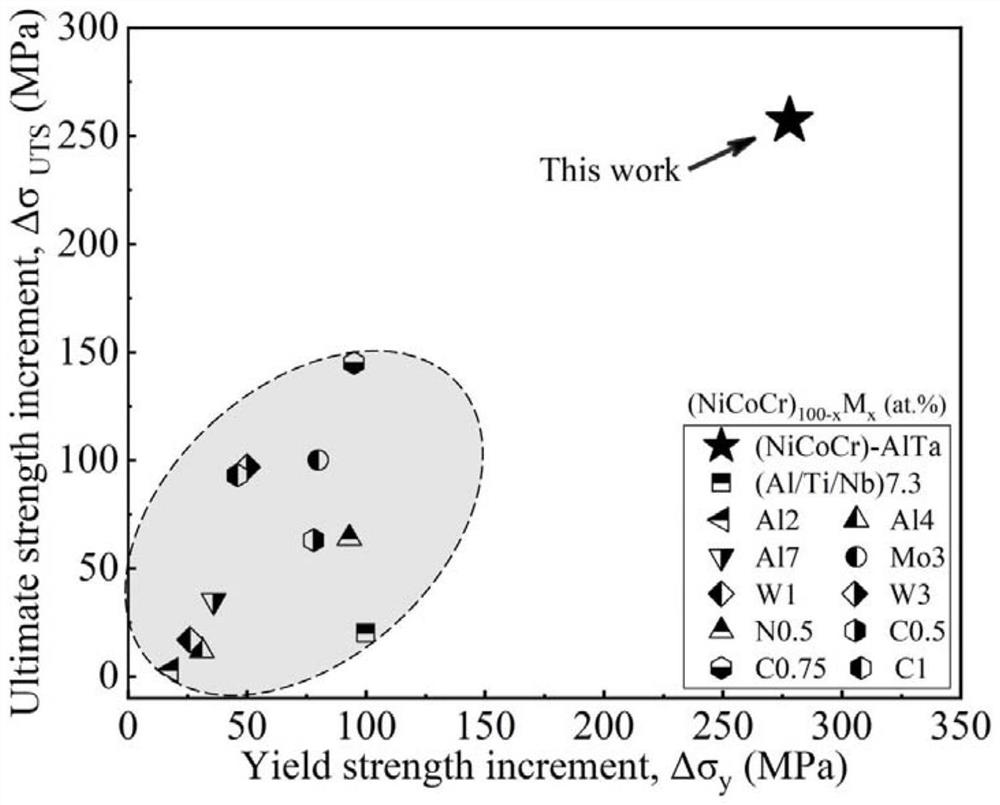

NiCoCr-based medium entropy alloy with excellent strength plasticity matching and preparation method

ActiveCN111893363AHigh strengthGood mechanical properties at room temperatureSolid solution strengtheningTensile ductility

The invention provides a NiCoCr-based medium entropy alloy with excellent strength plasticity matching and a preparation method. According to the NiCoCr-based medium entropy alloy with the excellent strength plasticity matching and the preparation method, microalloying treatment is performed by utilizing Al and Ta elements, and the alloy can obtain excellent strength-plasticity combination after being subjected to a simple deformation heat treatment process; and by means of Al / Ta element alloying, the grain size is reduced, the twin crystal content is increased, and a remarkable solid solutionstrengthening effect is generated, the lattice friction force is greatly increased, but the alloy still maintains a fcc matrix, so that the alloy still has good toughness while the alloy strength isimproved. The NiCoCr-based medium entropy alloy has excellent room-temperature mechanical properties, the NiCoCr medium entropy alloy yield strength is improved by 106% to be about 635 MPa, the tensile strength is improved by 35% to be about 1000 MPa, and meanwhile, the NiCoCr-based medium entropy alloy has a tensile ductility of 52% at the same time. Based on the above characteristics, the NiCoCr-based medium entropy alloy with the excellent strength plasticity matching is made to have a great competitive advantage in single-phase fcc high / medium entropy alloys and have the engineering application foreground extremely.

Owner:XI AN JIAOTONG UNIV

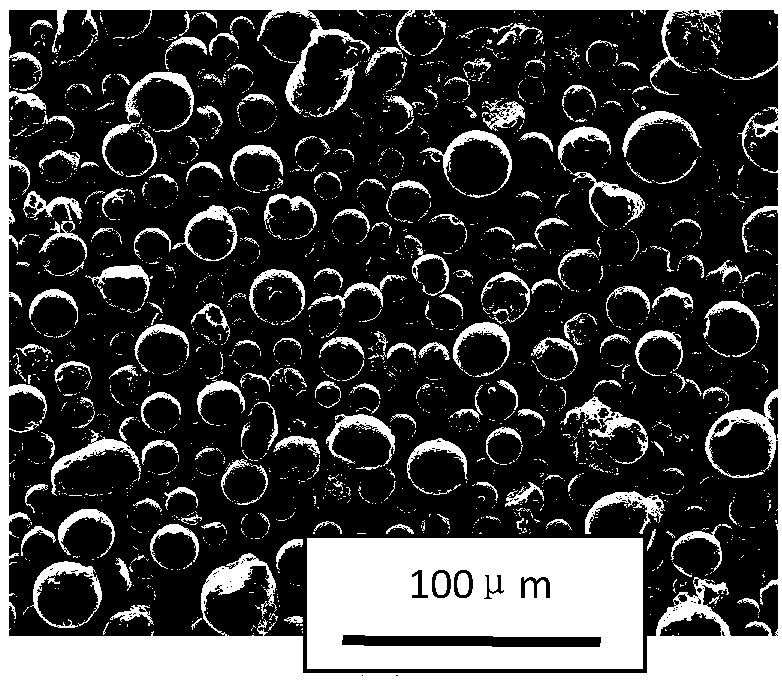

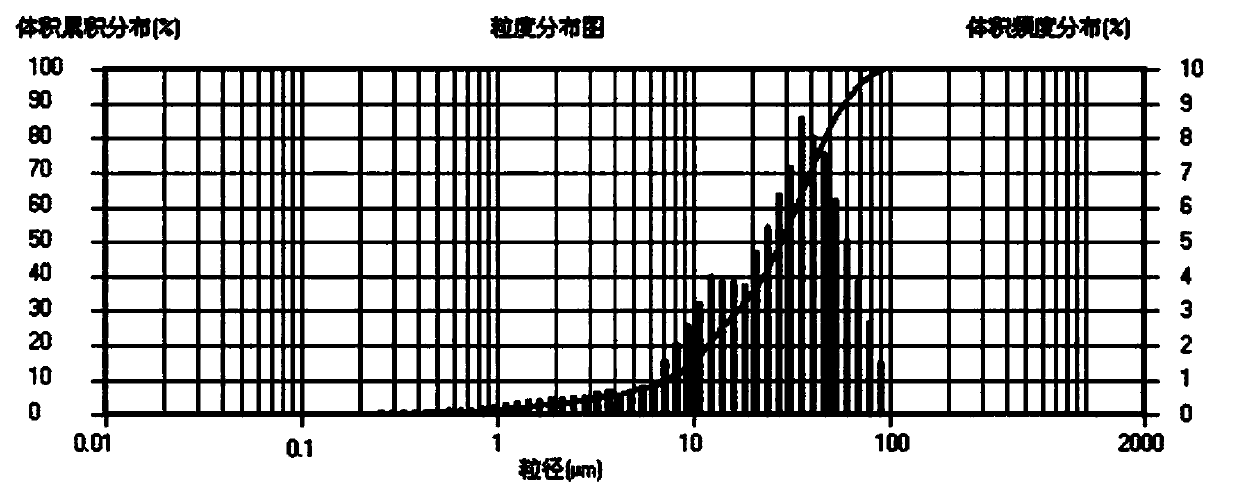

Ta-contained 3D printing cobalt chromium molybdenum alloy powder for dental department and preparation method thereof

ActiveCN107598151ASolve the broken porcelainSolve the problem of porcelain peelingAdditive manufacturing apparatusChemical compositionBond properties

The invention provides Ta-contained 3D printing cobalt chromium molybdenum alloy powder for the dental department and a preparation method thereof. The chemical components of the alloy power comprise,by weight, 26.0%-30.0% of Cr, 8.0%-10.0% of Mo, 0.5%-5.0% of Ta, 3.0%-8.0% of W and the balance Co. The preparation method of the Ta-contained 3D printing cobalt chromium molybdenum alloy powder comprises the three steps of mother alloy smelting, powder atomization, powder screening and drying treatment. According to the alloy powder, the particle size, the sphericility degree and the mechanicalproperty are ensured, and meanwhile, the gold-procelain bonding property, the thermal stability and the flowability are improved while the oxygen content is reduced, the problems of porcelain crackingand porcelain spalling of a cobalt chromium molybdenum alloy are effectively solved, and obtaining of dental rebuilt parts with the high quality is facilitated.

Owner:CHENGDU KENINGDA MATERIALS

Aluminum alloy profile for high-corrosion-resistance curtain wall and preparation method of aluminum alloy profile

InactiveCN106399778AHigh strengthGood repeatabilityAnodisationElectrophoretic coatingsElectrophoresisIngot

The invention discloses a preparation method of an aluminum alloy profile for a high-corrosion-resistance curtain wall. The preparation method of the aluminum alloy profile for the high-corrosion-resistance curtain wall comprises the following steps that molten aluminum comprising 3%-5% of Zn, 0.9%-1.3% of Mg, 0.6%-1.2% of Cu, 0.05%-0.15% of Mn, 0.06%-0.12% of Cr, 0.07%-0.12% of Re, 0.06%-0.12% of Zr, 0.03%-0.06% of Sc, 0.15%-0.35% of Fe, 0.15%-0.35% of Si, 0.02%-0.06% of Ti and the balance Al is cast into a cast ingot, and then homogenizing treatment and extrusion forming are conducted; degreasing, alkali washing and anodic oxidation treatment are conducted after stretching and straightening; and finally, electrophoresis treatment is conducted, so that the aluminum alloy profile is obtained. According to the aluminum alloy profile for the high-corrosion-resistance curtain wall and the preparation method of the aluminum alloy profile, the curtain wall made of the aluminum alloy profile is good in corrosion resistance, high in strength, not prone to deformation or color changing, and long in service life.

Owner:安徽省煜灿新型材料科技有限公司

Copper-chromium-zirconium alloy and preparation method thereof

Copper-chromium-zirconium alloy is characterized by being prepared from the following raw materials in percent by weight: 0.2-1.2% of chromium, 0.05-0.2% of zirconium, 0.06-0.10% of magnesium, 0.05-0.5% of scandium and the balance of copper. The invention further provides a preparation method of the copper-chromium-zirconium alloy. The preparation method sequentially comprises the following steps:(1), proportionally preparing copper, chromium, zirconium, magnesium and scandium elements, performing vacuum smelting, and performing split casting to obtain a casting blank; (2), performing homogenizing treatment and hot extrusion on the casting blank to obtain a bar blank; (3), performing solid solution treatment to the bar blank; (4), performing cold deformation processing on the bar blank obtained after the solid solution treatment; (5), performing aging treatment to a material obtained after the cold deformation processing to obtain the needed copper-chromium-zirconium alloy. The copper-chromium-zirconium alloy has high tensile strength, high electrical conductivity and high elongation and has relatively high high-temperature tensile strength and excellent comprehensive performance.

Owner:GUANGDONG HUAXING HEAT EXCHANGE EQUIP CO LTD +1

High-strength corrosion-resistant wrought magnesium alloy and preparing method thereof

ActiveCN107236884AImprove mechanical propertiesImprove corrosion resistanceSolid solution strengtheningCa element

The invention relates to a high-strength corrosion-resistant wrought magnesium alloy and a preparing method thereof. The magnesium alloy comprises, by mass percentage, 6.0%-9.0% of Sn, 1.5%-4.0% of Zn, 0.1%-1.0% of Mn, 0%-1.0% of Ca, 0.01%-0.1% of Na, less than 0.03% of inevitable impurities in total and the balance Mg. The Sn element serves as a main alloy element, and therefore the solution strengthening effect and the second phase strengthening effect are guaranteed, SnO2 can be formed in the corrosion process, and the protection performance of a Mg(OH)2 film is improved; the Zn element is added into a solution strengthening magnesium base; through adding of the Mn element, the content of impurity elements in the magnesium base can be reduced, the grain size of the extrusion state alloy is reduced, and the mechanical property and the decay resistance of the alloy are improved; through adding of the Ca element, a CaMgSn phase can be formed to participate in formation of an oxidation film, and the density of the oxidation film is increased; and through adding of the Na element, the size of a second phase can be refined. In cooperation with joint effects of several aspects, the alloy has the excellent mechanical property and decay resistance.

Owner:DONGHAO MECHANICAL & ELECTRONICS

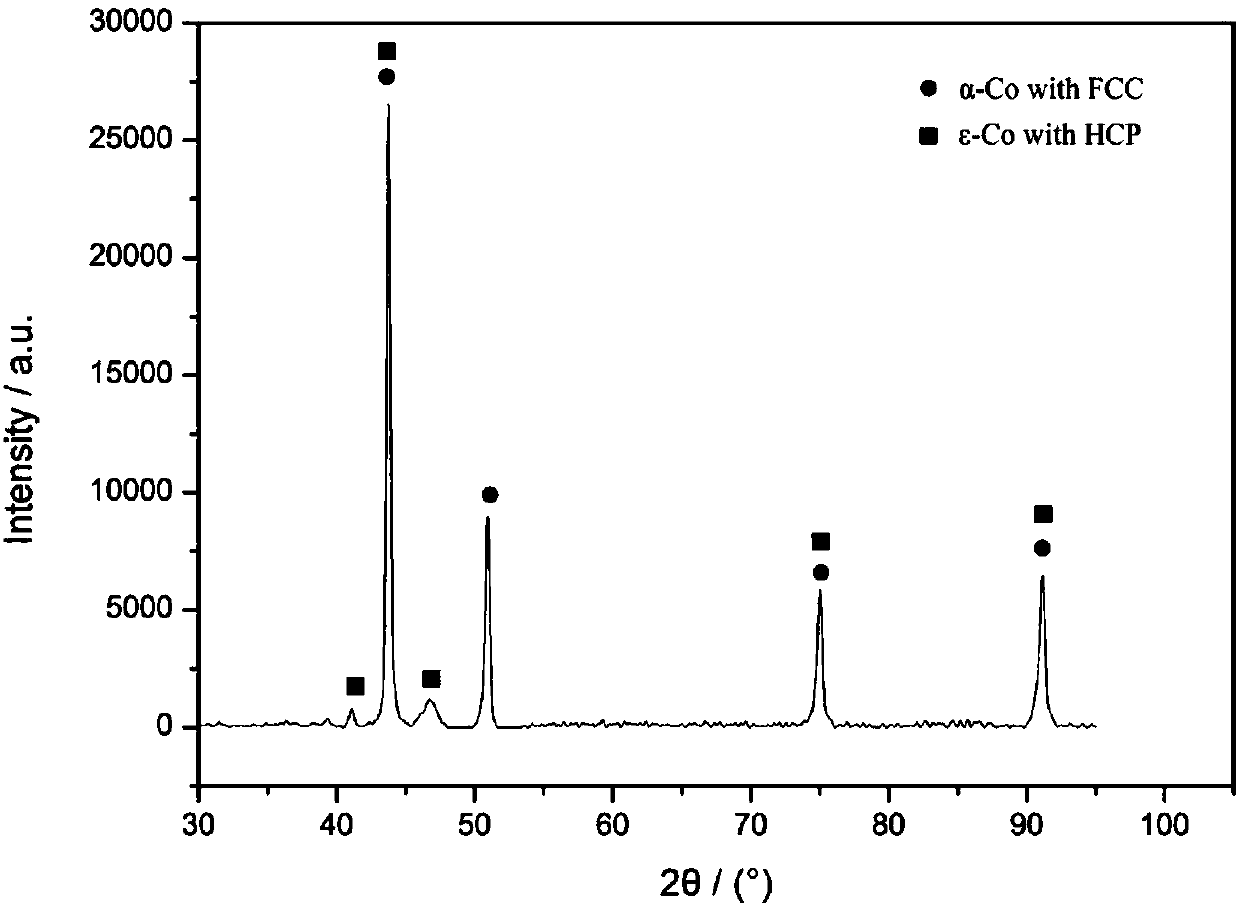

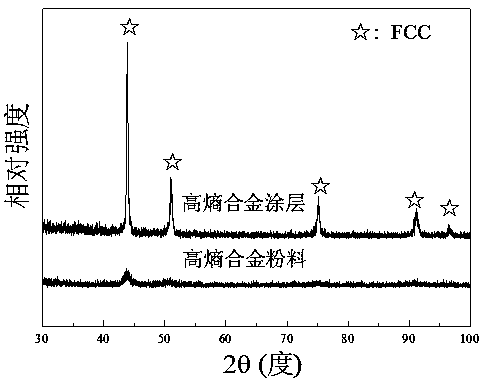

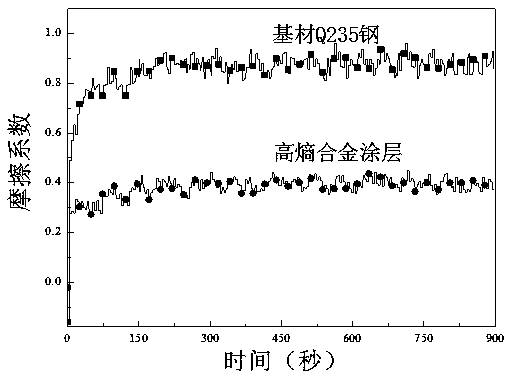

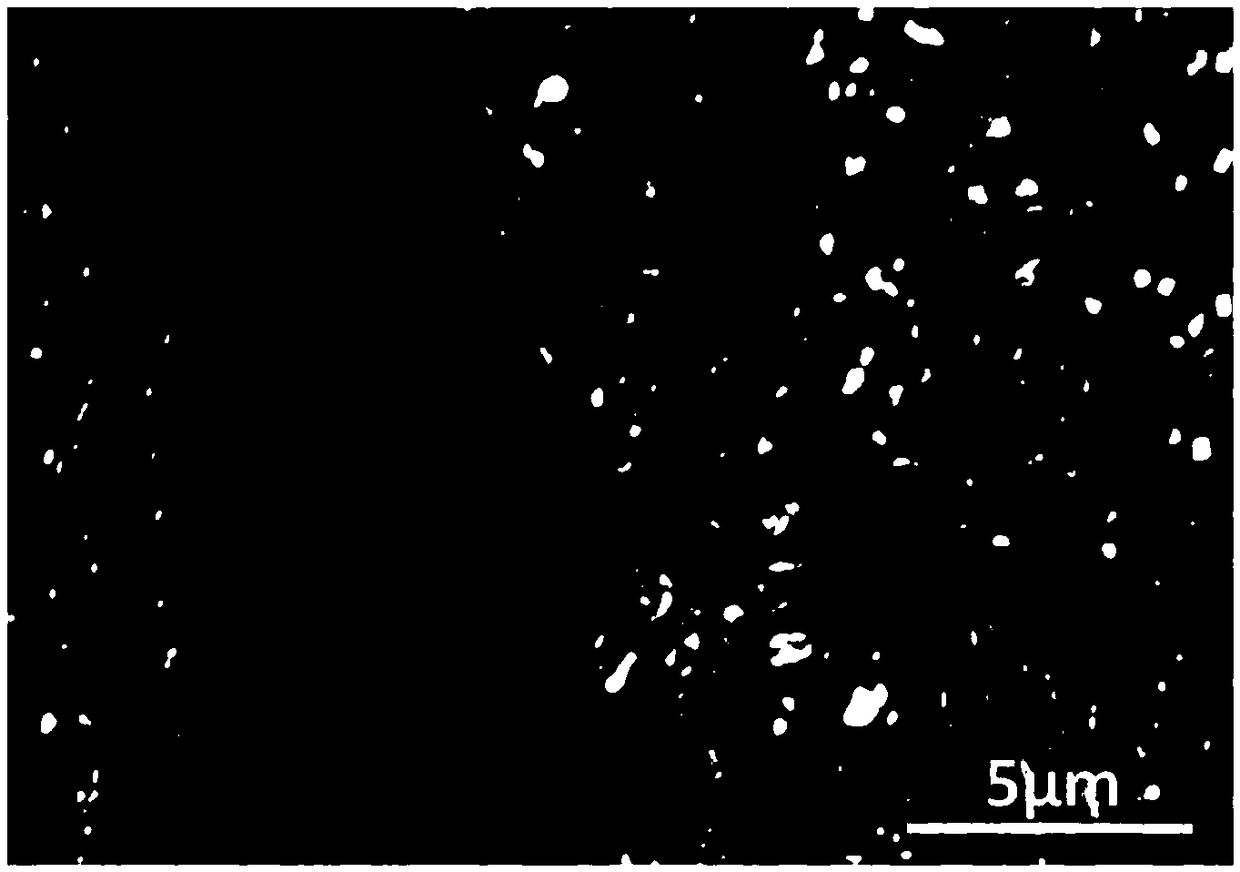

Preparation method for high-entropy alloy coating

ActiveCN105506613AHigh hardnessImprove wear resistanceHeat inorganic powder coatingHigh entropy alloysHardness

The invention relates to a preparation method for high-entropy alloy coating, and belongs to the technical field of alloy coating preparation. The preparation method comprises the following steps: placing high-entropy alloy powder presenting a single face-centered cubic structure on the surface of a steel base material; sintering by utilizing a vacuum hotpressing sintering furnace: firstly, adjusting the vacuum degree of a furnace chamber to be 1.0*10<-3> Pa, then rising the temperature to 800-1,000 DEG C with the temperature rising speed of 5-10 K / min, controlling the sintering pressure to be 20-40 Mpa, and sintering for 30-90 min. According to the preparation method, the high-entropy alloy powder presenting the single face-centered cubic structure is used as a raw material, the manner of vacuum hotpressing sintering which is simple in operation and common in used equipment is adopted for the first time to prepare the excellent high-entropy alloy coating; through control of the sintering process, the prepared CoCrFeNi coating still keeps the single face-centered cubic structure, and the hardness and the wear resistance of the coating are obviously improved.

Owner:UNIV OF JINAN

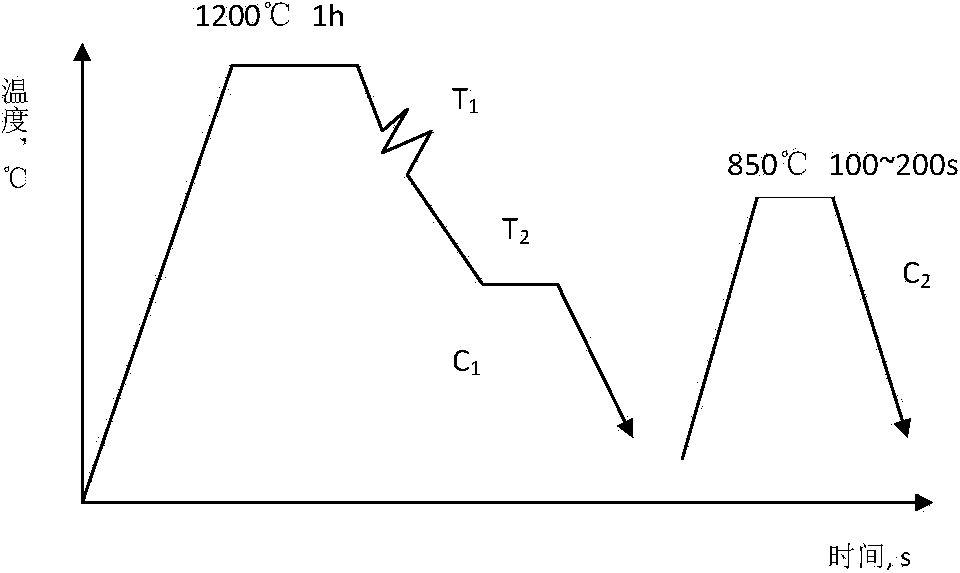

440MPa of precipitation strengthening-type cold rolled interstitial free (IF) steel containing niobium and production method thereof

InactiveCN103451531AObvious beneficial effectImprove deep drawing performanceChemical compositionNiobium

The invention discloses 440MPa of precipitation strengthening-type cold rolled interstitial free (IF) steel containing niobium and a production method thereof. The deep drawing forming property of the IF steel is improved when high strength is obtained. The IF steel comprises the following chemical components: 0.005-0.008% of C, 0.05-0.08% of Si, 1.5-2.0% of Mn, less than 0.04% of P, less than 0.004% of S, 0.003% or less of N, 0.08-0.12% of Nb, 0.0005-0.002% of B, 0.01-0.03% of Ti, and the balance of Fe and inevitable impurities. The production method comprises the following processes: smelting, hot rolling, cold rolling, continuous annealing or hot galvanizing; the technological parameters of rolling are as follows: the heating temperature of a plate blank is 1150-1250 DEG C; the finish rolling temperature is 880-900 DEG C; the plate blank is formed into 4mm from 35mm in a hot rolling manner; the coiling temperature is 620-660 DEG C / s; reduction in cold rolling is 80-85%; the continuous annealing temperature is 830-870 DEG C; the continuous annealing heat preservation time is 100-200 seconds; the cooling speed is 15-25 DEG C / s after annealing. By adopting the production method, the 440MPa of high-strength IF steel with good deep drawing property, of which the strength is greater than or equal to 440MPa, the yield ratio is smaller than 0.6, the ductility is 33-36%, and an r value is greater than or equal to 1.7 can be obtained.

Owner:UNIV OF SCI & TECH LIAONING

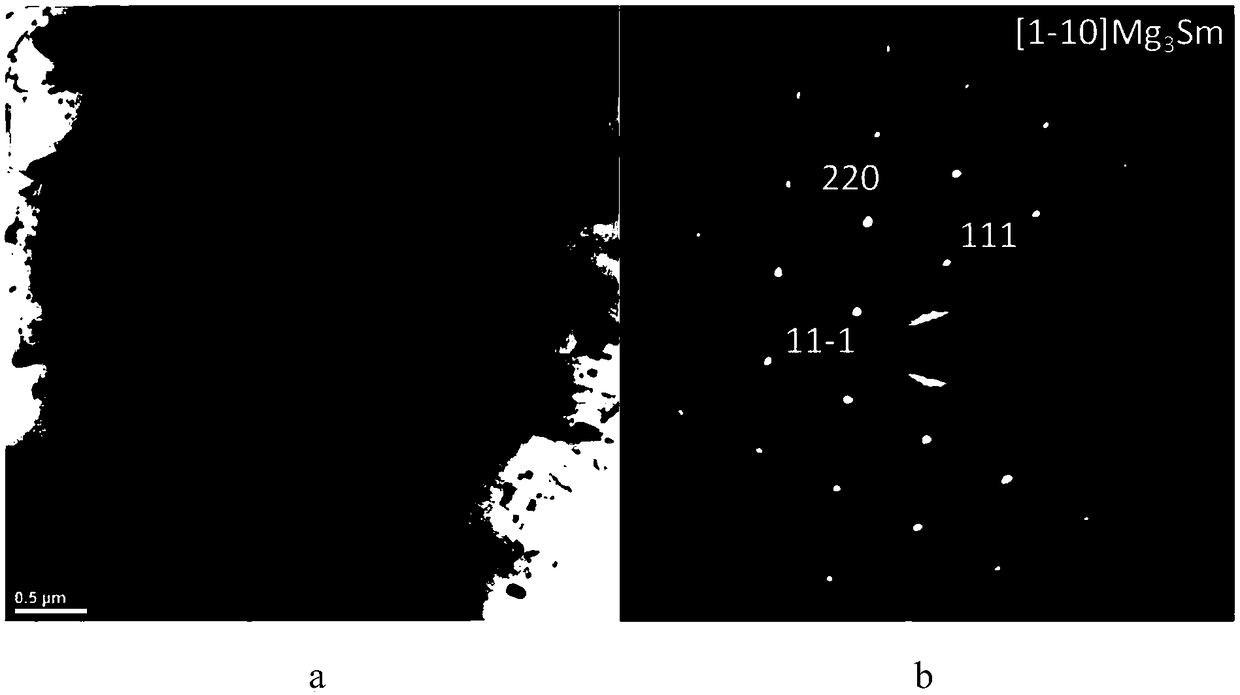

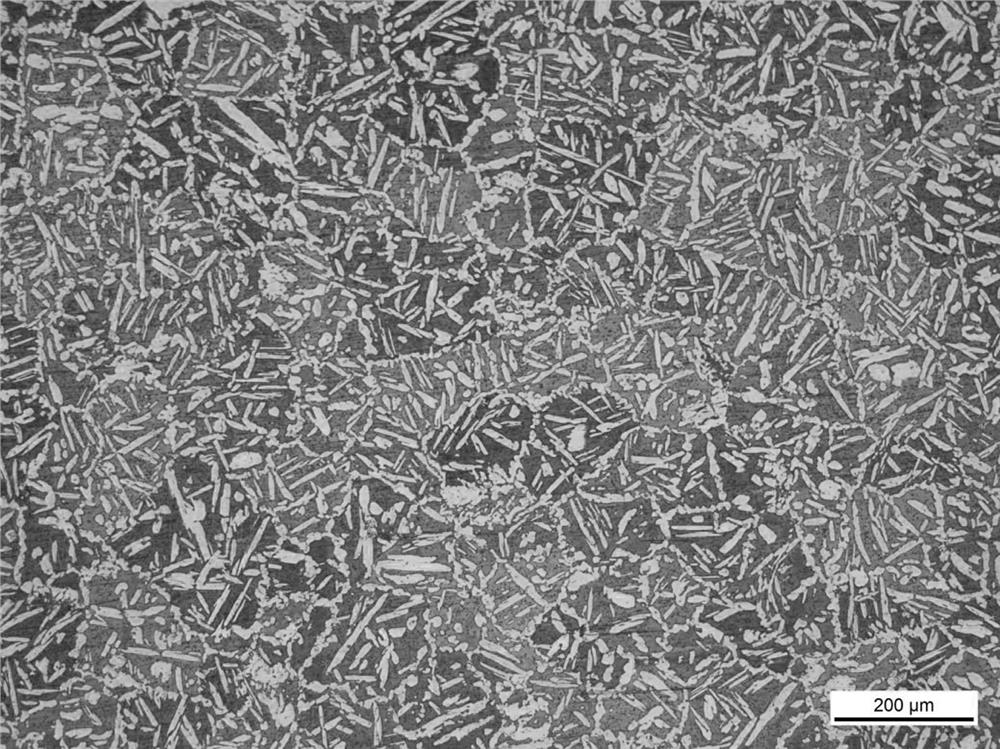

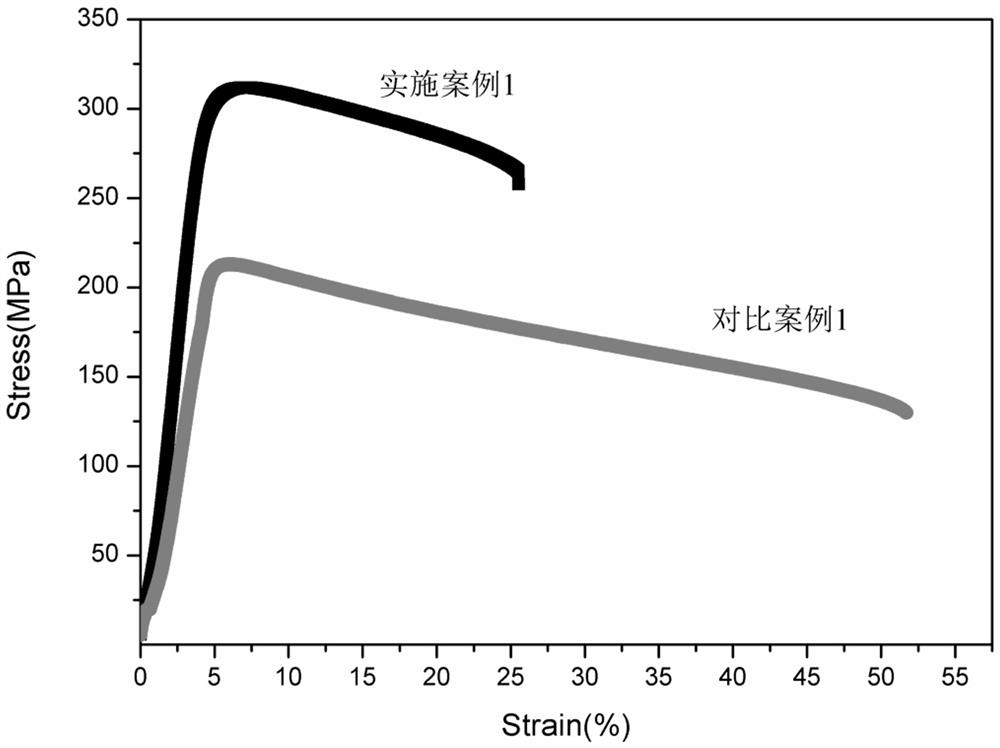

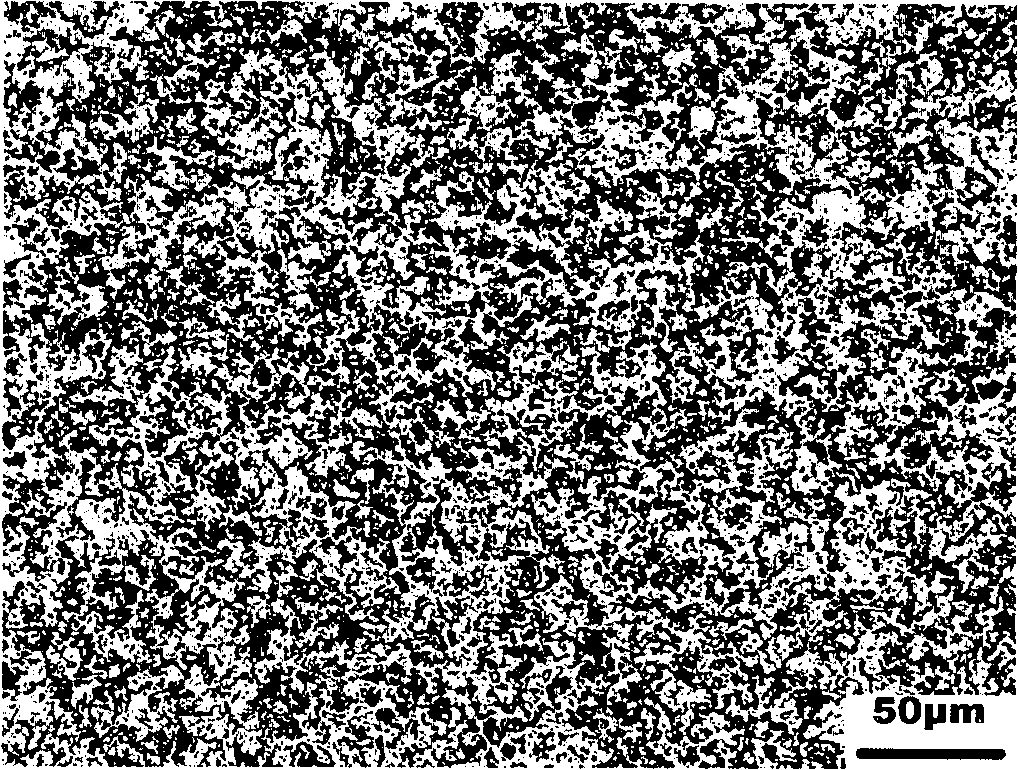

High-strength deformation magnesium alloy containing rare earth samarium, and preparation method thereof

The invention provides a high-strength deformation magnesium alloy containing rare earth samarium, and a preparation method thereof, belongs to the technical field of metal materials, and solves the problem of overhigh rare earth content and poor mechanical property of traditional magnesium alloy. The magnesium alloy disclosed by the invention is prepared from the following ingredients in parts byweight: 1.0-6.6wt% of Sm, 0.5-3.5wt% of Zn, 0.15-1.5wt% of Zr and the balance of Mg. The invention also provides a preparation method for the high-strength deformation magnesium alloy containing rareearth samarium. The high-strength deformation magnesium alloy containing rare earth samarium disclosed by the invention has excellent mechanical property. Mg-3.5Sm-0.6Zn-0.5Zr is taken as an exampleto show that the indoor temperature yield strength and the tensile strength are respectively 415MPa and 423MPa.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High-strength high-plasticity high-yield-ratio magnesium-lithium alloy and preparation method and application thereof

ActiveCN112593131AGood solid solution strengthening effectMorph coordinationDigital processing power distributionVacuum castingSolution treatment

The invention belongs to the technical field of magnesium-lithium alloy material preparation, and particularly relates to a high-strength high-plasticity high-yield-ratio magnesium-lithium alloy and apreparation method and application thereof. The high-strength high-plasticity high-yield-ratio magnesium-lithium alloy and the preparation method and application thereof are used for solving the problems of low absolute strength, difficult matching of strong plasticity and yield ratio of the magnesium-lithium alloy, the high-strength high-plasticity high-yield-ratio magnesium-lithium alloy material with high yield ratio, good plasticity, stable quality and high purity is obtained by designing the components of the magnesium-lithium alloy, optimizing a vacuum casting process and adopting a novel deformation heat treatment process, and the magnesium-lithium alloy has an industrialized practical application prospect. According to the preparation method of the high-strength, high-plasticity and high-yield-ratio magnesium-lithium alloy, the plastic processing procedure is simple, the maneuverability is high, only medium-high temperature solution treatment and medium-low temperature deformation are needed, intermediate process annealing is not needed, the yield is high, the economical efficiency is high, and the magnesium-lithium alloy product with the tensile strength of 330 MPa, the yield strength of 314 MPa, the elongation of 16% and the yield ratio of up to 95% or above can be obtained through the method.

Owner:郑州轻研合金科技有限公司

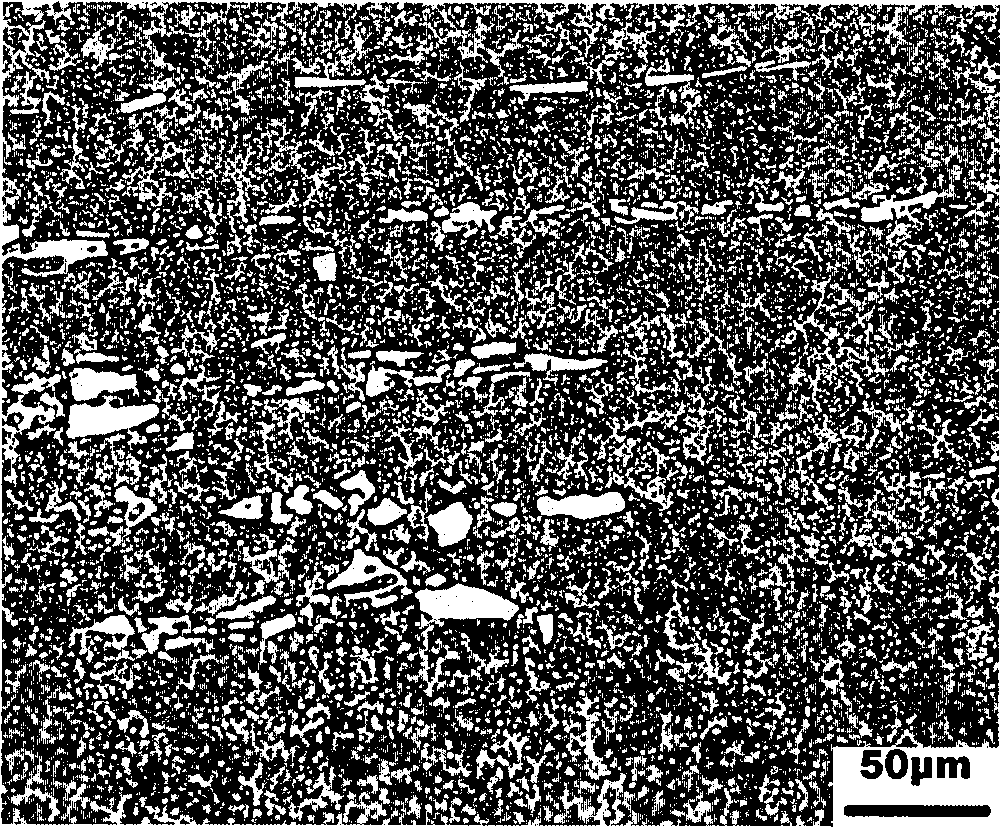

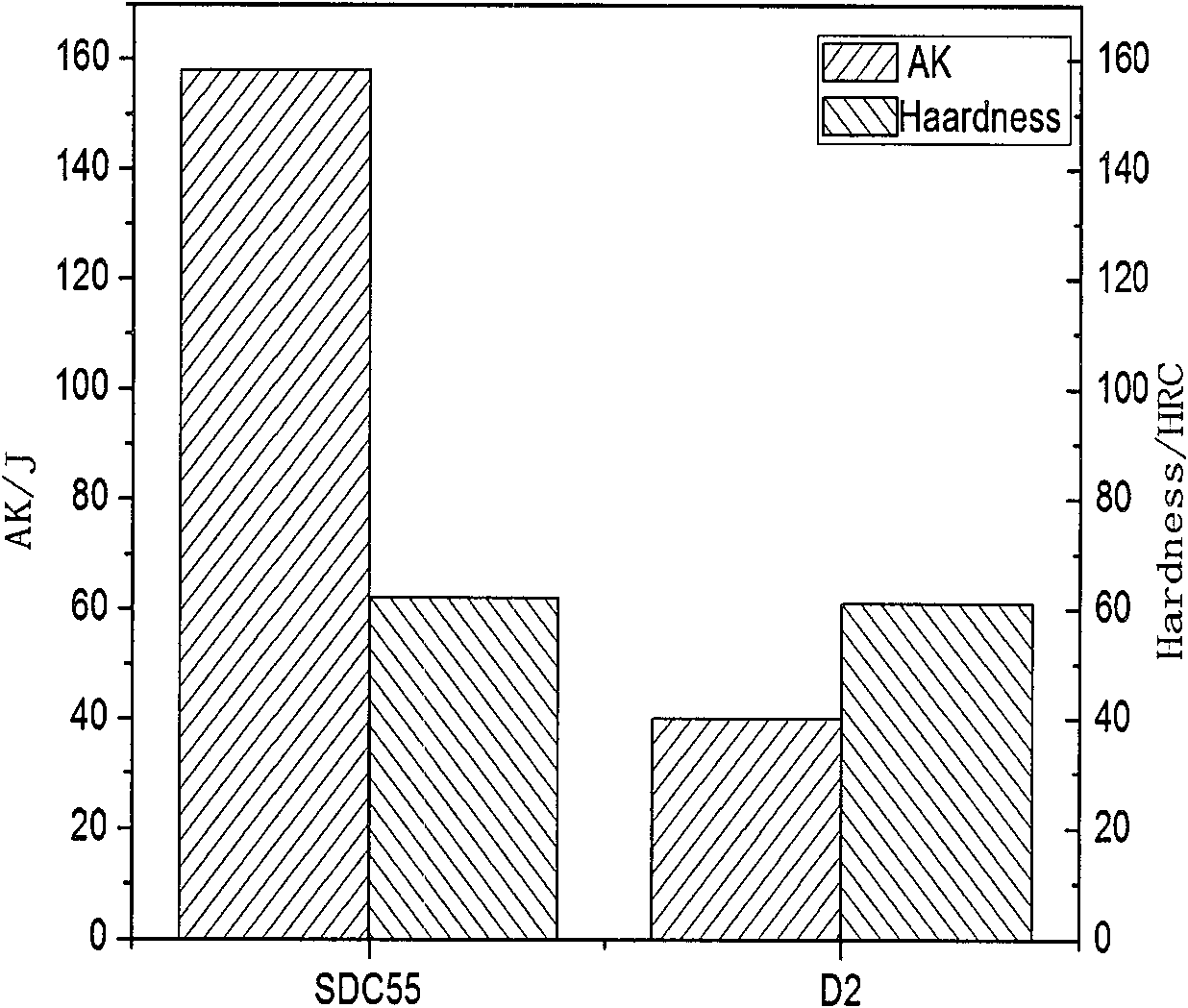

Low alloy die steel

The invention relates to a low alloy die steel material which comprises the following components by weight: 0.68-0.78% of C, 0.7-1.0% of Si, 0.7-1.1% of Mn, not more than 0.02% of P, not more than 0.02% of S, 2.2-2.5% of Cr, 0.2-0.3% of Mo, 0.15-0.35% of V, 0.3-0.4% of Ni, the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: performing smelting and casting of the components to obtain a steel ingot; adding the steel ingot into a radial forging machine heating furnace at 600-800 DEG C, heating to 1200-1230 DEG C with a heating speed of 60-120 DEG C / h, then performing thermal insulation for 3-5 hours; forging in a forging machine to obtain steel materials with an initial forging temperature of 1050-1100 DEG C and a final forging temperature of not less than 850 DEG C. After the obtained die steel is subject to quenching at 910-950 DEG C and tempering heat treatment at 160-200 DEG C, the impact toughness is above 135 J / cm2, and the hardness HRC is above 62.

Owner:宝武特种冶金有限公司

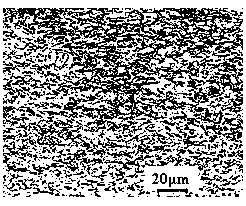

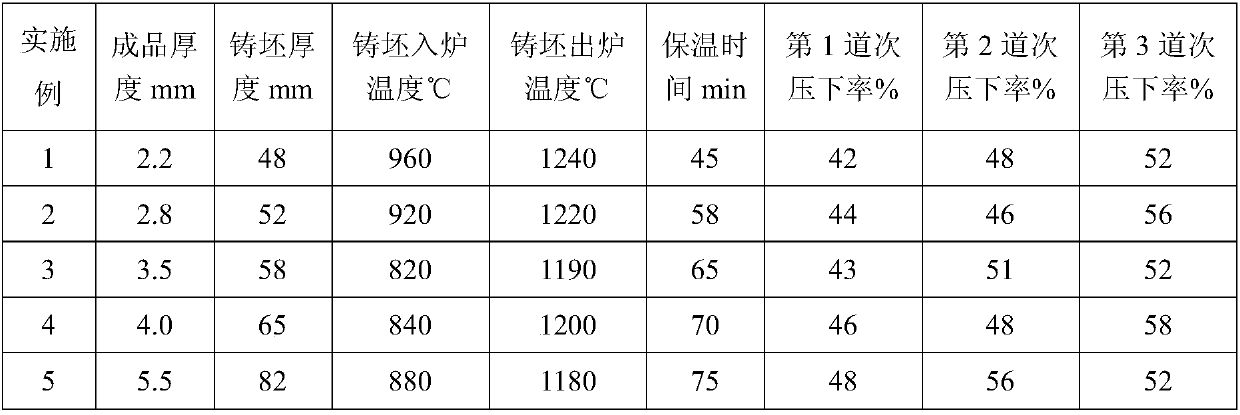

Holt-rolled bainite dual-phase steel with high reduction rate and high hole expansion rate and preparation method thereof

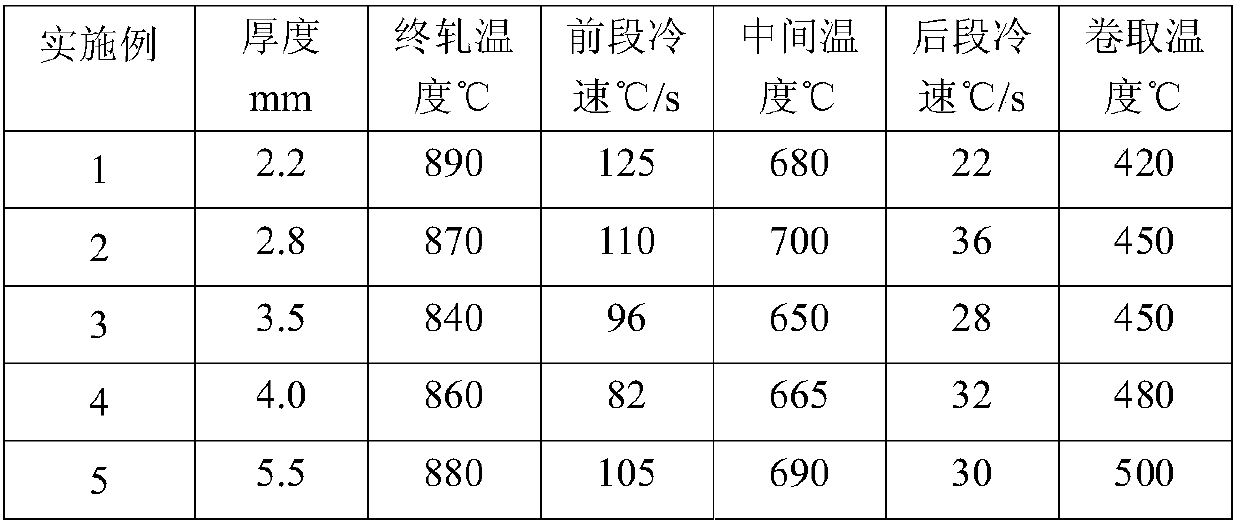

ActiveCN107723608AGood strength and plasticity matchingExcellent stretch flange performanceReduction rateLaminar cooling

The invention relates to holt-rolled bainite dual-phase steel with a high reduction rate and a high hole expansion rate and a preparation method thereof. According to the technical scheme, the chemical constituents of the holt-rolled bainite dual-phase steel with the high reduction rate and the high hole expansion rate comprise 0.05-0.09 wt% of C, 0.10-0.50wt% of Si, 1.40-1.80 wt% of Mn, 0.03-0.06wt% of Al, 0.03-0.05 wt% of Nb, 0.020 wt% or less of P, 0.005 wt% or less of S, 0.006 wt% or less of N, and the balance Fe and inevitable impurities. The chemical constituents are subjected to smelting, refining and casting or continuous casting so as to obtain a blank; the blank is put into a heating furnace with the charging temperature being 800-1000 DEG C, heated to 1180-1250 DEG C and subjected to heat preservation for 40-80 min; high reduction is carried out in first three passes, the reduction rate is 40-60%, and the finish rolling temperature is 840-900 DEG C; sectionally continuous laminar cooling and reeling are carried out; and the steel is naturally cooled to the room temperature. The process is simple and the production cost is low; and the prepared holt-rolled bainite dual-phase steel is good in strength and plasticity matching, excellent in welding performance and excellent in flange elongation.

Owner:WUHAN UNIV OF SCI & TECH

High-strength and high-toughness cast rare earth magnesium alloy and preparation method thereof

InactiveCN106591659AImprove mechanical propertiesImprove filling abilityMagnesium alloyRoom temperature

The invention provides a high-strength and high-toughness cast rare earth magnesium alloy and a preparation method thereof and belongs to the field of light metal materials. The cast rare earth magnesium alloy comprises the following components in percentage by mass: 0.1-3.3% of Yb, 0.2-1.0% of Zn, 0.3-0.8% of Zr and the balance Mg and unavoidable impurity elements. The invention also provides the preparation method of the high-strength and high-toughness cast rare earth magnesium alloy. The rare earth magnesium alloy prepared by using the preparation method has relatively high mechanical property and heat resistance; and experimental results prove that the high-strength and high-toughness cast rare earth magnesium alloy prepared by using the preparation method has the room-temperature ultimate tensile strength of 185-205MPa and the percentage elongation after fracture of 15.3-23.6%; and after being subjected to T5 treatment (200 DEG C*22h), the room-temperature ultimate tensile strength of the alloy can reach 295-320MPa.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

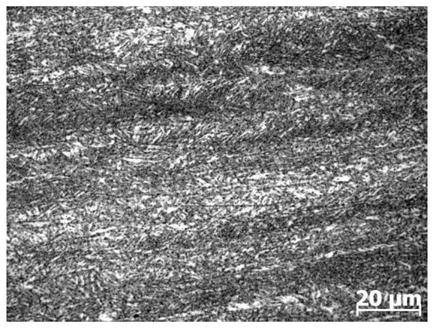

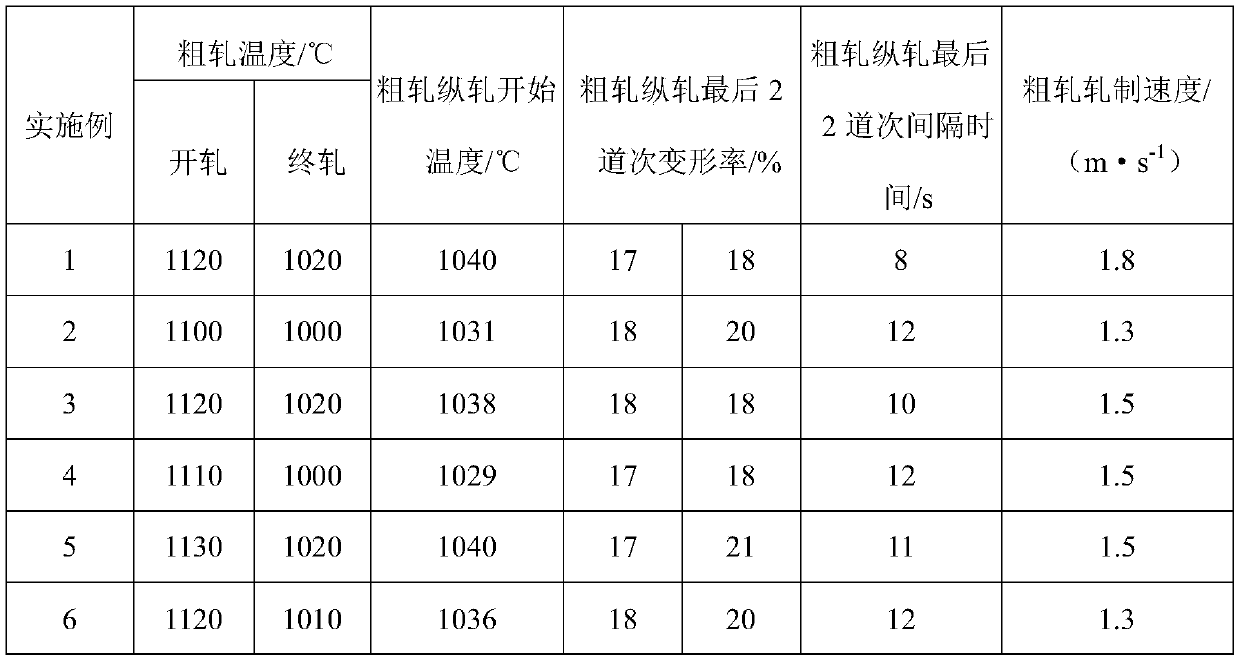

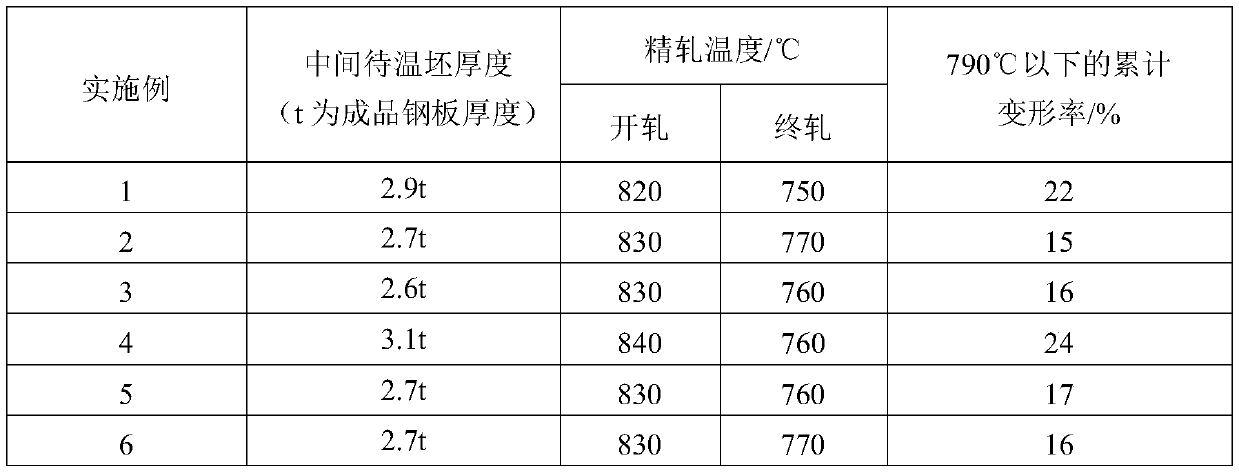

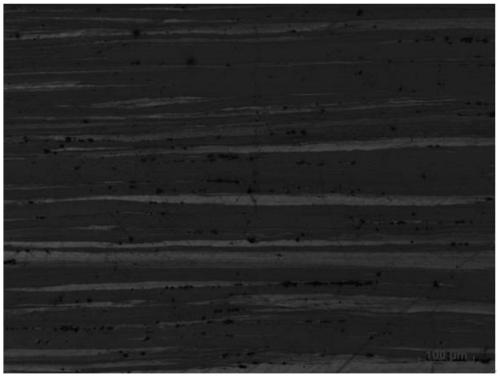

Ultrawide thick-wall and low-yield-ratio steel for X80 straight welding pipes and production method thereof

The invention discloses ultrawide thick-wall and low-yield-ratio steel for X80 straight welding pipes and a production method thereof. The steel contains 0.045-0.065% of C, 0.26-0.40% of Si, 1.60-1.80% of Mn, P not more than 0.010%, S not more than 0.0015%, 0.04-0.06% of Nb, 0.008-0.020% of Ti, 0.10-0.24% of Ni, 0.16-0.25% of Cu, Mo not more than 0.12%, Cr not more than 0.30%, 0.45-0.75% of Ni+Cu+Mo+Cr, 0.010-0.030% of Al, 0.0010-0.0040% of N, and the balance of Fe and inevitable impurities. The heating temperature of casting blanks is 1190-1220 DEG C; the uniform heating temperature is 1170-1200 DEG C; the rough rolling temperature is 1100-1140 DEG C; the finish rolling temperature is 810-840 DEG C; and the cooling temperature is 710-750 DEG C. The thickness of finished steel plates is not lower than 30 mm; the width is not lower than 4320 mm; and the low-temperature toughness and the strain resistance are excellent.

Owner:ANGANG STEEL CO LTD

Preparation method of medium-strength corrosion-resistant aluminum alloy sheet materials

PendingCN110042283AThe effect of reducing corrosion resistanceImprove the effect of solid solution strengtheningMetallic materialsHeat treated

The invention belongs to the field of metal materials and a machining and a preparation thereof, and discloses the preparation method of medium-strong corrosion-resistant aluminum alloy sheet materials. The preparation method comprises the following steps of designing the components of the aluminum alloy sheet materials; (2) smelting and casting, smelting the components, and casting into an aluminum alloy slab ingot; (3) homogenizing heat treatment and hot rolling, the aluminum alloy slab ingot head-removing milling six-surface, the aluminum alloy slab ingot is heated at the temperature of 480DEG C-510 DEG C, the heat preservation time is 6-12 hours, and the aluminum alloy slab ingot does not need to be cooled to the room temperature; when the temperature is reduced to be 480 DEG C or below, hot rolling is started, the hot rolling temperature ranges from 300 DEG C to 480 DEG C, and after 5-8 passes, the total deformation amount reaches 80%, (4) cold rolling, carrying out cold rollingto enable the cold rolling to reach the required thickness size of the sheet materials; and (5) carrying out the heat treatment and control, specifically, carrying out low-temperature annealing treatment on the cold-rolled sheet materials according to the requirements of the use performance of the aluminum alloy sheet materials. According to the preparation method, the problems of poor corrosion resistance, low efficiency and great internal stress in the traditional aluminum alloy sheet materials preparation process are solved.

Owner:YANTAI NANSHAN UNIV

Light refractory high-temperature-resistant eutectic high-entropy alloy and preparation method thereof

ActiveCN112981208AImprove high temperature performanceHigh phase contentChemical compositionHigh entropy alloys

The invention discloses a light refractory high-temperature-resistant eutectic high-entropy alloy and a preparation method thereof. The chemical component expression of the light refractory high-temperature-resistant eutectic high-entropy alloy is VaNbbMcSid, wherein M is one or more elements of Ti, Zr, Ta, Mo, Cr and Al, and a, b, c and d in the chemical expression respectively represent the molar percentages of the corresponding elements and meet the following relations: 0<a<= 45, 0<b<=35, 0<c<=35, 10<=d<=20, and a+b+c+d=100. The alloy is of a lamellar eutectic structure composed of a VNbM solid solution phase of a body-centered cubic structure and a (VNbM)5Si3 ordered compound phase of a tetragonal or hexagonal structure, has density far lower than that of a nickel-based and cobalt-based high-temperature alloy and an ultrahigh melting point, and has certain room-temperature plasticity, high high-temperature strength and excellent casting performance, thereby meeting the requirements for advanced high-temperature structural materials.

Owner:SHANGHAI JIAO TONG UNIV

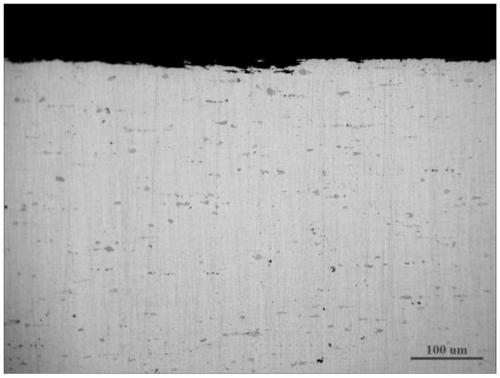

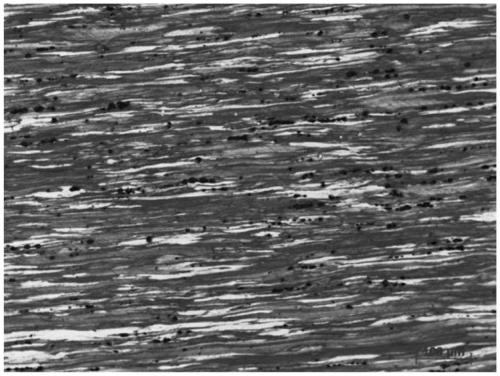

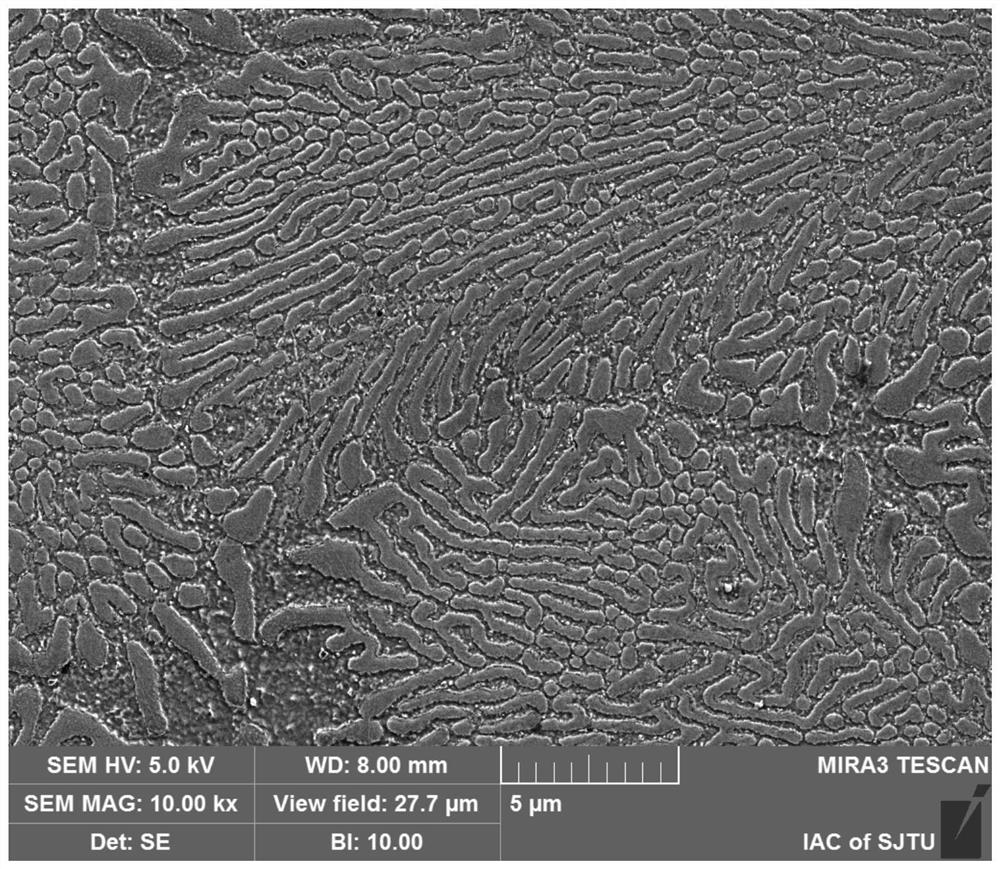

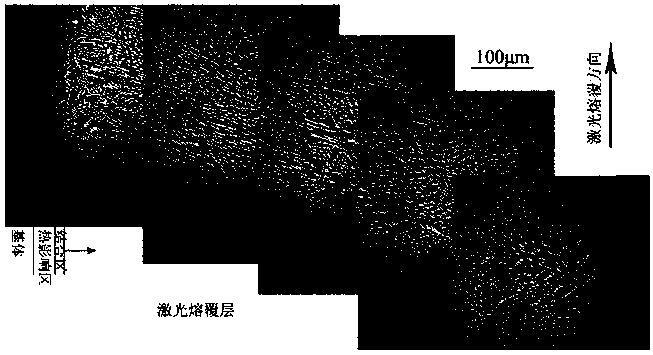

High-entropy alloy powder and preparation method and application of laser cladding layer

InactiveCN110804711AReduce oxidation rateHigh hardnessMetallic material coating processesHigh entropy alloysLight spot

The invention discloses high-entropy alloy powder and a preparation method and application of a laser cladding layer. The high-entropy alloy powder consists of Fe, Co, Cr, Mn, Ni and Al element powderin an equimolar ratio, the alloy powder is applied to laser cladding welding, the high-entropy alloy powder and ethanol are mixed and uniformly coat the surface of a base material, and the cladding layer can be obtained through laser cladding after drying. When laser cladding is carried out, the selected base material is H13 steel, the laser power is 1300-1600 KW, the light spot diameter is 2-4 mm, the scanning speed is 5-7 mm / s, the defocusing amount is 10 mm, and the protective gas flow rate is 20-25 L / min. Due to the fact that the chaos degree of the laser cladding high-entropy alloy coating is large, and becomes larger at high temperature, the high mixed entropy effect obviously reduces the diffusion and redistribution rates among elements, therefore, the phase structure in the coating is stable, the high-temperature hardness basically keeps unchanged, and the laser cladding high-entropy alloy coating has good high-temperature softening resistance.

Owner:TIANJIN UNIV

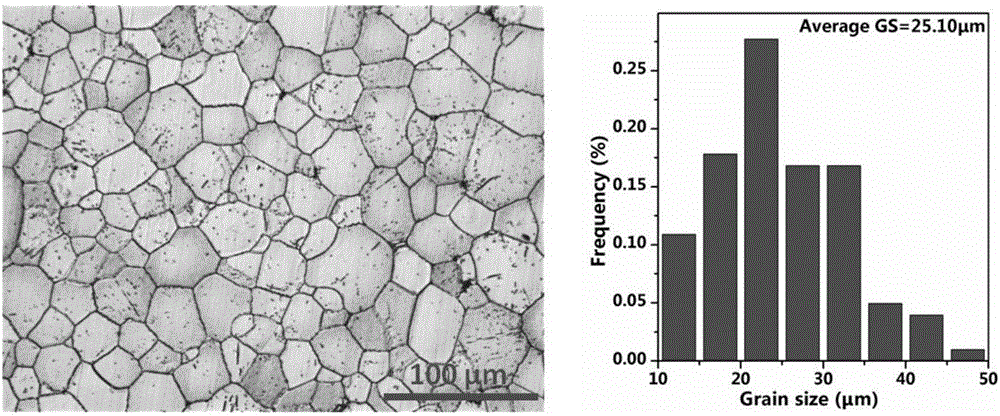

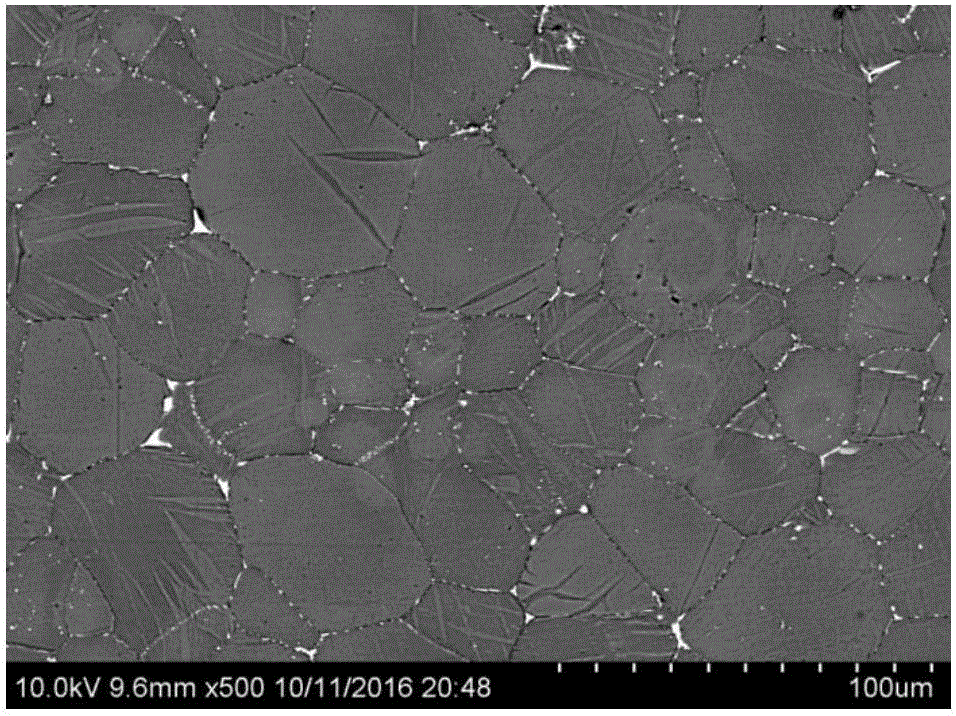

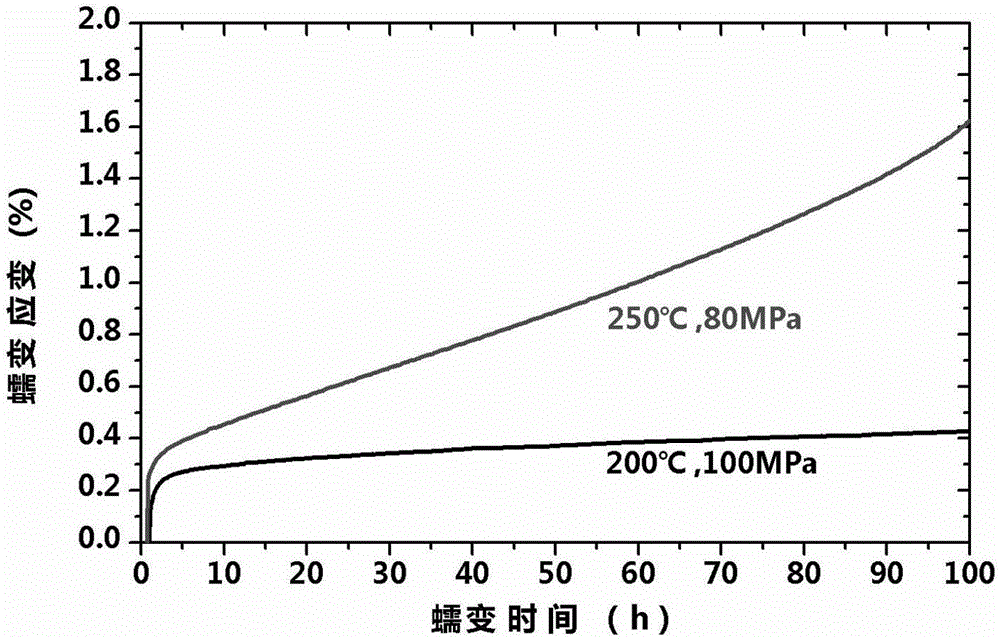

Heat-resistant creep-resistant magnesium alloy and preparing method thereof

The invention relates to a heat-resistant creep-resistant magnesium alloy and a preparing method thereof, which belong to the field of metal materials and metallurgy. The heat-resistant creep-resistant magnesium alloy is mainly formed by the following components in percent by mass: 7-8% of Sm, 0.7-0.9% of Nd, 1.5-2.0% of Zn, 1.0-1.3% of Ca, 1.2-1.5% of Mn, 1.1-1.3% of Al and the balance of Mg and inevitable impurities. The magnesium alloy in the invention has good tensile strength and better creep resistance under a high temperature, and has better application prospect.

Owner:HENAN UNIV OF SCI & TECH

Nickel-based powder superalloy with high tensile strength

The invention discloses nickel-based powder superalloy with high tensile strength and belongs to the technical field of powder superalloy. The nickel-based powder superalloy comprises the following chemical components by mass percent: 0.03-0.07% of C, 16.0-17.5% of Co, 8.5-10.5% of Cr, 5.8-6.2% of W, 4.0-4.5% of Mo, 4.8-5.3% of Al, 1.6-2.0% of Ti, 2.4-2.8% of Nb, 0.1-0.4% of Hf, less than 0.02% of B, less than 0.02% of Zr, less than 0.01% of Mg, less than 0.01% of Ce and the balance of Ni. The nickel-based powder superalloy has the advantages that the tensile strength and high temperature lasting life of the nickel-based powder superalloy are superior to those of FGH97 alloy.

Owner:BEIJING CISRI GAONA TECH

Nickel-based superalloy

The invention discloses a nickel-based superalloy, which consists of the following components in percentage by weight: 22.5 to 24.5 percent of Cr, 7.0 to 8.0 percent of Co, 6.5 to 7.5 percent of W, 3.0 to 4.0 percent of Mo, 1.2 to 1.8 percent of Al, 1.5 to 2.5 percent of Ti, 2.0 to 3.0 percent of Nb, 1.0 to 2.0 percent of Mn, 2.0 to 4.0 percent of Fe, 0.02 to 0.08 percent of B, 0.5 to 1.5 percent of Ce, less than or equal to 0.1 percent of C, less than or equal to 0.2 percent of Si, less than or equal to 0.008 percent of P, less than or equal to 0.008 percent of S and the balance of Ni.

Owner:NANTONG BEICHENG SCI & TECH ENTREPRENEURIAL MANAGEMENT

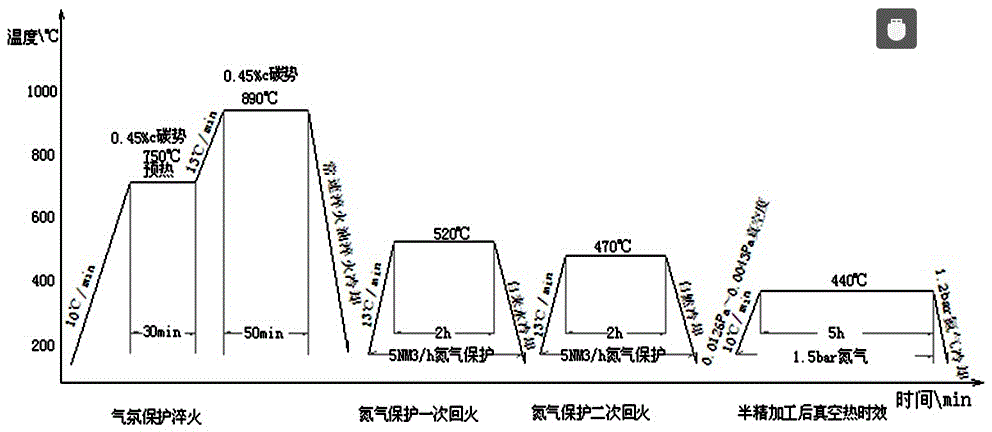

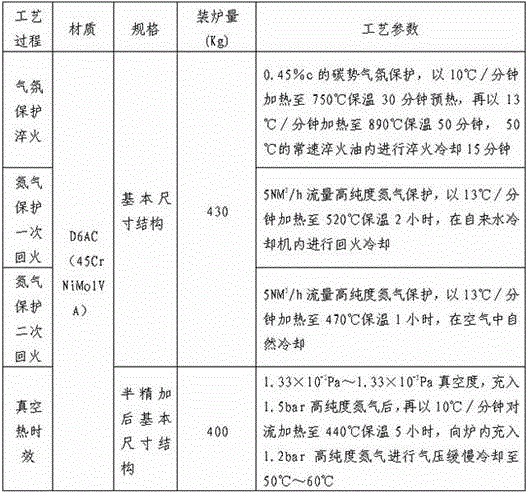

Atmosphere protection heat treatment technology of ultrahigh strength D6AC steel thin-wall tube

InactiveCN105543463AImprove mechanical propertiesHigh precisionFurnace typesHeat treatment furnacesNitrogenPhase change

The invention discloses an atmosphere protection heat treatment technology of an ultrahigh strength D6AC steel thin-wall tube. The atmosphere protection heat treatment technology is characterized by comprising the steps of atmosphere protection quenching, secondary nitrogen protection tempering, and vacuum heat aging after semi-finishing. Compared with the prior art, the solution strengthening effect, the phase change strengthening effect and the dispersion strengthening of ultrahigh strength steel can be improved, the internal stress is reduced, and oxygenation and decarbonization are eliminated, so that the tensile strength, the yield strength, the percentage elongation after fracture, the percentage reduction of area, and the size stability and precision after finishing of the thin-wall tube are improved, and a machining allowance before heat treatment is reduced.

Owner:HENAN NORTHERN HONGYANG ELECTROMECHANICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com