Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1396 results about "Zn element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

| references | in Wikidata. Zinc is a chemical element with symbol Zn and atomic number 30. It is the first element in group 12 of the periodic table. In some respects zinc is chemically similar to magnesium: both elements exhibit only one normal oxidation state (+2), and the Zn2+ and Mg2+ ions are of similar size.

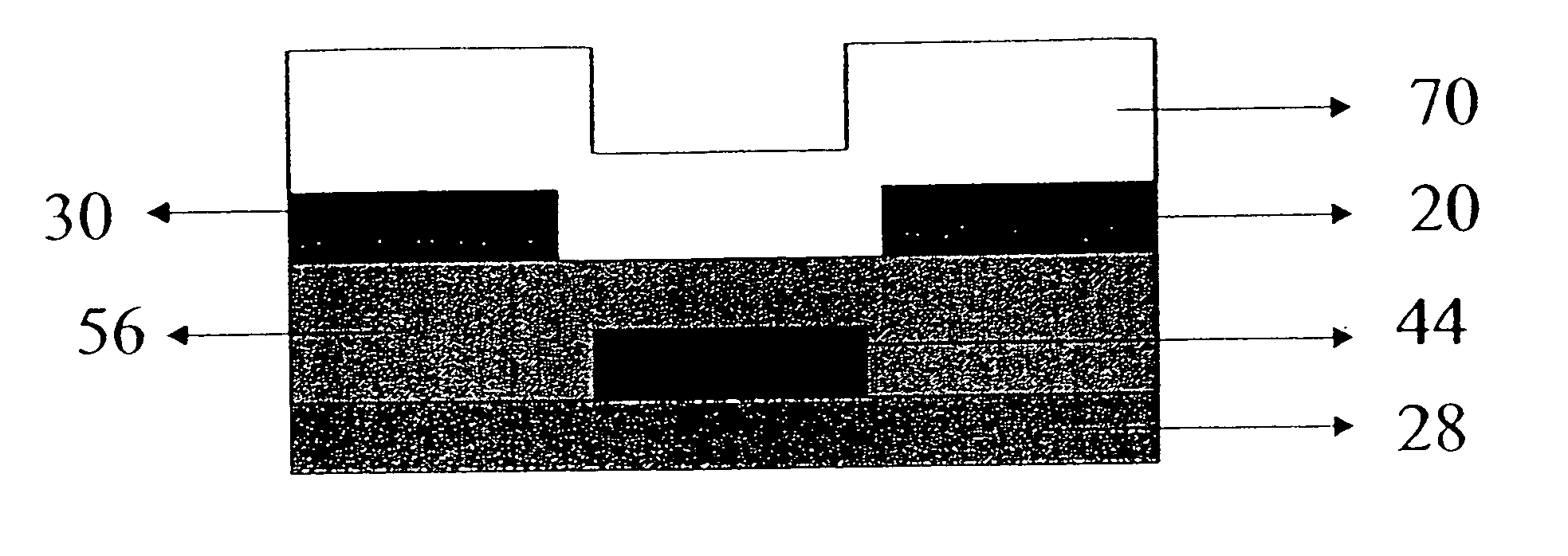

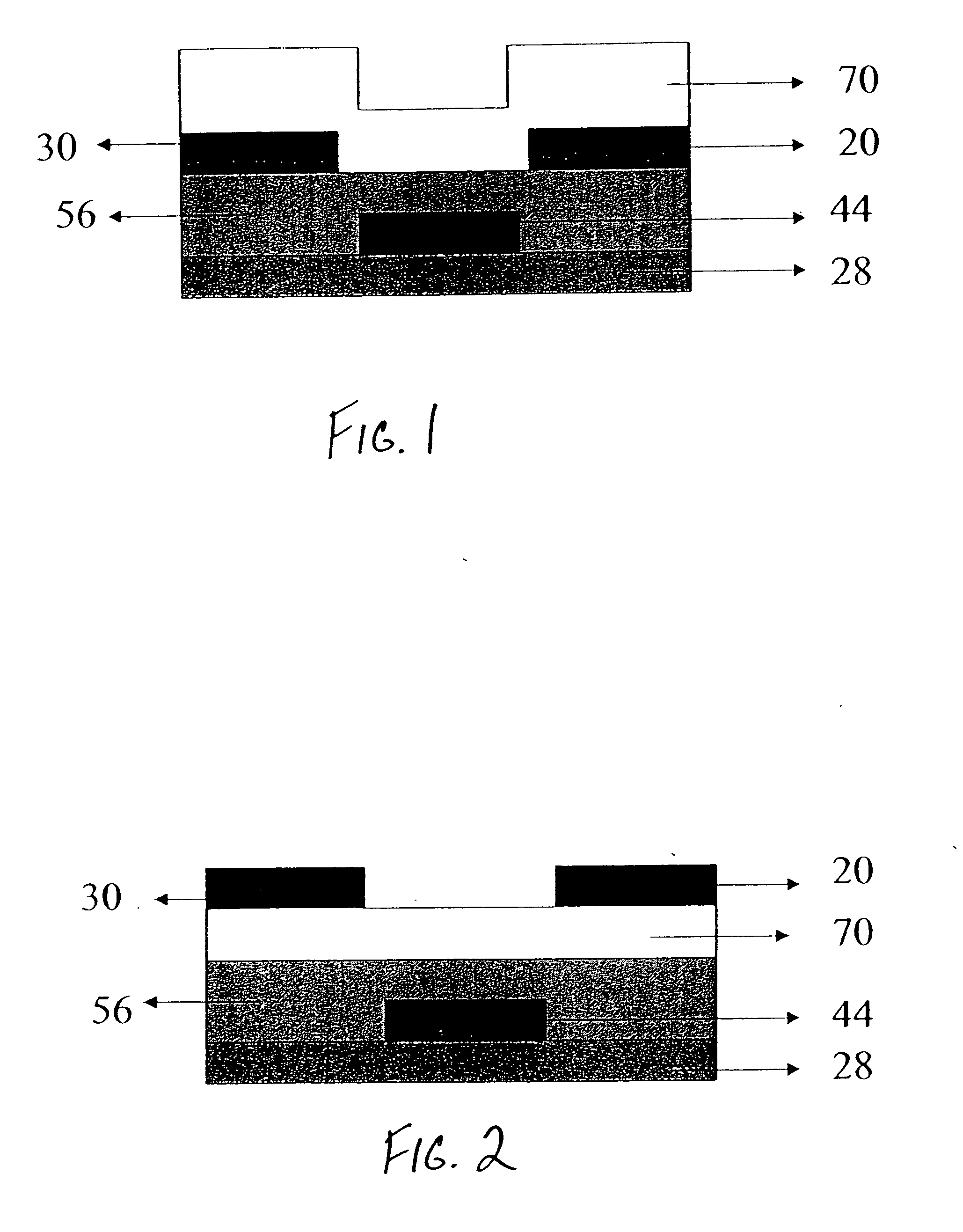

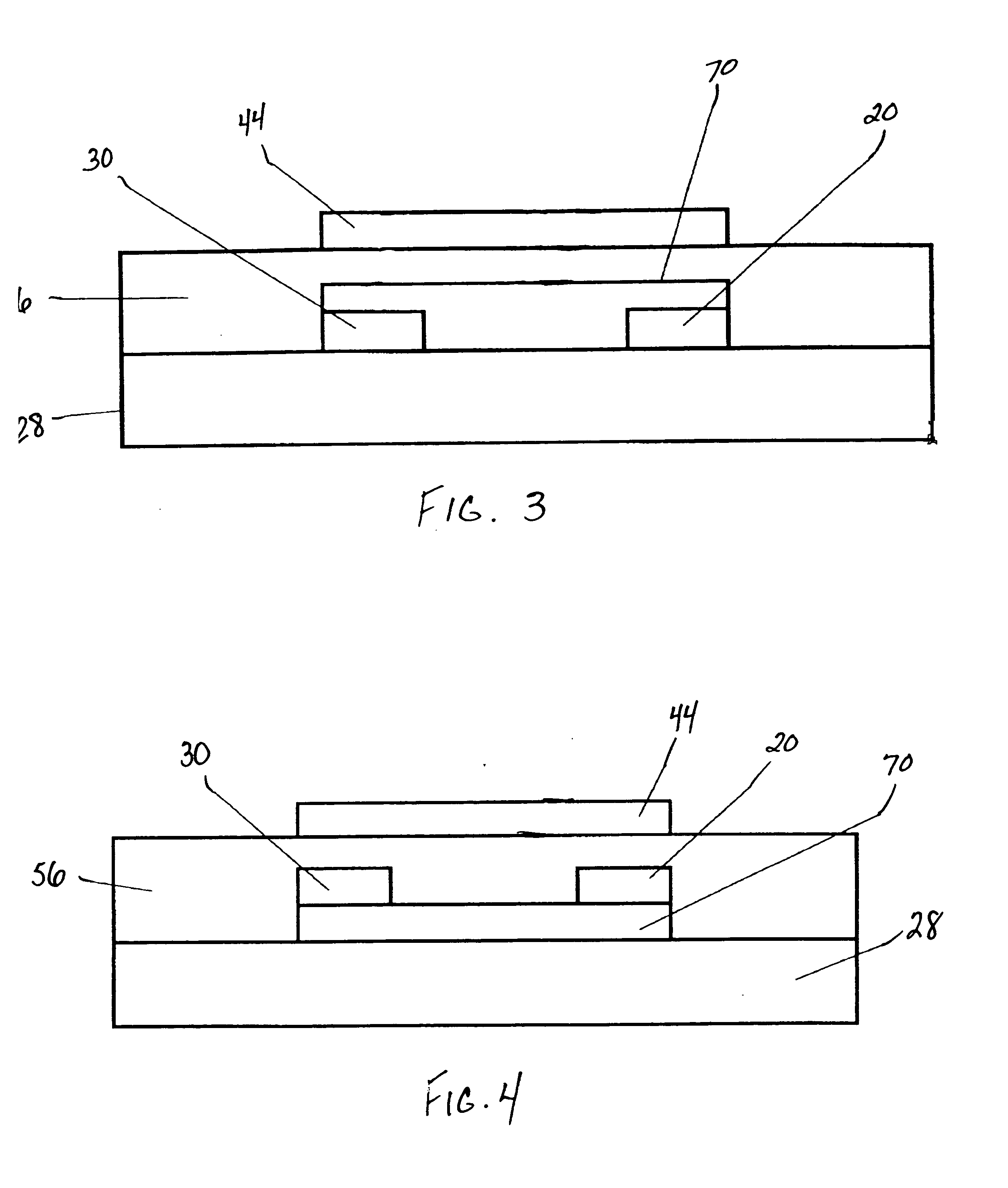

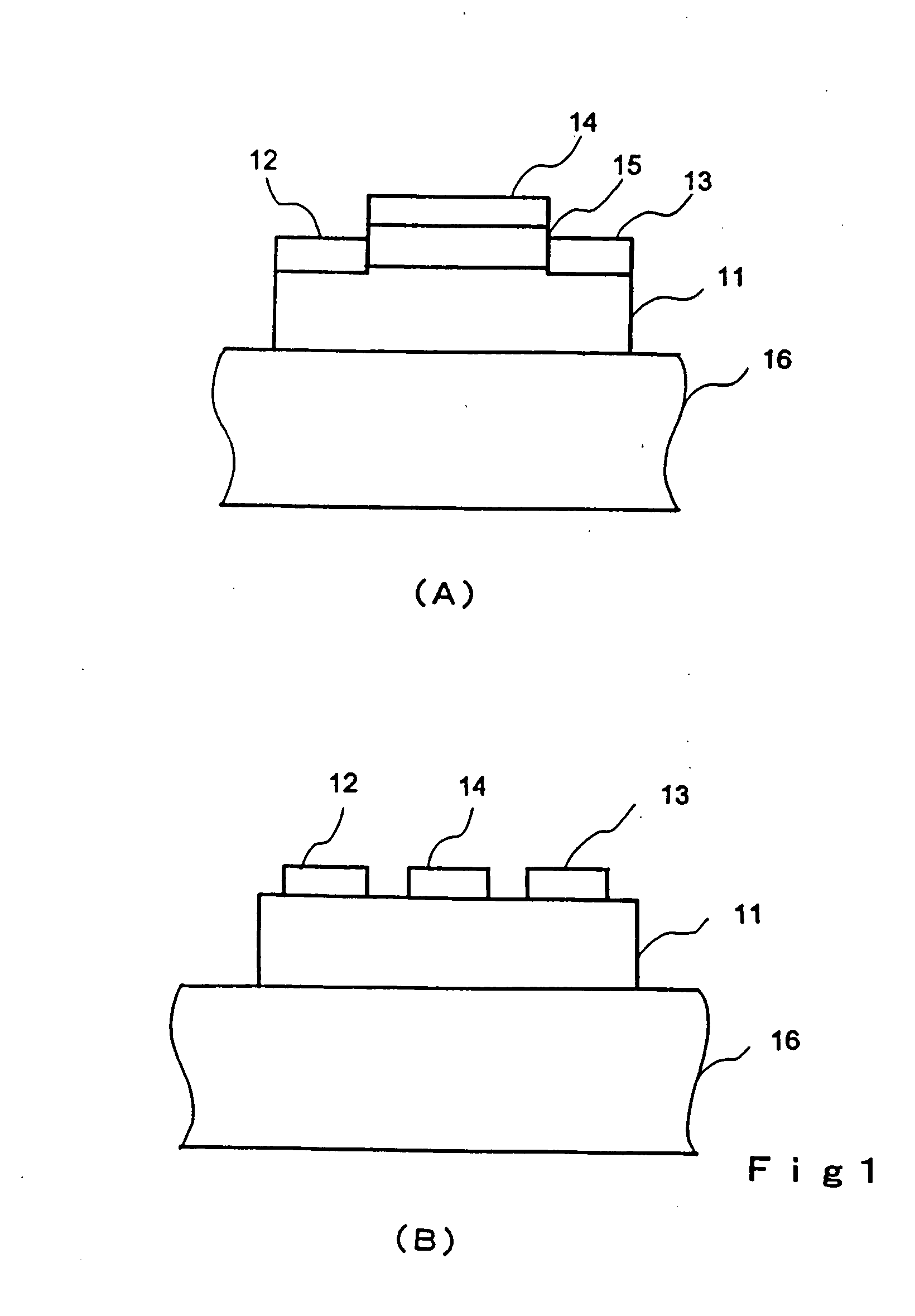

Methods of making thin film transistors comprising zinc-oxide-based semiconductor materials and transistors made thereby

A thin film transistor comprises a zinc-oxide-containing semiconductor material. Such transistors can further comprise spaced apart first and second contact means or electrodes in contact with said material. Further disclosed is a process for fabricating a thin film transistor device, wherein the substrate temperature is no more than 300° C. during fabrication.

Owner:EASTMAN KODAK CO

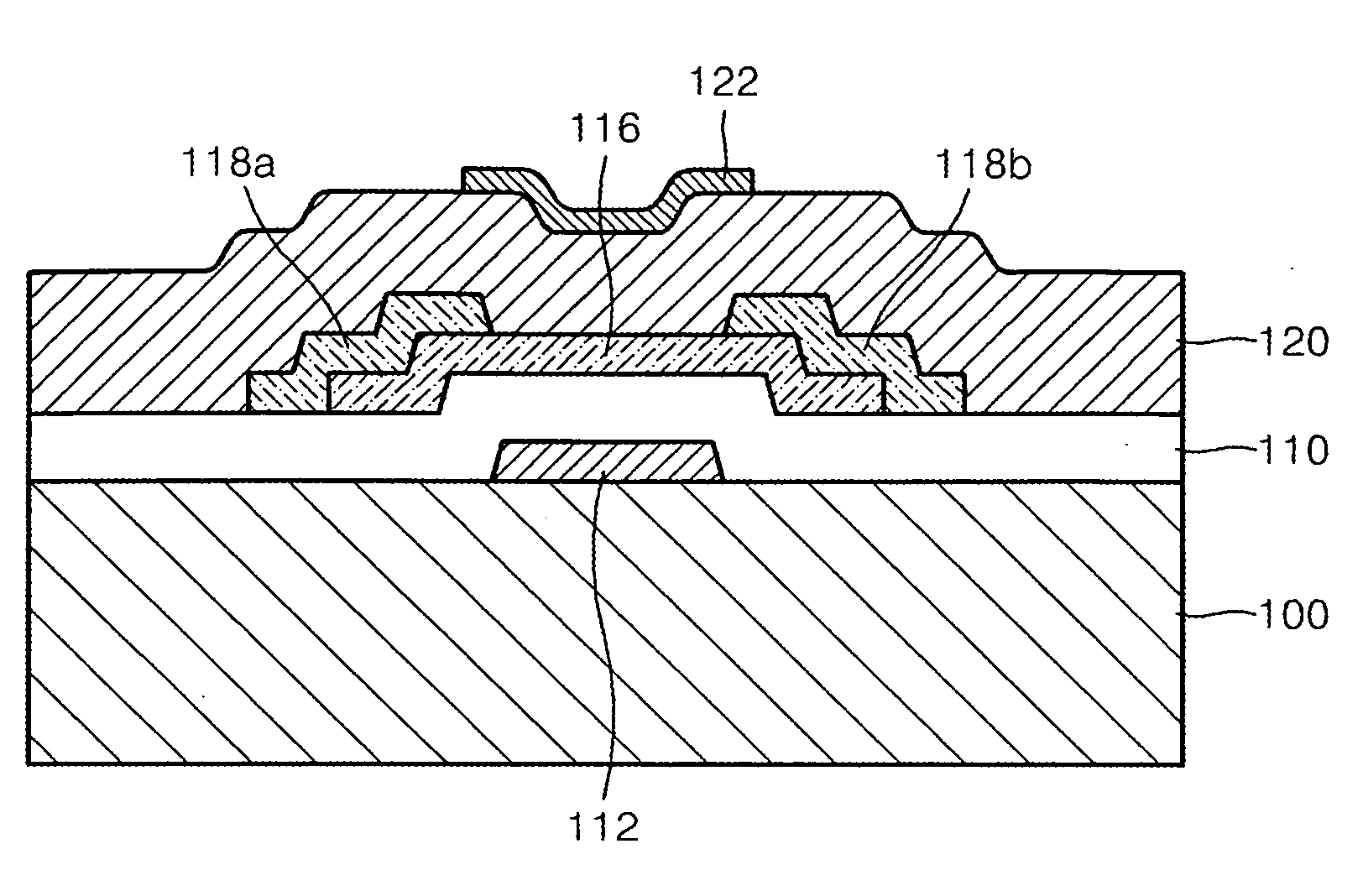

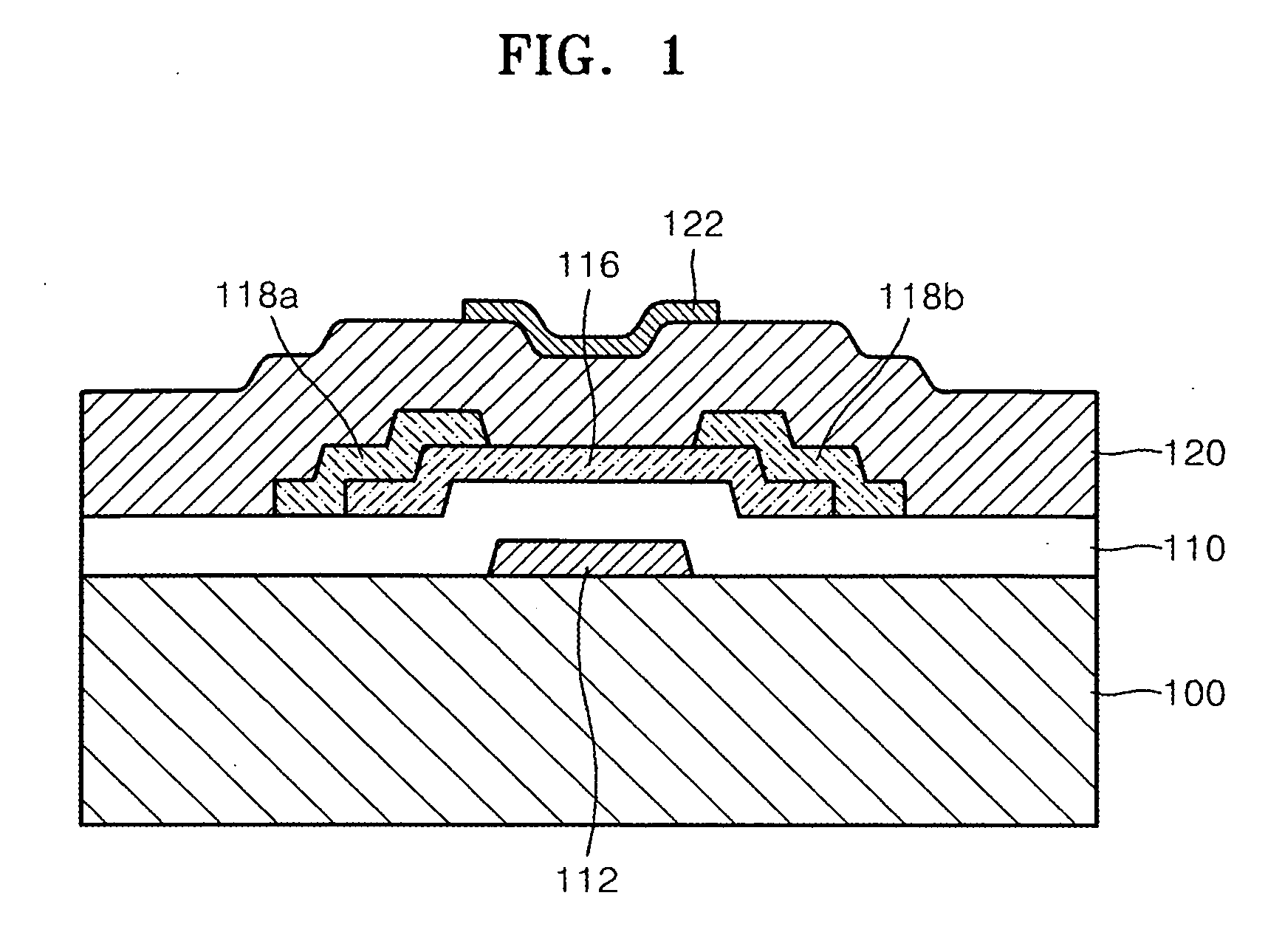

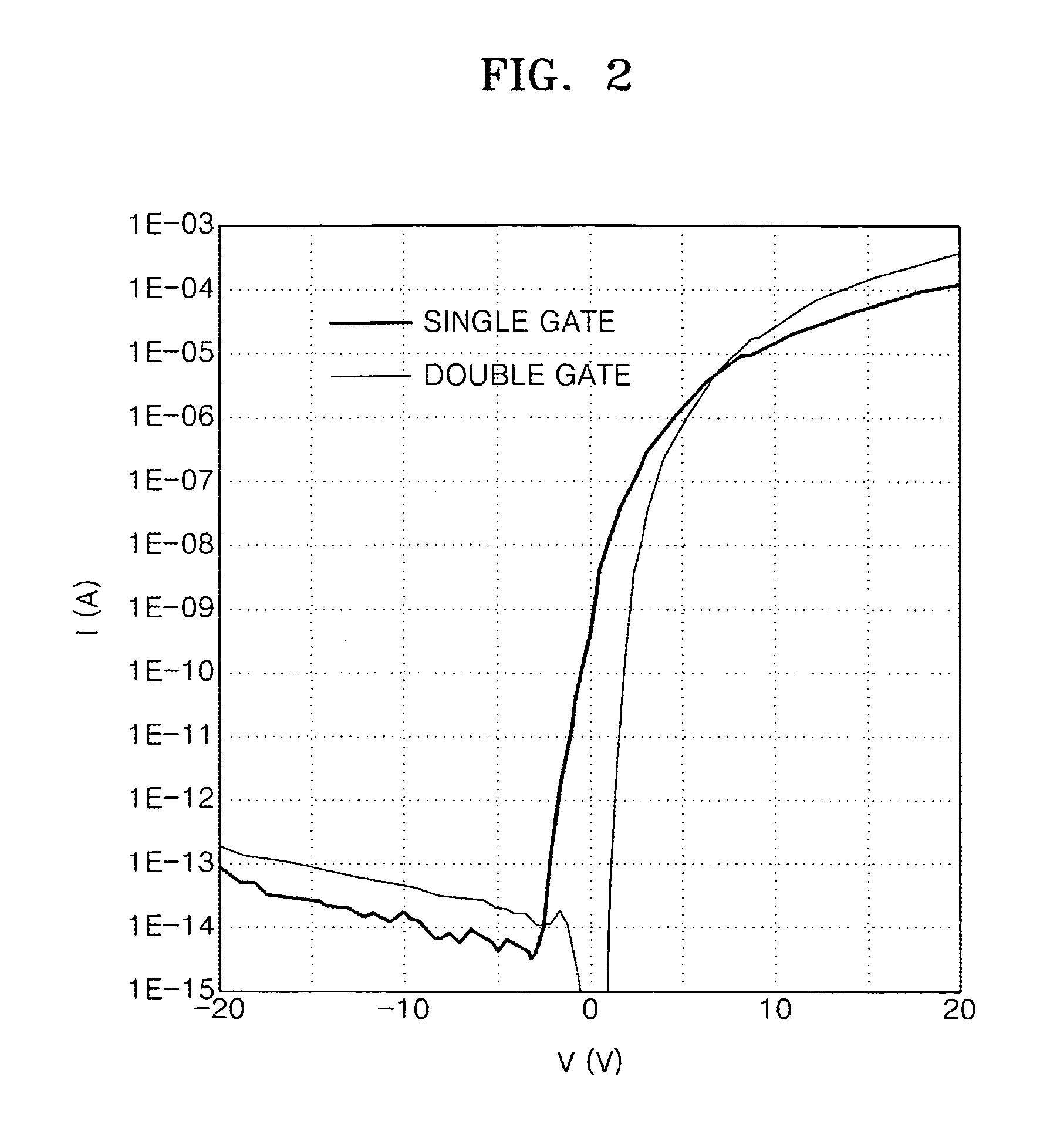

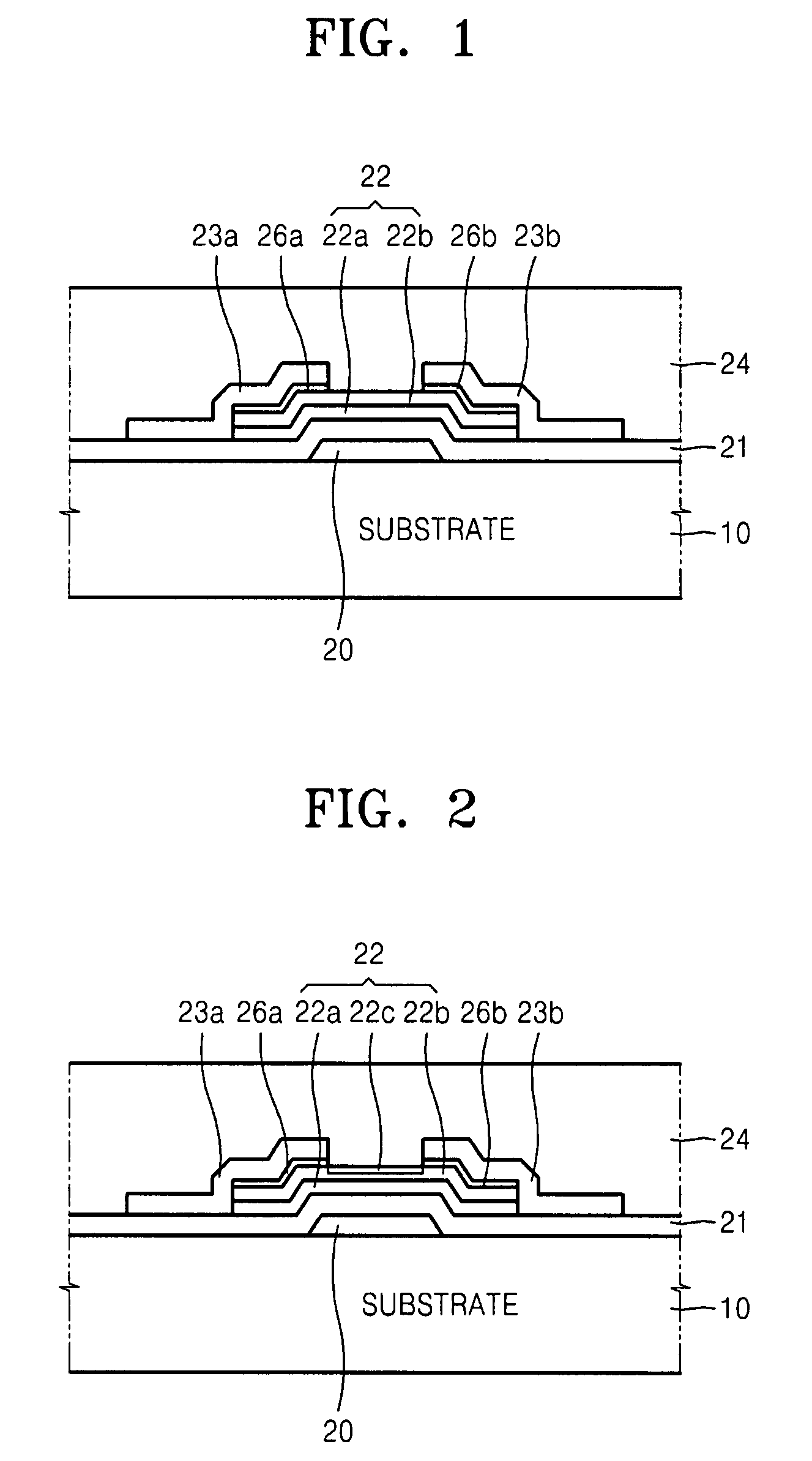

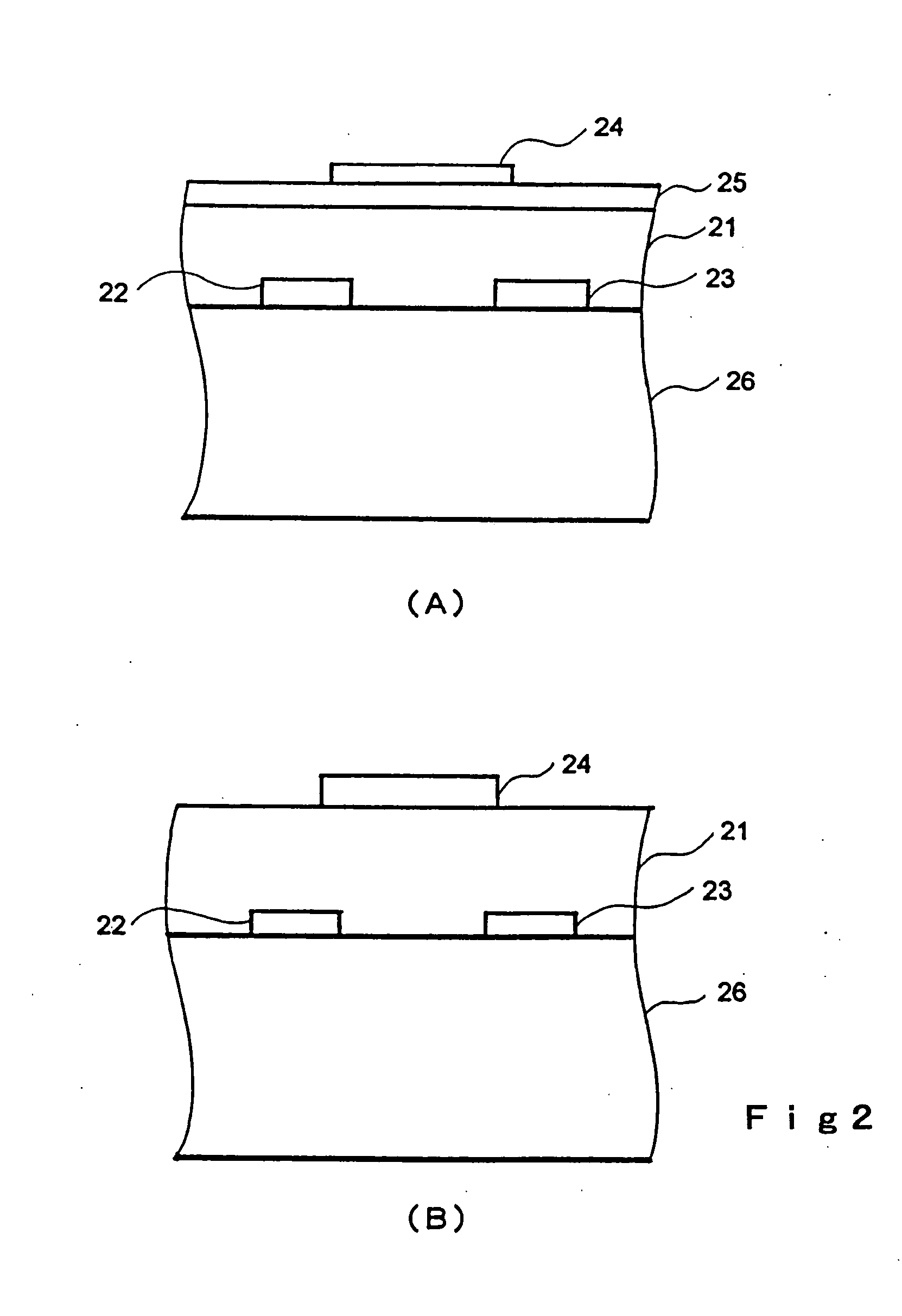

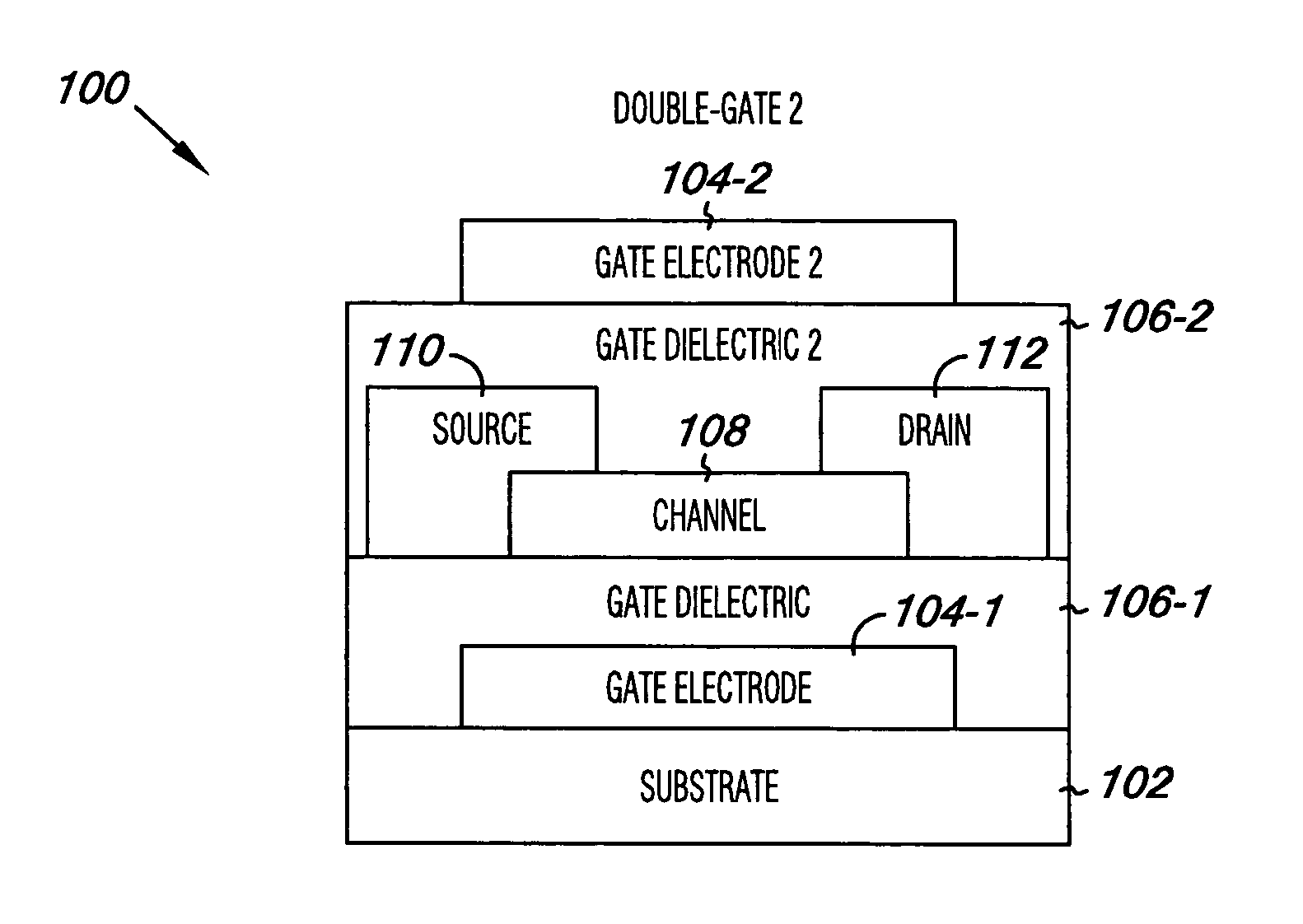

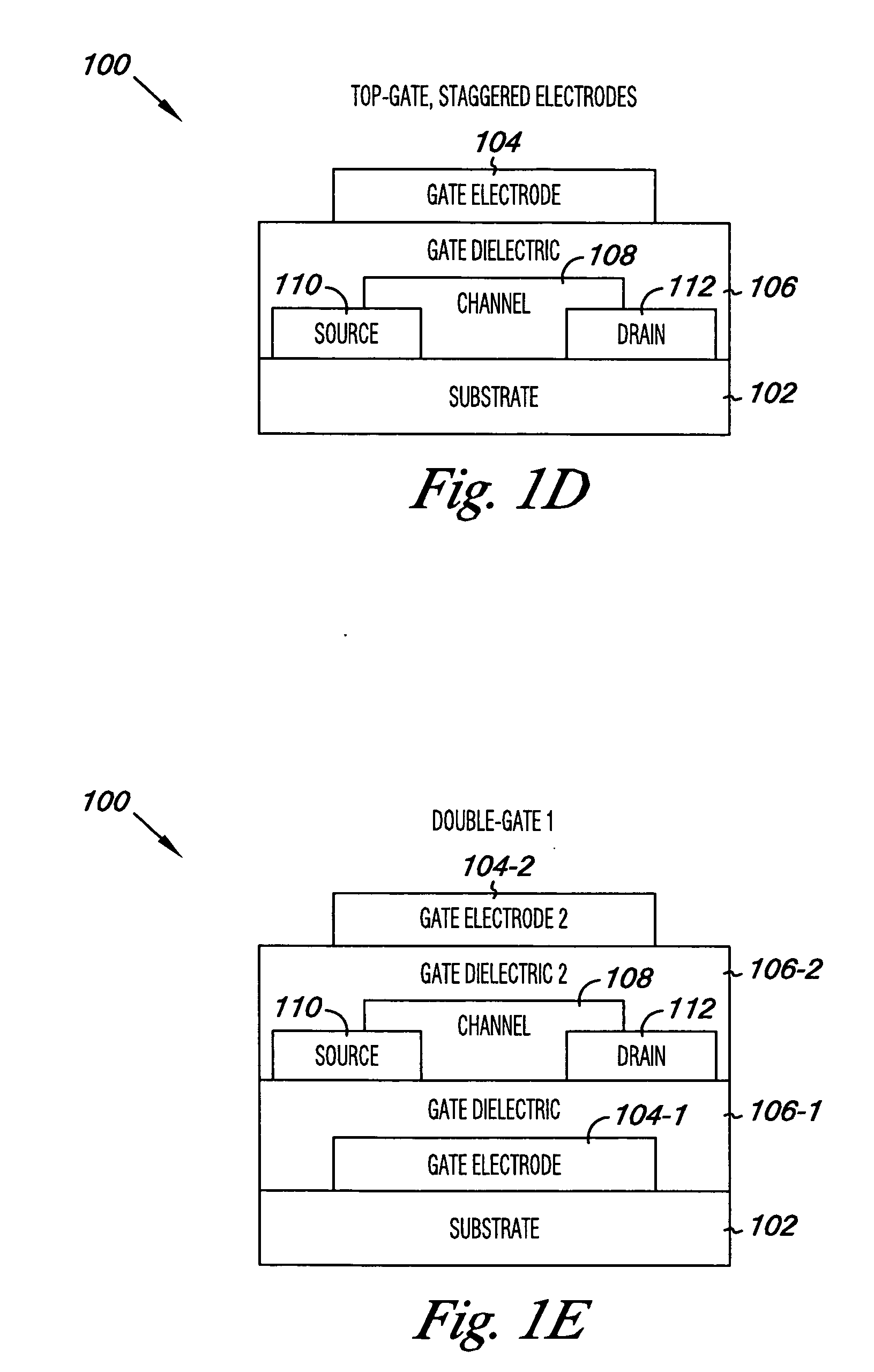

Oxide semiconductor transistor and method of manufacturing the same

ActiveUS20090206332A1TransistorSemiconductor/solid-state device manufacturingEngineeringSilicon oxide

An oxide semiconductor thin film transistor (TFT) and a method of manufacturing the oxide semiconductor TFT. The oxide semiconductor TFT includes a first gate insulating layer arranged between an oxide semiconductor channel layer and a first gate and a second gate insulating layer arranged between the channel layer and a second gate. The first and second gate insulating layers are made out of different materials and have different thicknesses. Preferably, the second gate insulating layer is silicon oxide and is thinner than the first gate insulating layer which is preferably silicon nitride. Oxide semiconductor refers to an oxide material such as Zinc Oxide, Tin Oxide, Ga—In—Zn Oxide, In—Zn Oxide, In—Sn Oxide, and one of Zinc Oxide, Tin Oxide, Ga—In—Zn Oxide, In—Zn Oxide and In—Sn Oxide.

Owner:SAMSUNG ELECTRONICS CO LTD

Oxide semiconductor, thin film transistor including the same and method of manufacturing a thin film transistor

InactiveUS20090008638A1Improve electrical performanceSemiconductor/solid-state device manufacturingSemiconductor devicesRare-earth elementGroup element

Example embodiments relate to an oxide semiconductor including zinc oxide (ZnO), a thin film transistor including a channel formed of the oxide semiconductor and a method of manufacturing the thin film transistor. The oxide semiconductor may include a GaxInyZnz oxide and at least one material selected from the group consisting of a 4A group element, a 4A group oxide, a rare earth element and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

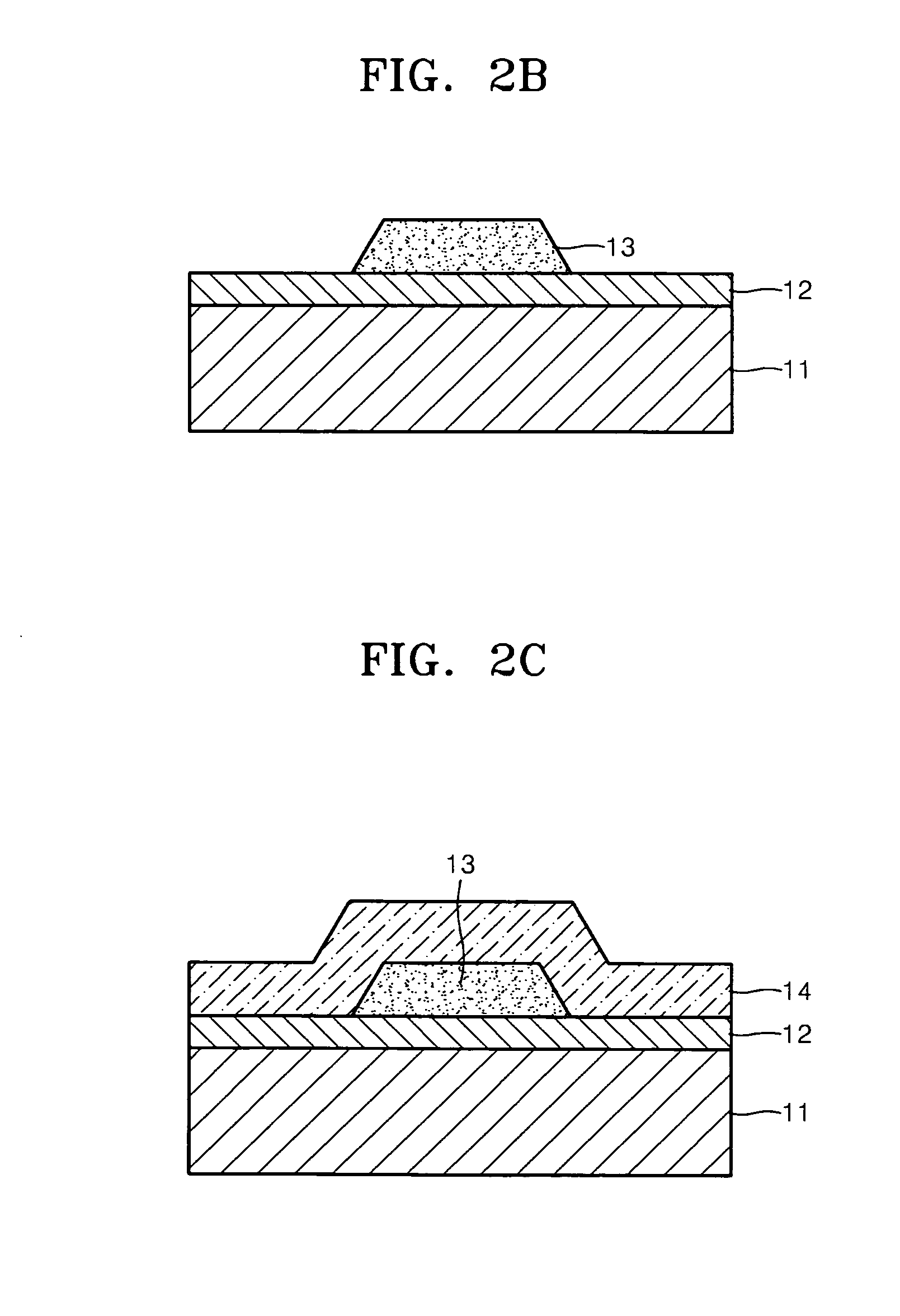

Aluminum/magnesium 3D-Printing rapid prototyping

InactiveUS20060045787A1Additive manufacturing apparatusTransportation and packagingCopperRapid prototyping

A 3D Printing Rapid Prototyping process using Al / Mg particles coated with a metal (i.e. copper, nickel, zinc, or tin) that (1) prevents oxidation of the Al / Mg particles, and (2) either alone, or when alloyed with the aluminum or magnesium core metal, melts below the liquidus temperature of the core.

Owner:GM GLOBAL TECH OPERATIONS LLC

Composition Containing Statins and Omega-3 Fatty Acids

InactiveUS20080089876A1Hydroxy compound active ingredientsPeptide/protein ingredientsFatty acidStatine

A combination is described comprising at least one omega-3 fatty acid, optionally esterified or salified, at least one statin, Coenzyme Q10, resveratrol, at least one policosanol, pantethine, selenium, and zinc. This combination is endowed with a synergistic effect and is useful in the treatment of disease forms due to insulin resistance and in cardiovascular diseases.

Owner:SIGMA TAU IND FARMACEUTICHE RIUNITE SPA

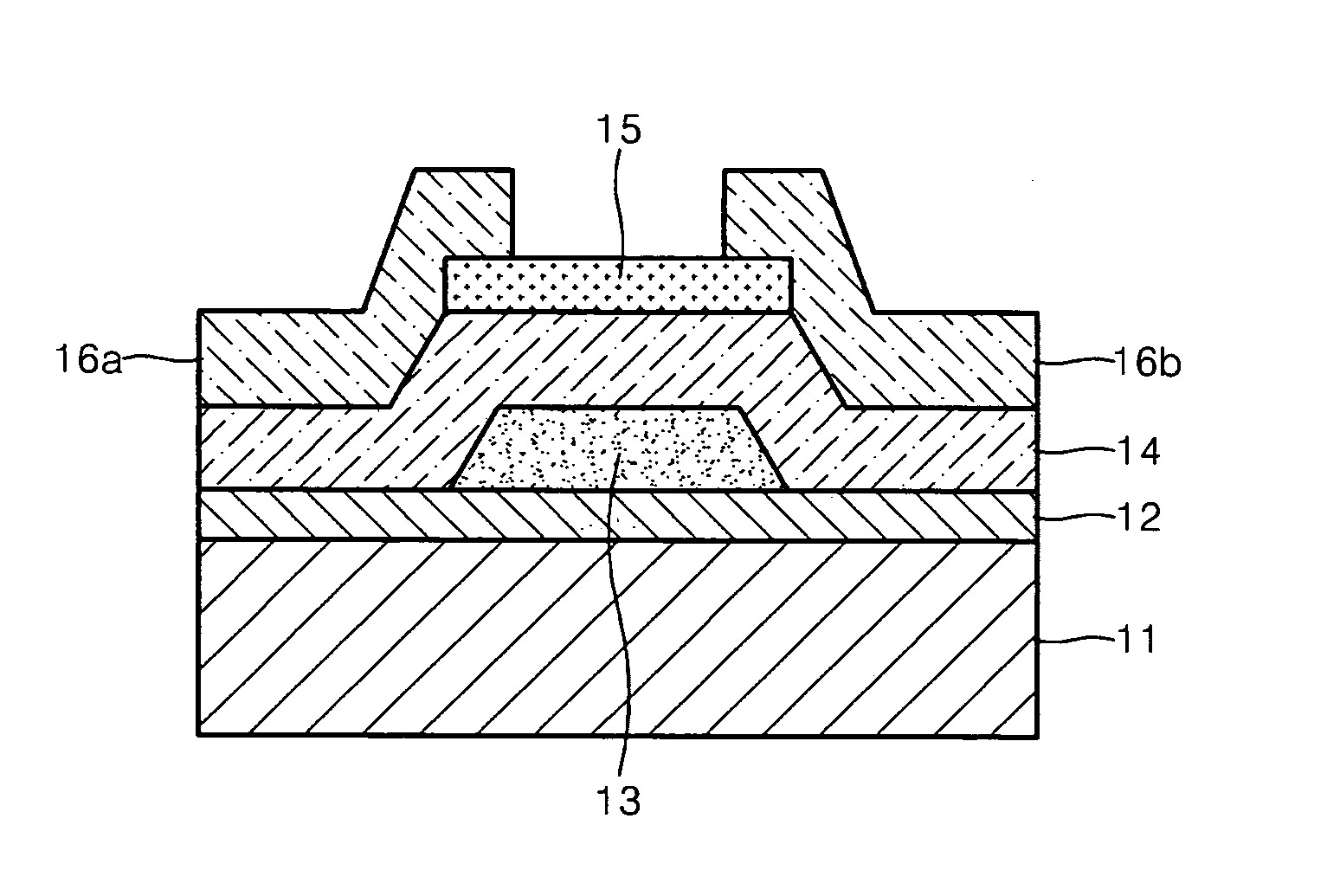

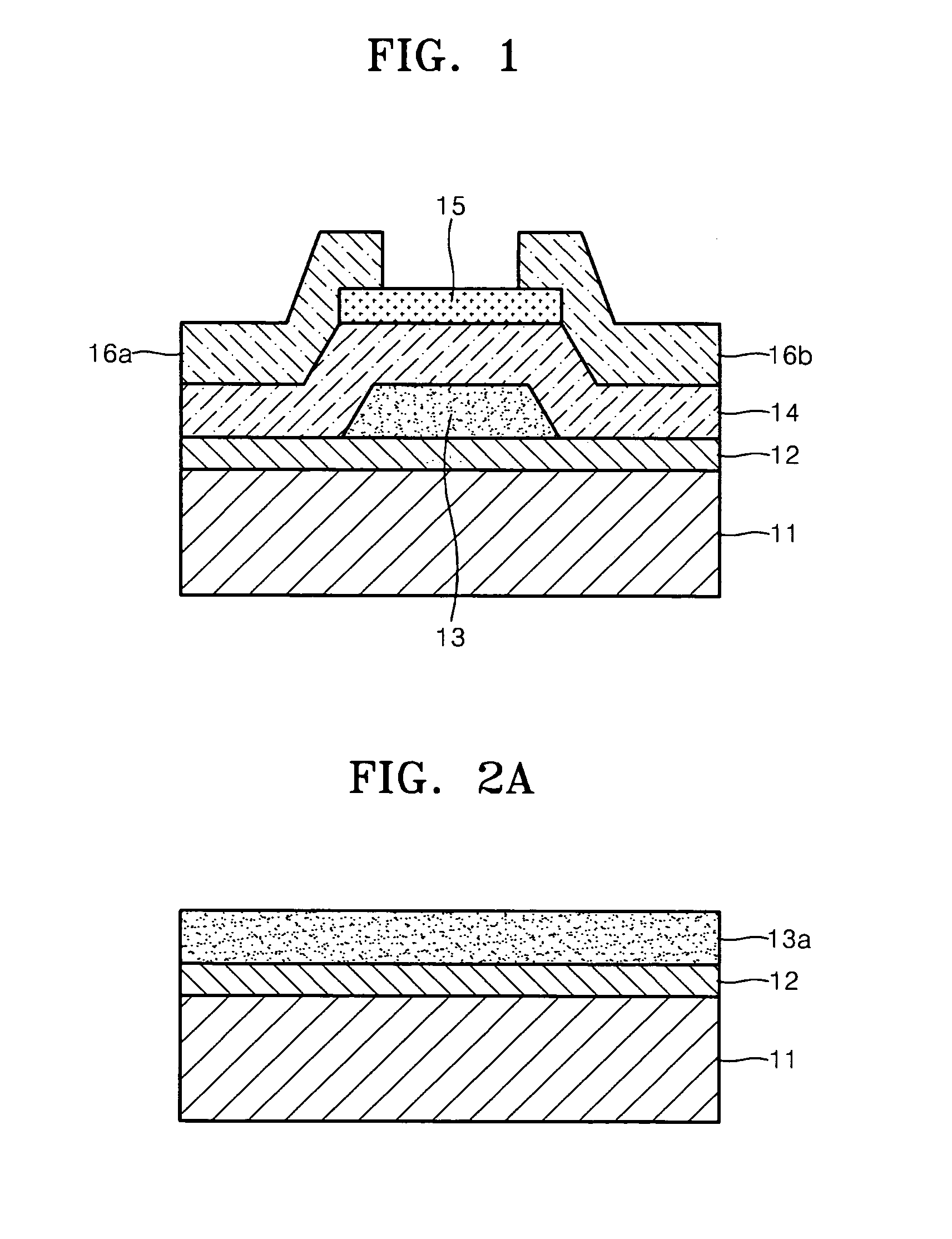

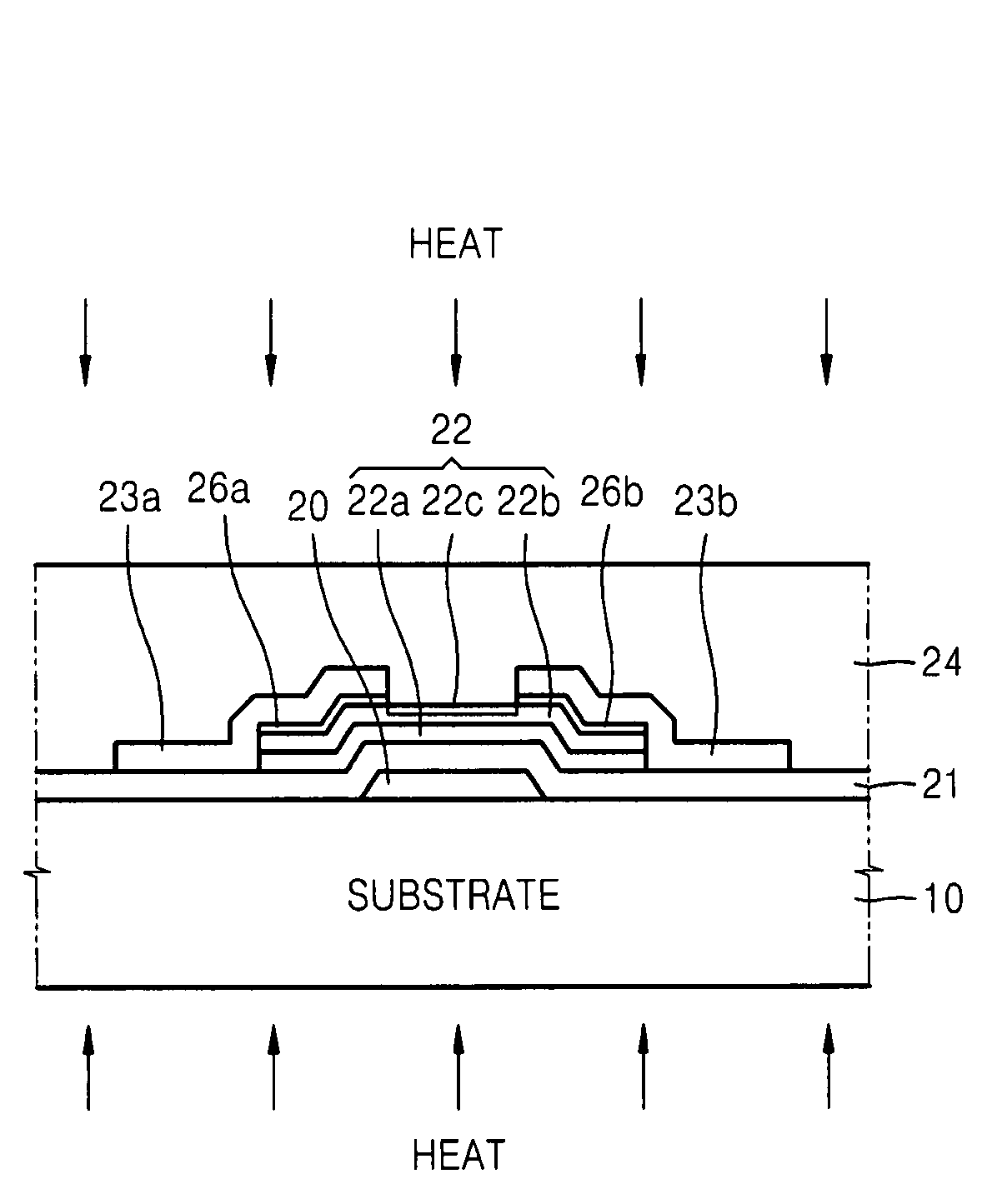

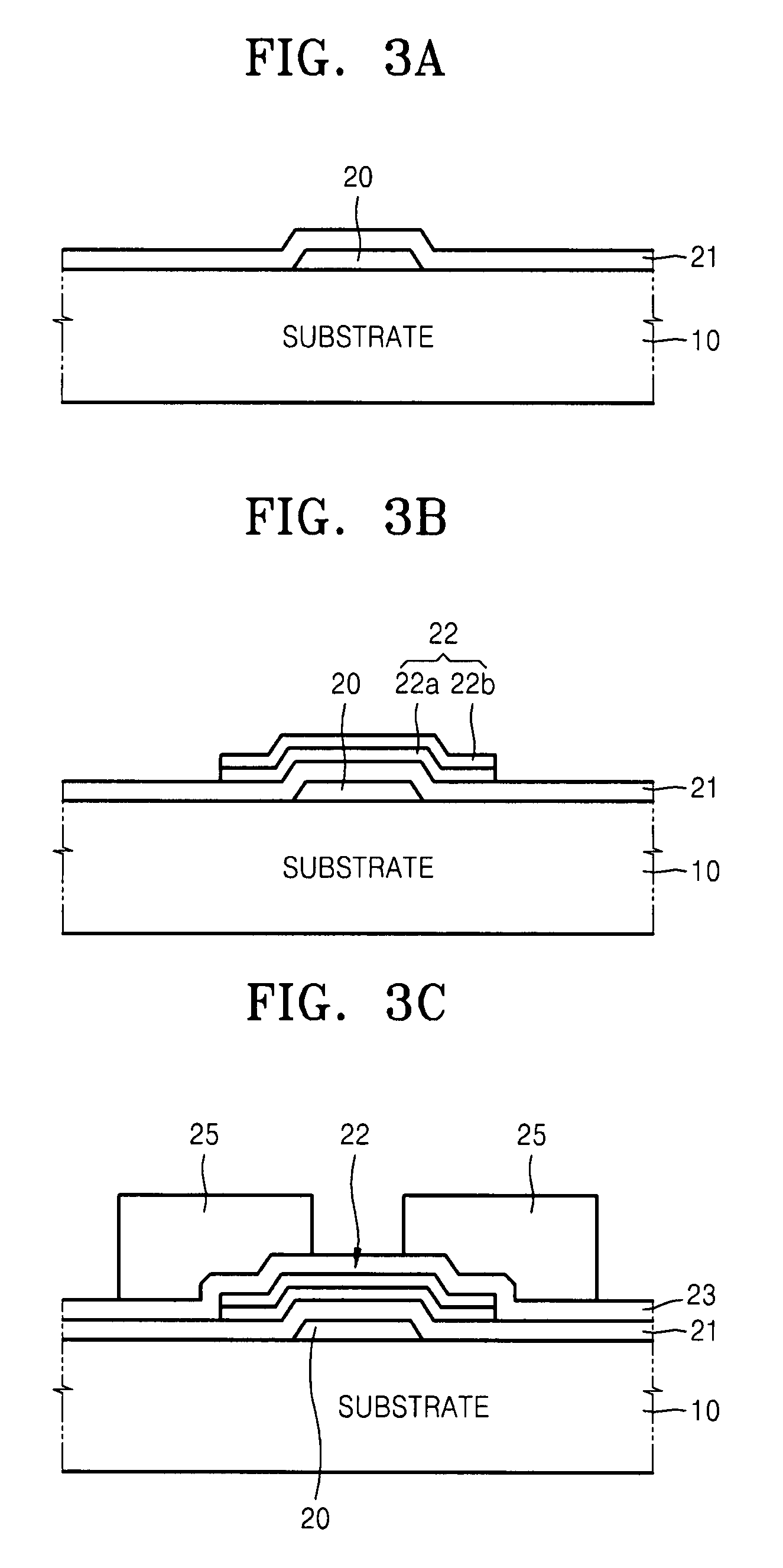

Thin film transistors and methods of manufacturing the same

ActiveUS7923722B2Avoid damageSemiconductor/solid-state device manufacturingSemiconductor devicesOxygen vacancyChloride

A TFT includes a zinc oxide (ZnO)-based channel layer having a plurality of semiconductor layers. An uppermost of the plurality of semiconductor layers has a Zn concentration less than that of a lower semiconductor layer to suppress an oxygen vacancy due to plasma. The uppermost semiconductor layer of the channel layer also has a tin (Sn) oxide, a chloride, a fluoride, or the like, which has a relatively stable bonding energy against plasma. The uppermost semiconductor layer is relatively strong against plasma shock and less decomposed when being exposed to plasma, thereby suppressing an increase in carrier concentration.

Owner:SAMSUNG ELECTRONICS CO LTD

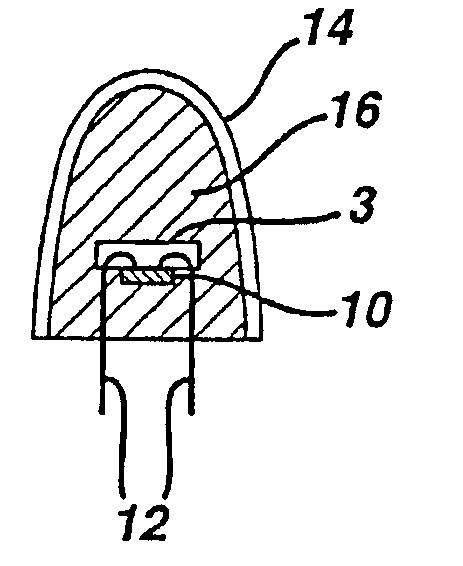

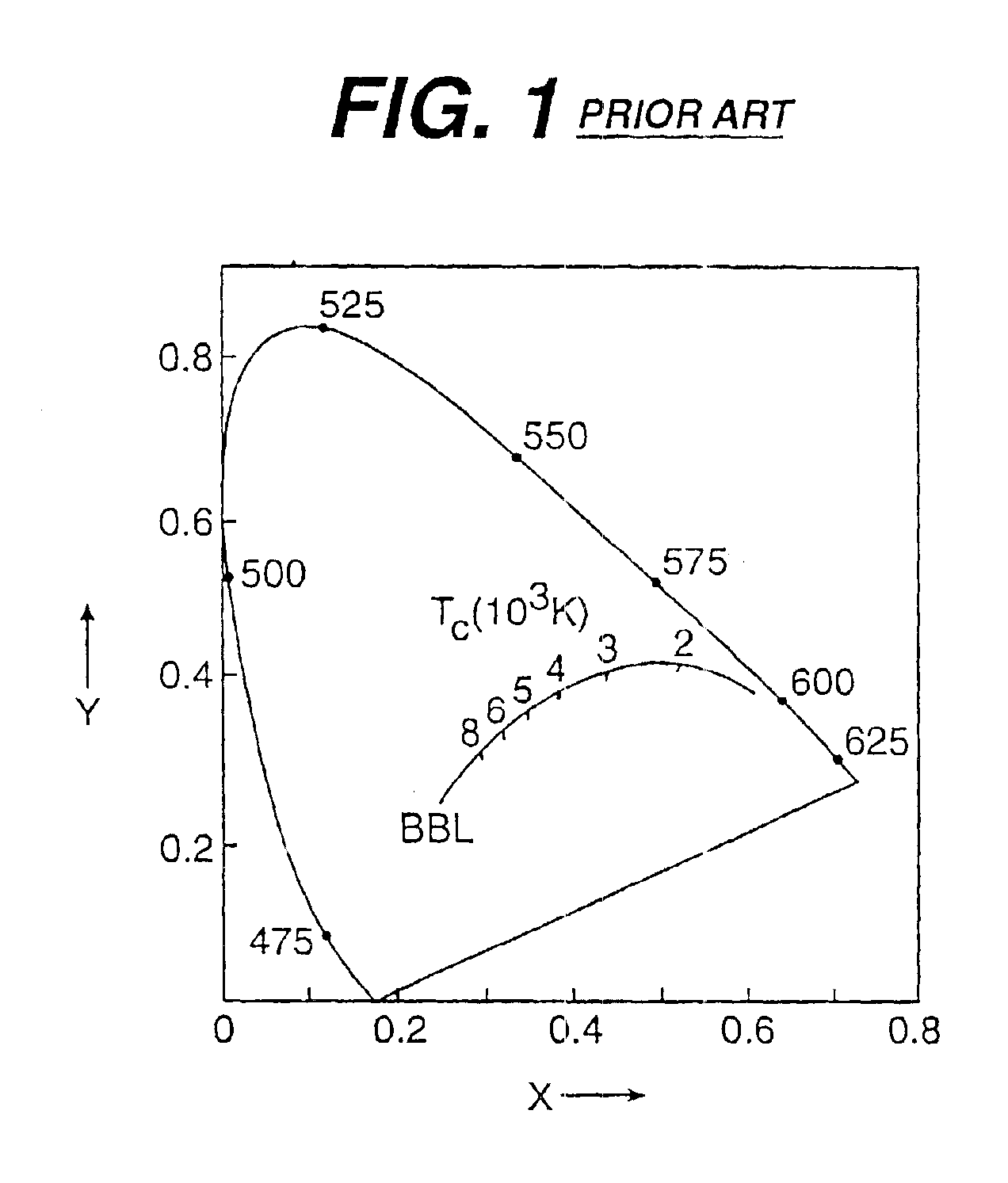

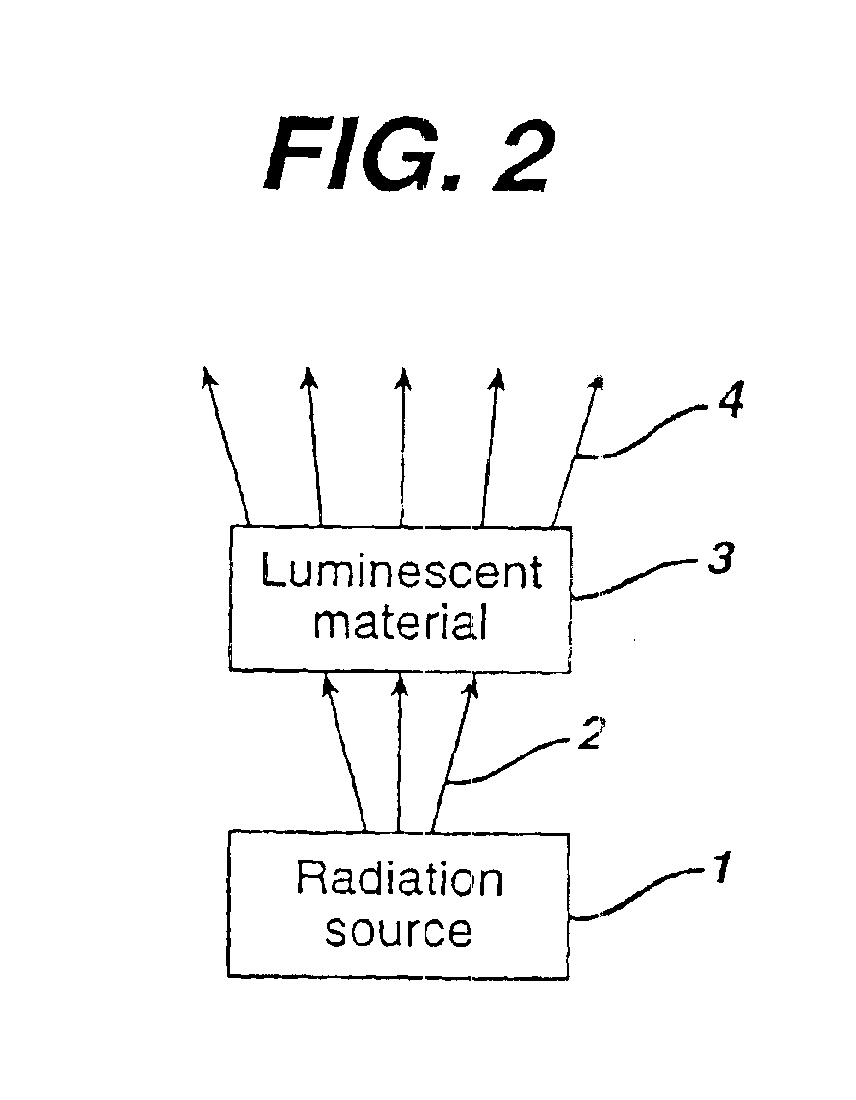

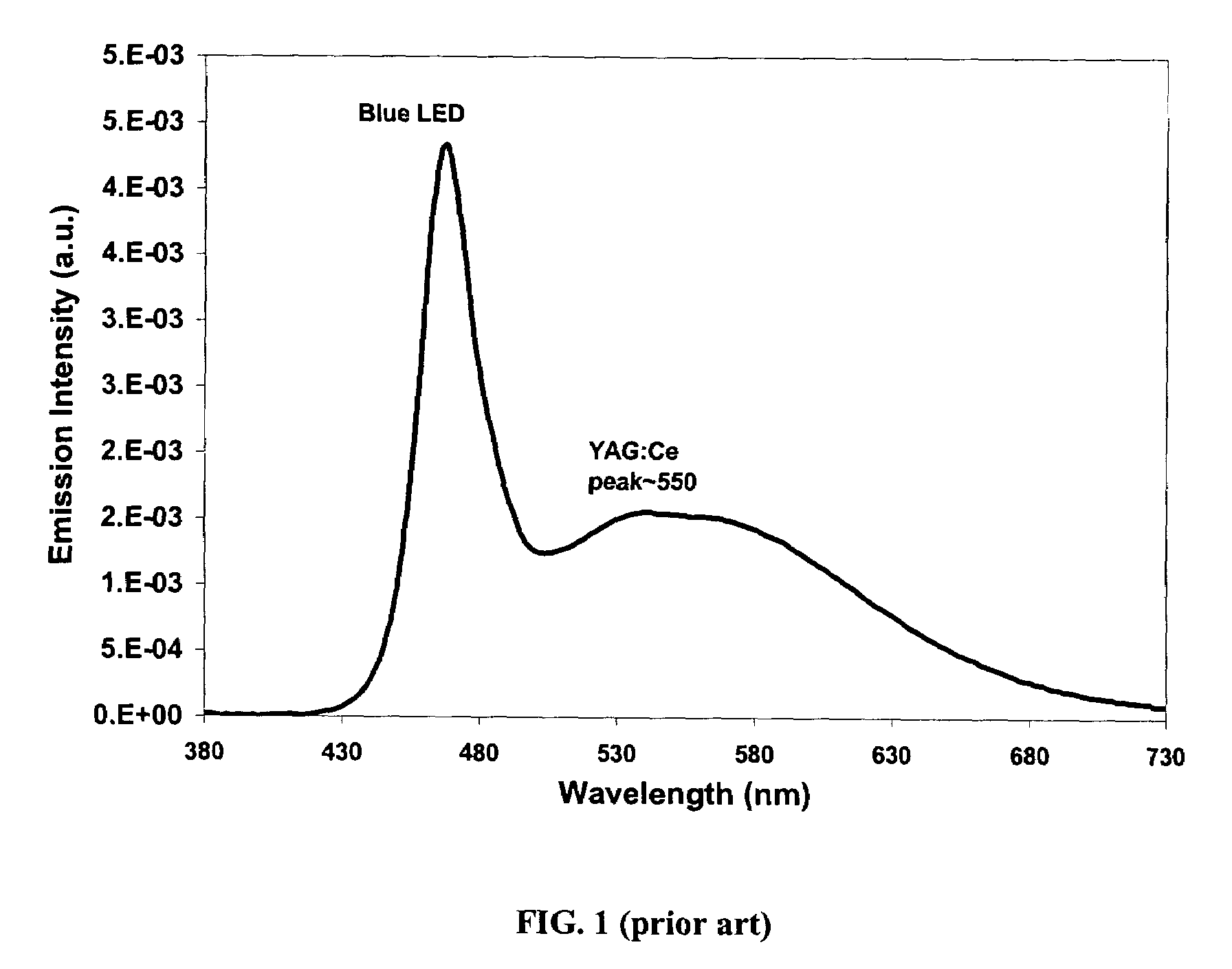

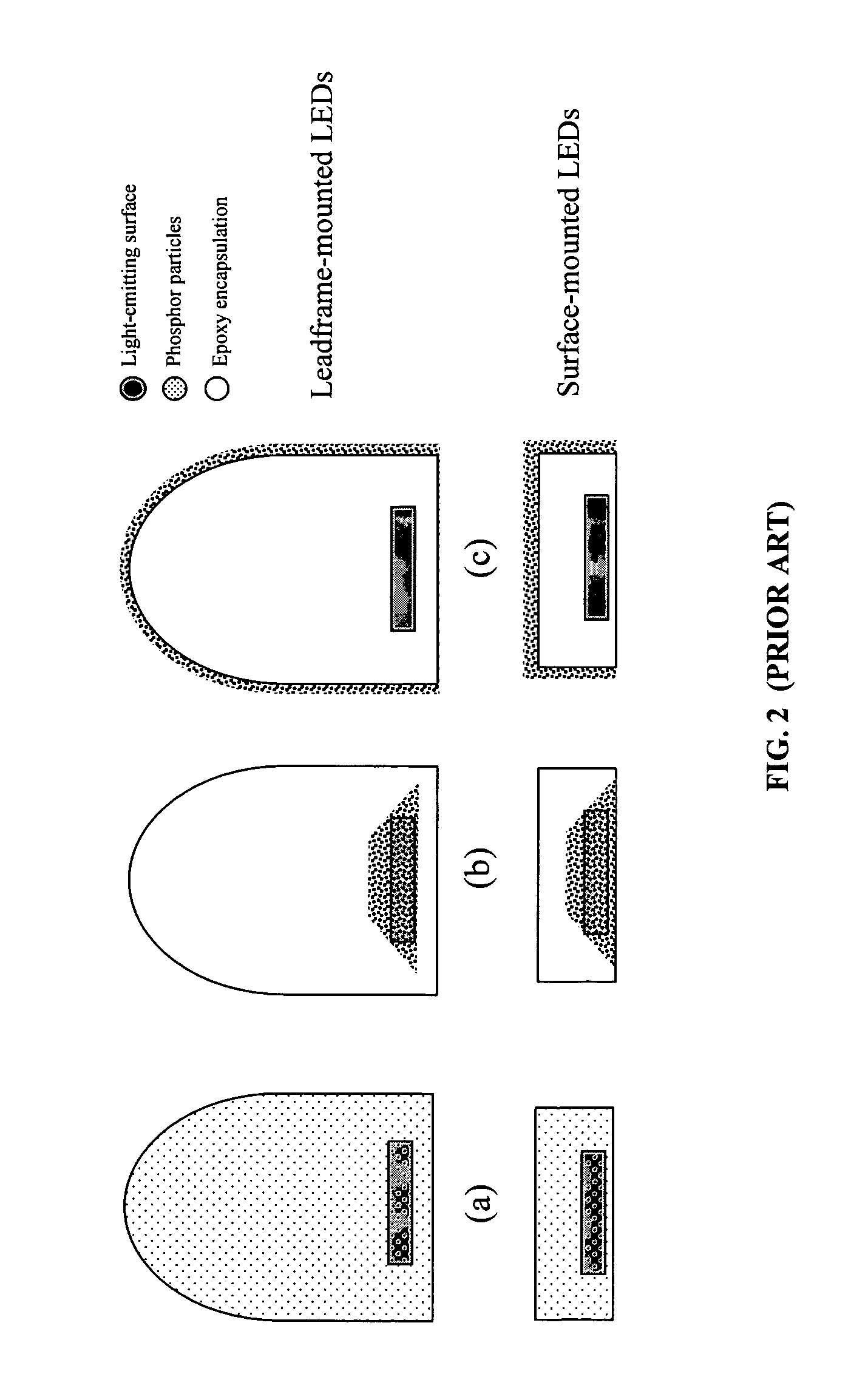

Single phosphor for creating white light with high luminosity and high CRI in a UV LED device

InactiveUS6853131B2Avoids and reduces problemGas-filled discharge tubesDischarge tube luminescnet screensX-rayUltraviolet

There is provided a white light illumination system. The illumination system includes a radiation source which emits either ultra-violet (UV) or x-ray radiation. The illumination system also includes a luminescent material which absorbs the UV or x-ray radiation and emits the white light. The luminescent material has composition A2−2xNa1+xExD2V3O12. A may be calcium, barium, strontium, or combinations of these three elements. E may be europium, dysprosium, samarium, thulium, or erbium, or combinations thereof. D may be magnesium or zinc, or combinations thereof. The value of x ranges from 0.01 to 0.3, inclusive.

Owner:GENERAL ELECTRIC CO

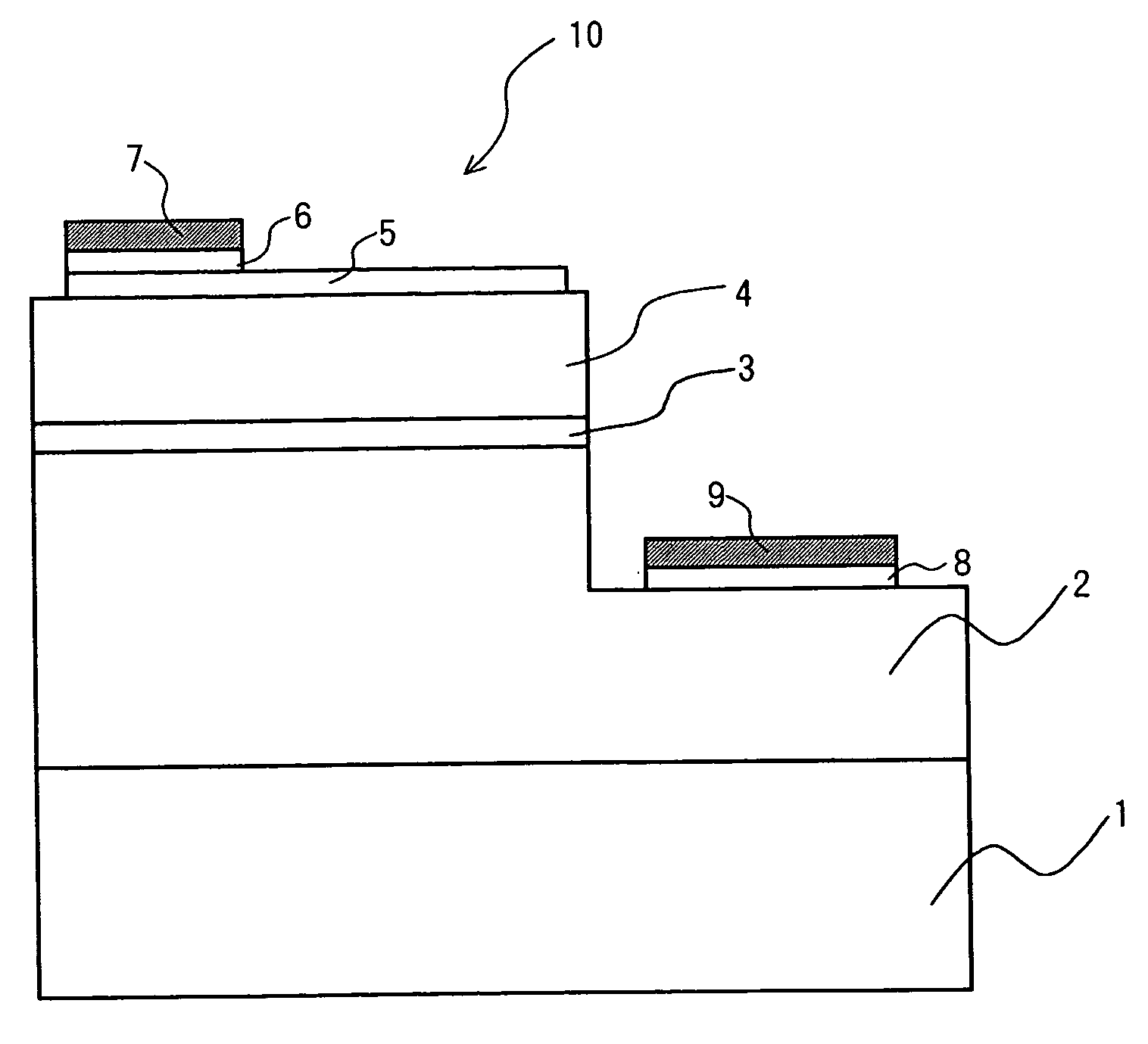

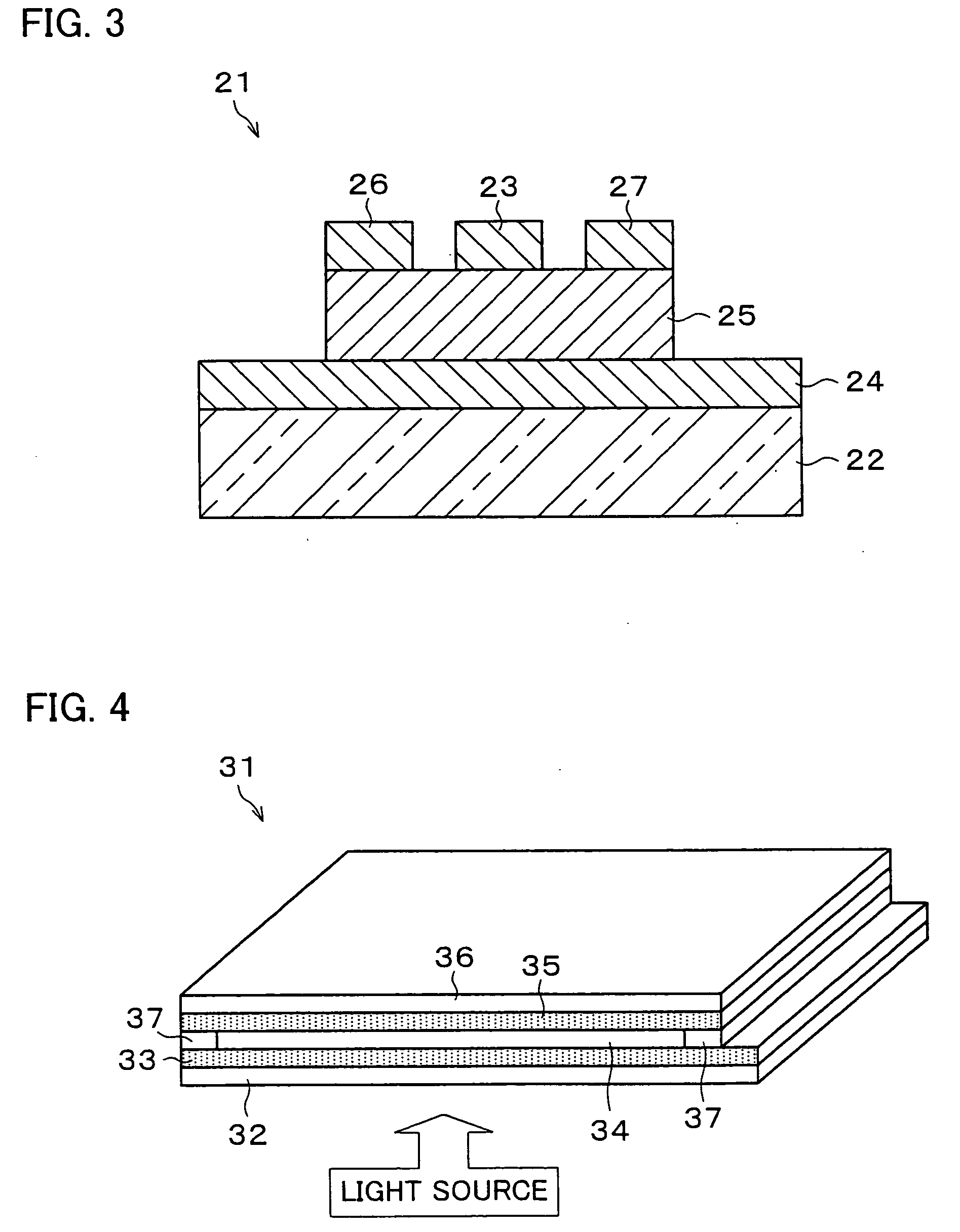

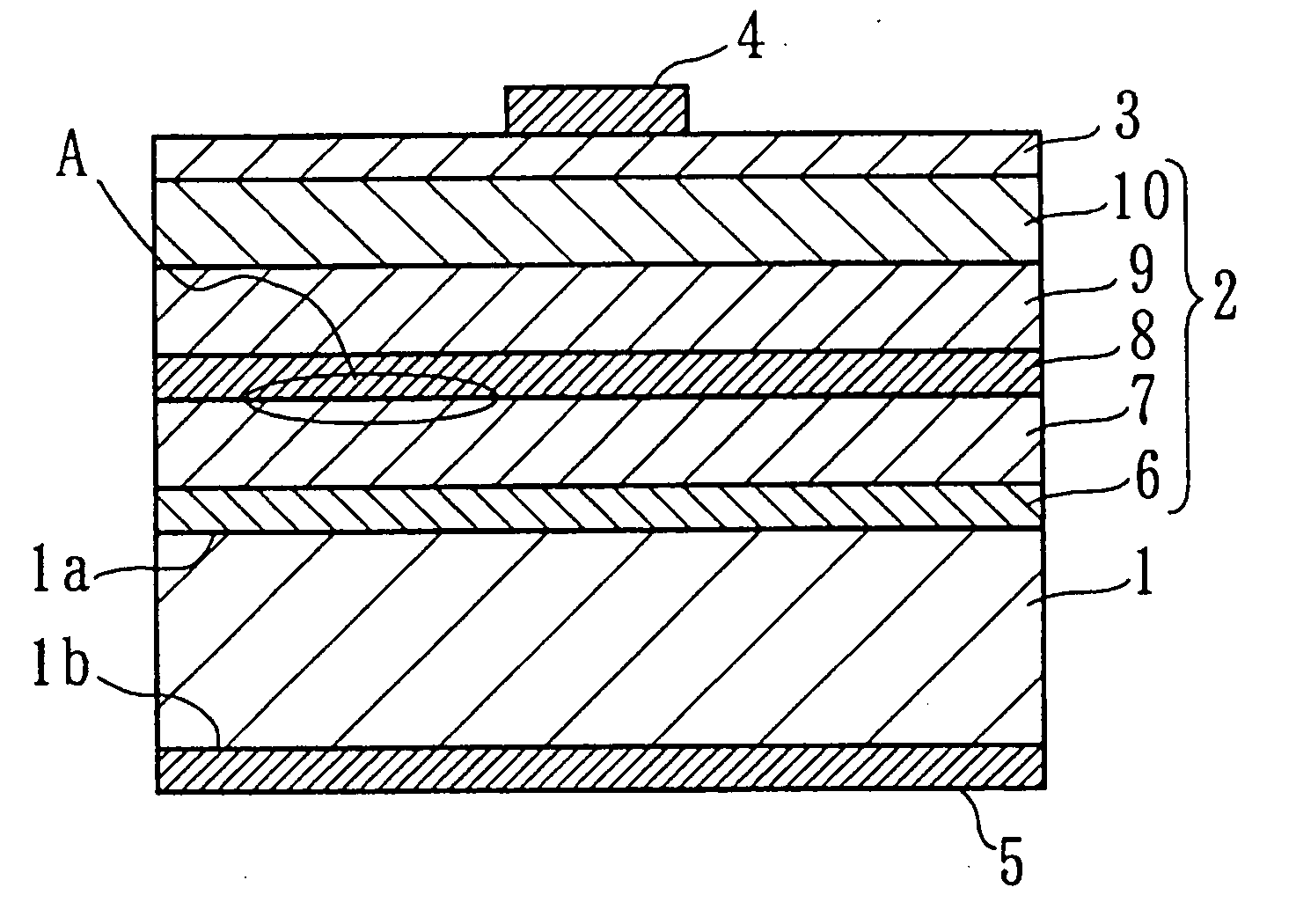

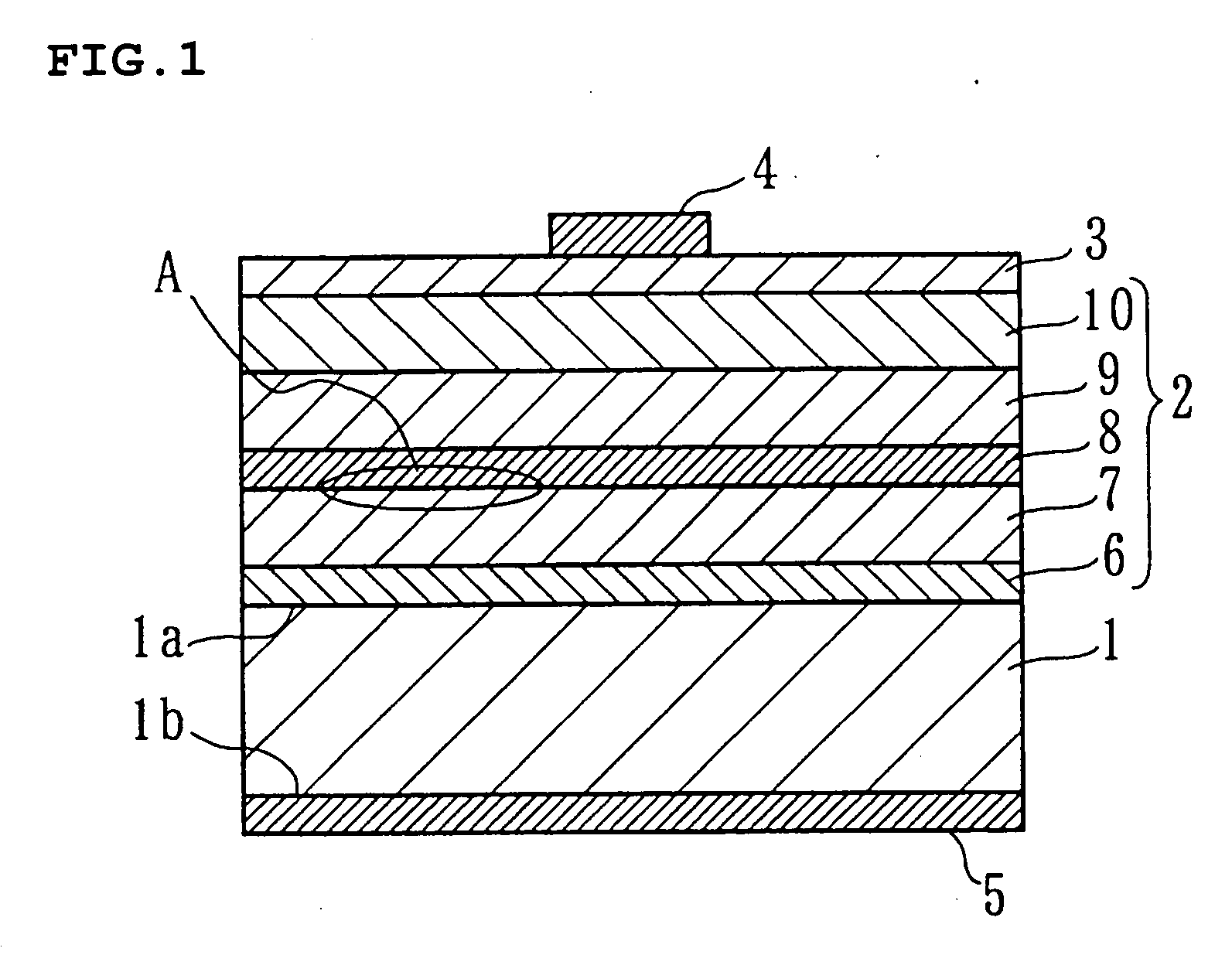

Semiconductor light emitting device

A semiconductor light emitting device with improved efficiency in extracting light is provided. The semiconductor light emitting device comprises a first conductive type semiconductor layer, a light emitting layer, and a second conductive semiconductor layer stacked in this order, electrodes respectively connected to the first and second conductive semiconductor layers, the electrode connected to the second conductive type semiconductor layer comprising a lower conductive oxide film and an upper conductive oxide film disposed on the lower conductive oxide film, and a metal film disposed only on the upper conductive oxide film. The upper and lower conductive oxide films comprise an oxide including at least one element selected from the group consisting of zinc (Zn), indium (In), tin (Sn), and magnesium (Mg).

Owner:NICHIA CORP

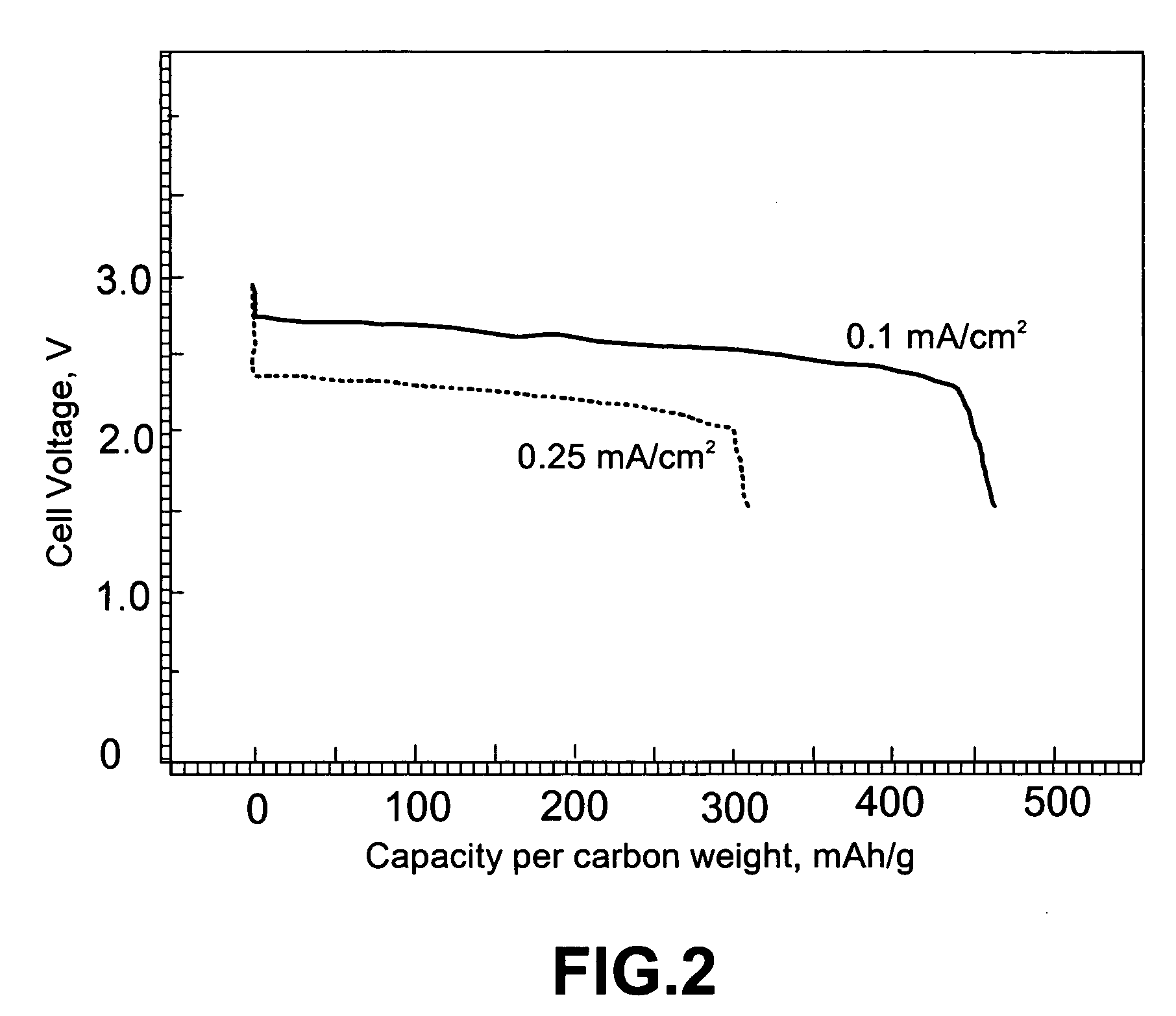

Metal-air battery with ion-conducting inorganic glass electrolyte

InactiveUS20060063051A1Safe and reliable solid-stateIncrease energy densityFuel and primary cellsSolid electrolytesMetal–air electrochemical cellIonic conductivity

A solid-state metal-air electrochemical cell comprising: (A) a metal-containing electro-active anode; (B) an oxygen electro-active cathode; and (C) an ion-conducting glass electrolyte disposed between the metal-containing anode and the oxygen electro-active cathode. The cathode active material, which is oxygen gas, is not stored in the battery but rather fed from the environment. The oxygen cathode is preferably a composite carbon electrode which serves as the cathode current collector on which oxygen molecules are reduced during discharge of the battery to generate electric current. The glass electrolyte typically has an ion conductivity in the range of 5×10−5 to 2×10−3 S / cm. The electrolyte layer is preferably smaller than 10 μm in thickness and further preferably smaller than 1 μm. The anode metal is preferably lithium or lithium alloy, but may be selected from other elements such as sodium, magnesium, calcium, aluminum and zinc.

Owner:JANG BOR Z

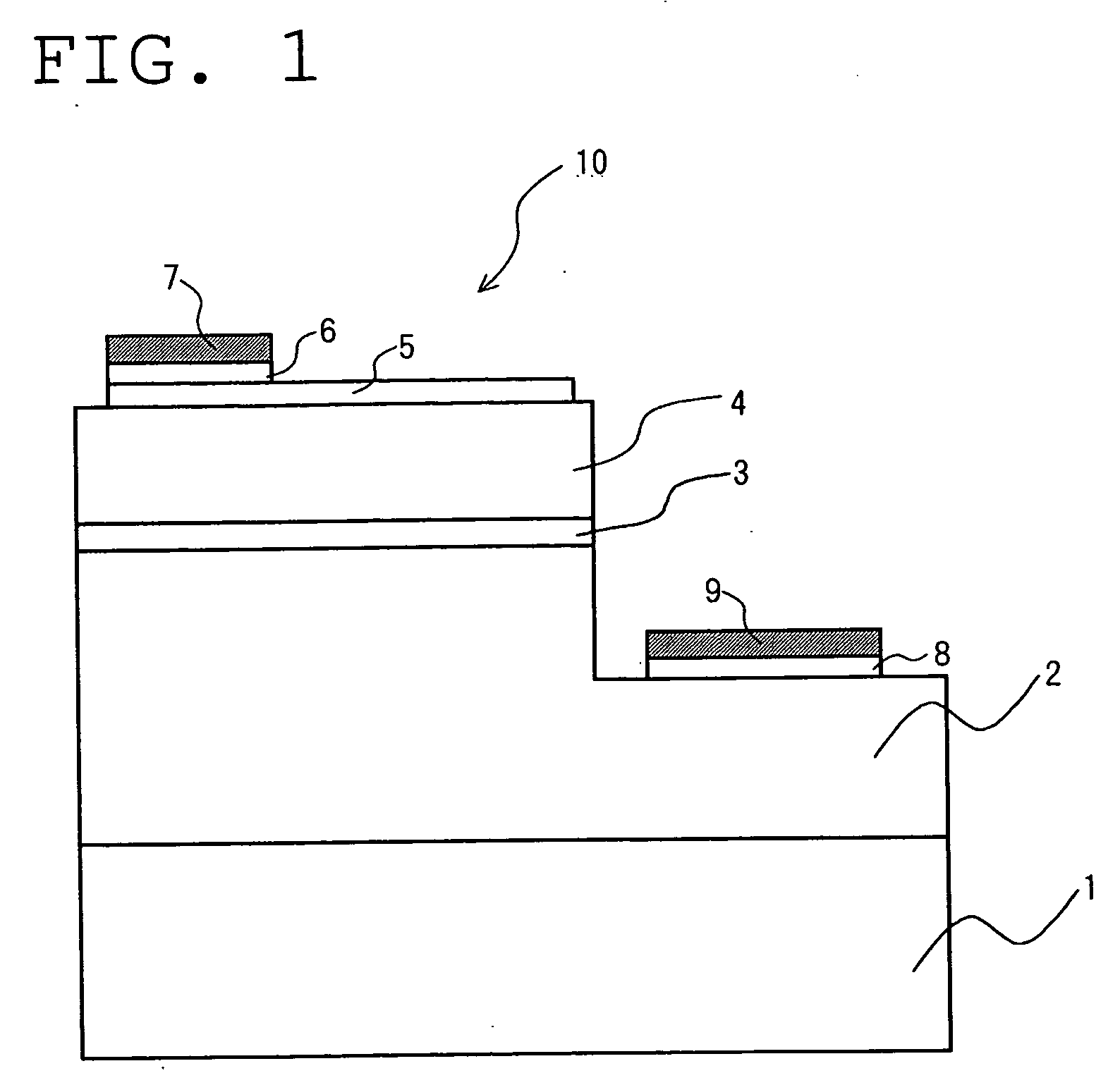

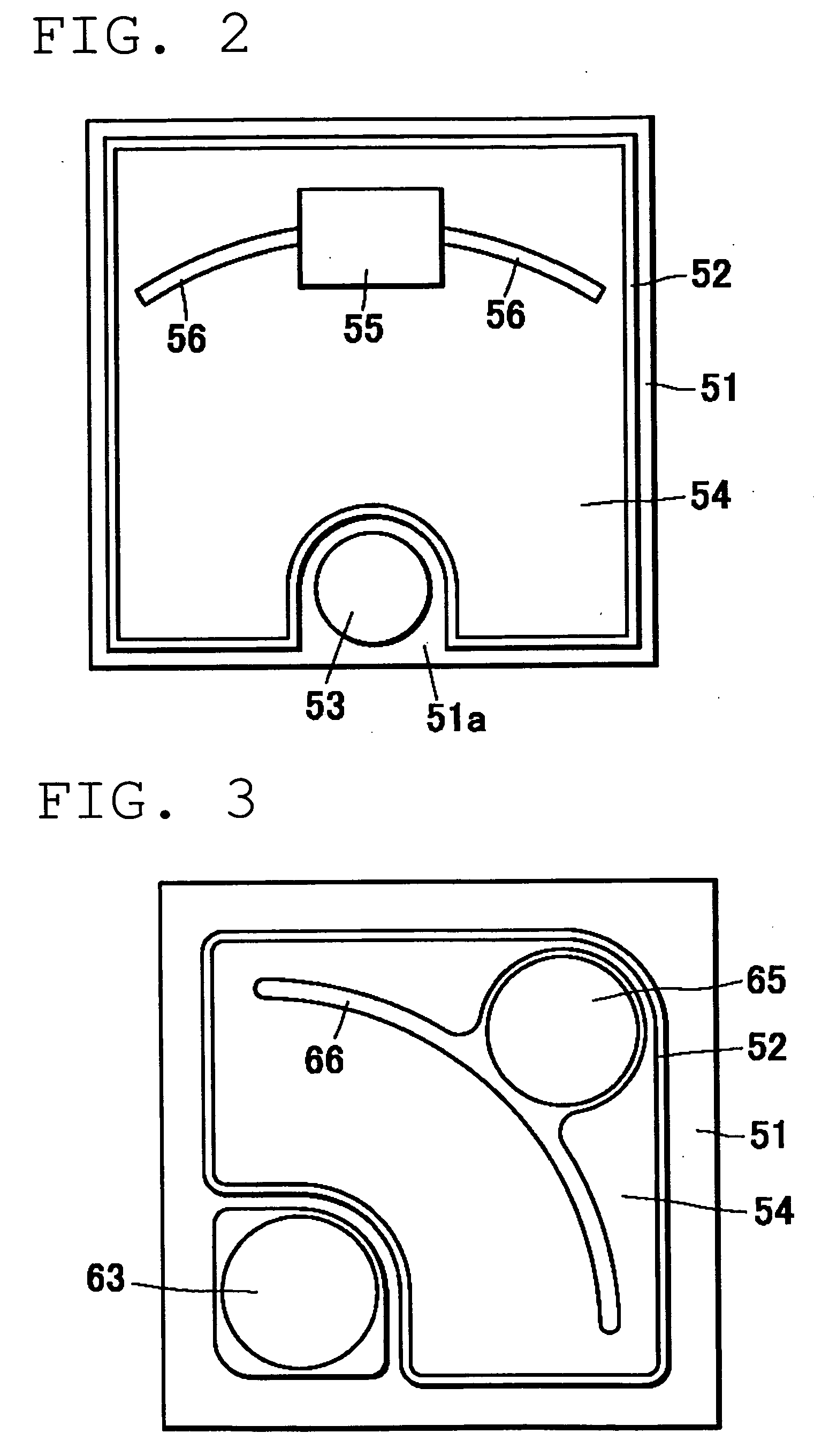

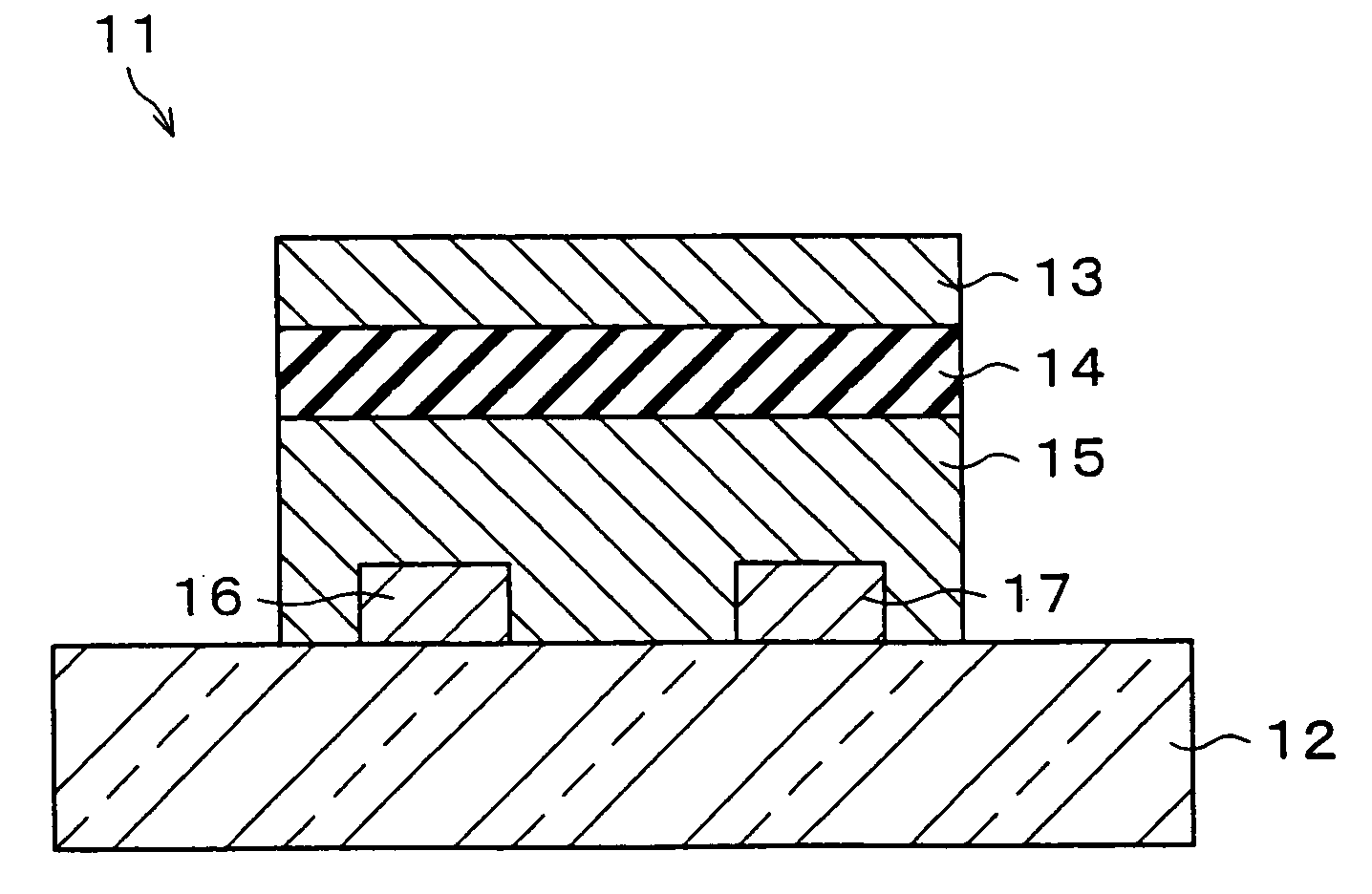

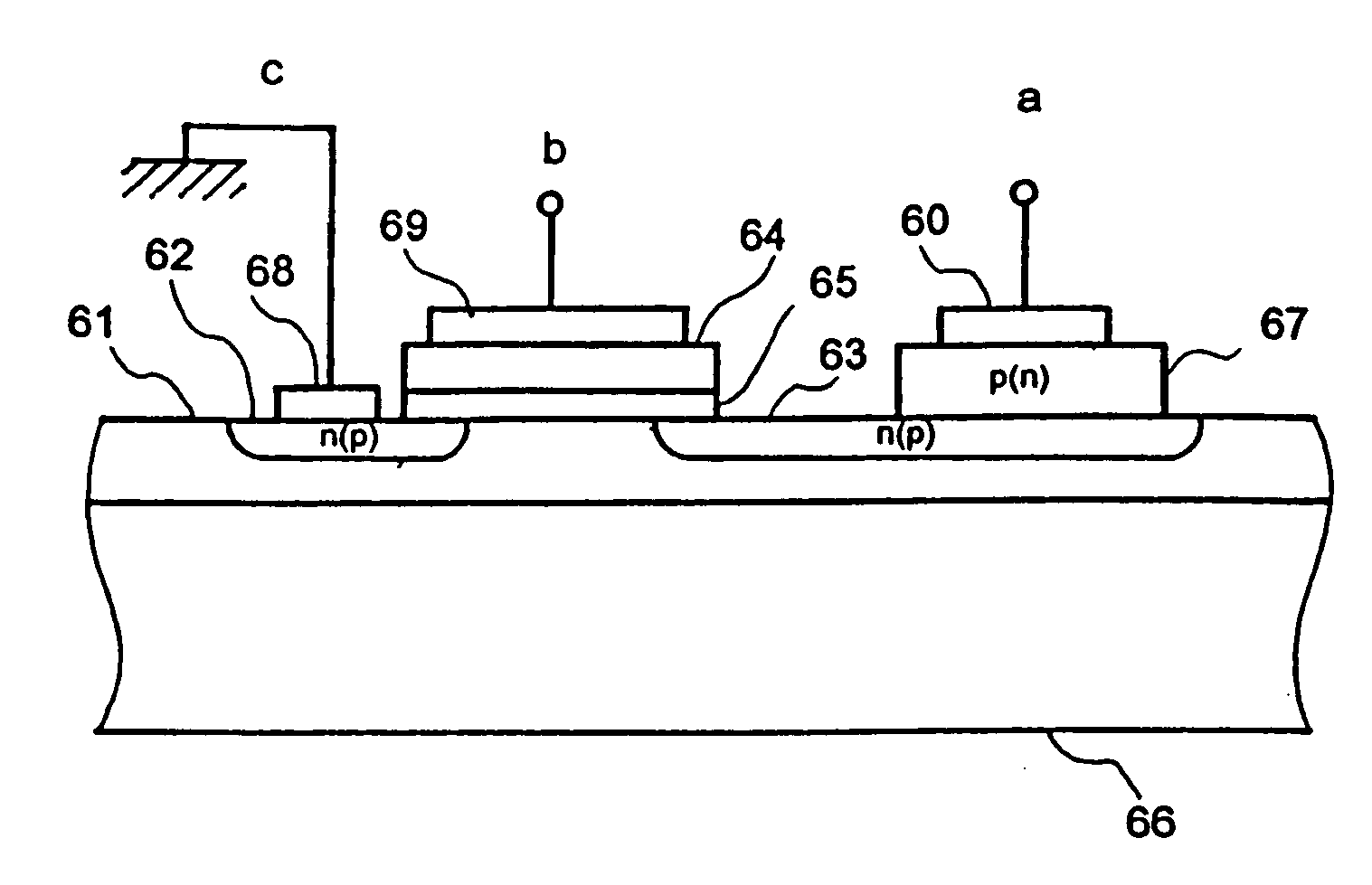

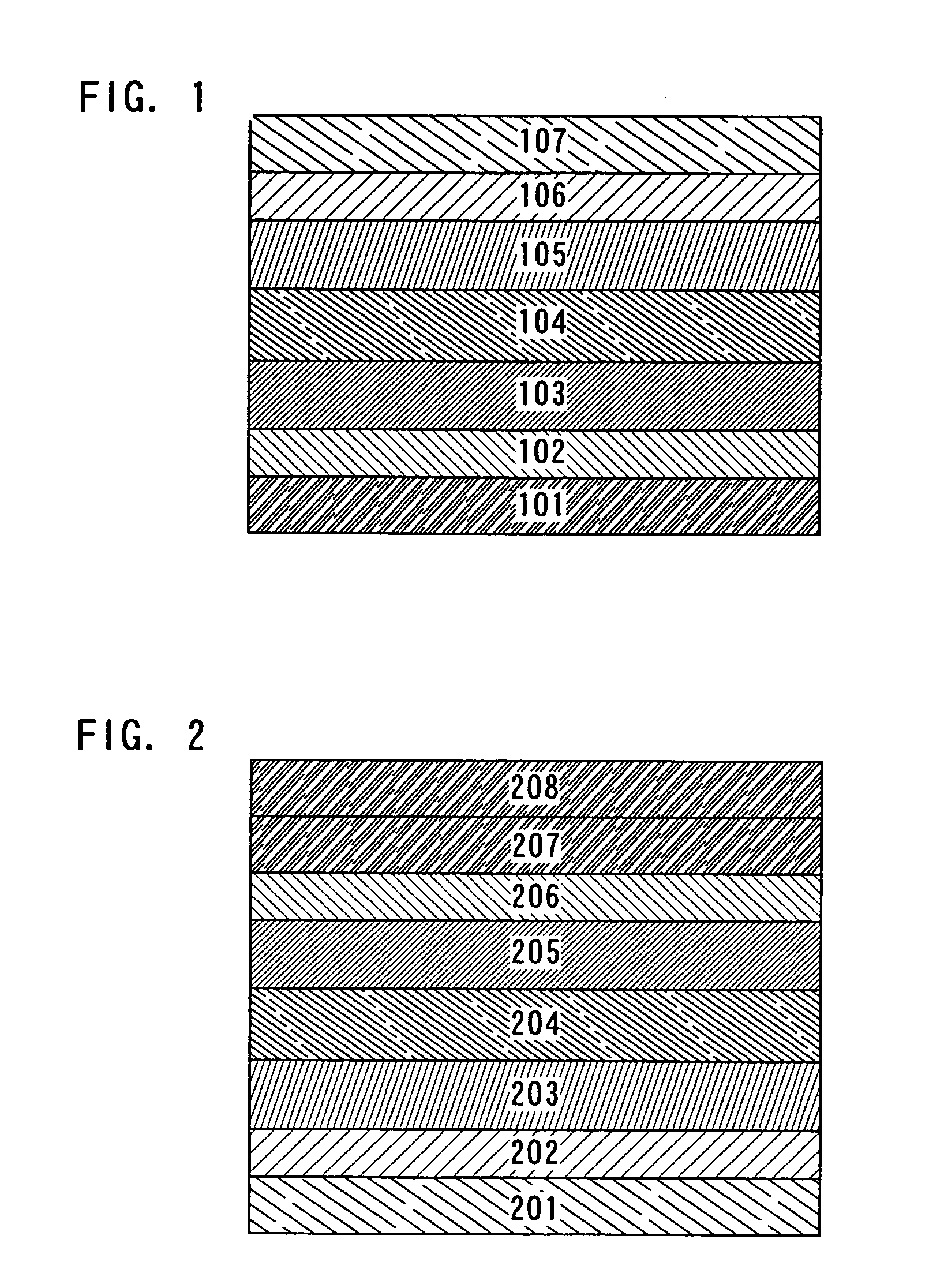

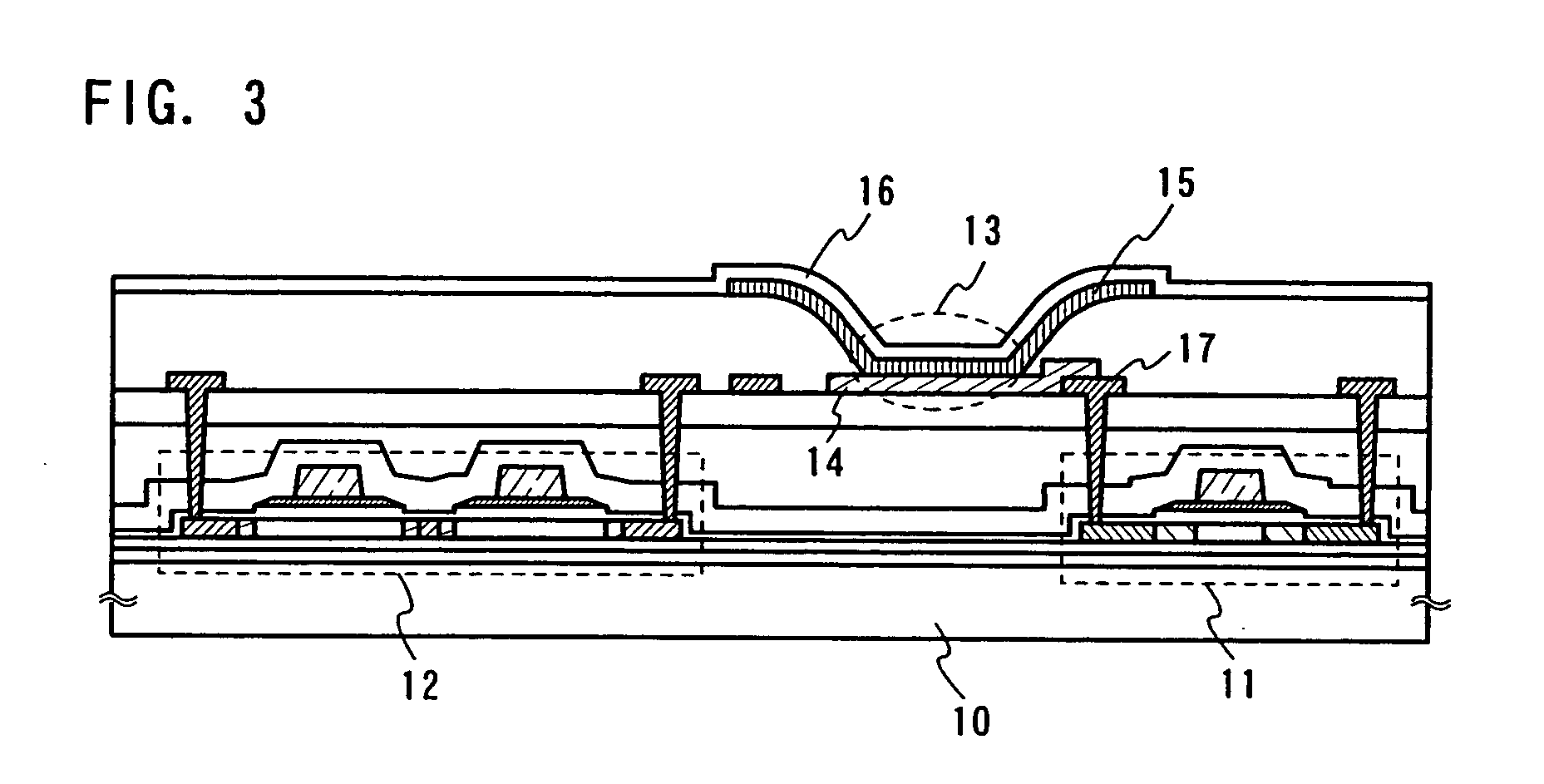

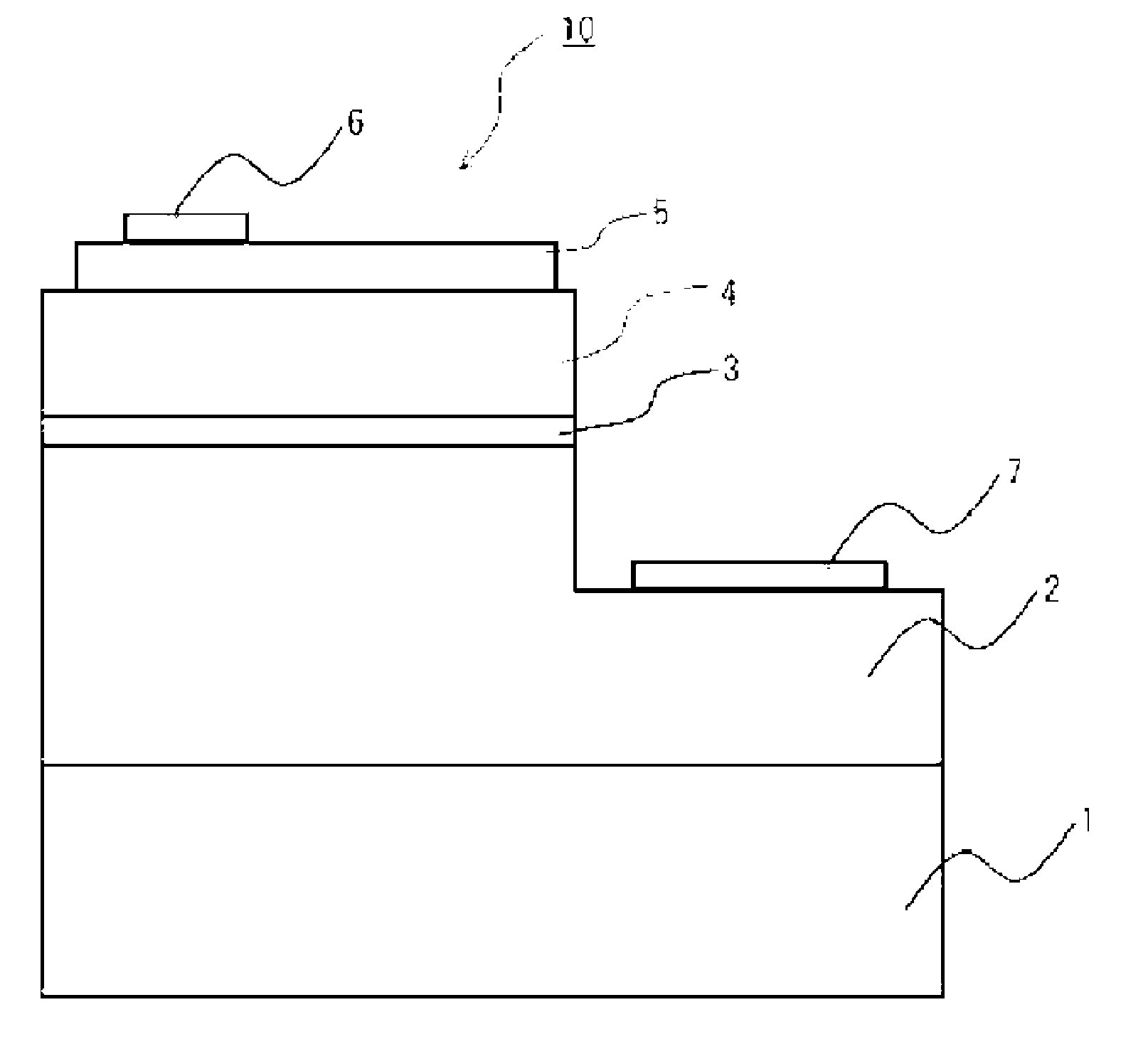

Semiconductor device and display comprising same

InactiveUS20050173734A1Improve performanceVersatile techniqueTransistorSemiconductor/solid-state device detailsMOSFETDevice material

In an inverse-stagger MOSFET (1), a gate insulating layer (4) made of amorphous aluminum oxide is so formed as to face a channel layer (5) which serves as the semiconductor layer, and which is made of zinc oxide. With this arrangement, a defect level at an interface between the channel layer (5) and the gate insulating layer (4) is reduced, thereby obtaining performance equivalent to that of a semiconductor apparatus in which all the layered films are crystalline. This technique is applicable to a staggered MOSFET and the like, and has high versatility.

Owner:MASASHI KAWASAKI +2

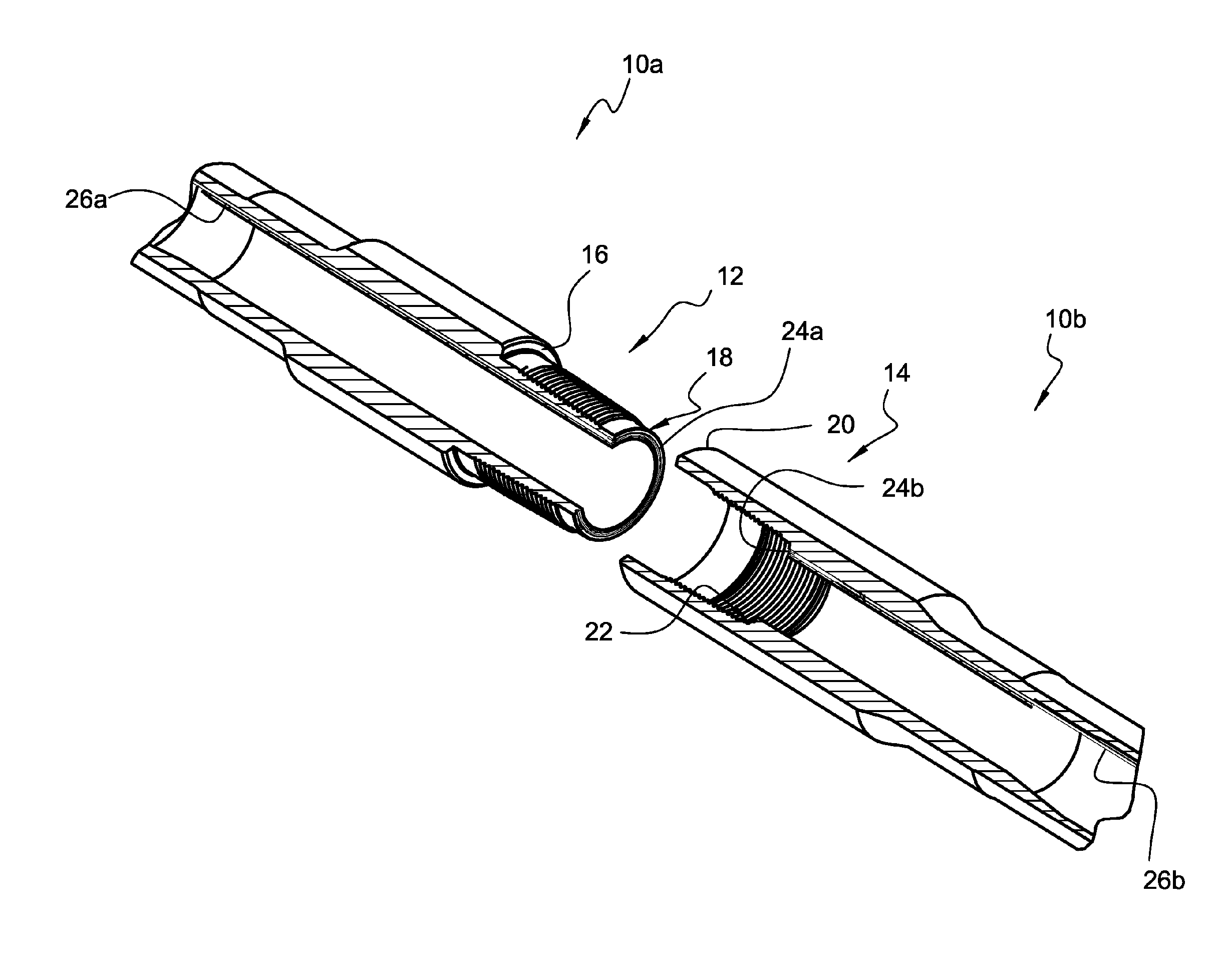

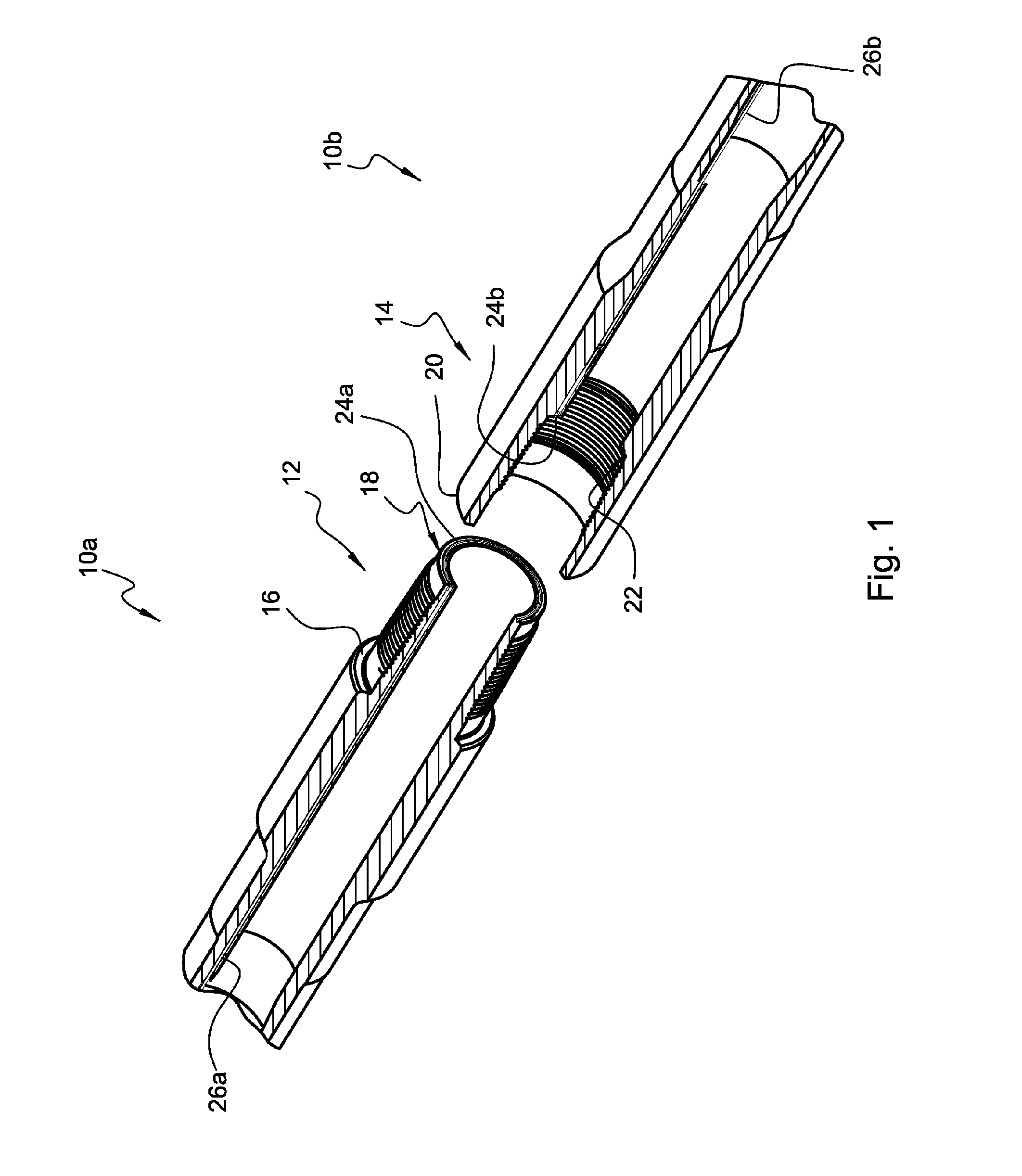

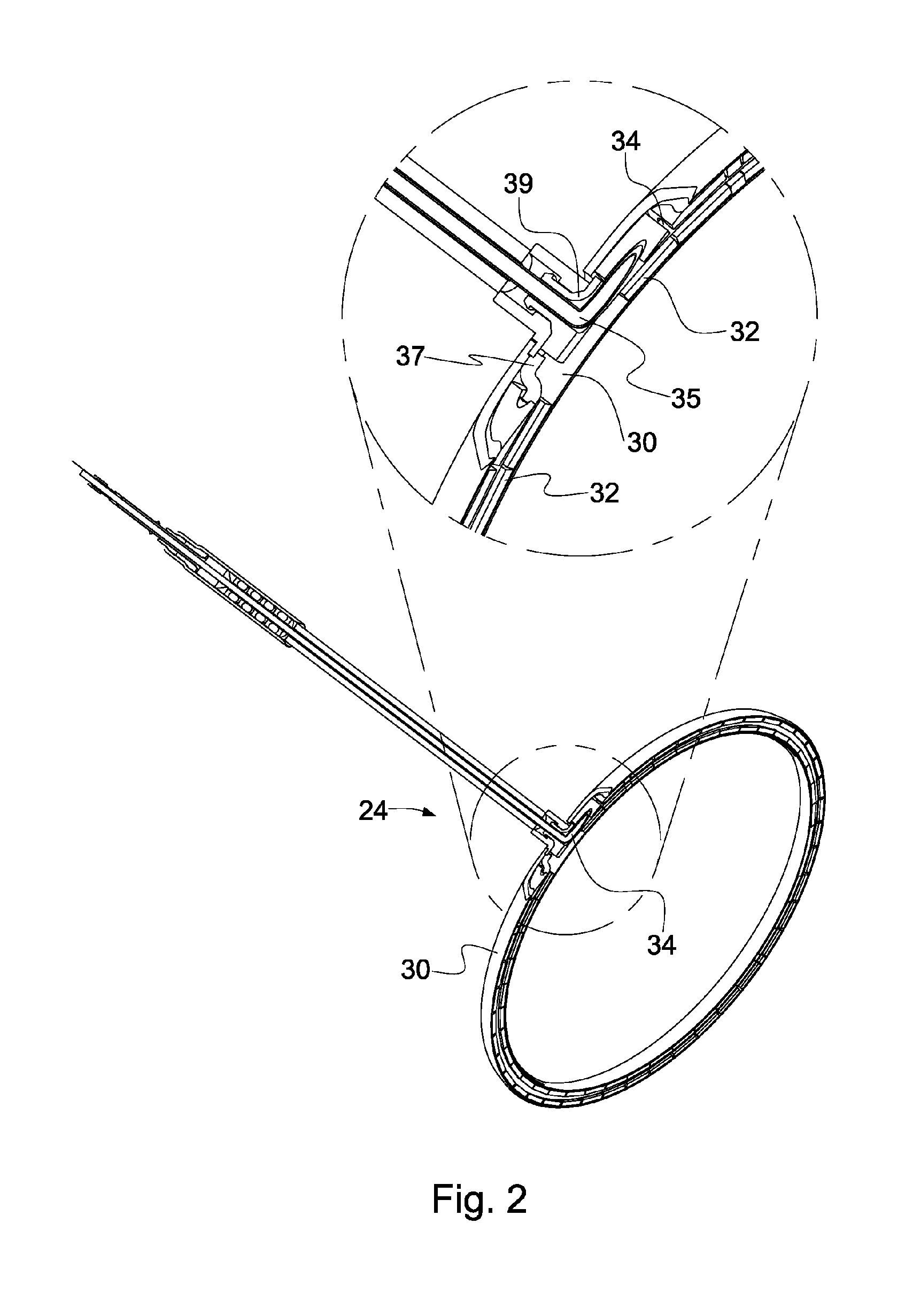

Corrosion-Resistant Downhole Transmission System

An apparatus in accordance with the invention may include a downhole tool and a data transmission path incorporated into the downhole tool. The data transmission path may include one or more contact surfaces providing electrical continuity to the data transmission path. To protect the contact surfaces from corrosion while maintaining electrical conductivity, a coating may be attached to one or more of the contact surfaces. The coating may include any of various materials that increase the corrosion-resistance of the underlying base metal, including but not limited to cobalt, nickel, tin, tin-lead, platinum, palladium, gold, silver, zinc, or combinations thereof.

Owner:INTELLISERV

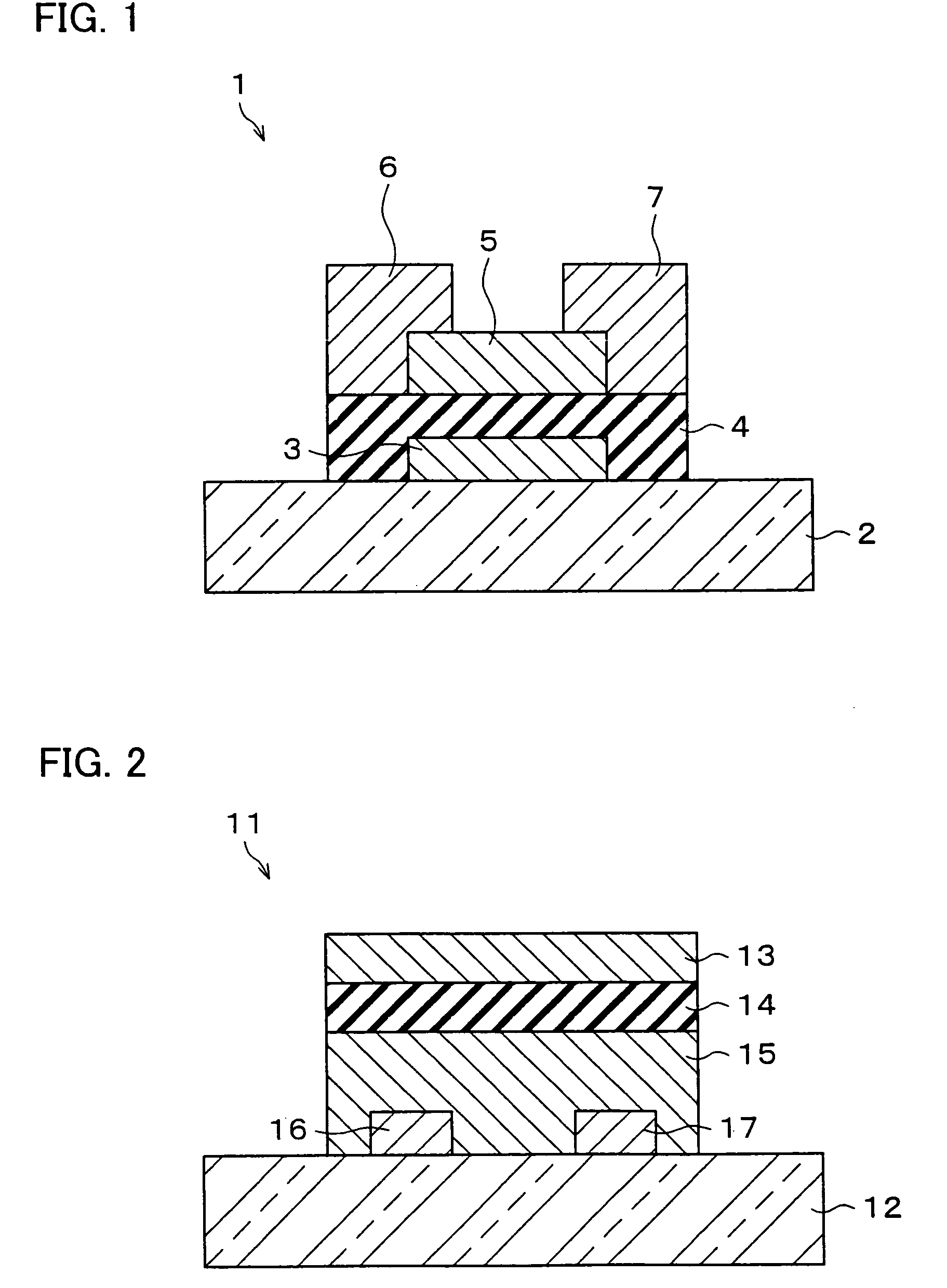

Transistor and semiconductor device

InactiveUS20050127380A1Increase brightnessIncrease ratingsTransistorLaser detailsDevice materialConductive materials

Owner:JAPAN SCI & TECH CORP

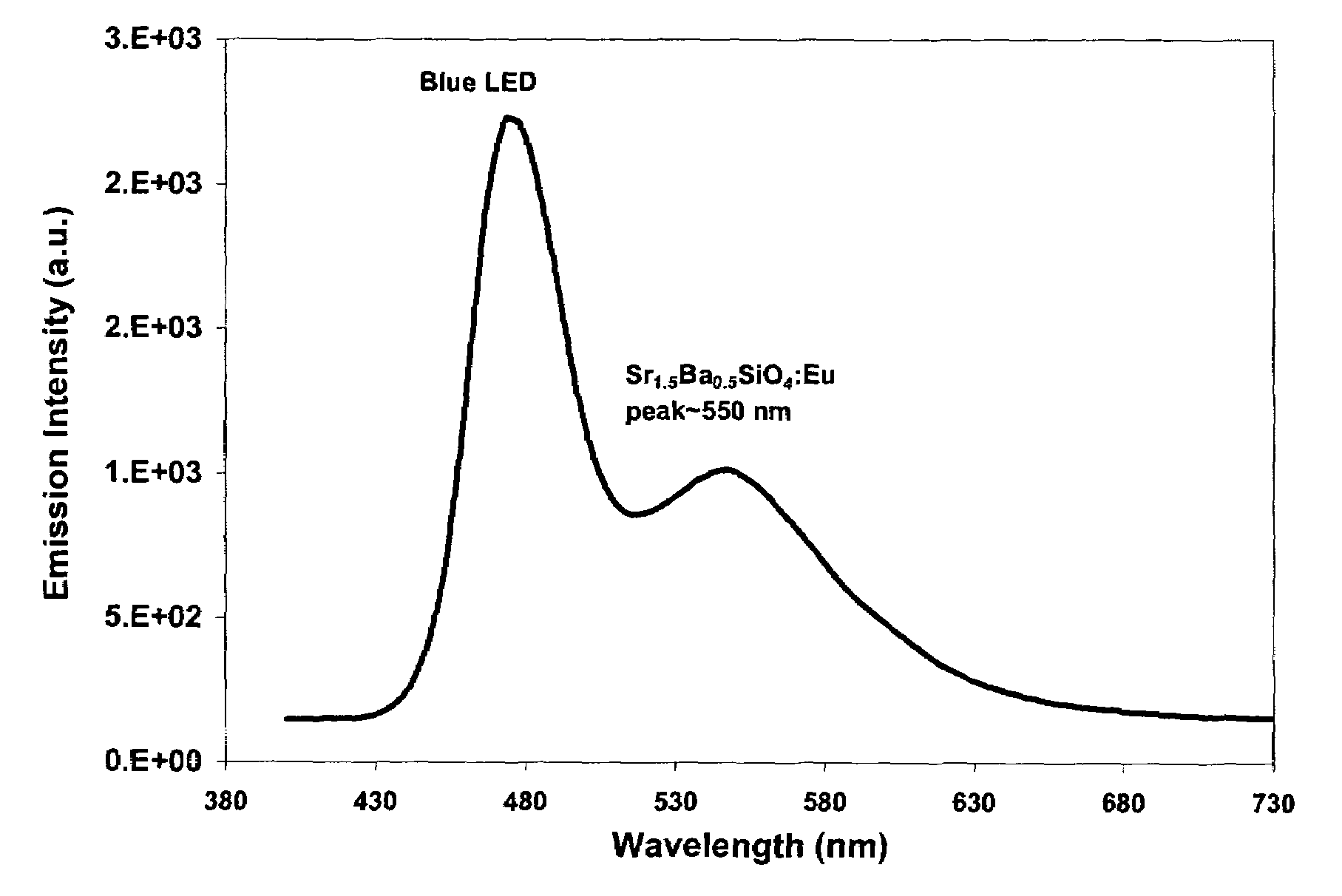

Light emitting device having silicate fluorescent phosphor

InactiveUS6982045B2Improve efficiencyDischarge tube luminescnet screensLamp detailsFluorescenceProviding material

Provided herein are novel phosphors useful in the manufacture of white light emitting diodes. The phosphors provided by the invention are described by the formula:SrxBayCazSiO4:Euin which x, y, and z are each independently variable to be any value between about 0 and about 2, including without limitation 0.001 and 2, and every thousandth therebetween, subject to the proviso that the sum of x, y, or z is equal to at least 1, and in which Eu is present in any amount between about 0.0001% and about 5% by weight based upon the phosphor's total weight, wherein substantially all of the europium present is present in the divalent state. A phosphor according to the invention may optionally further comprise an element selected from the group consisting of: Ce, Mn, Ti, Pb, and Sn and is present in any amount between about 0.0001% and about 5% by weight based on the phosphor's total weight. The silicate phosphor materials provided by the present invention do not require the addition of dissimilar blue and red phosphor compounds, and do not contain zinc and / or magnesium. In addition, the present invention provides materials which emit a broad yellowish color containing both green and red emissions.Standard techniques used in phosphor deposition for the manufacture of light emitting diodes which comprise phosphors may be employed to produce LED's having a white light output when the phosphors of the invention are utilized.

Owner:PHOSPHORTECH

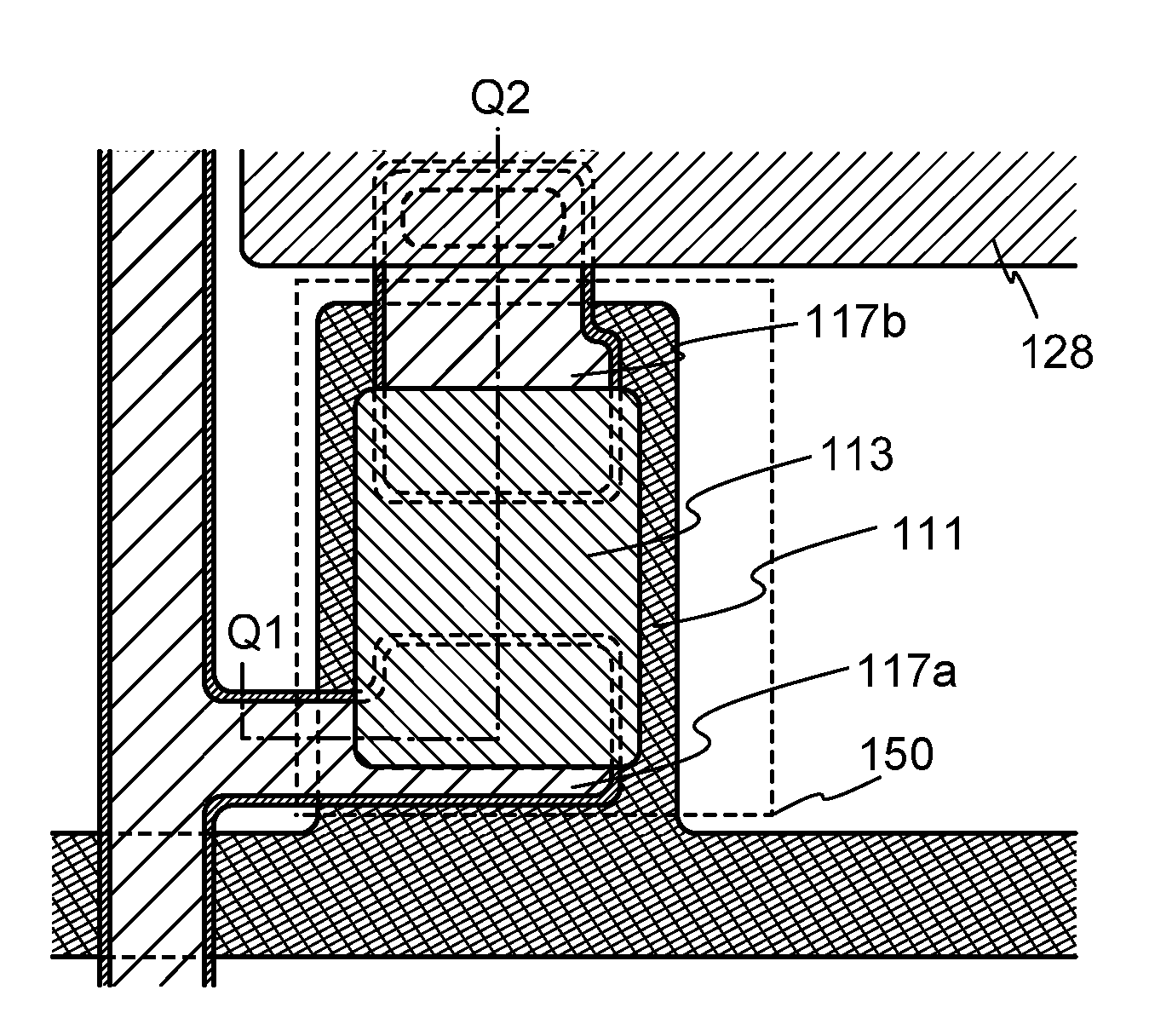

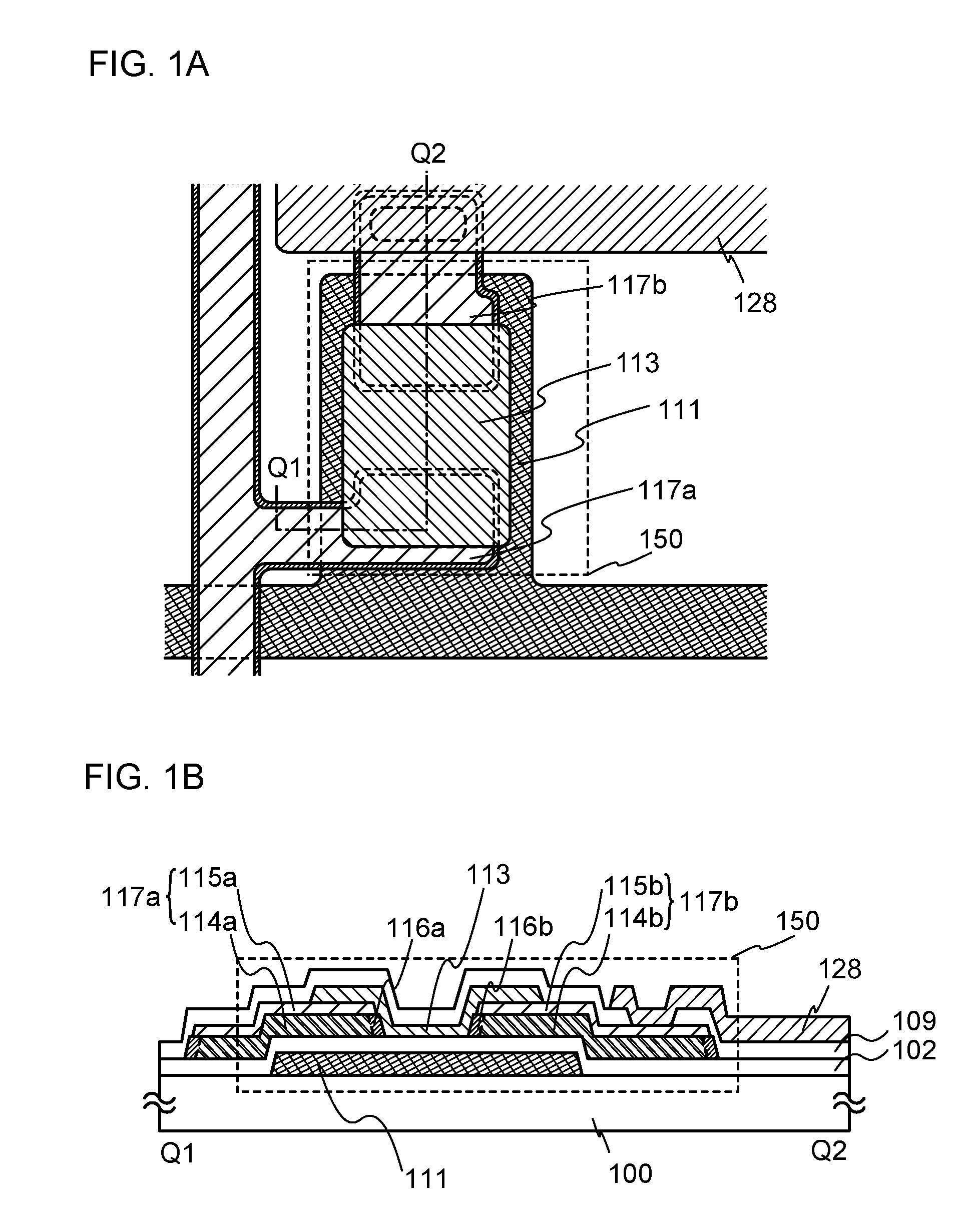

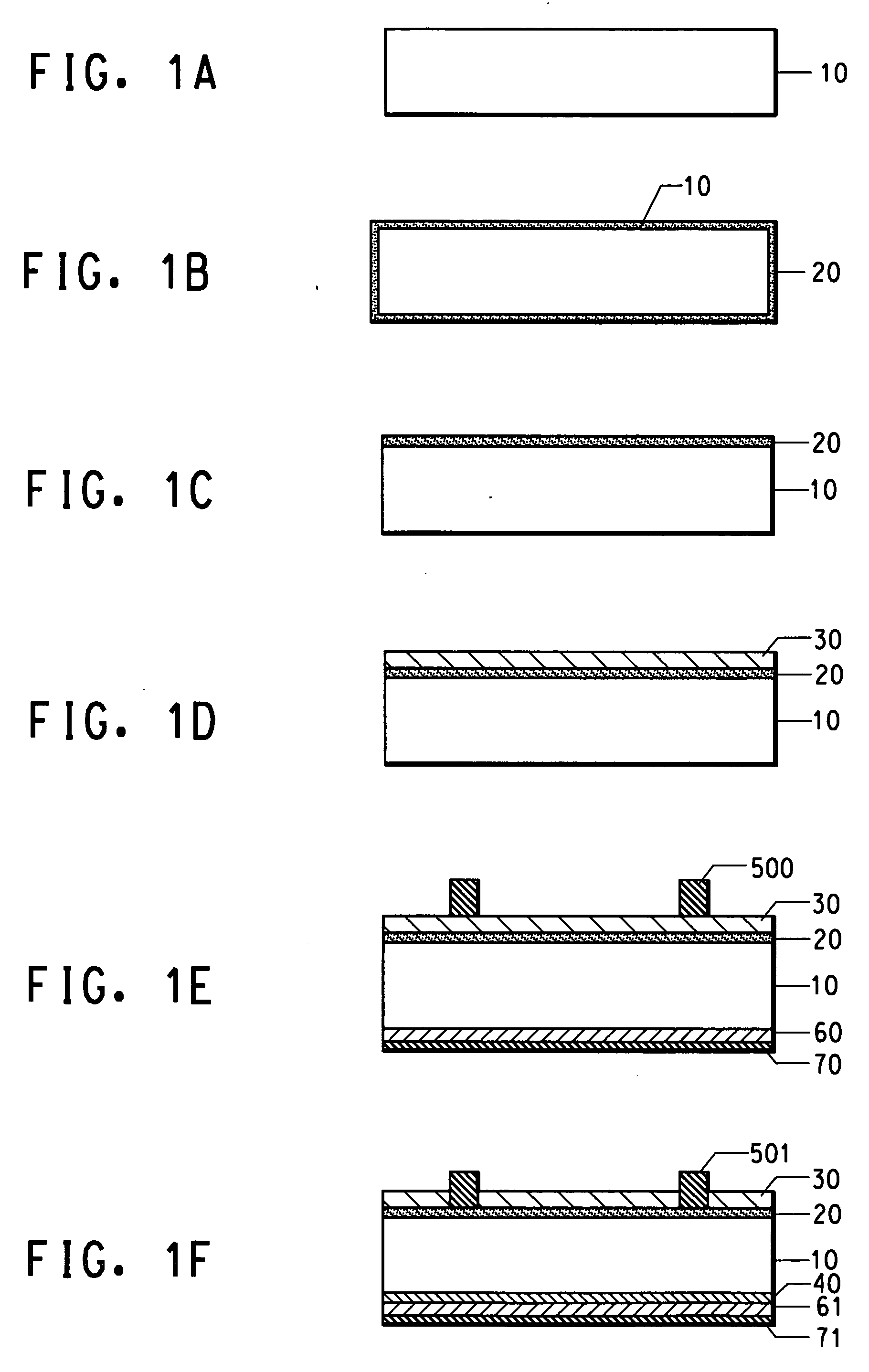

Semiconductor device and manufacturing method thereof

ActiveUS20100090217A1Inhibited DiffusionSuppress DiffuseSolid-state devicesSemiconductor/solid-state device manufacturingIndiumDevice material

Electric characteristics and reliability of a thin film transistor are impaired by diffusion of an impurity element into a channel region. The present invention provides a thin film transistor in which aluminum atoms are unlikely to be diffused to an oxide semiconductor layer. A thin film transistor including an oxide semiconductor layer including indium, gallium, and zinc includes source or drain electrode layers in which first conductive layers including aluminum as a main component and second conductive layers including a high-melting-point metal material are stacked. An oxide semiconductor layer 113 is in contact with the second conductive layers and barrier layers including aluminum oxide as a main component, whereby diffusion of aluminum atoms to the oxide semiconductor layer is suppressed.

Owner:SEMICON ENERGY LAB CO LTD

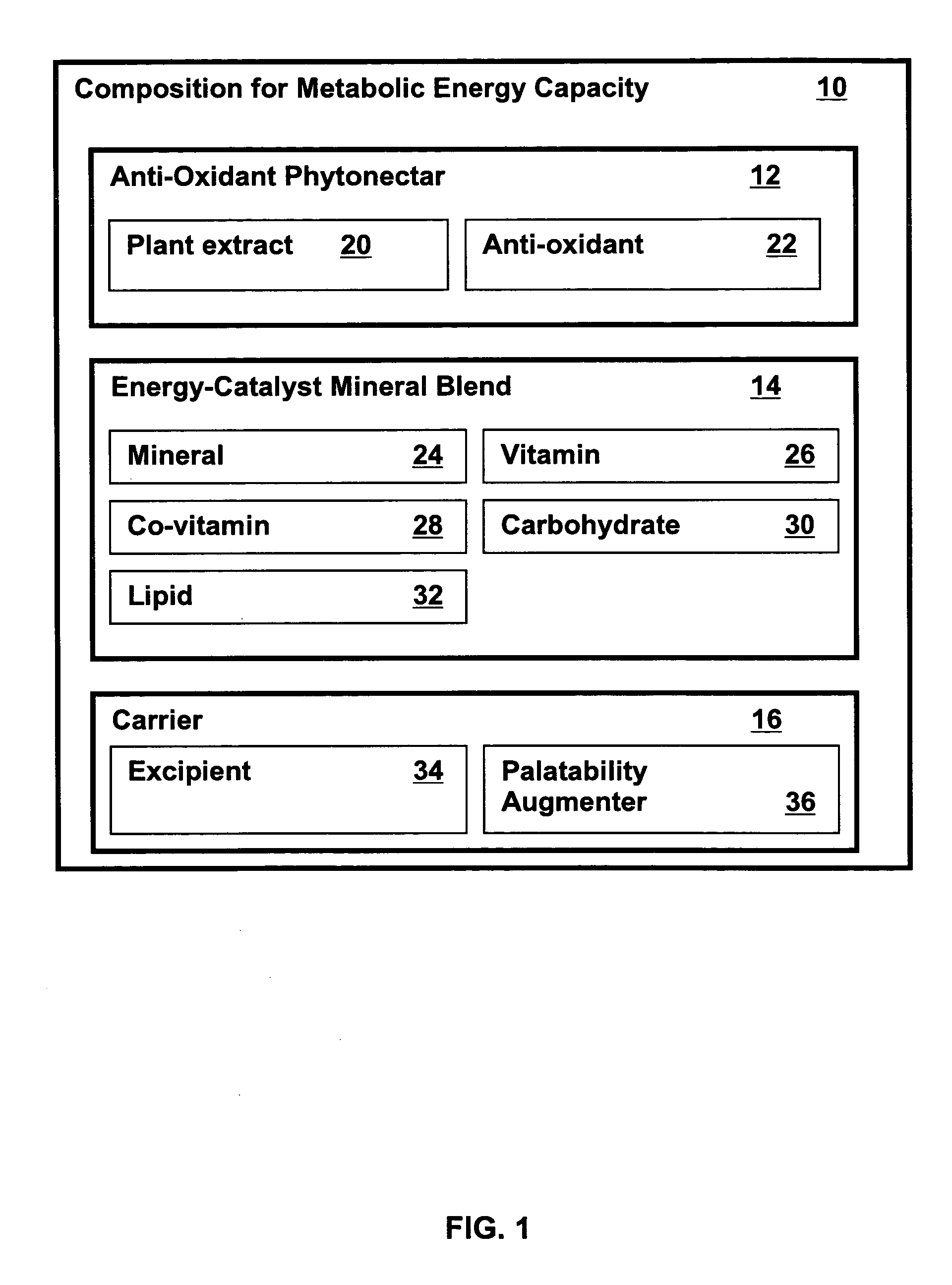

Metabolic capacity enhancing compositions and methods for use in a mammal

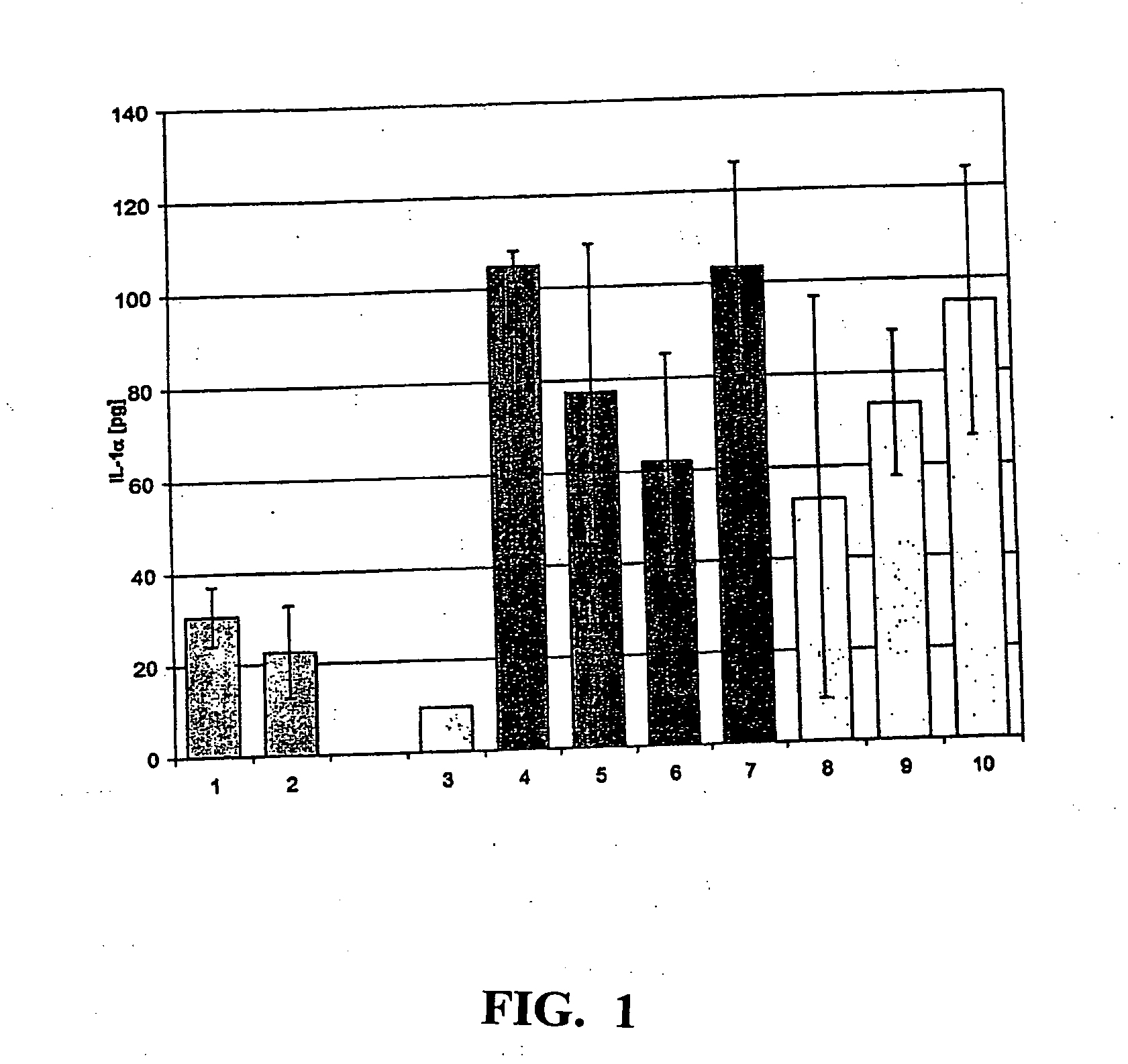

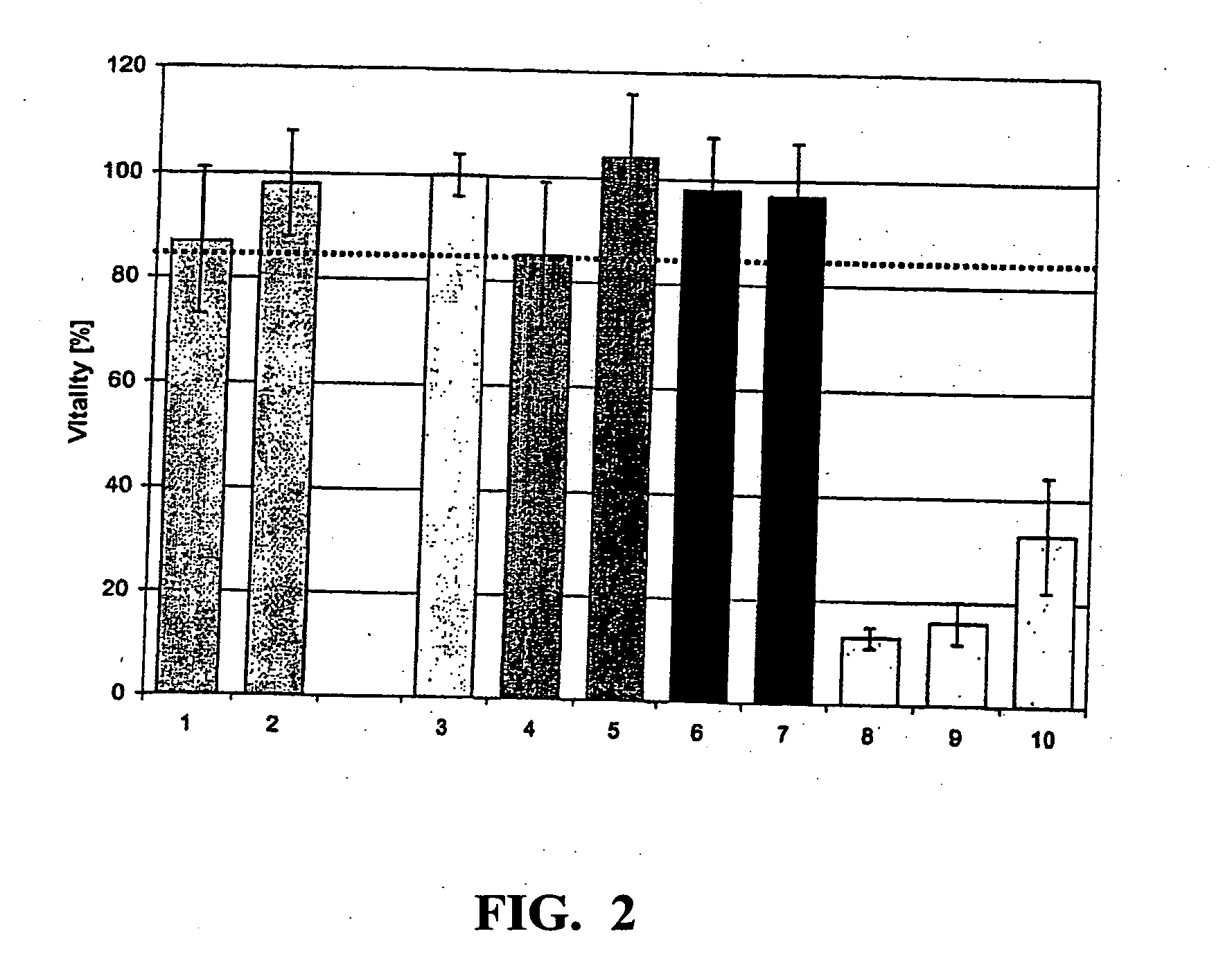

InactiveUS20060024385A1Increase vitalityImproved and increased energy processing of given caloric foods)BiocideOrganic active ingredientsLipid formationMammal

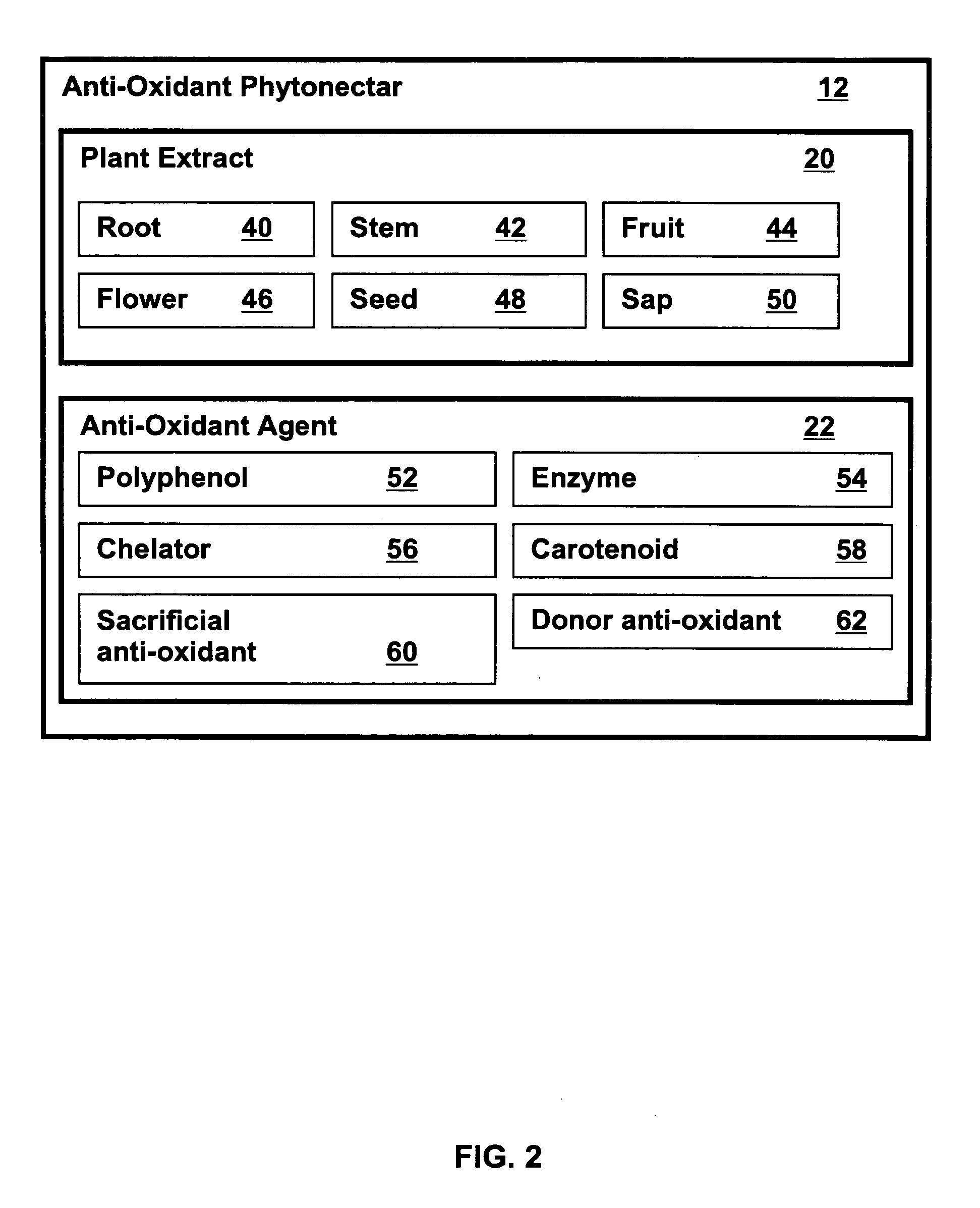

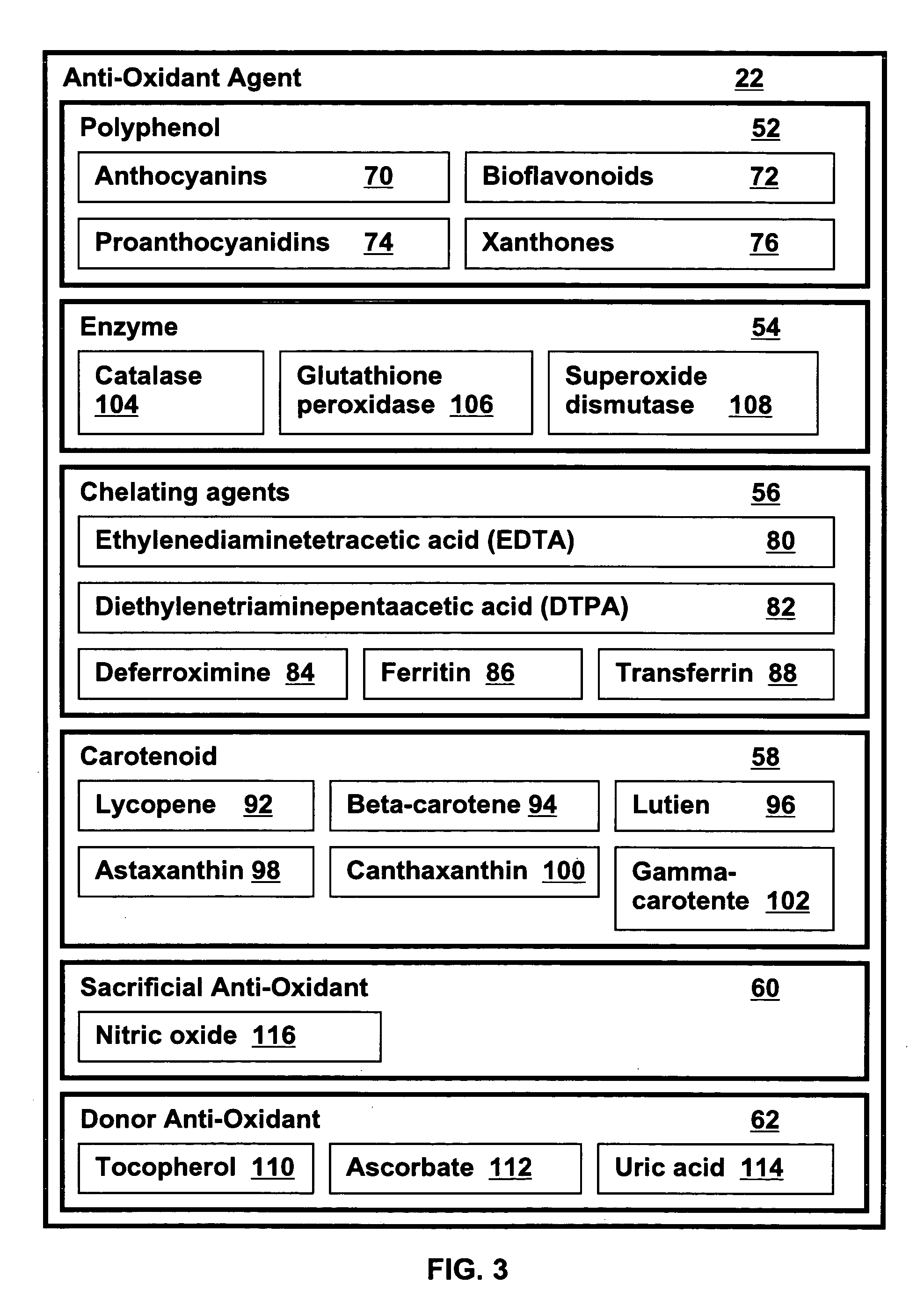

Metabolic energy capacity enhancing compositions and methods for reducing oxidative stress and improving vitality in a mammal are disclosed. A composition for increasing metabolic energy capacity may be in a palatable liquid formulation or a solid dosage form and typically includes an anti-oxidant containing phytonectar and an energy catalyst. An anti-oxidant may include a polyphenol, anthrocyanin, bioflavonoid, proanthocyanidin, and a xanthone. An energy catalyst may include a mineral, vitamin, co-vitamin, carbohydrate and a lipid. In a presently preferred embodiment a composition includes phytonectar extracts from grape, aloe vera, apple, morinda citrifolia, scullcap, blueberry, prune, cranberry, elderberry, bilberry, and gentain and a mineral blend containing calcium, magnesium, manganese, zinc, chromium, selenium, iron, copper, molybdenum, vanadium, potassium, iodine, and cobalt. A method for increasing metabolic energy capacity in a mammal may include consuming a chemical component having the ability to undergo oxidation, producing free radicals and administering a composition having an anti-oxidant containing phytonectar and an energy catalyst.

Owner:PEDERSEN MARK A

Method of manufacture of semiconductor device and conductive compositions used therein

InactiveUS20060231804A1Semiconductor/solid-state device detailsConductive materialDevice materialFrit

The present invention is directed to a thick film conductive composition comprising: (a) electrically conductive silver powder; (b) Zn-containing additive wherein the particle size of said zinc-containing additive is in the range of 7 nanometers to less than 100 nanometers; (c) glass frit wherein said glass frit has a softening point in the range of 300 to 600° C.; dispersed in (d) organic medium. The present invention is further directed to a semiconductor device and a method of manufacturing a semiconductor device from a structural element composed of a semiconductor having a p-n junction and an insulating film formed on a main surface of the semiconductor comprising the steps of (a) applying onto said insulating film the thick film composition as describe above; and (b) firing said semiconductor, insulating film and thick film composition to form an electrode.

Owner:EI DU PONT DE NEMOURS & CO

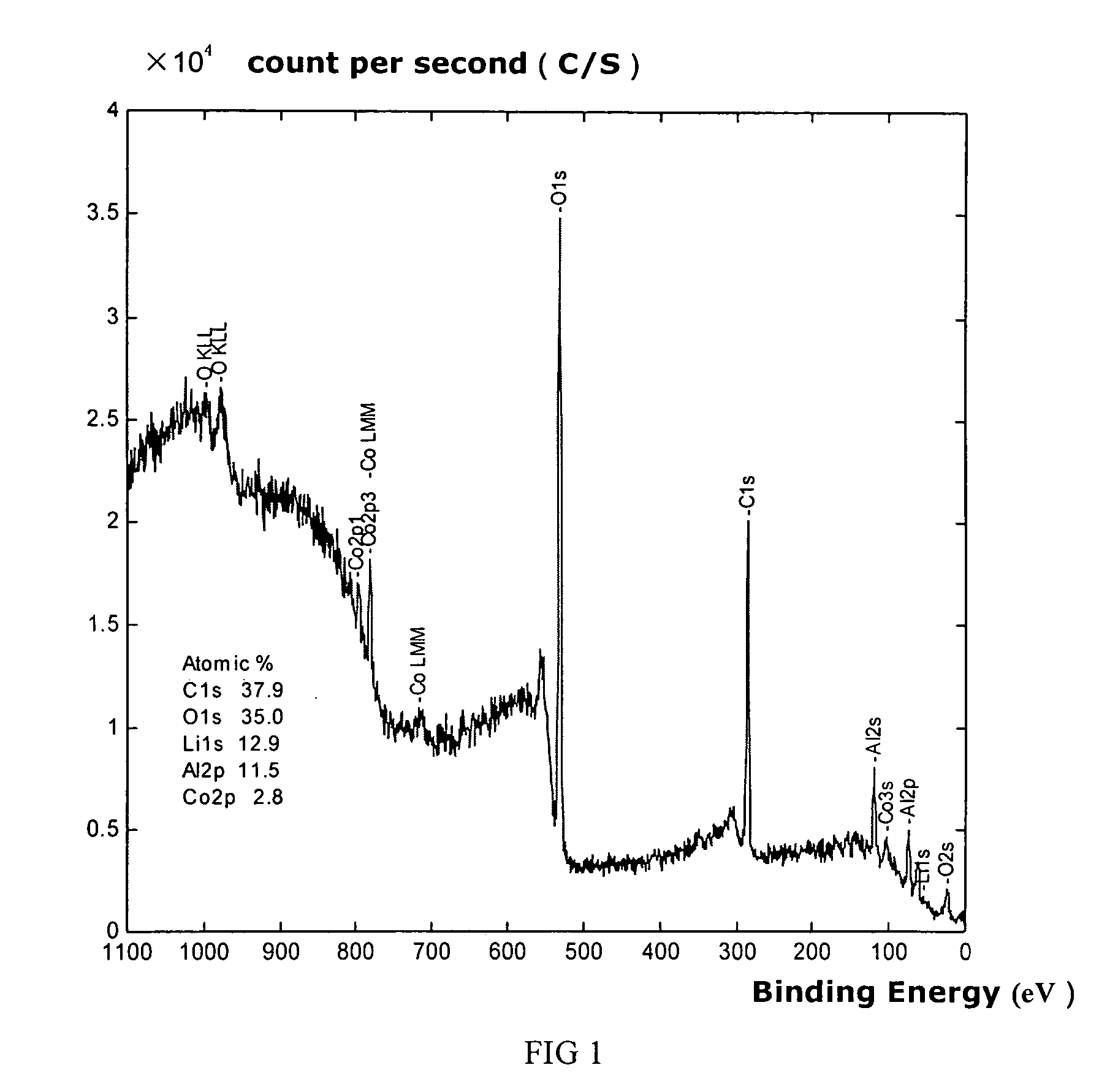

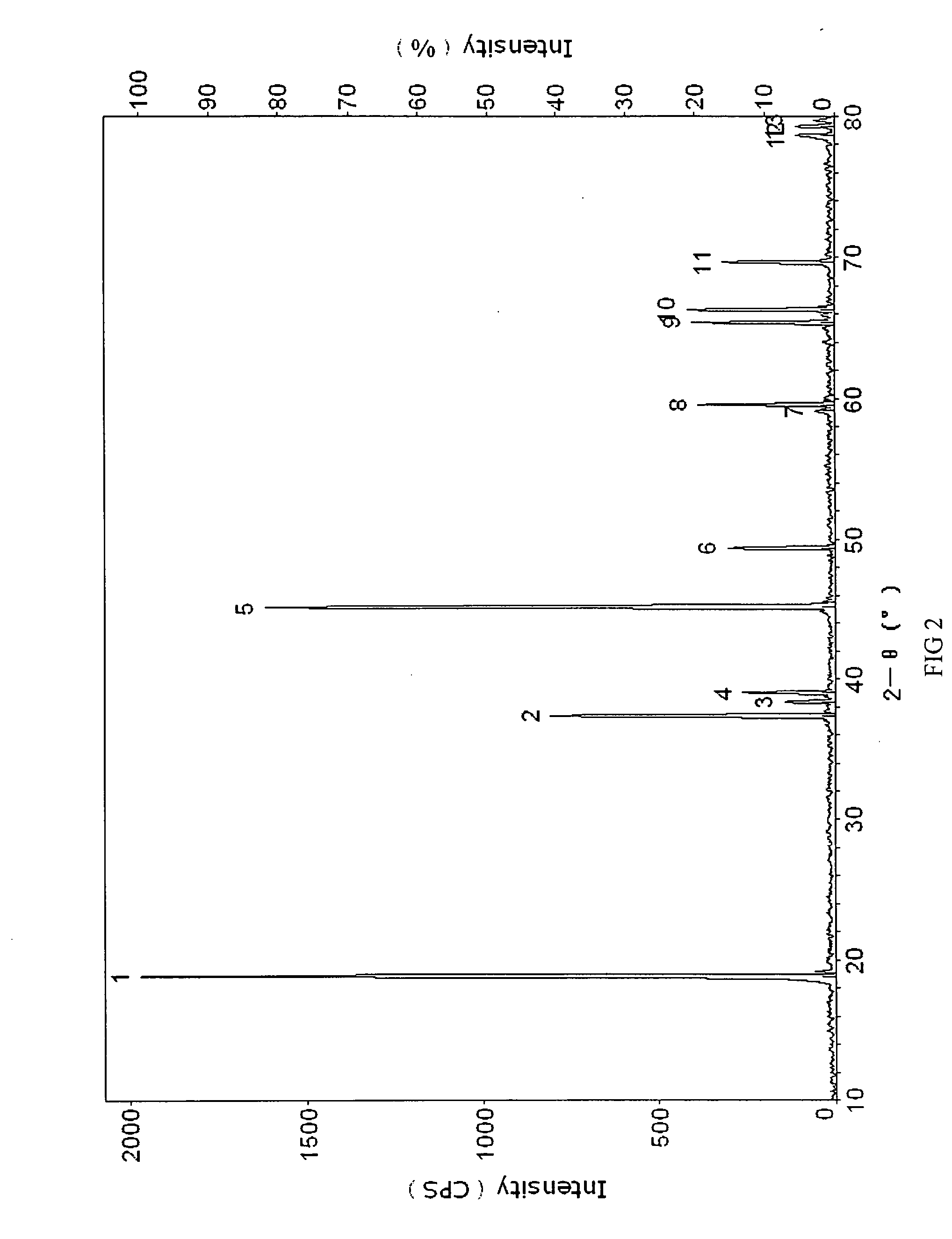

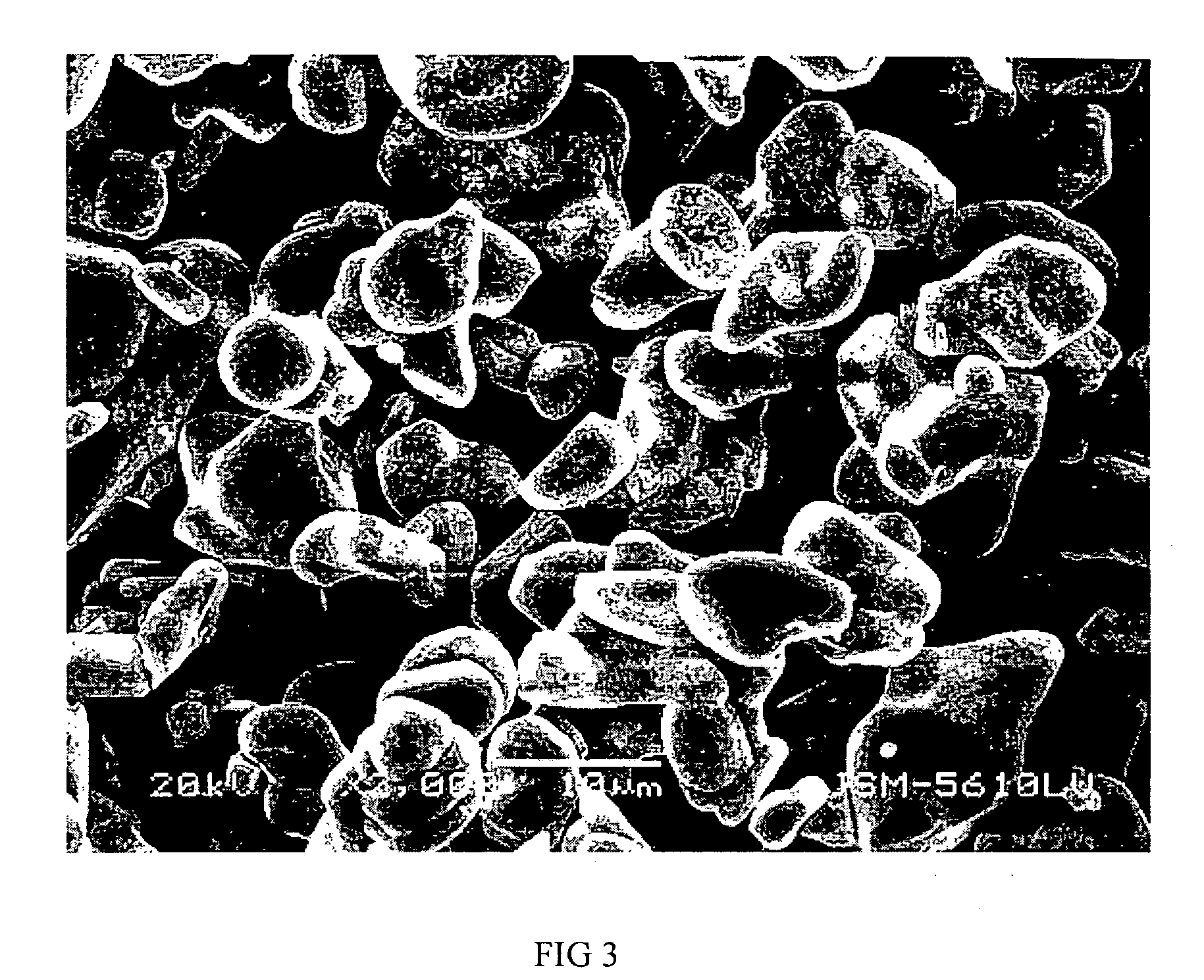

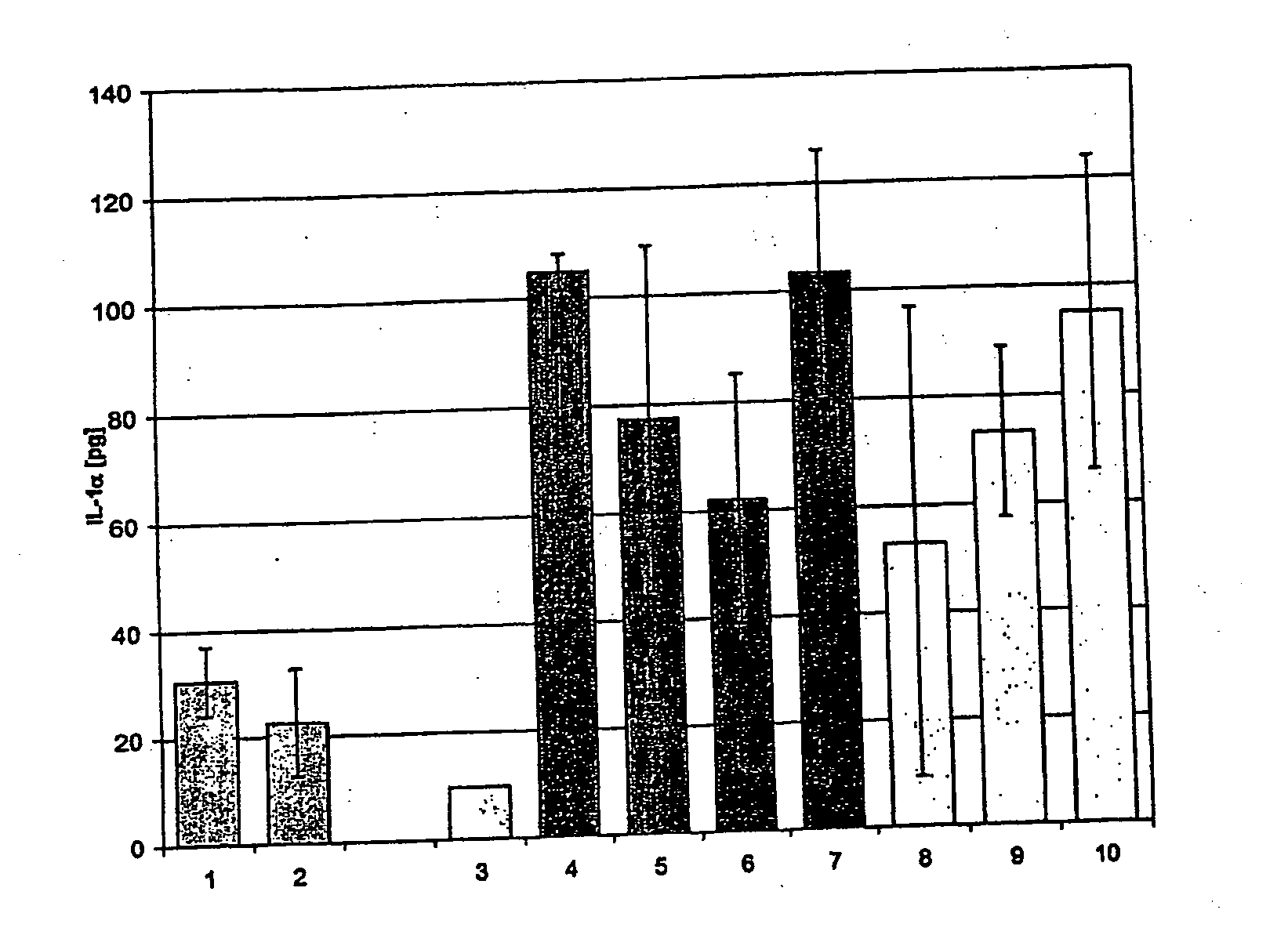

Materials for positive electrodes of lithium ion batteries and their methods of fabrication

InactiveUS20050130042A1Cycle wellEasy dischargeElectrode thermal treatmentSecondary cellsCeriumSolvent

This invention discloses materials for positive electrodes of secondary batteries and their methods of fabrication. Said materials comprise of granules of an active material for positive electrodes coated with an oxide layer. The active material is one or more of the following: oxides of lithium cobalt, oxides of lithium nickel cobalt, oxides of lithium nickel cobalt manganese, oxides of lithium manganese, LiCoO2, LiNi1-xCoxO2, LiNi1 / 3Co1 / 3Mn1 / 3O2, and LiMn2O4. The non-oxygen component in the oxide layer is one or more of the following: aluminum, magnesium, zinc, calcium, barium, strontium, lanthanum, cerium, vanadium, titanium, tin, silicon, boron, Al, Mg, Zn, Ca, Ba, Sr, La, Ce, V, Ti, Sn, Si, and B. Said non-oxygen component of the granules is between 0.01 wt. % to 10 wt. % of said granules of active material. The methods of fabrication for said materials includes the steps of mixing an additive and an active material for positive electrodes uniformly in water or solvent, evaporating said solvent or water, and heat treating the remaining mixture at 300° C. to 900° C. for between 1 hour to 20 hours. The additive is a compound of one or more of the following elements: aluminum, magnesium, zinc, calcium, barium, strontium, lanthanum, cerium, vanadium, titanium, tin, silicon, boron, Al, Mg, Zn, Ca, Ba, Sr, La, Ce, V, Ti, Sn, Si, and B where the element is between 0.01 wt. % to 10 wt. % of said active material. Using the materials of positive electrodes disclosed above or materials for positive electrodes fabricated in the methods disclosed above in batteries produces batteries with excellent cycling and high temperature properties.

Owner:BYD AMERICA CORP

Powder comprising silica-coated zinc oxide, organic polymer composition containing the powder and shaped article thereof

InactiveUS20060167138A1Help shapeSufficient UV shielding abilityPigmenting treatmentMaterial nanotechnologyMicroparticleSilicon dioxide

A powder comprising silica-coated zinc oxide fine particles in which the surface of each particle is coated with silica, wherein large particles of 5 μm or more account for 0.1 mass % or less. A powder comprising surface-hydrophobicized silica-coated zinc oxide fine particles in which the silica-coated zinc oxide fine particles whose surfaces have been coated with silica are further treated with a hydrophobicity-imparting agent, wherein large particles of 5 μm or more account for 0.1 mass % or less.

Owner:SHOWA DENKO KK

Surface-modified zinc oxide for the production of nanoparticulate dispersions

InactiveUS20050048010A1Laborious grinding process can be avoidedEasy to separateCosmetic preparationsBiocideLiquid mediumPolyethylene glycol

The present invention relates to a surface-modified nanoscale zinc oxide, where the surface modification involves coating with an oligo- or polyethylene glycol acid. This surface-modified zinc oxide is characterized in that it forms stable dispersions in a liquid medium. In addition, the present invention relates to a process for the production of surface-modified zinc oxide, and also to a process for the production of nanoscale zinc oxide dispersions.

Owner:HENKEL KGAA

Microbicidal composition

A microbicidal composition containing: (a) 1,2-benzisothiazolin-3-one; and (b) at least one microbicide selected from among benzalkonium chloride, benzethonium chloride, benzyl alcohol, caprylyl glycol, chlorphenesin, 2,2′-dithiobis(N-methylbenzamide), diazolidinyl urea, ethylenediamine tetraacetic acid, ethylparaben, imidazolidinyl urea, methylparaben, phenoxyethanol, linoleamidopropyl PG-dimonium chloride phosphate, cocamidopropyl PG-dimonium chloride phosphate, propylparaben, cis-1-(3-chloroallyl)-3,5,7-triaza-1-azoniaadamantane chloride, dehydroacetic acid or its salts, benzoic acid or its salts, sodium hydroxymethylglycinate and zinc pyrithione.

Owner:DDP SPECIALTY ELECTRONICS MATERIALS US 8 LLC

Light-emitting element and light-emitting device using the same

InactiveUS20050116633A1Luminous stabilityEfficient emissionsDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringCopper oxide

It is an object of the invention is to provide a light-emitting element in which failure of the light-emitting element due to separation can be controlled and stable luminescence can be obtained with high-efficiency and for a long stretch of time by controlling separation of layers constituting the light-emitting element. According to one aspect of a light-emitting element of the invention, the light-emitting element sandwiches a plurality of layers between a pair of electrodes, wherein at least one layer of the plurality of layers is a layer containing a substance selected from bismuth oxide, cobalt oxide, chromium oxide, copper oxide, nickel oxide, and titanium oxide, or at least one layer of layers different from a light-emitting layer among the plurality of layers is a mixed region of one substance selected from bismuth oxide, cobalt oxide, copper oxide, magnesium oxide, nickel oxide, zinc oxide, and titanium oxide and an organic compound.

Owner:SEMICON ENERGY LAB CO LTD

Assay

ActiveUS20060030050A1Improve bindingComponent separationDisease diagnosisBinding domainMicroparticle

Compositions and assay methods for and relating to the detection of glycated hemoglobin are provided. In particular, the presence and level of glycated hemoglobin can be detected in a blood sample. The compositions comprise microparticles which have zinc coating for use in the improved binding of proteins exhibiting a zinc binding domain, in particular glycated hemoglobin.

Owner:AXIS SHIELD DIAGNOSTICS

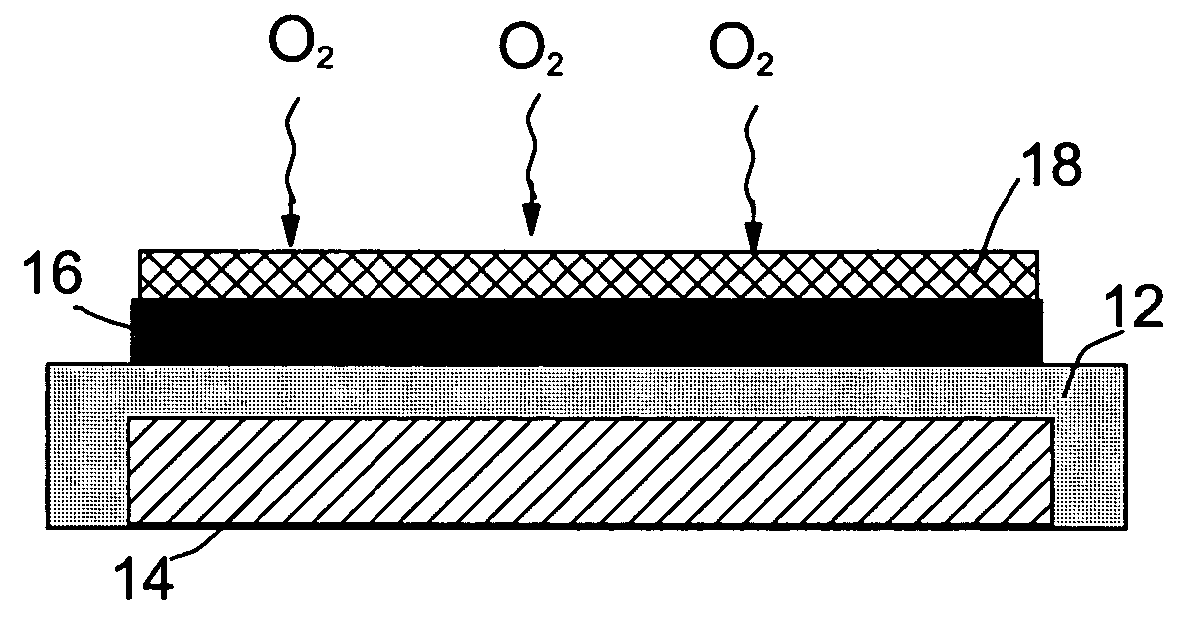

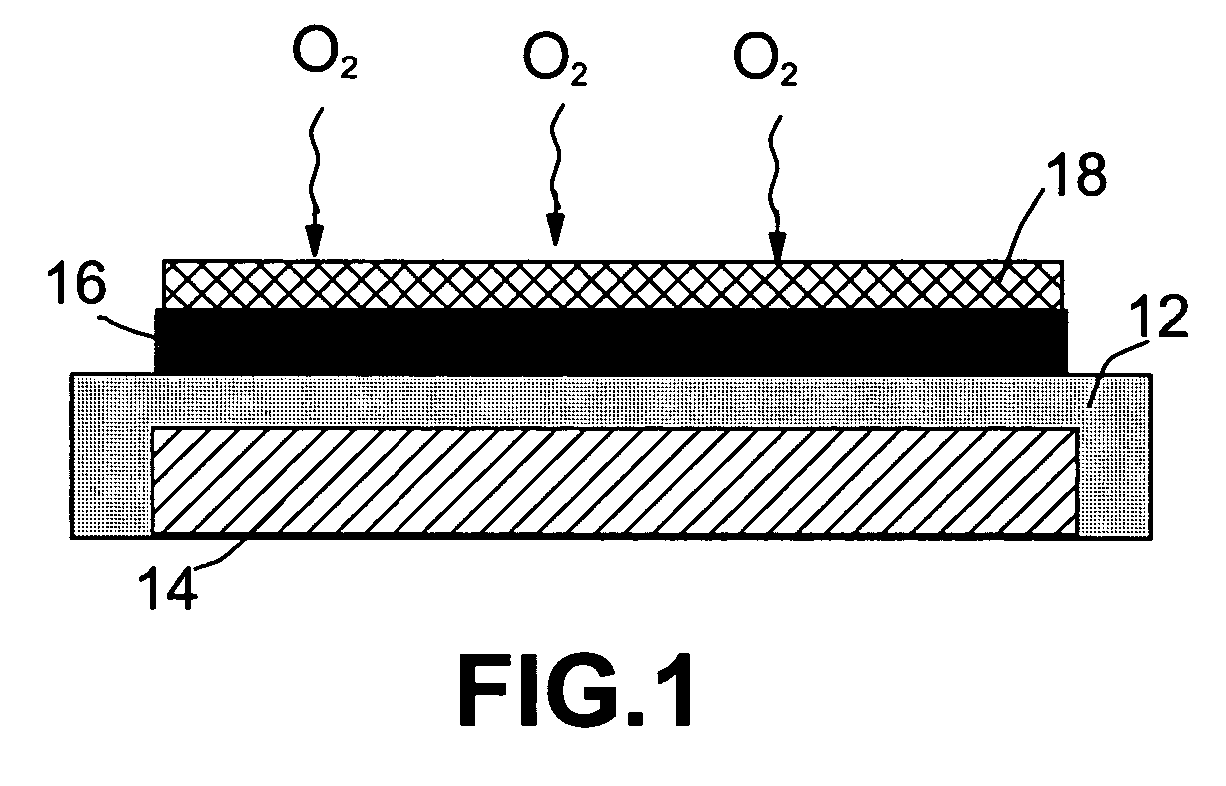

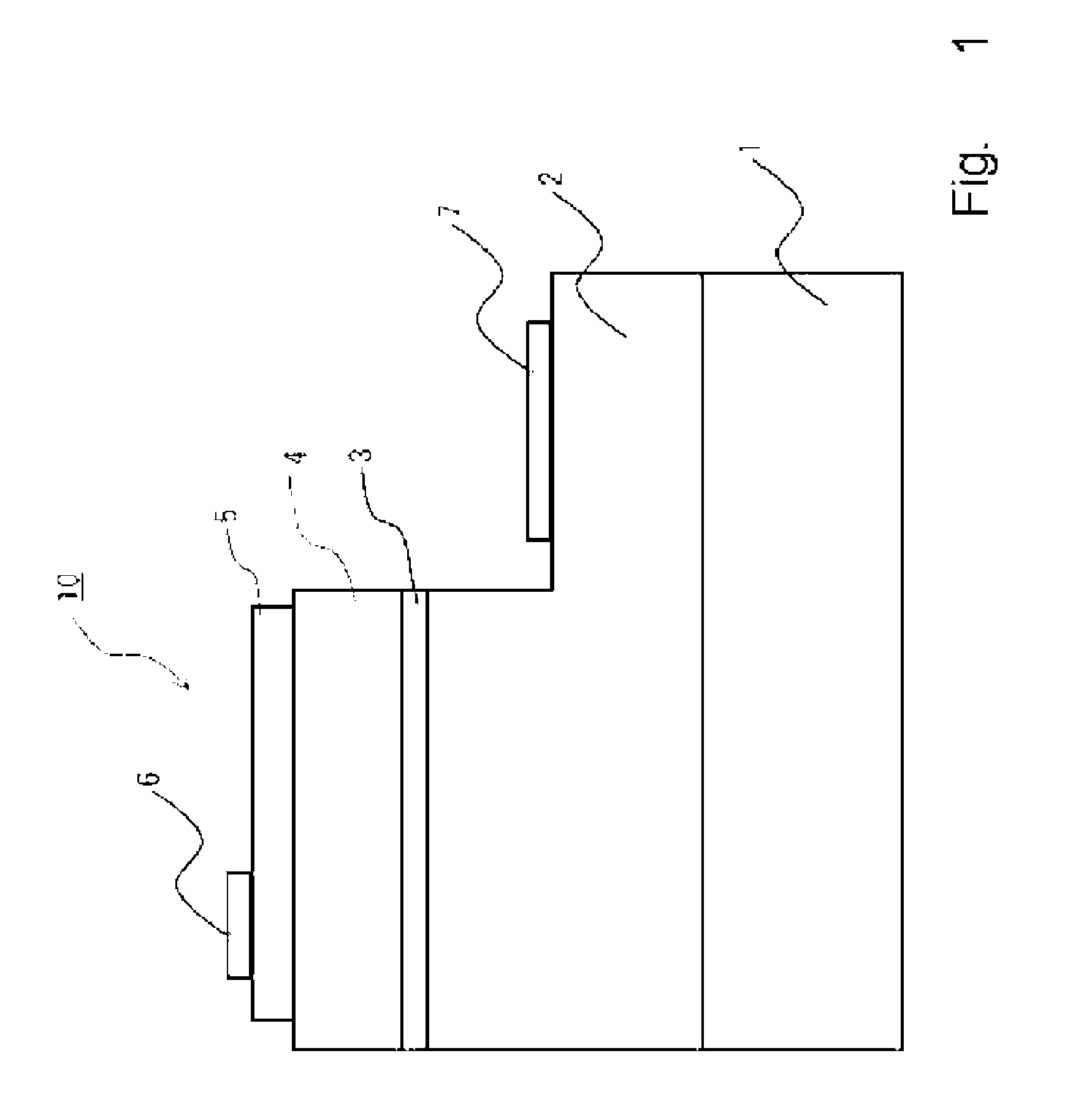

Semiconductor light emitting element

ActiveUS20050156189A1Prevent reduction in electrical power efficiencyReduce energy consumptionSolid-state devicesSemiconductor/solid-state device manufacturingIndiumZinc

A semiconductor light emitting element includes an conductive oxide film containing at least one element selected from the group consisting of zinc, indium, tin, and magnesium that is electrically connected to the semiconductor layer. The conductive oxide film includes a plurality of voids in the vicinity of the interface with the semiconductor layer.

Owner:NICHIA CORP

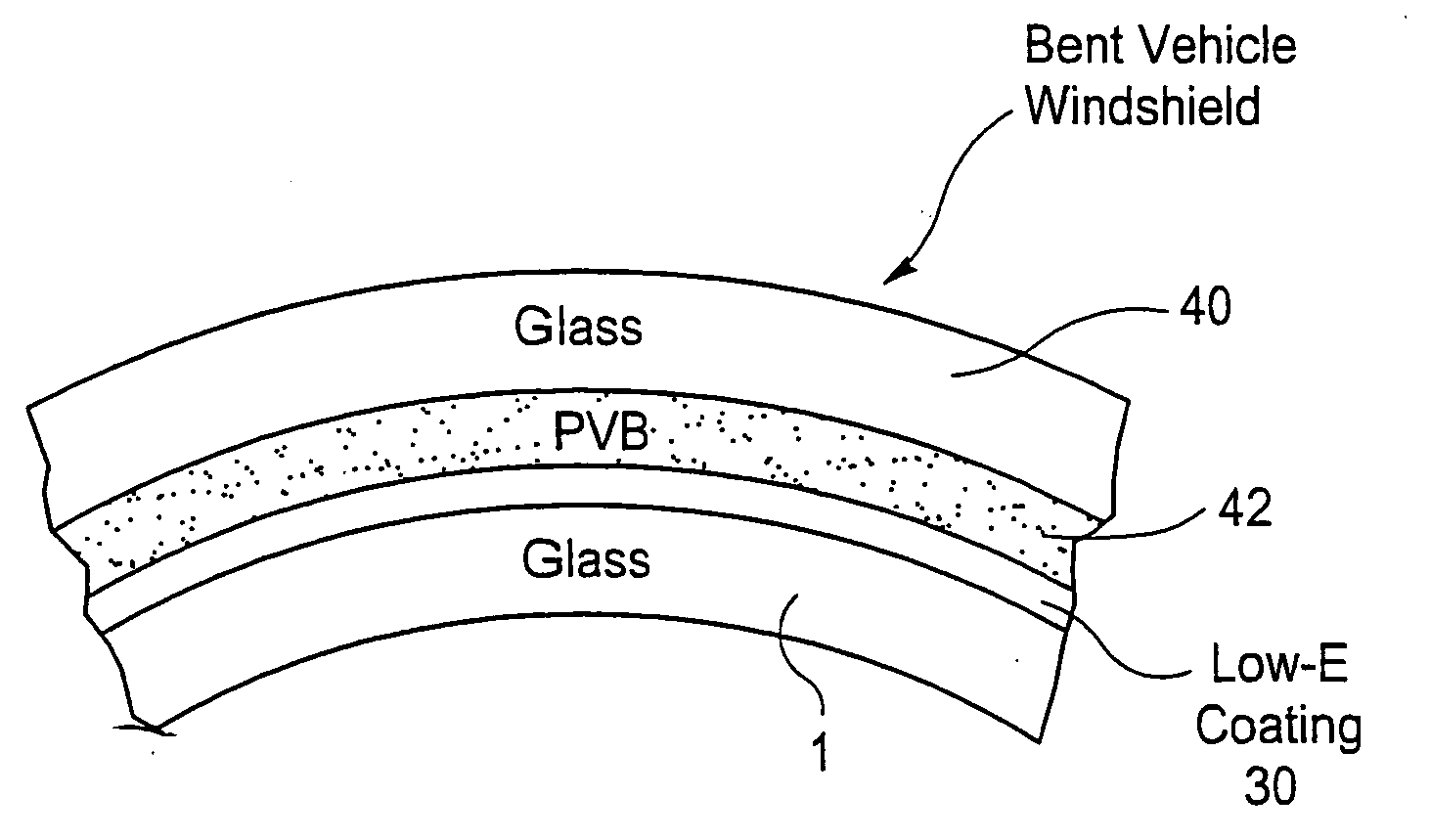

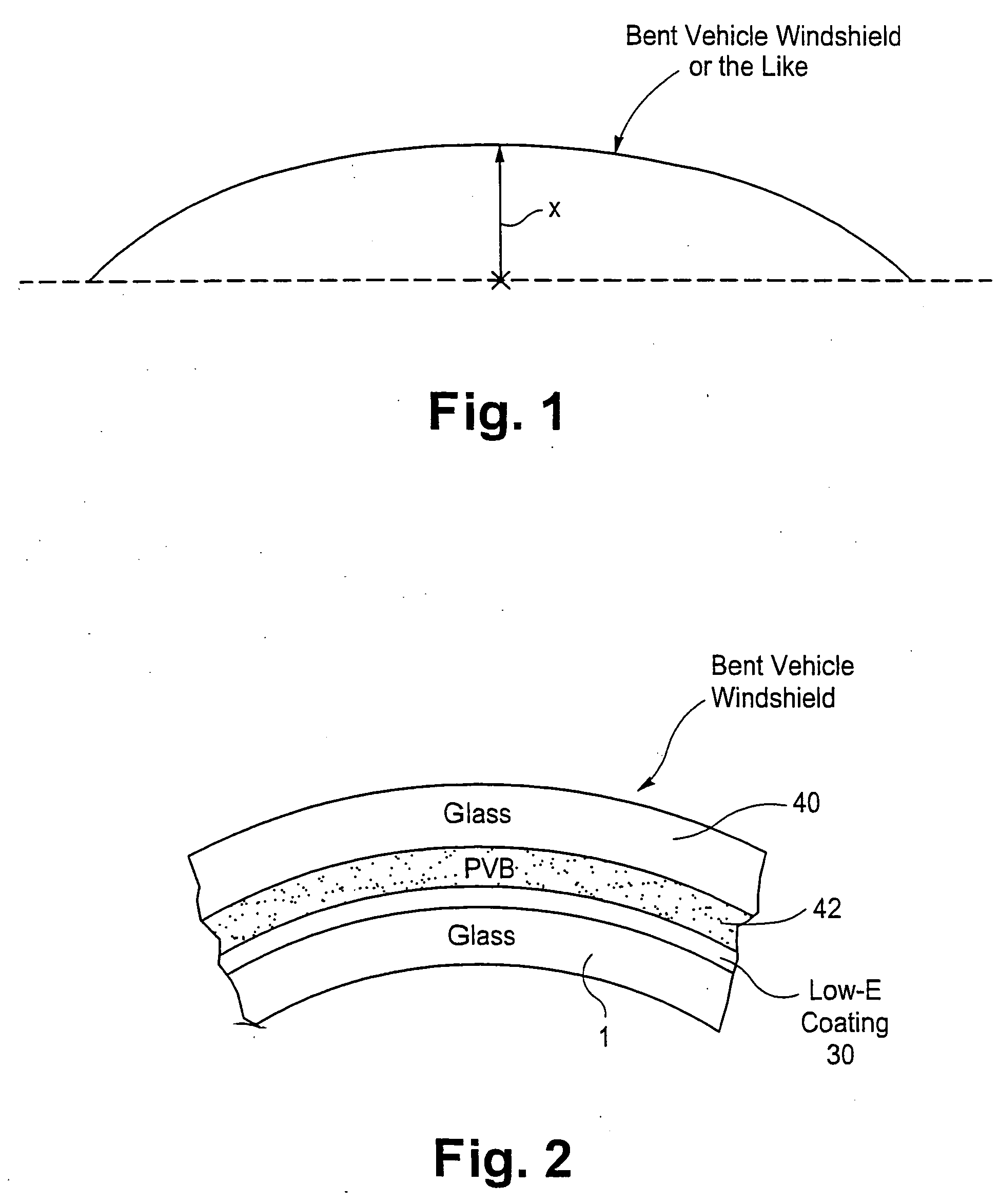

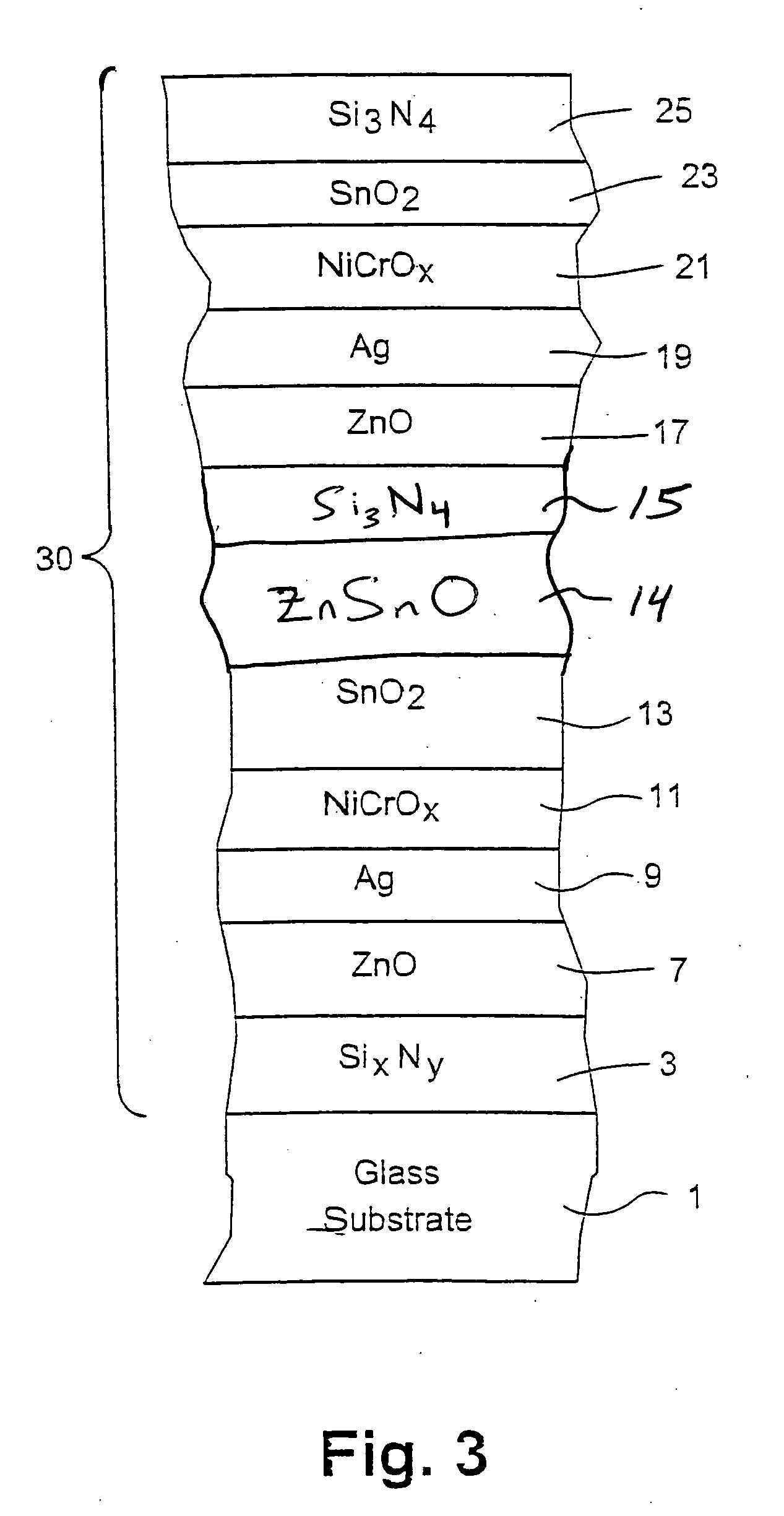

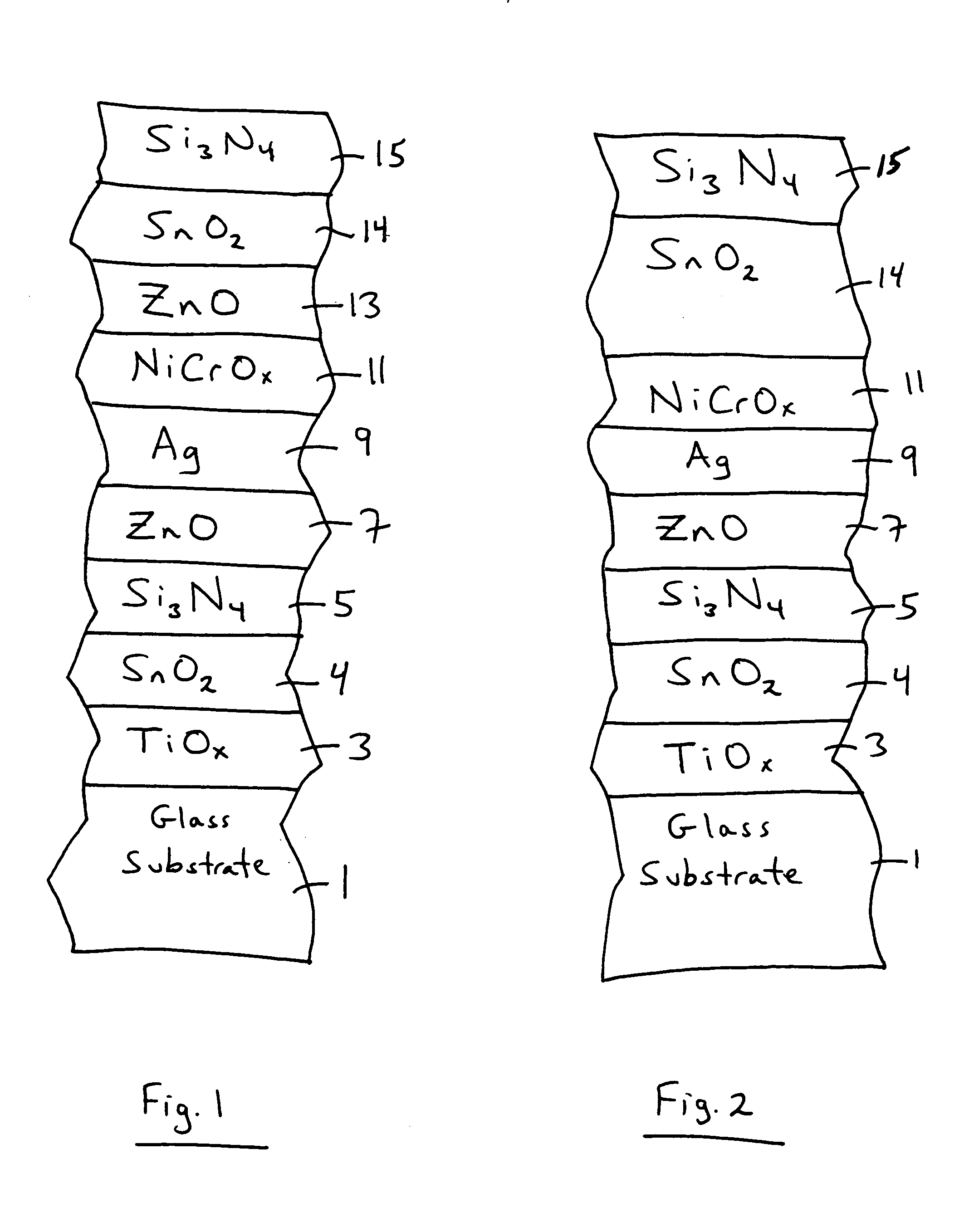

Coated article with low-e coating having zinc stannate based layer between IR reflecting layers for reduced mottling and corresponding method

ActiveUS20100295330A1Improve mechanical durabilityReduction in mottling damageWindowsWindscreensReflective layerStannate

A coated article is provided which may be heat treated (e.g., thermally tempered) and / or heat bent in certain example instances. In certain example embodiments, a zinc stannate based layer is provided between a tin oxide based layer and a silicon nitride based layer, and this has been found to significantly reduce undesirable mottling damage upon heat treatment / bending. This results in significantly improved bendability of the coated article in applications such as vehicle windshields and the like.

Owner:GUARDIAN EURO S A R L +1

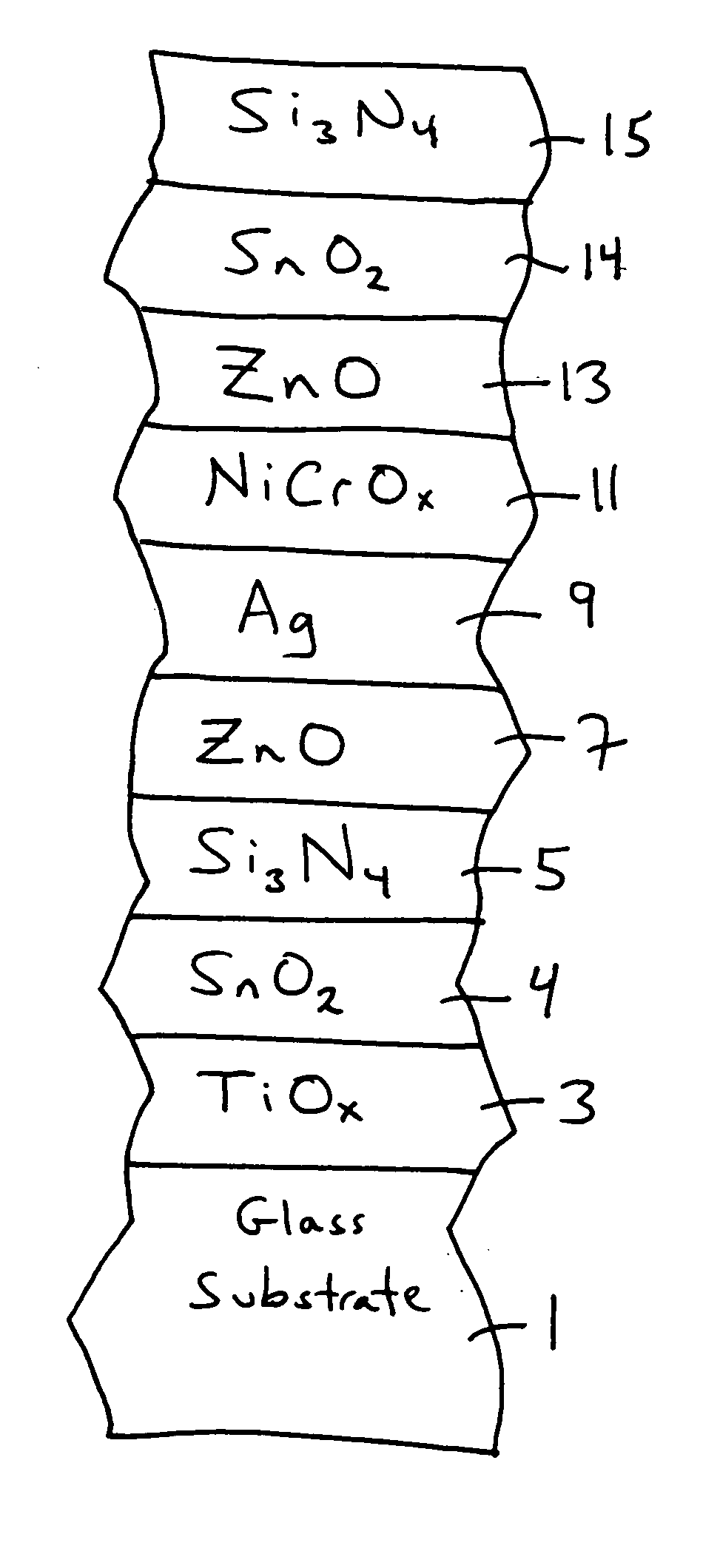

Coated article with tin oxide, silicon nitride and/or zinc oxide under IR reflecting layer and corresponding method

ActiveUS20050042460A1Improve thermal stabilityReduce sheet resistanceDoors/windowsGlass/slag layered productsElectrical resistance and conductanceLow emissivity

A coated article is provided that may be heat treated in certain example embodiments. A coating of the coated article includes a tin oxide inclusive layer, a silicon nitride inclusive layer and / or a zinc oxide inclusive layer located under an infrared (IR) reflecting layer of a material such as silver. It has been found that this may result in improved thermal stability upon heat treatment, higher visible transmission, desirable coloration, lower sheet resistance (Rs), and / or lower emissivity in certain example embodiments of this invention. In certain embodiments, a zinc oxide inclusive layer may be provided above a contact layer over the IR reflecting layer, again for improving thermal stability, coloration, sheet resistance and / or visible transmission.

Owner:GUARDIAN EURO S A R L +1

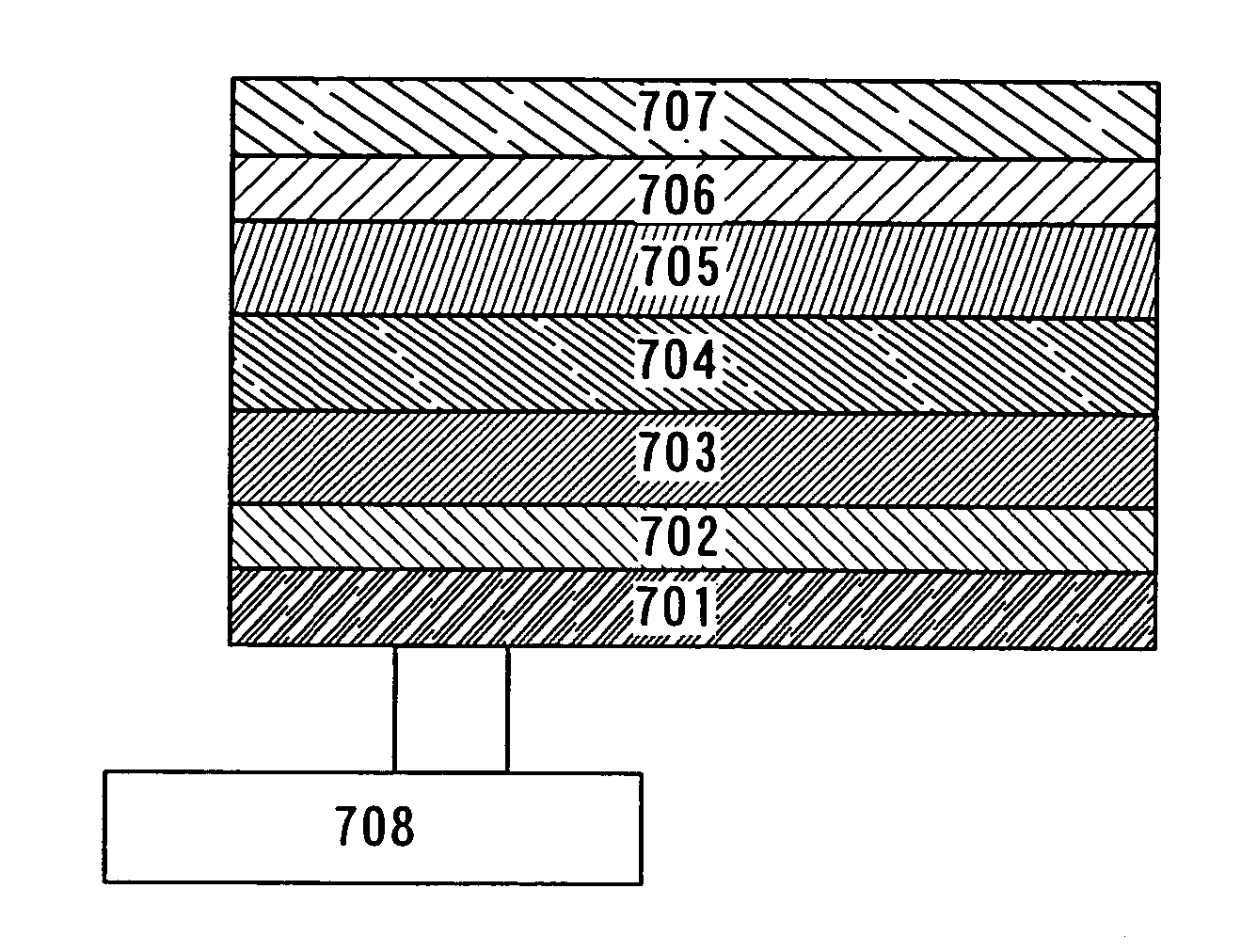

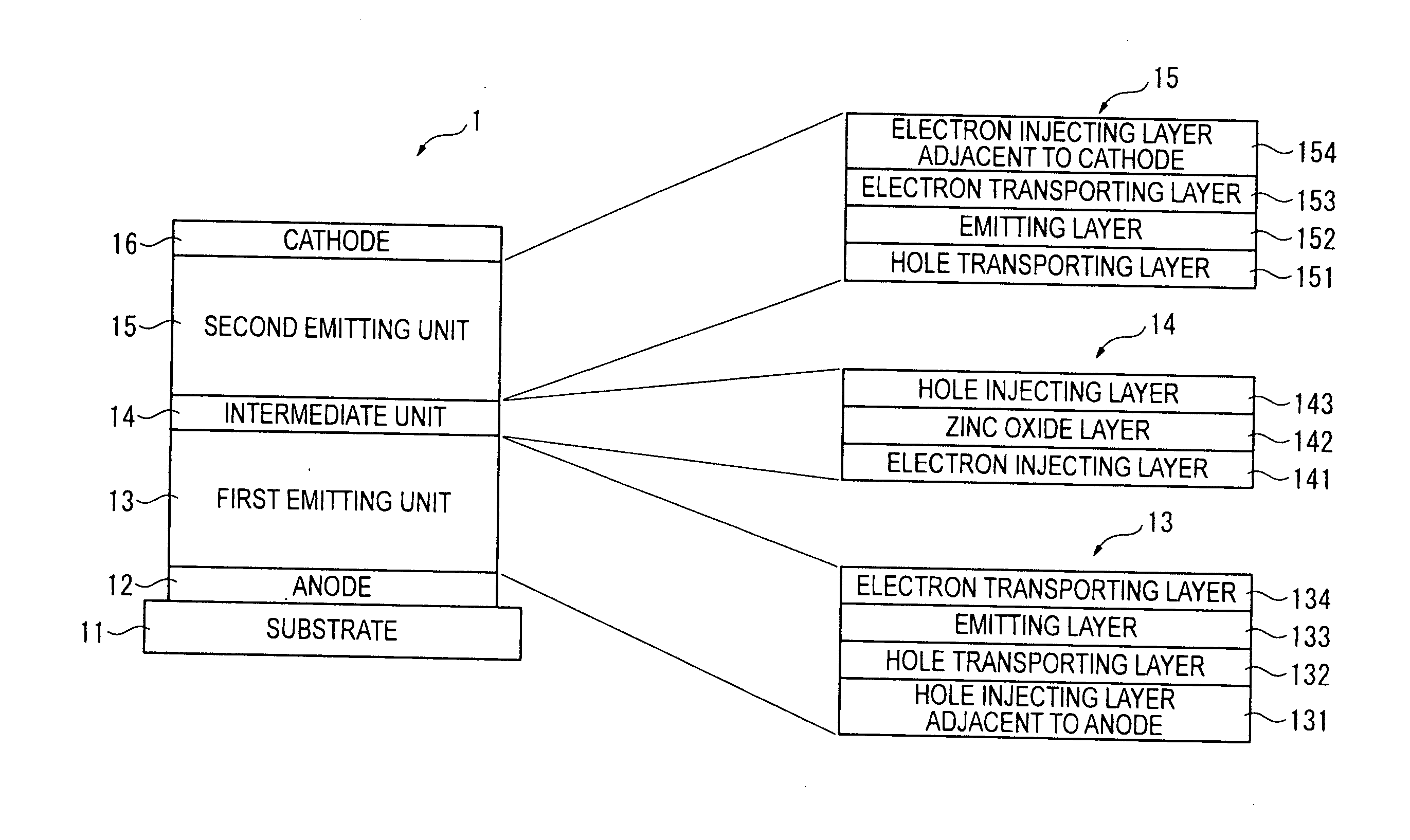

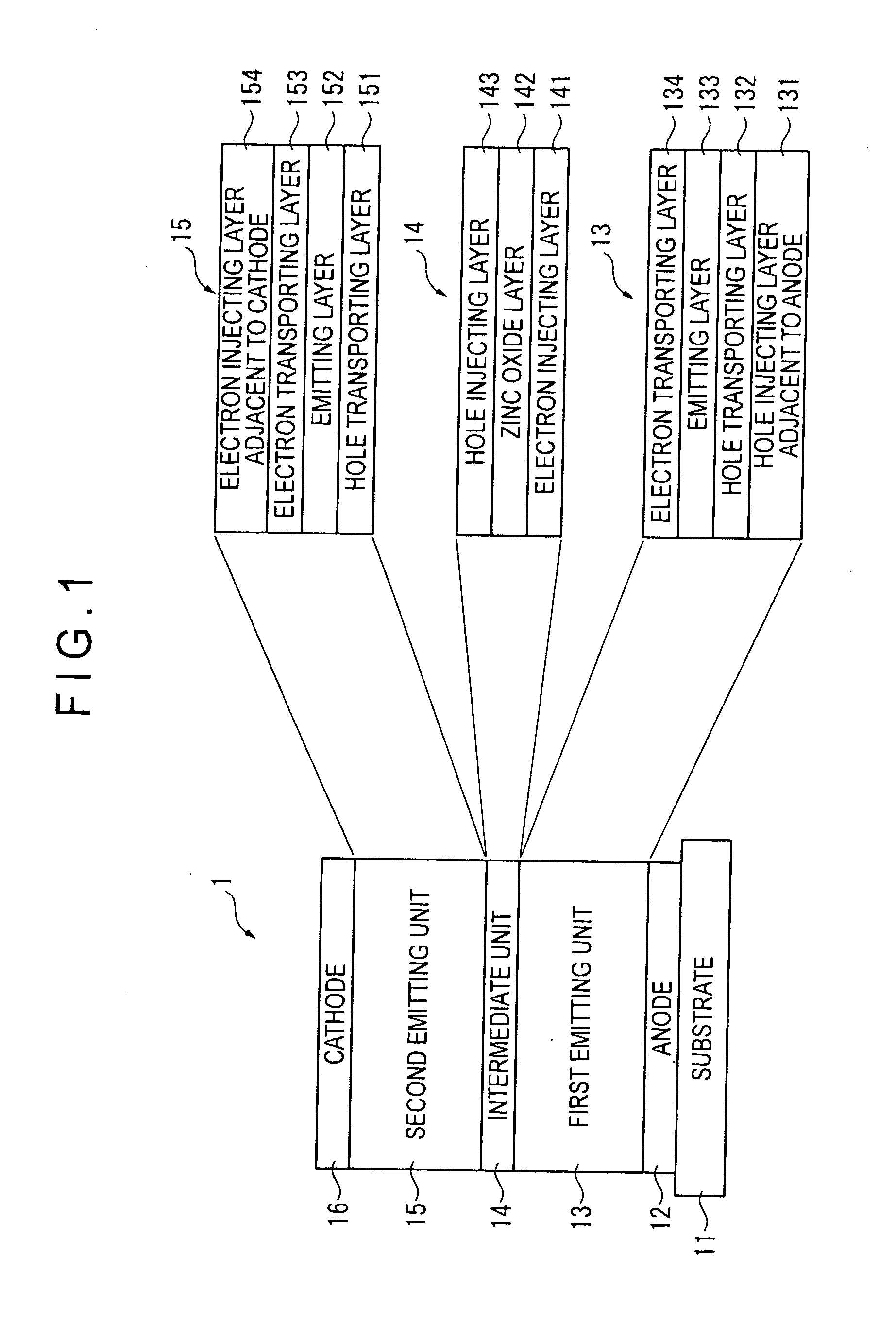

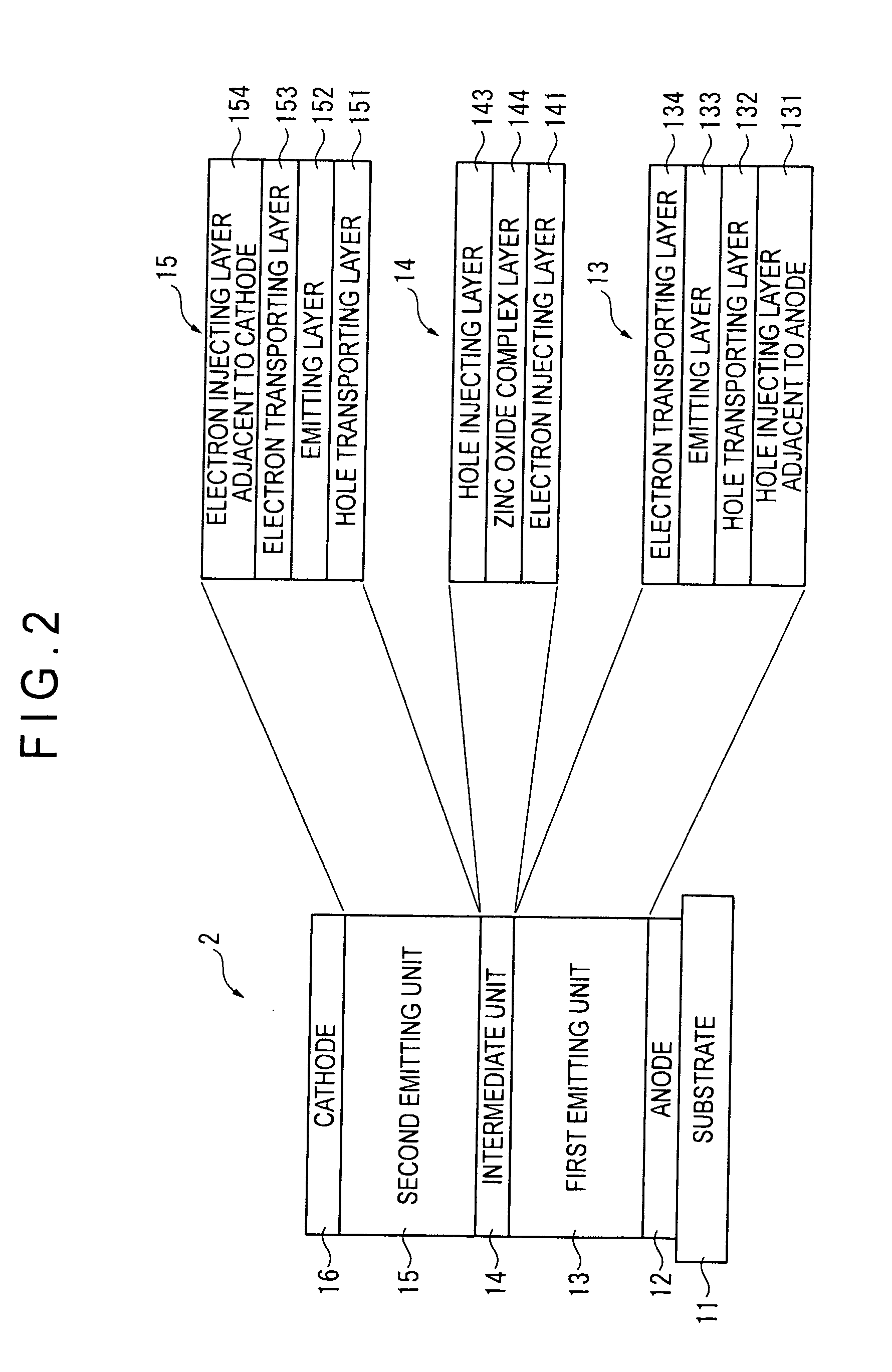

Organic electroluminescence device and method for producing organic electroluminescence device

ActiveUS20120012820A1Reduce reflectivityReduce the differenceSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerOrganic electroluminescence

An organic electroluminescence device includes: an anode; a cathode opposed to the anode; and a plurality of emitting units including at least a first emitting unit and a second emitting unit. The plurality of emitting units each includes: an emitting layer; and an intermediate unit between the first emitting unit and the second emitting unit. The intermediate unit includes an electron injecting layer, a zinc oxide layer and a hole injecting layer in this sequence from the anode. The electron injecting layer contains an electron donating material and is adjacent to the first emitting unit. The hole injecting layer contains an organic electron accepting material and is adjacent to the second emitting unit.

Owner:IDEMITSU KOSAN CO LTD

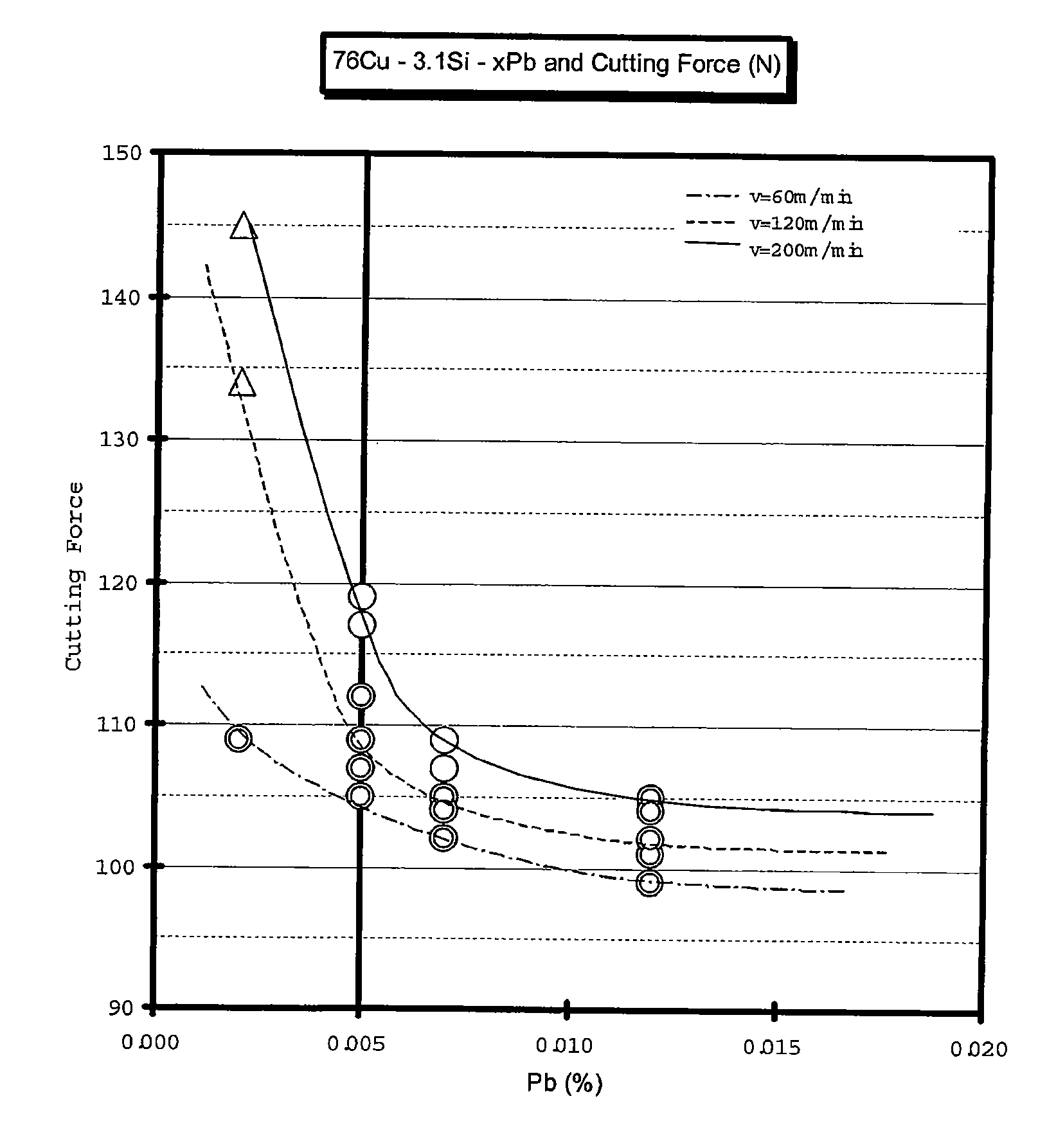

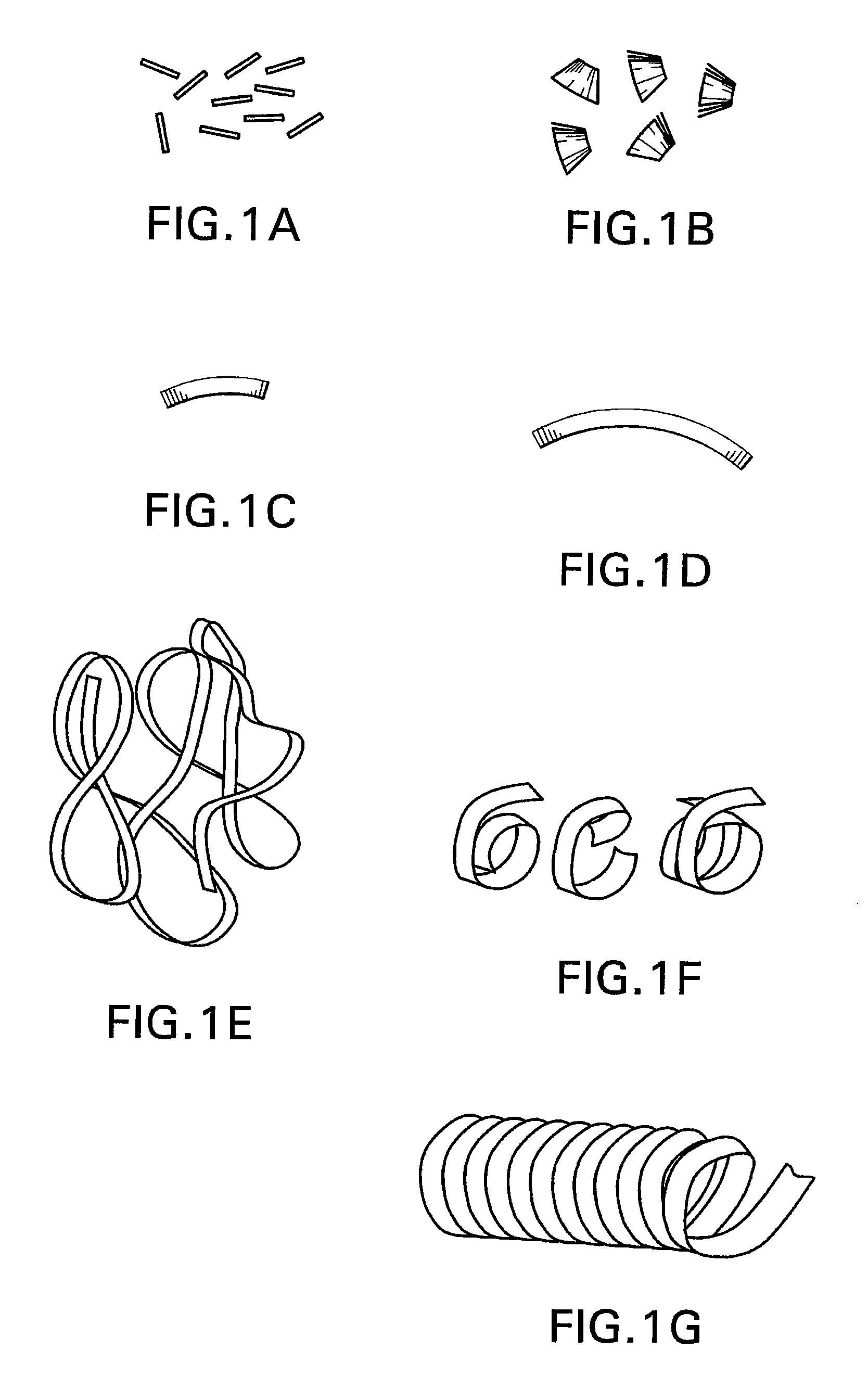

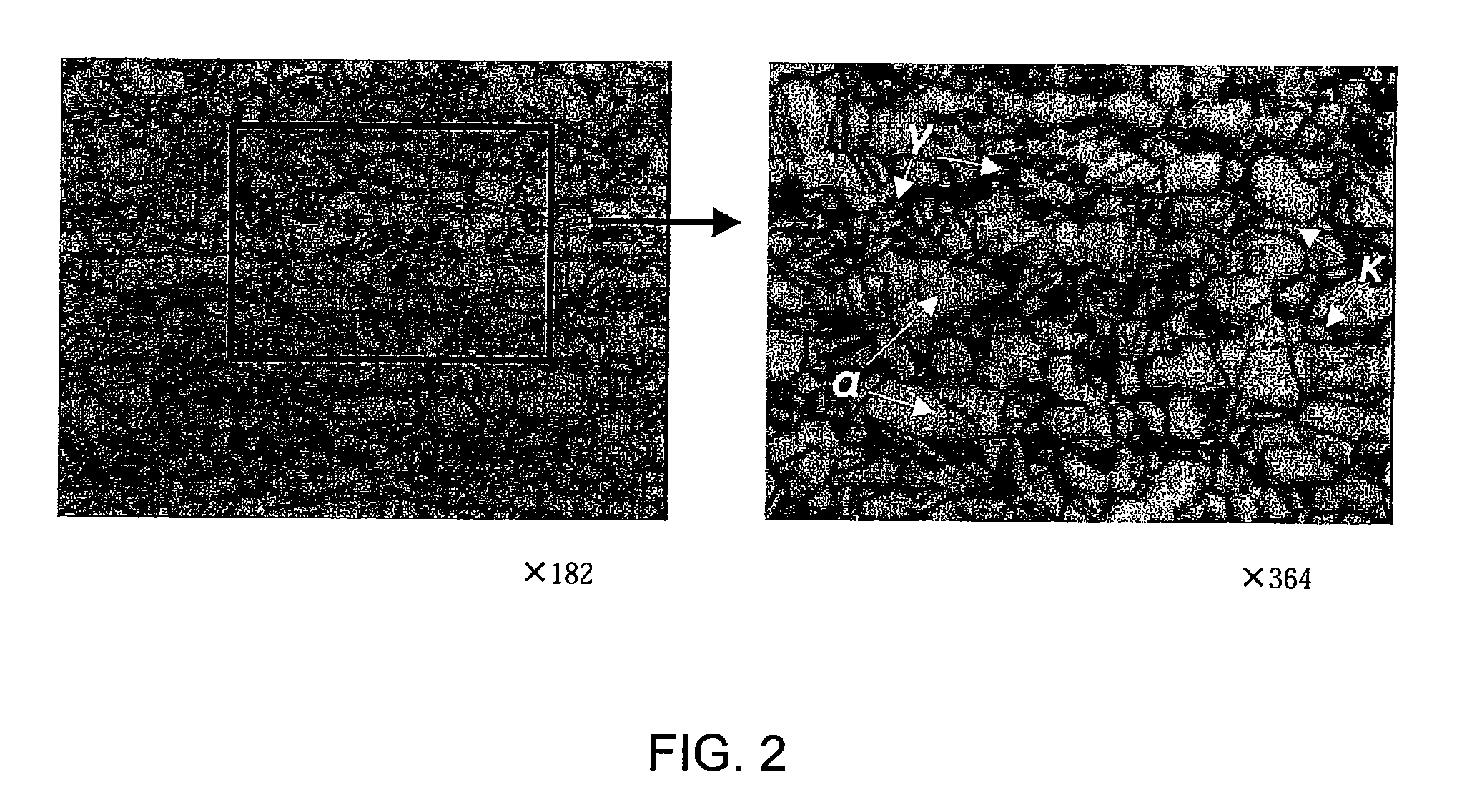

Free-cutting copper alloy containing very low lead

The free-cutting copper alloy according to the present invention contains a greatly reduced amount of lead in comparison with conventional free-cutting copper alloys, but provides industrially satisfactory machinability. The free-cutting alloys comprise 71.5 to 78.5 percent, by weight, of copper, 2.0 to 4.5 percent, by weight, of silicon, 0.005 percent up to but less than 0.02, by weight, of lead, and the remaining percent, by weight, of zinc.

Owner:SANBO SHINDO KOGYO CO LTD

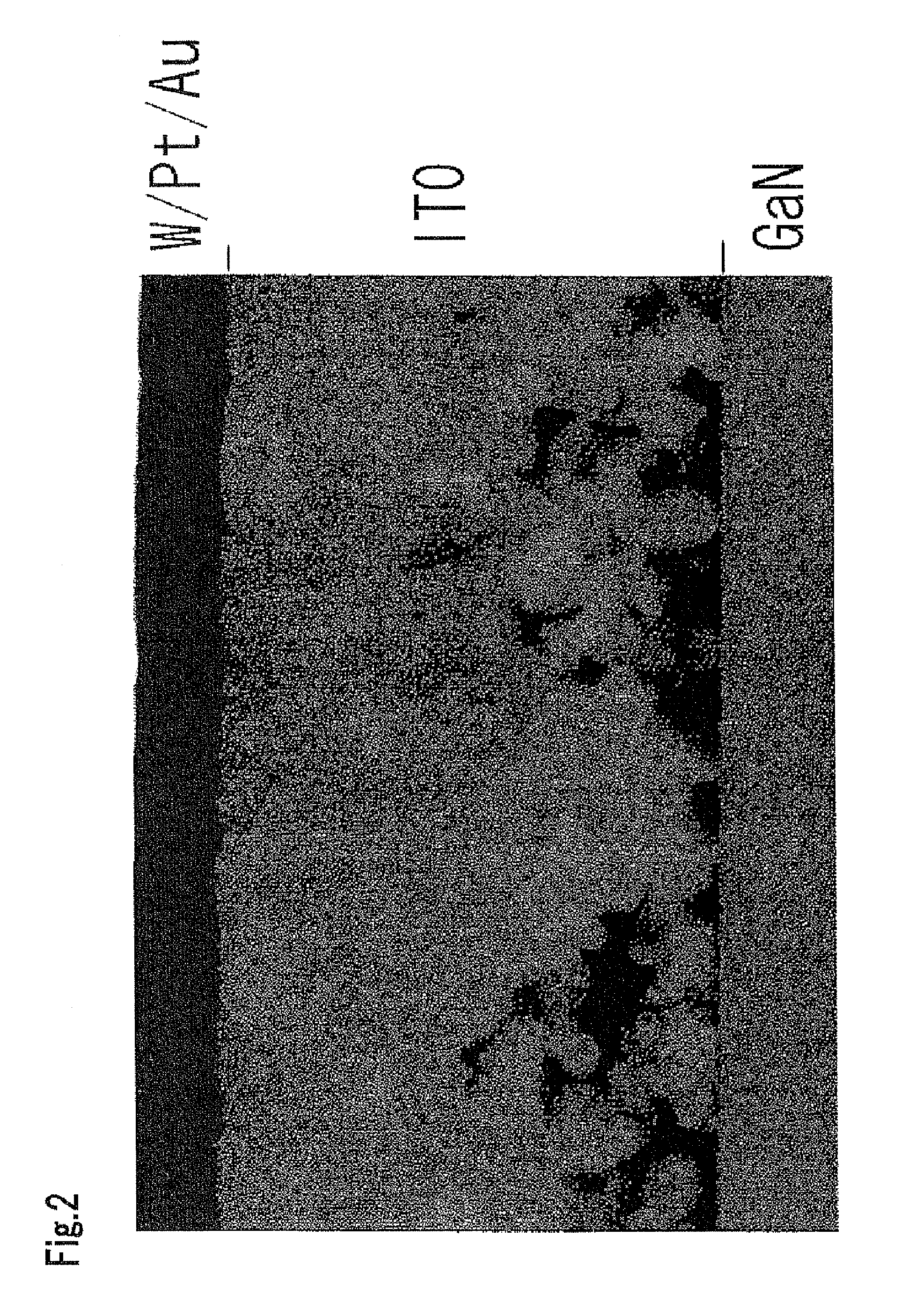

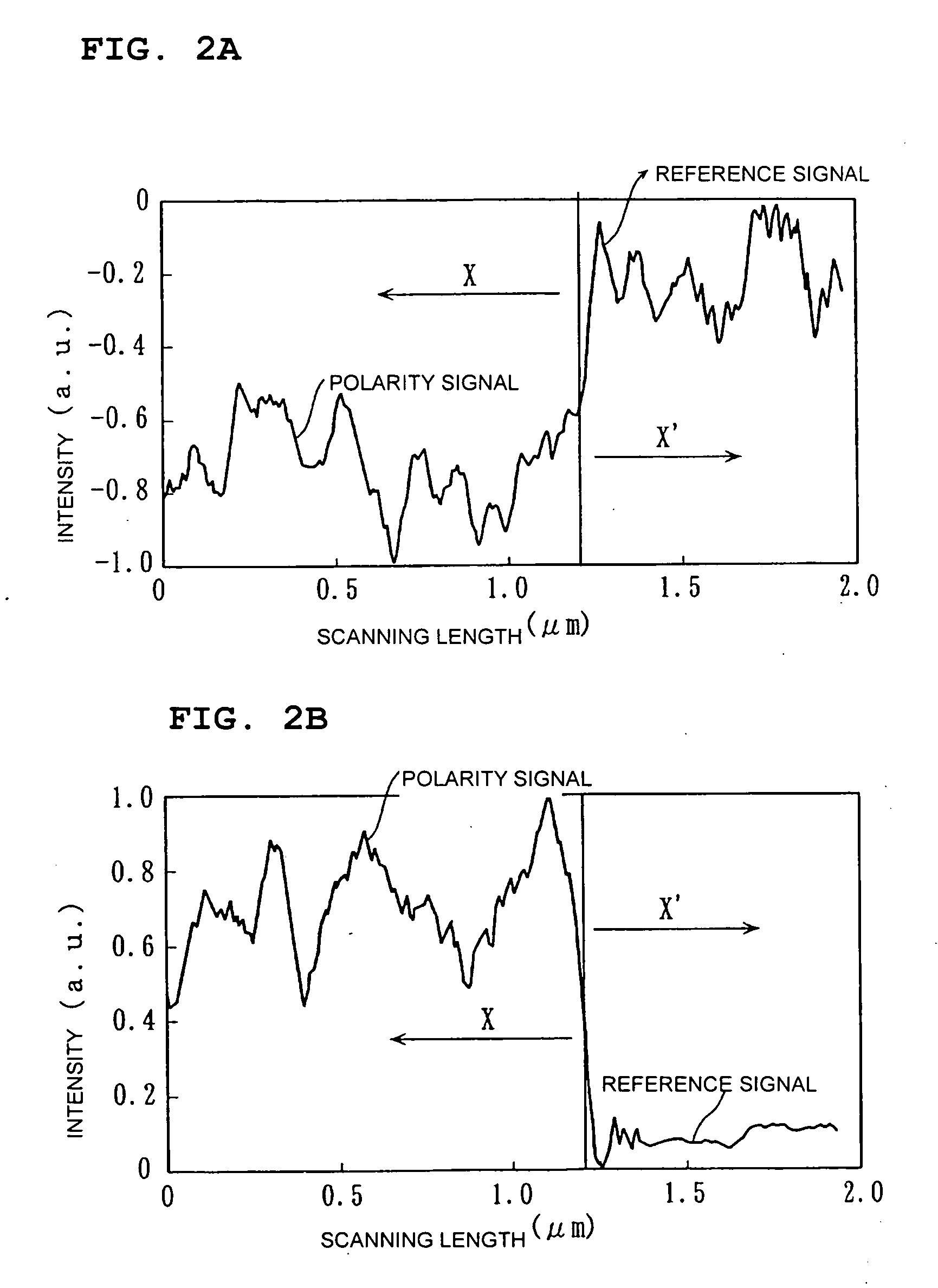

Semiconductor device and method for manufacturing semiconductor device

ActiveUS20060054888A1Improve surface smoothnessHigh crystallinityTransistorLaser detailsDevice materialEvaporation

A semiconductor device having excellent crystallinity and excellent electric characteristics includes a ZnO thin film having excellent surface smoothness. ZnO-based thin films (an n-type contact layer, an n-type clad layer, an active layer, a p-type clad layer, and a p-type contact layer primarily including ZnO are formed sequentially by an ECR sputtering method or other suitable method on a zinc-polar surface of a ZnO substrates. A transparent electrode and a p-side electrode are formed by an evaporation method or other suitable method on a surface of the p-type contact layer, and an n-side electrode is formed on an oxygen-polar surface of the ZnO substrate.

Owner:MURATA MFG CO LTD

Semiconductor device

Owner:HEWLETT PACKARD DEV CO LP

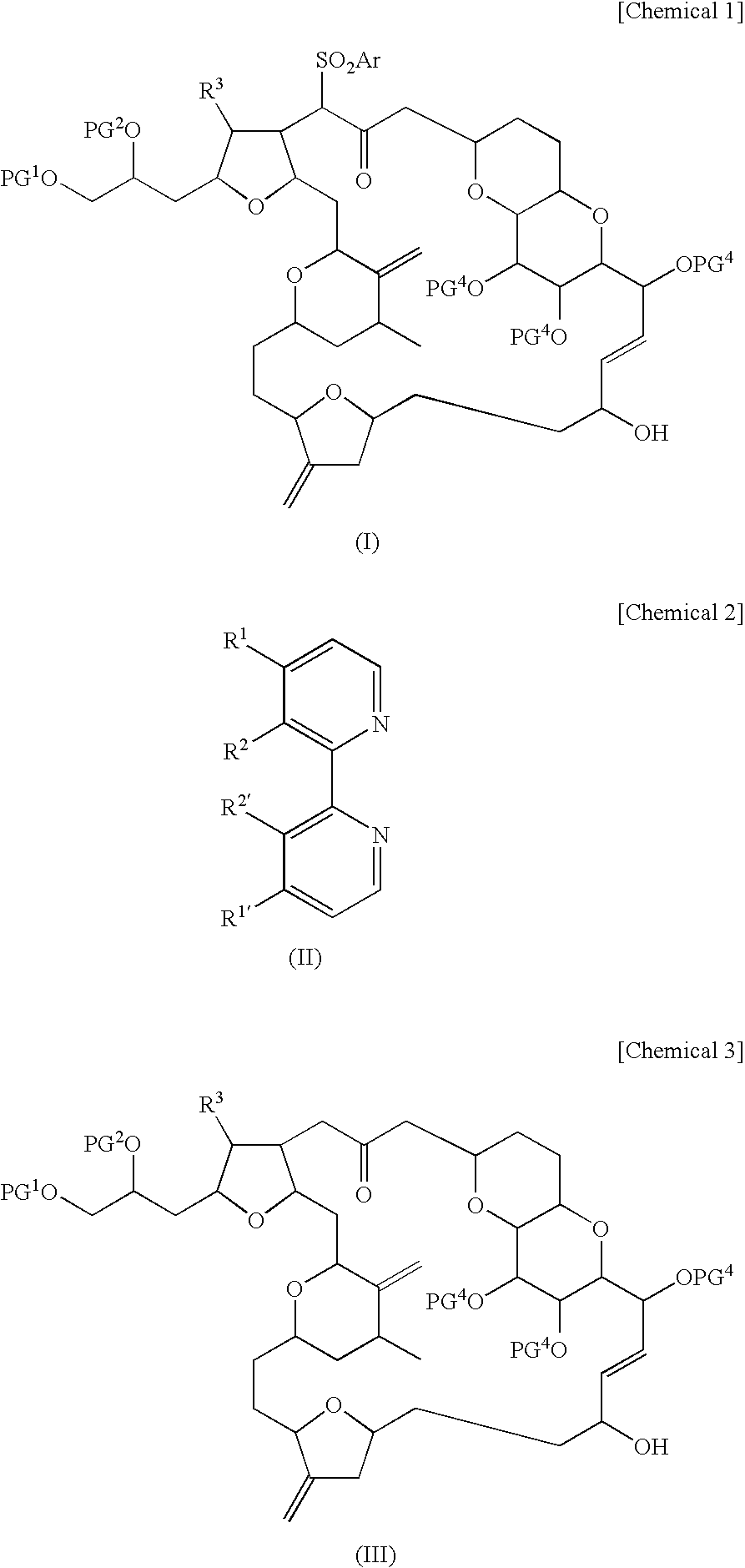

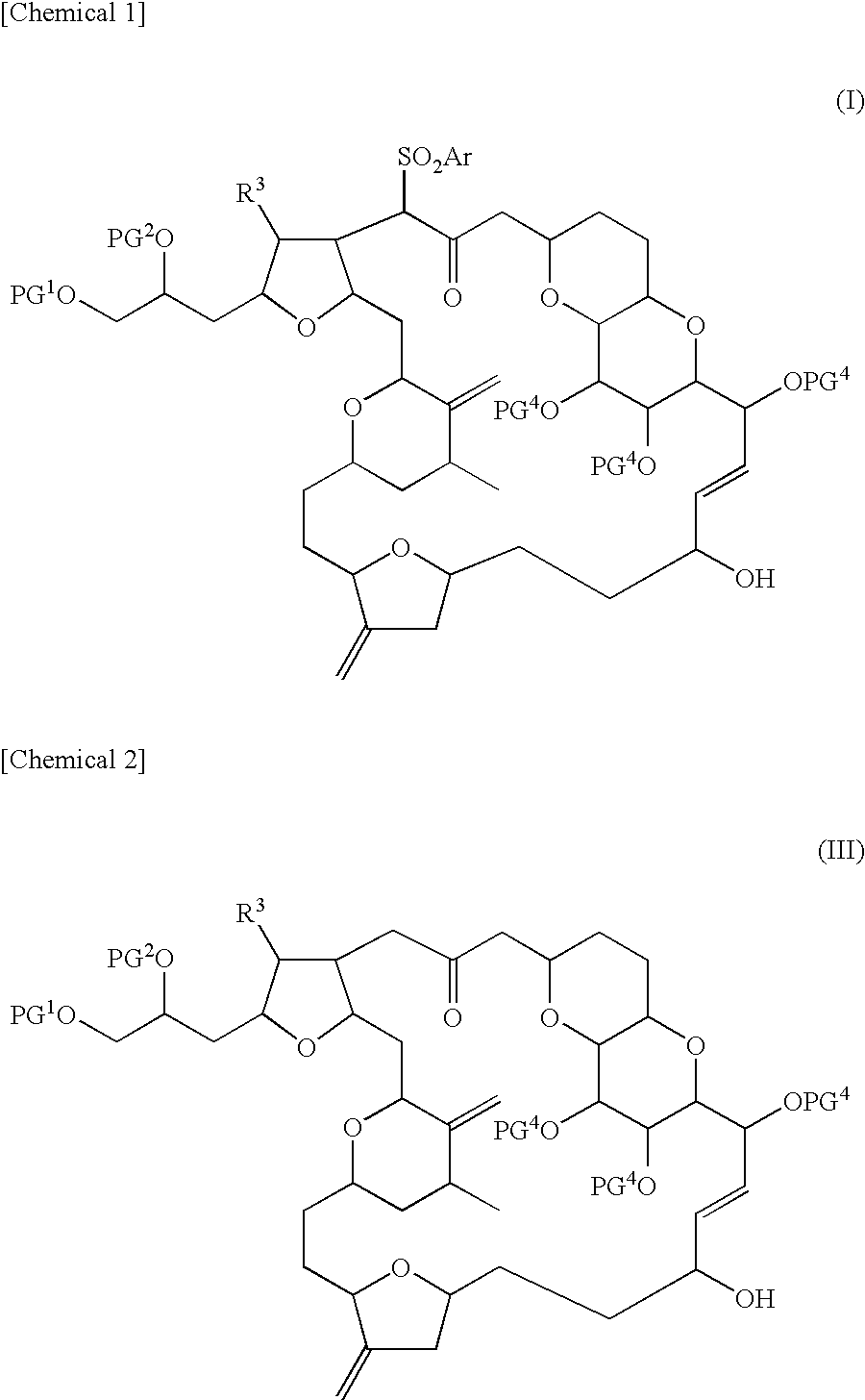

Novel intermediate for halichondrin b analog synthesis and novel desulfonylation reaction used for the intermediate

InactiveUS20090203771A1Readily availableHigh yieldBiocideOrganic active ingredientsChromium CompoundsManganese

The present invention provides a novel method for producing a compound represented by formula (III) shown below, which comprises treating a compound represented by formula (I) shown below with a trivalent chromium compound and at least one kind of metal selected from the group consisting of manganese and zinc in a solvent in the presence of a ligand represented by formula (II) shown below, and the present invention further provides the novel compound represented by formula (I).

Owner:EISIA R&D MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com