Low alloy die steel

A die steel and low alloy technology, which is applied in the manufacture of precision and complex moulds and low alloy cold work die materials, can solve problems such as reducing material toughness, and achieve the effect of improving performance, preventing brittleness and improving performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

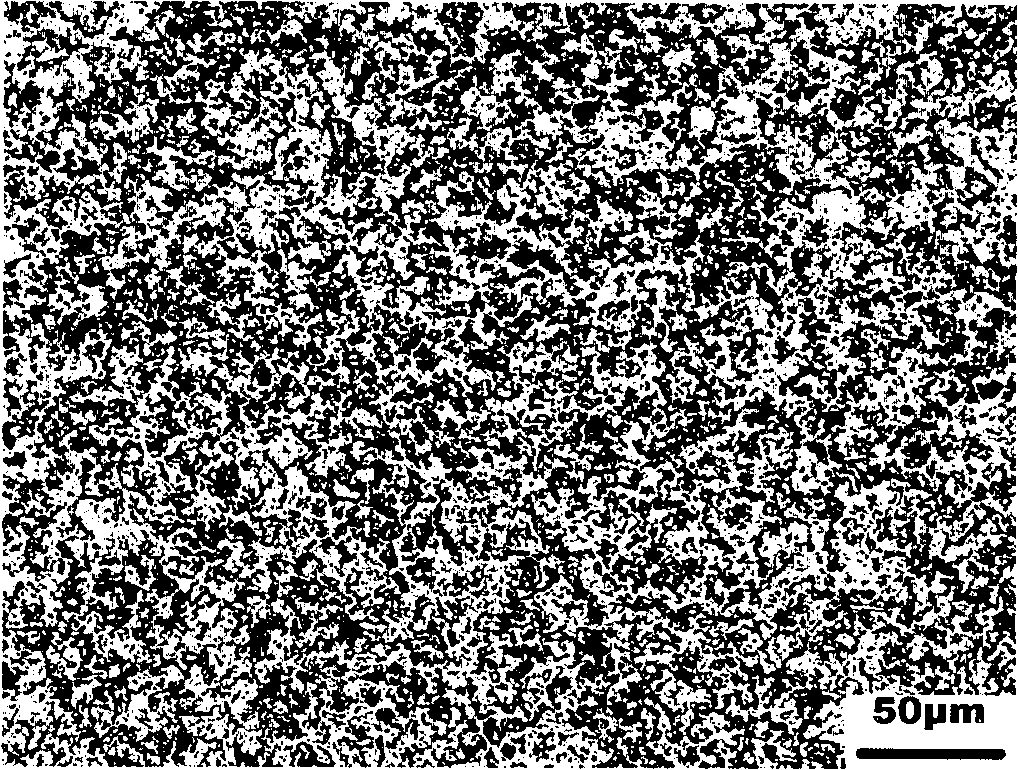

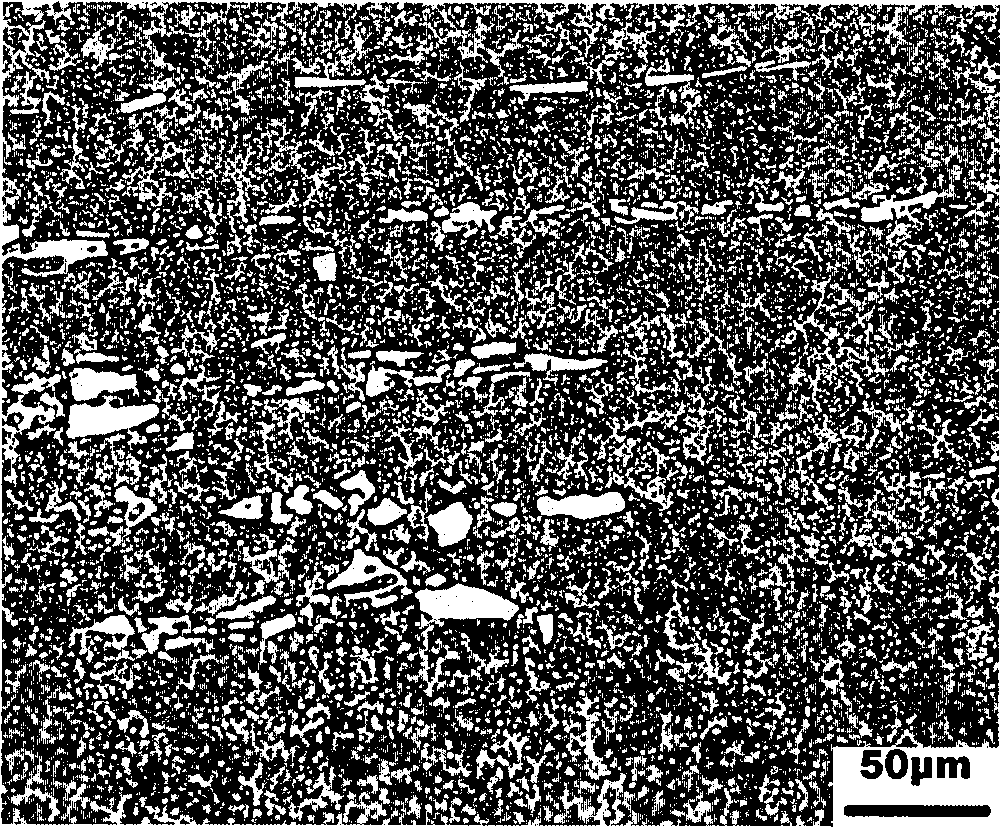

Image

Examples

Embodiment 1

[0044] In this example, the composition and weight percentage of the cold work die steel are as follows:

[0045] C: 0.69%, Si: 0.72%, Mn: 0.89%, Cr: 2.33%, Mo: 0.25%, V: 0.25%, Ni: 0.37%, P: 0.016%, S: 0.011%, and the balance is Fe.

[0046] In the present embodiment, the process and steps of cold working die steel are as follows:

[0047] The steel ingot cast after smelting in an induction furnace is placed in the electroslag remelting device as a consumable electrode for electroslag remelting, and the liquid metal falls through the slag layer of the slag pool to the water-cooled crystallizer below, and then re-melted Solidify into 2.0 tons of steel ingot; heat the above steel ingot, the temperature of the steel ingot into the furnace is 750°C, the temperature of the steel ingot is 110°C, and the steel ingot is heated to 1230°C for 4 hours and then forged; the initial forging temperature: 1100°C, the final The forging temperature is 870°C.

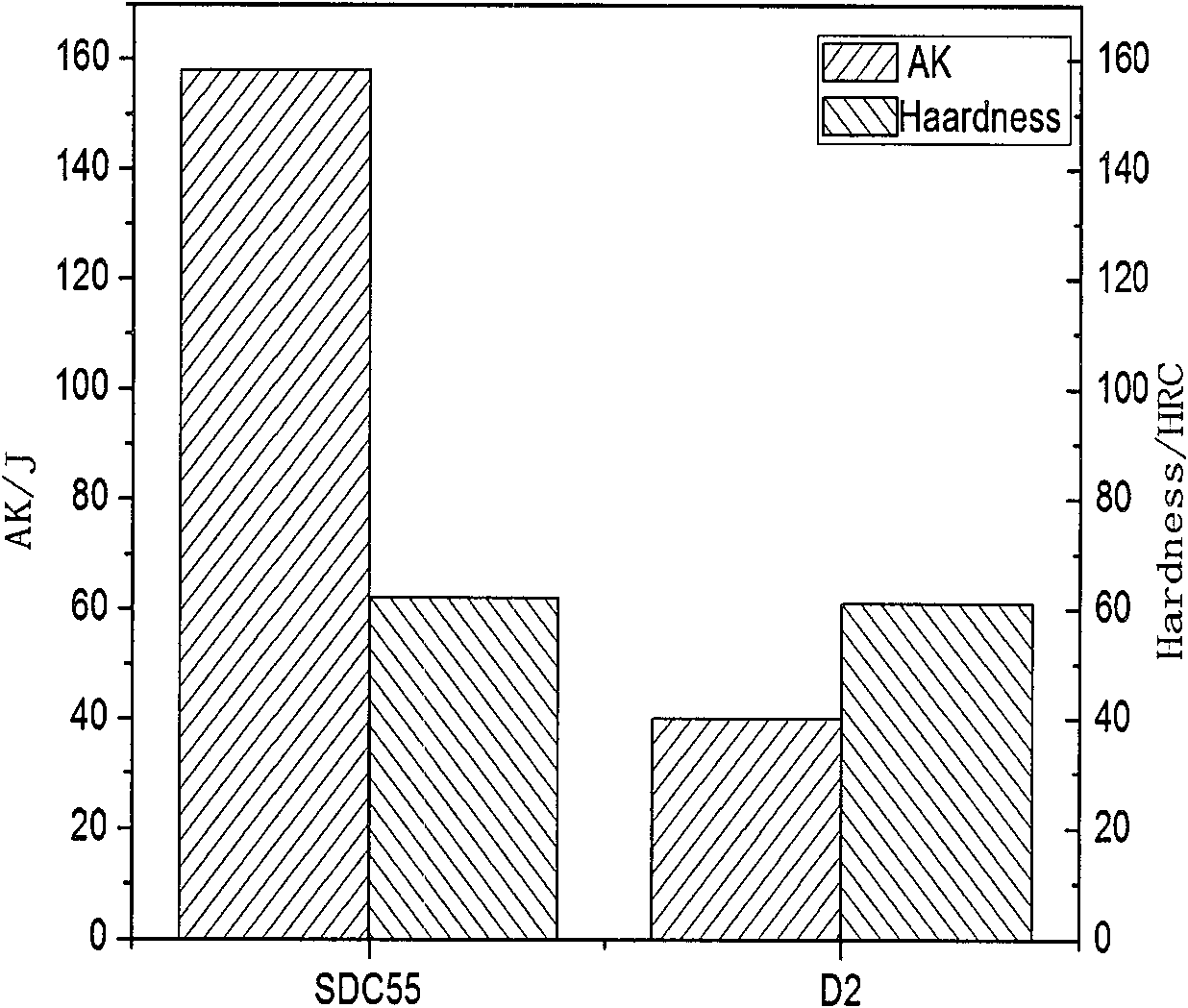

[0048] The heat-treated hardnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com