Light refractory high-temperature-resistant eutectic high-entropy alloy and preparation method thereof

A high-entropy alloy and high-temperature-resistant technology, applied in the field of VNbMSi light-weight refractory eutectic high-entropy alloy and its preparation, can solve the test that eutectic high-entropy alloy cannot withstand high temperature conditions, low melting point, FCC solid solution phase strength Insufficient and other problems, to achieve the effect of enhancing the solid solution strengthening effect, excellent high temperature performance, and excellent microstructure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

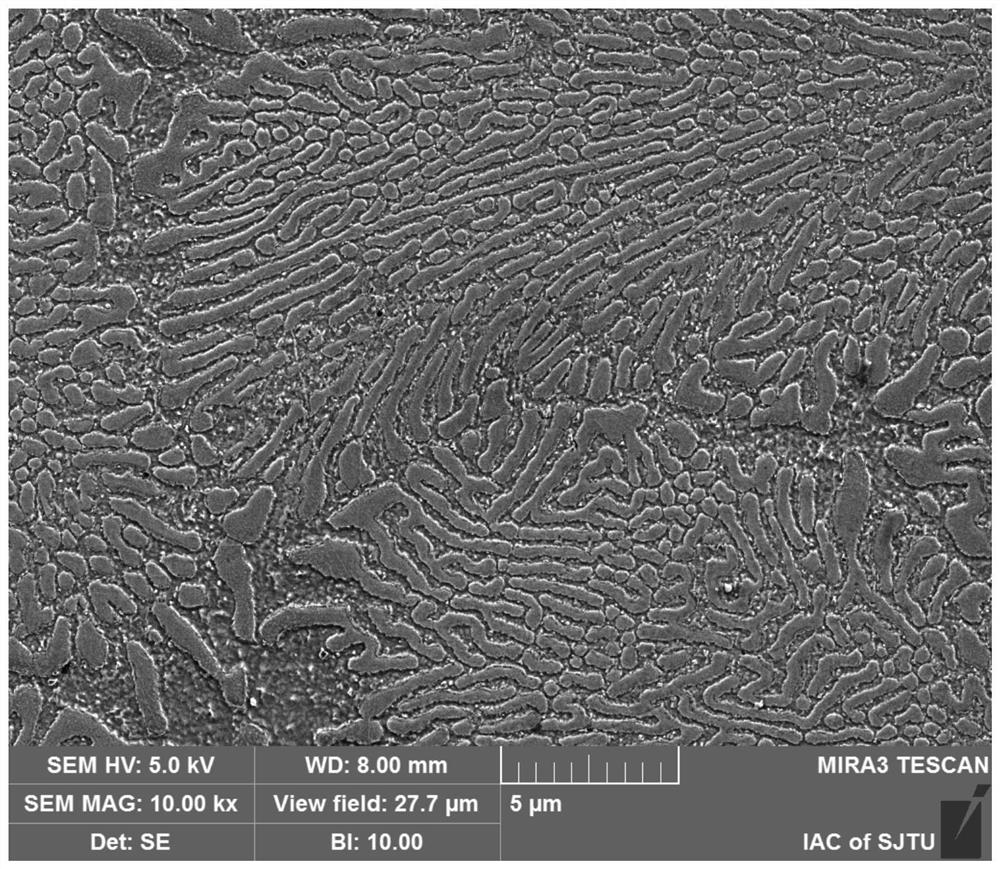

Image

Examples

Embodiment 1-3

[0057] Embodiment 1-3: The preparation process of light-weight refractory high-temperature resistant eutectic high-entropy alloy is as follows:

[0058] 1) Raw material preparation: use raw materials V, Nb, Ti, Cr, Mo and Si with a purity of more than 99.95% for smelting metal raw materials, use sandpaper to remove oxide scales on the raw materials, and then use a balance to accurately weigh them for smelting. Among them, The ratio of each alloy composition is shown in Table 1.

[0059] Table 1 is the nominal composition (at%) of the alloys of the examples.

[0060]

[0061]

[0062] 2) Smelting of high-entropy alloys: Take weighed raw materials and put them into a vacuum electric arc furnace. According to the smelting requirements, elements with high melting points are placed on the upper layer to cover elements with lower melting points. When smelting, first use a small electric arc to burn the upper layer of high melting point elements red, and then adjust the curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com