Polyurethane high-temperature-resistant anti-rutting modifier for road asphalt

A technology of road asphalt and modifier, applied in building insulation materials, building components, buildings, etc., to achieve excellent anti-rutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

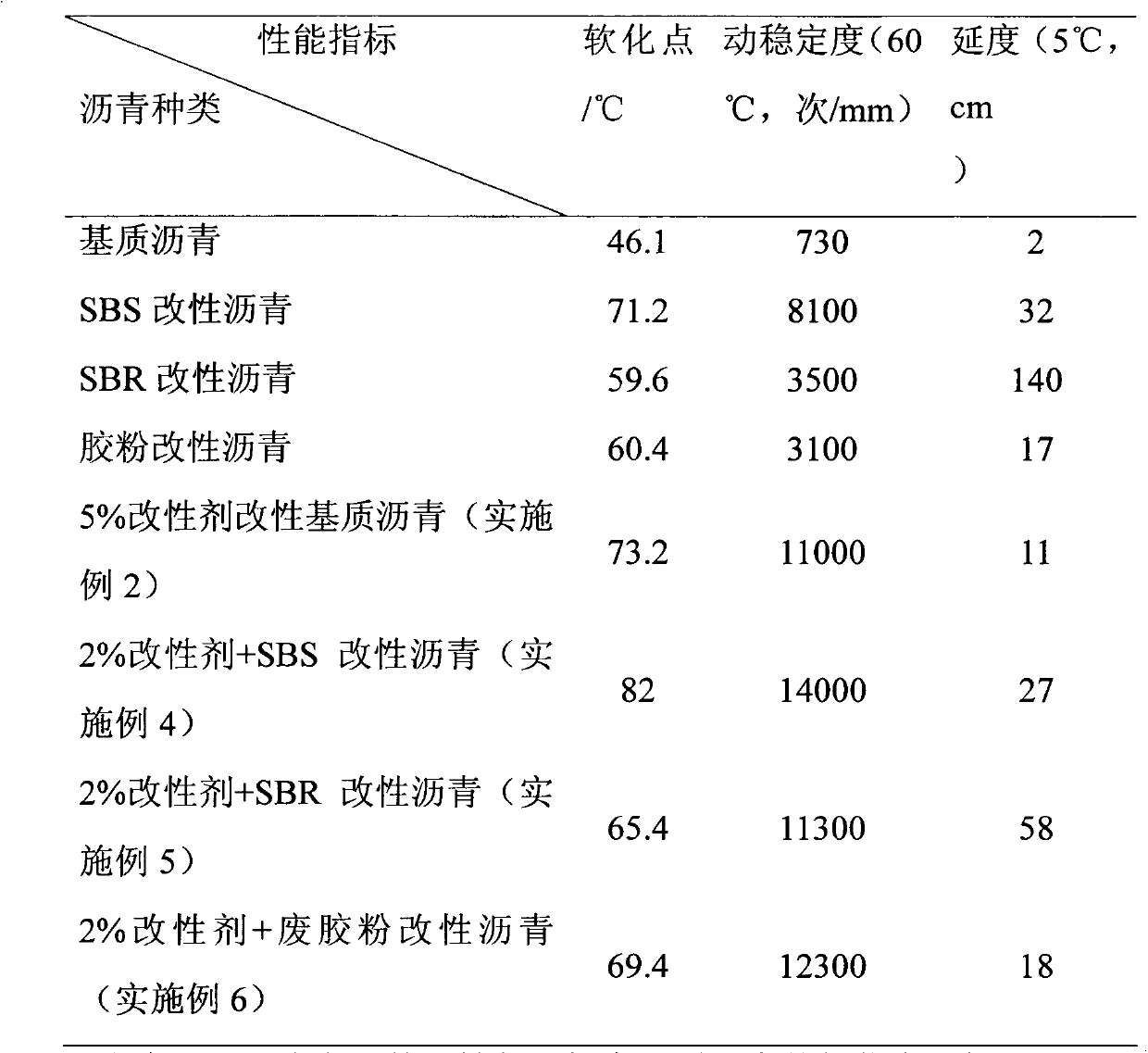

Examples

Embodiment 1

[0037] The formula of modifying agent of the present invention is as follows: 30wt% diphenylmethane diisocyanate (MDI-100, NCO content 33.6%, Yantai Wanhua Polyurethane Co., Ltd.), 55wt% number average molecular weight is the polyoxypropylene diisocyanate of 2000 Amine (D-2000, Huntsman company), 3wt% 1,4 butanediol, 5wt% number average molecular weight is the liquid polybutadiene (LBR, Kuraray company) of 30000, the bismuth isooctanoate of 0.5wt% , 0.5wt% dewatering agent Zoldine MS-Plus (oxazolidines, Angus company), 1wt% antioxidant 2,6-di-tert-butyl-4-methylphenol, 4wt% plasticizer ortho Dioctyl phthalate, 1 wt% antihydrolysis agent bis(2,6-diisopropyl)carbodiimide. The amount of free NCO groups in diphenylmethane diisocyanate is in excess of 36% relative to the sum of the amount of active hydrogen contained in the amino groups of D-2000 and the hydroxyl groups in 1,4-butanediol. The substances in the modifier formula are added in proportion to No. 70 straight-run road as...

Embodiment 2

[0039] The formula of modifier of the present invention is as follows: 60wt% polymethylene polyphenyl polyisocyanate (PM-200, NCO content 31.2%, Yantai Wanhua Polyurethane Co., Ltd.), 15wt% functionality is 3, several Polyoxypropylene triamine (T-3000, Huntsman company) that average molecular weight is 3000, 5wt%, functionality is 2, the polycarbonate polyol (CD210 that number average molecular weight is 1000, Japanese Daicel Chemical Industry Co., Ltd. ), 5wt% trimethylolpropane, 5wt% 4,4'-diaminodiphenylmethane (MDA, Yantai Wanhua Polyurethane Co., Ltd.), 5wt% number average molecular weight is 4000 hydroxyl-terminated polybutylene Alkene (HTPB, Qilong Chemical Co., Ltd.), 0.5wt% dibutyltin dilaurate, 0.5wt% N, N-dimethylethanolamine, 0.5wt% dewatering agent pTSI (oxazolidines, Bayer company) , 1wt% antioxidant 1035, 0.5wt% antioxidant 1076, 1wt% plasticizer dioctyl sebacate, 1wt% antihydrolysis agent phenyl glycidyl ether. The amount of free NCO groups in polymethylene pol...

Embodiment 3

[0041] The formula of modifier of the present invention is as follows: the liquefied MDI of 45wt% (MP-35, NCO content 27.5%, Yantai Wanhua Polyurethane Co., Ltd.), 35wt%, functionality is 2, and number-average molecular weight is 1000 hexadiene Acid-based polyester polyol (PEA-1000, Yantai Synthetic Leather Factory), 3wt% adipic acid, 2wt% 1,6 hexanediol, 5wt% number average molecular weight is 10000 polybutadiene-styrene copolymer (LIR, Kuraray company), 0.5wt% dibutyltin dilaurate, 0.5wt% tetramethylammonium chloride, 0.5wt% dewatering agent Zoldine MS-Plus (oxazolidines, Angus company), 1wt% Antioxidant 1035, 3 wt% plasticizer dioctyl phthalate, 3.5 wt% dioctyl sebacate, 1 wt% UV absorber Tinuvin 101 (Ciba Specialty Chemicals). The amount of free NCO groups in the liquefied MDI is 103% greater than the sum of active hydrogens contained in the hydroxyl groups in PEA-1000 and 1,6 hexanediol and the carboxyl groups in adipic acid. The substances in the modifier formula are ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com