Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Increased tensile strength at room temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium alloy of high intensity and high yield ratio and preparation method thereof

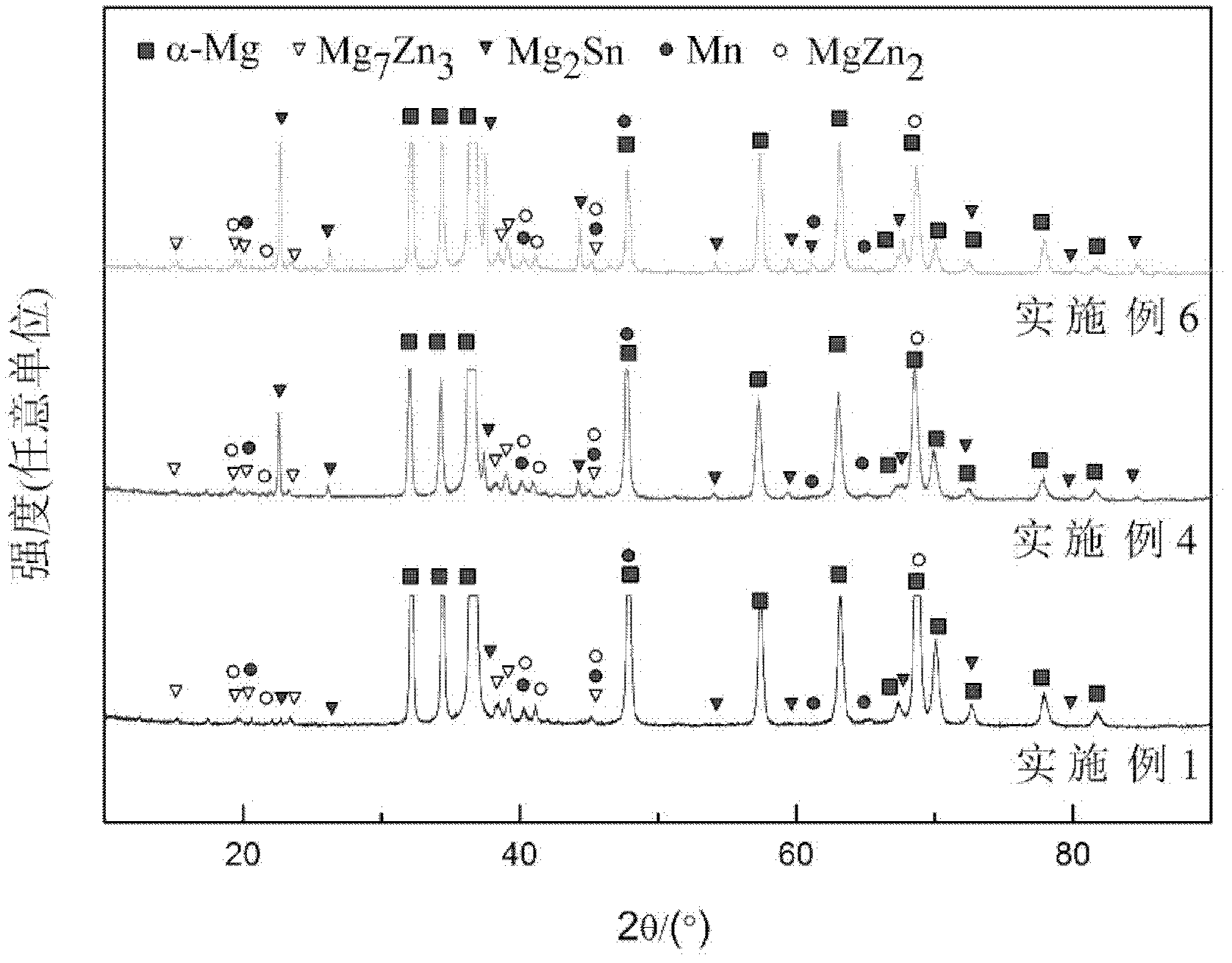

The invention provides a magnesium alloy material of high intensity and high yield ratio. The alloy comprises the following components by mass: 5.0-9.0% of Zn; 0.5-1.5% of Mn; 1-10% of Sn; less than 0.15% of inevitable impurities; and the balance magnesium. By means of plastic forming and a choice of reasonable technological conditions for heat treatment after forming, the magnesium alloy material of the invention can be of high intensity and high yield ratio, and is higher than the high-strength wrought magnesium alloy ZK60 in terms of yield strength and tensile strength. With low cost, good extrudability and formability at a low temperature, the magnesium alloy material provided in the invention boasts substantial application potential, thus being able to partly replace the magnesium alloy material ZK60.

Owner:QINGHAI SUNGLOW MAGNESIUM

Ceramic base compound material bolt preparation method

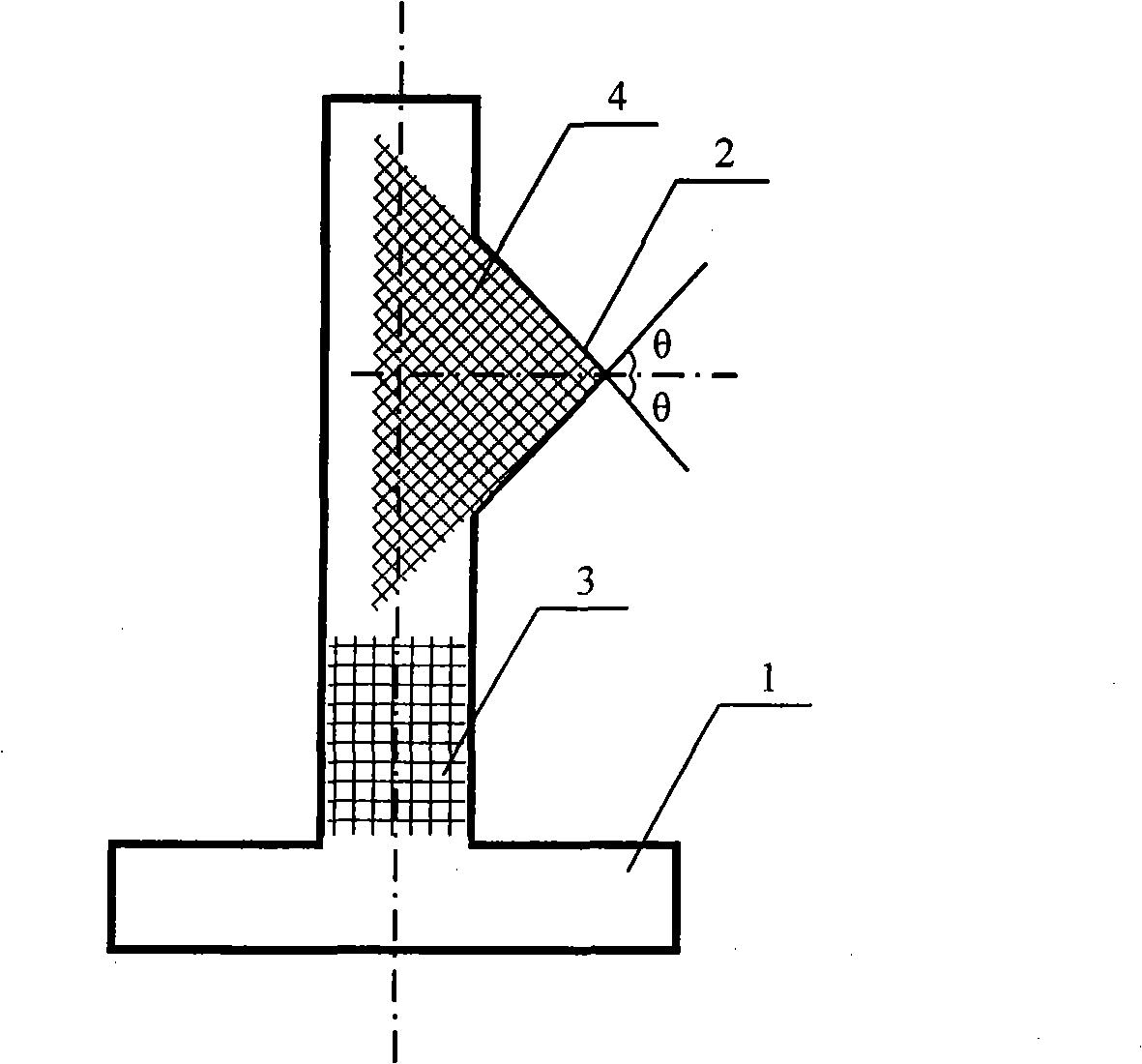

The invention discloses a preparation method for a ceramic matrix composite bolt, which is characterized in that the method comprises the following steps: producing a fiber prefabricated product by shaping with a graphite plate after alternatively laminating a 1K carbon fiber 0 / 90 degree positive ply and a plus / minus Theta inclined ply; depositing a pyrolysis carbon interface layer on the prefabricated product and then depositing a silicon carbide matrix on the two-dimensional sheet with a deposited pyrolysis carbon interface layer to produce a semi-finished product of ceramic matrix composite sheet which is cut to form a bolt blank; grinding wheel and tapping the bolt blank; lastly obtaining the product of C / SiC composite bolt after many times of infiltration pyrolysis of polycarbosilane and continuing CVI depositing of SiC anti-oxidation coating. By the method, the bolt is processed and tapped on the semi-finished ceramic matrix composite prefabricated product which is not fully deposited and dense, so that the diamond grinding wheel wear is slow and the production cost is reduced. The technology of CVI combining with PIP process enables the elongation breaking strength of composite bolts to improve from 180 to 190MPa in prior art to 210 to 230MPa.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

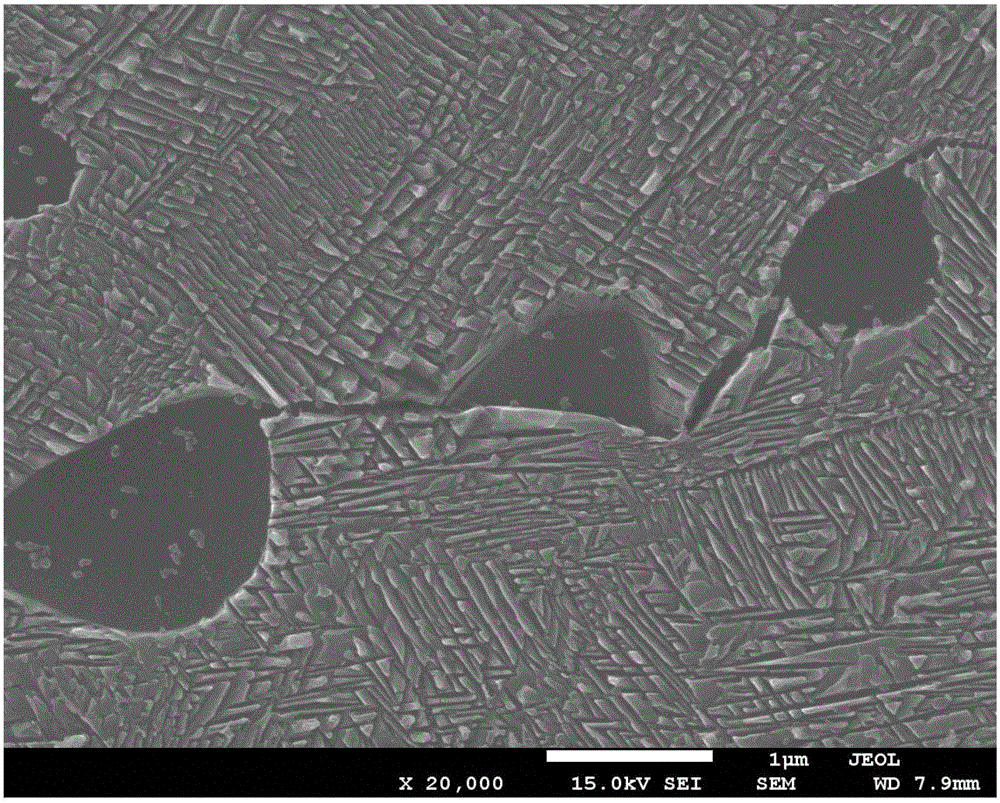

Repeated solid solution aging thermal treatment process of titanium alloy

The invention relates to a repeated solid solution aging thermal treatment process of titanium alloy. The process includes the steps that a titanium alloy forge is subjected to heat preservation at the temperature T for t minutes, wherein T is larger than or equal to Tbeta-15 DEG C but smaller than or equal to Tbeta+15 DEG C, t is equal to eta*delta max, delta max is the maximum section thickness of the forge and is shown in millimeters, and eta is the heating coefficient and ranges from 0.2 min / mm to 0.8 min / mm; then the forge is discharged out of a furnace to be air-cooled or wind-cooled or water-cooled to be at the room temperature, then the cooled forge is subjected to heat preservation at the temperature of T for t minutes, wherein T is larger than or equal to Tbeta-25 DEG C but smaller than or equal to Tbeta-50 DEG C, the computational formula of t is as above, namely t=eta*delta max, and the heating coefficient eta ranges from 0.3 min / mm to 1.2 min / mm; then the forge is discharged out of the furnace to be air-cooled or wind-cooled or water-cooled to be at the room temperature, the cooled forge is subjected to heat preservation at the temperature T ranging from 540 DEG C to 600 DEG C, and the heat preservation time t ranges from 0.5 hour to 2 hours; the forge is discharged out of the furnace to be air-cooled to be at the room temperature, the cooled forge is subjected to heat preservation at the temperature T ranging from 400 DEG C to 540 DEG C, and the heat preservation time t ranges from 4 hour to 24 hours; and then the forge is discharged out of the furnace to be air-cooled to be at the room temperature. The repeated solid solution aging thermal treatment process of the titanium alloy is suitable for thermal treatment of near-beta type, metastable beta type and steady beta type ultrahigh-toughness titanium alloy so as to obtain required microscopic structures with high overall performance and multi-scale precipitated phases mixed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

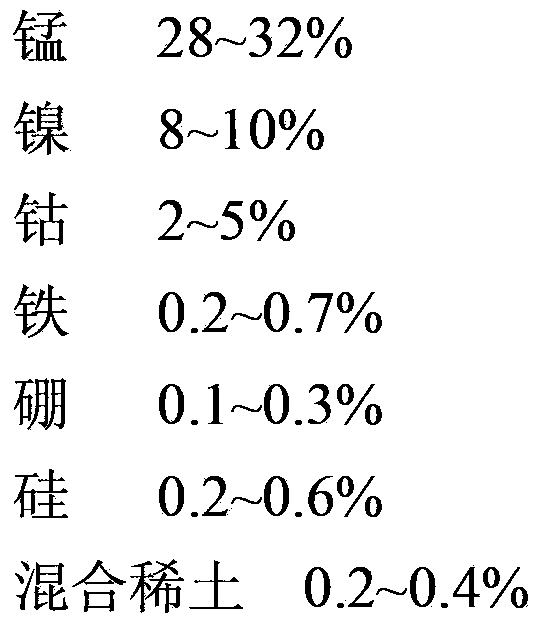

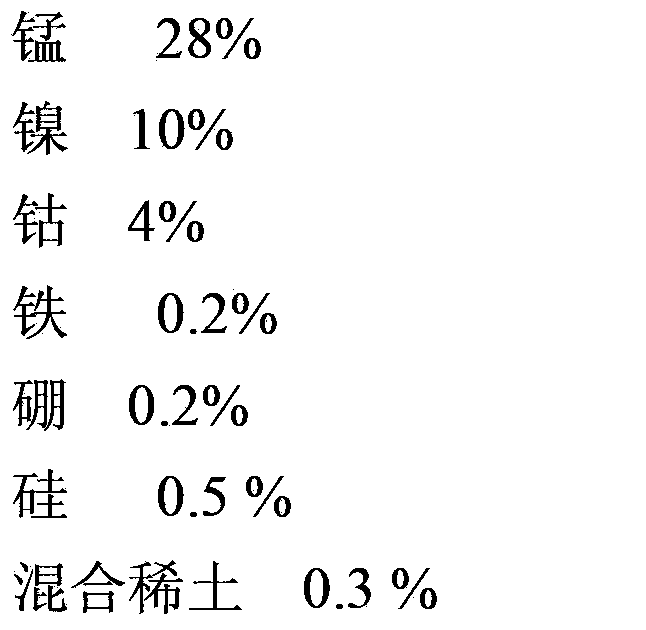

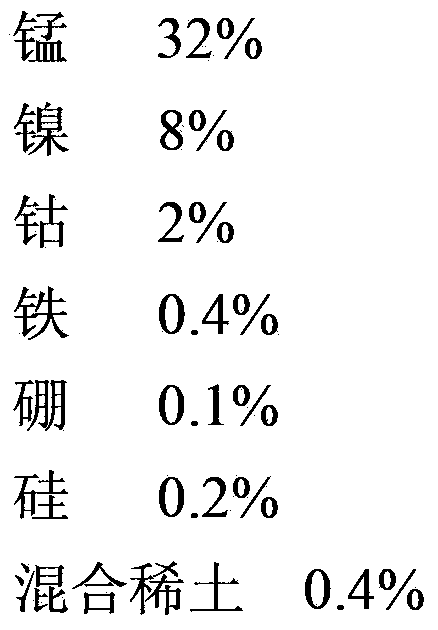

Copper-based solder and preparation method thereof

ActiveCN103358051ALower melting temperatureImprove wettabilityWelding/cutting media/materialsSoldering mediaCorrosionSmelting process

The invention discloses a method for preparing a copper-based solder. The method comprises the following steps: (1) burdening: preparing a furnace burden from copper, manganese, nickel, cobalt, silicon, a copper-ferrous intermediate alloy, a copper-boron intermediate alloy and a copper-mixed rare earth intermediate alloy serving as raw materials; (2) casting: putting the prepared furnace burden into the a corundum crucible according to the sequence of manganese, copper, nickel, cobalt, silicon, copper-boron intermediate alloy, copper-mixed rare earth intermediate alloy and copper-ferrous intermediate alloy, smelting by adopting medium-frequency induction, and cooling along with the furnace to obtain an alloy blank, wherein the smelting process is performed under the protection of argon gas; and (3) rolling: rolling the alloy blank with a cold-rolling mill to obtain the copper-based solder. The copper-based solder provided by the invention can be applied to an ODS (Oxide Dispersion Strengthened) high-temperature alloy welding joint, has high brazing process performance, heat resistance, corrosion resistance and machining process, and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

High-temperature-resisting material as well as preparation method and application thereof

ActiveCN107382342AImprove thermal shock performanceIncreased tensile strength at room temperatureFoundry mouldsFoundry coresPorosityGranularity

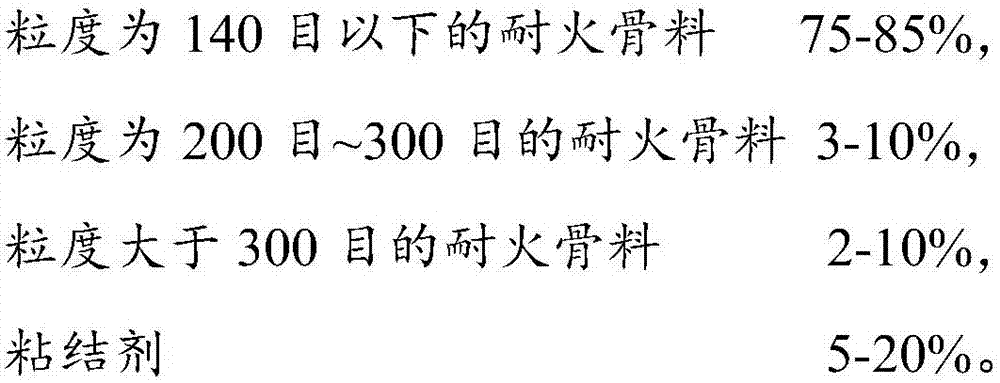

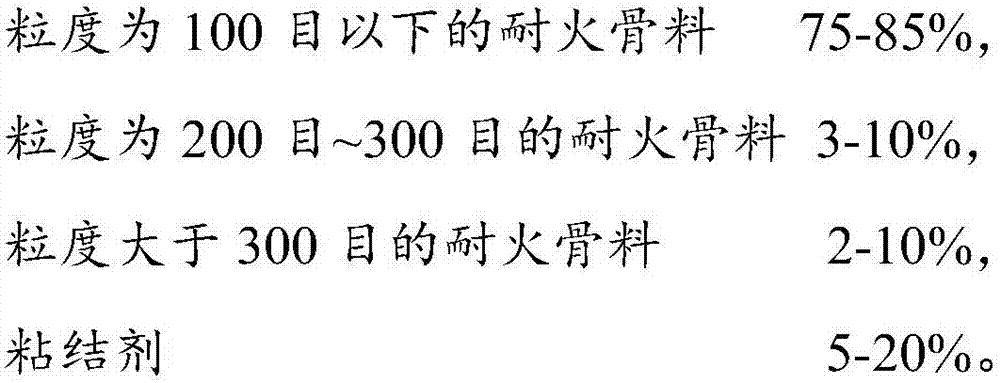

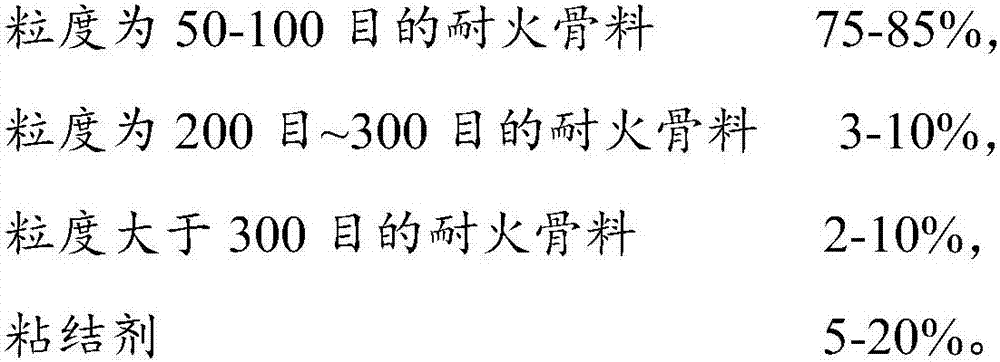

The invention provides a high-temperature-resisting material as well as a preparation method and application thereof. The high-temperature-resisting material is mainly prepared from the following components by mixing and sintering: based on the weight percentage content, 60 percent to 90 percent of refractory aggregate with the granularity of 140 meshes or less, 1 percent to 25 percent of refractory aggregate with the granularity of 200 meshes or more and 2 percent to 25 percent of a binding agent. According to the high-temperature-resisting material provided by the invention, the refractory aggregate with different granularities is combined according to a scientific proportion and then is sintered, so that bridging connection, realized by point contact, between the refractory aggregate (namely aggregate) and the other aggregate can be promoted, and tight connection of bridging is also promoted; a microscopic structure is adopted so that the porosity of the material reaches 30 percent or more and the volume density is less than or equal to 1.5g / cm<3>; cracks are not easily expanded so that the thermal shock performance is good, the pouring temperature is greater than or equal to 1650 DEG C and the room-temperature tensile strength is greater than or equal to 1.0MPa.

Owner:JINAN SHENGQUAN DOUBLE SURPLUS CERAMIC FILTER

Titanium alloy, polish sucker rod made of titanium alloy and application of polish sucker rod

ActiveCN103667789AImprove performanceImprove fatigue strengthDrilling rodsDrilling casingsMetallurgyAlloy

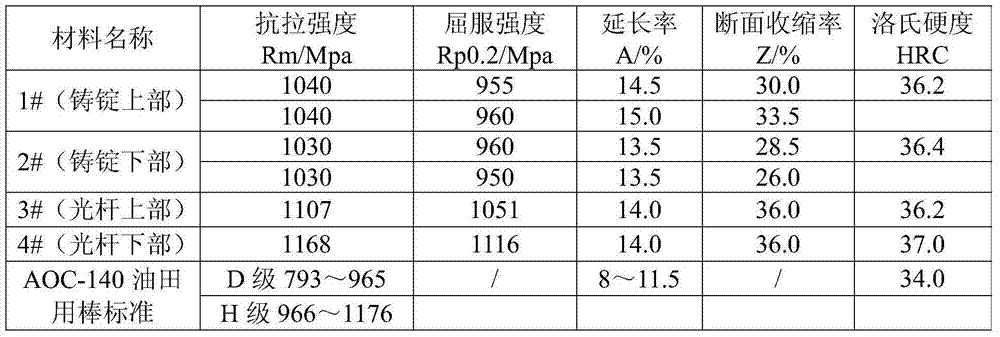

The invention relates to titanium alloy, which is characterized by comprising the following ingredients in percentage by weight: 4 to 8 weight percent of Al, 2 to 5 weight percent of Mo, 2 to 4 weight percent of V, 0.5 to 3 weight percent of Zr, 0.1 to 1 weight percent of Si, 0.02 to 1 weight percent of Fe, 0 to 0.4 weight percent of other impurities and the balance Ti. The invention also relates to a polish sucker rod made of the titanium alloy and an application of the polish sucker rod to oil well equipment.

Owner:BEIJING GRAND TITANIUM TRADE

Gadolinium-containing die-casting thermostable high-zinc magnesium alloy and method for making same

The invention relates to die-casting and heat-resistant high zinc magnesium alloy with gadolinium content and preparation method thereof and is used in the metal material field. The alloy components and weight percentages thereof are that: Zinc: 6-10 percent, aluminum: 3-7percent, gadolinium: 0.2-2.0 percent, impurity element Fe is less than 0.005 percent, Cu is less than 0.015 percent, Ni is less than 0.002 percent and the rest is magnesium. Pure magnesium, pure zinc, pure aluminum and Mg-25percent Gd are preheated, and then the pure magnesium is put into a melting furnace with the protection of gas to be melted; the pure zinc and the pure aluminum are added immediately after magnesium ingot is thoroughly melted, and scum on the surface is skimmed after the pure zinc and the pure aluminum are thoroughly melted; the temperature rises continuously, Mg-25 percent Gd master alloy is added, and scum on the surface is skimmed after the master alloy is completely melted; melted mixture obtained is stirred, and then refined, stirred and led to be still after the furnace temperature is adjusted; alloy liquid obtained is die-cast after scum on the surface is skimmed and the temperature of the alloy liquid is adjusted down. The invention has low cost and high production efficiency, and improves mechanical properties of the alloy in room temperature and high temperature and creep properties of the alloy.

Owner:SHANGHAI LIGHT ALLOY NET FORMING NAT ENG RES CENT

Preparation method of TiAl-based alloy with fine fully lamellar microstructure

The invention relates to a preparation method of a TiAl-based alloy with a fine fully lamellar microstructure, which belongs to the technical field of preparation of titanium alloys. The preparation method comprises the following steps: placing a powder metallurgic TiAl-based alloy at a temperature which is 5 DEG C-15 DEG C higher than the alpha-phase beta-phase transformation temperature Talpha; and preserving the heat for 15-25 minutes under a protective environment, and cooling to obtain the TiAl-based alloy with the fine fully lamellar microstructure, wherein the powder metallurgic TiAl-based alloy matrix structure is a nearly gamma structure or a gamma structure. According to the preparation method of the TiAl-based alloy with the fine fully lamellar microstructure disclosed by the invention, the fully lamellar microstructure with eutectic cell dimension of 150 microns-320 microns and lamellar spacing of 0.2 micron-0.4 micron can be obtained by a simple thermal treatment method. Moreover, the preparation method is free of hot mechanical treatment, simple in process and low in cost, so that not only can structure optimization be carried out before alloy forming, but also treatment can be directly carried out onto a formed piece. Besides, the preparation method has the advantages of being capable of controlling the microscopic structure of the alloy, simple in production process, regular in used equipment, low in production cost and the like, and is convenient for industrial production.

Owner:CENT SOUTH UNIV

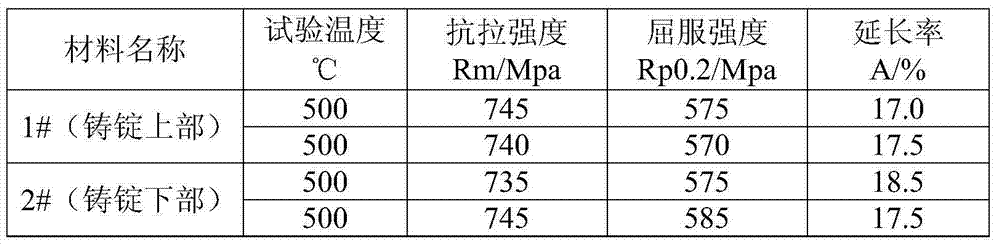

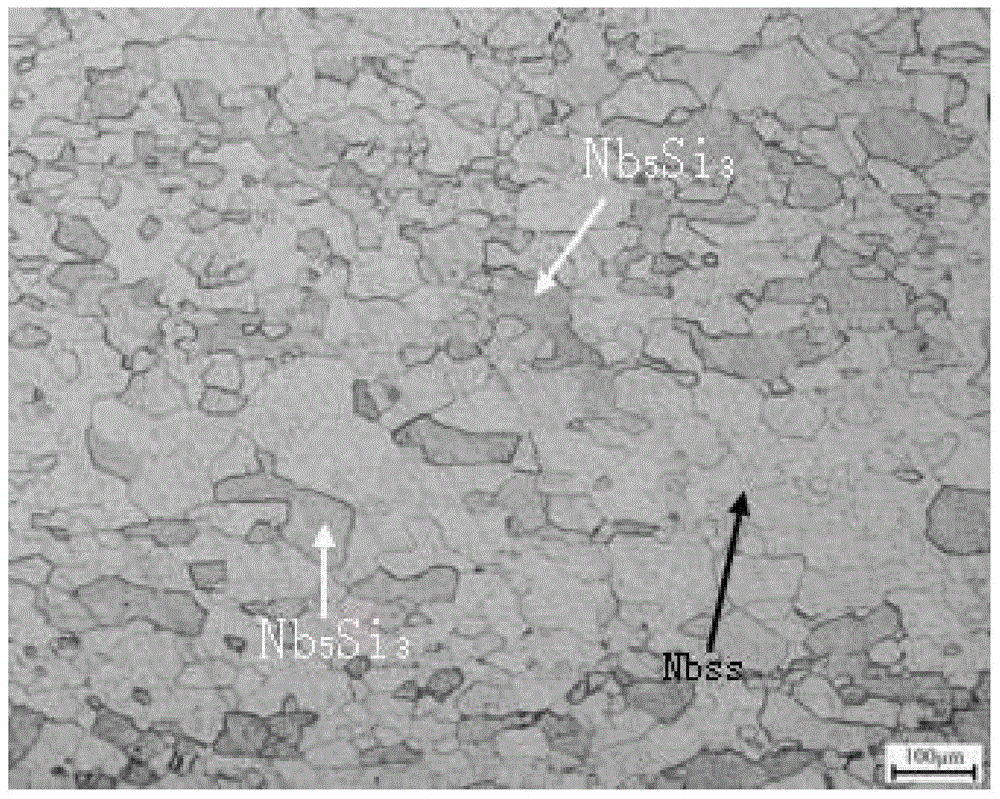

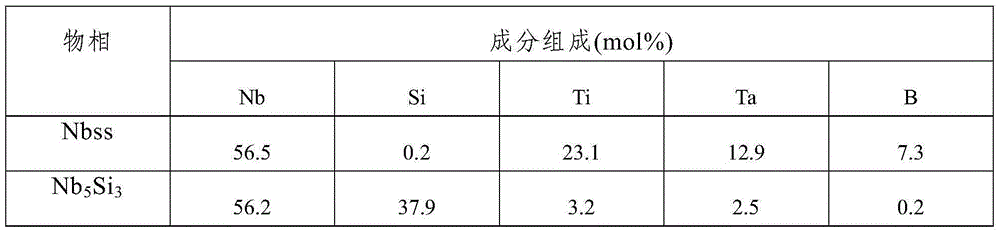

Nb-Si-Ti-Ta-B alloy material and preparation method thereof

ActiveCN105200295ARoom temperature ductility balanceBalance of Mechanical PropertiesNiobiumMechanical property

The invention discloses an Nb-Si-Ti-Ta-B alloy material which is prepared from the following raw materials according to the following atom percentage: 6-20% of Si, 16-30% of Ti, 5-15% of Ta, 2-8% of B and the rest of Nb and unavoidable impurities. In addition, the invention also discloses a method for preparing the Nb-Si-Ti-Ta-B alloy material. The method comprises the following steps: 1, silicon powder, titanium powder, tantalum powder, boron powder and niobium powder are uniformly mixed and the mixture is compacted to form an electrode, and electric arc melting is carried out to obtain an alloy ingot; and 2, the alloy ingot undergoes extrusion so as to obtain the Nb-Si-Ti-Ta-B alloy material. Tensile strength of the Nb-Si-Ti-Ta-B alloy material under the condition of 1300 DEG C is 267MPa-425MPa. Ductility and toughness at room temperature, room-temperature mechanical property and high temperature tensile strength of the Nb-Si-Ti-Ta-B alloy material are well balanced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

High-strength deforming magnesium alloy containing Ti

InactiveCN1614062AIncreased tensile strength at room temperatureHigh strengthCrystalliteContinuous distributions

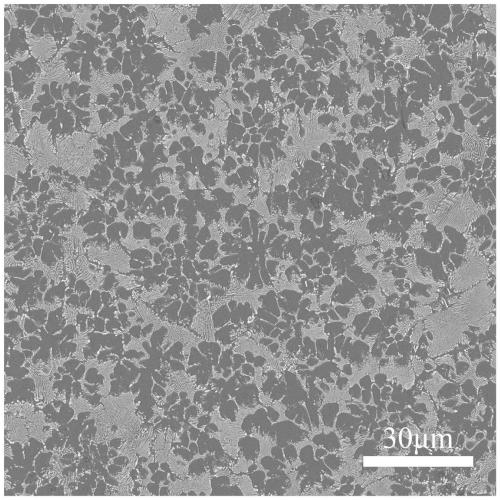

The invention was involved in high strength distorted magnesium alloy containing Ti. The alloy consist of 3-9%Al, 0.1-0.5%Mn, 0.05-0.5%Zn, lower than 0.02% impurity and the rest was Mg. The method with low cost and high efficiency improved obviously room temperature strength of extension, yield strength and extensibility .The microscopic structure of magnesium alloy was refined obviously and the coarse Mg17Al12 phase was changed into exiguous strip or graininess. Continuous distribution of magnesium alloy was changed into isolated diffusion distribution. For example, Mg-5Al-0.5Ti alloys, the grain size reduced to 10um from 40um..The room temperature strength of extension was 292MPa,yield strength was 145 MPa, and extensibility was 22%. Compared with AZ91D, the intensity of magnesium alloy was improved obviously, while the cost was equivalent to AZ91D.

Owner:江苏锦绣铝业有限公司

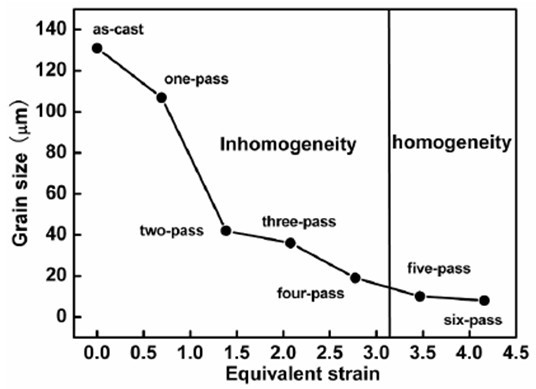

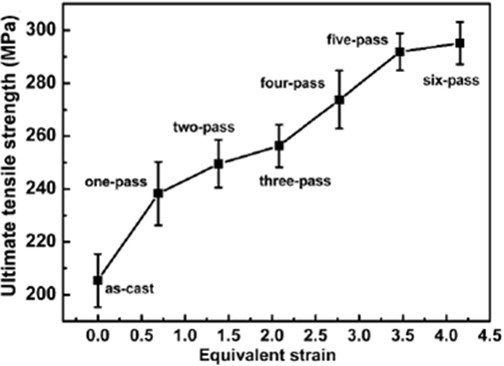

Preparation method of fine grain magnesium alloy

The invention relates to a preparation method of a fine grain magnesium alloy. In the method, the preheating temperature of a mould is 350+ / -5 DEG C; a magnesium alloy blank is subjected to at least five passes of extrusion and deformation; the preheating temperature of the magnesium alloy blank is 250+ / -5 DEG C-380+ / -5 DEG C; the extrusion rate is 2mm / s-15mm / s, and the extrusion direction each time is different; and the preheating temperature of the magnesium alloy blank changes from high to low, and the extrusion rate is varied from large to small. According to the preparation method provided by the invention, a multi-pass multi-direction temperature-variable extrusion technology is adopted, i.e., the temperature and extrusion rate of the magnesium alloy blank are gradually reduced along with the increase of extrusion pass, and forces are applied in the different directions of magnesium alloy so as to carry out extrusion and deformation, thereby improving the deformation nonuniformity of a magnesium alloy structure in the conventional isothermal extrusion deformation and preventing full growth and grain mixing of dynamically recrystallized grains due to high temperature in the extrusion process. Thus, the grains of the magnesium alloy obtained by using the multi-pass multi-direction temperature-variable extrusion deformation are obviously fined, and the size of the grain is uniform.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

High-thermal-conductivity corrosion-resistant Al-RE-Y-Zr alloy suitable for gravity casting and preparation method thereof

ActiveCN111378875AIncreased tensile strength at room temperatureImprove performanceCorrosion resistantDuctility

The invention provides a high-thermal-conductivity corrosion-resistant Al-RE-Y-Zr alloy suitable for gravity casting and a preparation method thereof. The alloy comprises, by mass percent, 5%-16% of RE, 0.1%-7% of Y, 0.5%-0.8% of Mg, 0.01%-0.5% of Zr and the balance Al and inevitable impurity elements. RE is at least one of La and Ce. After the high-thermal-conductivity corrosion-resistant Al-RE-Y-Zr alloy is subjected to gravity casting, the room temperature tensile strength reaches up to 175 MPa, the yield strength is 86 MPa or above, the ductility is 10% or above, and the heat conductivitycoefficient is 160 W / (m.K) or above; and the high-end requirements of aerospace, war industry, cars and other industries for light weight development are met

Owner:SHANGHAI JIAO TONG UNIV

Extrusion type aluminium alloy

The invention provides an extrusion type aluminium alloy which belongs to the technical field of aluminium alloy preparation. The aluminium alloy comprises the following components by mass percent: 4.0-5.5% of Zn, 1.0-2.0% of Mg, 0.6-0.8% of Mn, 0.3-0.8% of Cu, 0.3-0.5% of Cr, 0.05-0.3% of Zr, 0.03-0.1% of rare earth element, no more than 0.3% of unavoidable impurity elements in total and the balance of aluminium. The aluminium alloy has the tensile strength of 396.17-540.03MPa and the yield strength of 303.61-480.13MPa at room temperature; and the aluminium alloy after fusion welding has the tensile strength of 389.17-530.03MPa and the yield strength of 292.61-460.13MPa, and the constituents of welding wires and matrixes are consistent in a welding process. The aluminium alloy can be used for solving a problem that the welding performance and high strength of the conventional aluminium alloy is difficult to match. The aluminium alloy is simple in operation and convenient in industrial production.

Owner:浙江极铝新材料有限公司

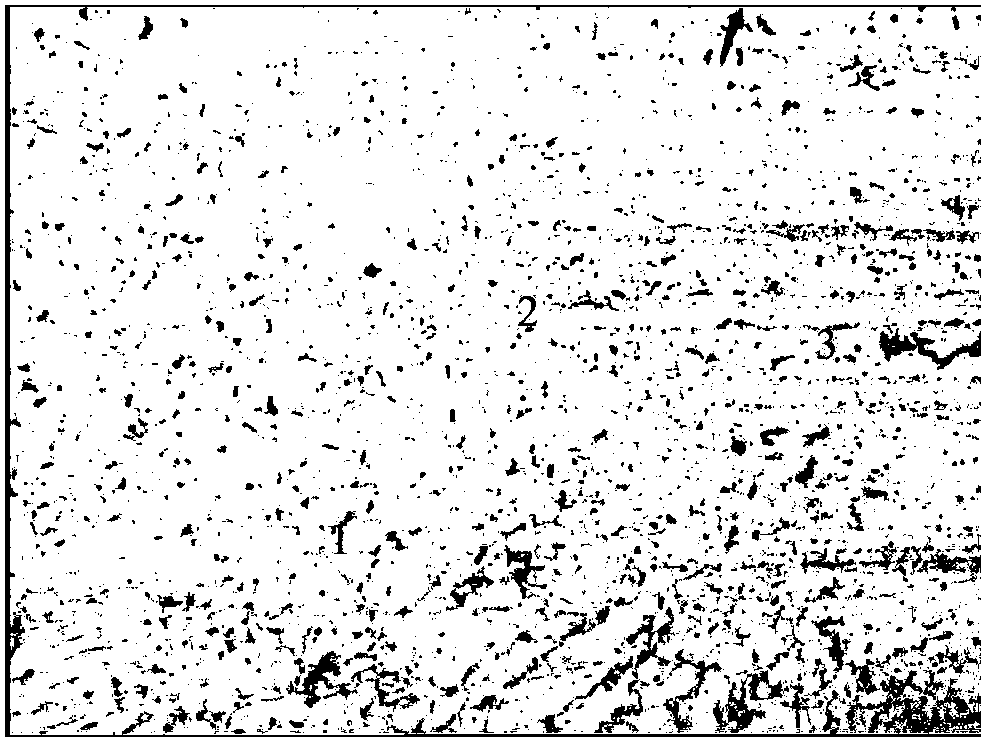

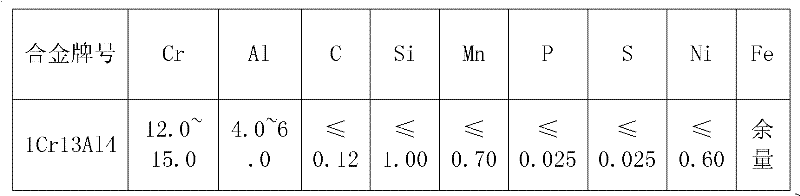

Iron-chromium-aluminum alloy with high plasticity and long service life

The invention relates to an iron-chromium-aluminum alloy with high plasticity and long service life. The iron-chromium-aluminum alloy comprises the following components in percentage by weight: 13.5-14.5 percent of chromium, 3.5-4.5 percent of aluminum, less than or equal to 0.03 percent of carbon, less than 0.24 percent of silicon, 0.3-0.5 percent of titanium, 0.25-0.35 percent of vanadium and the balance of iron. In the invention, the carbon content of the alloy is controlled: carbon plays a harmful role in the inoxidability of the iron-chromium-aluminum alloy, and the formation of harmful carbonates and nitrides can be avoided by lowering the carbon content, so that the plasticity of the alloy is improved. A reasonable aluminum-chromium content ratio is selected: the oxidizing speed of the iron-chromium-aluminum alloy is lowered along with the increase in the aluminum and chromium content, but the plasticity is lowered along with the increase in the aluminum and chromium content. Titanium is doped: the nitriding resistance and corrosion resistance of the alloy are improved. Vanadium is added: tissue product grains of the alloy can be fined, the grain coarsening temperature is raised, the overheat sensitivity of the alloy is lowered, and high hardness and chemical stability with a silicide formed by silicon are realized.

Owner:DANYANG HUALONG SUPERIOR STEEL

Rare earth magnesium alloy and preparation method thereof

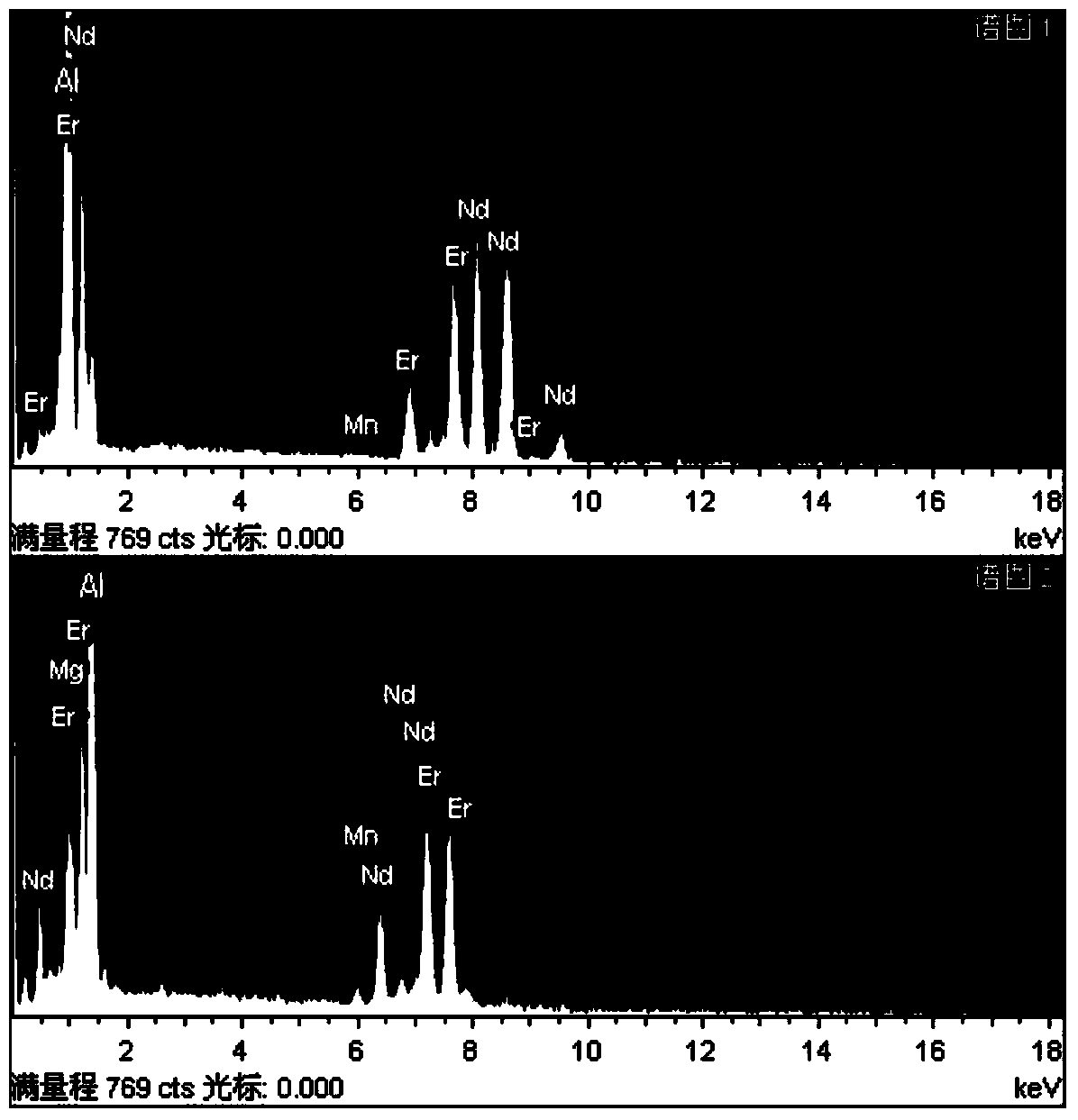

ActiveCN103911534AIncreased tensile strength at room temperatureHigh temperature tensile strengthRare-earth elementRoom temperature

The invention discloses a rare earth magnesium alloy and a preparation method thereof. The rare earth magnesium alloy contains the following components in percentage by mass: 8.4-8.7% of Al, 0.85-0.89% of Zn, 0.28-0.30% of Mn, 0.39-1.21% of Nd, 0.41-0.43% of Er, less than 0.04% of impurity elements (Si, Fe and Cu) in total, and the balance of Mg. According to the method, rare earth elements Nd and Er are compounded and added in a magnesium alloy by smelting so as to modify the magnesium alloy and the obtained casting-state rare earth magnesium alloy is subjected to T6 heat treatment. Compared with the prior art, the rare earth magnesium alloy prepared by the method is relatively high in room-temperature tensile strength and high-temperature tensile strength and the plasticity is enhanced greatly.

Owner:WUHU INST OF TECH

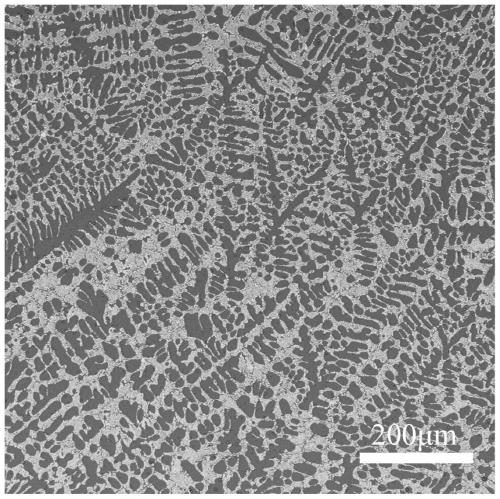

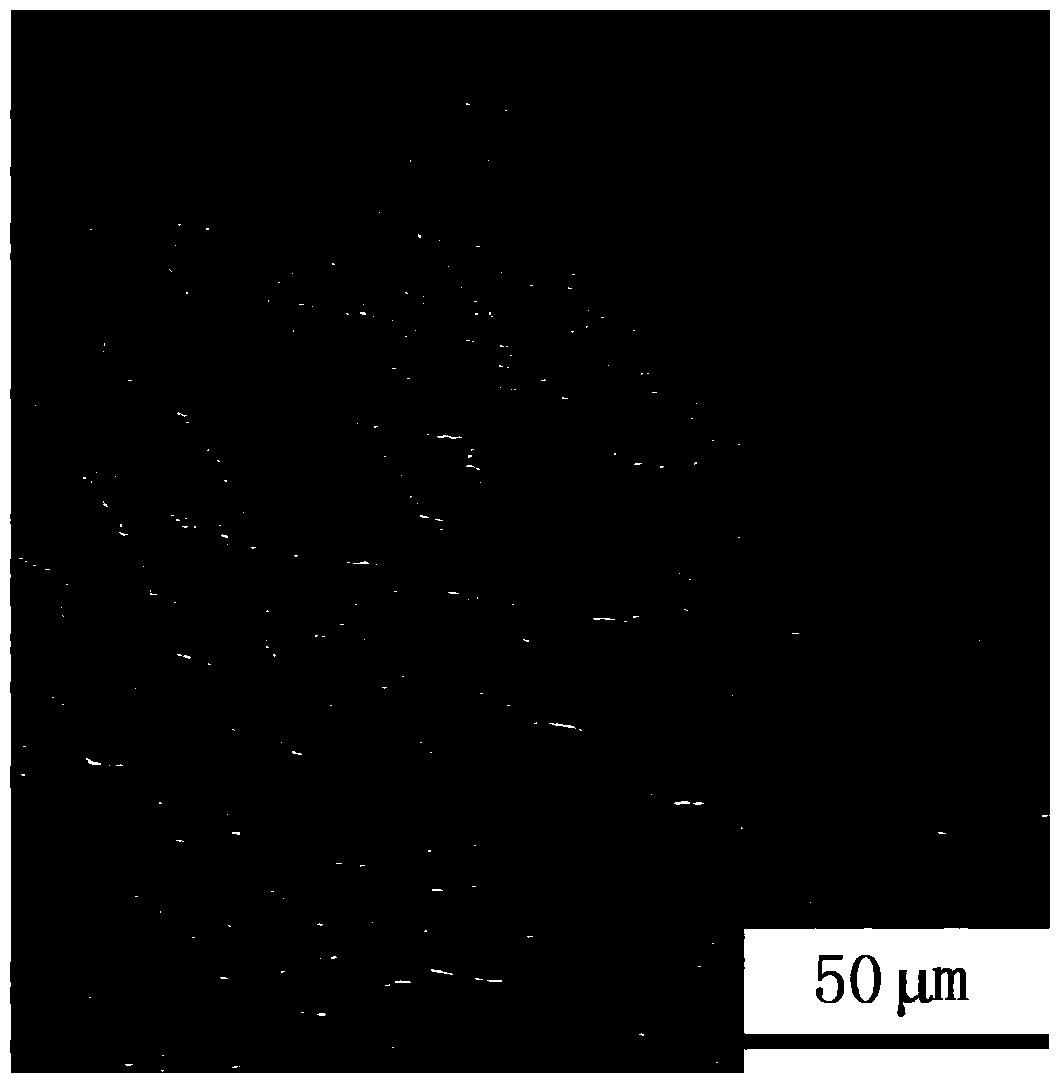

Method for improving room-temperature tensile property of Ti-48Al-2Cr-2Nb alloy through adding of nano Y2O3

InactiveCN105821232AImprove plasticityIncreased tensile strength at room temperatureCrucibleRoom temperature

The invention discloses a method for improving the room-temperature tensile property of a Ti-48Al-2Cr-2Nb alloy through adding of nano Y2O3, and belongs to the field of room-temperature mechanical properties of metal materials. The method for improving the room-temperature tensile property of the Ti-48Al-2Cr-2Nb alloy through adding of the nano Y2O3 aims at solving the problem that an existing directly-casted Ti-48Al-2Cr-2Nb alloy is coarse in structure, and serious in segregation. The method comprises the steps that nano Y2O3 particles are added in the Ti-48Al-2Cr-2Nb alloy, a water cooled copper crucible is adopted to induce a solidification shell smelting furnace, and under the high-vacuum / argon environment, through the melt reaction, a full-lamellar structure with the fine Y2O3 particles evenly distributed in a dispersed manner is directly generated. After the nano Y2O3 is added, the room-temperature tensile strength of the alloy is obviously improved, and the room-temperature plasticity of the alloy is greatly improved.

Owner:HARBIN INST OF TECH

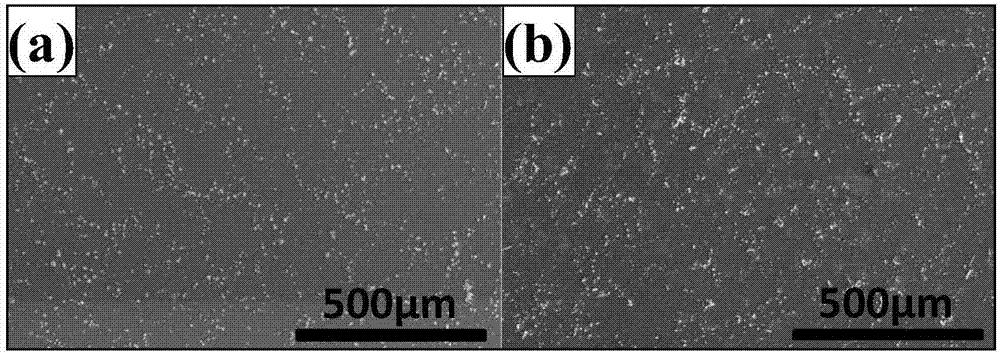

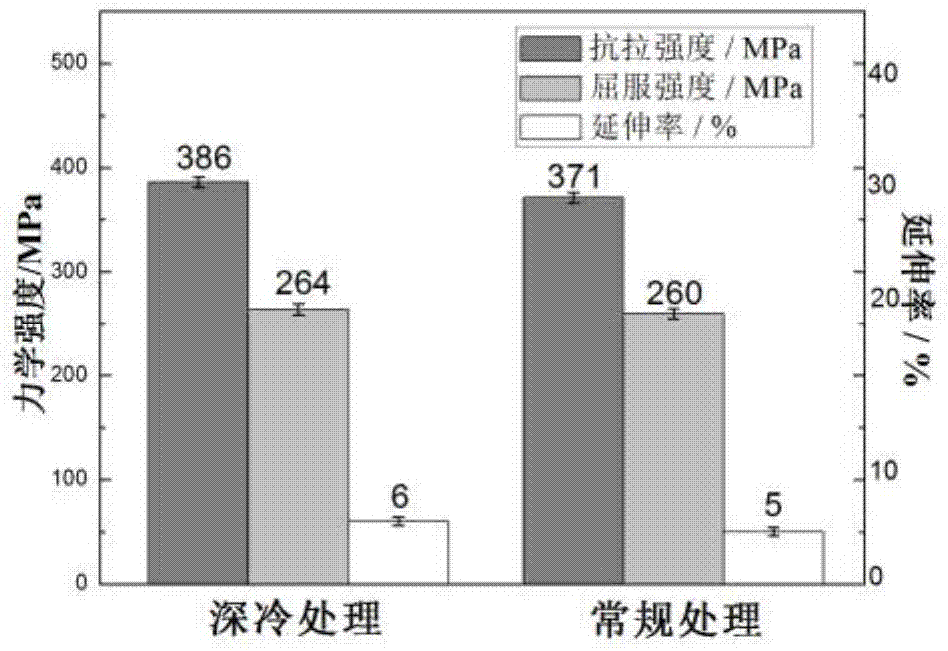

Processing method for improving corrosion resistance of Mg-Y-Nd based alloy

ActiveCN107574392AImprove mechanical propertiesImprove wear resistanceSolution treatmentSolid solution

The invention belongs to the technical field of metal material thermal treatment and particularly relates to a processing method for improving corrosion resistance of an Mg-Y-Nd based alloy. The method comprises the steps that the to-be-processed alloy is subjected to deep cooling and solid solution treatment, soaked in a liquid nitrogen environment for quenching after being treated, and placed inthe liquid nitrogen environment after being quenched; and then the alloy is subjected to deep cooling aging treatment again, soaked in the liquid nitrogen environment for quenching after being treated, and placed in the liquid nitrogen environment after being quenched, the sample is completely stabilized at the liquid nitrogen temperature of minus 196 DEG C, and thus the magnesium alloy with thecorrosion resistance improved is obtained. By adoption of the method, the corrosion resistance of the Mg-Y-Nd based alloy can be remarkably improved while the excellent mechanical performance is ensured. The application range of the Mg-Y-Nd based alloy treated by the deep cooling treatment process is broad.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

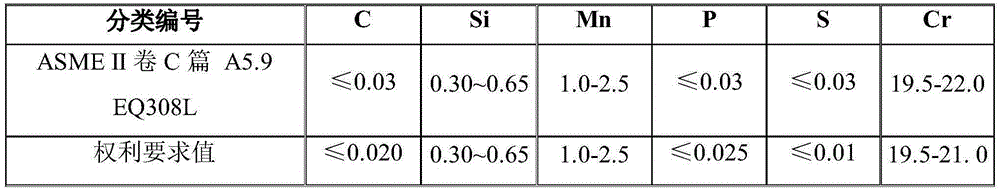

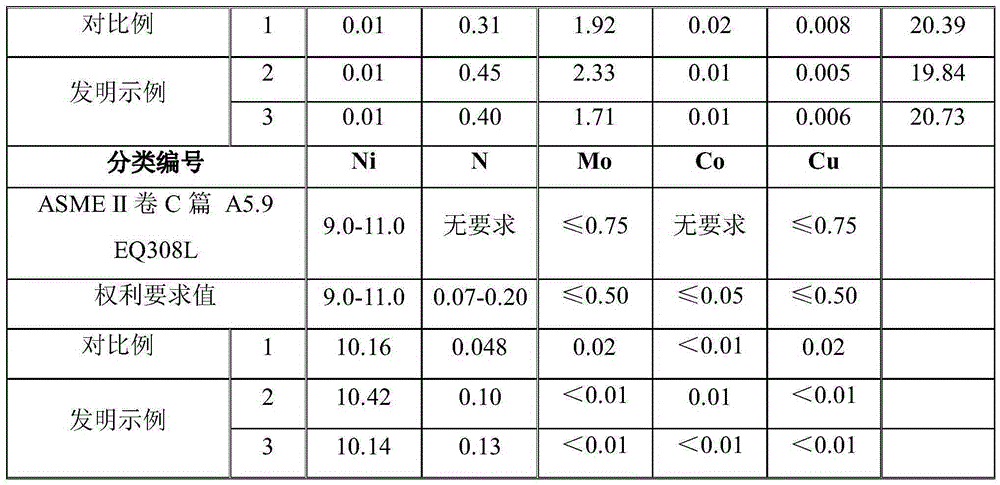

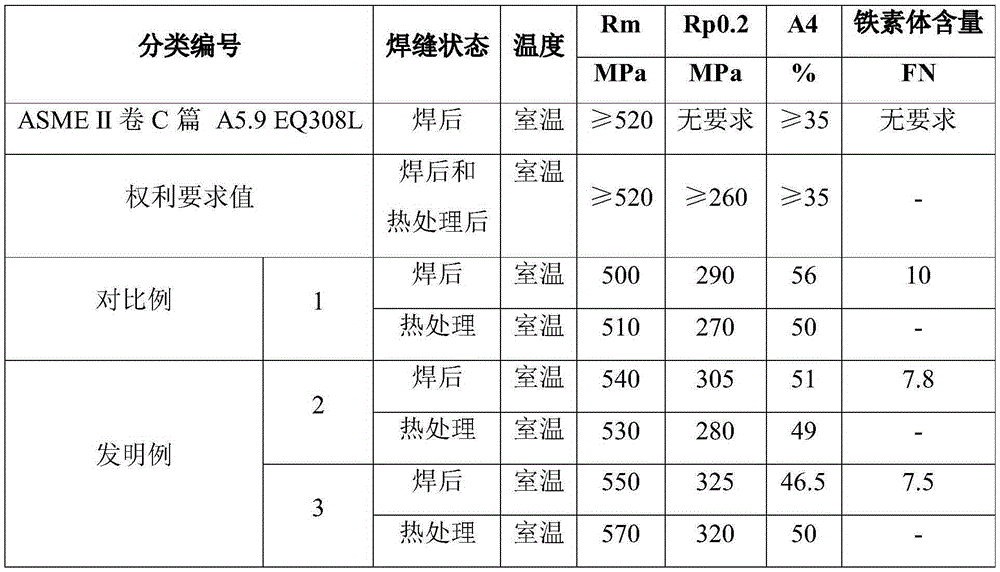

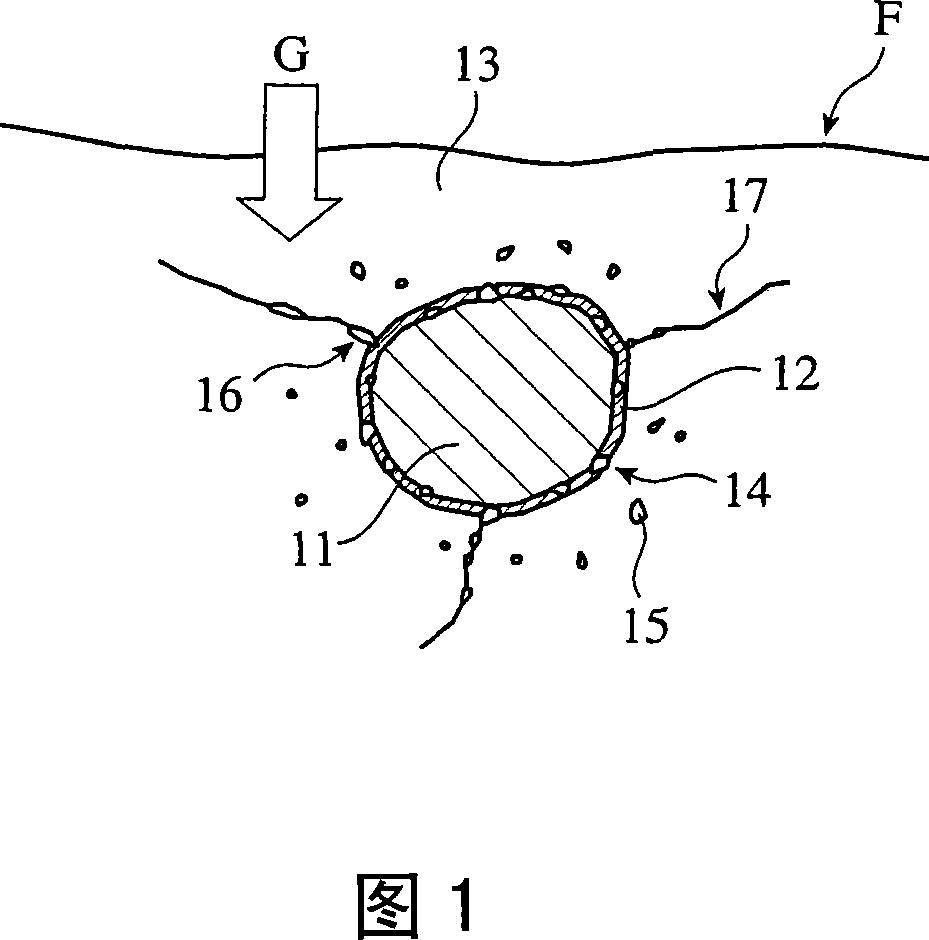

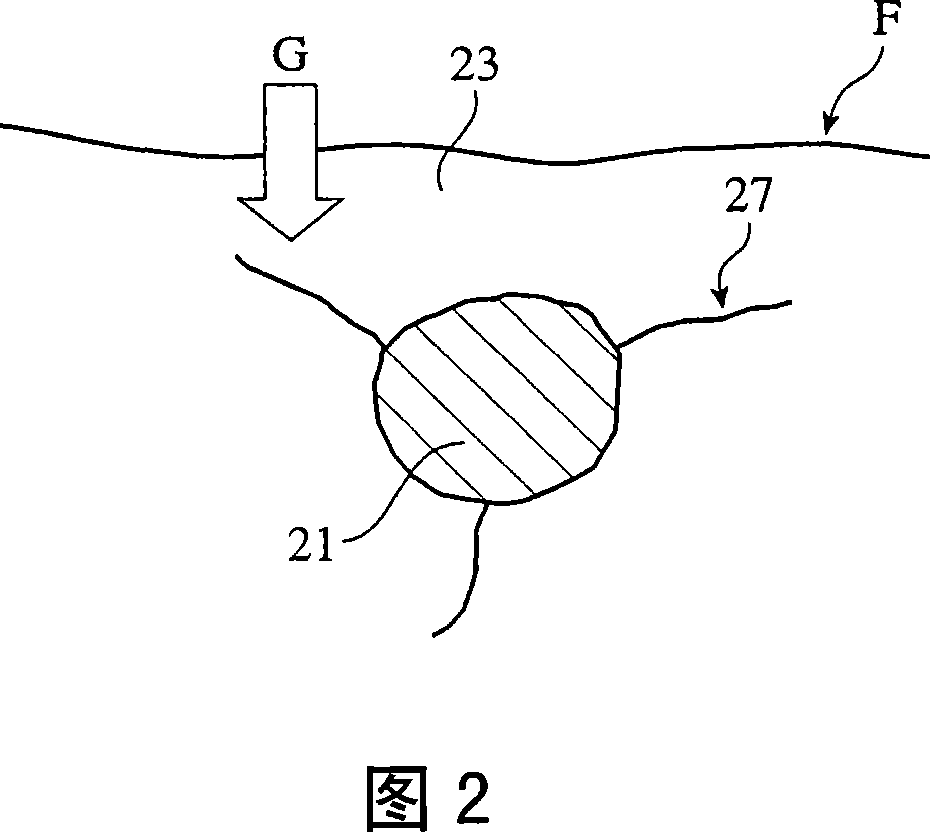

Stainless steel submerged-arc welding strip with improved room temperature tensile strength

InactiveCN105252170AIncreased tensile strength at room temperatureSolve the technical problem of low surfacing welding strengthArc welding apparatusWelding/cutting media/materialsRoom temperatureThermal treatment

The invention provides a stainless steel submerged-arc welding strip with improved room temperature tensile strength. The stainless steel submerged-arc welding strip with improved room temperature tensile strength comprises the following components by mass percentage: less than or equal to 0.020 of C, 0.30-0.65 of Si, 1.0-2.5 of Mn, less than or equal to 0.01 of S, less than or equal to 0.025 of P, 19.5-21.0 of Cr, 9.0-11.0 of Ni, less than or equal to 0.50 of Mo, less than or equal to 0.50 of Cu, less than or equal to 0.50 of Co, 0.07-0.20 of N and the balance Fe. After welding and thermal treatment, the room temperature mechanical properties of deposited metal is as follows: Rm is greater than or equal to 520Mpa, Rp0.2 is greater than or equal to 260MPa, and A4 is greater than or equal to 35%. Compared with the prior art, the stainless steel submerged-arc welding strip with the improved room temperature tensile strength has the advantages that the room temperature tensile strength of the welding strip is improved, and the manufacturing requirements of AP1000 and AP1400 nuclear power equipment are satisfied.

Owner:HARBIN WELDING INST LTD +2

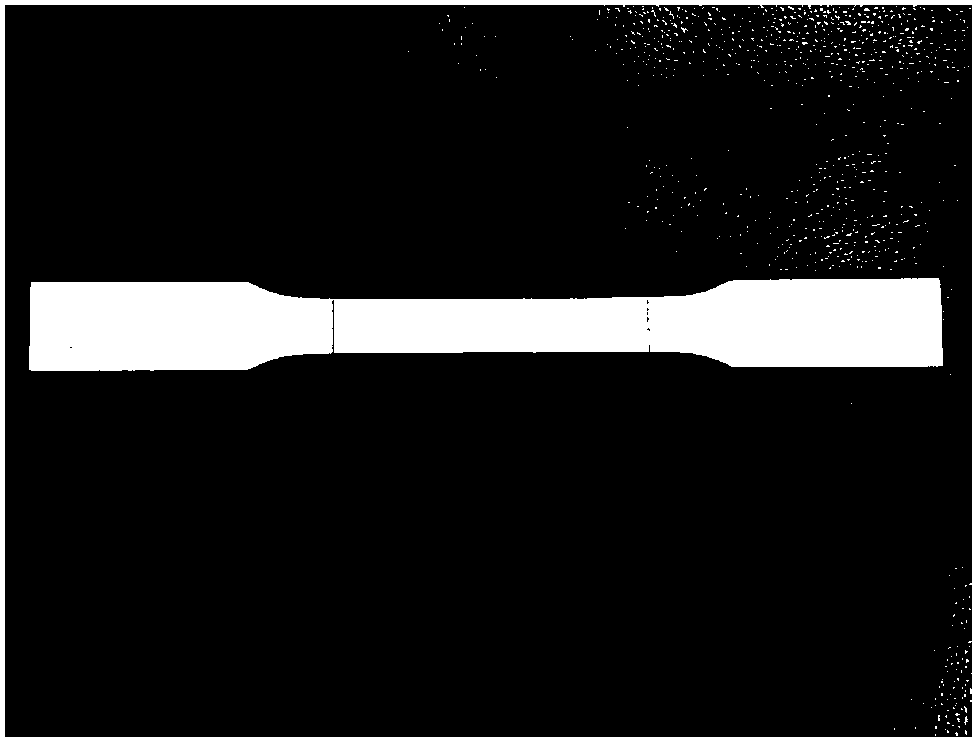

Forging method for improving mechanical property of TC4 alloy blade

InactiveCN102319865AIncreased tensile strength at room temperatureEngine componentsAfter treatmentRoom temperature

The invention relates to a forging method for improving the mechanical property of a TC4 alloy blade, which is used for solving the technical problem of poor mechanical strength in a traditional TC4 titanium alloy blade. The invention has the technical scheme that the forging method comprises the following steps of: carrying out solid hydrogen distributing treatment on the TC4 alloy; machining the obtained solid hydrogen distributing titanium alloy blank after treatment into a solid hydrogen distributing titanium alloy prefabricated blank; blowing sand and polishing; spraying a lubricating agent; heating before forging; forging the solid hydrogen distributing titanium alloy blank to obtain a solid hydrogen distributing titanium alloy blade forging piece; removing flash; blowing sand and polishing; and removing hydrogen. The TC4 titanium alloy is subjected to solid hydrogen distributing treatment, so that the tensile strength of the TC4 titanium alloy at room temperature is improved to be 1055-1065MPa from 925-985MPa in the background art; the yield strength of the TC4 titanium alloy at room temperature is improved to be 990-1000MPa from 884-945MPa in the background art; the tensile strength of the TC4 titanium alloy at 400DEG C is improved to be 700-710MPa from 630-675MPa in the background art; and the yield strength of the TC4 titanium alloy at 400DEG C is improved to be 605-615MPa from 593MPa in the background art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Heat resisting cast iron and exhaust system part therefrom

ActiveCN1926255AImprove oxidation resistanceImprove heat resistanceExhaust apparatusSilencing apparatusInter layerThermal fatigue

A heat resisting cast iron containing graphite for use in exhaust system parts used at temperatures exceeding 800 DEG C, which heat resisting cast iron comprises, on weight basis, 3.5 to 5.6% of Si and 1.2 to 15% of W, having an interlayer with W and Si concentrated therein on boundaries of graphite and the base structure. Exhaust system parts comprised of this heat resisting cast iron have an AC1 transformation point, as measured while raising temperature from 30 DEG C at a rate of 3 DEG C / min, of 840 DEG C or higher and exhibit a thermal crack life of 780 cycles or more at a thermal fatigue test in which heating and cooling are performed under such conditions that the upper limit temperature is 840 DEG C, the temperature amplitude 690 DEG C and the constraint ratio 0.25.

Owner:PROTERIAL LTD

High-strength-toughness and heat-resistant Al-RE-Y-Zr alloy suitable for pressure casting and preparation method thereof

The invention provides a high-strength-toughness and heat-resistant Al-RE-Y-Zr alloy suitable for pressure casting and a preparation method thereof. The alloy comprises the following elements in percentage by mass: 3-11% of RE, 0.1-5% of Y, 0.1-0.4% of Mg, 0.01-0.5% of Zr and the balance of Al element and inevitable impurity elements, wherein RE is at least one of La and Ce. After the high-strength-toughness and heat-resistant Al-RE-Y-Zr alloy is subjected to pressure casting, the room-temperature tensile strength of the die-cast alloy is up to 275MPa, and the elongation percentage is up to 19.5%; and the high-temperature tensile strength at 250 DEG C is up to 134MPa, and the elongation percentage is up to 25%. The alloy can be used without subsequent heat treatment, and satisfies the high-end demands for lightweight development in aerospace, military industry, automobiles and other industries.

Owner:SHANGHAI JIAO TONG UNIV

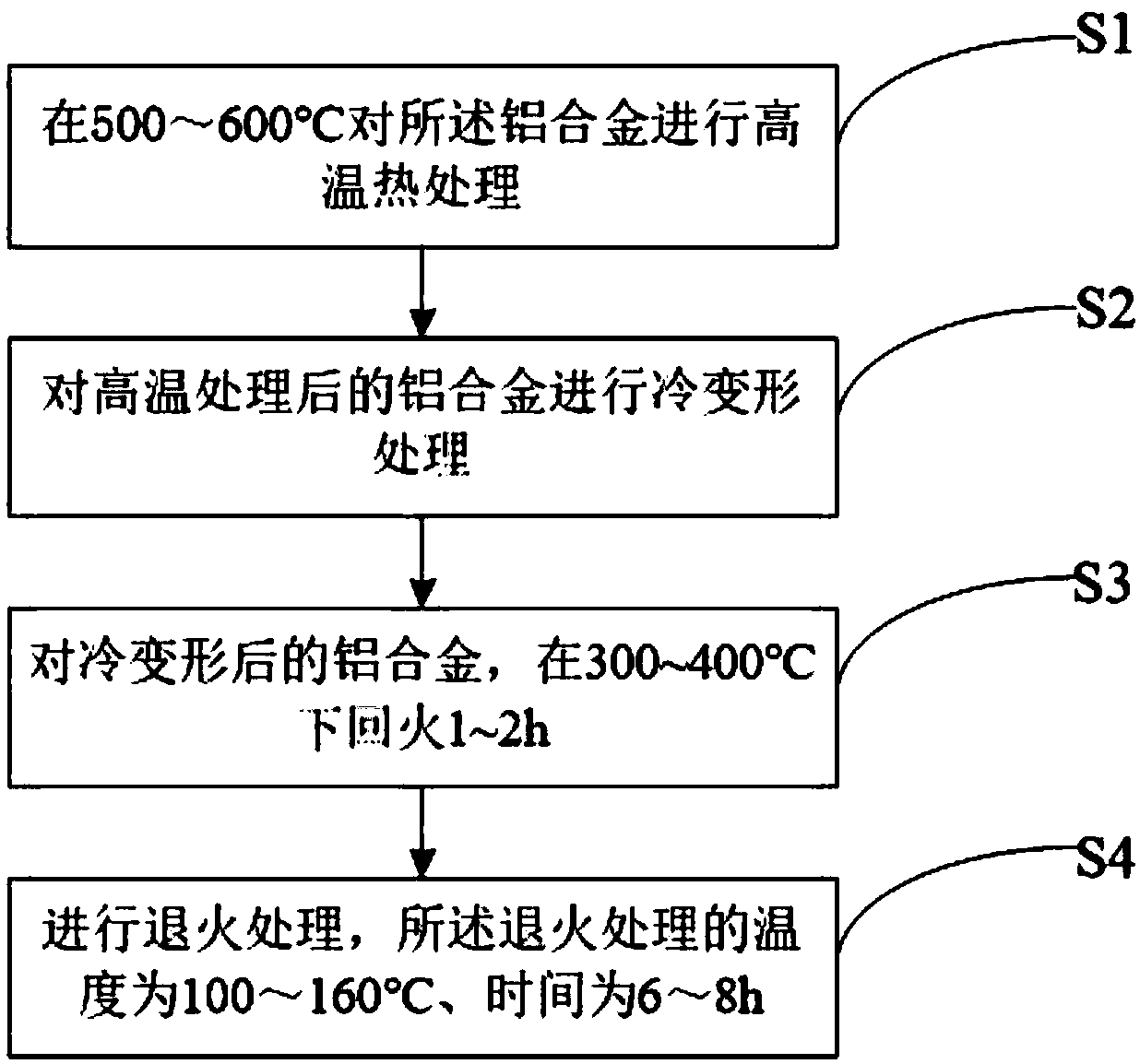

Aluminum alloy and heat treatment method thereof

The invention discloses heat treatment method of an aluminum alloy. The aluminum alloy comprises, by mass, 8%-10% of metal fibers, 5.5%-7.2% of Mg, 1.0%-2.5% of Zn, 0.8%-1.8% of Cu, 0.08%-0.18% of Sc,0.08%-0.18% of Zr, 0.12%-0.22% of Y, 0.02%-0.07% of Si, 0.02%-0.07% of Mn, 0.01%-0.03% of Er, 0.01%-0.03% of Ce, no more than 0.15% of impurities, and the balance Al. The heat treatment method comprises the steps that S1, high-temperature heat treatment is conducted on the aluminum alloy at the temperature of 500-600 DEG C, and after high-temperature heat treatment, quenching is conducted on thealuminum alloy with PAG quenching liquid, so that the aluminum alloy subjected to high-temperature treatment is obtained, wherein the content of PAG polymers in the PAG quenching liquid is 15-60 wt%,the temperature of the PAG quenching liquid is 40-80 DEG C, and the stirring speed of the PAG quenching liquid is 100-200 r / s; S2, cold-deformation treatment is conducted on the aluminum alloy subjected to high-temperature treatment, so that the aluminum alloy subjected to cold deformation is obtained; S3, the aluminum alloy subjected to cold deformation is tempered at the temperature of 300-400 DEG C for 1-2 h; and S4, afterwards, annealing treatment is conducted on the aluminum alloy at the temperature of 100-160 DEG C for 6-8 h, and thus, the strength of the aluminum alloy is improved. Theinvention further provides the aluminum alloy prepared through the heat treatment method.

Owner:益阳仪纬科技有限公司

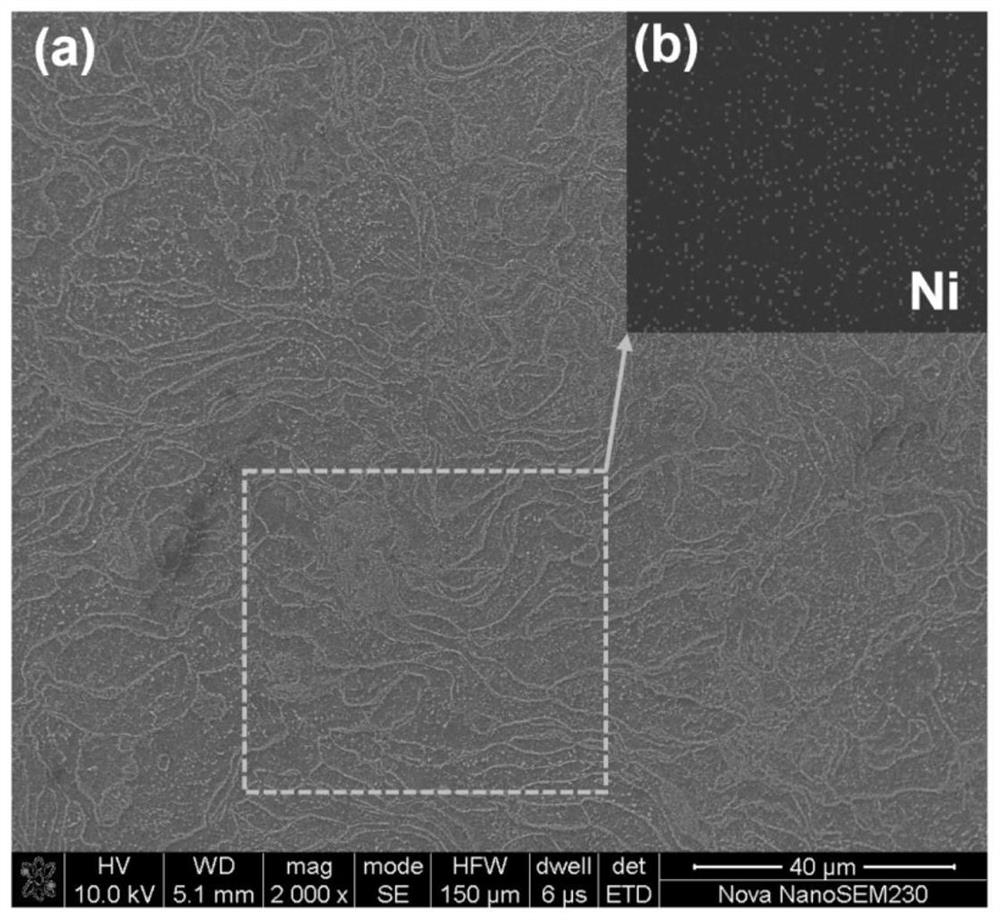

Method for improving comprehensive performance of carbon nanomaterial reinforced nickel-based superalloy

InactiveCN112008087AEliminate agglomerationEvenly dispersedMaterial nanotechnologyAdditive manufacturing apparatusOxidation resistantSuperalloy

The invention provides a method for improving the comprehensive performance of a carbon nanomaterial reinforced nickel-based superalloy, and belongs to the field of powder metallurgy and superalloy. Aiming at the problem that the high-temperature oxidation resistance of the carbon nanomaterial reinforced nickel-based superalloy is reduced, the surface of a carbon nanomaterial is coated with a compact Ni layer for the first time, so that the problems of poor mechanical property and high-temperature oxidation resistance caused by easy agglomeration of the carbon nanomaterial, poor bonding with amatrix interface and the like are solved. Through a specific ball milling process, mixed powder with uniformly dispersed carbon nanomaterials is obtained, and further uniform dispersion of the carbonnanomaterials is realized. A carbon nanomaterial reinforced Rene104 nickel-based composite material is prepared through spark plasma sintering (SPS), hot isostatic pressing, hot pressing, hot extrusion or hot forging, or 3D printing and other powder forming methods, so that the prepared material is excellent in mechanical property and excellent in high-temperature oxidation resistance, and the problem that the carbon nanomaterial reinforced metal-based composite material cannot be used as a high-temperature structural material is effectively solved.

Owner:CENT SOUTH UNIV

Flame-retardant graphene titanium-aluminum-based composite material and preparation method

ActiveCN108411154AImprove flame retardant performanceImprove heat strengthTitanium alloyMechanical property

The invention belongs to the technical field of titanium alloy materials, and relates to a flame-retardant graphene titanium-aluminum-based composite material and a preparation method. The composite material is prepared from the following components in percentage by mass: 0.01 to 1 percent of graphene oxide and a titanium and aluminum compound. By adoption of a method of combining temperature-controlled mechanical stirring, vacuumizing treatment, hot isostatic pressing and the like, interface bonding characteristics of graphene oxide and titanium and aluminum compound mixed powder are improved, and the bulk density and the subsequent forming property of the mixed powder are improved; furthermore, the graphene oxide is basically decomposed to form graphene which is uniformly dispersed, so that the excellent mechanical property and the physical and chemical properties of the graphene are fully exerted; the flame retardant property of the obtained composite material is twice that of a common high-temperature titanium alloy or above, and the heat resistance is higher; and a brand-new technical scheme is provided for solving titanium fire of an aero-engine. The flame-retardant graphenetitanium-aluminum-based composite material is a novel material concept; a prepration process is short, can accurately control parameters, and is suitable for batch preparation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

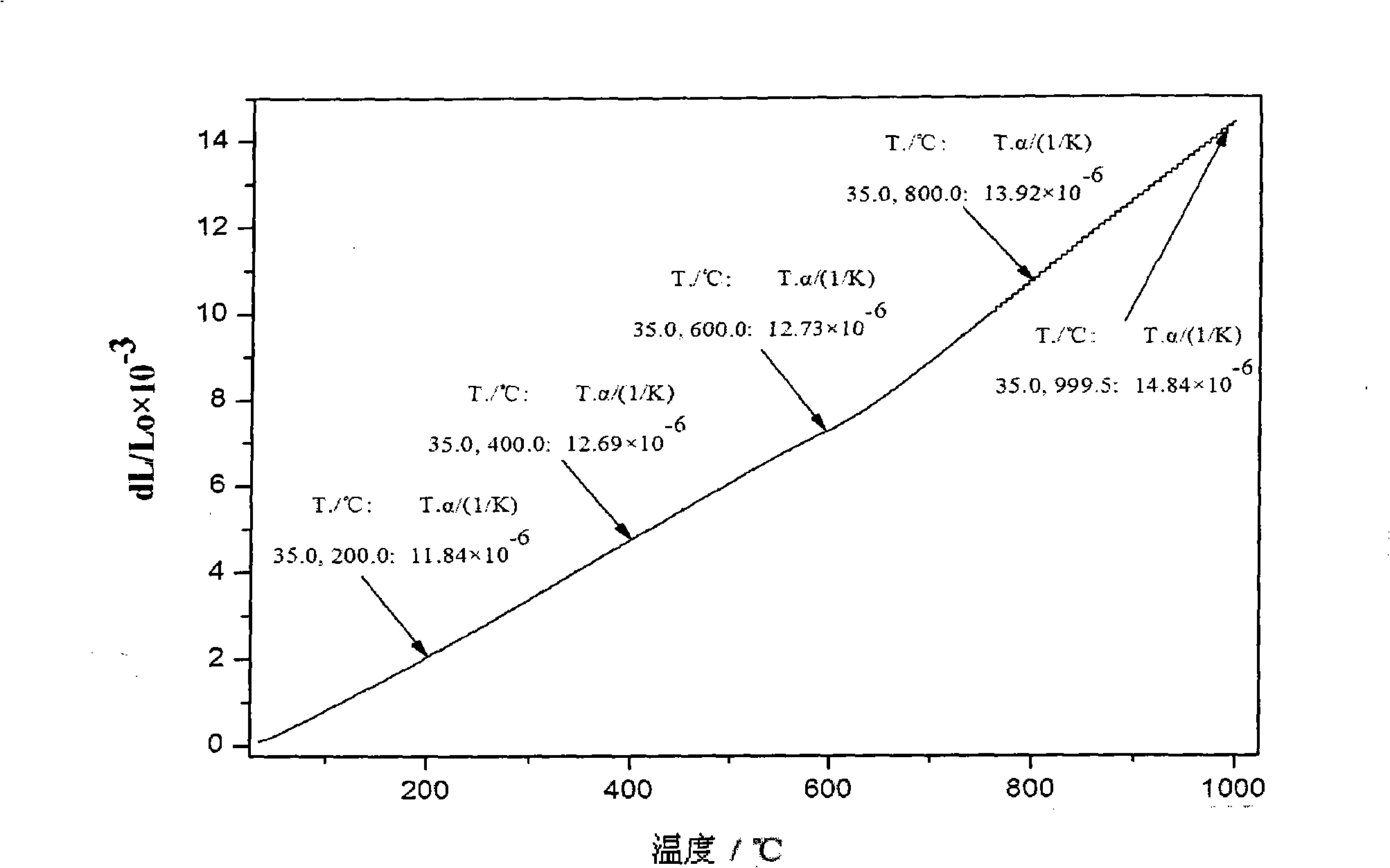

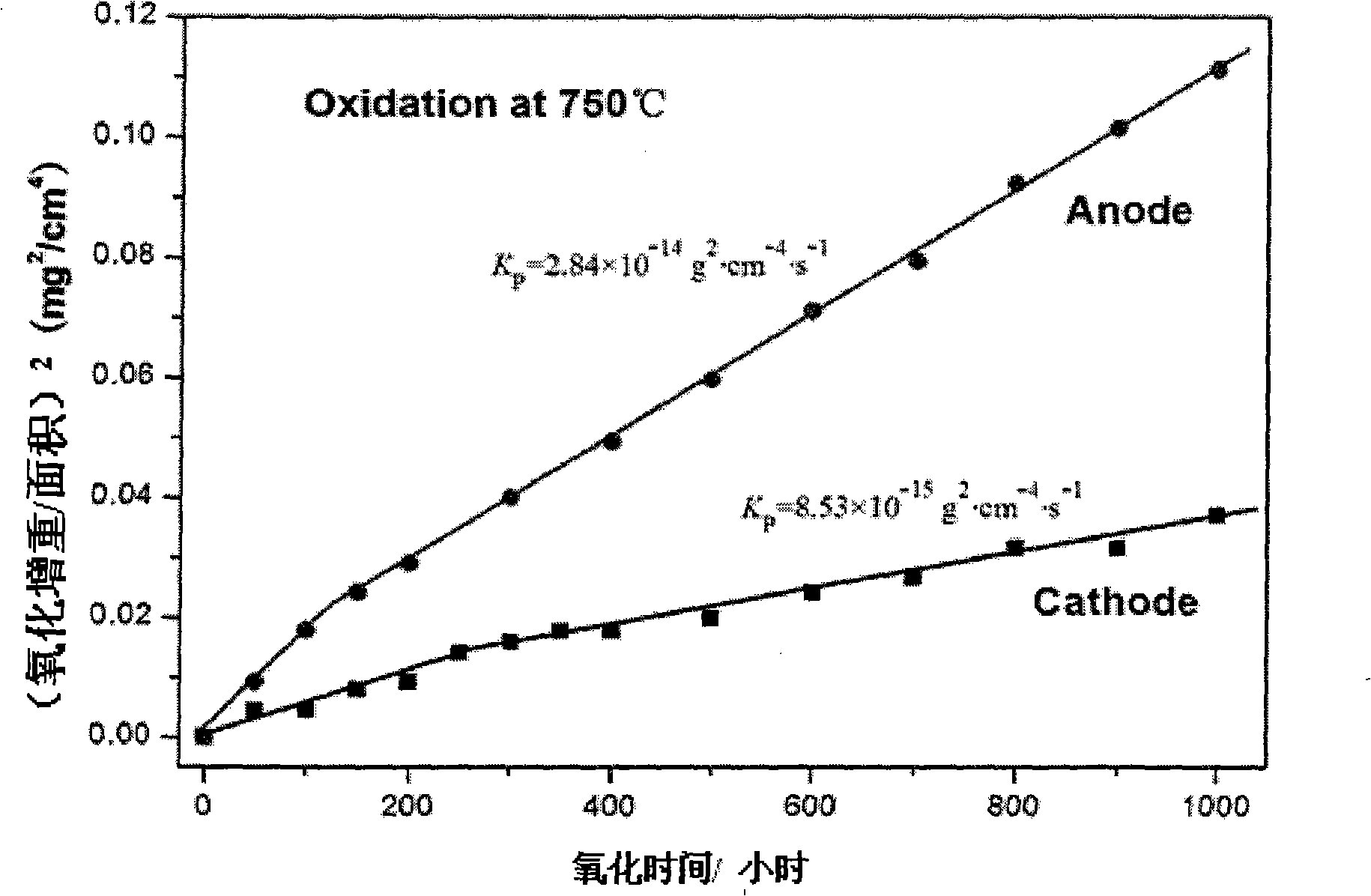

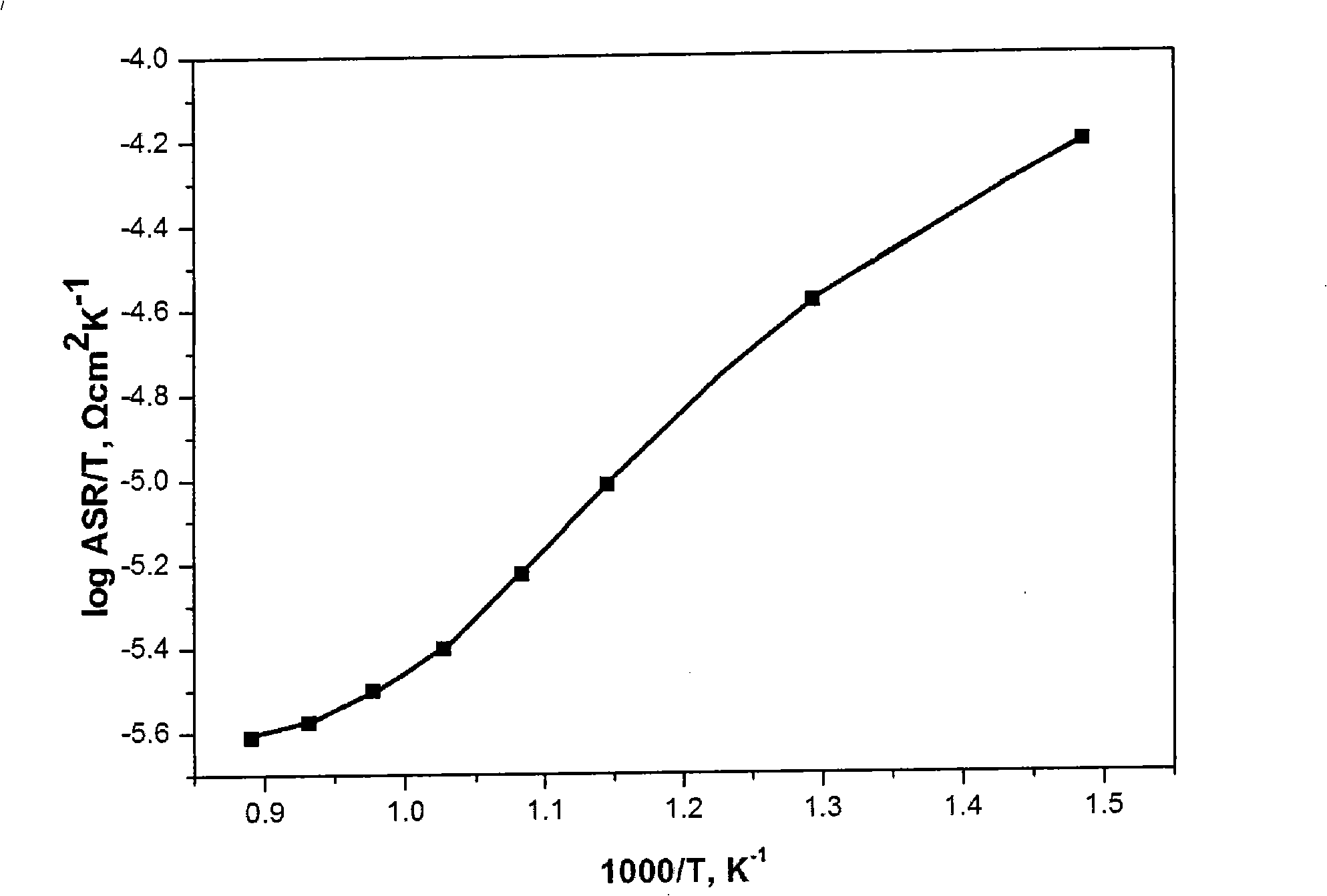

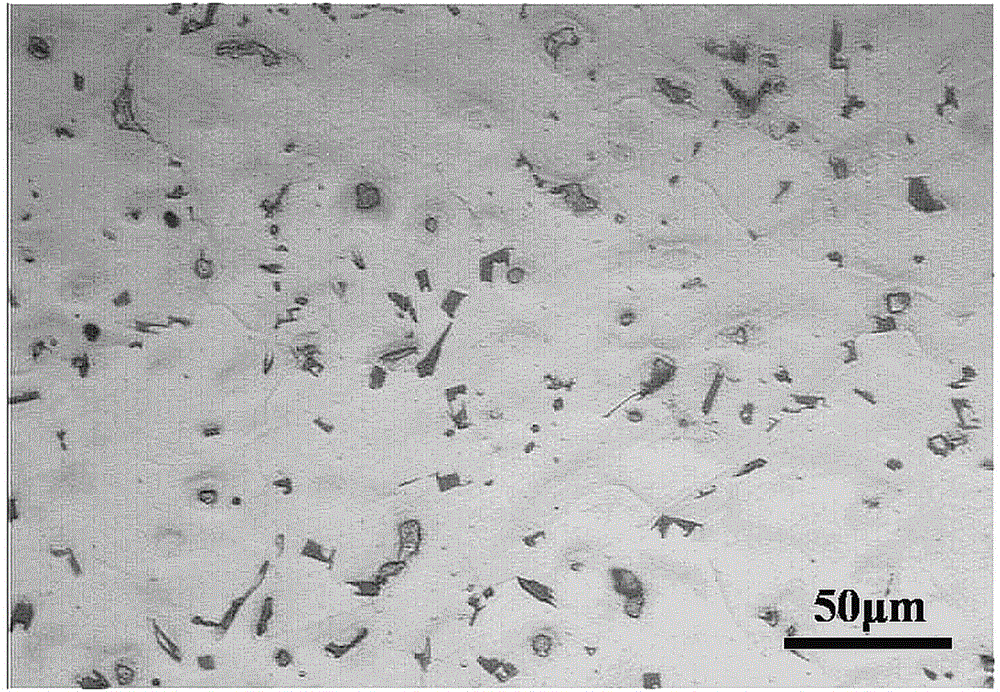

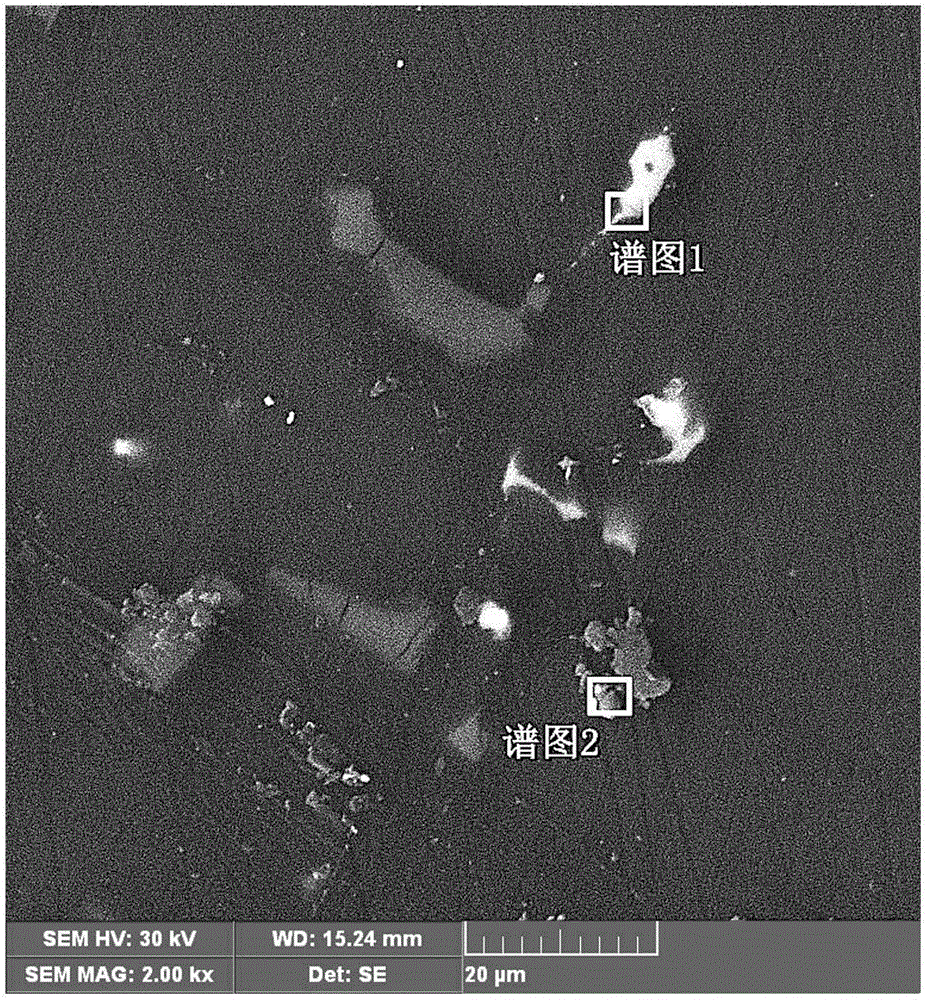

Nickel-based expansion alloy for metal connector of medium temperature plate type solid-oxide fuel battery

InactiveCN101333613AIncreased tensile strength at room temperatureGood expansion compatibilityInterconnectorChemical composition

The invention belongs to the alloy steel field, in particular to a nickel base expanding alloy used on an intermediate temperature flat-plate type solid oxide fuel cell metallic interconnector. The alloy has chemical compositions (in weight percent): Mo 18.0 to 24.0 percent, Cr 10.0 to 14.0 percent, Co 2.5 to 3.5 percent, W 3.5 to 4.5 percent, Ti 1.0 to 1.5 percent, Mn 0.8 to 1.2 percent, Si<=0.05 percent, La<=0.02 percent, Y<=0.01 percent, C<=0.005 percent, S<=0.005 percent, P<=0.005 percent, balance Ni. Compared with the prior art, the alloy has the advantages of good compatibility of expansion properties with surrounding materials in the solid oxide fuel cell operational environment, good pyroconductivity, oxidation resistance and mechanical property. The tensile strength of alloy is higher than 1100MPa under room temperature, the elongation at break is higher than 18 percent, and the coefficient of expansion from the room temperature to 1000DEG C is controlled under 15x10<-6>DEG C<-1>.

Owner:CENT IRON & STEEL RES INST

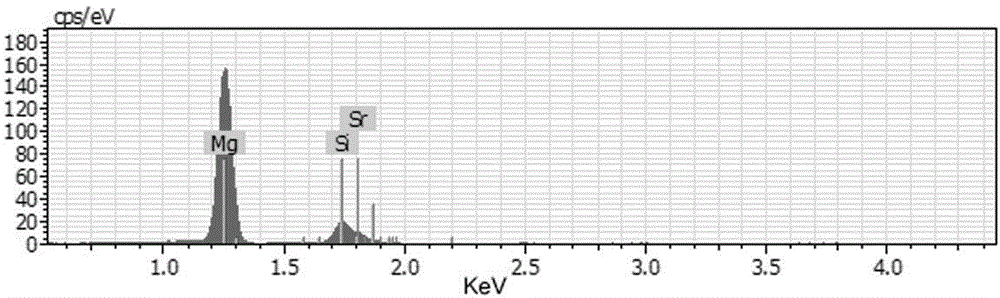

Alkaline-earth element modified heat-resistant magnesium alloy and preparation method thereof

The invention relates to an alkaline-earth element modified heat-resistant magnesium alloy. The magnesium alloy comprises the following components by weight percent: 2.5-3.4% of Al, 0.5-1.4% of Si, 0.05-0.14% of Mn, 0.05-1.54% of Sr and the balance of Mg. The magnesium alloy is modified by adding Mg-Si and Al-Sr intermediate alloys to the magnesium alloy by a smelting method, and T6 heat treatment is carried out on the obtained as-cast heat-resistant magnesium alloy. Compared with the prior art, the prepared heat-resistant magnesium alloy has higher room temperature tensile strength and high temperature tensile strength and better plasticity.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Method for improving fluidity of water glass for casting through polyethylene glycol

ActiveCN110052572AImprove surface potential energyImproved solvation abilityAdditive manufacturing apparatusFoundry mouldsPolyethylene glycolComposite material

The invention relates to a method for improving the fluidity of water glass for casting through polyethylene glycol. The method comprises the steps that the polyethylene glycol serves as a modifier tobe added in a water glass solution for making a reaction, and a modified water glass binder can be obtained; and under the same preparation conditions, compared with a water glass binder without thepolyethylene glycol modifier, the fluidity of the modified water glass binder is improved, the normal temperature tensile strength is improved, and the normal temperature flexure strength is reduced.The fluidity of the modified water glass binder is good, and the modified water glass binder is suitable for sand mold 3DP manufatcuring.

Owner:SOUTHEAST UNIV

TiC/AI high-damp composite material and preparing method thereof

A high damping TiC / Al composite material and its preparation are disclosed. It consists of Cu 4 - 5.3 wt%, Ti 0.15 - 0.35 wt%, Mn 0.3 - 1 wt%, Cd 0 - 0.25 wt%, V 0 - 0.3 wt%, Zr 0 - 0.2 wt%, B 0 - 0.06 wt%, TiC 0.1 - 20 wt%, and balanced of Al. It is prepared by making TiC granules contained high damping pre-fabricated blocks by high temperature vacuum sintering process, melting Al ingots, adding a coating agent on the molten Al metal and the said dry pre-fabricated blocks to melt, stirring, adding Cu, Ti, Mn or Cu, Ti, Mn, Cd or Cu, Ti, Mn, Cd, V, Zr, B to regulate chemical constituent, settling, and casting into ingots to obtain original high damping TiC / Al material. The tensile strength of the said material has obviously been increased and it can be used in development of structure-functional materials.

Owner:SHANGHAI JIAO TONG UNIV

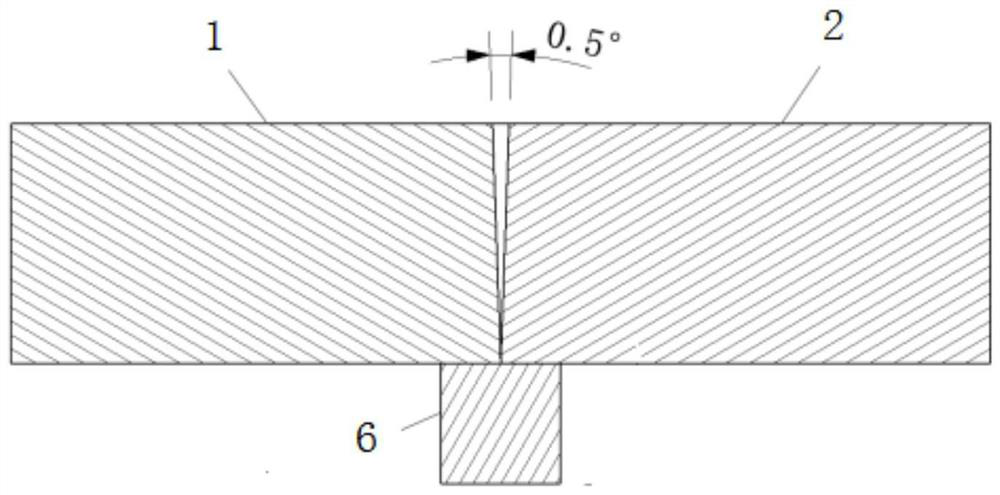

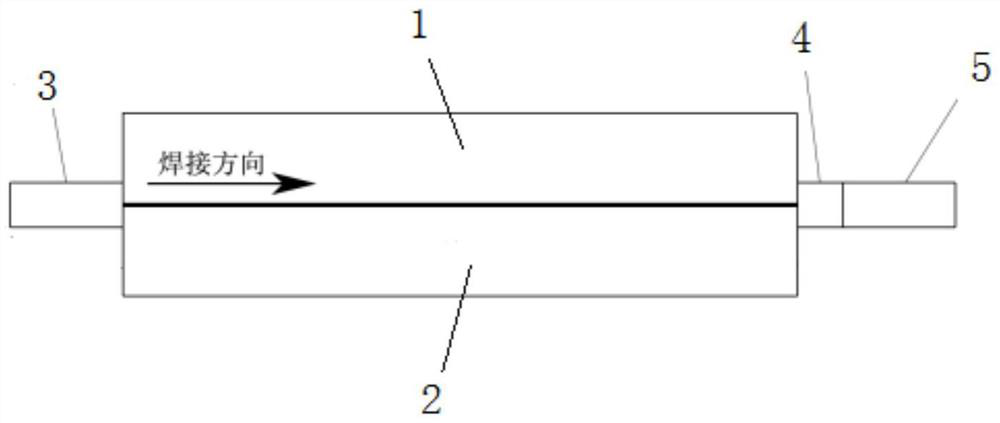

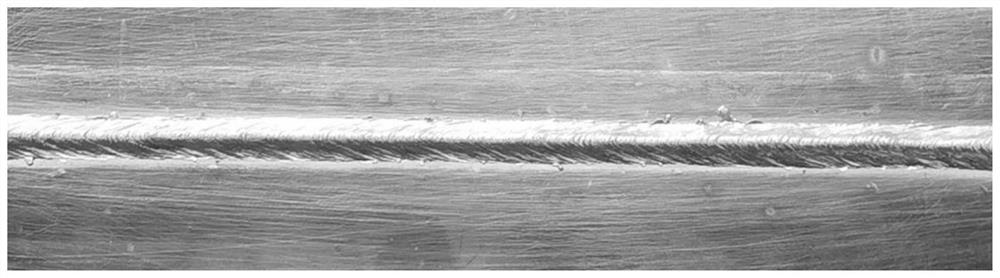

Vacuum electron beam welding method for low-activation martensitic steel and nuclear fusion reactor

PendingCN114589387AWeld firmlyReduce distortionNuclear energy generationElectron beam welding apparatusWeld seamVacuum electronics

The invention discloses a low-activation martensitic steel vacuum electron beam welding method and a nuclear fusion reactor. The method comprises the steps of machining a V-shaped groove, placing a leading-in plate, a transition leading-out plate, a leading-out plate and a base plate at the welding position, conducting positioning welding, conducting penetration welding and the like. The nuclear fusion reactor comprises a component formed by welding the low-activation martensitic steel through the vacuum electron beam welding method. The welding method is simple, the welding seam which is free of cracks, small in splashing and smooth in appearance fish scale line transition can be obtained, the B-level welding seam requirement of ISO13919-1 is met, a weldment is small in deformation, the room-temperature tensile strength of a welded joint is larger than that of base metal, and a lateral bending test of the welded joint is qualified.

Owner:合肥聚能电物理高技术开发有限公司

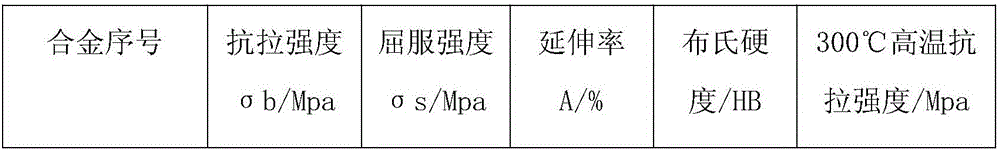

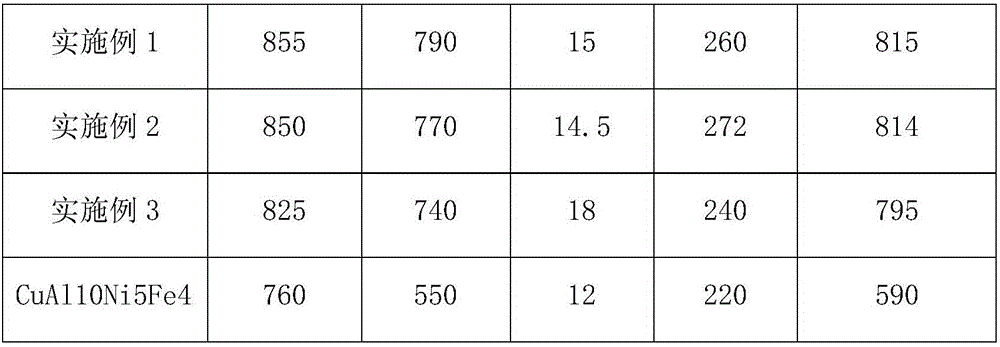

Novel material for retraction ring of traction motor of high-speed train and preparation method of novel material

ActiveCN106676320AIncreased tensile strength at room temperatureHigh temperature tensile strengthElectric machineryHigh intensity

The invention discloses a novel material for a retraction ring of a traction motor of a high-speed train and a preparation method of the novel material and particularly relates to the technical field of motor rotor material manufacturing. The novel material comprises the chemical compositions including, by weight, 13.0-16.0% of Ni, 1.8-2.8% of Al, 0.5-1.5% of Mn, 0.8-1.8% of Fe, and the balance Cu. The preparation method includes the steps of proportioning, smelting, pouring, forging and annealing heat treatment. The alloy retraction ring has high strength, elongation and high-temperature strength, the strength at the room temperature reaches 850 MPa, the elongation reaches 15%, and the strength at the high temperature of 300 DEG C reaches 815 MPa. The cooper alloy retraction ring can meet the requirements for high rotation speed, high working temperature and good stability of asynchronous traction motors, and can particularly meet the requirement for good performance at 350 DEG C.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com