Extrusion type aluminium alloy

An aluminum alloy, extruded technology, applied in the field of aluminum alloy, can solve the problem that welding performance and high strength are difficult to match

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

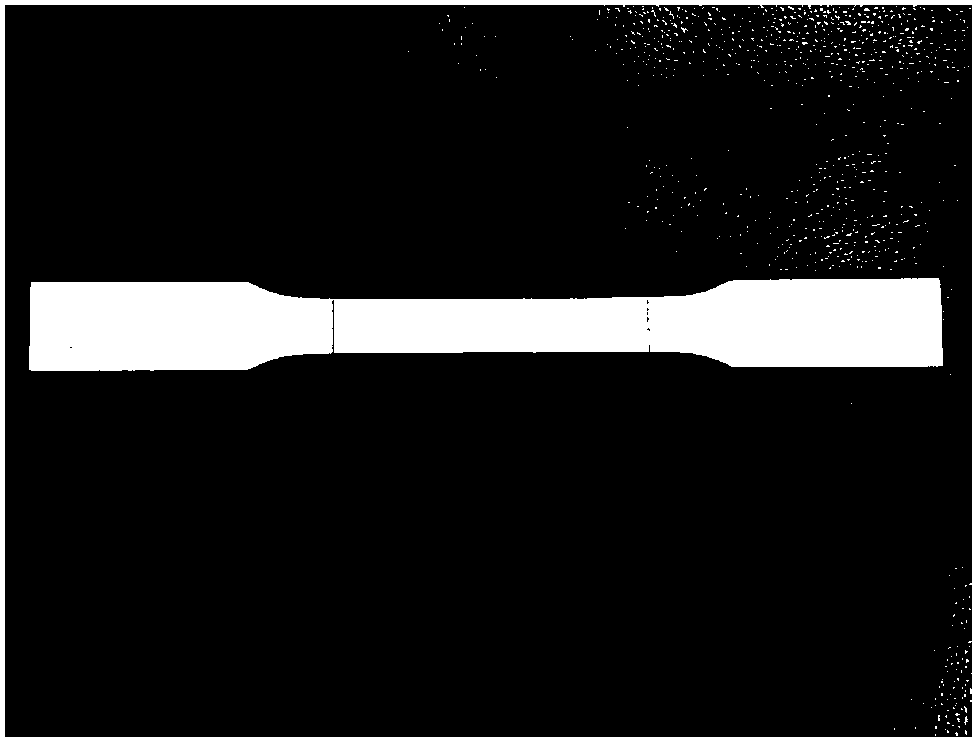

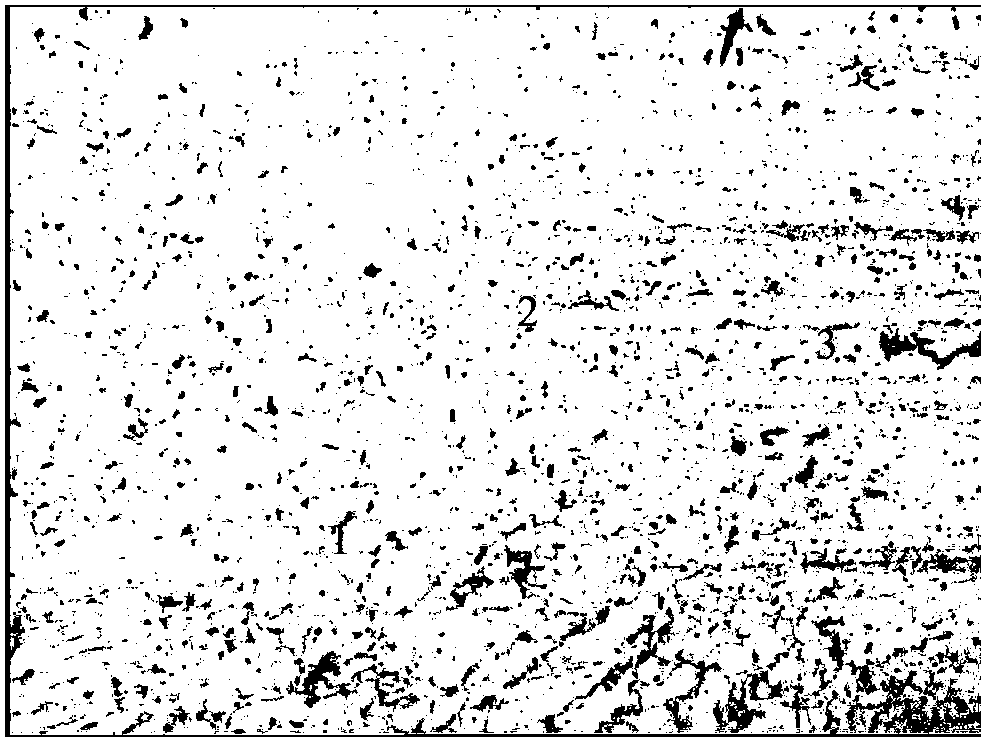

[0023] Alloy composition (by weight percentage): Zn5.0%; Mg2.0%; Mn0.6%; Cu0.4%; Cr0.3%; Zr0.1%; Sc0.03%; Fe≤0.2%; Si≤ 0.1%; the balance is Al; pure Al, pure Mg, pure Zn, pure Cu, Al-10wt.%Mn, Al-5wt.%Cr, Al-2wt.%Sc, and Al-5wt are obtained according to the above ingredients .%Zr is used as raw material, wherein the purity of pure Al, pure Mg, pure Zn, and pure Cu is ≥99.99wt.%. The prepared raw materials are alloyed in a 10-ton melting furnace, and ingots are obtained after semi-continuous casting. The furnace temperature is 728°C, the furnace mouth temperature is 709°C, the filter box inlet temperature is 701°C, the platform inlet temperature is 681°C, and the platform end temperature is 663°C; the casting speed is 25-35mm / min, and the cooling water flow rate is 20-30m3 / h, the water temperature at the cooling water outlet is 22°C. After the ingot is cooled, it is homogenized at 460°C for 24 hours under a protective atmosphere, and then extruded. The forming pattern is divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com