Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "6111 aluminium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

6111 is the premiere aluminum alloy used for automotive paneling. Favorable characteristics include corrosion resistance and precipitation hardening. Extensive work has been done on various aging techniques by Dr. George K. Quainoo.

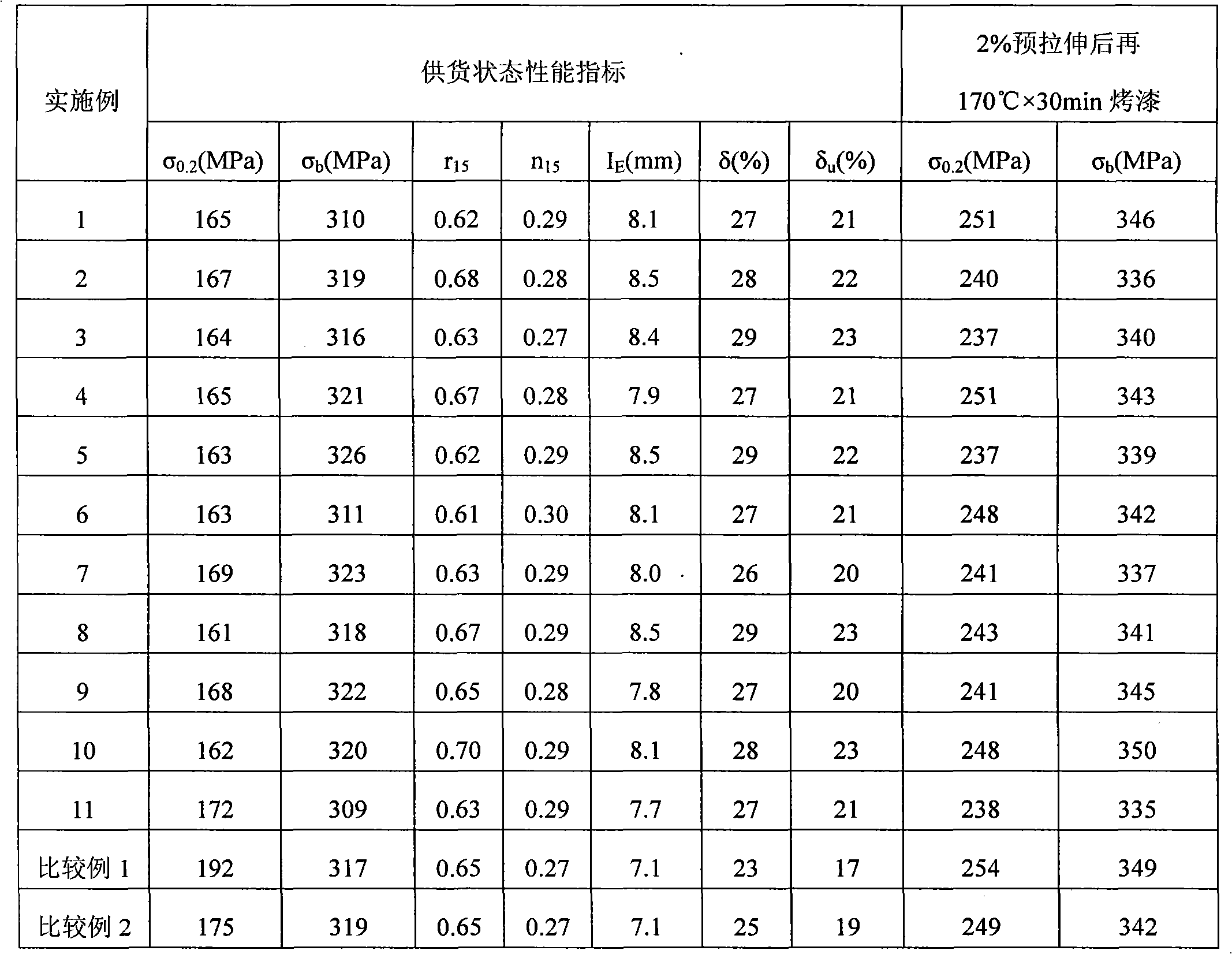

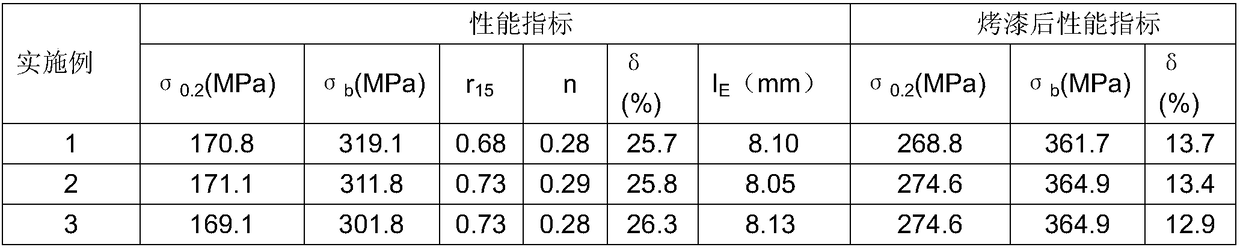

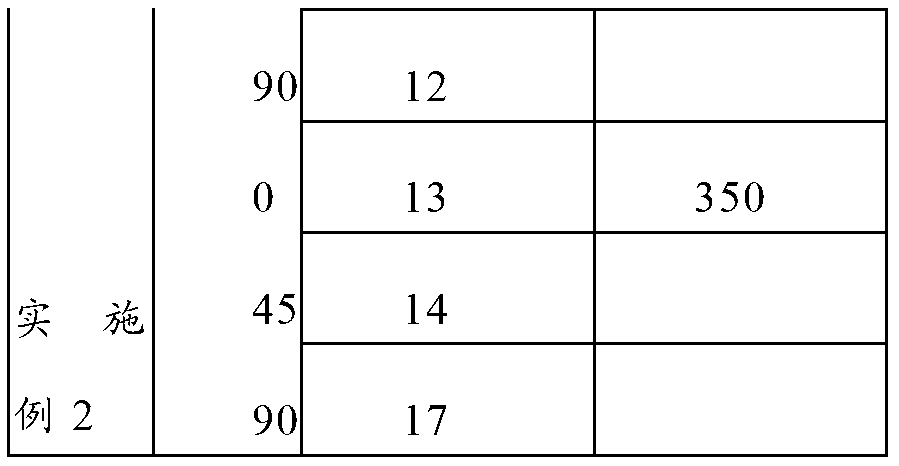

Preheat treatment for improving automobile plate of 6111 aluminium alloy formation and baking paint hardening performance

The invention is about the pretreatment of the formability of the 6111 A-alloy autocar board and the sclerosing of the stoving varnish. The process is to treat the 6111 board by the solution hardening, stable it for 2h-5d in the room temperature, then to preheating treatment for 7min-15min in 180 DEG C-200 DEG C. The formability of the 6111 A-alloy autocar board and the sclerosing of the stoving varnish are all improved qpparently, it is used to improve the presswork ratio. So the car factory can use the A-alloy board to produce the car body instead of the steel plate.

Owner:NORTHEASTERN UNIV

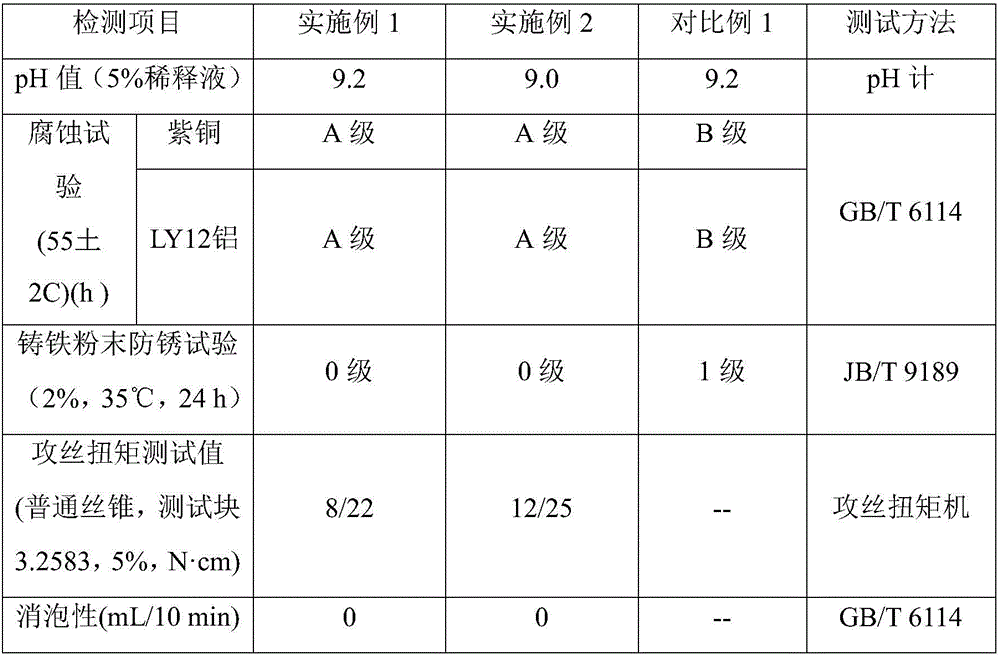

Long-life and low-foam emulsion for aluminium alloy cutting

InactiveCN106281616AImprove the lubrication effectHigh surface finishLubricant compositionMaterials science6111 aluminium alloy

The invention relates to a long-life and low-foam emulsion for aluminium alloy cutting, belonging to the technical field of metal processing media. The emulsion has the beneficial effects that the lubricating capacity of cutting fluid and the surface finish of workpieces are improved by adopting combination of extreme pressure lubricants and oily lubricants; the alkali retention capacity and pH stability of the cutting fluid are improved by adopting optimized alcohol amine combination and through cooperation of monoethanolamine, triethanolamine and special alcohol amines; the requirements of different aluminium alloys for aluminium corrosion inhibition are achieved by adopting compound aluminium corrosion inhibitor combination and combining the characteristics of phosphorus-containing aluminium corrosion inhibitors and silicon-containing aluminium corrosion inhibitors; the stability of the cutting fluid primary fluid and a diluent is enhanced and adverse effects on machine tool paint are avoided by adopting special coupling agent combination; control of foam in a high pressure fluid supply system and a high precision filtering system is achieved by adopting the foam inhibition properties of the systems and the defoaming properties of defoaming agents.

Owner:NANJING KERUN LUBRICANTS

Production process of aluminium alloy casting rod specially used for rotary-swaged D061 wheel-type automobile hub

An aluminium alloy casting rod specially used for rotary-swaged D061 wheel-type automobile hubs comprises the following components by weight: 0.70-0.80% of Si, 0.20-0.3% of Fe, 0.20-0.30% of Cu, 0.06-0.10% of Mn, 0.90-1.20% of Mg, 0.05-0.15% of Cr, not more than 0.05% of Zn, not more than 0.05% of Ti, and the balance of Al. The process comprises the following steps: weighing the components of Si, Fe, Cu, Mn, Cr, Zn, Ti, and Al, melting the components in a melting furnace, when the temperature reaches 735+ / -5 DEG C, removing scum, adding Mg according to the weight ratio, uniformly stirring, and removing slag to prepare aluminium alloy melt; introducing the aluminium alloy melt into a standing furnace, when the temperature reaches 735+ / -5 DEG C, adding refining powder and performing slag removing and refining; degassing with argon and an Al-Ti-B rod, and refining; putting the refined aluminium alloy melt into a standing furnace at a temperature of 730 DEG C-740 DEG C, standing for 30 min, performing casting molding by a hot-top casting machine, treating the cast aluminium alloy casting rod, performing uniform annealing treatment and cooling treatment, and performing detection to obtain the aluminium alloy casting rod specially used for rotary-swaged D061 wheel-type automobile hubs when detection shows that the product is qualified.

Owner:秦皇岛开发区美铝合金有限公司

Production technology for aluminium alloy casting rod special for automobile Peugeot hubs

The invention relates to a production technology for an aluminium alloy casting rod special for automobile Peugeot hubs. The casting rod comprises the following compositions in percent by weight: 95.95-97.30% of Al, 0.8-1.3% of Si, 0.20-0.4% of Fe, 0.1% or less of Cu, 0.5-0.9% of Mn, 0.8-1.0% of Mg, 0.15% or less of Cr, 0.1% or less of Zn and 0.05-0.10% of Ti. The production technology comprises: weighing the compositions, placing in a melting furnace for melting with the melting temperature of 745 DEG C + / -5 DEG C, removing slag by employing a metallurgy slag-removing apparatus, so as to prepare an aluminium alloy melt; introducing the aluminium alloy melt into a standing furnace, adding a fluxing agent powder No. 2 for refining for 30 min, then standing the refined alloy aluminium melt in the standing furnace with the standing furnace temperature of 735 DEG C-745 DEG C for 30 min; performing molding casting on the aluminium alloy melt by employing a hot-top casting machine, so as to obtain an aluminium alloy casting rod; processing the casted aluminium alloy casting rod, and placing in a homogenization furnace to process for 12 h; transferring the aluminium alloy casting rod subjected to homogenization processing into a cooling chamber, and employing a blower fan to perform forced cooling, so as to prepare the aluminium alloy casting rod special for automobile Peugeot hubs.

Owner:秦皇岛开发区美铝合金有限公司

Aluminium alloy section for high speed train body and manufacturing method of aluminium alloy section

The invention provides an aluminium alloy section for a high speed train body and a manufacturing method of the aluminium alloy section. The aluminium alloy section comprises the following components in percentage by mass: 5.5-6.5 percent of Zn, 1.5-2.5 percent of Mg, 0.5-1.0 percent of Si, 0.1-0.3 percent of Ru, 0.1-0.3 percent of V, 0.03-0.05 percent of Ti, and the balance of Al and inevitable impurities, wherein the content of single impurities is lower than 0.05%, and the total content of the impurities is lower than 0.15%. The aluminium alloy section has the advantages of being high in strength, high in plasticity, high in corrosion resistance and high in welding performance, the tensile strength of the aluminium alloy section is higher than 450 MPa, the yield strength of the aluminium alloy section is higher than 380 MPa, the elongation of the aluminium alloy section is higher than 10%, and the aluminium alloy section is suitable for manufacturing a center sill, a sleeper beam and an end beam of an underframe of the high speed train body and a bottom panel, a top panel, a side wall and an end wall of a carriage; and the aluminium alloy section has a wide market prospect.

Owner:佛山市三水凤铝铝业有限公司 +1

Aluminium alloy engine cast iron cylinder sleeve processing technology

ActiveCN103894586AWill not negatively affectInhibitory responseHot-dipping/immersion processesMetalCast iron

The invention relates to an aluminium alloy engine cast iron cylinder sleeve processing technology. An HT250 cast iron cylinder sleeve is immersed in a plating auxiliary with the temperature ranging from 60 DEG C to 70 DEG C after surface treatment, so that plating assistant processing is conducted on the surface of the HT250 cast iron cylinder sleeve for 6-10 min in the plating auxiliary, and then drying is conducted; the HT250 cast iron cylinder sleeve is placed in zinc-aluminium alloy melt for hot dipping after plating assistant processing, and cooling is conducted; then the HT250 cast iron cylinder sleeve is placed in aluminium alloy melt for hot dipping; the HT250 cast iron cylinder sleeve plated with aluminium alloy is taken out, and aluminium alloy melt casting is conducted; cooling is conducted, mould opening is conducted, and aluminium alloy engine cylinder body composite materials are taken out. According to the technology, the cast iron cylinder sleeve is processed through the prepared plating auxiliary, two steps of hot dipping and the composite casting technology are combined to achieve more than 99.9% of metallurgical bonding between ZL101A aluminium alloy and HT250 cast iron, and the aluminium alloy engine cast iron cylinder sleeve processing technology is simple, practical, low in cost and prominent in effect.

Owner:烟台路通精密科技股份有限公司

Processing method for increasing stamping formability of 6111 aluminium alloy automobile sheet

InactiveCN101885000ASolve bottlenecksImprove stamping yieldRoll mill control devicesMetal rolling arrangementsRoom temperatureIngot

The invention relates to a processing method for increasing the stamping formability of the 6111 aluminium alloy automobile sheet. The method comprises the following steps: 1. performing heat treatment to 6111 alloy ingot, which is prepared through semicontinuous casting, at 220-480 DEG C for 1-15h, heating to 550 DEG C with the furnace, keeping temperature for 24h to perform the conventional homogenizing treatment; 2. cropping the ingot and milling the face of the ingot, heating to 440-450 DEG C for hot rolling, wherein hot rolling adopts the mode of longitudinal and lateral alternation, thetotal rolling deformation is more than 85%, the finishing temperature is more than 300 DEG C and the final thickness of the hot rolled sheet is 6mm; 3. keeping the temperature of the hot-rolled sheetto 420-430 DEG C for 1h-2h, performing intermediate annealing, performing cold rolling to ensure the thickness of the sheet is 0.8 mm-1.0 mm, wherein the cold deformation is more than 75%; 4. keepingthe temperature of the cold-rolled sheet to 550 DEG C for 7min, performing solution treating and water quenching, standing at the room temperature for 1min-48h; 5. performing pre-aging treatment in adrying box at 150-220 DEG C for 4min-15min; and 6. standing at the room temperature for more than two weeks to obtain T4P temper. After the sheet is processed by the method of the invention, the stamping formability and after-painting strength are obviously improved, thus facilitating to increase the rate of stamping products and reduce the stamping cost.

Owner:NORTHEASTERN UNIV LIAONING

Aluminium alloy for sliding bearing

The present invention relates to one kind of aluminum alloy for sliding bearing, and belongs to the field of material science. The chemical composition of the aluminum alloy includes Sn 5.0-8.0 wt%, Cu 1.5-2.5 wt%, Ni 0.6-1.9 wt%, S 0.2-0.8 wt%, Fe 0.3-0.7 wt%, Mn 0.05-0.1 wt%, Mg 0.4-0.9 wt%, Ti 0.1-0.5 wt% and Zn 0.4-0.7 wt%. The aluminum alloy has properly regulated components and added Mn and Zn components, and possesses good physical performance and high lipophilicity.

Owner:王士忠

Scandium-containing oxidable die-casting aluminium alloy, preparation method and structural part

The invention discloses a scandium-containing oxidable die-casting aluminium alloy and a preparation method thereof. The aluminium alloy comprises the following components by mass: 1-2 percent of Mn, 1-2 percent of Ni, 1-3 percent of Zn, 0.8-2 percent of Mg, 0.05-0.3 percent of Sc, 0.05-0.2 percent of Zr, 90-95 percent of Al and less than 0.15 percent of Fe and Si impurities. The invention further discloses a structural part containing the aluminium alloy. The aluminium alloy provided by the invention has the advantages of high strength, good anodic oxidation property and good die-casting property, and can be used for manufacturing thin-walled casing members meeting high appearance and performance requirements.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

Calcium carbide ferro-aluminium alloy used for smelting steel, and preparation method thereof

InactiveCN102827997AQuality is not affectedGuarantee the quality of steelmakingImpurityCalcium carbide

The invention relates to a calcium carbide ferro-aluminium alloy used for smelting steel, and a preparation method thereof. The calcium carbide ferro-aluminium alloy employs calcium carbide, aluminium, ferrum and the like as raw materials, is produced by a remelting perrin process, and is used for deoxidation and desulphurization of smelting the steel. The calcium carbide ferro-aluminium alloy comprises the following components of, by mass, 20-60% of aluminium, 5-40% of calcium, 1-15% of carbon, and the balance being ferrum and inevitable impurities. The calcium carbide ferro-aluminium alloy has good effects of deoxidation and desulphurization, and can reduce cost for smelting the steel while guaranteeing the quality of the steel.

Owner:谢应旭

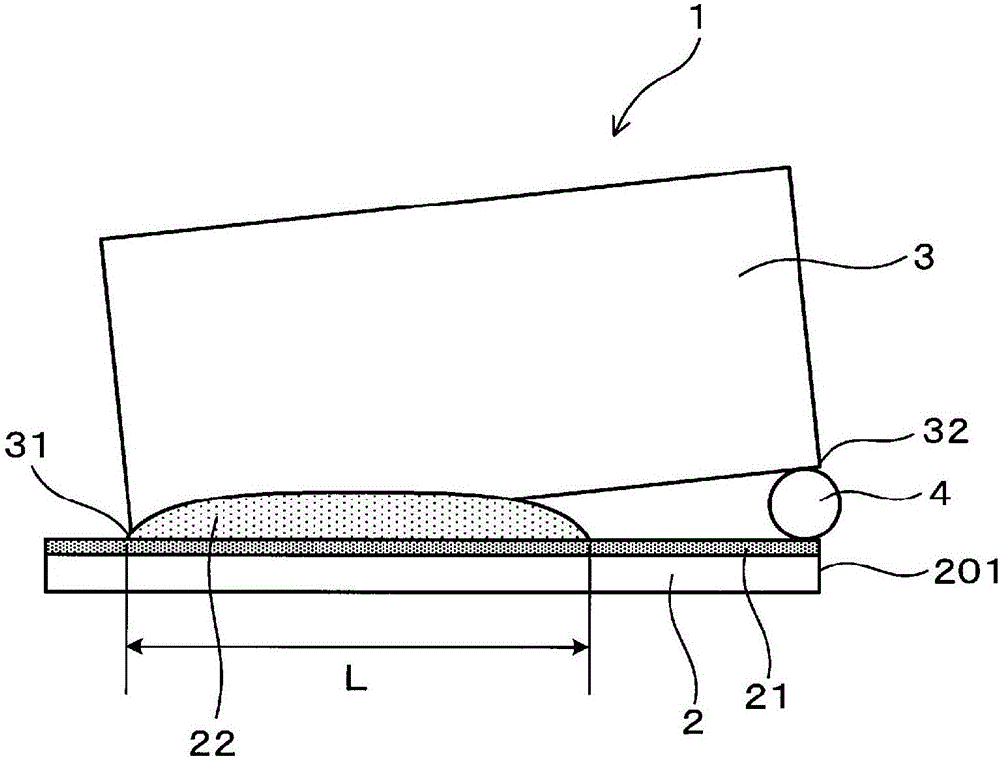

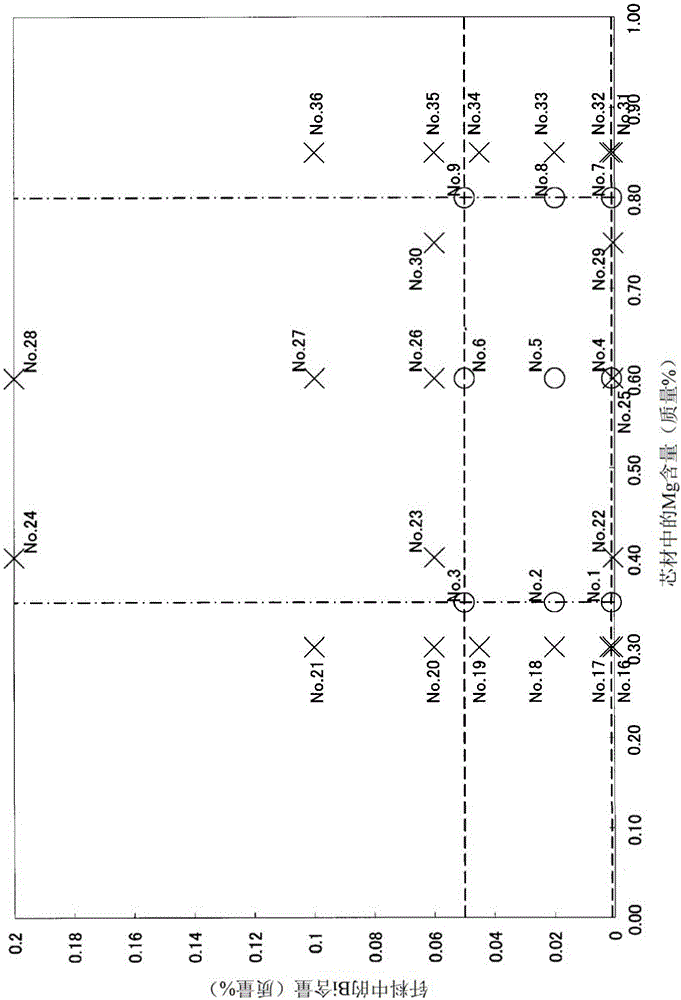

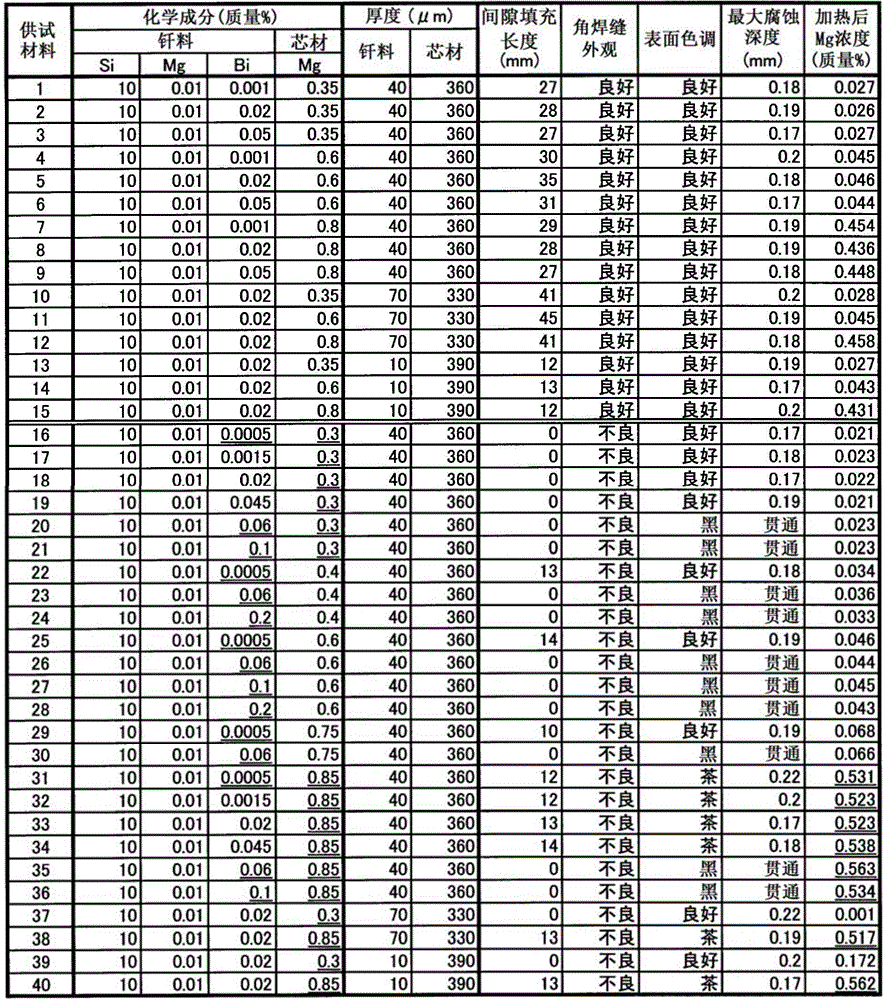

Aluminium alloy brazing sheet

ActiveCN106661677AImprove brazing performanceImprove corrosion resistanceWelding/cutting media/materialsWelding/soldering/cutting articlesChemical composition6111 aluminium alloy

This brazing sheet has a core material and a brazing material clad on one or both sides of the core material, and is used for brazing in an inert gas atmosphere without using a flux. The core material contains 0.35-0.8% (mass%, same hereafter) of Mg, wherein the balance has a chemical composition comprising Al and inevitable impurities. The brazing material contains 6-13% of Si and 0.001-0.05% of Bi, and restricts Mg to less than 0.05%, wherein the balance has a chemical composition comprising Al and inevitable impurities.

Owner:FURUKAWA SKY ALUMINUM CORP

In-situ multiphase mixed-scale ceramic reinforced Al-Zn-Mg-Cu aluminium alloy in melt and preparation method thereof

The invention discloses an in-situ multiphase mixed-scale ceramic reinforced Al-Zn-Mg-Cu aluminium alloy in melt and a preparation method thereof. the in-situ multiphase mixed-scale ceramic reinforcedAl-Zn-Mg-Cu aluminium alloy in melt consists of the following chemical components in percentage by mass: 5.1wt%-6.1wt% of Zn, 2.1wt%-2.9wt% of Mg, 1.2wt%-2.0wt% of Cu, 0wt%-0.40wt% of Si, 0wt%-0.50wt% of Fe, 0wt%-0.30wt% of Mn, 0wt%-0.20wt% of Ti, 0.18wt%-0.28wt% of Cr, 0.05wt%-0.4wt% of TiCN, TiB2 and AlN, and the balance of Al. The invention further discloses a preparation method for the in-situ multiphase mixed-scale ceramic reinforced Al-Zn-Mg-Cu aluminium alloy in melt. In the alloy melt, multi-phase micro-nano mixed-dimension TiCN, TiB2 and AlN ceramic particles are uniformly dispersedthrough in-situ self-propagating combustion reaction, content of the TiCN, TiB2 and AlN ceramic particles is optimized, and toughness of the aluminium alloy is improved.

Owner:JILIN UNIV

Aluminium alloy casting moulding sand

ActiveCN104014714AEmission reductionZero pollutionFoundry mouldsFoundry coresElectrolysisMicrosphere

The invention discloses aluminium alloy casting moulding sand. The casting moulding sand comprises following raw materials by weight: 60-64 parts of new quartz roughing sand, 24-28 parts of used quartz roughing sand, 3-5 parts of electrolytic aluminium slag powder, 4-6 parts of zircon sand, 1-6 parts of hollow microspheres, 16-18 parts of binder slurry and 22-26 parts of water, wherein the particle size of the new quartz roughing sand is 100-200 meshes, the particle size of the used quartz roughing sand is 150-250 meshes, the particle sizes of the electrolytic aluminium slag powder and the zircon sand are -300 meshes, the particle size of the hollow microspheres is 10-60 [mu]m, and the binder comprises 36-40% by weight of starch, 6-8% by weight of furan resin, 14-16% by weight of calcium bentonite, 3-5% by weight of bagasse cellulose powder having a size of -100 meshes, 1-2% by weight of zinc stearate and 2-3% by weight of sodium tripolyphosphate, with the balance being water. The electrolytic aluminium slag powder having the particle size of -300 meshes is obtained by a method as follows: electrolytic aluminium slag recovered from an electrolytic aluminium factory is subjected to impurity removal and dirt removal, cleaned, dried, subjected to ball milling, and sieved with a standard sieve having a size of 300 meshes.

Owner:湖南精量重工科技有限公司

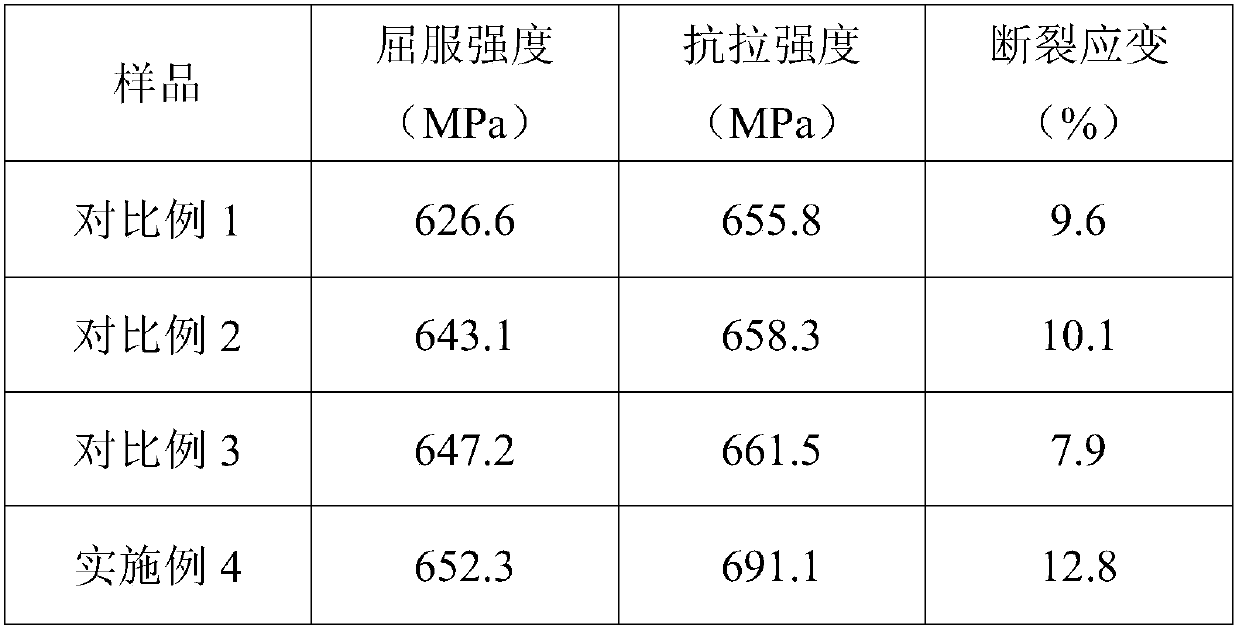

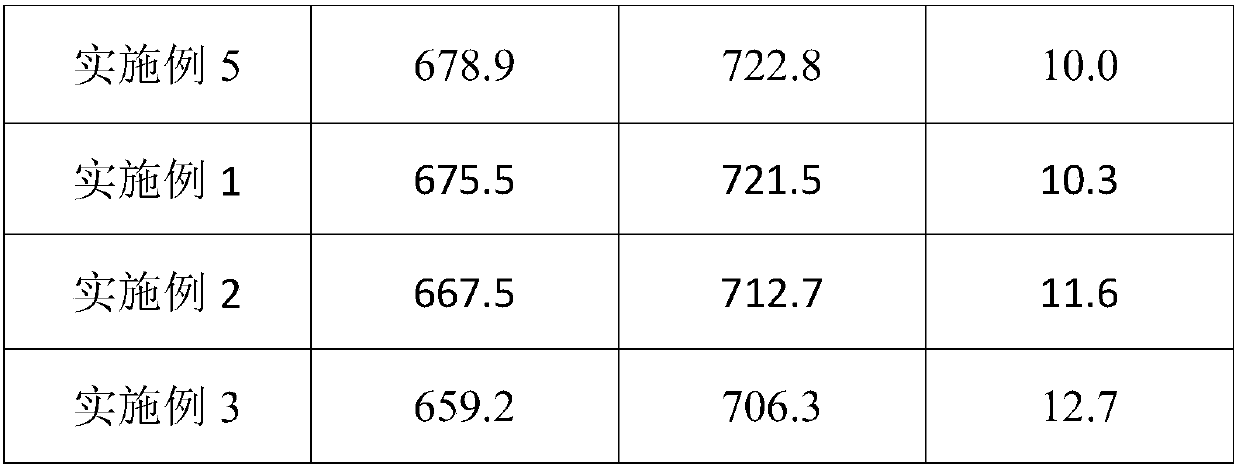

Method for preparing rare-earth yttrium containing super-high-strength wrought aluminium alloy

InactiveCN103305732AHigh tensile strengthImprove stress corrosion resistanceRare-earth elementMechanical equipment

The invention discloses a method for preparing a rare-earth yttrium containing a super-high-strength wrought aluminium alloy, which comprises the followings steps of: (1) satisfying the requirements that the yttrium containing super-high-strength wrought aluminium alloy comprises the following components in percentage by mass: 7.5-9.0% of zinc, 2.0-2.6% of Cu, 2.0-3.0% of Mg, 0.2-0.3% of Y, 0.1-0.2% of Zr, less than or equal to 0.05% of Fe, and less than or equal to 0.05% of Si; respectively weighting metal zinc, metal copper, an aluminum-magnesium intermediate alloy, an aluminium-yttrium intermediate alloy, an aluminum-zirconium intermediate alloy and a refined aluminium ingot according to the proportion; and carrying out melting step by step. According to the invention, a rare-earth element yttrium is added into an Al-Zn-Mg-Cu alloy, thereby improving the heat resistance of the alloy through process control, improving the heat resistance of Al-Zn-Mg-Cu high-strength aluminum alloys, and satisfying the requirements of currently rapidly developed aerospace and special mechanical equipment.

Owner:TIANJIN LIZHONG ALLOY GROUP

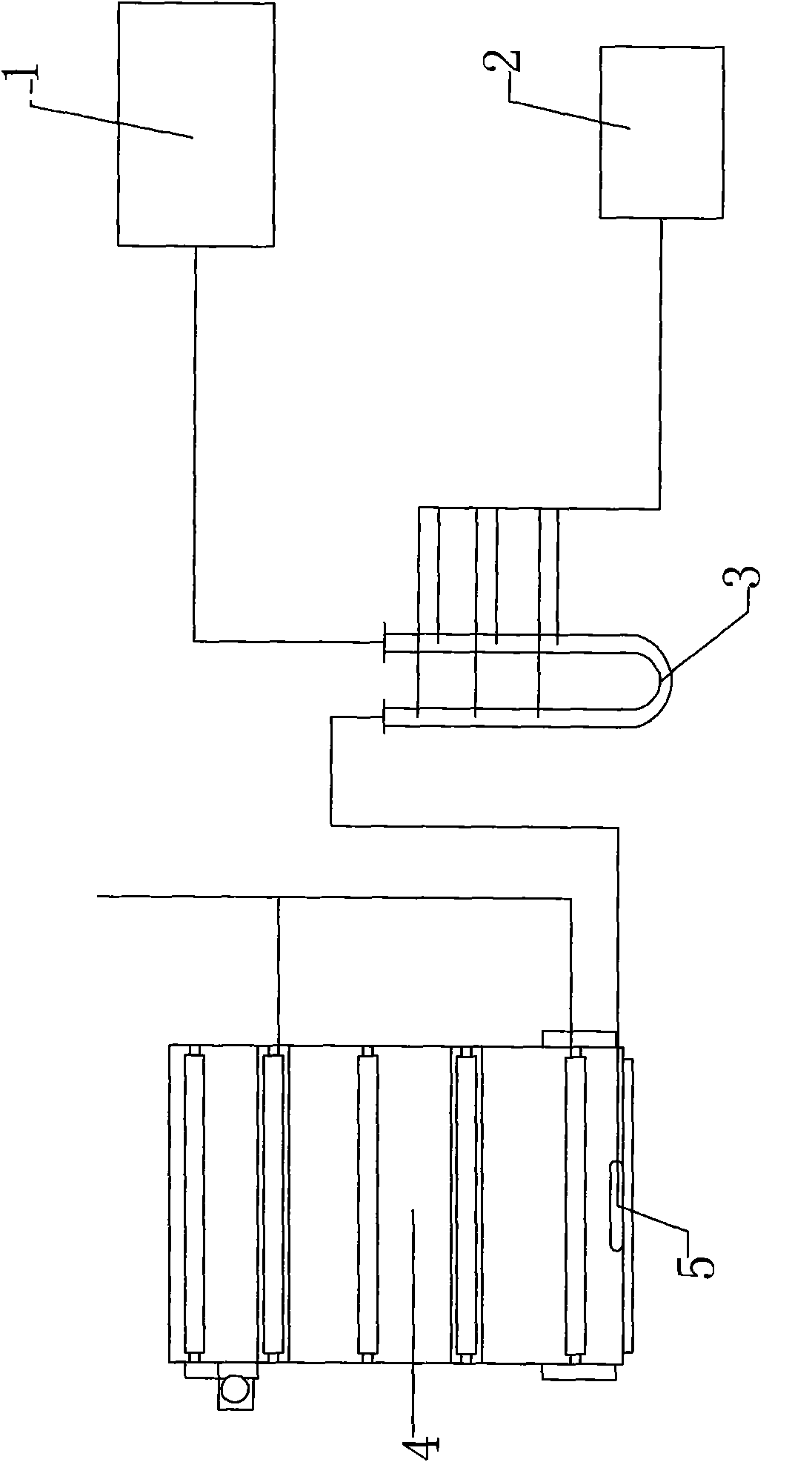

Aluminium alloy anodized waste water belt type press filteration system

InactiveCN101618287AImprove performanceReduce maintenance rateFiltration circuitsPressesSlagHigh energy

The invention relates to an aluminium alloy anodized waste water belt type press filteration system. The system mainly comprises a sewage sedimentation tank, a flocculant stirring tank, a coagulation reactor and a belt type pressure filter, wherein the sewage sedimentation tank and the flocculant stirring tank are respectively connected with the coagulation reactor by a pipeline; the coagulation reactor guides the mixed liquid therein into a blanking hopper positioned on the belt type pressure filter by the pipeline. Compared with the prior art, the aluminium alloy anodized waste water belt type press filteration system has the following advantages of continuous production, stable performance, low maintenance rate, strong corrosion resistance, low energy and drug consumption, large treatment capacity, low water content of filter cakes, easy operation, easy maintenance and easy cleaning and the like. The aluminium alloy anodized waste water belt type press filteration system really solves the actual problems that the dehydration treatment of industrial acid-base neutralization waste residue has high energy consumption and low slag-pressing efficiency, thus being ideal equipment for saving energy, protecting environment, treating sewage, improving production efficiency and reducing labor intensity.

Owner:李其真

High-thermal-stability wrought aluminium alloy and preparation method thereof

The invention discloses a high-thermal-stability wrought aluminium alloy and a preparation method thereof, and belongs to the technical field of non-ferrous metals. The preparation method comprises the following steps: taking 0.3% of erbium, 0.3-0.6% of zirconium and the balance of aluminum and unavoidable impurities, smelting aluminum in a resistance furnace, adding an Er-Zr intermediate alloy into smelted aluminum at the temperature of 750-800 DEG C, heating the obtained object to 900 DEG C, carrying out stirring and slag removal on the heated object, standing and cooling a molten metal to 850 DEG C, casting the obtained product into a cast ingot by using an iron die, and after the cast ingot is solidified, quickly taking out the cast ingot, and cooling the cast ingot to room temperature through water cooling; carrying out face milling on the aluminium alloy cast ingot, carrying out cold rolling on the cast ingot on a rolling mill, and keeping the deformation of the cast ingot at 70-90%. After the wrought aluminium alloy with the components is subjected to annealing at a temperature of 375 DEG C for 150 hours, obvious recrystallization phenomenon still does not occur, so that the wrought aluminium alloy has good thermal stability.

Owner:BEIJING UNIV OF TECH

Production process of aluminium alloy casting rod specially used for Ford automobile rotary-swaged hub decorative rings

A production process of an aluminium alloy casting rod specially used for Ford automobile rotary-swaged hub decorative rings. The aluminium alloy casting rod comprises the following components by weight: 95.95-97.30% of Al, 0.95-1.05% of Mg, 0.72-0.8% of Si, 0.21-0.24% of Cu, 0.20-0.24% of Fe, 0.16-0.20% of Cr, 0.06-0.10% of Mn, 0-0.05% of Zn, and 0-0.05% of Ti. The process comprises the following steps: melting the components of Al, Mg, Si, Cu, Fe, Cr, Mn, Zn, and Ti in a melting furnace according to the weight ratios, uniformly stirring the melt, removing slag to obtain aluminium alloy melt; introducing the aluminium alloy melt into a standing furnace, refining with argon, nitrogen and No.2 flux powder; allowing the refined aluminium alloy melt to stand in a standing furnace at a temperature of 735 DEG C-745 DEG C for 30 min; performing casting molding by a hot-top casting machine, performing oil-gas mixing treatment on a casting machine by using oil-gas mixing lubrication graphite ring technology to obtain the aluminium alloy casting rod; cutting the aluminium alloy casting rod, and performing uniformization treatment and cooling treatment to obtain the aluminium alloy casting rod specially used for Ford automobile hubs.

Owner:秦皇岛开发区美铝合金有限公司

Extrusion type aluminium alloy

The invention provides an extrusion type aluminium alloy which belongs to the technical field of aluminium alloy preparation. The aluminium alloy comprises the following components by mass percent: 4.0-5.5% of Zn, 1.0-2.0% of Mg, 0.6-0.8% of Mn, 0.3-0.8% of Cu, 0.3-0.5% of Cr, 0.05-0.3% of Zr, 0.03-0.1% of rare earth element, no more than 0.3% of unavoidable impurity elements in total and the balance of aluminium. The aluminium alloy has the tensile strength of 396.17-540.03MPa and the yield strength of 303.61-480.13MPa at room temperature; and the aluminium alloy after fusion welding has the tensile strength of 389.17-530.03MPa and the yield strength of 292.61-460.13MPa, and the constituents of welding wires and matrixes are consistent in a welding process. The aluminium alloy can be used for solving a problem that the welding performance and high strength of the conventional aluminium alloy is difficult to match. The aluminium alloy is simple in operation and convenient in industrial production.

Owner:浙江极铝新材料有限公司

Die casting aluminium alloy with high strength

The invention discloses a die casting aluminium alloy with high strength, relating to the technical field of aluminium alloys. The die casting aluminium alloy comprises the following components by weight percent: 10-15% of Si, 3-5% of Cu, no more than 1.2% of Zn, 0.3-1% of Mn, 0.1-0.6% of Mg, 0.05-0.15% of Ti, 0.01-0.02% of Sr, no more than 0.15% of Cr, 0.02-0.04% of B, less than 0.25% of Fe, less than 0.25% of total other impurities and the balance of Al. The problems that the existing die casting aluminium alloys have lower strength and elongation are solved by adopting the die casting aluminium alloy.

Owner:LIUZHOU BAITIAN MACHINERY

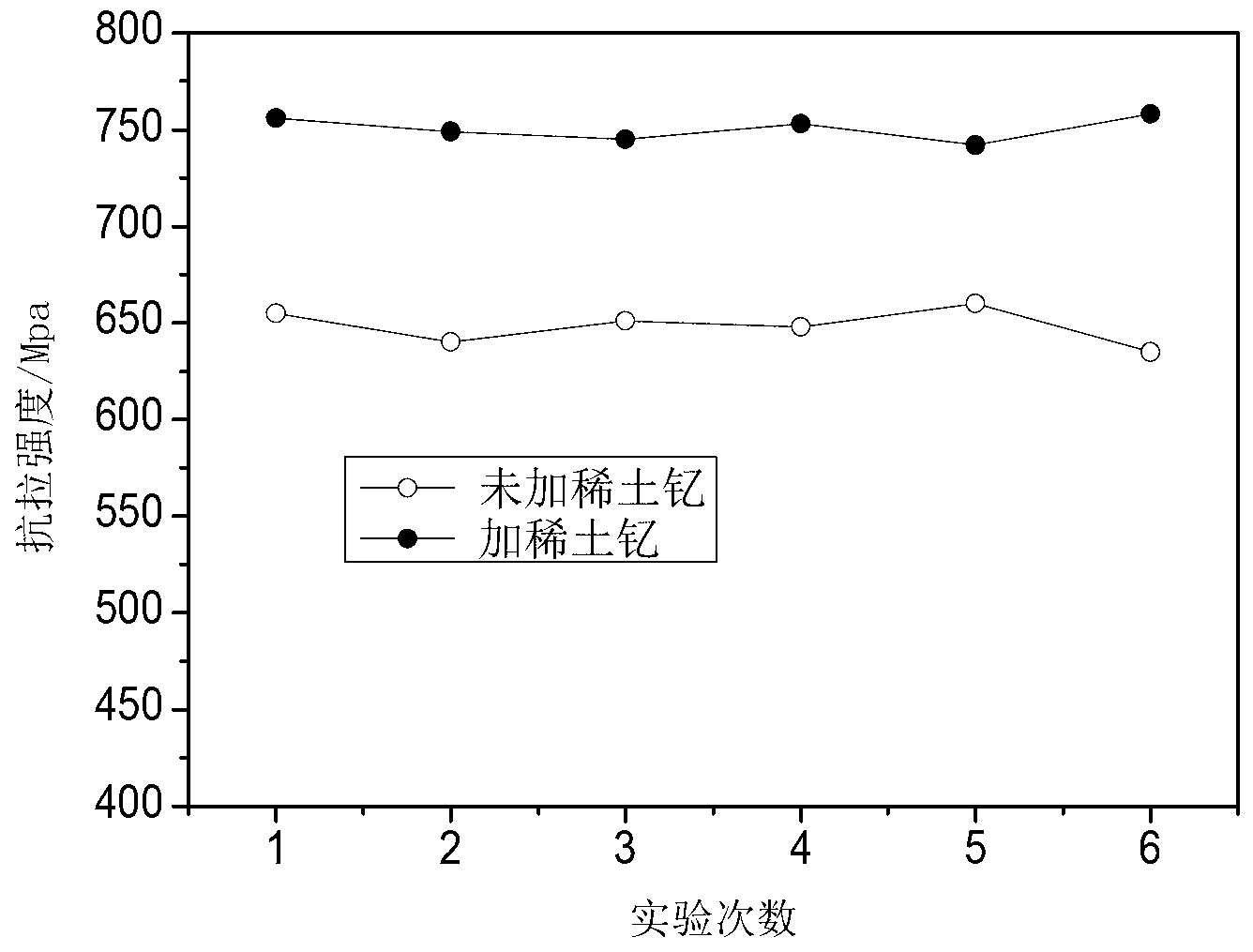

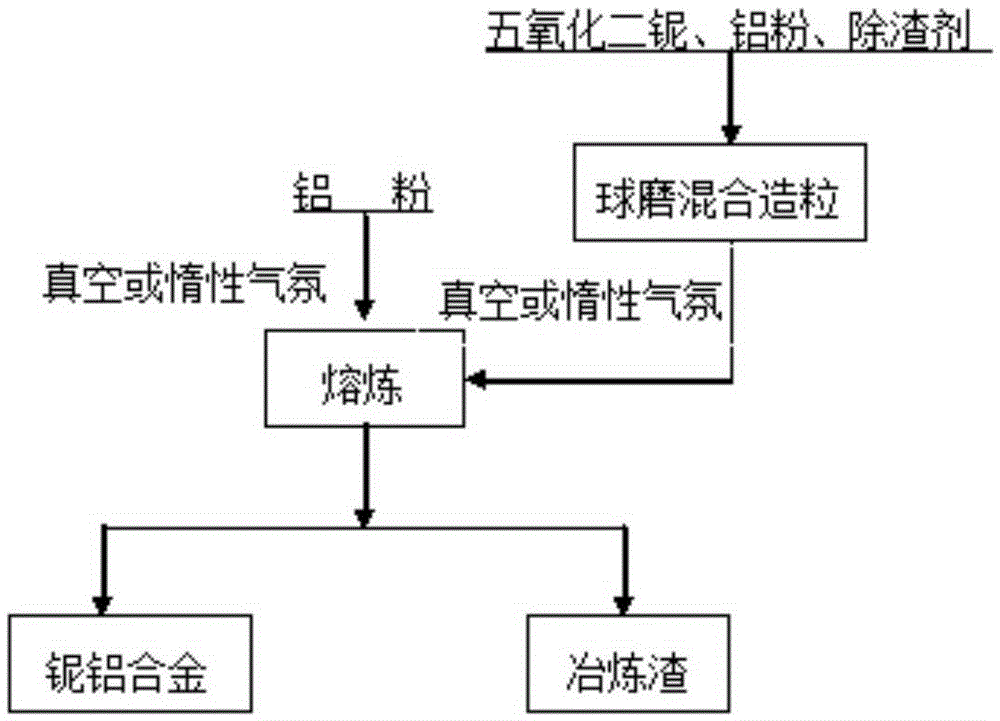

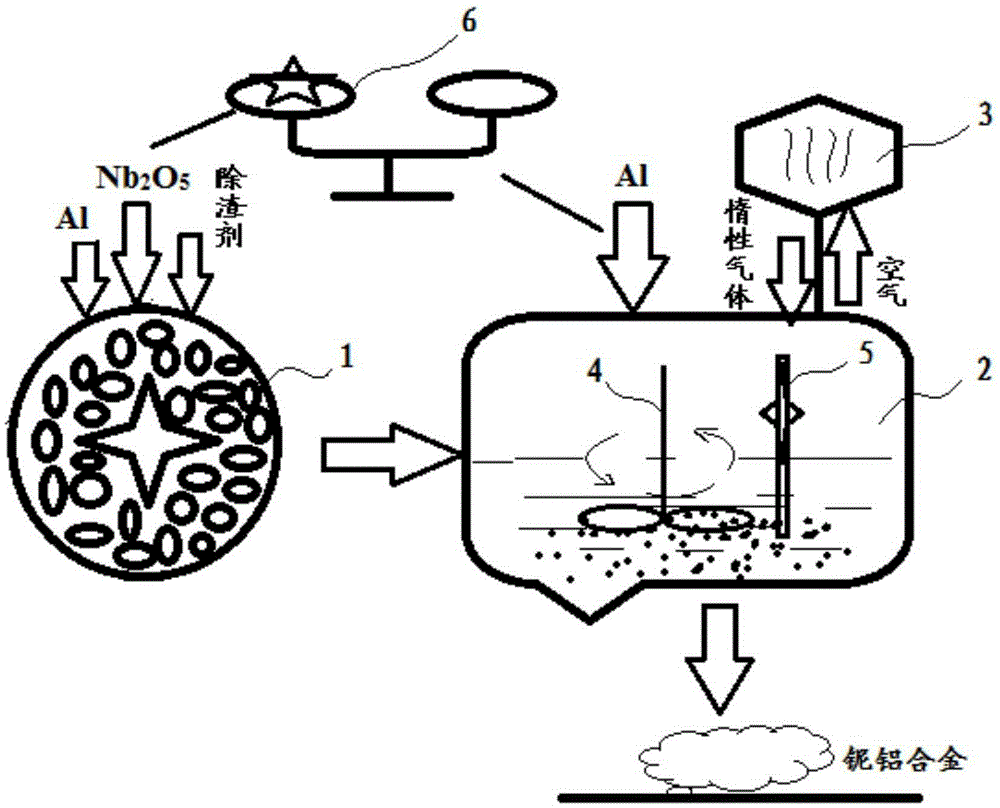

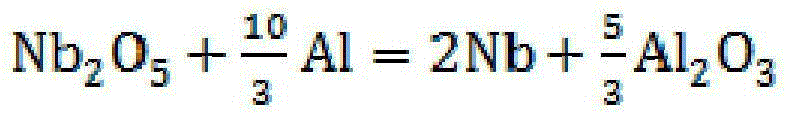

Preparation method and system of niobium-aluminium alloy

InactiveCN105385866AFacilitated DiffusionInhibition of segregationMixed materialsMelting temperature

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

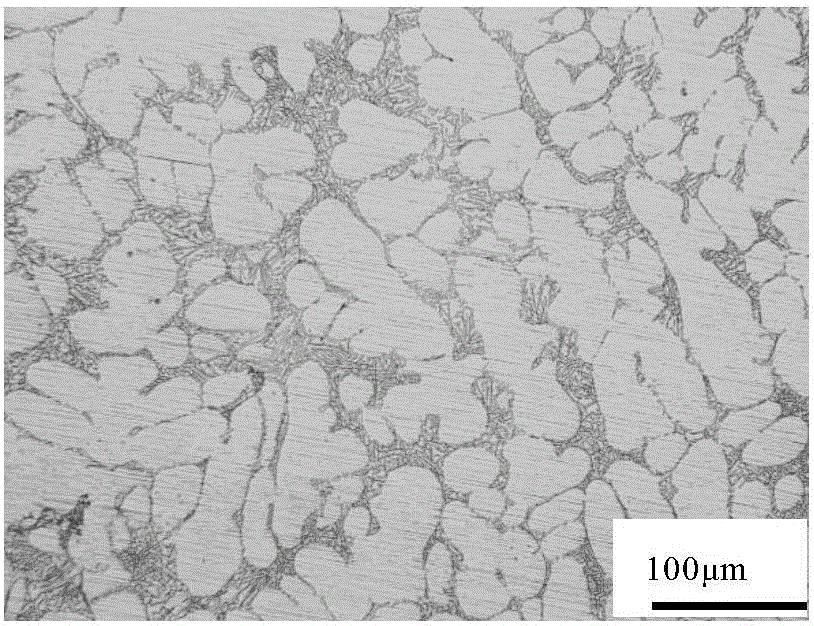

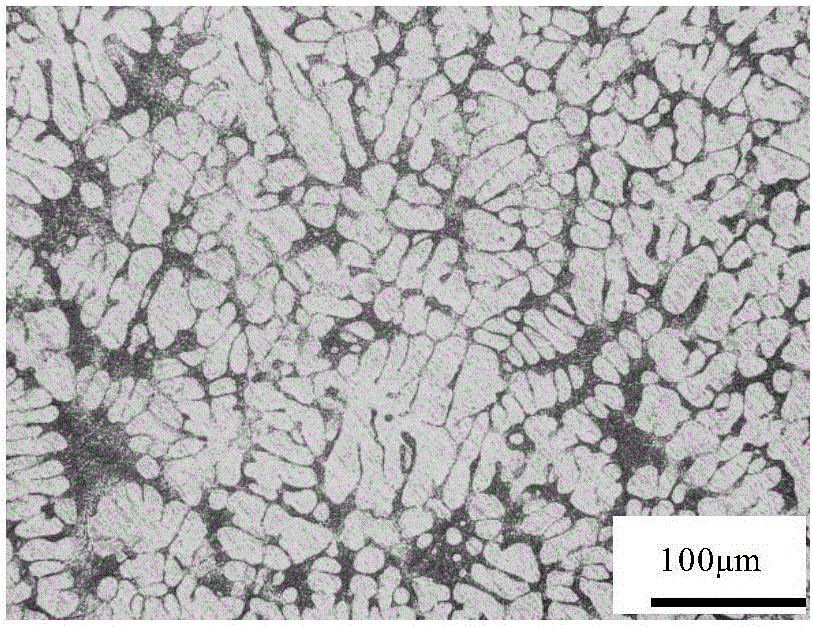

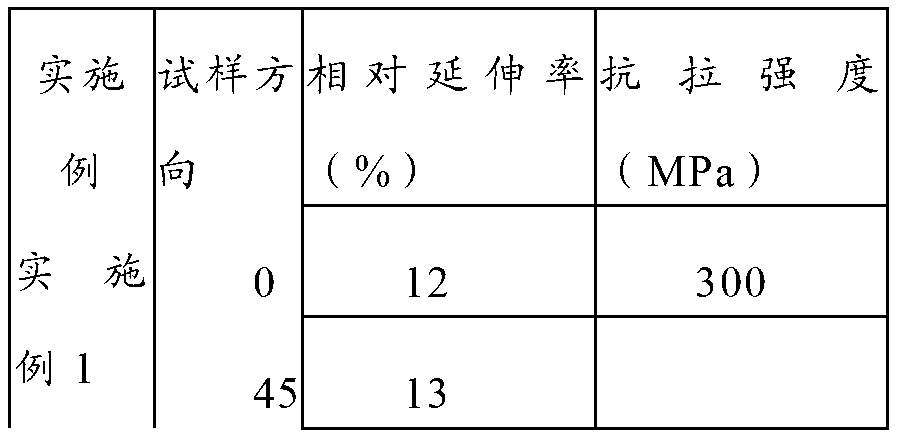

Preparation method of 6111 aluminum alloy plate for automobile body

The invention provides a preparation method of a 6111 aluminum alloy plate for an automobile body. The preparation method comprises the following steps that (1) a 6111 aluminum alloy ingot is preparedby a DC casting method; (2) the ingot is heated to 200-400 DEG C, and heat is preserved for 2-6 hours, the ingot is heated to 460-500 DEG C, heat preservation is carried out for 2-4 hours, and discharging and hot rolling are carried out; (3) a hot rolled plate is heated to 480-550 DEG C, the temperature is kept for 2-6 hours, and the hot rolled plate is cooled along with a furnace; (4) cold rolling is carried out; (5) solid solution treatment on the cold-rolled plate is carried out; (6) the cold-rolled plate is placed for 5-15 minutes at the room temperature; (7) pre-aging treatment is carried out; and (8) the cold-rolled plate is placed at room temperature, namely the plate subjected to pre-aging treatment is placed at room temperature for more than 4 weeks. The method not only can shorten the production process of a 6111 aluminum alloy body plate, saves the energy, greatly reduces the production cost of the 6111 aluminum alloy body plate, and can remarkably improve and the stampingforming property and the baking varnish hardening property of the 6111 aluminum alloy body plate.

Owner:NORTHEASTERN UNIV

Modification treatment method of aluminium alloy

The invention belongs to the technical field of aluminium alloys, and relates to a modification treatment method of an aluminium alloy. The modification treatment method is characterized in that Al-10Zr and Al-12Er intermediate alloys are adopted as an alterant, an A356 aluminium alloy is adopted as a modification object; 0.20% of Zr and 0.40% of Er are added, and the microstructure and performance of the A356 aluminium alloy are remarkably improved through the technological processes like batching, smelting and modification treatment; and tensile strength of the A356 aluminium alloy subjected to modification treatment of the Al-10Zr intermediate alloy and the Al-12Er intermediate alloy is 225 MPa, elongation is 6.4%, and tensile strength and elongation are respectively improved by 52.8% and 36.2% compared with tensile strength and elongation of the A356 aluminium alloy which is not subjected to modification treatment.

Owner:JIANGSU UNIV OF TECH

Special aluminum alloy ingot for wheel hub and preparation method of aluminum alloy ingot

InactiveCN105506411AThe average grain size is smallEvenly distributedMechanical property6111 aluminium alloy

The invention discloses a special aluminum alloy ingot for a wheel hub. The aluminum alloy ingot comprises the components by mass percent: 1.2-2.0% of Si, 0.05-0.2% of Mn, 0.05-0.1% of Cr, 2.0-2.8% of Mg, 0.1-0.3% of Cu, 0.1-0.3% of Zn, 0.3-0.8% of Ti, 0.09-0.25% of Sn, 0.1-0.2% of Zr, 0.1-0.2% of Er, 0.1-0.2% of Sr, less than or equal to 0.5% of gross other metallic and nonmetallic impurity elements, and the balance Al. A preparation method of the aluminum alloy ingot comprises the steps of melting, refining, standing and casting. According to the aluminum alloy ingot, the elements such as Ti, Zr, Er and Sr are added, so that metamorphism and refining functions can be exerted on the structure of an aluminium alloy, so that the mechanical property of the aluminium alloy is improved, and a guarantee is provided for improving the mechanical property of the aluminium alloy wheel hub.

Owner:BAISE UNIV

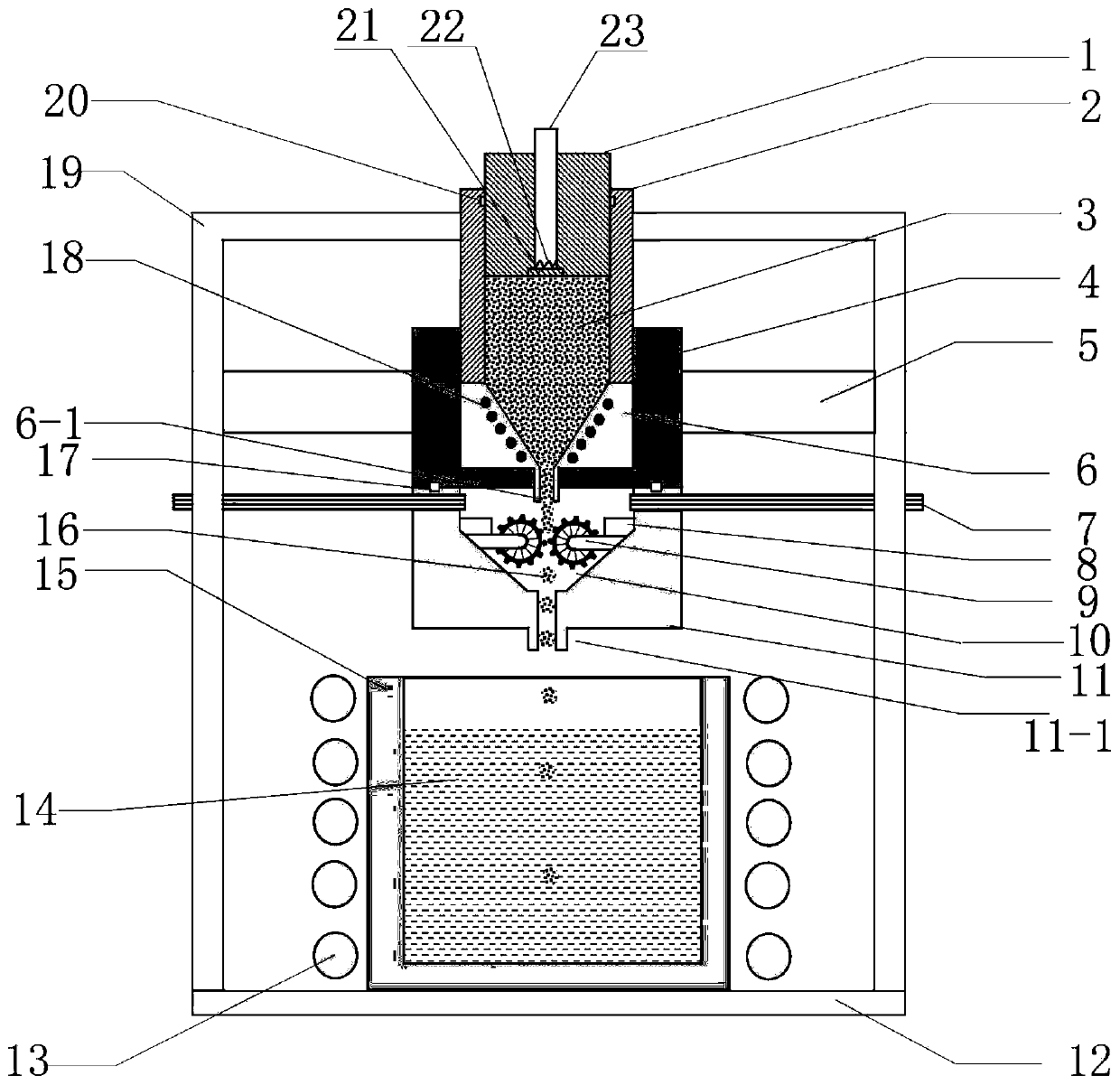

Smelting furnace for producing vanadium-aluminium alloy and manufacturing method of smelting furnace

The invention discloses a smelting furnace for producing a vanadium-aluminium alloy and a manufacturing method of the smelting furnace. A furnace body of the smelting furnace comprises a furnace body casing and a furnace lining arranged on the inner surface of the furnace body casing, and the furnace body casing comprises a furnace base and a body which are connected with each other. The manufacturing method comprises steps as follows: preparation of a refractory material: evenly mixing magnesite, magnesium refractory mortar and a binder to obtain the refractory material; manufacturing of the furnace lining: coating the inner surface of the furnace body casing with the refractory material, and performing roasting to form the furnace lining. The furnace lining of the smelting furnace is high in refractoriness and good in heat-insulation performance, and the vanadium-aluminium alloy produced by using the smelting furnace is better in quality.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Aluminium alloy sheet material for labour protection leather shoes head and preparation method thereof

ActiveCN103290282AHigh hardnessMeet strength requirementsUpperBootlegsHardnessUltimate tensile strength

The invention provides an aluminium alloy sheet material for labour protection leather shoes head and preparation method thereof, and the aluminium alloy sheet material is 7xxx series aluminium alloy, and concretely comprises the following components by weight percent: 0.50-1% of Fe, 0.40-1.0% of Mn, 0.4-0.80% of Mg, 0.20-0.80% of Si, 0.2-0.3% of Zr, 0.10-0.2% of Ti, 3.5-4.5% of Cu and Al the rest amount. The aluminium alloy contains Zr, Ti, Si, Cu and Mg, and has a high hardness and intensity, and belongs to the superhard aluminium alloy, the invention has a good wear resistance, and after the stress is relieved by processing, the product does not deform and warp, thereby shortening the moulding time and improving the work efficiency. The aluminium alloy sheet material provided by the invention can satisfy the requirements of intensity and hardness, and ensure the thickness of the aluminium alloy sheet material is the lowest.

Owner:SOUTHWEST ALUMINUM GRP

Preparation method of cast aluminium alloy with high heat conductivity

The invention discloses a preparation method of a cast aluminium alloy with high heat conductivity, relating to the technical field of casting. The method comprises the following steps: preparing raw materials of the alloy; firstly oppressively heating a graphite crucible to 350-400 DEG C in a resistance furnace, then melting a pure aluminium ingot to form molten aluminium, adding Si and Mn to the molten aluminium when the temperature of the molten aluminium is 750-780 DEG C, melting Si and Mn in sequence, then reducing the temperature to 680-720 DEG C and pressing Mg in the alloy liquid entirely; putting Sc in the alloy liquid in the graphite crucible, stirring the alloy liquid under the protection of argon, then adding the remaining raw materials and stirring the materials for 4-6 minutes after the remaining raw materials are completely molten; removing dross, refining at 770-780 DEG C, stirring for 20-30 minutes, and then slagging off and degassing; carrying out blast furnace component analysis, and then casting after the components are qualified. The problems that the existing cast aluminium alloys have lower heat conductivity and can not meet the development requirements of automobiles are solved by adopting the preparation method.

Owner:LIUZHOU BAITIAN MACHINERY

Aluminium alloy

The invention relates to an alloy, in particular to an aluminium alloy. The aluminium alloy consists of the following substances by weight: 93-97 percent of aluminium, 0.8-2.0 percent of nickel, 0.2-1.0 percent of iron, 1.0-2.0 percent of zinc, 0.05-0.1 percent of copper, 0.01-005 percent of cerium, 0.1-0.5 percent by weight of tin and the balance of impurities. The aluminium alloy is high in heat conductivity, excellent in runnability and good in strength.

Owner:青岛市市南区隆德中医药研究所

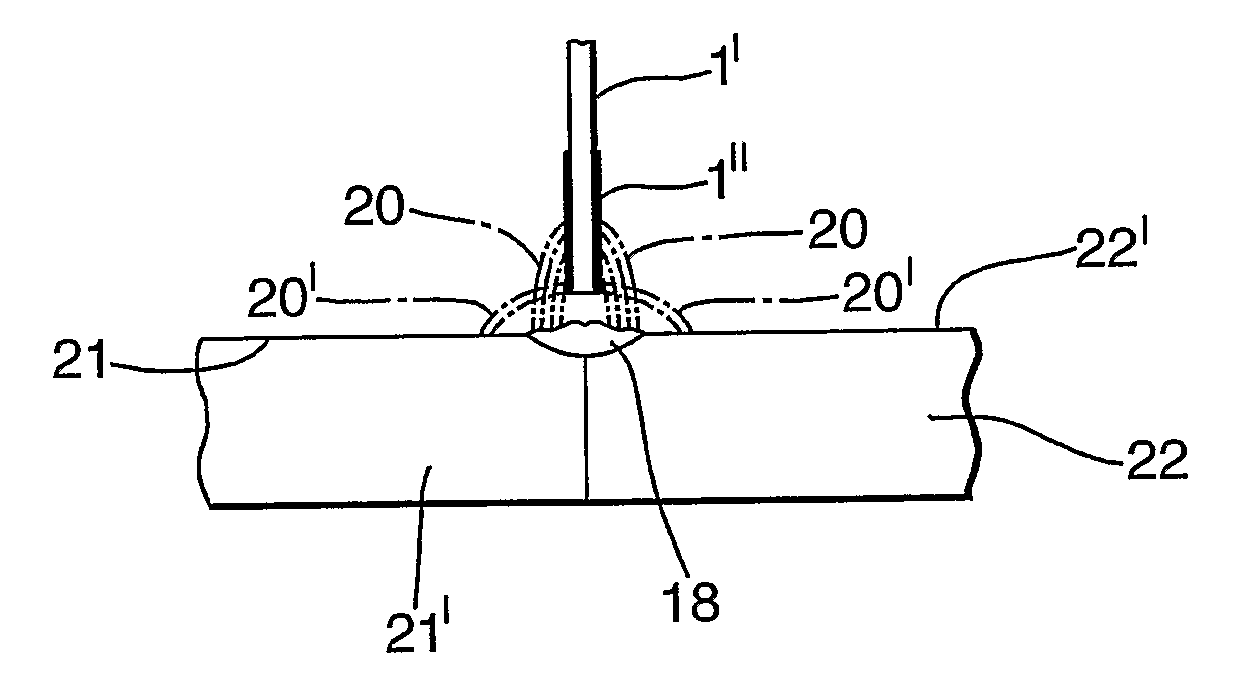

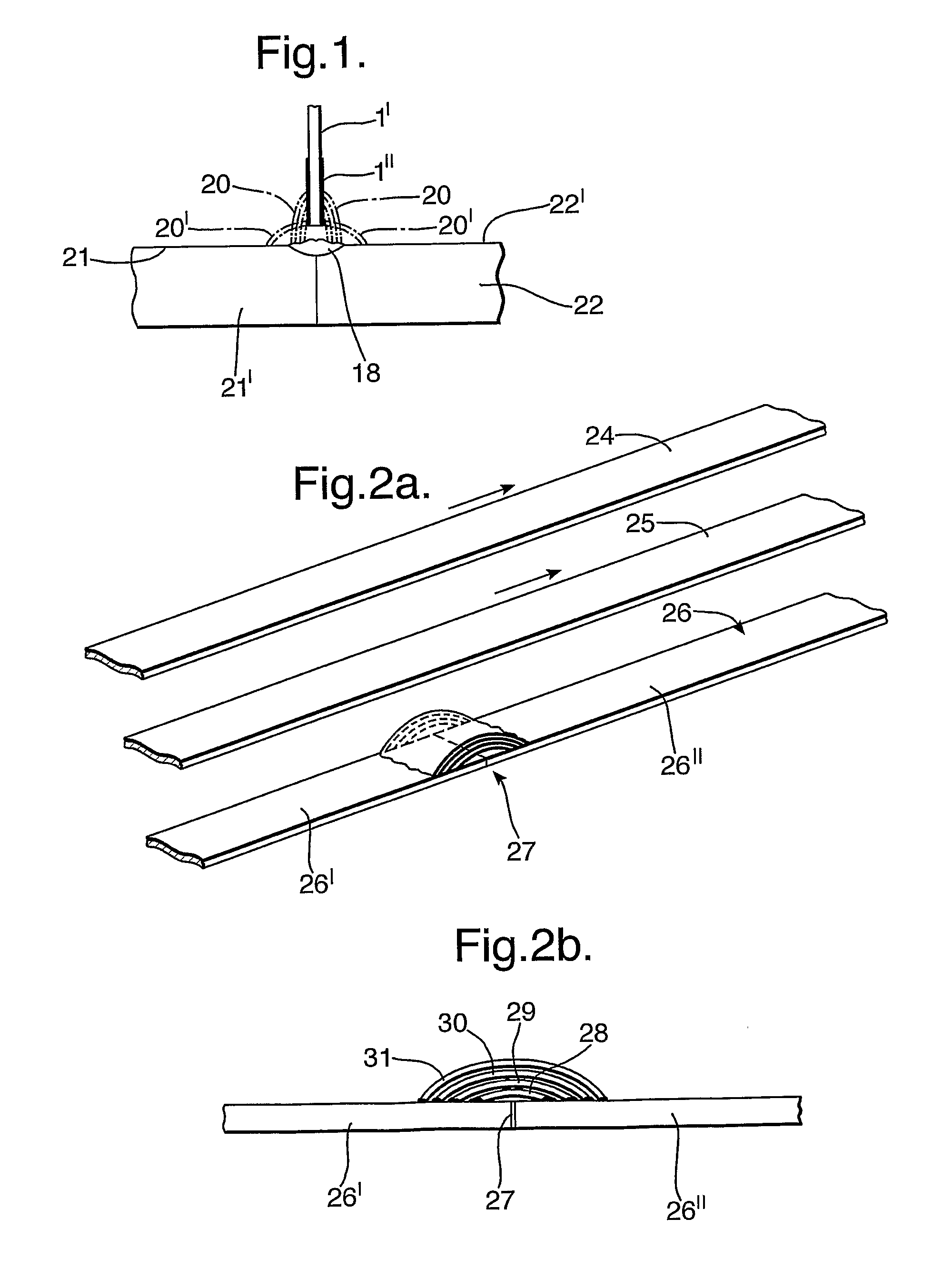

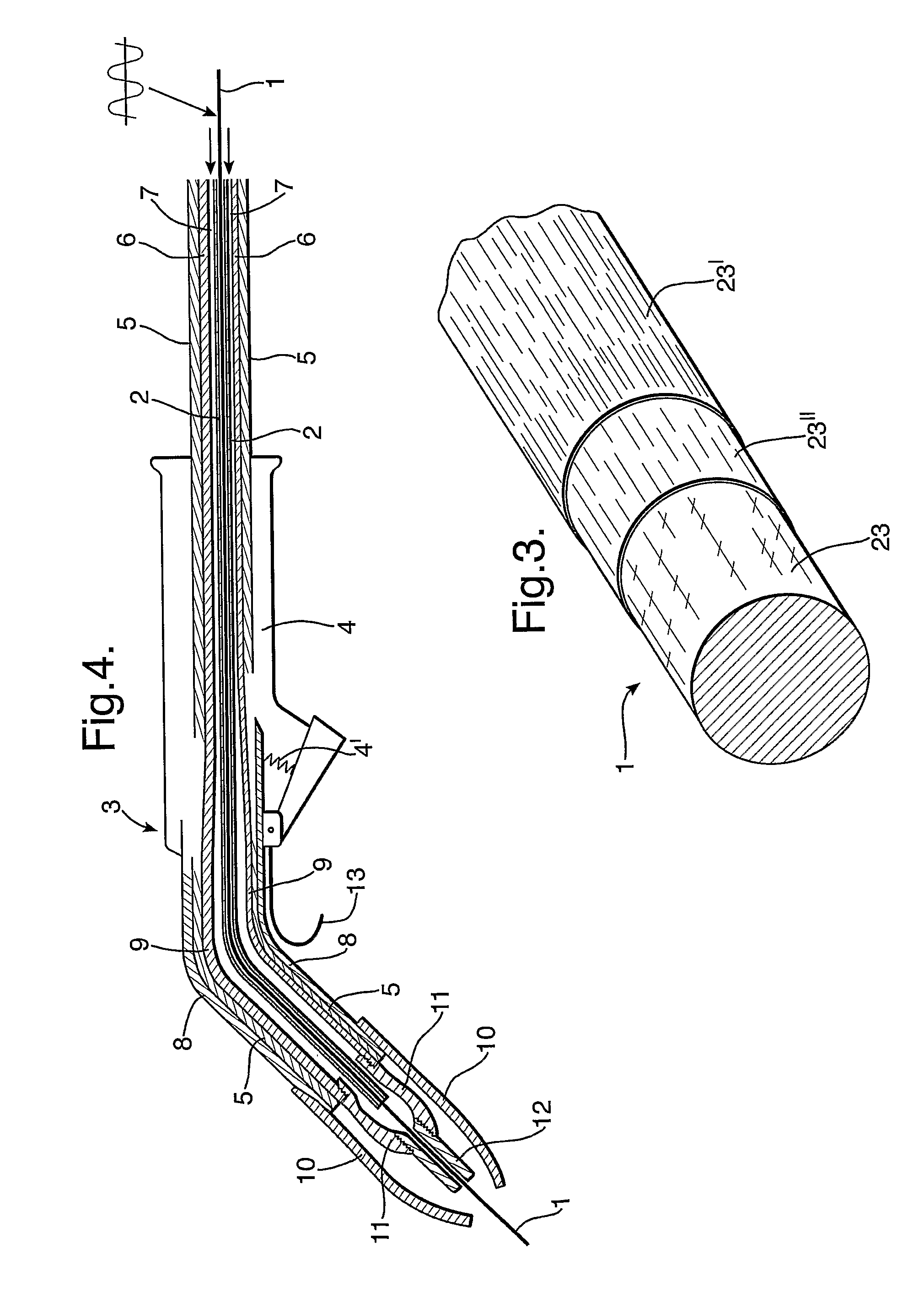

Electric welding of aluminium or aluminium alloy

InactiveUS20110168677A1Reduce the influence of magnetic fieldReduce the impactPretreated surfacesArc welding apparatusShielding gasOxygen

Electric welding method is provided of aluminium or aluminium alloy in a magnetic field, the aluminium or aluminium alloy adjacent to a weld joint under formation has an oxide layer, and the free end of a welding wire is supplied with a surrounding shielding gas. Furthermore, a welding wire is used that comprises aluminium or aluminium alloy provided with an oxide-inhibiting coating, which forms the outer covering or sheath of the welding wire and / or that as said shielding gas there is used a shielding gas with oxygen incorporated therein, or that the shielding gas is supplied with oxygen during the welding process. When the process is carried out in a magnetic field, the minimum frequency of the welding current is selected as a function of the strength of the magnetic field. A method is also provided for producing the welding wire and necessary material conditions for a usable welding gun.

Owner:EFD INDUCTION AS

Aluminium alloy casting preparing method

The invention discloses an aluminium alloy casting preparing method, and relates to the technical field of aluminum alloy preparing methods. According to the method, pure aluminum powder, pure titanium powder and borohydride titanium powder are mixed evenly to serve as a refiner, the refiner mixed powder is subjected to high-temperature preheating to enable borohydride titanium to be decomposed, through high-temperature, the self-propagating reaction in the refiner mixed powder forms fine TiAl3 and TiB2 particles, through high-temperature extrusion, a filamentous refiner containing hydrogen holes is formed, and then is cut into fine blocky refiners, finally, through the high-pressure spraying method, the fine blocky refiners are sprayed to aluminum alloy melt, after the melt is solidified,the refining effect is achieved, and residual hydrogen in the aluminum alloy melt is subjected to vacuum pumping so as to be removed. The method is simple in process, the prepared aluminum alloy is good in refining effect, and the aluminum alloy casting strength is improved.

Owner:刘燕岭

Processing method for increasing stamping formability of 6111 aluminium alloy automobile sheet

InactiveCN101885000BSolve bottlenecksImprove stamping yieldRoll mill control devicesMetal rolling arrangementsRoom temperatureIngot

The invention relates to a processing method for increasing the stamping formability of the 6111 aluminium alloy automobile sheet. The method comprises the following steps: 1. performing heat treatment to 6111 alloy ingot, which is prepared through semicontinuous casting, at 220-480 DEG C for 1-15h, heating to 550 DEG C with the furnace, keeping temperature for 24h to perform the conventional homogenizing treatment; 2. cropping the ingot and milling the face of the ingot, heating to 440-450 DEG C for hot rolling, wherein hot rolling adopts the mode of longitudinal and lateral alternation, thetotal rolling deformation is more than 85%, the finishing temperature is more than 300 DEG C and the final thickness of the hot rolled sheet is 6mm; 3. keeping the temperature of the hot-rolled sheetto 420-430 DEG C for 1h-2h, performing intermediate annealing, performing cold rolling to ensure the thickness of the sheet is 0.8 mm-1.0 mm, wherein the cold deformation is more than 75%; 4. keepingthe temperature of the cold-rolled sheet to 550 DEG C for 7min, performing solution treating and water quenching, standing at the room temperature for 1min-48h; 5. performing pre-aging treatment in adrying box at 150-220 DEG C for 4min-15min; and 6. standing at the room temperature for more than two weeks to obtain T4P temper. After the sheet is processed by the method of the invention, the stamping formability and after-painting strength are obviously improved, thus facilitating to increase the rate of stamping products and reduce the stamping cost.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com