Preparation method and system of niobium-aluminium alloy

A preparation system and aluminum alloy technology, which is applied in the field of non-ferrous alloys, can solve the problems of increasing preparation costs and achieve the effects of low production costs, accelerated diffusion, and reduced impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

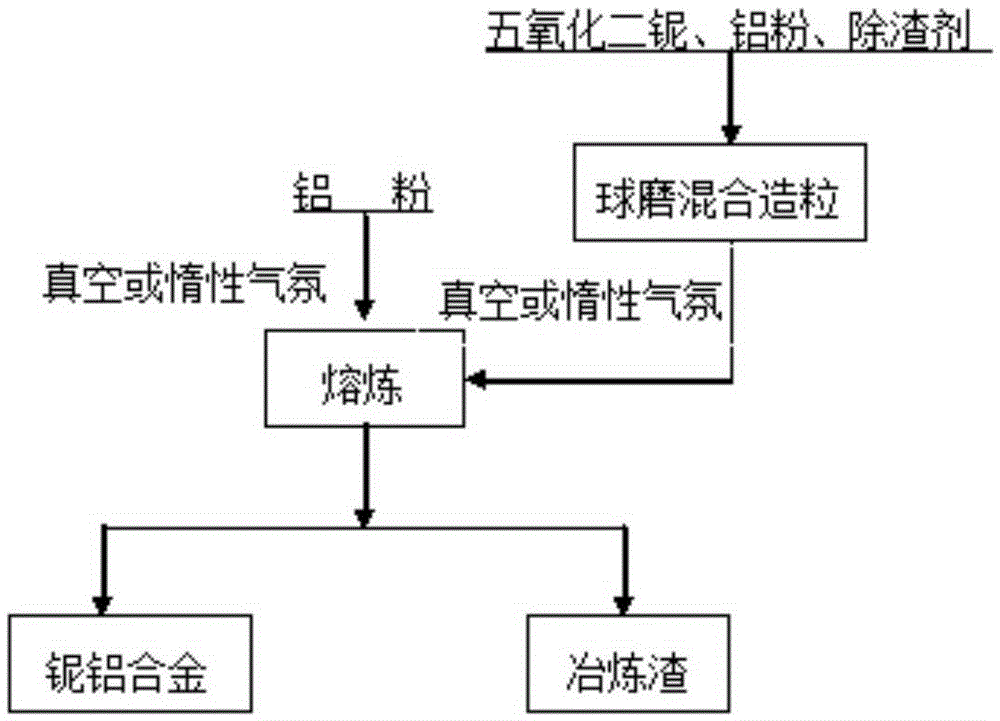

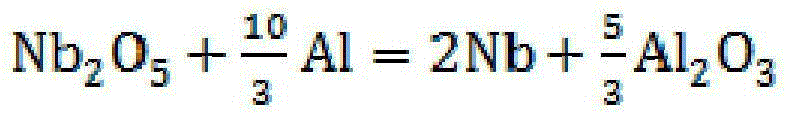

[0028] Such as figure 1 As shown, the preparation method of the niobium aluminum alloy of the present invention at least includes the following steps: mixing niobium pentoxide, aluminum and a small amount of slag remover to form a mixed material; melting the remaining aluminum to form aluminum liquid; The material is added into the aluminum liquid, so that it can generate niobium through the aluminothermic reduction reaction, and evenly distribute in the aluminum liquid, and react with excess aluminum to form a uniform niobium aluminum alloy.

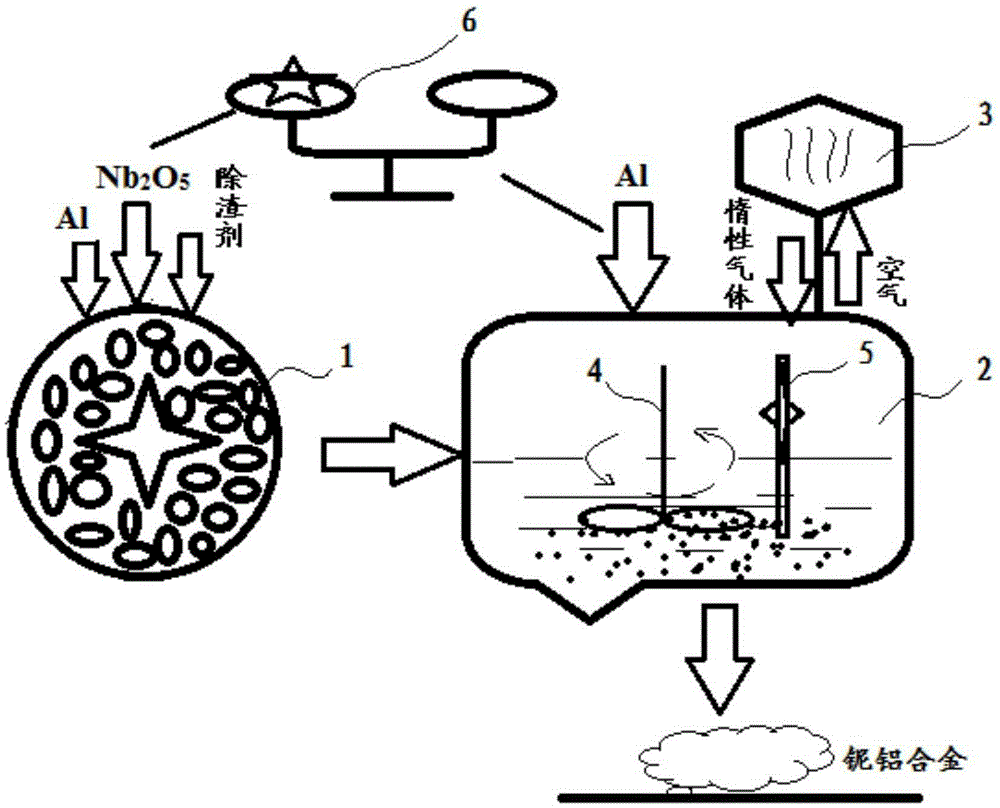

[0029] Such as figure 2 As shown, according to an embodiment of the present invention, the niobium-aluminum alloy preparation system includes a ball mill pressing granulation device 1, a smelting device 2, a vacuum and / or an inert gas input device 3, a stirring device 4, a temperature control device 5, and a weight Proportioning device6.

[0030] In one embodiment of the present invention, the niobium-aluminum alloy comprises the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com