Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

606 results about "Niobium pentoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Niobium pentoxide is the inorganic compound with the formula Nb₂O₅. It is a colourless insoluble solid that is fairly unreactive. It is the main precursor to all materials made of niobium, the dominant application being alloys, but other specialized applications include capacitors, lithium niobate, and optical glasses.

Niobium suboxide powder

ActiveUS20050013765A1High currentReduce residual currentOxide/hydroxide preparationLiquid electrolytic capacitorsCapacitorTungsten

A niobium suboxide powder comprising 100 to 600 ppm of magnesium is described. The niobium suboxide powder may (alternatively or in addition to 100 to 600 ppm of magnesium) further include 50 to 400 ppm of molybdenum and / or tungsten. The niobium suboxide powder is suitable for the production of: capacitors having an insulator layer of niobium pentoxide; capacitor anodes produced from the niobium suboxide powder; and corresponding capacitors.

Owner:TANIOBIS GMBH

Niobium suboxide powder

ActiveUS7381396B2Reduce residual currentReduce volatilityOxide/hydroxide preparationLiquid electrolytic capacitorsTungstenSuboxide

A niobium suboxide powder comprising 100 to 600 ppm of magnesium is described. The niobium suboxide powder may (alternatively or in addition to 100 to 600 ppm of magnesium) further include 50 to 400 ppm of molybdenum and / or tungsten. The niobium suboxide powder is suitable for the production of: capacitors having an insulator layer of niobium pentoxide; capacitor anodes produced from the niobium suboxide powder; and corresponding capacitors.

Owner:TANIOBIS GMBH

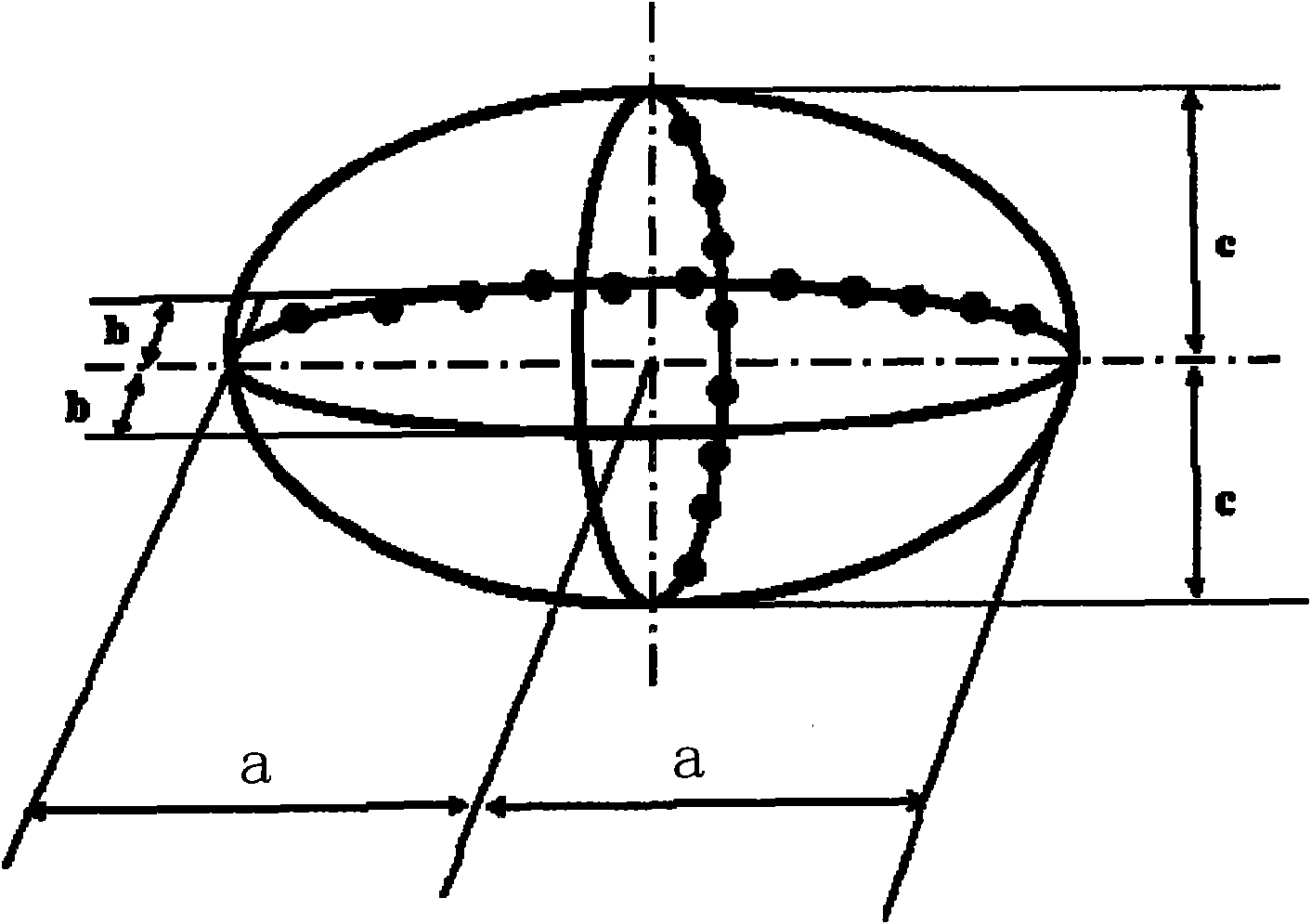

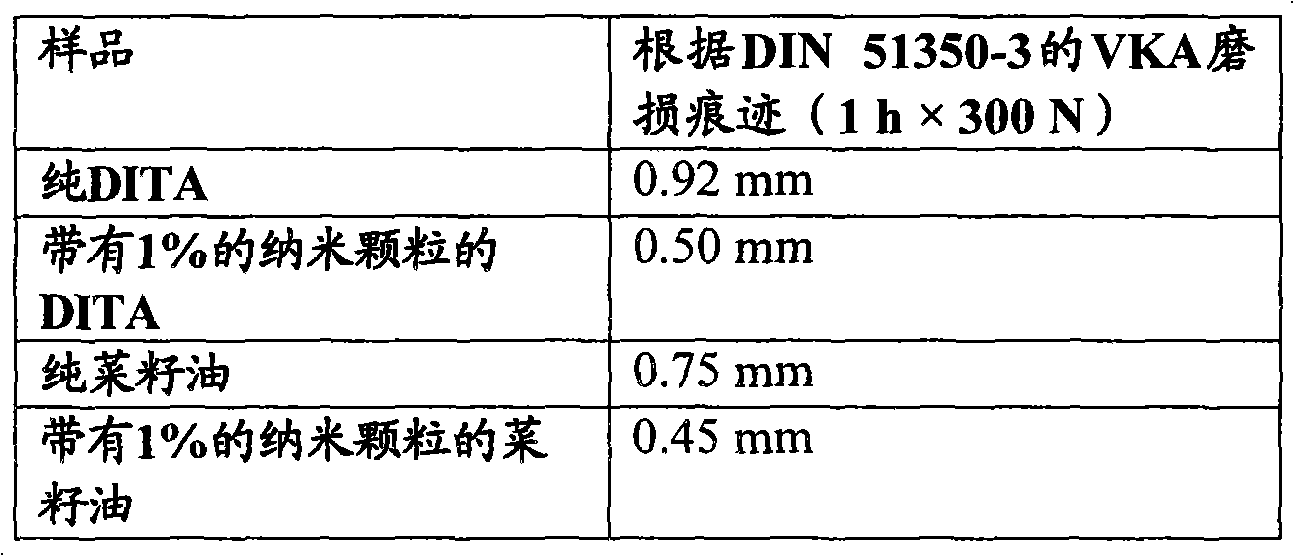

Additive for lubricant for improving the tribologic properties, a method for its production and application

The present invention relates to novel lubricant additives for improving the tribological properties, novel lubricants containing these additives, processes for the preparation thereof and the use thereof. Lubricant comprises ceramic nanoparticles as additives comprising aluminum oxide, aluminum nitride, silicon dioxide, titanium dioxide, zirconium oxide, yttrium oxide, tungsten oxide, tantalum pentoxide, vanadium pentoxide, niobium pentoxide, cerium dioxide, boron carbide, aluminum titanate, boron nitride, molybdenum disilicide, silicon carbide, silicon nitride, titanium carbide, titanium nitride, zirconium diboride and / or clay minerals, and thermally stable carbonates and / or sulfates. The nanoparticles represent an ellipsoid with three semi-axes a, b and c, which are not equal to each other, or equal to each other. The ratio of a and b is 1-100, a and c is 1-1000, and b and c is 1:100.

Owner:แลนด์เซสส์ ดอยช์แลนด์ จีเอ็มบีเอช

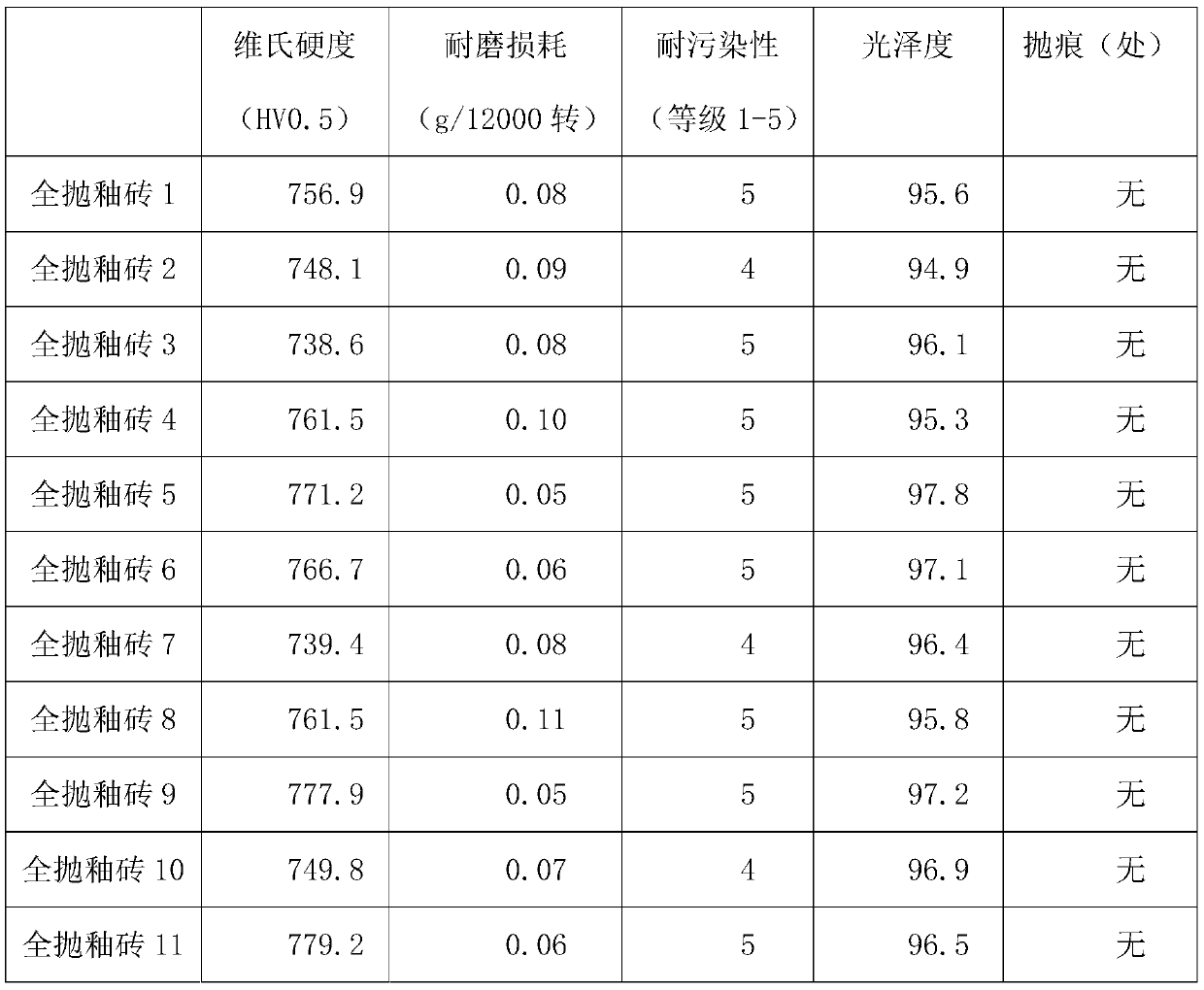

Wearing-resistant high-hardness ceramic glaze and preparation method thereof

The invention discloses a wearing-resistant high-hardness ceramic glaze and a preparation method thereof and relates to the technical field of ceramic glazes. The wearing-resistant high-hardness ceramic glaze comprises the following raw materials: albite, potassium feldspar, kaolin, quartz sand, zinc white, high-aluminum clay, calcite, talc, lithium porcelain, cordierite, zirconium sand, mullite powder, wollastonite, boron carbide, niobium pentoxide, zinc oxide and frit. Both the Vickers hardness and the wearing resistance of a full polish glaze brick made of the glaze disclosed by the invention can be improved, and market requirements on full polish glaze bricks with high hardness and wearing resistance can be met; when a glaze surface is sintered, a great number of bubbles are not generated, and the product is good in antifouling performance and high in glossiness after polishing; expansion coefficients of the full polish brick and a glaze layer are approximate to those of a porcelain blank, the glaze layer is subjected to small inner stress, polishing omission or partial exposure phenomena can be avoided in polishing, and thus product quality can be ensured.

Owner:黄奕雯

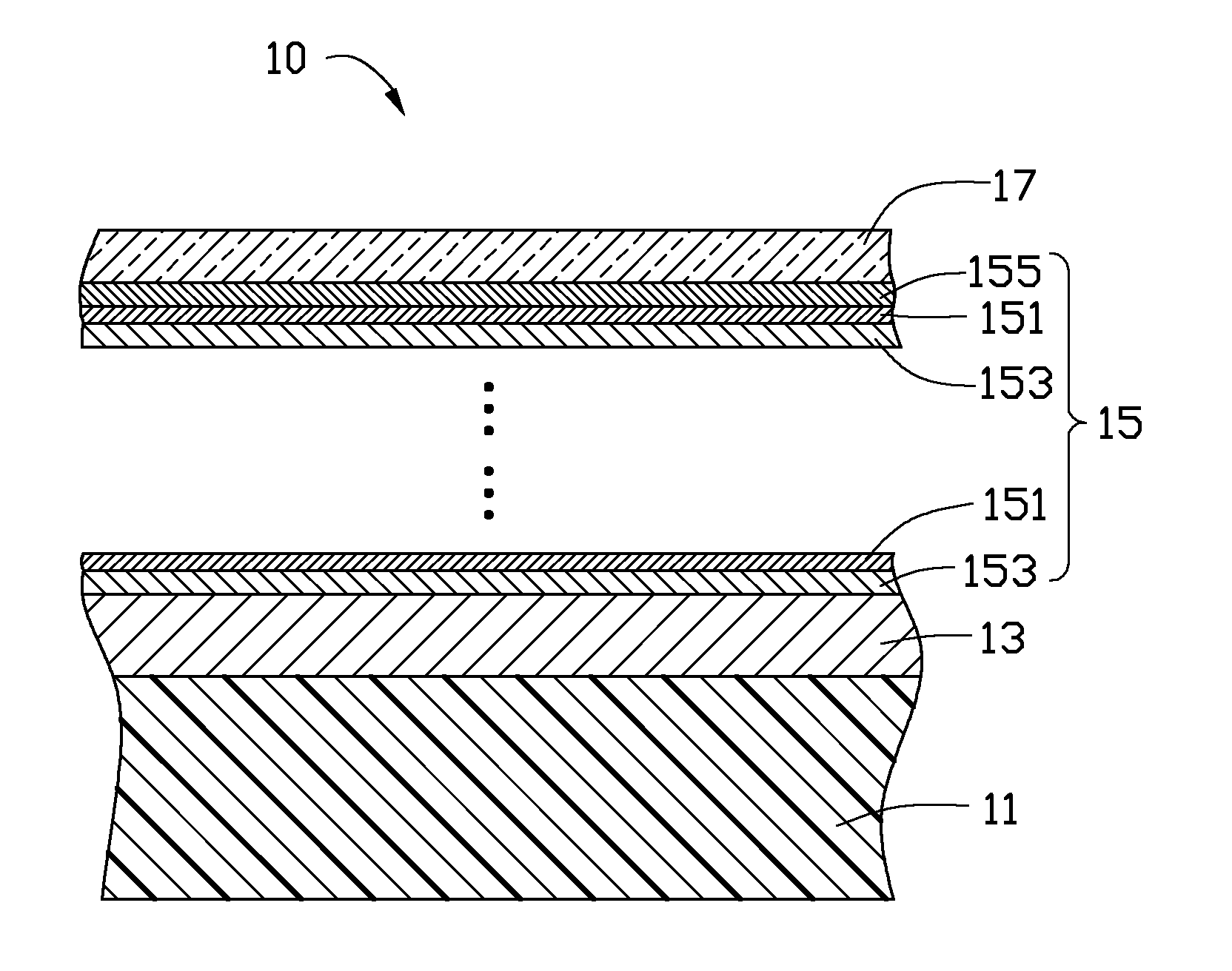

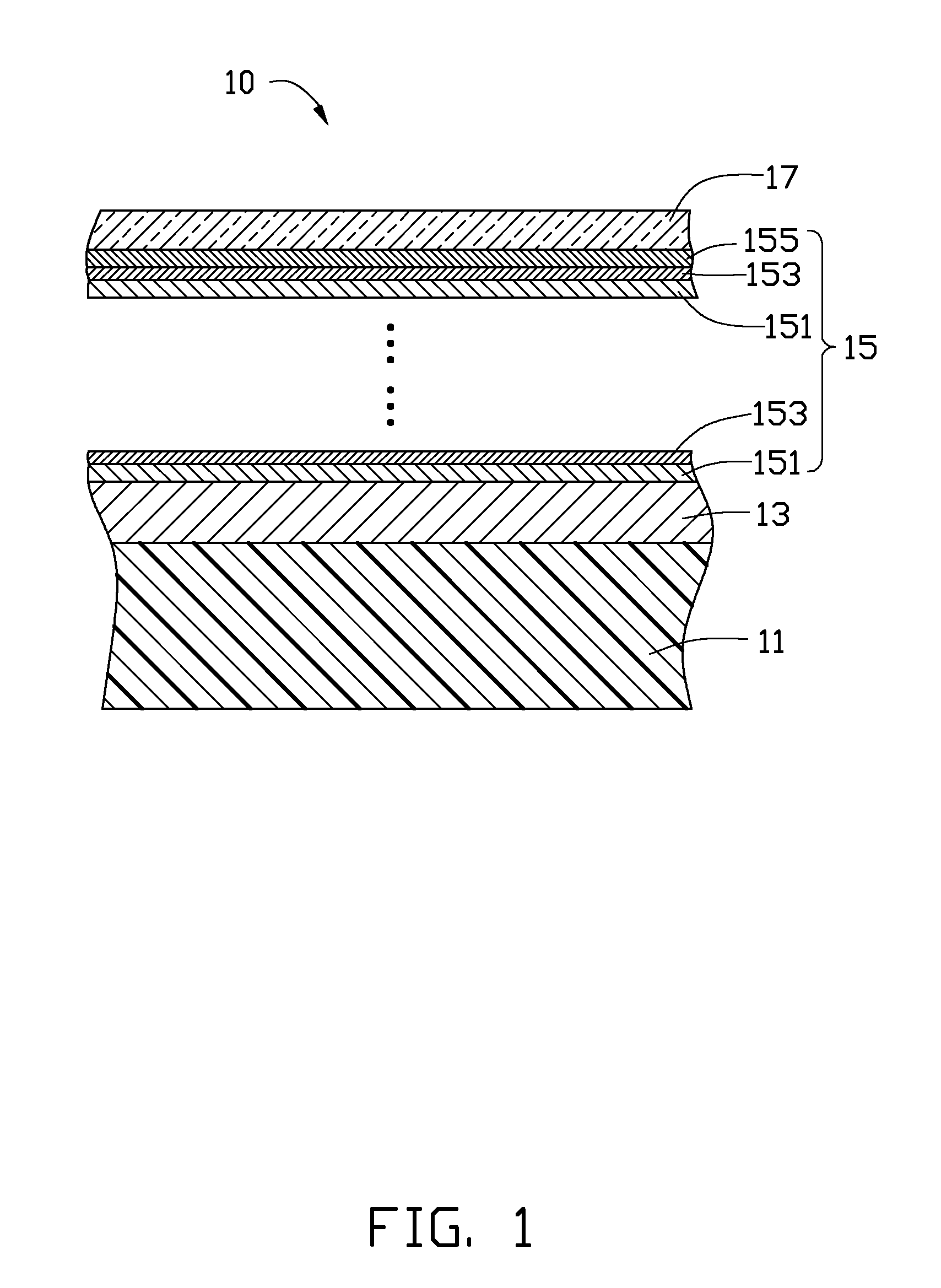

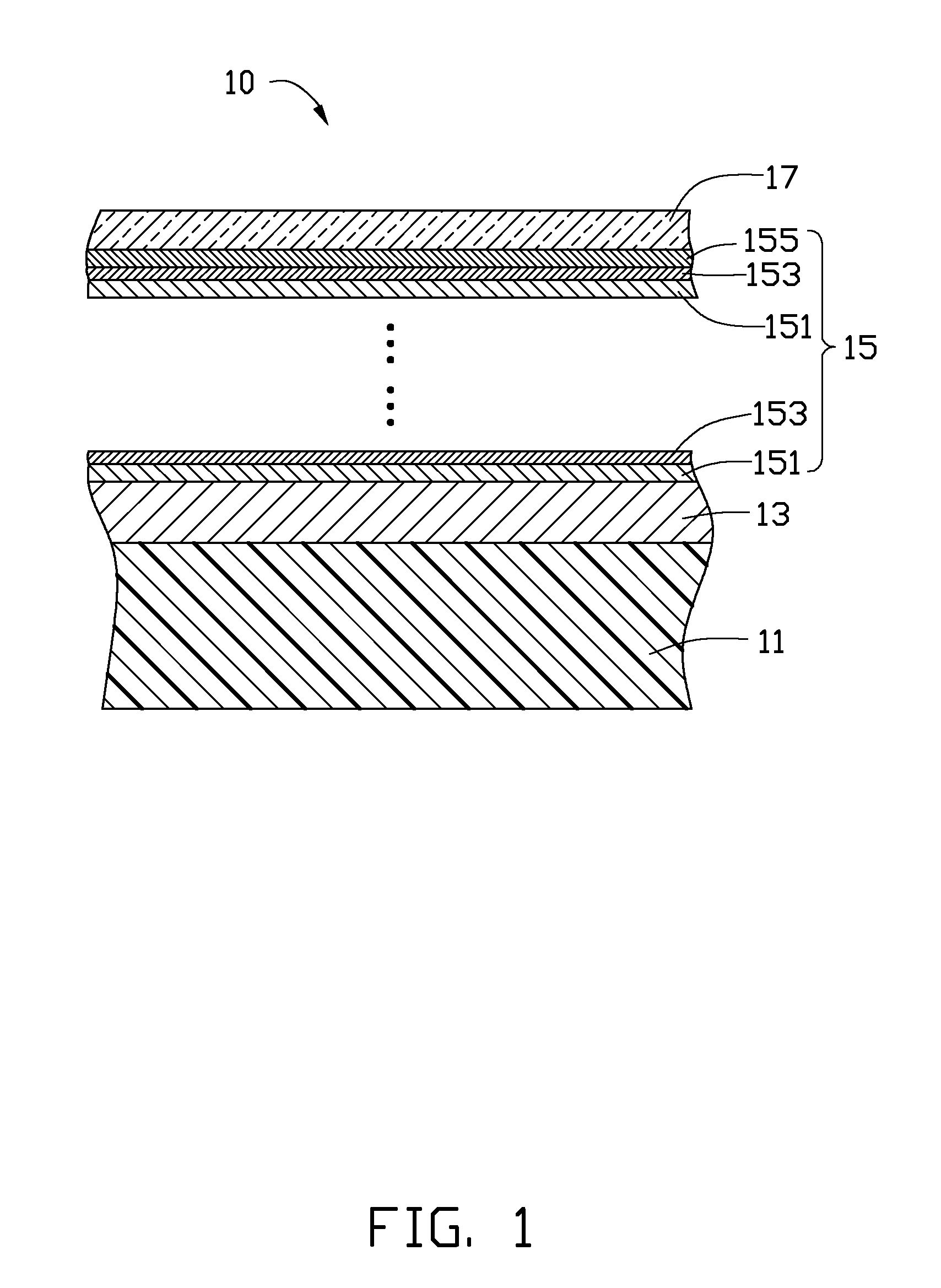

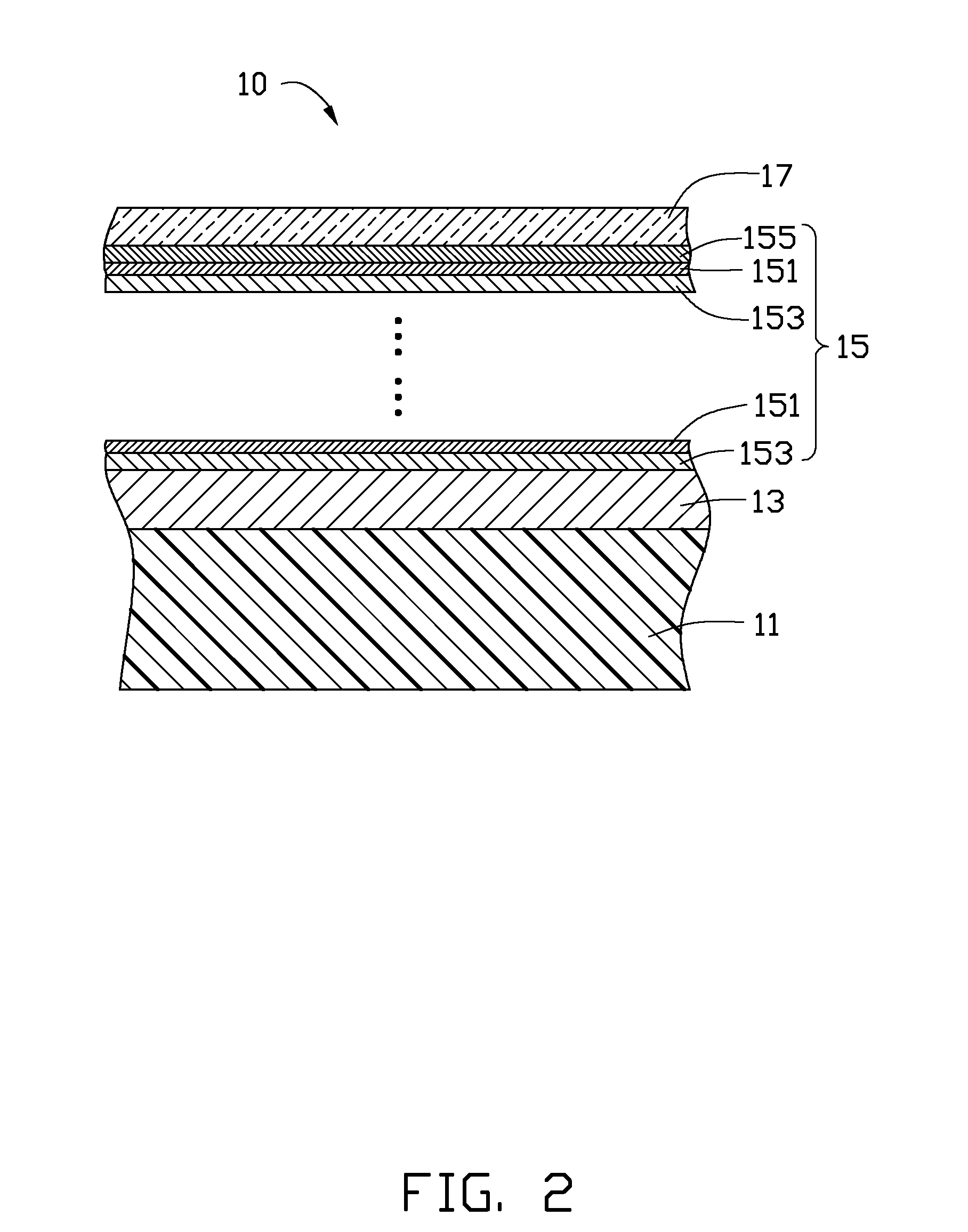

Electronic device housing

ActiveUS20110159277A1Ornamental structuresSynthetic resin layered productsMagnesium fluorideSilicon dioxide

An electronic device housing is provided. The electronic device housing comprises a substrate, a base paint coating formed on the substrate, and a metallic coating formed on the base paint coating. The metallic coating comprises a plurality of first layers interleaved with a plurality of second layers, and a third layer provided outermost. The first layer and the second layer are respectively a zirconium dioxide layer and an aluminum oxide layer, or are respectively composite component layer of niobium pentoxide and zirconium dioxide, and silicon dioxide layer. The third layer is a magnesium fluoride layer.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Method for preparing tantalum or niobium powders used for manufacturing capacitors

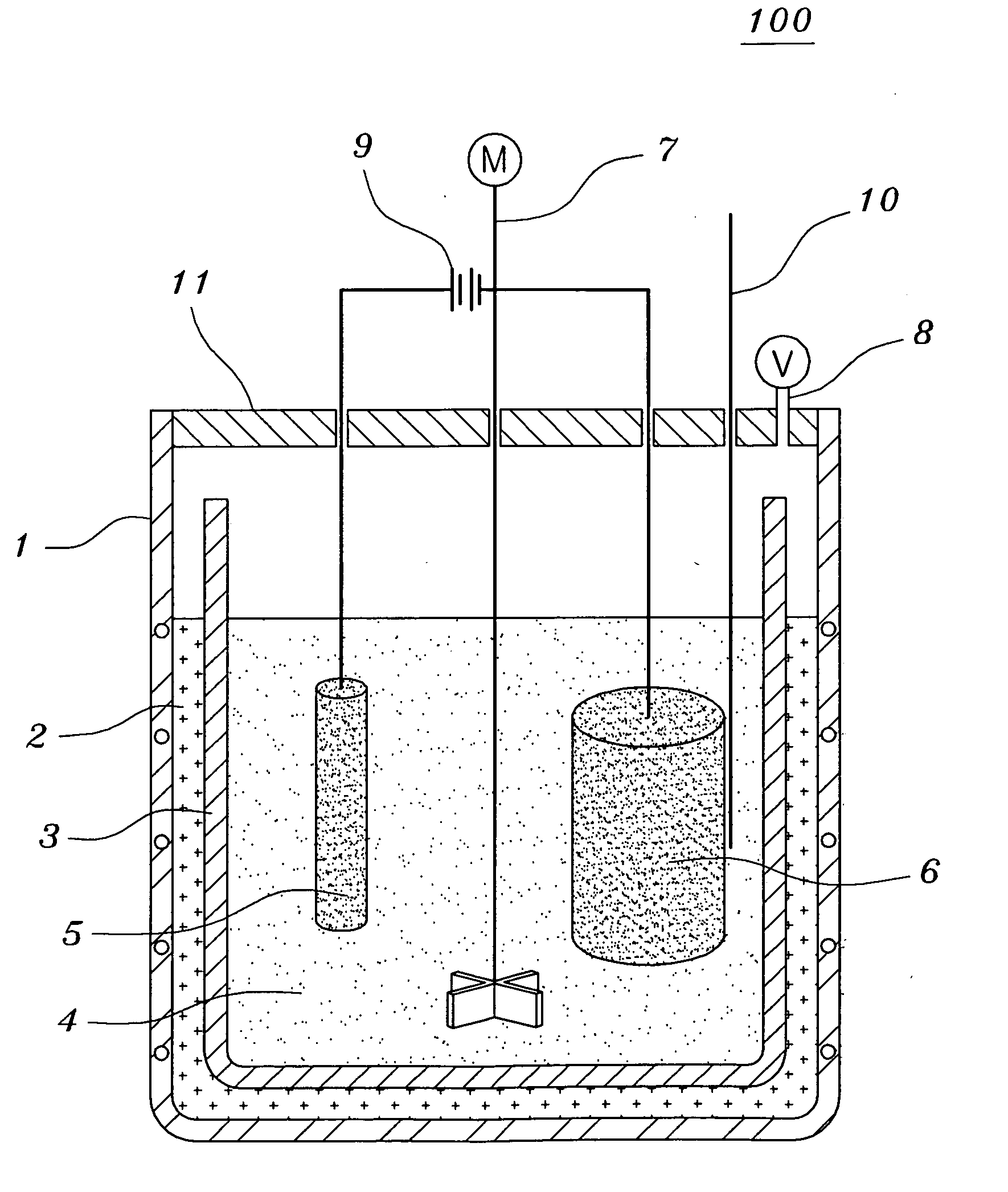

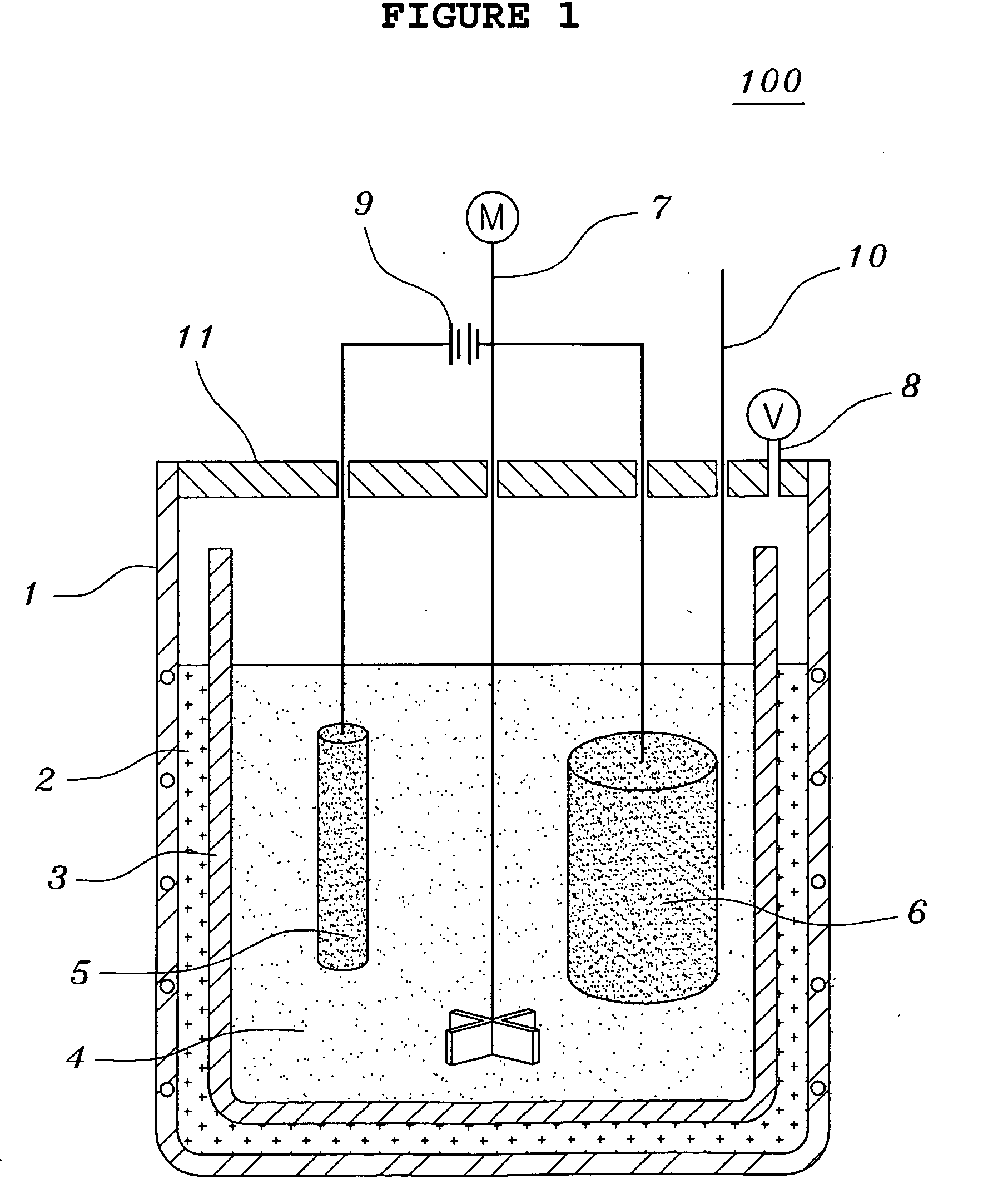

Disclosed relates to a method for preparing tantalum or niobium powders used for manufacturing capacitors in an electrolytic reducing reactor including an anode, a cathode and a molten salt, the method comprising: obtaining a tantalum or niobium oxide, expressed by Ta2O(5-y) or Nb2O(5-y) where y=2.5 to 4.5, from a tantalum pentoxide Ta2O5 or a niobium pentoxide Nb2O5 generated partially by an alkaline metal electrolytically reduced via a first electrolytic reducing reaction that reduces an alkaline metal oxide from a molten salt comprising at least one metal halogen compound, selected from the group consisting of alkaline metal and alkaline earth metal, and an alkaline metal oxide on the cathode; and preparing a tantalum or niobium powder by a first electrolytic reducing reaction that reduces at least one metal halogen compound selected from the group consisting of the alkaline metal oxide and the alkaline earth metal on the cathode and by a second reducing reaction with the tantalum or niobium oxide, represented by Ta2O(5-y) or Nb2O(5-y) where y=2.5 to 4.5.

Owner:KOREA ATOMIC ENERGY RES INST +1

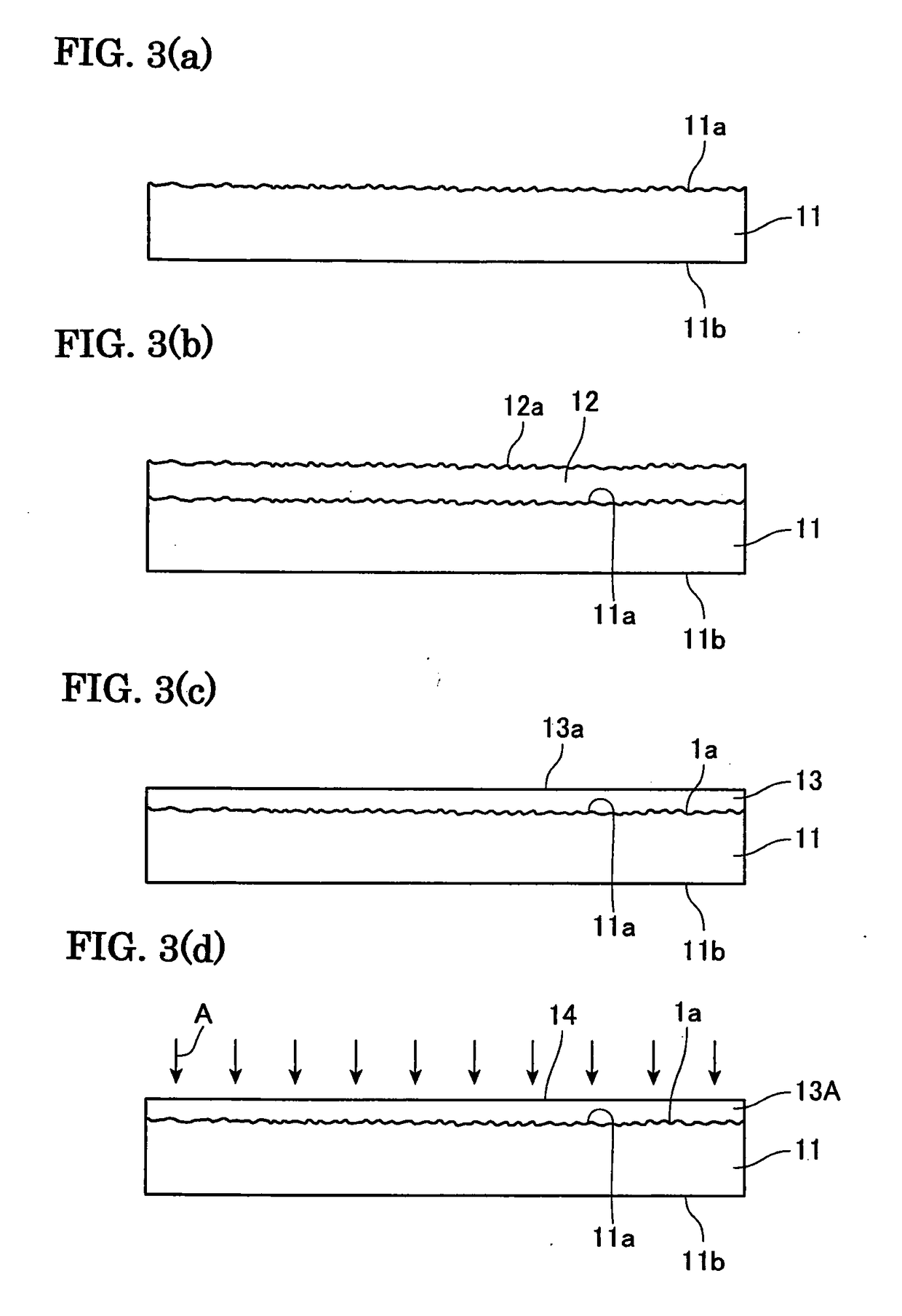

Bonding method

ActiveUS20190036009A1High bonding strengthReduce intensityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksMulliteNitride

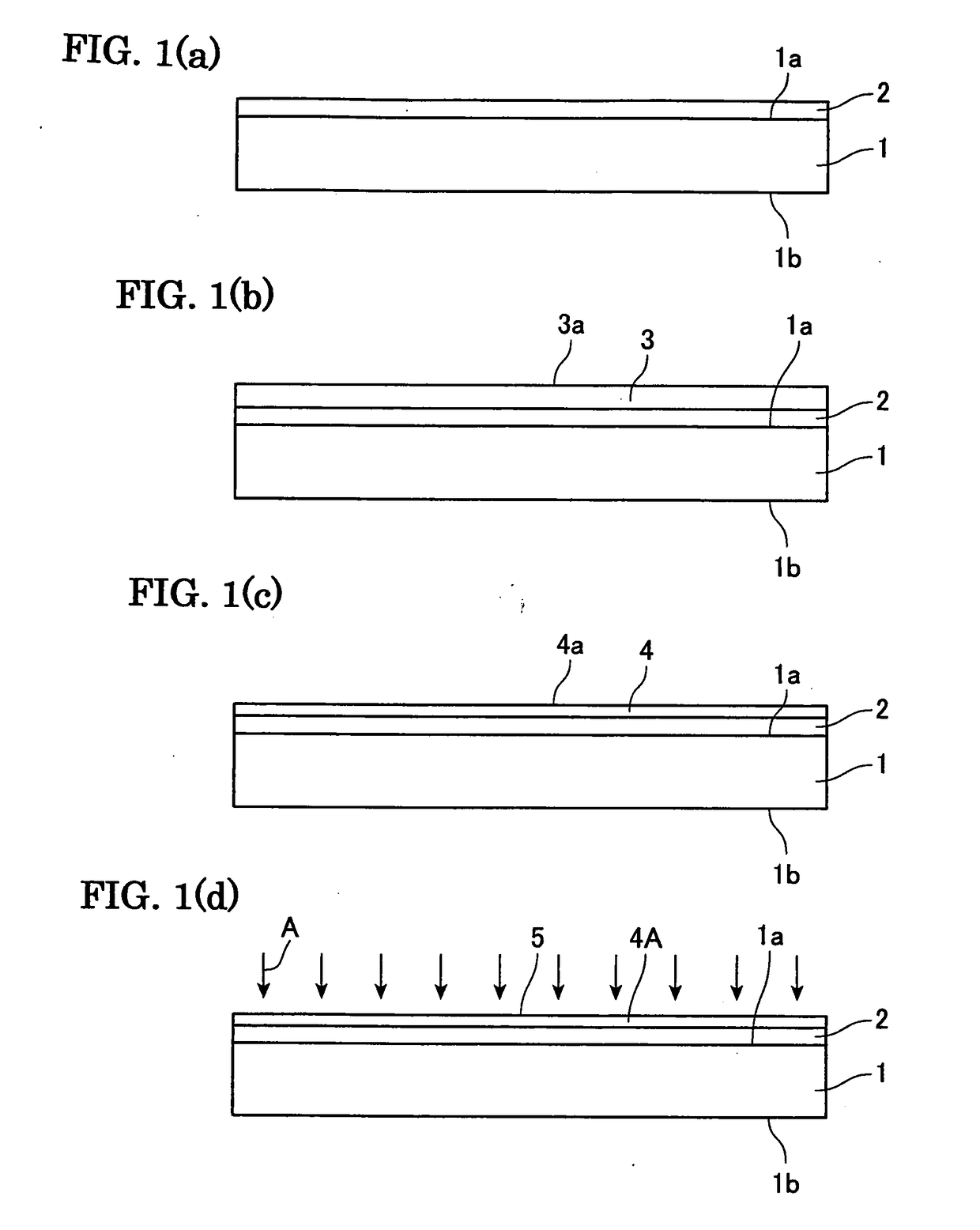

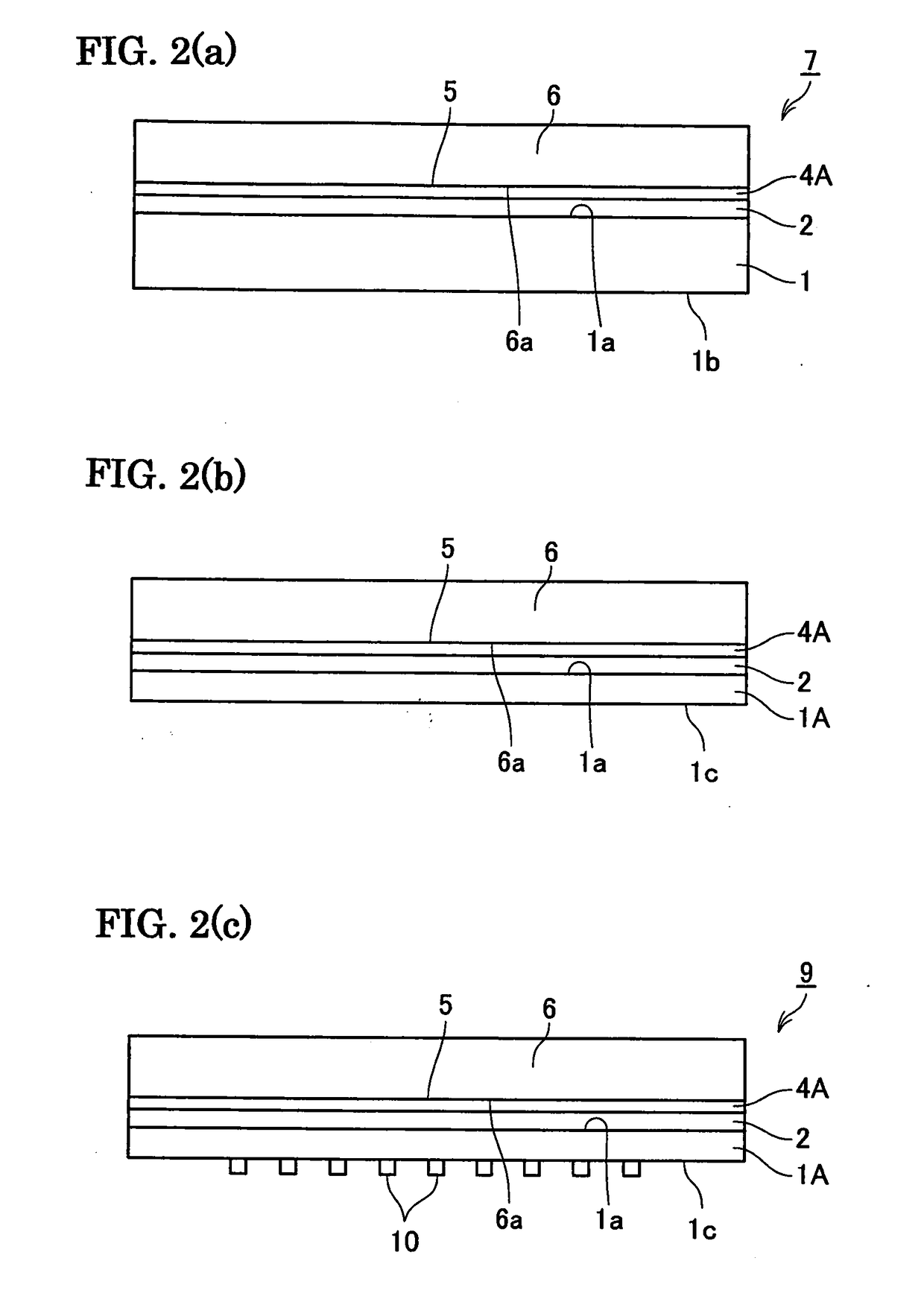

A bonding layer 3 is formed over a piezoelectric material substrate, and the bonding layer 3 is made of or more material selected from the group consisting of silicon nitride, aluminum nitride, alumina, tantalum pentoxide, mullite, niobium pentoxide and titanium oxide. Neutralized beam A is irradiated onto a surface 4 of the bonding layer and a surface of a supporting body to activate the surface of the bonding layer and the surface of the supporting body. The surface of the bonding layer and the surface of the supporting body are bonded by direct bonding.

Owner:NGK INSULATORS LTD

Capacitor powder

InactiveUS6992881B2Improve insulation performanceIncrease capacitanceLiquid electrolytic capacitorsCapacitor electrodesCapacitorNiobium pentoxide

Disclosed herein are capacitors having an anode based on niobium and a barrier layer based on niobium pentoxide, at least the barrier layer having a content of vanadium and process for their preparation and use.

Owner:TANIOBIS GMBH

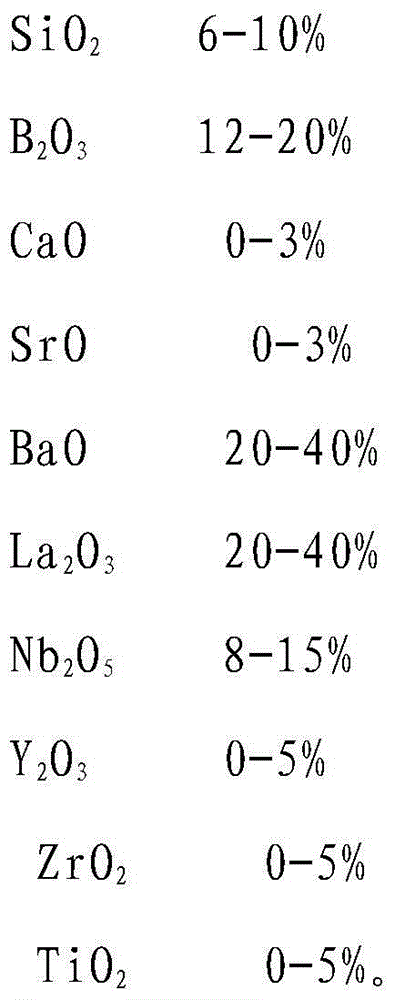

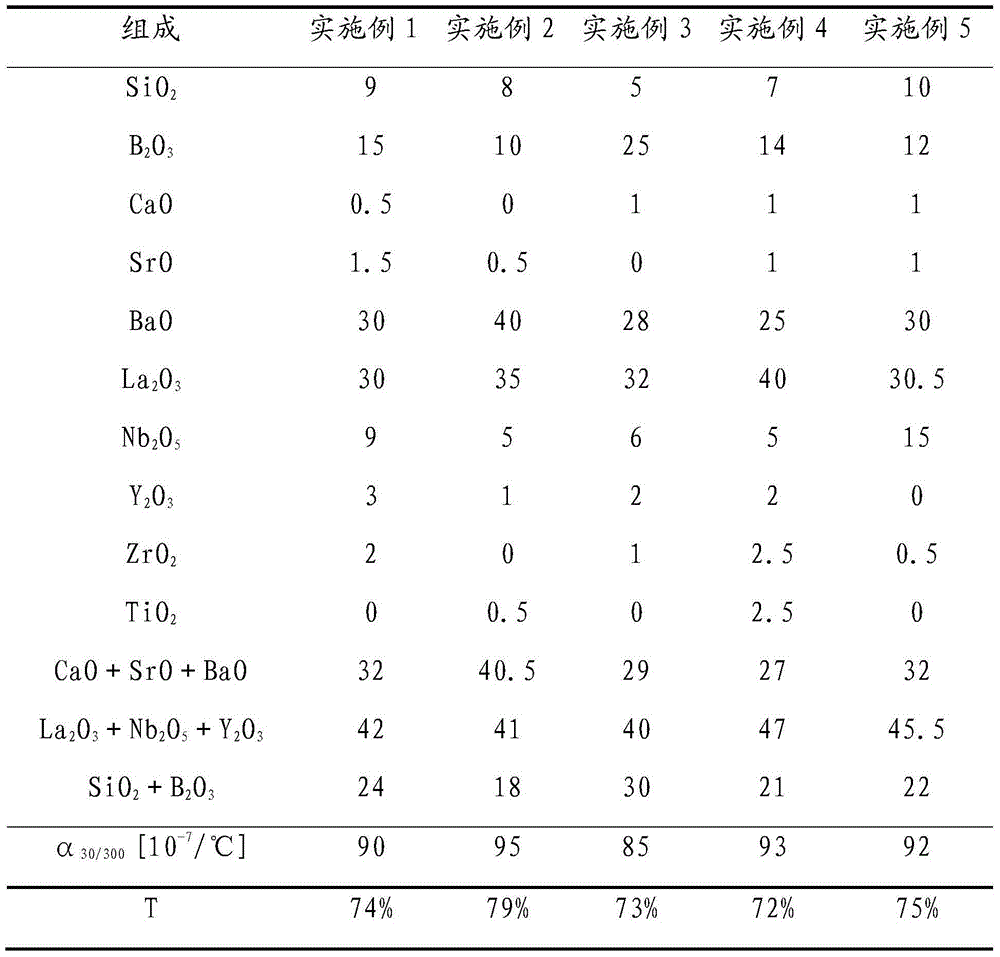

High-refractive-index ultraviolet-transparent glass and manufacturing method thereof

ActiveCN104402218AHigh refractive indexExcellent acid resistance and chemical stabilityFiberRefractive index

The invention discloses high-refractive-index ultraviolet-transparent glass and a manufacturing method thereof. The high-refractive-index ultraviolet-transparent glass comprises following components, by weight, 5-15% of SiO2, 10-25% of B2O3, 0-5% of CaO, 0-5% of SrO, 10-50% of BaO, 10-50% of La2O3, 5-15% of Nb2O5, 0-5% of Y2O3, 0-5% of ZrO2 and 0-5% of TiO2. The invention also provides the manufacturing method of the high-refractive-index ultraviolet-transparent glass. The method includes following steps: placing quartz sand, boronic acid or boron anhydrous, calcium carbonate, strontium carbonate, barium carbonate, lanthanum oxide, niobium pentoxide, yttria, zirconium oxide and titanium dioxide according to requirement in a formula into a pure-platinum crucible with addition of a reduction agent, melting the materials at 1400-1600 DEG C for 6-10 hours with stirring for 2-3 times during the melting process, and casting the molten glass into a specified specification. The invention also discloses an application of the high-refractive-index ultraviolet-transparent glass in an ultraviolet-transparent optical fiber plate. The high-refractive-index ultraviolet-transparent glass is high in refractive index and transmittance and is good in chemical stability.

Owner:CHINA BUILDING MATERIALS ACAD

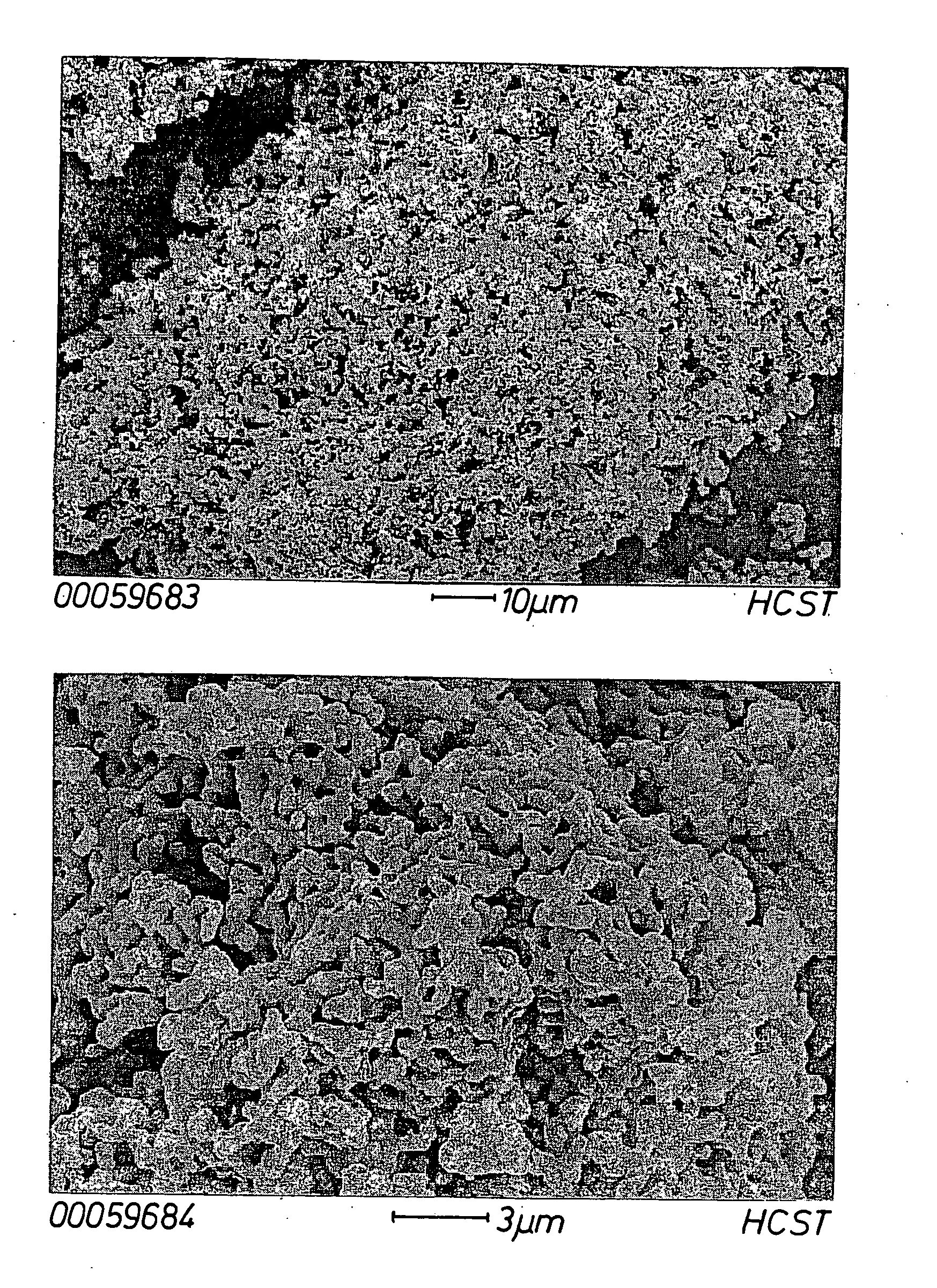

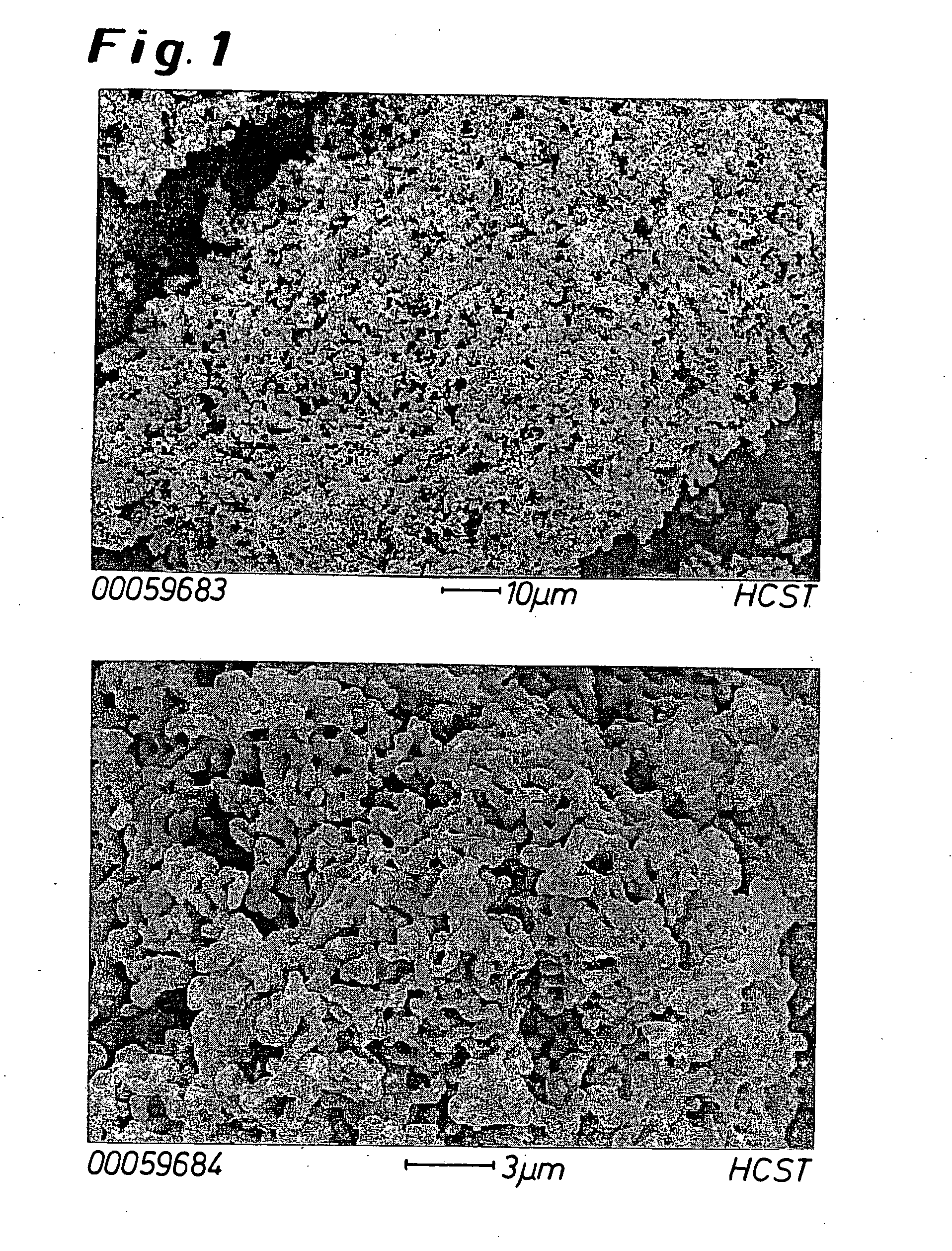

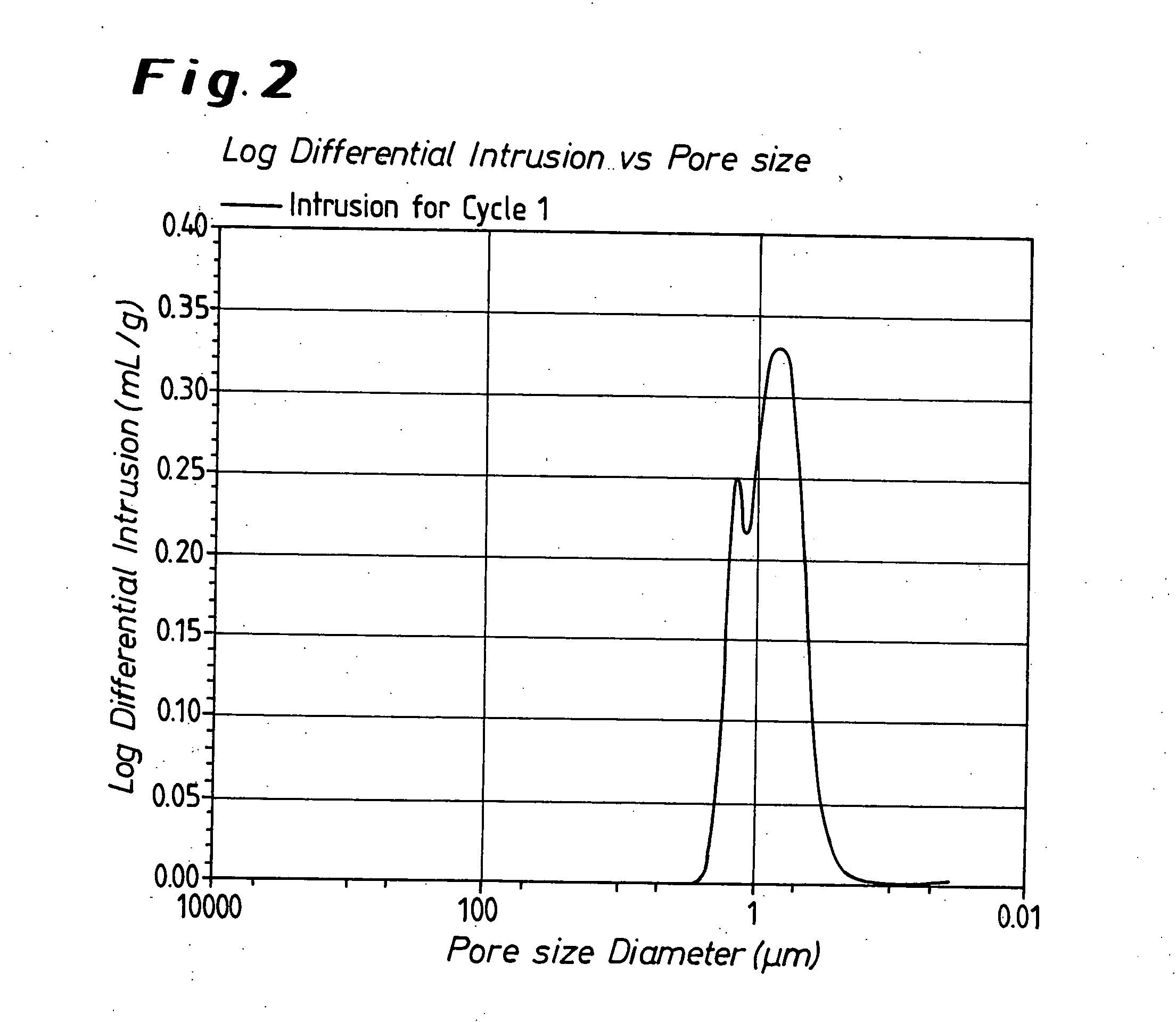

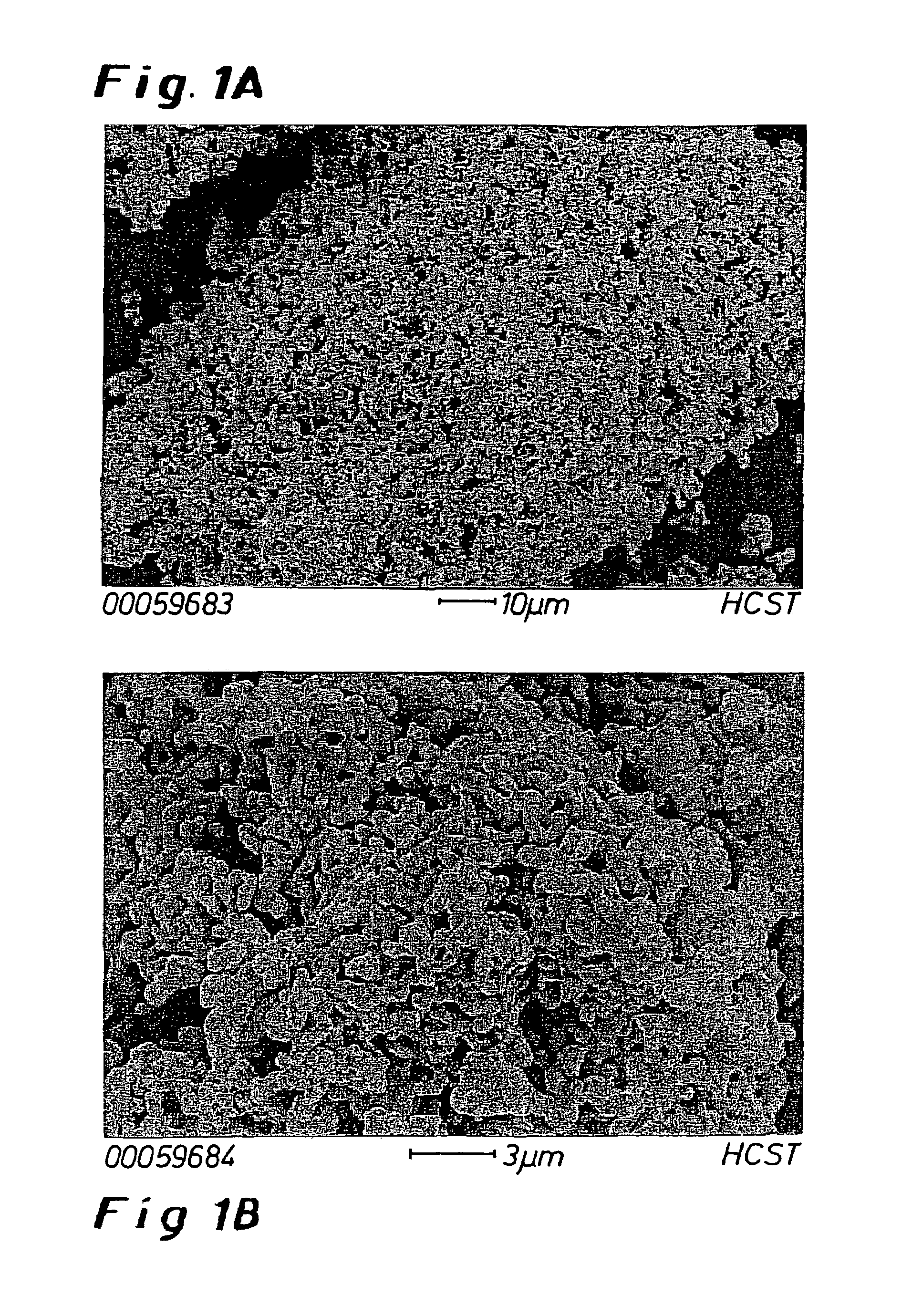

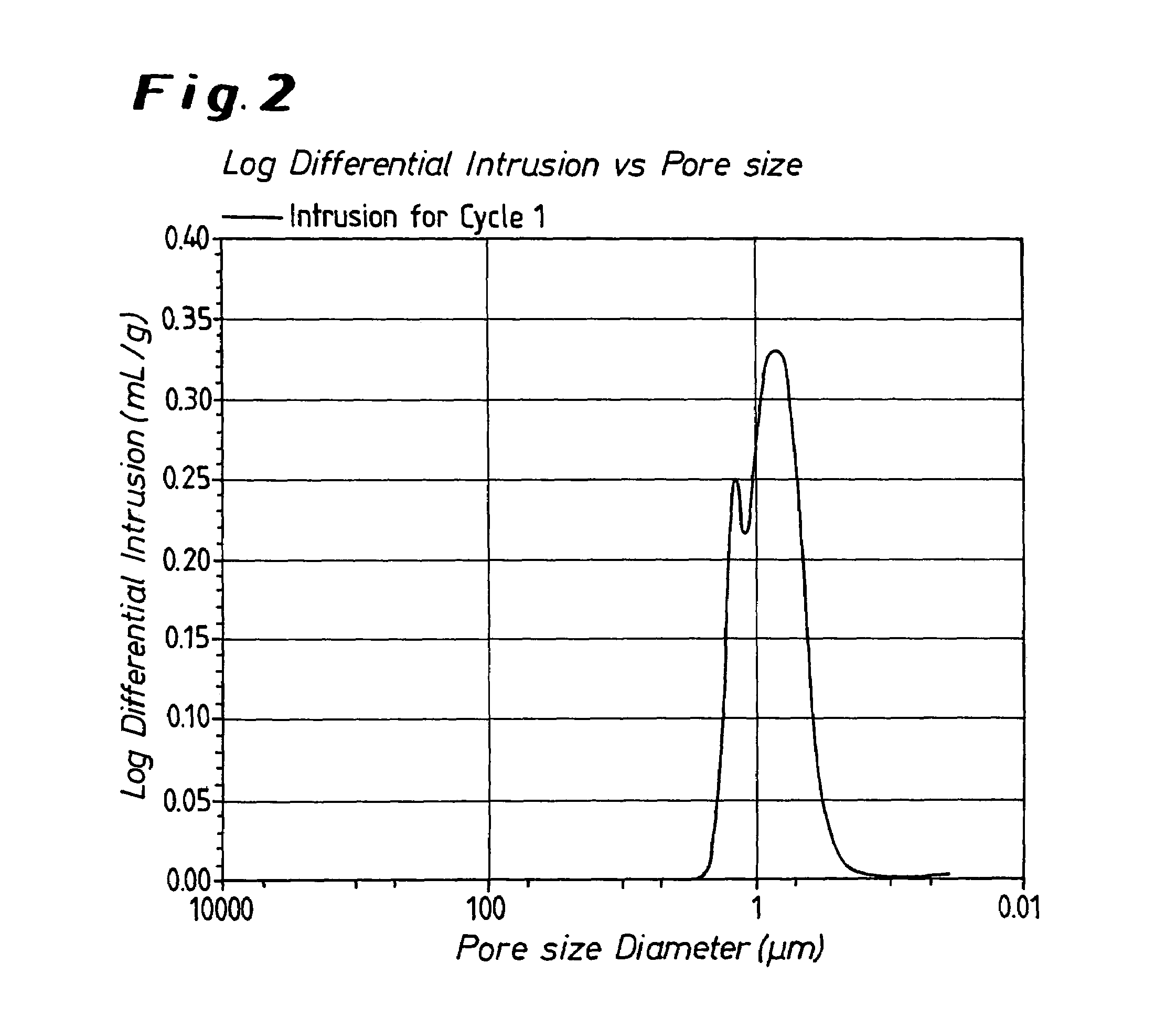

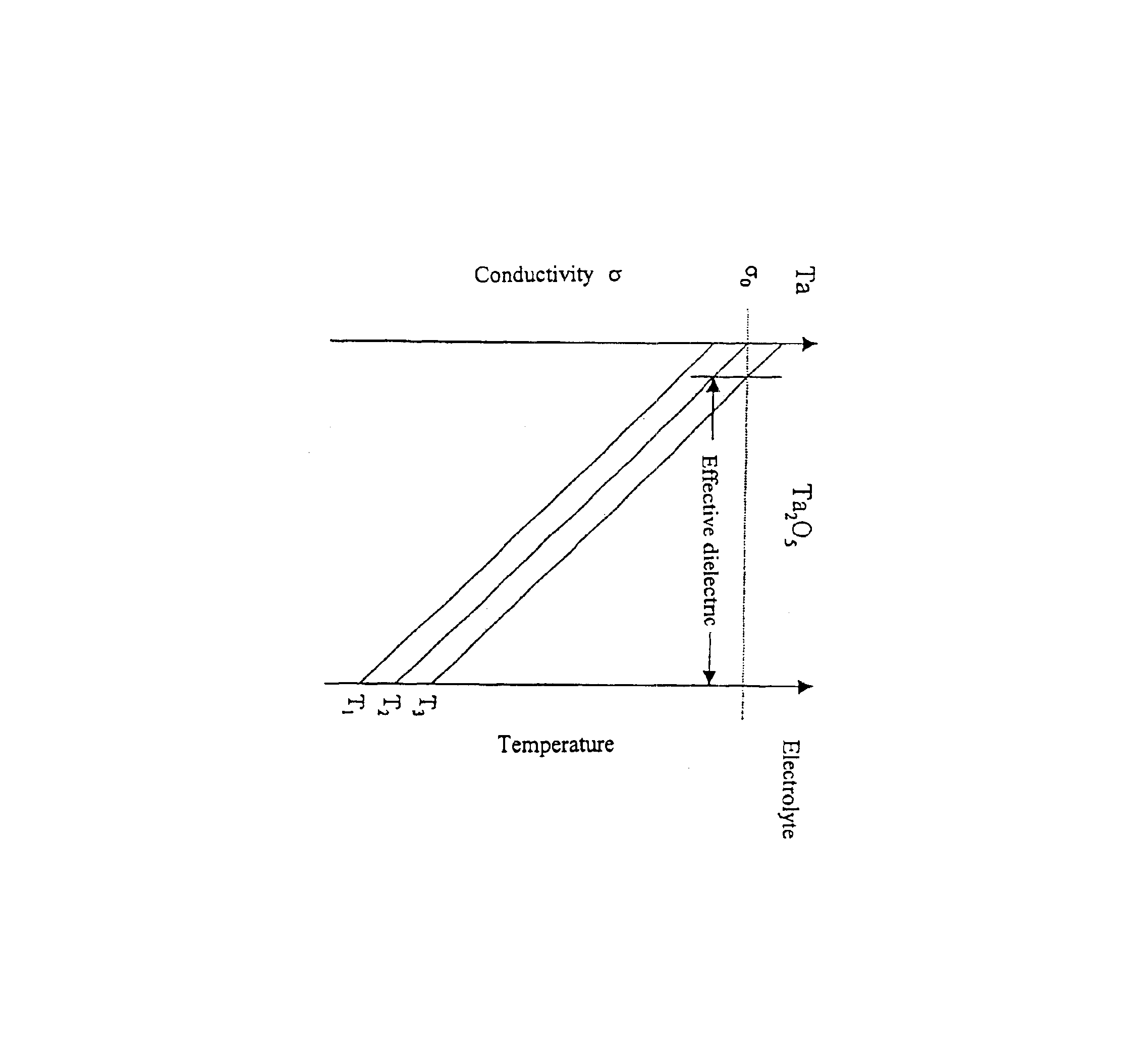

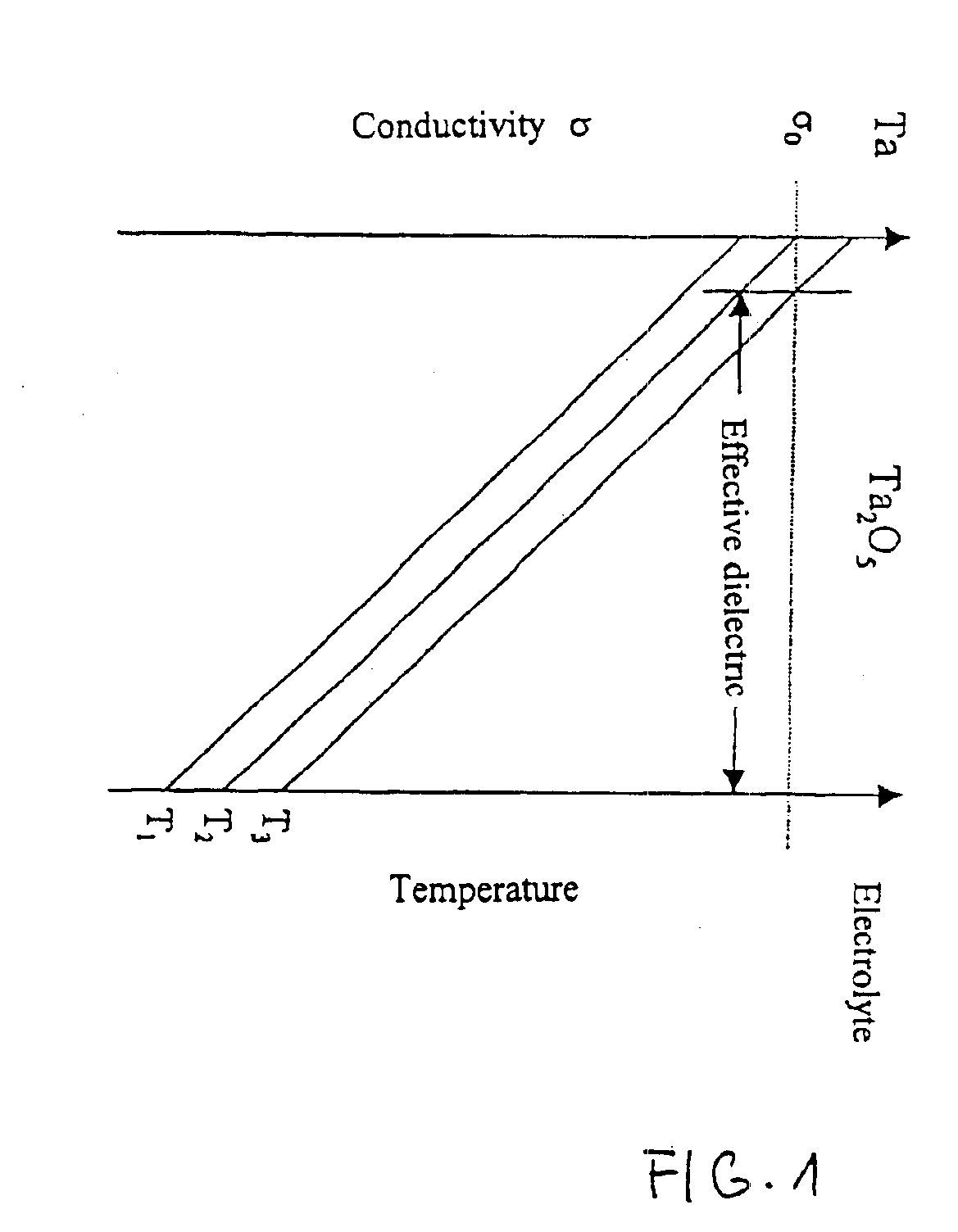

Process for producing capacitors

InactiveUS20050018384A1Avoid disadvantagesImprove liquidityFixed capacitor electrodesSolid electrolytic capacitorsPowder mixtureCapacitor

The invention relates to a process for producing capacitors based on niobium suboxide, and having an insulator layer of niobium pentoxide. Also described is a powder mixture suitable for production of capacitors. Pressed bodies produced from the powder mixture, and capacitors having specific properties are also disclosed.

Owner:H C STARCK GMBH

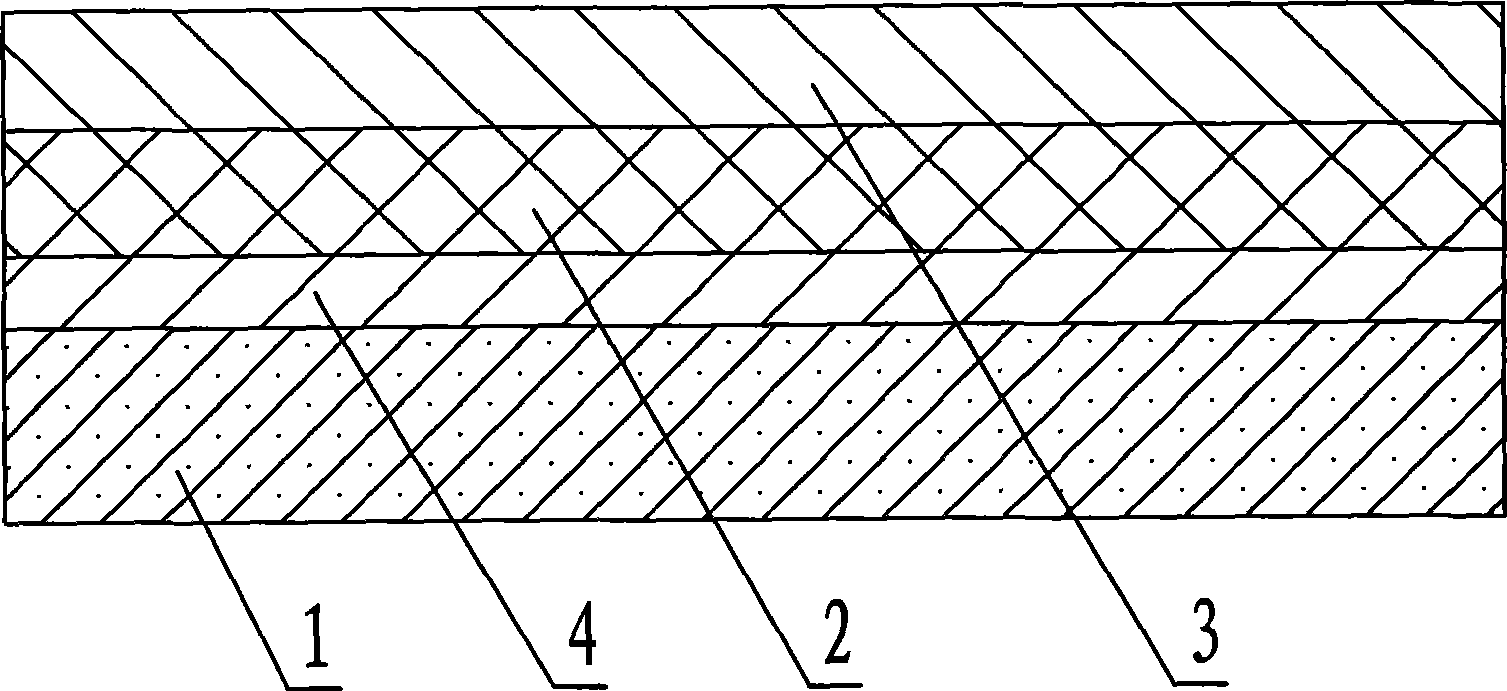

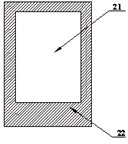

High transmittance conductive glass for touch screen and technique for producing the same

The invention discloses a high-transmissivity conductive glass for a touch screen and a process for producing the same. The high-transmissivity conductive glass for the touch screen comprises a glass substrate; the surface of the glass substrate is sequentially provided with a silicon dioxide film plating layer and a tin indium oxide film plating layer; the silicon dioxide film plating layer is positioned in an inner layer; the tin indium oxide film plating layer is positioned in an outer layer; a niobium pentoxide film plating layer is arranged between the glass substrate and the silicon dioxide film plating layer; a process flow comprises that: the qualified glass substrate is selected and cleaned; the cleaned glass substrate is sent into a film plating machine; the surface of the glass substrate is subjected to film plating processing; a finished product plated with a film is taken out from the film plating machine; the finished product is subjected to performance detection; and the qualified finished product is packaged and enters a warehouse. The high-transmissivity conductive glass utilizes good insulation and stable refractive index of columbium pentoxide and silicon dioxide and can improve the visible light transmittance of the conductive glass to 94 percent above; and a reasonable process course is favorable for improving controllability of operation and stability of product quality and can meet requirement of large-batch production.

Owner:常州津通光电技术有限公司

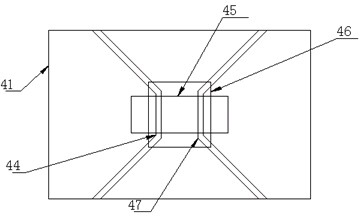

Novel ITO (indium tin oxide) gap-bridge integrated capacitive touch screen and manufacturing method of novel ITO gap-bridge integrated capacitive touch screen

ActiveCN102662543AImprove reliabilityImprove transmittanceElectronic switchingPhotomechanical exposure apparatusCapacitanceGraphics

The invention discloses a novel ITO (indium tin oxide) gap-bridge integrated capacitive touch screen and a manufacturing method of the novel ITO gap-bridge integrated capacitive touch screen. The novel ITO gap-bridge integrated capacitive touch screen comprises a transparent baseplate as well as a silicon dioxide layer, a niobium pentoxide layer, a black resin layer, an ITO gas-bridge electrode, a first insulating layer, an ITO electrode, a metal electrode and a second insulating layer which are sequentially stacked on the transparent baseplate; wherein the silicon dioxide layer is covered overall by glass, and the niobium pentoxide layer is covered overall by the silicon dioxide layer; the ITO electrode comprises a capacitive screen drive and a sensing electrode and is provided with the structure of regular graphics; the capacitive screen drive and the sensing electrode are in the identical layer, mutually independent and insulating from each other and are vertically designed. Due to the reasonable design of the stacked structure of the capacitive touch screen and the bridging conduction mode, the transmissivity of the capacitive touch screen is improved effectively, the visuality of the ITO pattern is reduced, and the reliability of the touch screen is further improved.

Owner:SHENZHEN BAOMING TECH

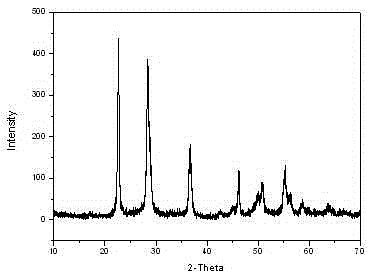

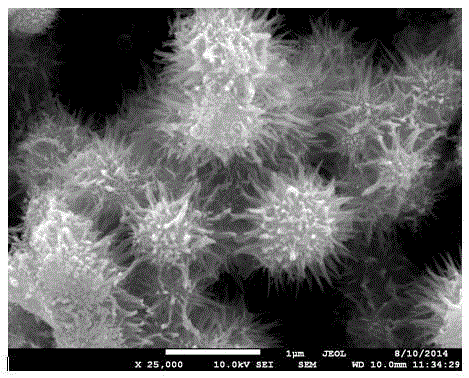

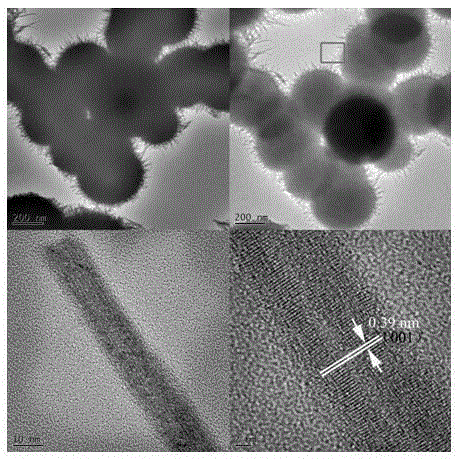

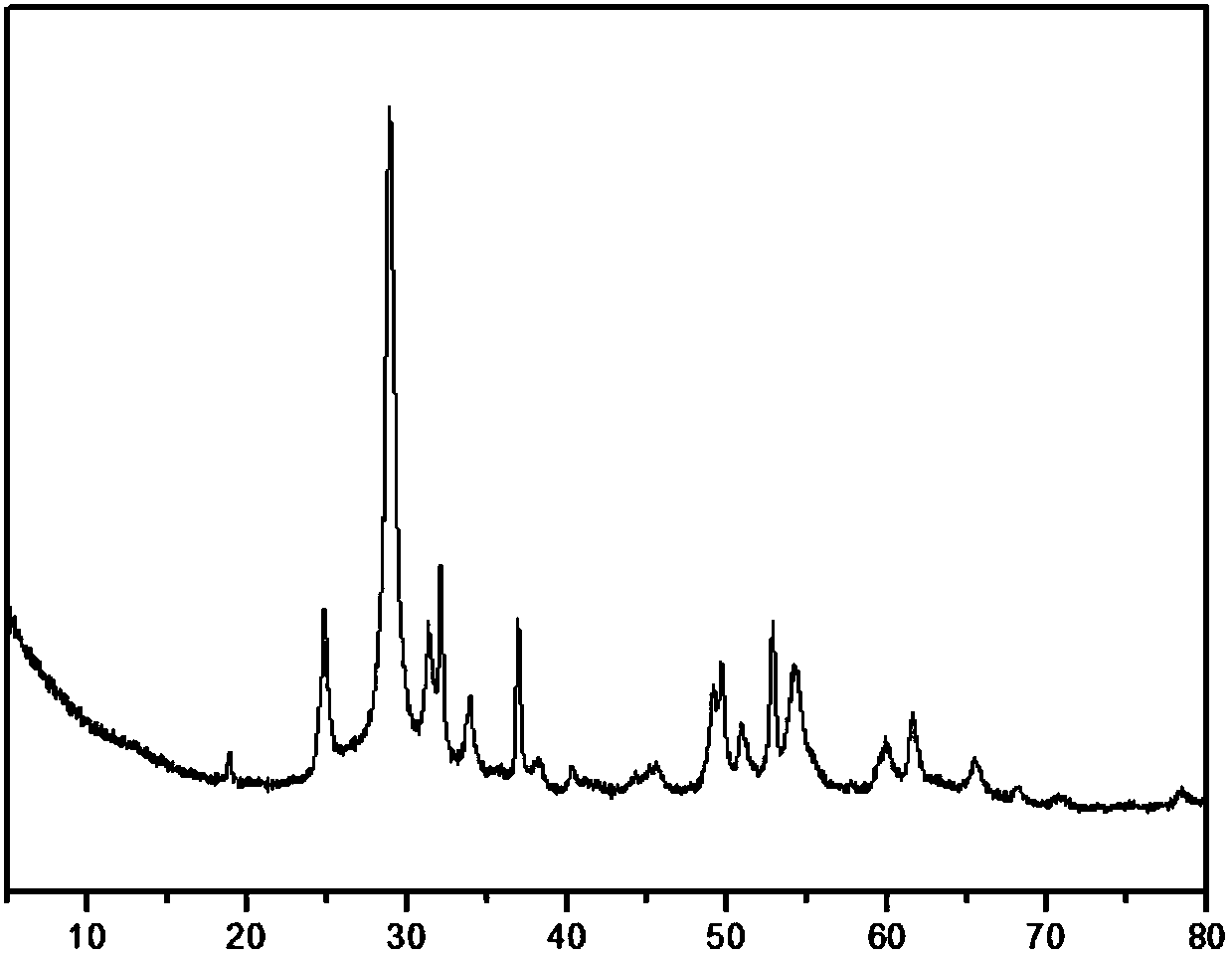

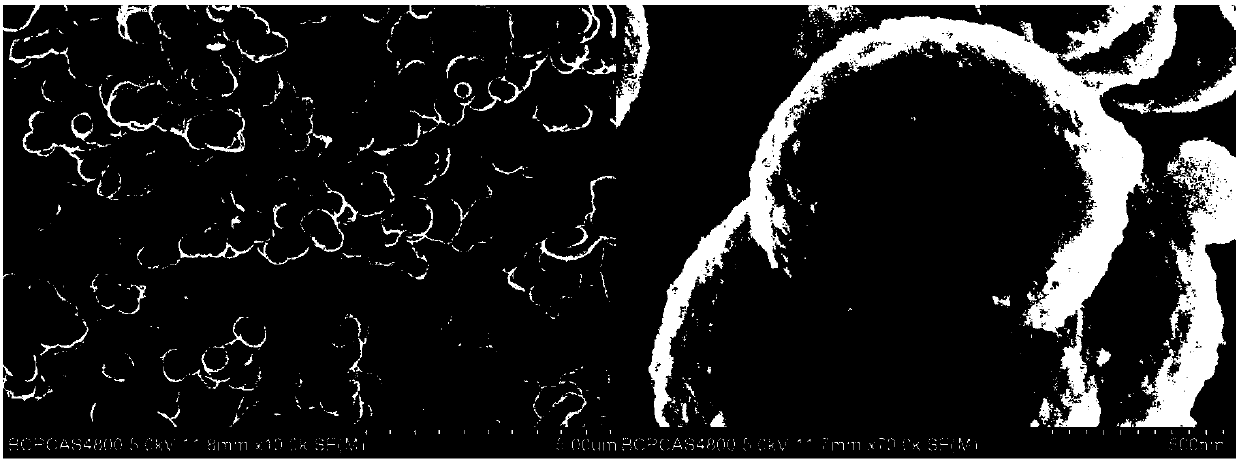

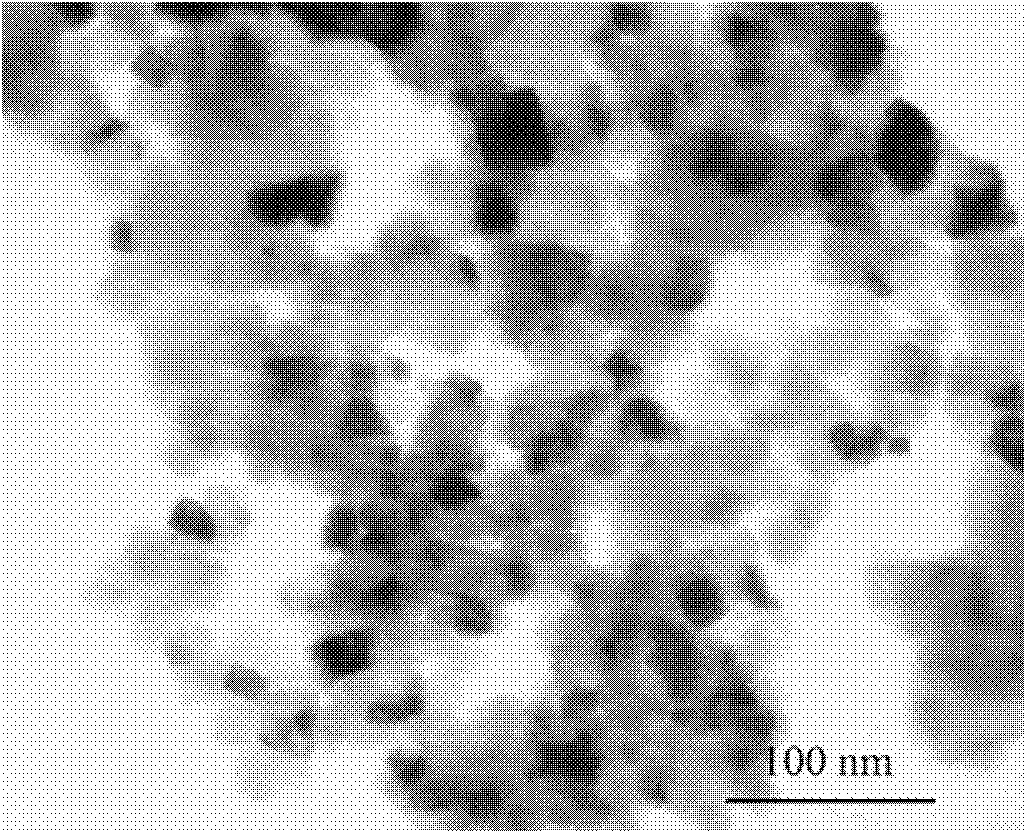

Preparation method of niobium (V) pentoxide urchin-like nano sphere and application of nano sphere as photocatalyst

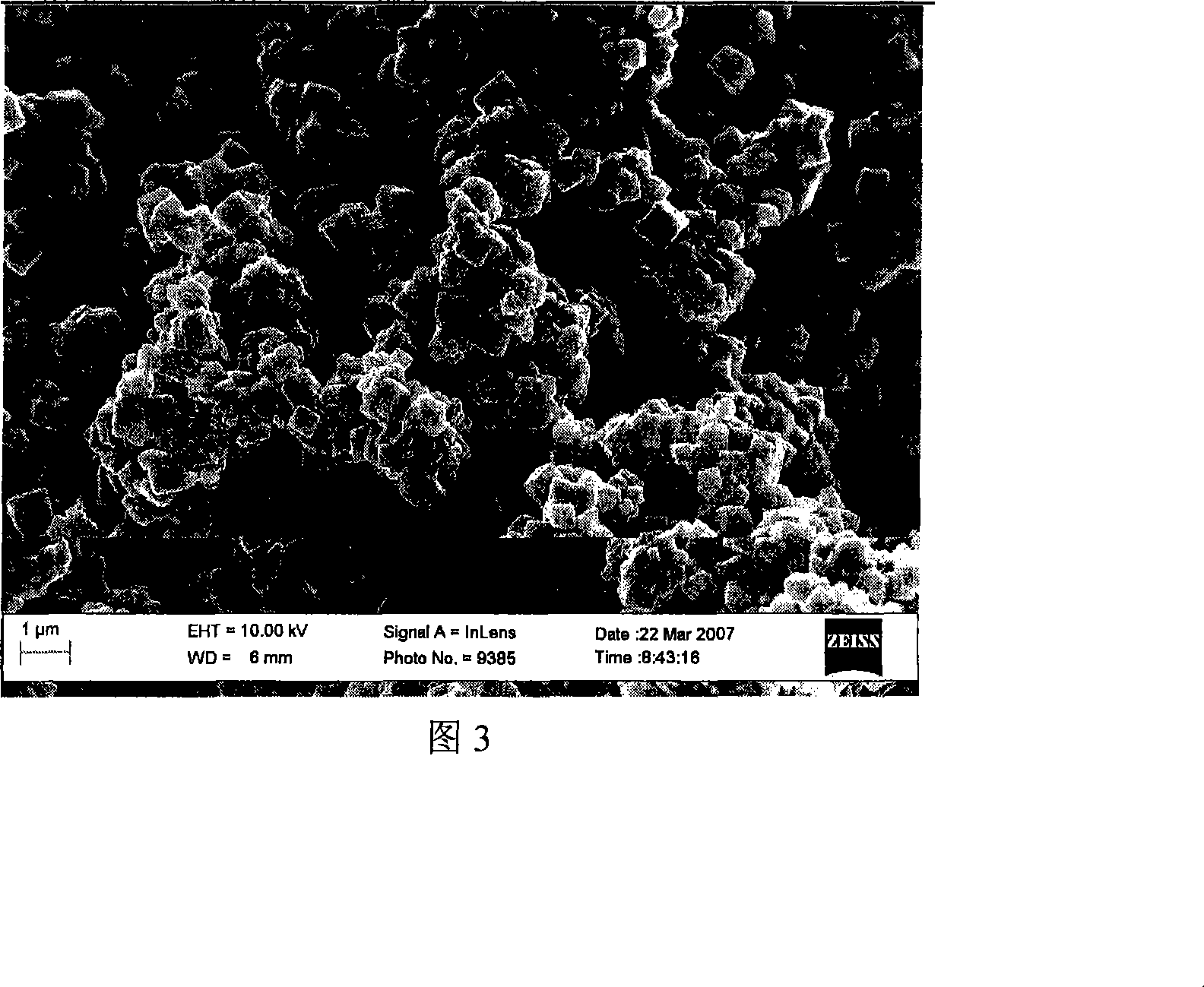

ActiveCN105384193AGood lookingMulti-level microstructureMetal/metal-oxides/metal-hydroxide catalystsNiobium compoundsMaterials scienceNiobium oxide

The invention relates to a preparation method of a niobium (V) pentoxide urchin-like nano sphere and an application of the nano sphere as a photocatalyst. The preparation method comprises the following steps: step one, weighing alcohol and deionized water according to a volume ratio of 20:1 to 1:100 at a room temperature, mixing water and alcohol, and stirring to prepare an alcohol solution; step two, weighing soluble niobium salt, dissolving the soluble niobium salt into the alcohol solution obtained in the step one, and stirring for 0.5 to 5 hours to obtain a transparent solution; step three, transferring the obtained transparent solution to a hydrothermal reactor, wherein the transparent solution accounts for 50 to 70% of the total volume of the reactor, and the hydrothermal reactions are performed at a temperature of 100 to 220 DEG C, after reactions, naturally cooling the reactor to the room temperature, and washing and drying the reaction products to obtain the niobium (V) pentoxide urchin-like nano spheres. According to the preparation method, alcohol is used to adjust the polarity of the solution so as to adjust the growth speed of niobium, and thus niobium (V) pentoxide urchin-like nano spheres, which have uniform morphology and controllable diameters, are obtained. The prepared niobium (V) pentoxide urchin-like nano spheres has a high catalytic activity on degrading dyes in water in the presence of visible light.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

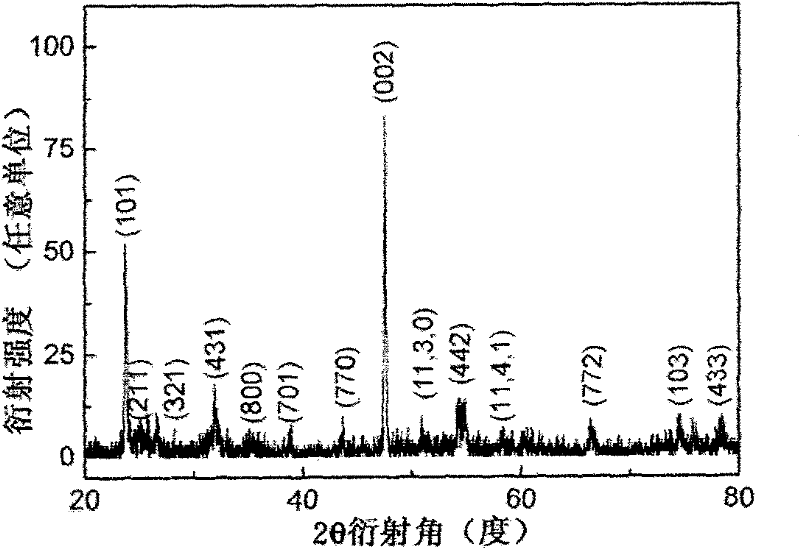

Conductive niobium oxide target and preparation method and application thereof

InactiveCN101864555AHigh refractive indexVacuum evaporation coatingSputtering coatingIntermediate frequencyRefractive index

The invention relates to a conductive niobium oxide target and a preparation method and application thereof. The niobium oxide target consists of NbOx, wherein x is more than 0.05 and less than 2.5, and according to the Archimedes method, the relative density of the niobium oxide target is not lower than 99 weight percent, the crystal structure is of a cubic crystal shape, the tensile strength is 10-20MPa, the Young's modulus is 1500-2800MPa and the resistivity is 0.03-1Omega.cm. The average transmittance of the film prepared with the conductive niobium oxide target is more than 94 percent within the visible spectral range. The preparation method comprises the following steps: mixing niobium pentoxide powder and niobium powder; filling the mixture into a die, placing the die into a sintering furnace, and carrying out pressure sintering in the inert or vacuum environment; and maintaining the temperature for 8-15 hours under the constant temperature and the constant pressure, and releasing the pressure, thereby obtaining the niobium oxide target. The invention has the advantages that the prepared niobium oxide target has excellent electrical conductivity, and the film with a high refractive index can be prepared through DC sputtering and intermediate-frequency sputtering.

Owner:上海高展金属材料有限公司 +1

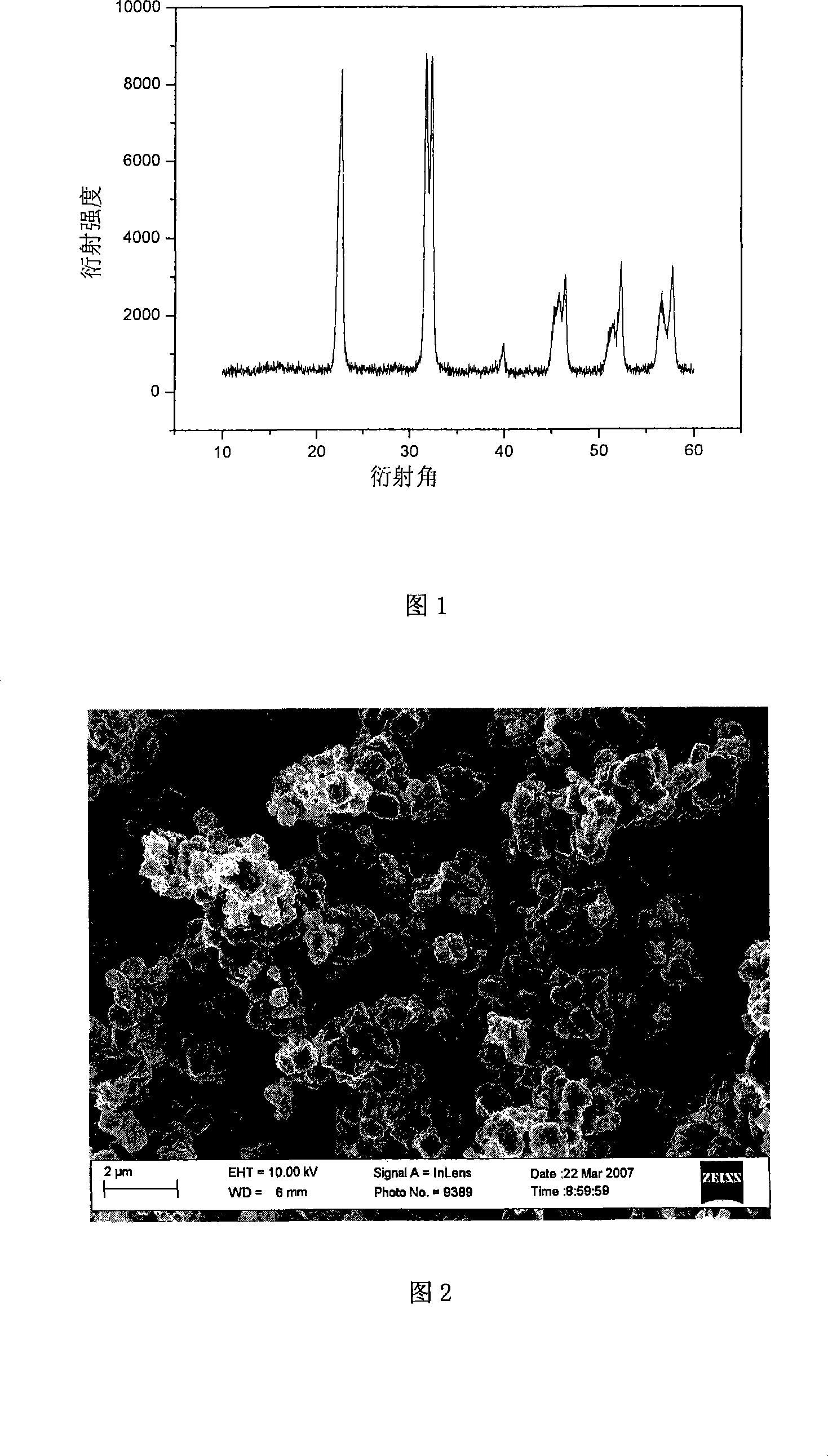

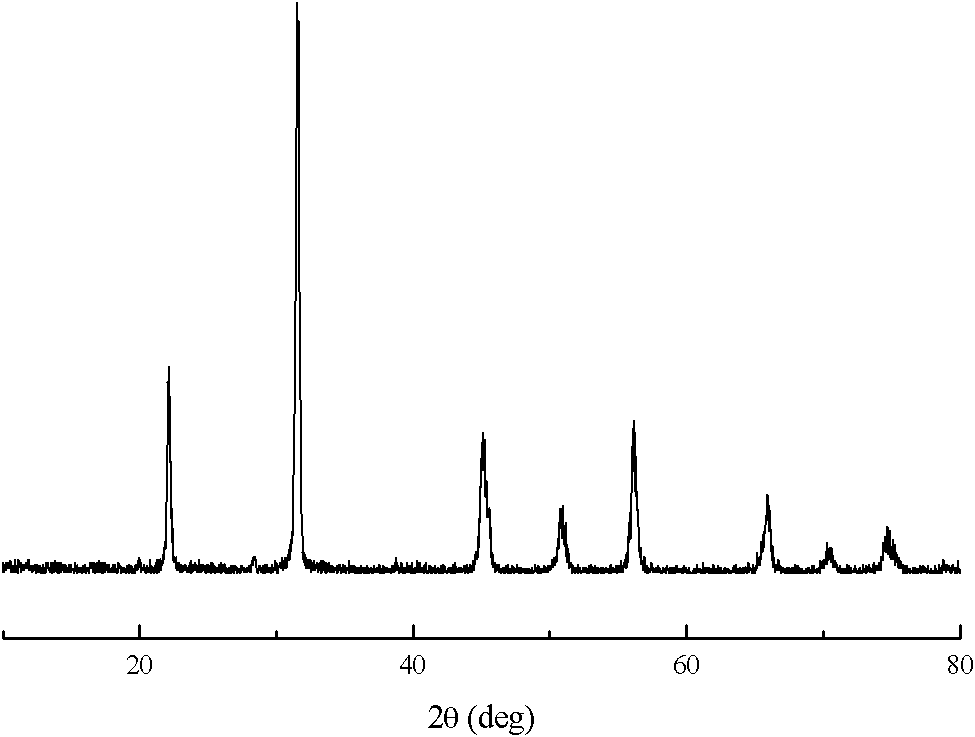

Hydro-thermal synthesis method for tantalum adulterated potassium sodium niobate leadless piezoelectric ceramic powder

InactiveCN101186338APiezoelectric/electrostrictive/magnetostrictive devicesNiobium compoundsCeramic sinteringSynthesis methods

The invention relates to a hydrothermal synthesis method for preparation of sodium-potassium niobate lead-free piezoelectric ceramic powder intermingled with tantalum, which belongs to the functional ceramic material field. The invention is characterized in that sodium hydroxide, potassium hydroxide, niobium pentaoxide and tantalum pentoxide are used as raw materials at the temperature ranging from 200 to 250 DEG C, and K0.5Na0.5NbO3 piezoelectric ceramic powder intermingled with Ta can be achieved by hydrothermal synthesis while preserving the heat for 20 to 36 hours; the molar ratio of the total added amount of niobium pentaoxide and tantalum pentoxide to alkali solution is 1:10 to 1:25, and the molar ratio of the added niobium pentaoxide to tantalum pentoxide is 1:9 to 4:6; the solution mixture ratio of sodium hydroxide to potassium hydroxide is 1:4 to 1:6, and the concentration of alkali solution is 4-10mol / L. The synthesis temperature is low and the powder grain is fine and average with a diameter about hundreds of nanometers in the invention. And the surface activity is great, which is favorable to the ceramic sintering at the latter stage.

Owner:UNIV OF SCI & TECH BEIJING

MnZn ferrite material and method of manufacturing the magnetic core

InactiveCN101183585AImprove DC Superposition CharacteristicsReduce power lossInorganic material magnetismInductances/transformers/magnets manufactureManganese oxideNitrogen gas

The invention discloses a Mn-Zn ferrite magnetic material, a magnetic core and a related manufacturing method. The primary composition of Mn-Zn soft magnetic ferrite materials: 49.5 to 53.9 mol percentages of iron oxide Fe2O3, 34.6 to 39.8 mol percentages of manganese oxide MnO, and 8.5 to 13.8 percentages of zinc oxide ZnO. Furthermore, a first assistant component with a weight of 100 to 600ppm, as well as a second assistant component with a weight of 50 to 3000ppm are added into the primary composition; wherein the first assistant component refers to one or more materials as silicon dioxide SiO2 or tantalum oxide Ta2O5; the second assistant component refers to one or more materials as bismuth trioxide Bi2O3, niobium pentoxide Nb2O5 or \ tungsten trioxide WO3. A magnetic billet can be prepared according the formula, followed by high temperature sintering under 1280 to 1360 DEG C in a nitrogen-protected kiln. The manufactured magnetic core has the advantages of high anti-DC-superposing performance and lower power consumption.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +1

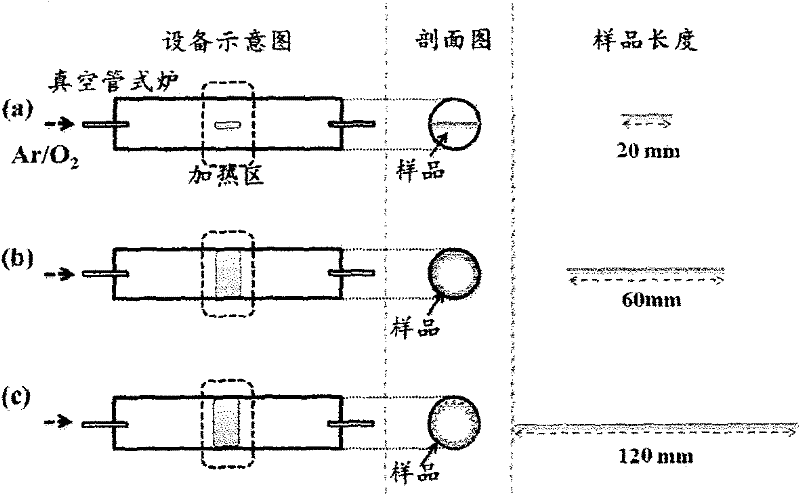

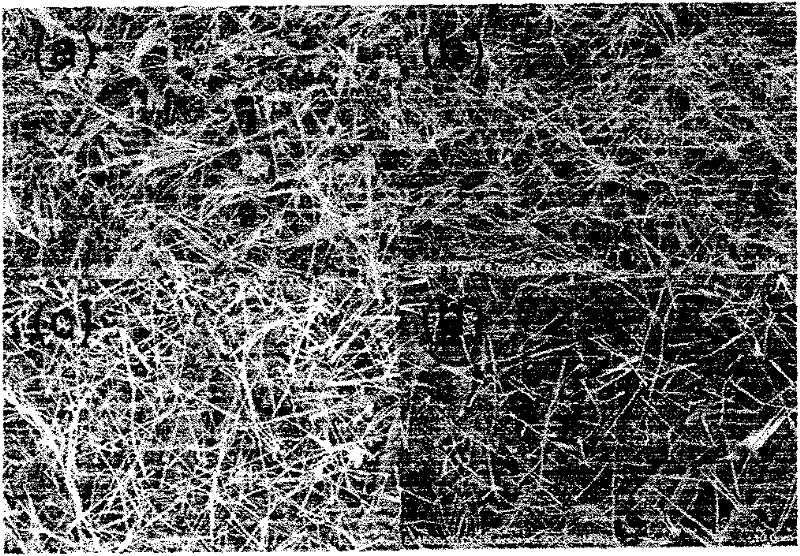

Large-scale preparation method of niobium pentoxide nanowires and hydrogen-sensitive element thereof

InactiveCN102180518AIncrease surface areaRealize large-area synthesisSolid-state devicesNanotechnologyNanowireEngineering

The invention discloses a large-scale preparation method of niobium pentoxide nanowires and a hydrogen-sensitive element thereof. The preparation method particularly comprises the following steps of: strictly cleaning Nb foils cut into suitable sizes, arranging the foils in a vacuum tube type furnace after a bending or folding treatment, and strictly controlling processing conditions (such as Ar flow rate, O2 flow rate, holding temperature, time and the like) of a thermal oxidation process to synthesize large-scale Nb2O5 nanowires with higher length diameter ratios. By adopting the large-scale preparation method disclosed by the invention, the large-scale synthesis of the Nb2O5 nanowires with the higher length diameter ratios can be realized in a limited-volume furnace tube, thus the production cost can be effectively reduced. Hydrogen-sensitive elements manufactured from Pt electrodes, prepared by sputtering Nb2O5 nanowires as sensitive materials, have the characteristics of small size, low energy consumption and the like, and represent higher response speed and higher sensitivity at the room temperature towards a hydrogen-containing atmosphere; and the size, the energy consumption and the production cost of hydrogen sensors can be hopefully reduced.

Owner:武汉正光恒远科技有限公司

Electronic device housing

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Photocatalytic hydrogen production catalyst and preparation method thereof

ActiveCN107185558AEasy to prepareGood photocatalytic hydrogen production activityCatalyst activation/preparationHydrogen productionSodium molybdateChemical composition

The invention discloses a photocatalytic hydrogen production catalyst and a preparation method thereof. The catalyst is molybdenum disulfide composite carbon-doped potassium niobate, the chemical composition formula of the catalyst is xMoS2 / C-KNbO3, x refers to the molar ratio of molybdenum disulfide to potassium niobate, C-KNbO3 refers to carbon-doped potassium niobate, and 0.001<=x<=0.01. Firstly, niobium pentoxide, glucose and potassium hydroxide are used for preparing the carbon-doped potassium niobate. Secondly, the carbon-doped potassium niobate, sodium molybdate and thiourea are used for preparing the molybdenum disulfide composite carbon-doped potassium niobate. The catalyst has efficient photocatalytic hydrogen production performance and good stability.

Owner:ZHEJIANG NORMAL UNIVERSITY

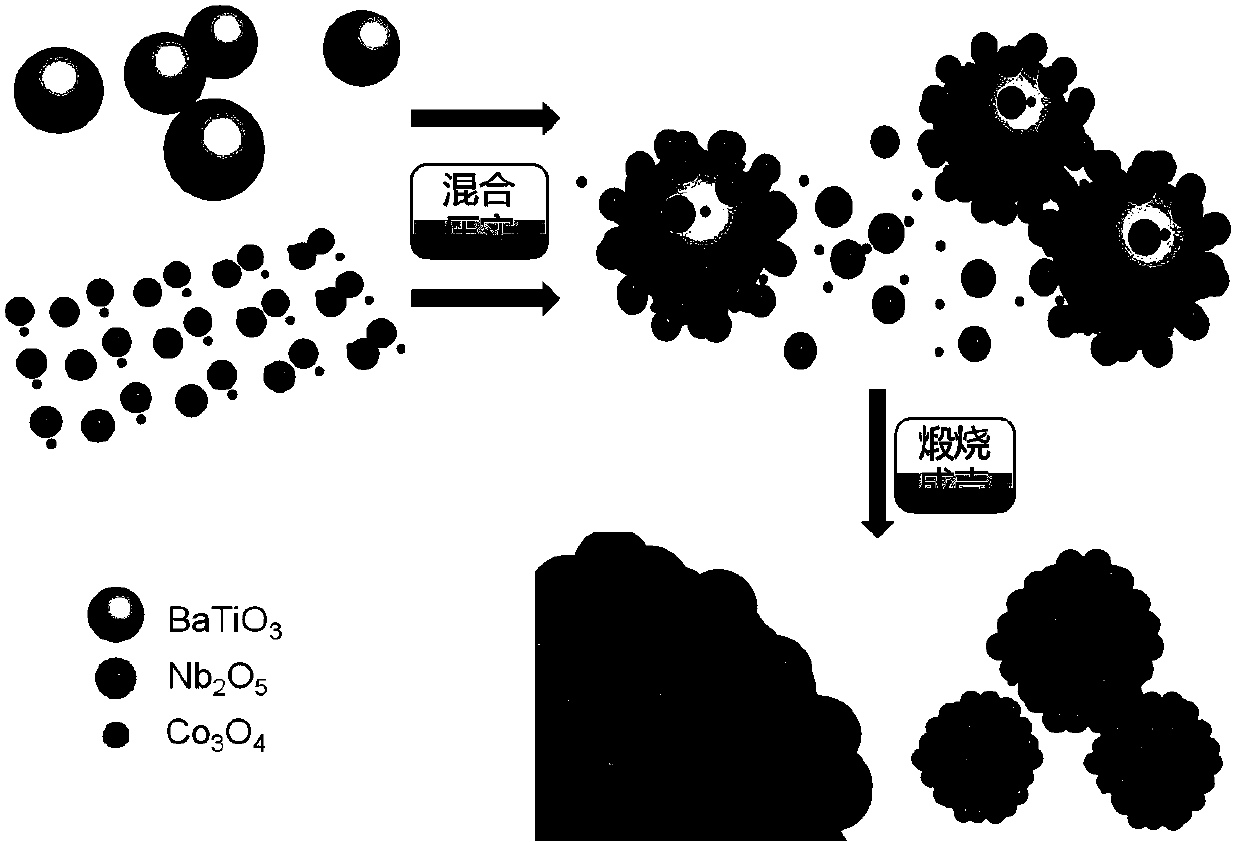

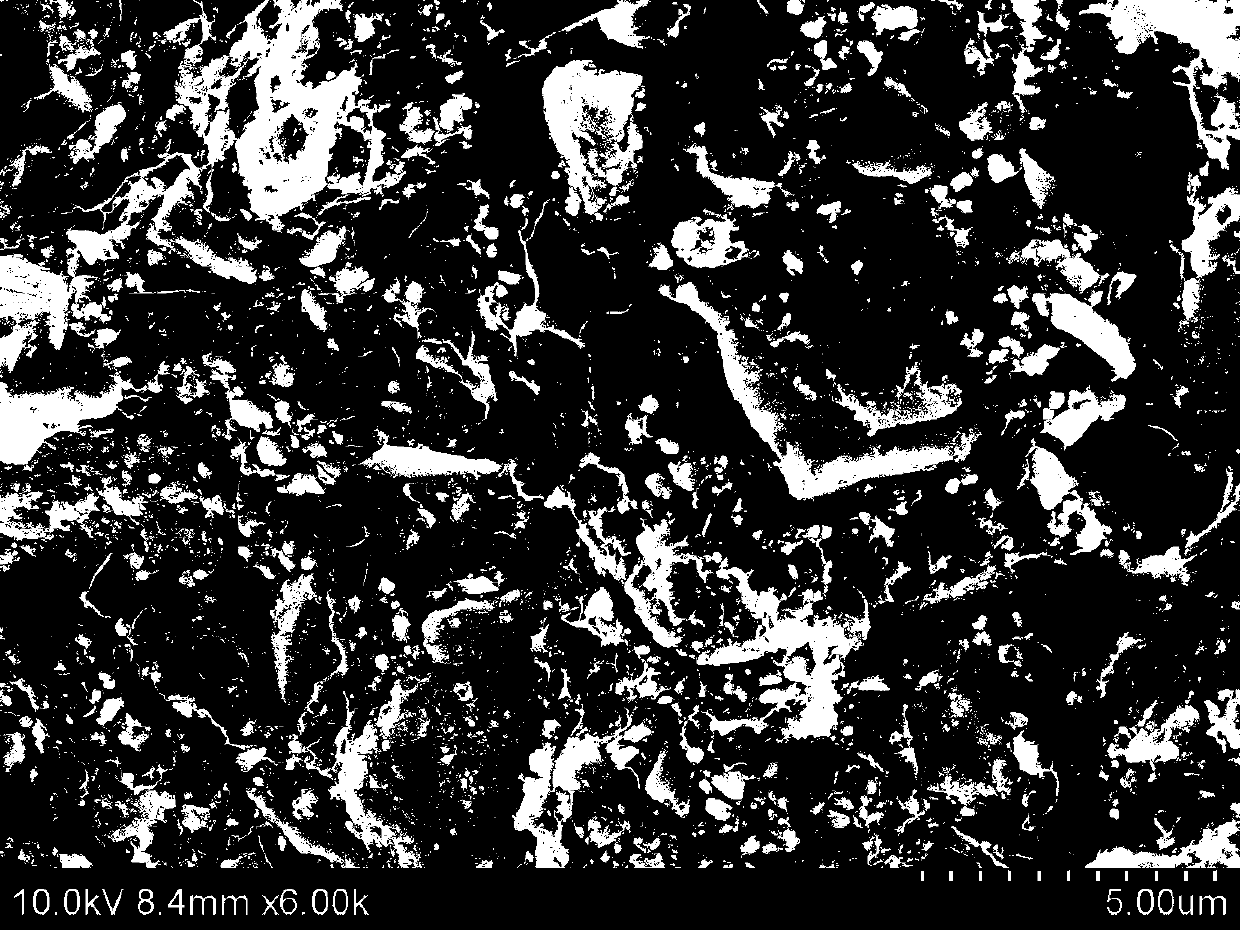

High temperature stable X9R type multilayer ceramic capacitor dielectric material and preparation method thereof

ActiveCN103936414AOvercome the high temperature reduction effectReduce lossBarium titanateCeramic capacitor

The invention discloses a high temperature stable X9R type multilayer ceramic capacitor dielectric material and a preparation method of the high temperature stable X9R type multilayer ceramic capacitor dielectric material. The high temperature stable X9R type multilayer ceramic capacitor dielectric material disclosed by the invention is prepared by the steps of adding a calcium-boron-silicon compound to a barium titanate-sodium bismuth titanate-niobium pentoxide eutectic compound serving as a matrix, compounding one or more of Ce, Nd and La oxides, and compounding one or more of barium-manganese oxide, magnesium oxide and zinc oxide; and the invention provides the preparation method of the high temperature stable X9R type multilayer ceramic capacitor dielectric material. The X9R type multilayer ceramic capacitor dielectric material prepared by using the material and the method provided by the invention has high temperature resistance (above 200 DEG C), and good temperature stability, and enable components and parts such as multilayer ceramic capacitors, tuners and duplexers to be suitable for the application at a high temperature (above 200 DEG C), thus having extremely high industrialization prospect and industrial application value.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

Single donor-doped positive temperature coefficient thermal-sensitive ceramic and preparation method thereof

The invention relates to the field of single donor-doped positive temperature coefficient thermal-sensitive ceramics, and discloses a single donor-doped positive temperature coefficient thermal-sensitive ceramic and a preparation method thereof. The preparation method comprises the following steps of (1) mixing and sintering BaTiO3 (barium titanate), PbTiO3 (lead titanate), TiO2 (titanium dioxide) and Nb2O5 (niobium pentoxide) for a first time, so as to obtain BaTiO3 and PbTiO3 mixed powder with a formula of Ba1-xPbxTiO3; (2) mixing and sintering the mixed powder, SiO2 and a manganese source for a second time, so as to obtain the single donor-doped positive temperature coefficient thermal-sensitive ceramic, wherein the usage amounts of BaTiO3 and PbTiO3 meet the formula of Ba1-xPbxTiO3, and x is equal to 0.15 to 0.25; corresponding to 100mol of Ba1-xPbxTiO3, the usage amount of TiO2 is 1 to 2mol, the usage amount of Nb2O5 is 0.08 to 0.1mol, the usage amount of SiO2 is 1 to 3mol, and the usage amount of MnO2 is 0.04 to 0.08mol. The single donor-doped positive temperature coefficient thermal-sensitive ceramic has the advantages that the positive temperature coefficient thermal-sensitive ceramic can be prepared by the single donor Nb2O5 doping; under the conditions of same batch and same formula, the resistance dispersion of a room-temperature resistor of a product is small, and the breakdown voltage is high.

Owner:汕尾比亚迪实业有限公司

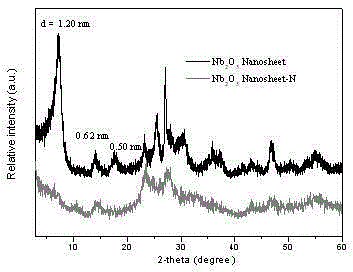

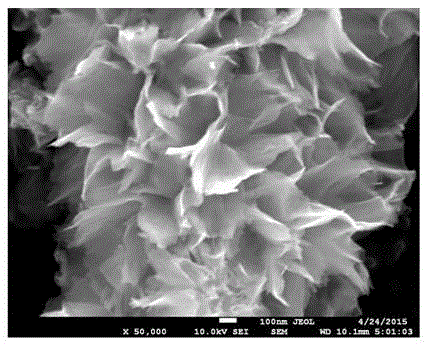

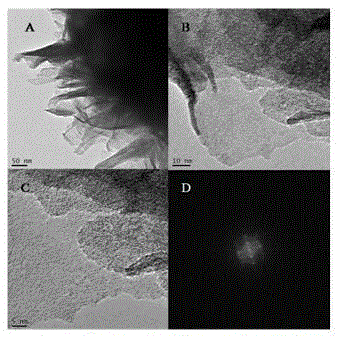

Preparation method of carbon and nitrogen doped niobium (V) pentoxide nano sheet and application of nano sheet as photocatalyst

ActiveCN105381813AGood lookingGood repeatabilityPhysical/chemical process catalystsOrganic compound preparationBenzaldehydeNitrogen gas

The invention discloses a preparation method of a carbon and nitrogen doped niobium (V) pentoxide nano sheet and an application of the nano sheet as a photocatalyst. The preparation method comprises the following steps: weighing soluble niobium salt at a room temperature, adding anhydrous ethanol to form an ethanol solution of niobium salt, dropwise adding an organic ammonium hydroxide solution into the ethanol solution of niobium salt, wherein in the initial phase, white turbidity appears, keeping on adding the organic ammonium hydroxide solution until the white turbidity disappears so as to form a clear and transparent solution; transferring the obtained solution to a hydrothermal reactor, wherein the solution accounts for 50 to 70% of the volume of the hydrothermal reactor, carrying out hydrothermal reactions at a temperature of 100 to 280 DEG C, after reactions, naturally cooling the reactor to the room temperature, washing and drying the reaction product to obtain white powder; and burning the white powder for 2 to 12 hours at a temperature of 400 to 1200 under the protection of nitrogen gas so as to obtain the carbon and nitrogen doped niobium (V) pentoxide nano sheet. The invention also discloses an application of the carbon and nitrogen doped niobium (V) pentoxide nano sheet as a photocatalyst. The photocatalyst can be applied to benzyl alcohol oxidation to prepare benzaldehyde.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Copper oxide-doped potassium-sodium niobate antibacterial piezoelectric ceramic implant as well as preparation and application of implant

InactiveCN107721420AImprove stabilityImprove mechanical propertiesBiocideFungicidesCopper oxideSodium niobate

The invention belongs to the technical field of antibacterial implant materials, and discloses a copper oxide-doped potassium-sodium niobate antibacterial piezoelectric ceramic implant as well as preparation and application of the implant. The method comprises the following steps: (1) adding a solvent, niobium pentoxide, sodium carbonate and potassium carbonate into a ball milling device for ballmilling, standing, drying, calcining, and grinding into powder, to obtain potassium-sodium niobate precursor powder; (2) adding a solvent, copper oxide and the potassium-sodium niobate precursor powder into the ball milling device for ball milling, standing, drying, and calcining, to obtain copper oxide-doped potassium-sodium niobate ceramic powder; (3) evenly mixing the copper oxide-doped potassium-sodium niobate ceramic powder with a binder, granulating, forming, discharging glue, performing dense sintering, to obtain a ceramic sheet; and (4) polarizing the ceramic sheet, to obtain the copper oxide-doped potassium-sodium niobate antibacterial piezoelectric ceramic implant. The method is simple, and the prepared implant has a good antibacterial effect and stability.

Owner:SOUTH CHINA UNIV OF TECH

Preparation and application of stable niobium precursor

InactiveCN102951683ALow costEasy to makePhosphorus compoundsNiobium compoundsHydrofluoric acidPhosphate

The invention relates to a preparation method of stable water-soluble niobium precursor. Niobium pentoxide is dissolved in hydrofluoric acid solution to obtain niobium pentafluori solution. Niobium is precipitated in the form of niobic acid hydrate by alkali liquor. Precipitation is dissolved in tartaric acid solution to obtain stable soluble-niobium tartrate precursor solution which is faintly acid. The concentration of the niobium tartrate solution can be controlled according to the amount of the niobium pentoxide added in early regulation. The stable niobium tartrate solution can be used to synthesize mesoporous niobium oxide, mesoporous niobium phosphate and mesoporous niobium-silicon materials, and the materials are as excellent as commercial niobium chloride soluble salt in property. The highly stable water-soluble niobium tartrate precursor is obtained from low-cost materials in a simple and feasible synthesis path.

Owner:EAST CHINA UNIV OF SCI & TECH

Epoxy-resin-based high-dielectric composite material and preparation method thereof

ActiveCN105949725AIncrease contact interfaceSignificant interface polarizationEpoxyCobalt(II,III) oxide

The invention discloses an epoxy-resin-based high-dielectric composite material and a preparation method thereof. According to the composite material, epoxy resin serves as a base body, modified barium titanate serves as filler, and the modified barium titanate is modified barium titanate BTNC doped with niobium pentoxide and cobaltosic oxide. The modified barium titanate BTNC is fully mixed with epoxy resin and a curing agent, heating and curing are conducted, and the BTNC / epoxy resin dielectric composite material is obtained. Compared with an epoxy resin composite material filled with barium titanate which is not modified, the composite material has a higher dielectric constant, lower dielectric consumption and better temperature stability.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Ceramic chopper material and preparation method thereof

The invention discloses a ceramic chopper material. The ceramic chopper material is prepared from the following components by weight percent: 65-92.99% of matrix ceramics, 0.1-30% of auxiliary ceramics, and 0.1-30% of additive. The matrix ceramics is at least one of aluminum oxide and zirconium oxide. The auxiliary ceramics is at least one of zirconium oxide, chromium oxide, erbium oxide, niobium pentoxide, zinc oxide, iron oxide, titanium oxide, calcium oxide, magnesium oxide, silicon carbide, strontia oxide, barium oxide, silicon nitride, and tungsten carbide. The invention further discloses a ceramic chopper made of the ceramic chopper material. The invention further discloses a preparation method of the ceramic chopper material. The ceramic formed by the ceramic chopper material prepared by the method has high hardness, high density, small average particle size, good toughness, and excellent wear resistance, and the crystalline particles are difficult to drop in use. The preparation method of the ceramic chopper material is simple, and can be used for industrial mass production.

Owner:CHAOZHOU THREE CIRCLE GRP

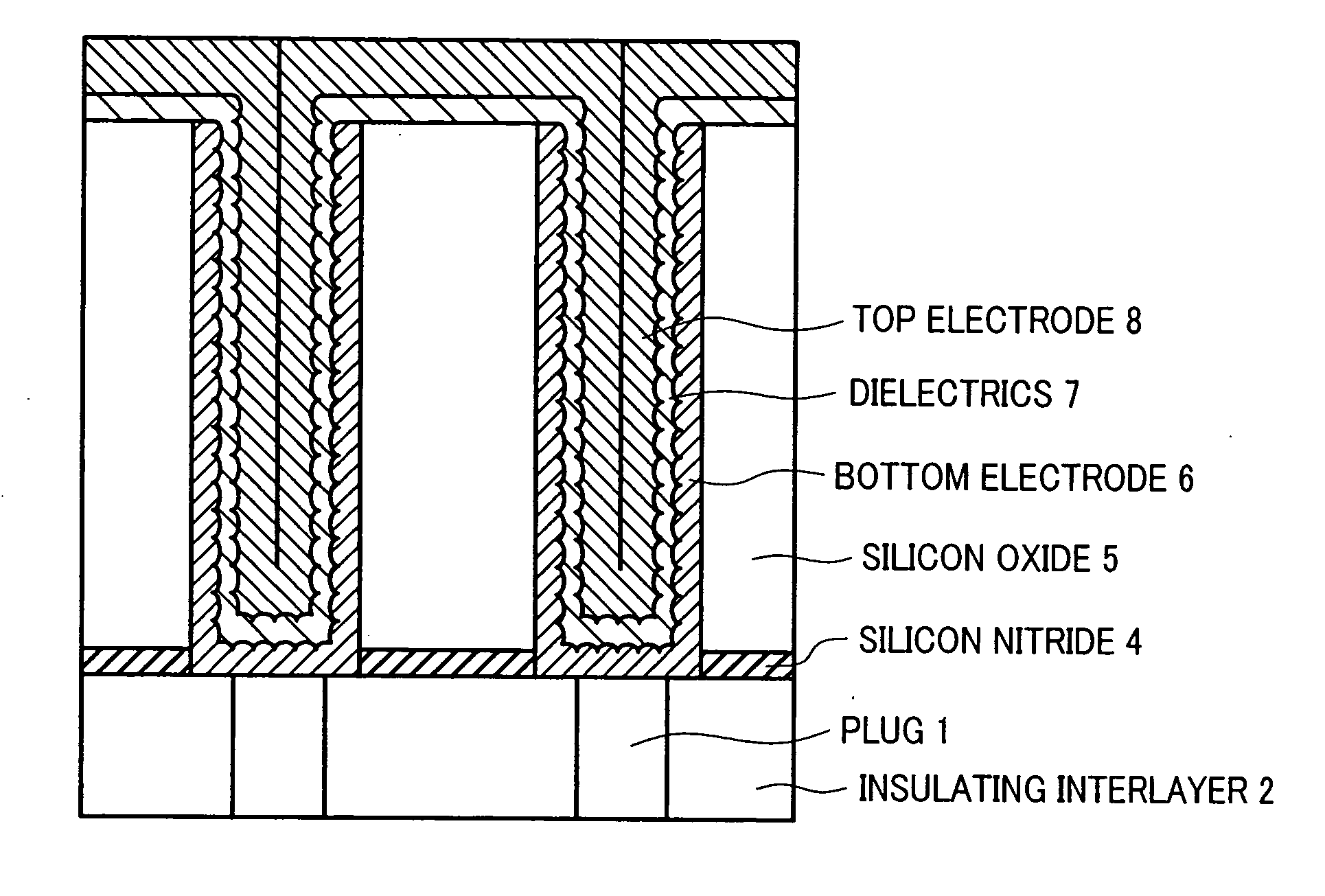

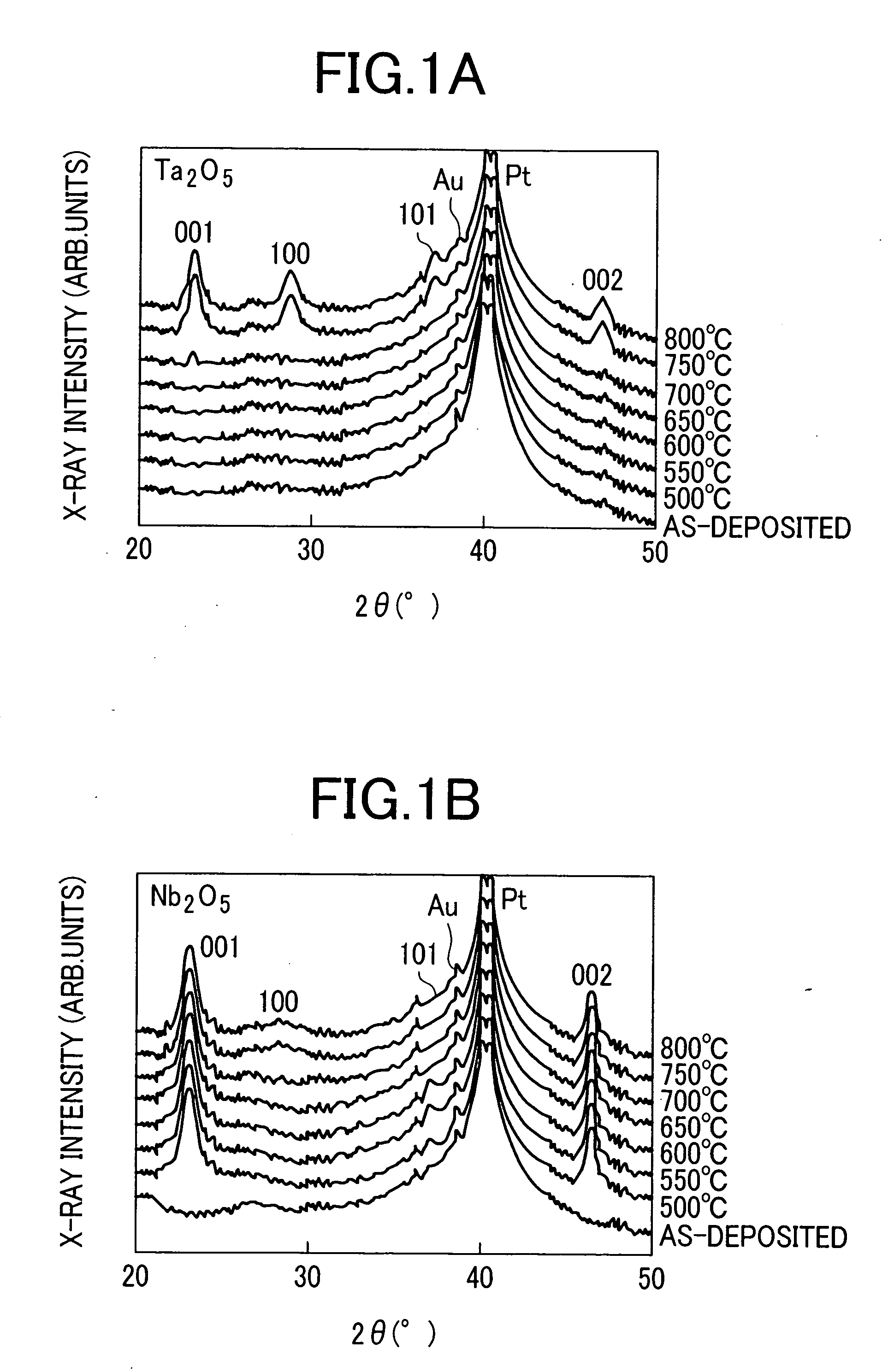

Semiconductor device and manufacturing method thereof

ActiveUS20050001212A1Solve the large leakage currentReduce leakage currentTransistorSingle unit pavingsDevice materialCrystallization temperature

A capacitor uses niobium pentoxide in the manufacture of a semiconductor device. The niobium pentoxide has a low crystallization temperature of 600° C. that provides control over the oxidation of the bottom electrode during heat-treatment. A dielectric constituent present as an amorphous oxide along the grain boundaries of polycrystalline niobium pentoxide is used for a capacitor insulator., thereby providing a method to decrease the leakage current along the grain boundary of niobium pentoxide and to realize a high dielectric constant and low-temperature crystallization.

Owner:KOKUSA ELECTRIC CO LTD

Method for preparing tin niobate nanospheres by using alcohol solvent heat

ActiveCN107601564AGain operabilityGood repeatabilityMetal/metal-oxides/metal-hydroxide catalystsNiobium compoundsAlcoholGlycerol

The invention relates to a method for preparing tin niobate nanospheres by using alcohol solvent heat, and belongs to the field of functional materials. The method comprises the following steps: mixing SnCl2.2H2O and niobium pentoxide (Nb2O5) powder, concocting a pasty material, adding an organic alcohol (such as ethanol, isopropanol, ethylene glycol and glycerol) and a surfactant polyvinylpyrrolidone (PVP), and performing alcohol heat treatment on the above mixture to obtain the thermodynamically-metastable SnNb2O6 nanosphere material. The obtained SnNb2O6 nanospheres have better applicationprospects in the field of photocatalysis.

Owner:BEIJING UNIV OF TECH

Mg-based hydrogen storage material with metal oxide added and preparation method of Mg-based hydrogen storage material

InactiveCN102862958AGood hydrogen storage kineticsHigh hydrogen storage capacityMaterial nanotechnologyHydrogen productionCerium(IV) oxideEvaporation

The invention relates to Mg-based hydrogen storage nano-sized powder and a preparation method thereof. The hydrogen storage nano-sized powder is obtained by performing high-temperature melting and evaporation to mixture of magnesium metal and metal oxide and performing passivation. The metal oxide is one or more of yttrium oxide, cerium oxide, iron oxide, titanium oxide and niobium oxide. Weight percentage of the metal oxide is 0.1%-20%, and the balance is magnesium metal. The Mg-based hydrogen storage nano-sized powder has high hydrogen storage dynamics performance and high hydrogen storage capacity and can be stored stably in air, hydrogen absorption amount at about 300 DEG C reaches 7%, and hydrogen absorption amount at 350 DEG C within 100s reaches more than 5weight%.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing potassium niobate nano powder

InactiveCN102153350ASmall granularityHigh sintering activityNanotechnologyPotassium hydroxidePotassium niobate

The invention relates to a method for preparing potassium niobate nano powder. The single-phase nano KNbO3 powder can be obtained at a low temperature by the method. The method comprises the following steps of: mixing potassium hydroxide and niobium pentaoxide in a molar ratio of 8-12:1, calcining the mixture for 1 to 4 hours at the temperature of between 320 and 400 DEG C, dissolving the obtained solid into deionized water, adding oxalic acid, regulating the pH value of the solution to between 4 and 5, and obtaining white sediment; dissolving the white sediment into aqueous solution of citric acid, adding potassium nitrate according to the component proportion of KNbO3, and obtaining a precursor by sol-gel and burning processes; and calcining the precursor at the temperature of between 600 and 800 DEG C to obtain the potassium niobate powder with grain diameter of between 10 and 70 nanometers and with perovskite structure. The process is simple and quick, the prepared powder has high purity and low granularity, and the cost is reduced.

Owner:DALIAN JIAOTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com