Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

215results about How to "Increase contact interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perovskite solar cell

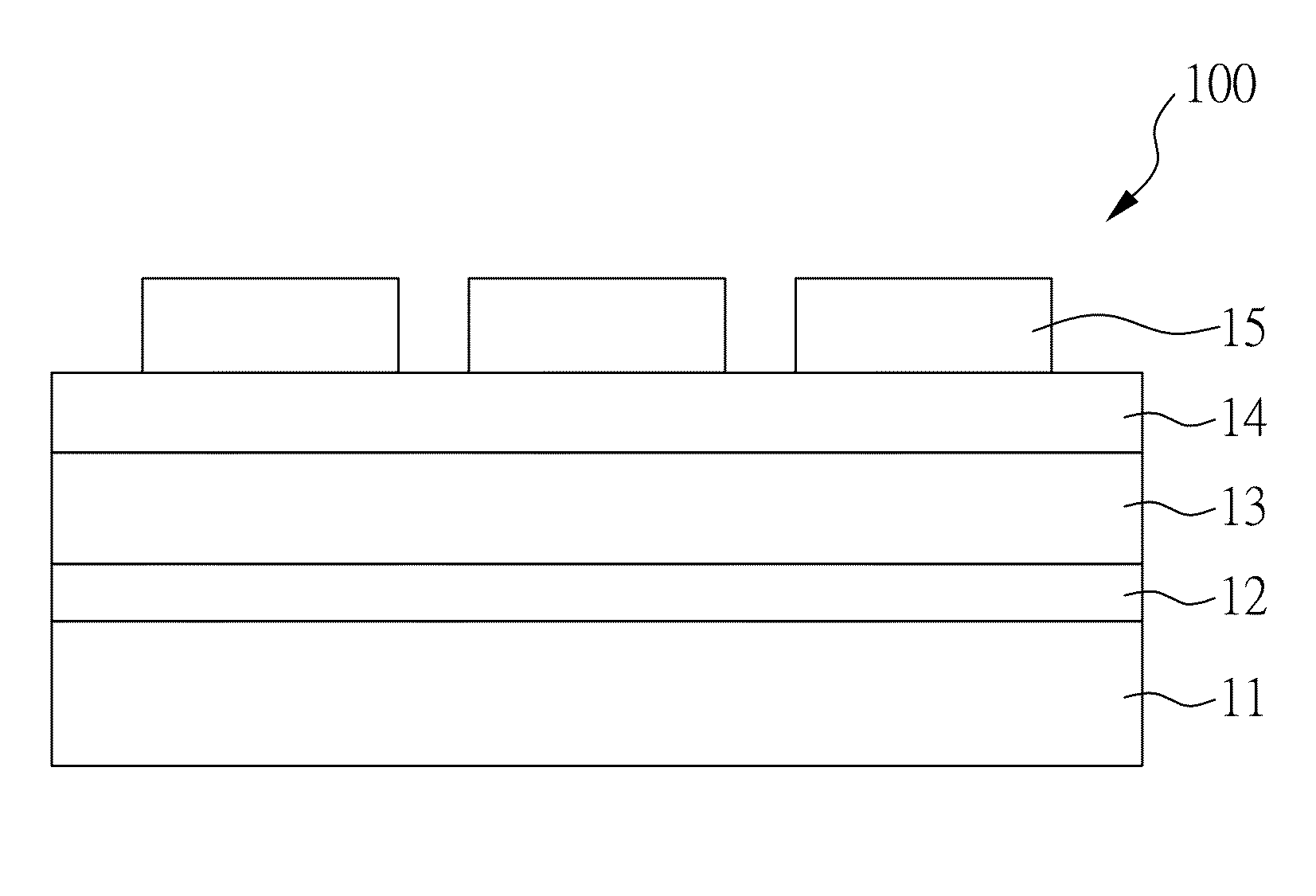

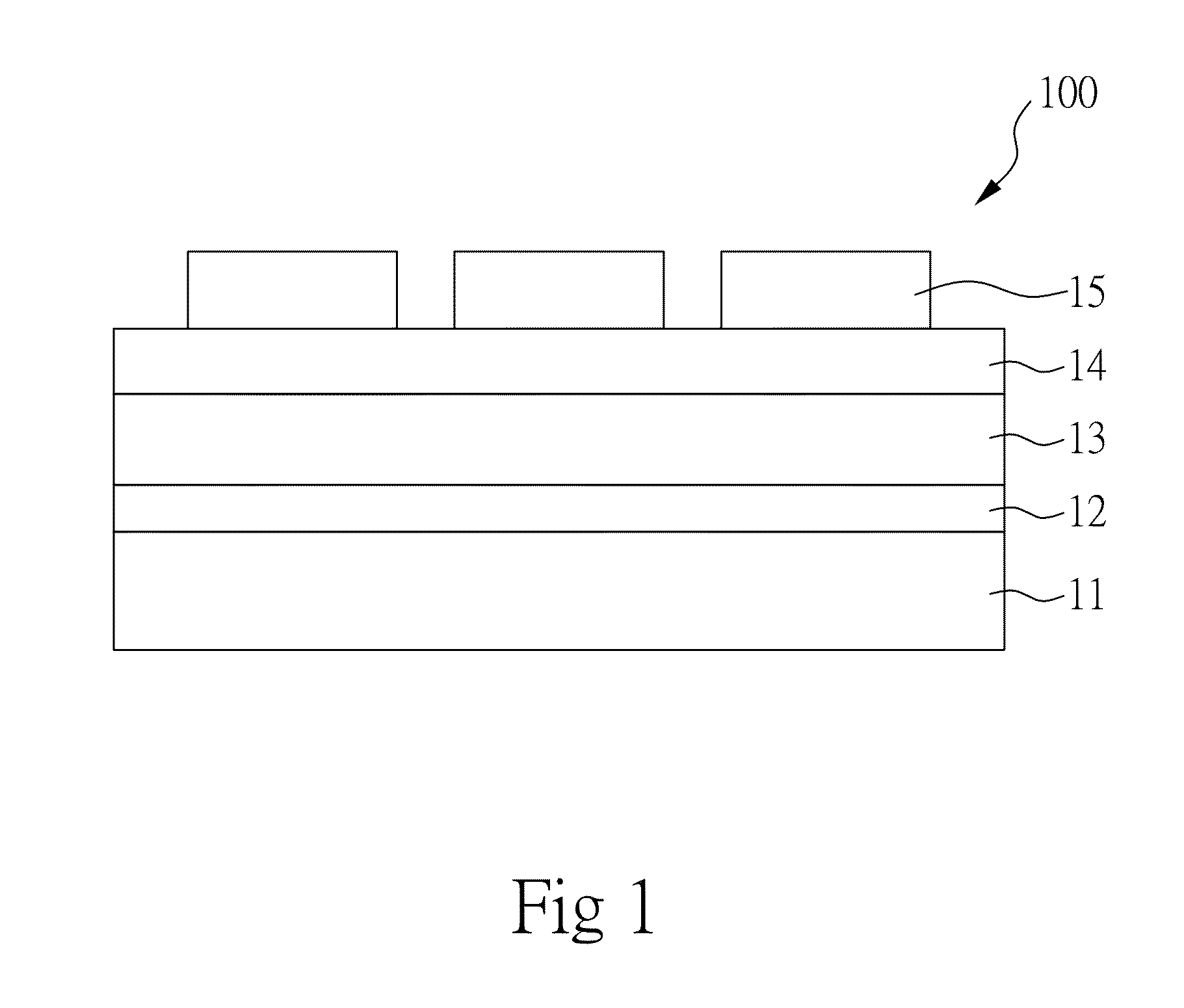

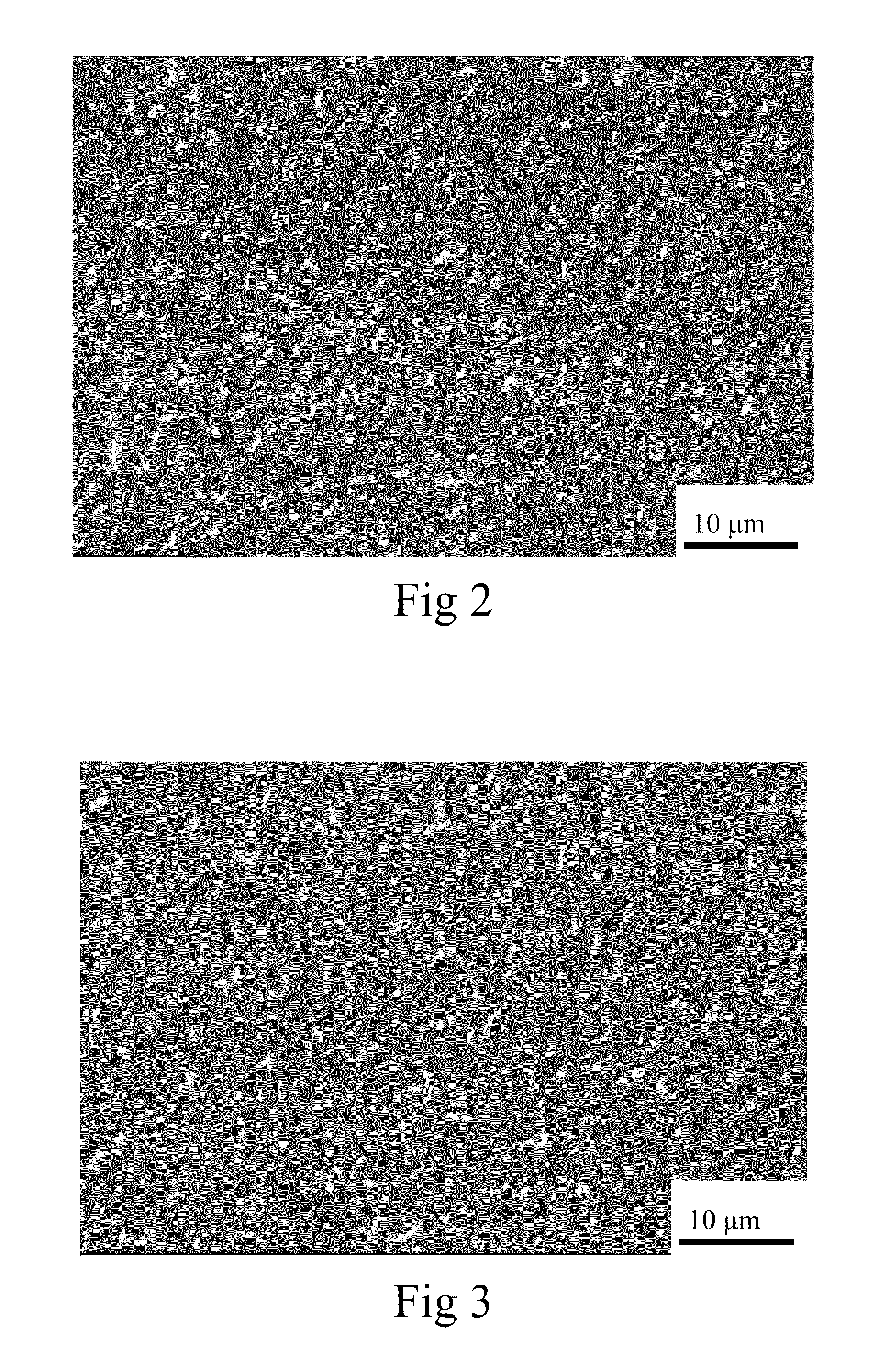

InactiveUS20160079552A1Expand coverageReduce roughnessSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellElectron transport layer

The present invention relates to a perovskite solar cell, which comprises a first electrode substrate; a perovskite material layer comprising a perovskite organic-inorganic material and a polymer additive, wherein the perovskite material layer is disposed above the first electrode substrate; and a second electrode, which is disposed above the perovskite material layer and corresponds to the first electrode substrate. The coverage of the perovskite material layer on the electrode or an electron-transport layer is significantly improved, and the roughness thereof is also decreased, thereby increasing the photoelectric conversion efficiency of the perovskite solar cell.

Owner:NAT TAIWAN UNIV

Lead-carbon battery negative plate containing lead and graphene composite materials

ActiveCN102881866AImproved HRPSoC cycle performanceExtended service lifeLead-acid accumulator electrodesHigh rateElectric vehicle

The invention discloses a lead-carbon battery negative plate containing lead and graphene composite materials. A collector plate grid is made of lead, copper, titanium, tantalum, tungsten, aluminum, carbon foam or hard plastics, lead is plated on the surface of a non-lead collector plate grid, and lead plaster solid materials comprise, by weight, 0-90% of lead powder, 1-90% of the lead and graphene composite materials, 0.5-5% of hydrogen-evolution inhibitors and other additives. The lead-carbon battery negative plate containing the lead and graphene composite materials has the advantages that uniform mixing of the lead powder and graphene carbon materials can be achieved, instant large current is effectively buffered, sulfation on the surface of a negative electrode is inhibited, negative electrode charging receiving capability is greatly improved, HRPSoC (high-rate partial state of charge) cycling performance of a battery is remarkably improved, and the lead-carbon battery negative plate is simple in manufacture process and simplified in internal structure and has wide application prospects in the fields of hybrid electric vehicles, solar energy storage, wind energy storage and the like.

Owner:JIESHOU HUAYU POWER SUPPLY

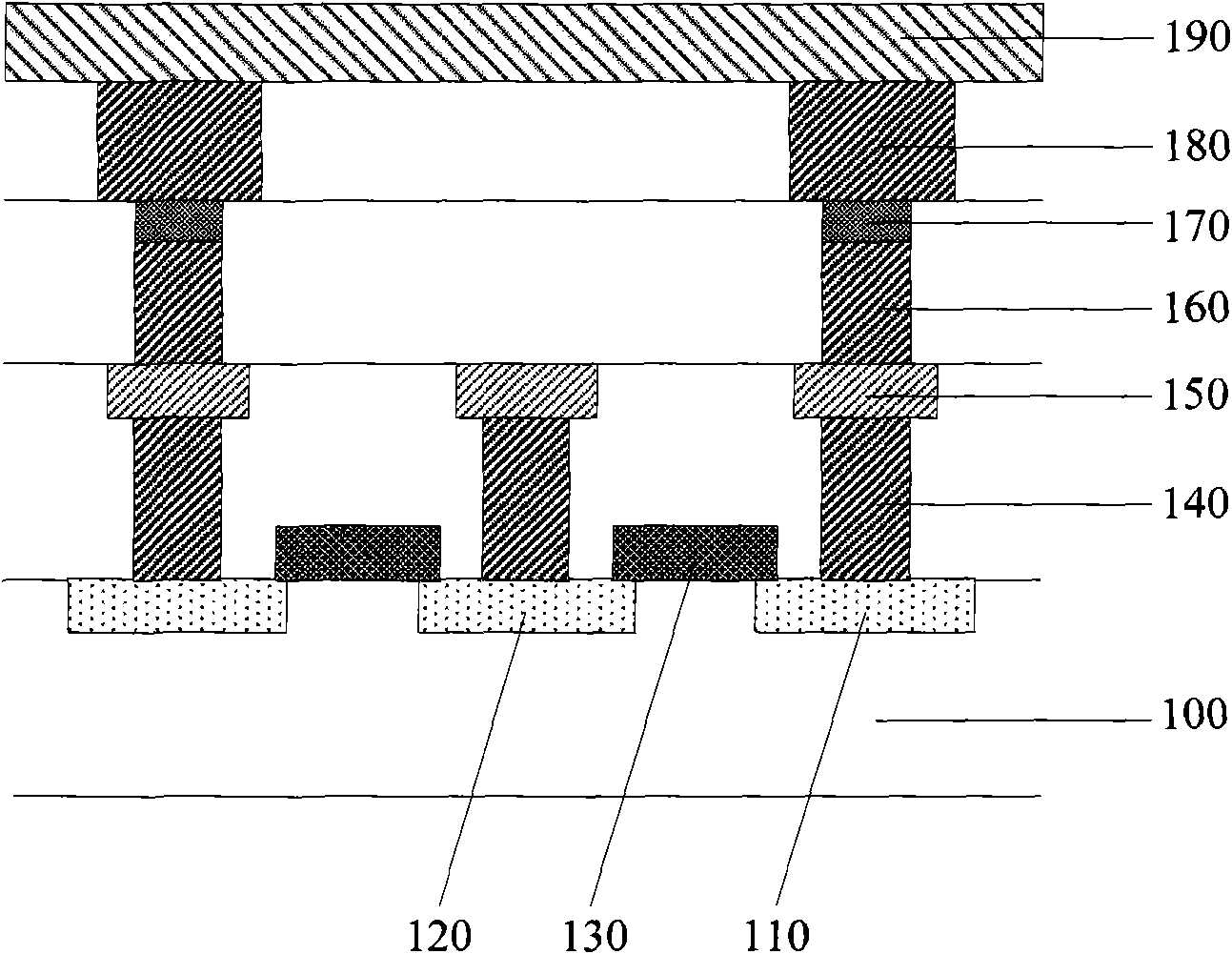

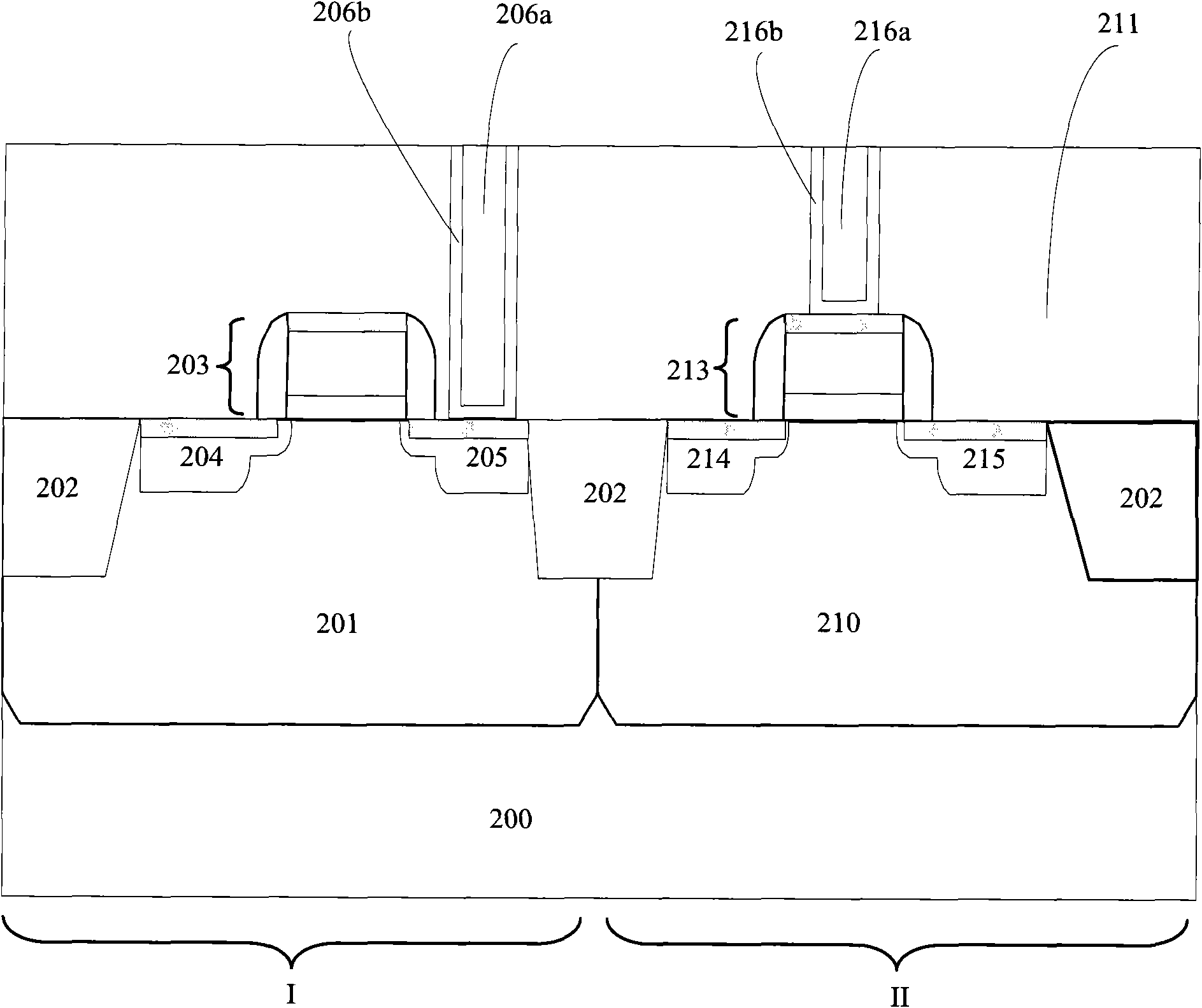

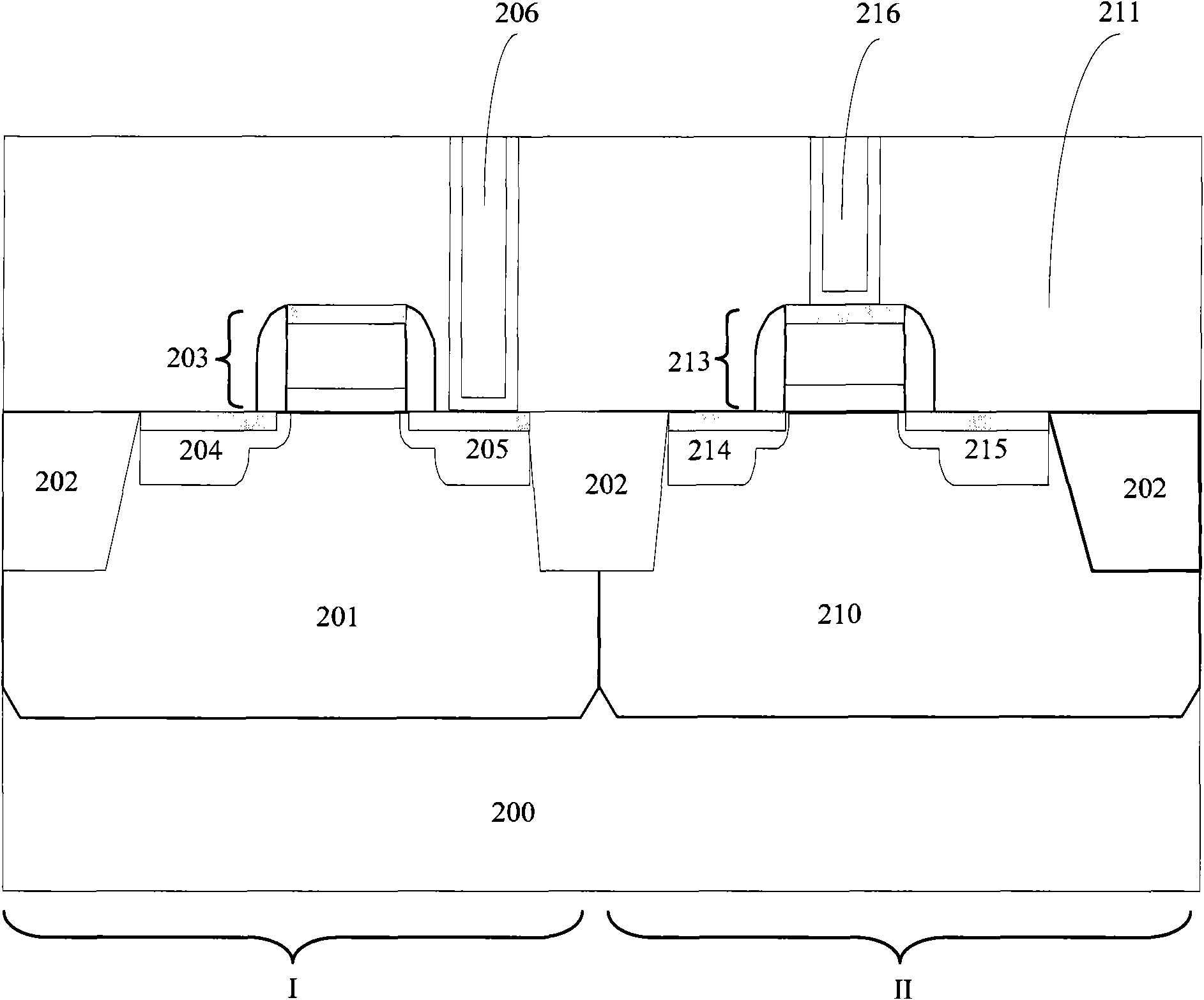

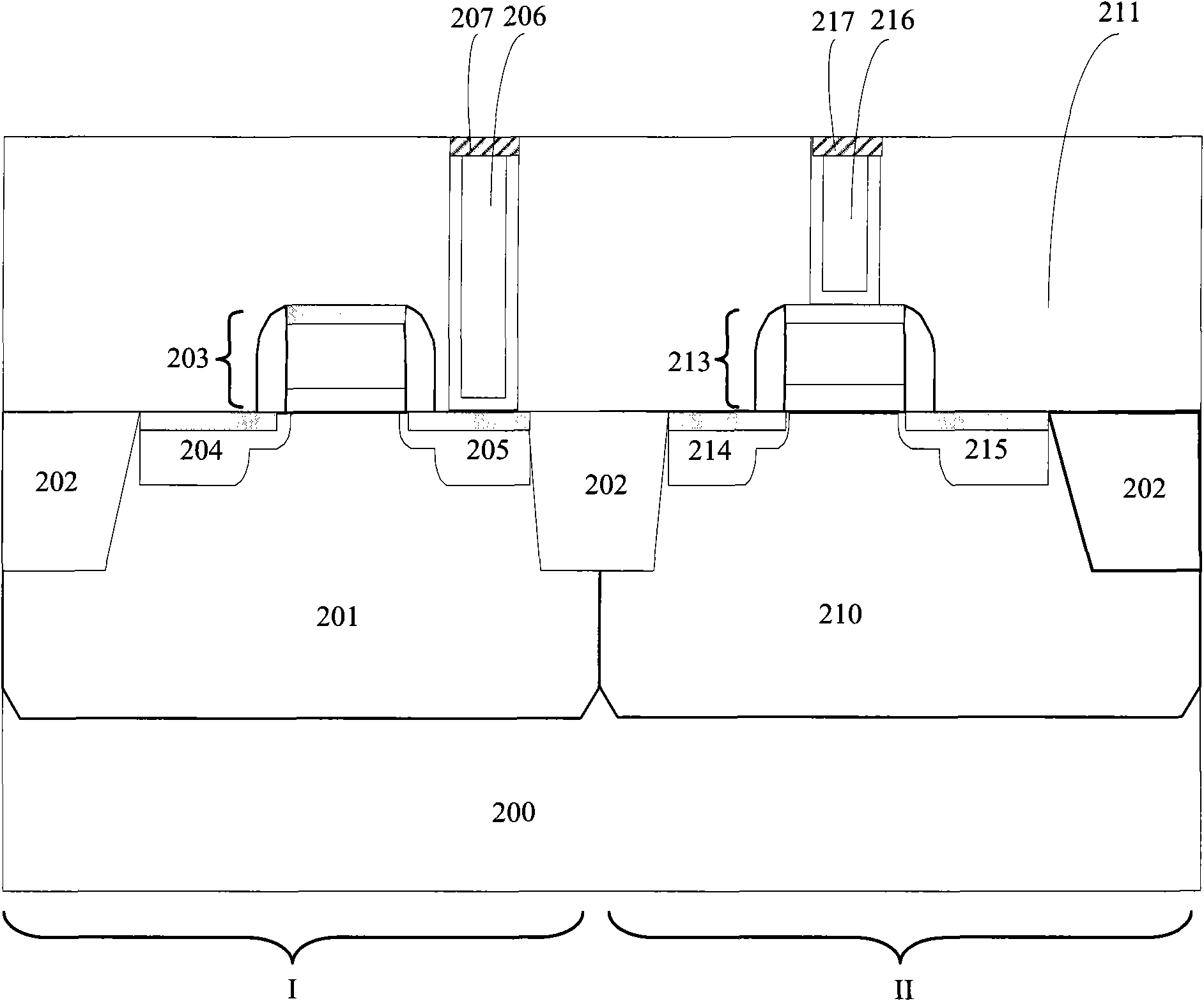

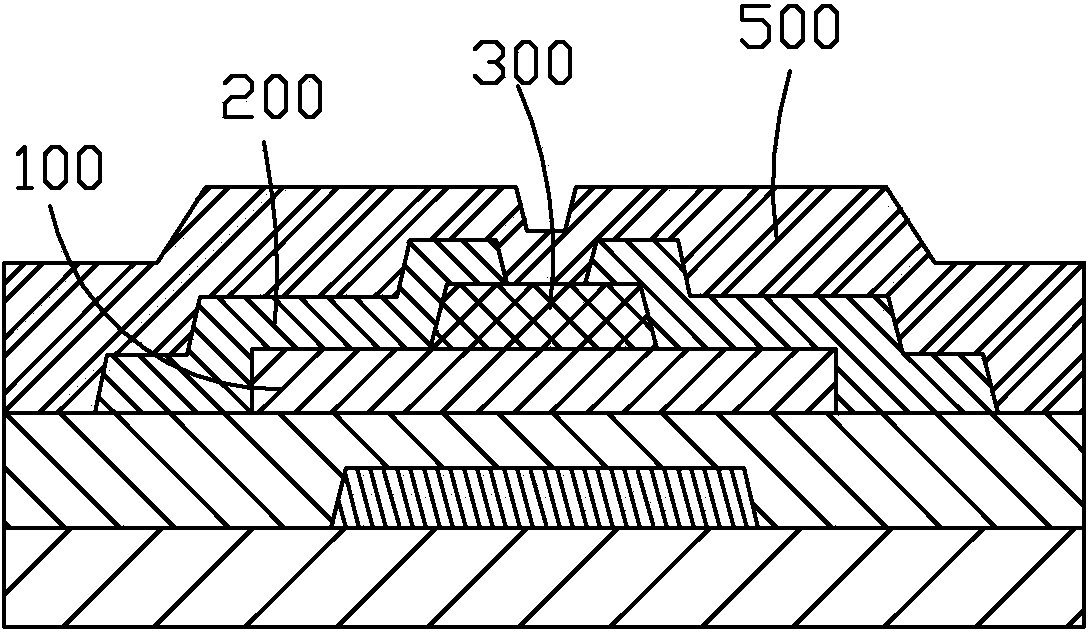

Resistance memory an a method for fabricating integrated circuit with same

ActiveCN101572246ARealize interlayer interconnect structureSimple processSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceCore component

The invention relates to a method for fabricating an integrated circuit with a resistance memory, comprising the following steps: providing an interlaminar dielectric layer comprising a core component area and a peripheral circuit area; forming a first interconnection structure and a second interconnection structure which are respectively formed by a blocking layer and a metal wiring structure in the interlaminar dielectric layer; forming a blocking dielectric layer on the interlaminar dielectric layer; etching the blocking dielectric layer to expose the metal wiring structure of the core component area; forming a first dielectric layer on the metal wiring structure; forming a first conductive layer covering the blocking dielectric layer and the first dielectric layer; forming a masking film on the first conductive layer; etching the first conductive layer and the blocking dielectric layer until the second interconnecting structure is exposed; keeping the first conductive layer and a blocking dielectric layer on the first interconnecting structure; and forming a second conductive layer and a third conductive layer respectively on the first conductive layer and the second interconnecting structure. Due to the adoption of the method for fabricating the integrated circuit with the resistance memory, when the resistance memory is formed, the interlaminar interconnection structures of the core component area and the peripheral circuit area can be also formed.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

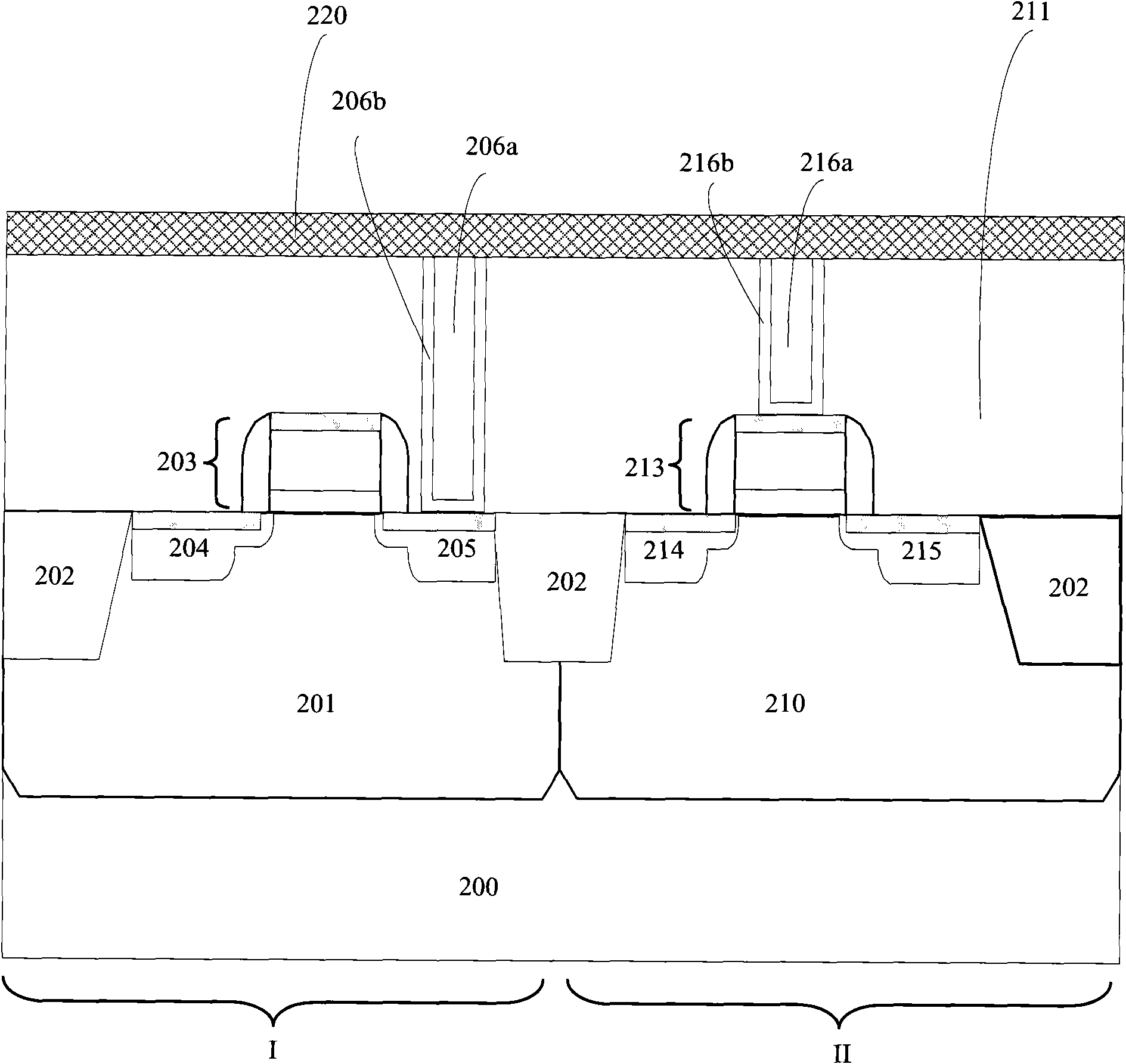

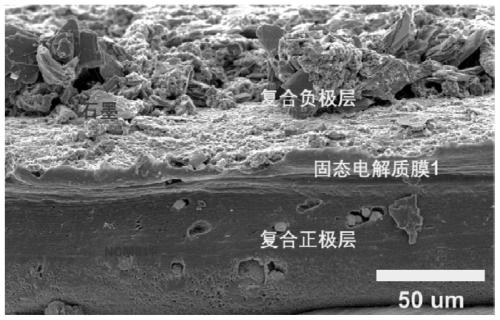

Composite solid-state electrolyte, solid-state battery and preparation method of solid-state battery

InactiveCN111244537AImprove conductivityImprove mechanical propertiesSecondary cellsComposite electrolytesSolid state electrolyteElectrical battery

The invention belongs to the technical field of batteries, and particularly relates to a composite solid-state electrolyte which comprises an organic polymer, a lithium salt, an ionic liquid and an inorganic solid electrolyte material, wherein the mass ratio of the polymer to the lithium salt to the ionic liquid to the inorganic solid electrolyte material is 1: (0.1-0.6): (0.1-1): (0.05-0.2). Thecomposite solid-state electrolyte disclosed by the invention is high in ionic conductivity, high in stability, good in compatibility with positive and negative electrodes and excellent in mechanical property, and the composite solid-state electrolyte has excellent mechanical property due to a polymer framework; the lithium salt provides lithium ions for the solid electrolyte; the ionic liquid improves the conductivity of the electrolyte; the inorganic solid electrolyte material can be crosslinked with the polymer to further improve the mechanical properties of the solid electrolyte and increase the strength.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

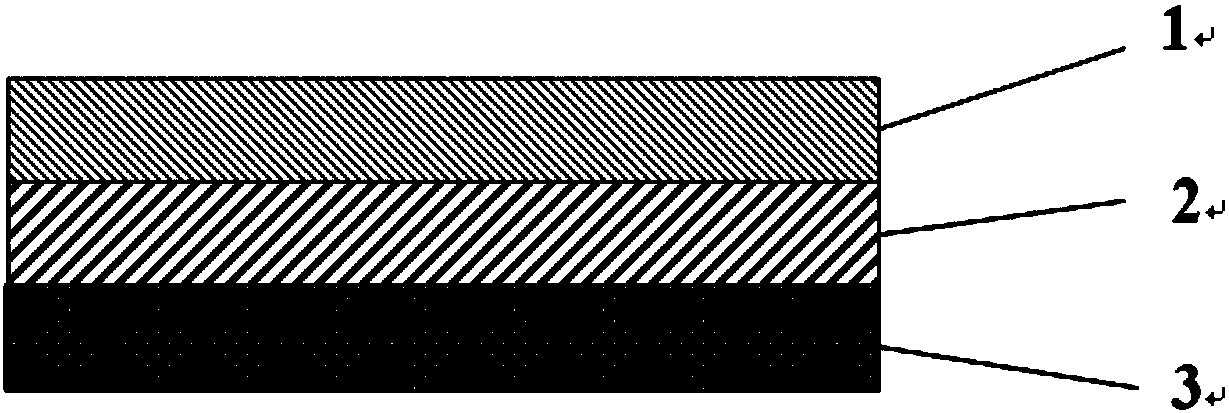

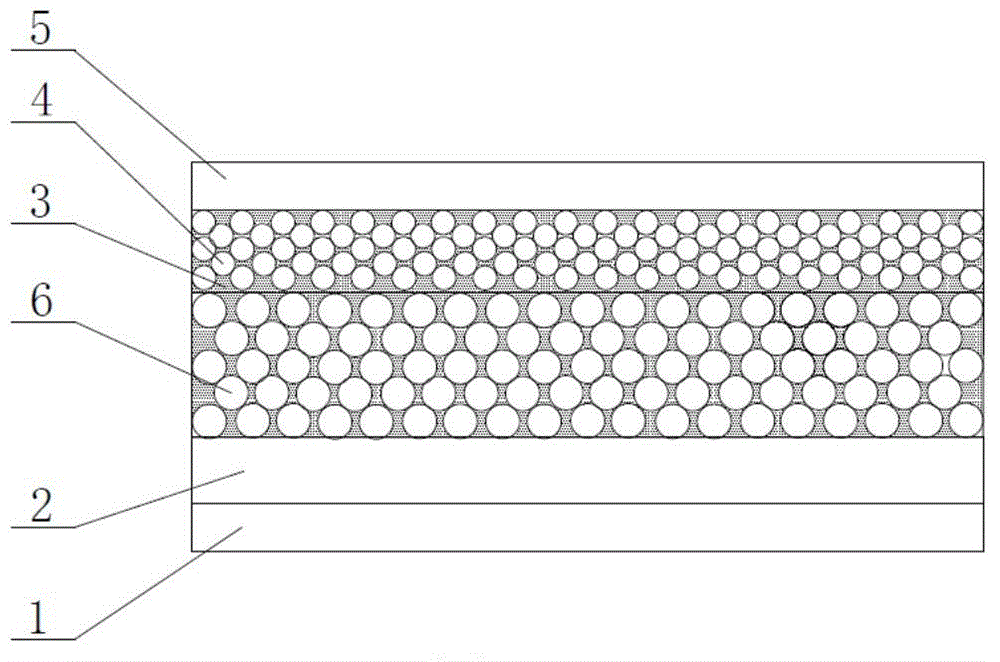

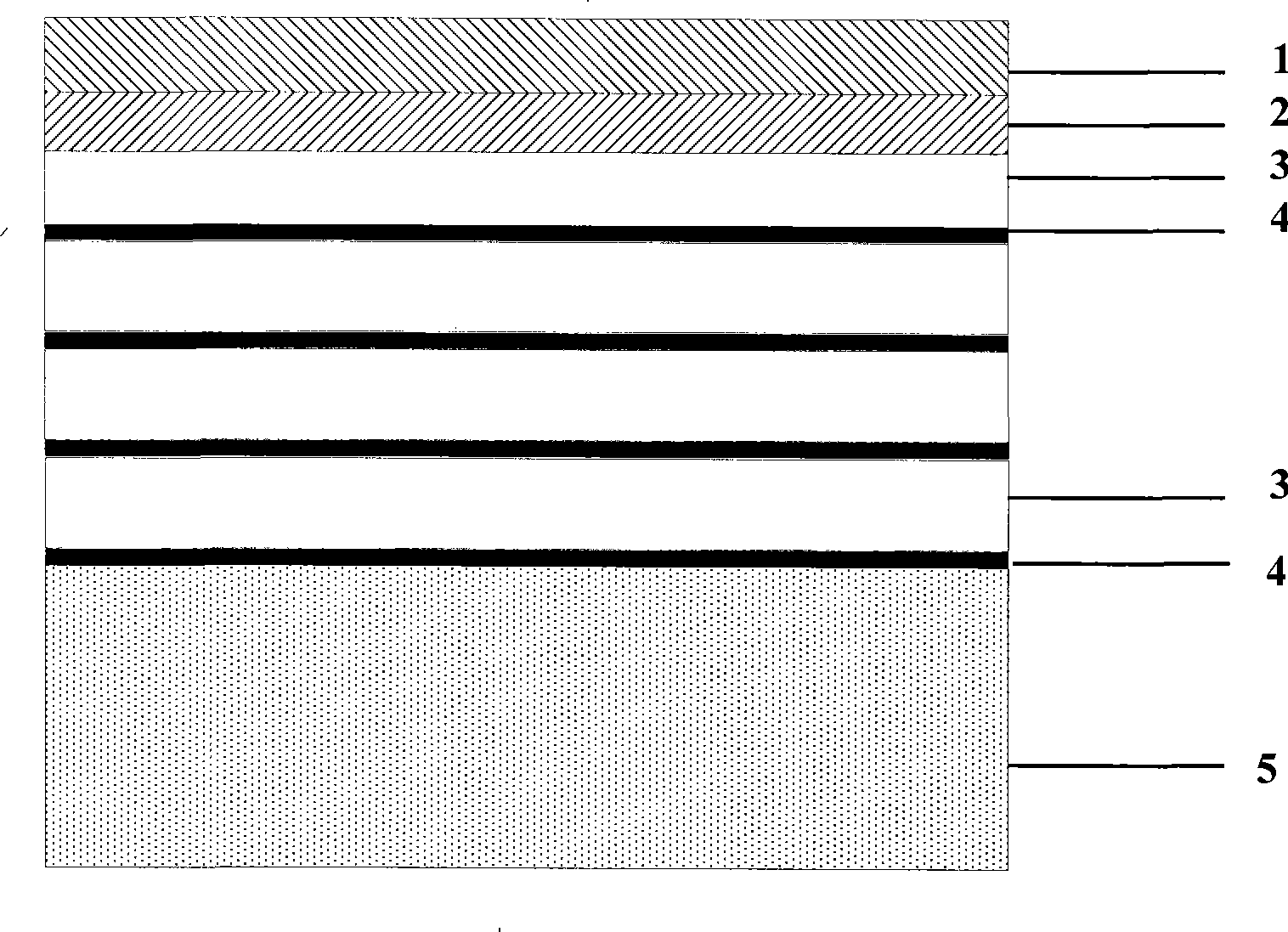

Lithium negative electrode preform, preparation method thereof, lithium negative electrode, and lithium secondary battery

PendingCN108321355AIncrease contact interfaceImprove performanceFinal product manufactureLi-accumulatorsAll solid stateSolid state electrolyte

The invention relates to a lithium negative electrode preform, a preparation method thereof, a lithium negative electrode, and a lithium secondary battery. The lithium negative electrode preform is prepared by integrally laminating a plastic base layer, a solid electrolyte layer, and a lithium layer. The manufacturing is simple and easy to perform. The contact interface between the lithium negative electrode and solid electrolyte is effectively improved to prevent the formation of lithium dendritic crystals, and the performance of an all solid state battery is obviously enhanced.

Owner:CHINA ENERGY CAS TECH CO LTD

Method for preparing carbon fiber reinforced carbon and hexagonal boron nitride double-matrix friction material

ActiveCN101875562AUniform tissueThe production process is simple and easy to controlHexagonal boron nitridePyrolytic carbon

The invention relates to a method for preparing a carbon fiber reinforced carbon and hexagonal boron nitride double-matrix friction material. The method comprises the following steps of: 1, spreading powder in layers: uniformly adhering boron nitride (BN) powder on two sides of each monolayer carbon fiber felt; 2, superimposing, needling and compounding: superimposing the felts obtained in the step 1 on one another, and needling the superimposed felts to obtain a BN powder-containing carbon fiber prefabricated body material; 3, chemical vapor infiltration: depositing a pyrolytic carbon matrix from the BN powder-containing carbon fiber prefabricated body material by adopting a chemical vapor infiltration method to obtain a carbon fiber reinforced carbon and boron nitride double-matrix (C / C-BN) friction material; and 4, graphitizing: graphitizing the C / C-BN composite material which is obtained by the step 3 to obtain the desired C / C-BN friction material. The method for preparing the carbon fiber reinforced carbon and hexagonal boron nitride double-matrix friction material has the advantages of simple and controllable production process, low preparation cost, controllable microstructure and performance of the prepared material, uniform structure, high strength, high temperature resistance, corrosion resistance, high frictional and abrasive properties and capacity of realizing industrial production.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

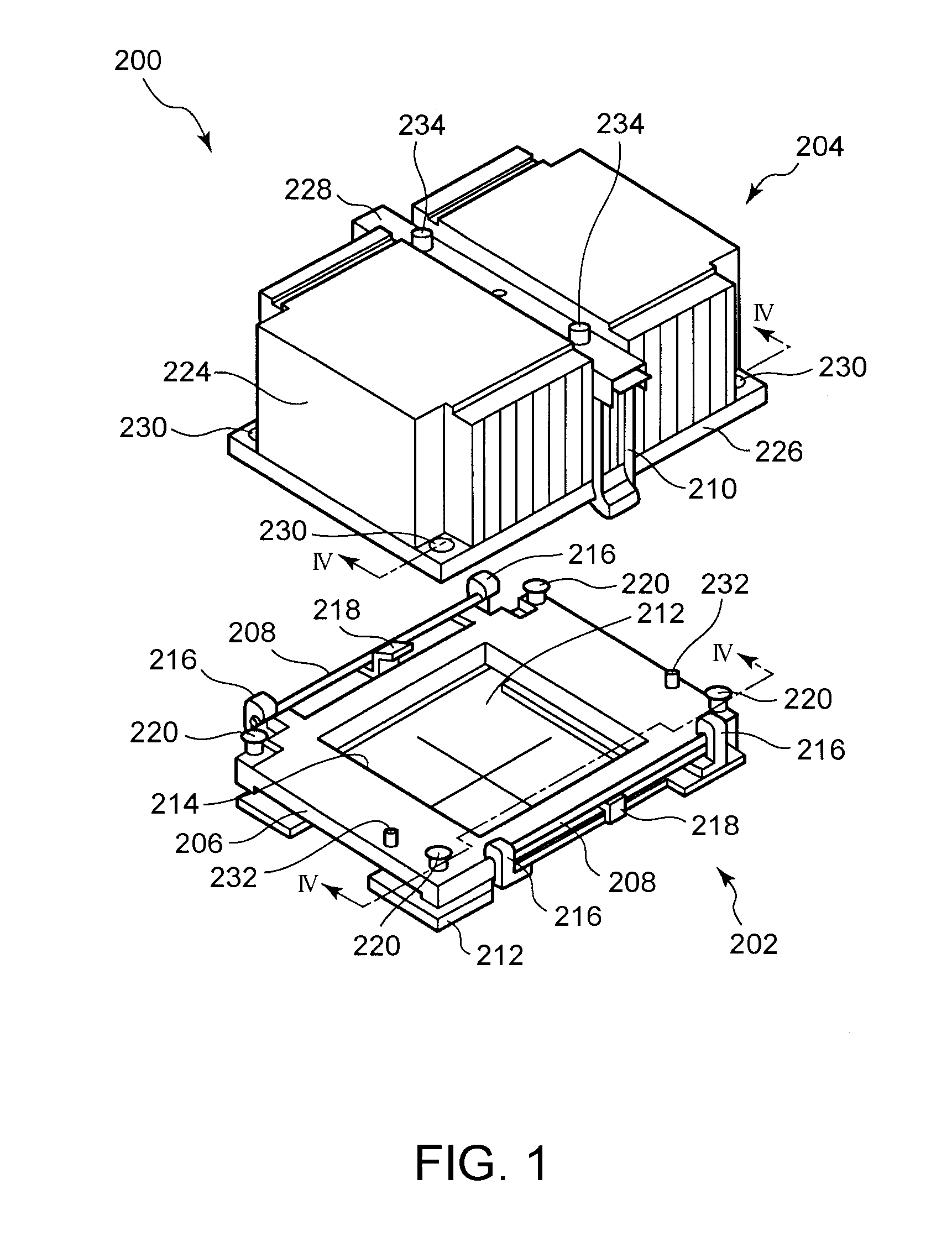

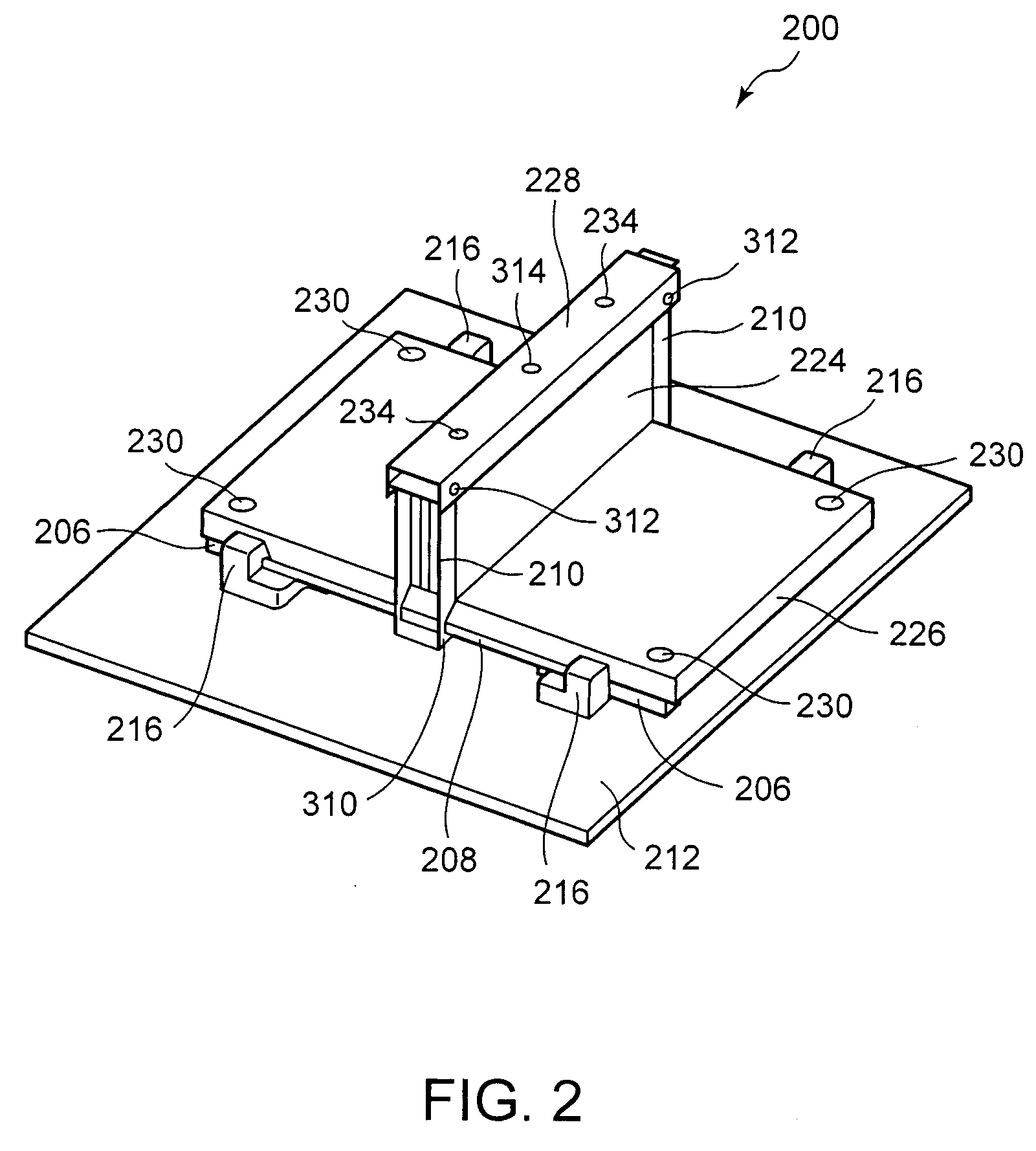

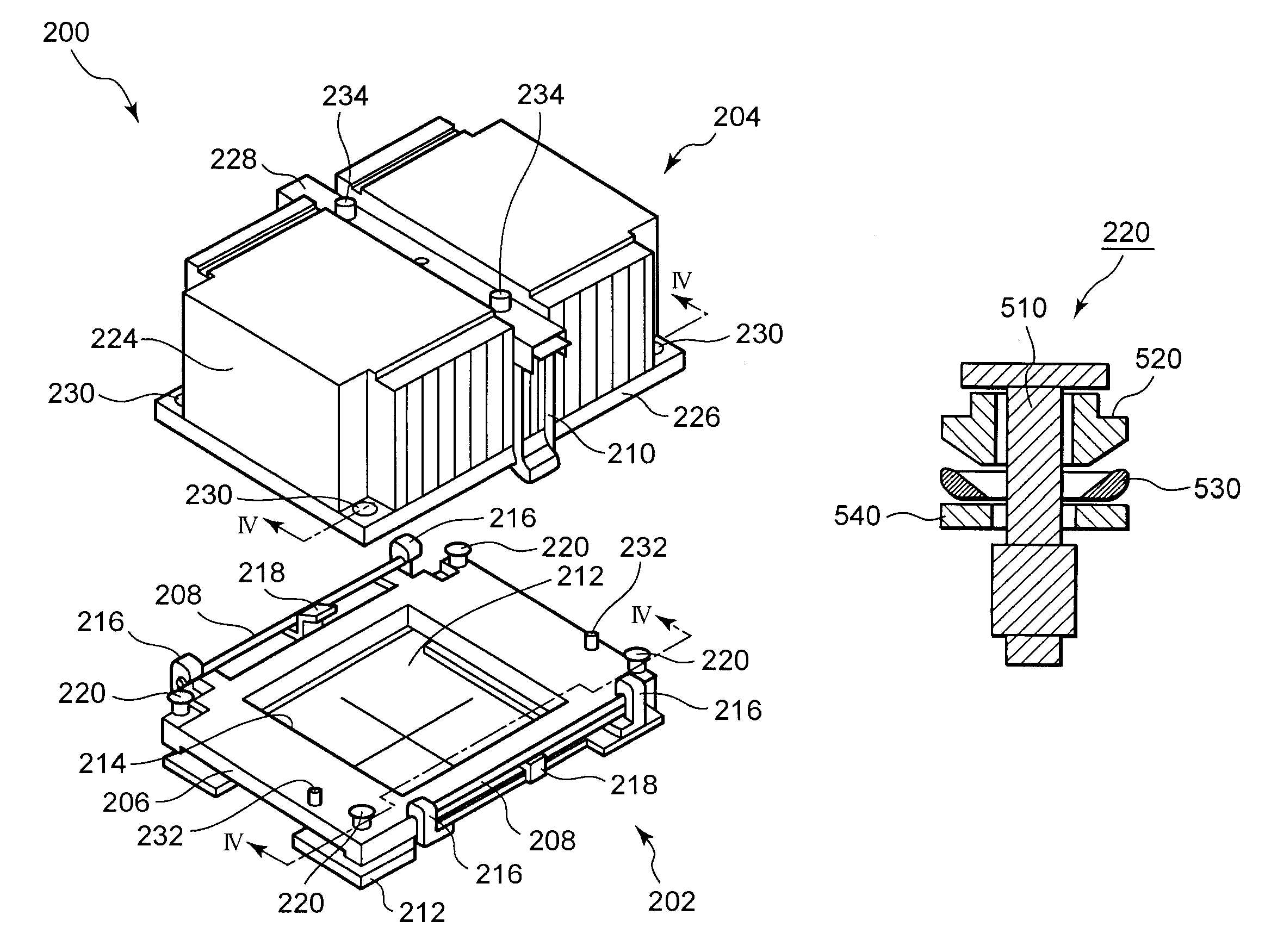

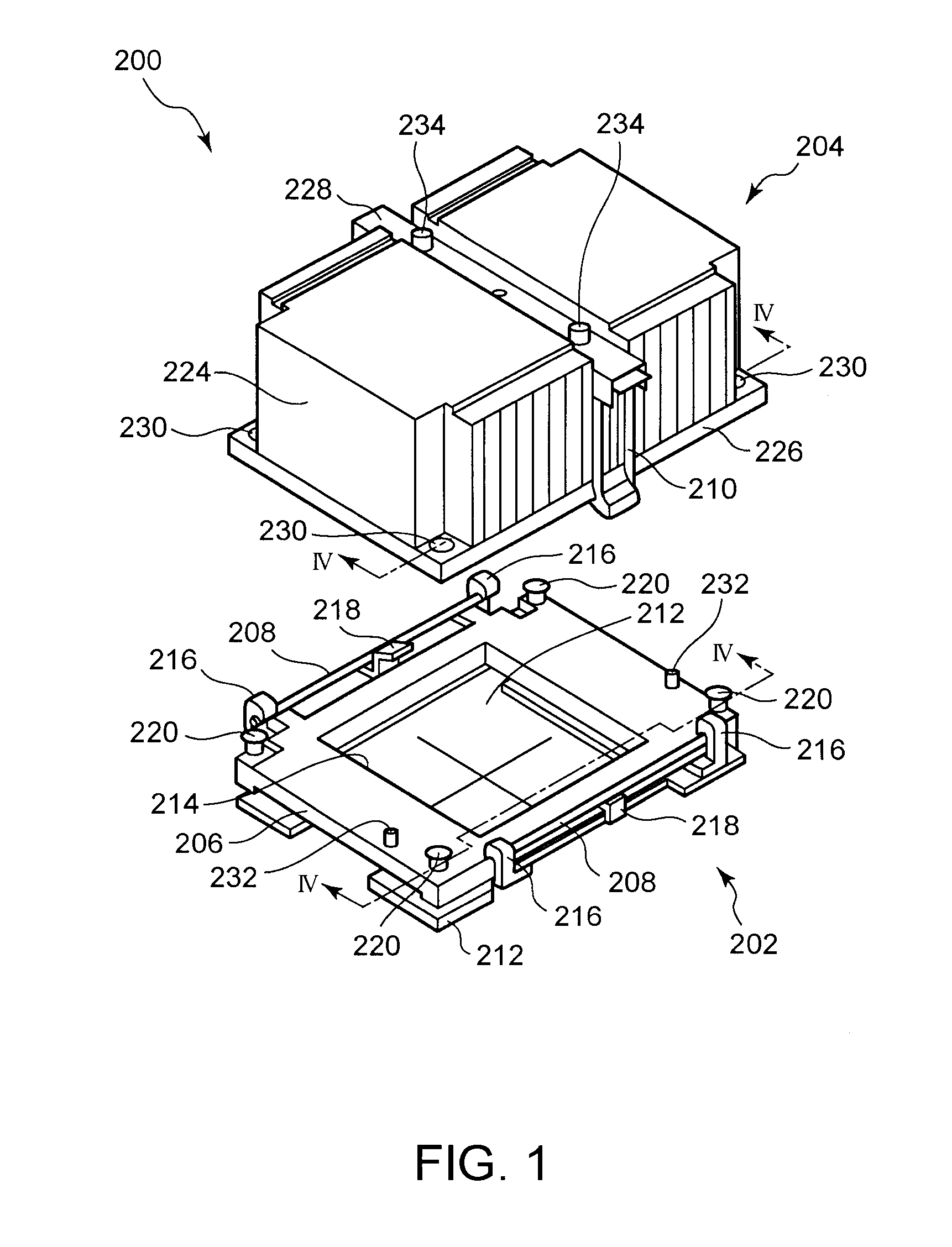

Non-Influencing Fastener for Mounting a Heat Sink in Contact with an Electronic Component

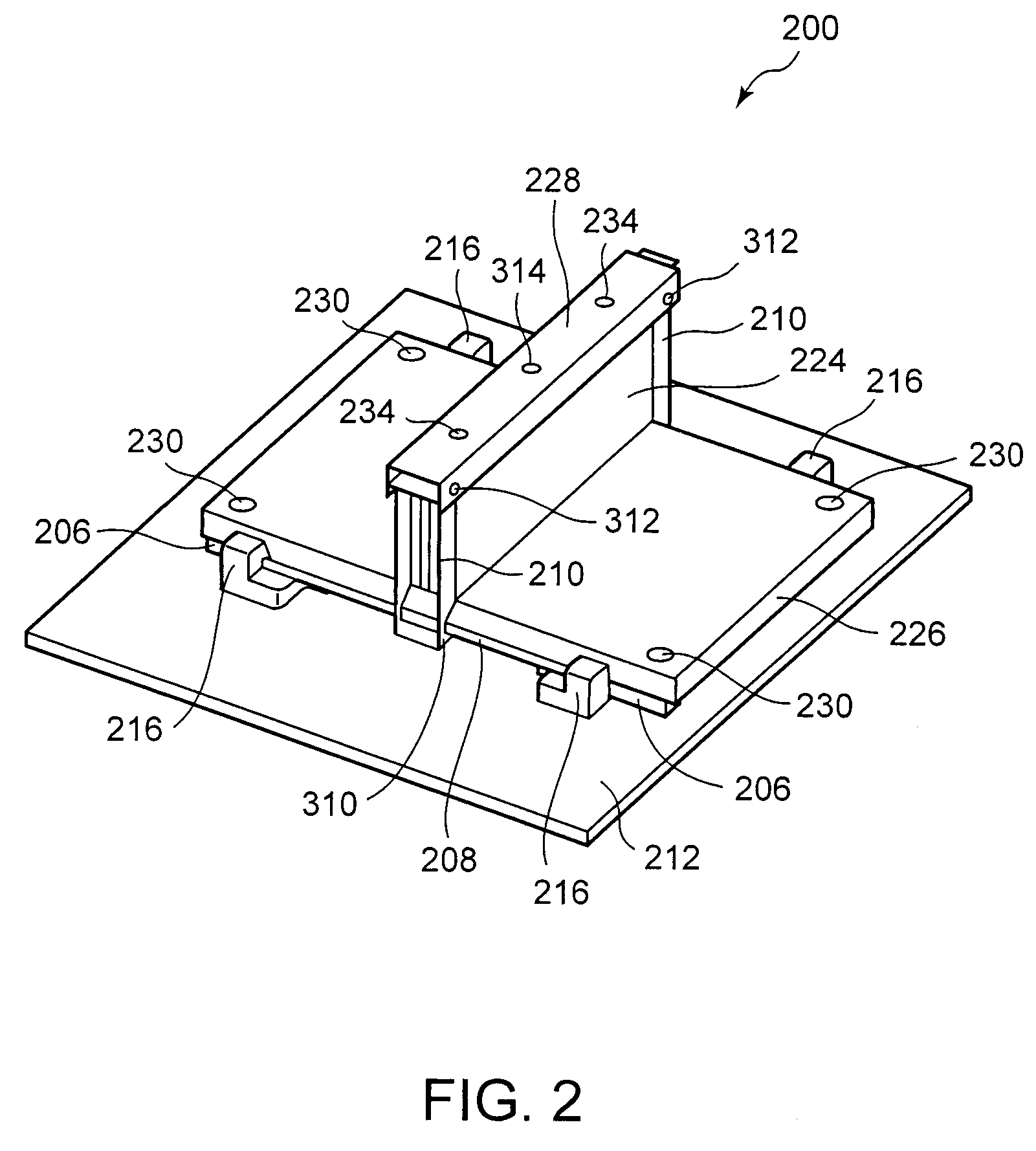

ActiveUS20070247813A1Increase contact interfaceSnap fastenersSemiconductor/solid-state device detailsEngineeringThermal contact

A load frame has an open region exposing a surface of an electronic component. A heat sink is disposed on the load frame and has a surface in thermal contact with the surface of the electronic component. A non-influencing fastener is disposed within a bore in the heat sink and threaded into the load frame for securing the heat sink to the load frame. The non-influencing fastener includes a screw with a head; a tapered ring disposed below the head of the screw and having a tapered lower peripheral surface; a sealing ring engaging the tapered lower peripheral surface of the tapered ring; and a load washer disposed between the sealing ring and the load frame. Compression of the rings by turning of the screw into the load frame causes the sealing ring to expand against the bore of the heatsink. Preferably, the sealing ring has a curved outer surface.

Owner:LENOVO GLOBAL TECH INT LTD

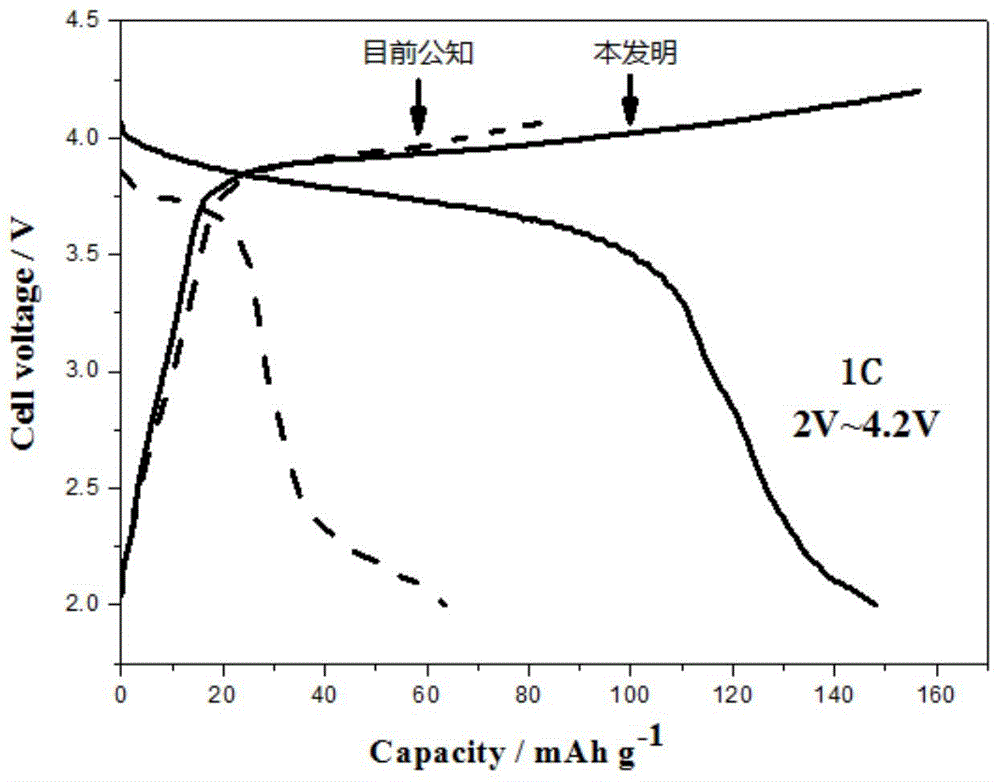

Preparation method of safe high-rate and all-solid-state battery

InactiveCN105789682AEnsure safetyImprove high-current discharge performanceFinal product manufactureLi-accumulatorsHigh rateEngineering

The invention relates to a preparation method of a safe high-rate and all-solid-state battery. The method comprises the following steps: (1) pressing a negative current collector, a negative material, a solid electrolyte, a composite positive electrode and a positive current collector into a whole in a battery pressing mold from bottom to top in a dry environment to form the all-solid-state battery before liquid injection; (2) injecting a liquid electrolyte solution into the all-solid-state battery before liquid injection prepared in the step (1) in a vacuum environment; and (3) carrying out aerating treatment on the vacuum environment into which an ionic liquid is injected in the step (2) to prepare the safe high-rate and all-solid-state battery. The trace electrolyte is injected into the all-solid-state battery molded in a cold-press manner in the dry environment and is subjected to aerating treatment, so that the electrolyte is evenly dispersed into the all-solid-state battery. The trace electrolyte does not react with a solid electrolyte material and has good lithium-ion conduction ability, so that the contact resistance between the internal materials of the all-solid-state battery is reduced by the electrolyte as a transition electrolyte layer; and the high-current discharge capacity of the battery is greatly improved under the premise of ensuring the safety of the battery.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

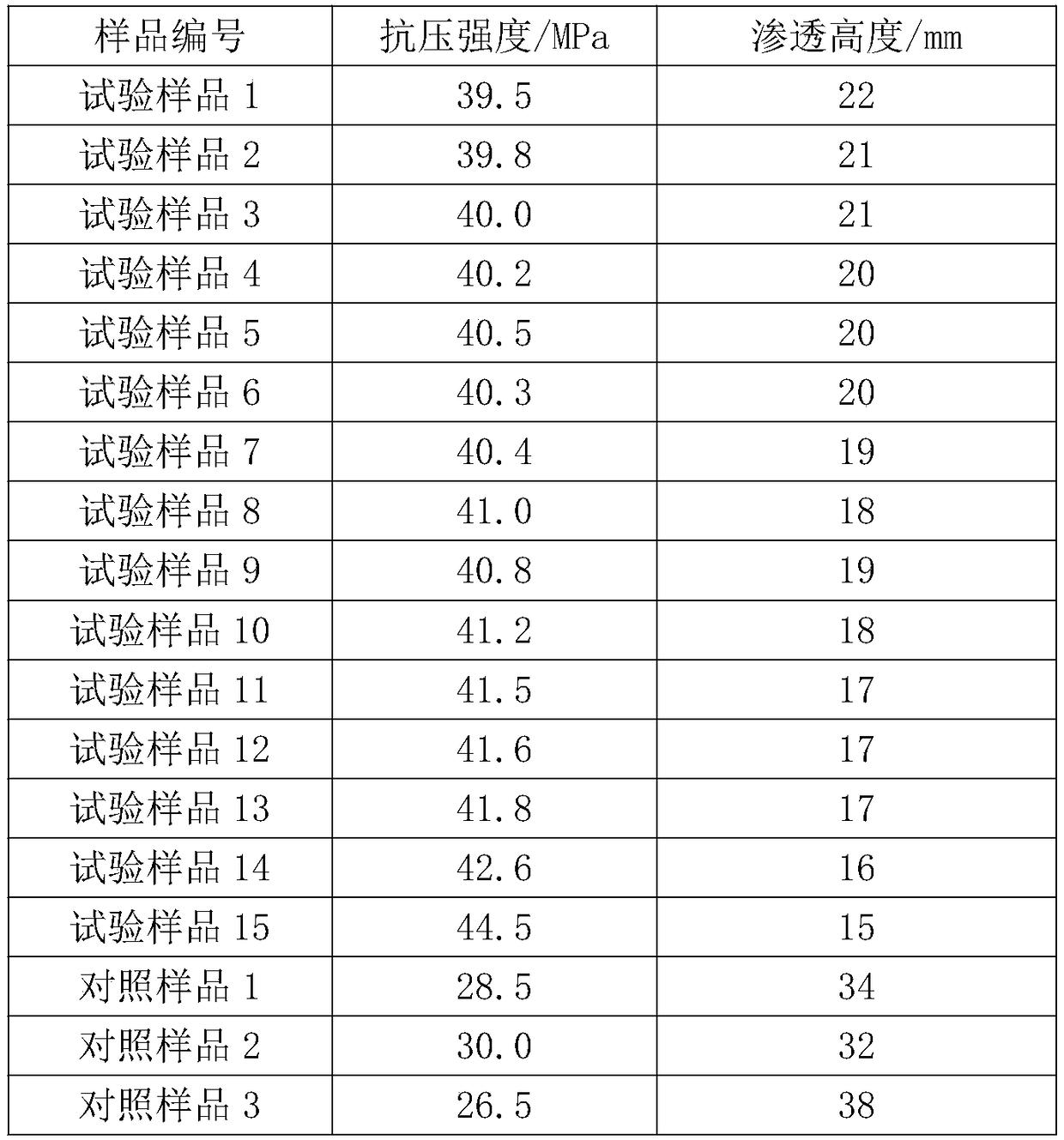

Anti-seepage recycled concrete and preparation method thereof

The invention discloses an anti-seepage recycled concrete and a preparation method thereof, and relates to the technical field of building materials. The anti-seepage recycled concrete is prepared from the following raw materials in parts by weight: 75 to 85 parts of ordinary Portland cement, 50 to 60 parts of natural fine aggregate, 90 to 100 parts of modified recycled coarse aggregate, 8 to 10 parts of fly ash, 1 to 2 parts of polycarboxylate water reduction agent, 8 to 12 parts of sodium gluconate, 5 to 6 parts of nanometer carbon fiber, and 35 to 45 parts of water. The preparation method of the modified recycled coarse aggregate comprises the following steps of (1) crushing the waste concrete into the aggregate with size of 5 to 40 mm, cleaning the crushed aggregate by water, and naturally airing, so as to obtain the dried aggregate; (2) uniformly mixing a penetrant, nanometer titanium dioxide and water to form a modifying liquid, feeding the dried aggregate into the modifying liquid, and uniformly stirring and mixing, so as to obtain a suspension liquid; (3) putting the suspension liquid into a sealed container, leading carbon dioxide gas into the suspension liquid, filtering,and airing the aggregate, so as to obtain the modified recycled coarse aggregate. The anti-seepage recycled concrete has the advantage of good anti-seepage property.

Owner:曙光装配式建筑科技(浙江)有限公司

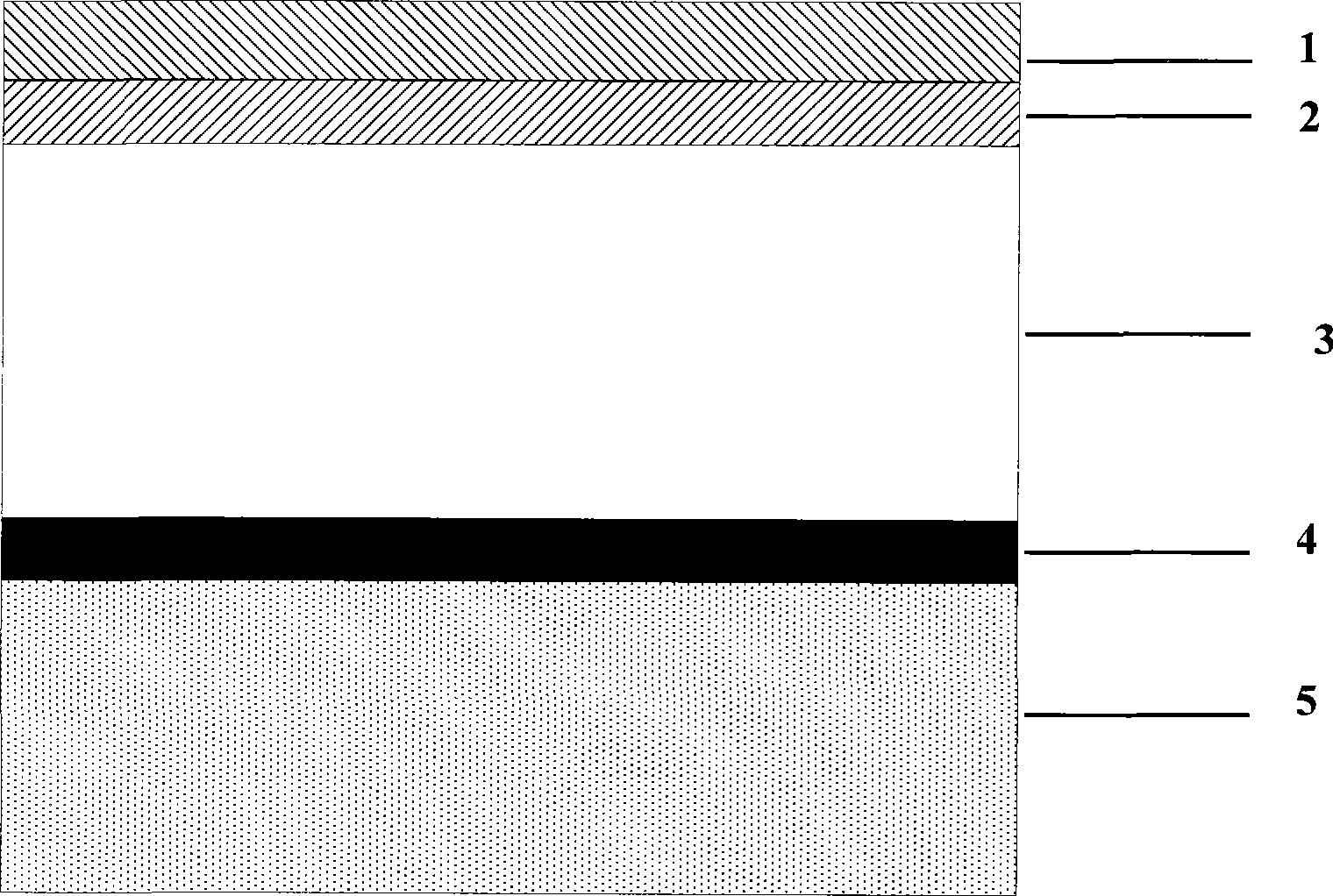

Lithium ion battery

InactiveCN104868156AImprove thermal stabilityIncrease contact interfaceSecondary cellsCell component detailsWater basedSilicon dioxide

The invention relates to a lithium ion battery and provides a lithium ion battery. The lithium ion battery comprises a cathode, an anode, and a water-based multi-layer diaphragm arranged between the anode and the cathode and an electrolyte. The water-based multi-layer diaphragm comprises: (A) a polymer diaphragm base material; (B) an inorganic or organic particle coating which coats one side or two sides of the polymer diaphragm base material (A); and (C) an organic particle coating which coats the inorganic or organic particle coating (B). The inorganic or organic particle coating (B) is formed by a following composition, wherein the following composition comprises 15-70 wt% of inorganic or organic particles and 30-85 wt% of water, and the inorganic or organic particles are selected from aluminum oxide, silicon dioxide, barium sulfate, boehmite or polyimide.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

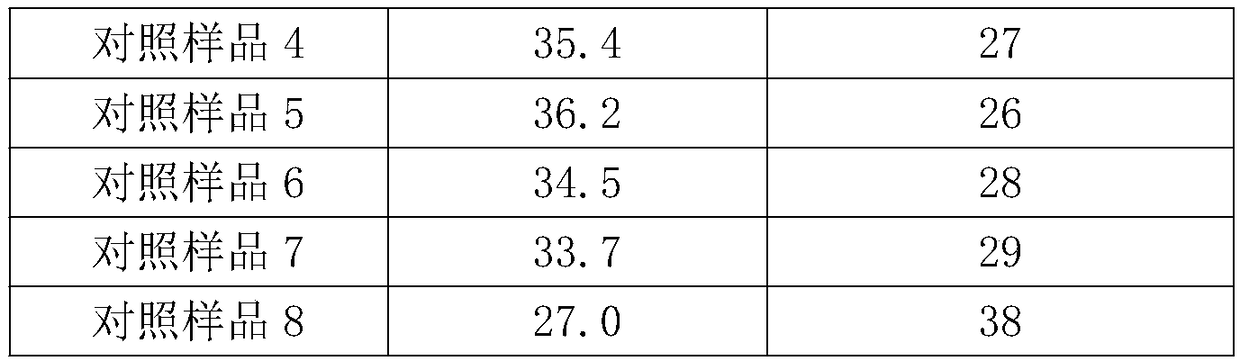

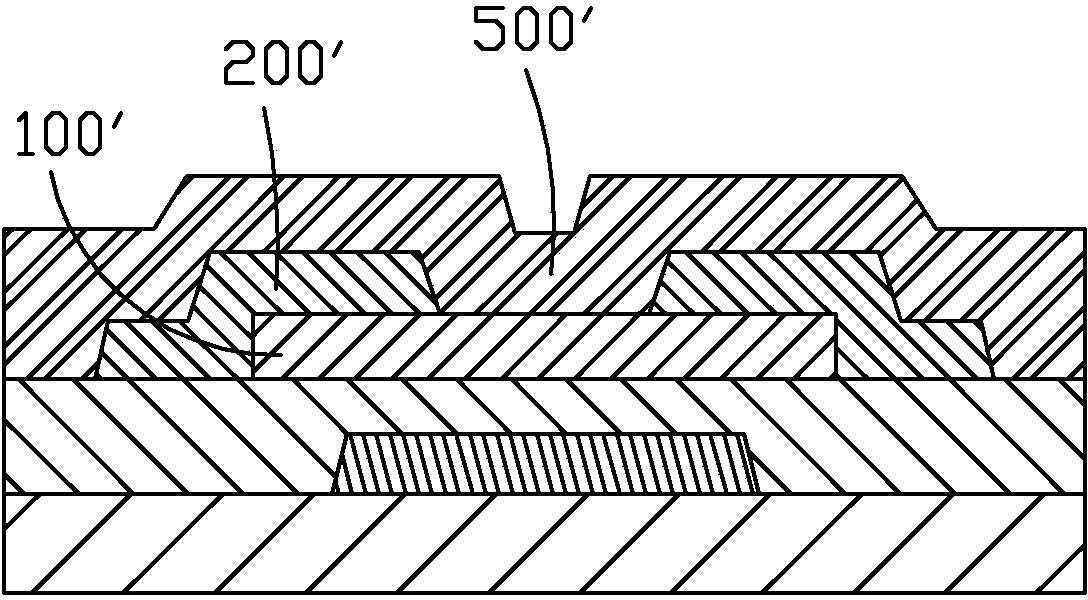

Resistance memory and method for fabricating integrated circuit with same

ActiveCN101572248ARealize interlayer interconnect structureSimple processSemiconductor/solid-state device detailsSolid-state devicesCore componentInterconnection

The invention relates to a method for fabricating an integrated circuit with a resistance memory, comprising the following steps: providing an interlaminar dielectric layer comprising a core component area and a peripheral circuit area; forming a first interconnection structure and a second interconnection structure in the interlaminar dielectric layer; respectively forming a first dielectric layer and a second dielectric layer on the surface of the first interconnection structure and on the surface of the second interconnection structure; forming first conductive layers covering the interlaminar dielectric layer, the first dielectric layer and the second dielectric layer; removing a first conductive layer and a second conductive layer on the peripheral circuit area to expose the second interconnection structure and only keeping the first conductive layer on the first dielectric layer in the core component area; and respectively forming a second conductive layer and a third conductive layer on the first conductive layer of the first dielectric layer and on the second interconnection structure. Due to the adoption of the method for fabricating the integrated circuit with the resistance memory, when the resistance memory is formed, the interlaminar interconnection structure of the core component area and the peripheral circuit area can be also formed.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

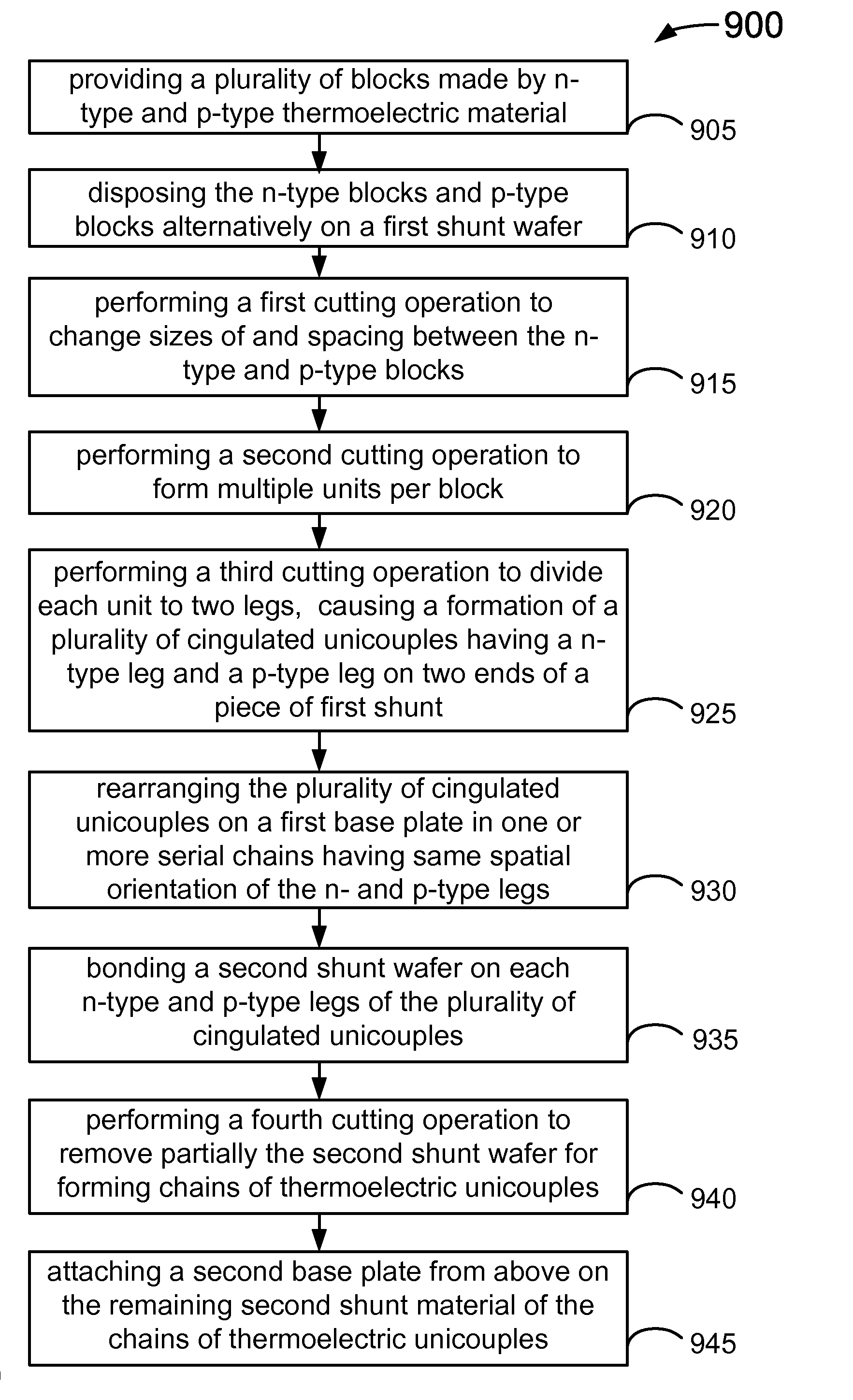

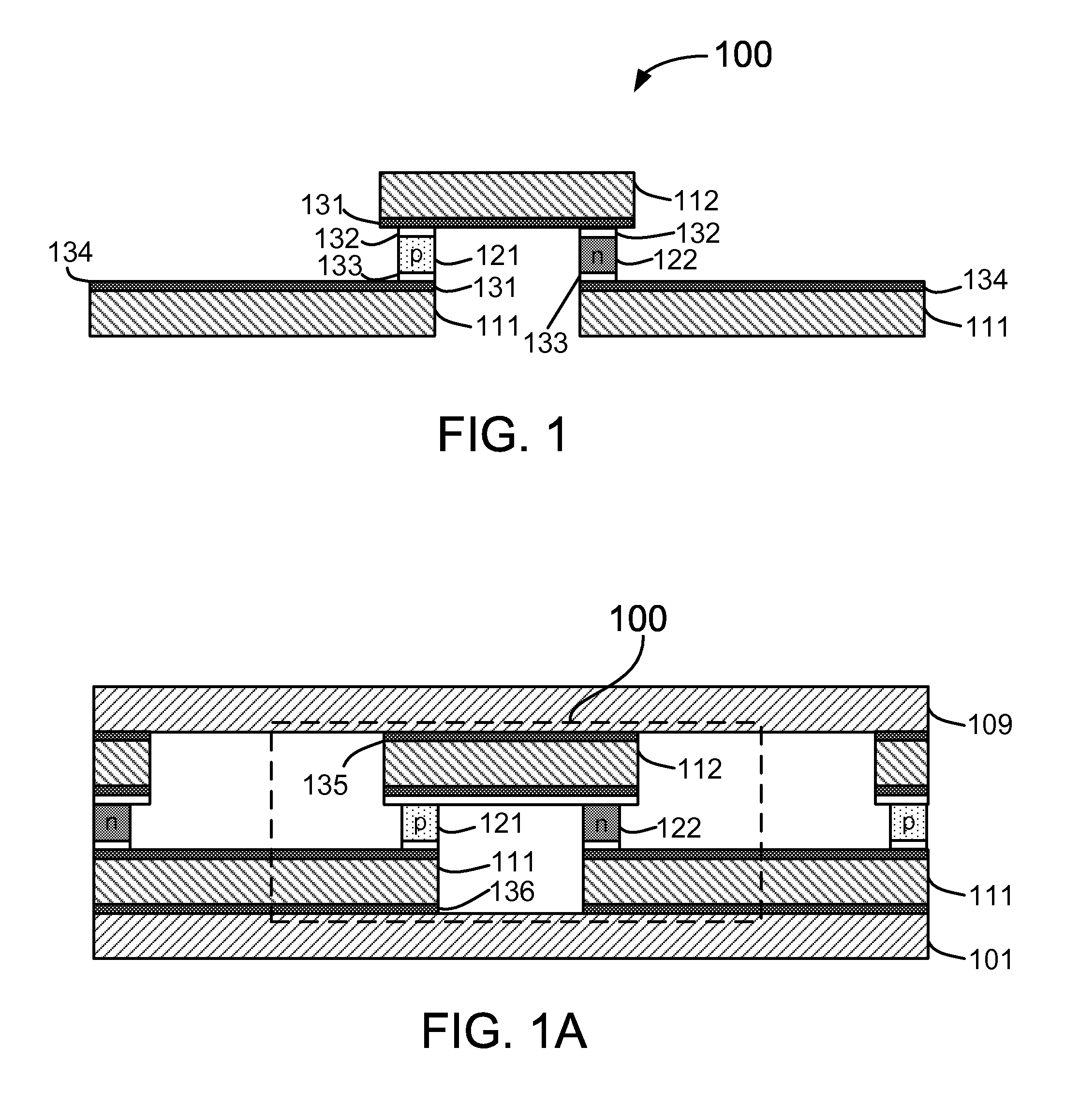

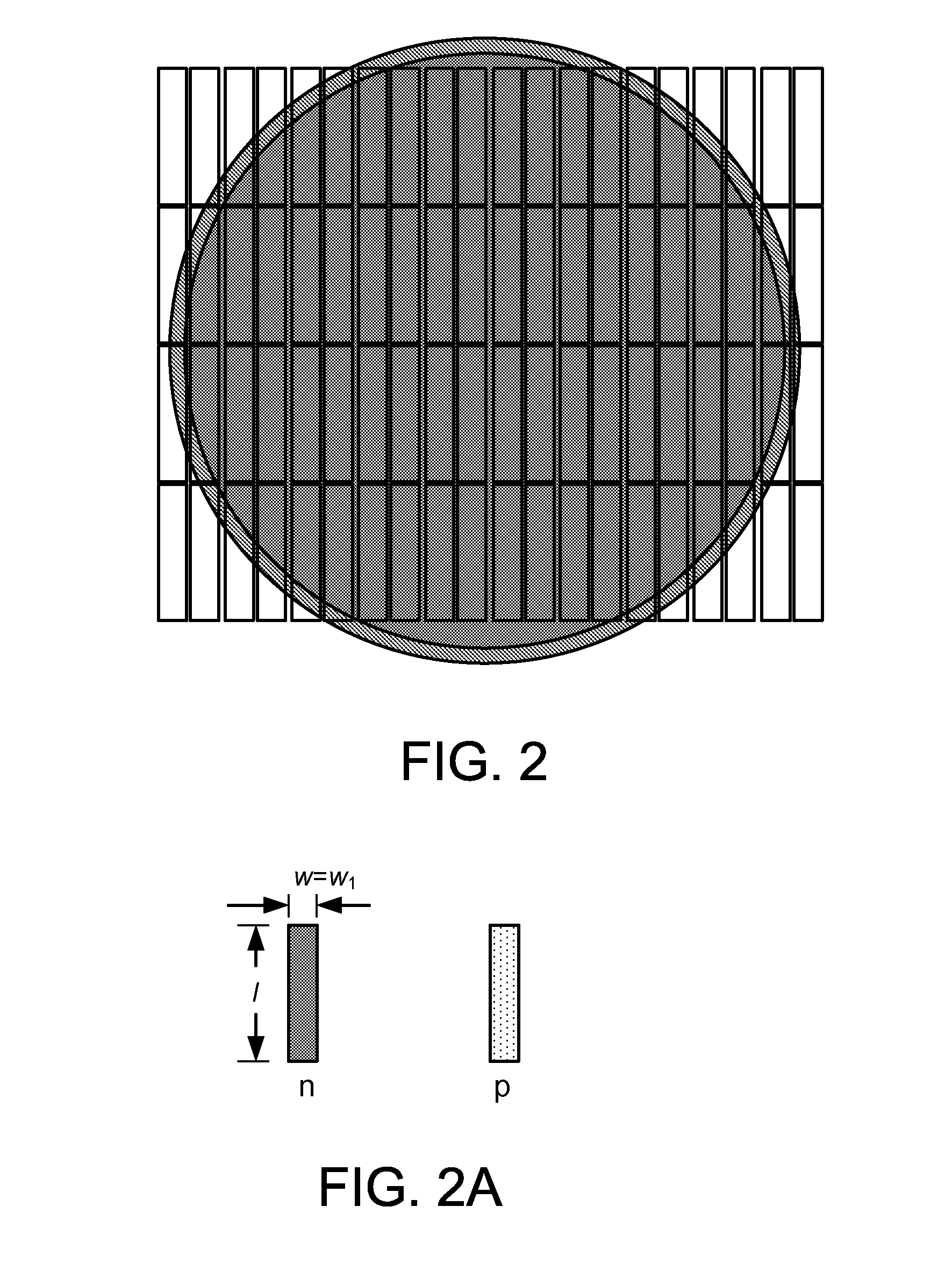

Method and structure for thermoelectric unicouple assembly

ActiveUS20140024163A1Wide range of applicationsImprove efficiencyThermoelectric device manufacture/treatmentSemiconductor/solid-state device manufacturingDaisy chainSilicon based

Method for assembling thermoelectric unicouples is provided and applied with silicon-based nanostructure thermoelectric legs. The method includes preparing and disposing both n-type and p-type thermoelectric material blocks in alternative columns on a first shunt material. The method includes a sequence of cutting processes to resize the thermoelectric material blocks to form multiple cingulated unicouples each having an n-type thermoelectric leg and a p-type thermoelectric leg bonded to a section of the first shunt material. Additionally, the method includes re-disposing these cingulated unicouples in a serial daisy chain configuration with a predetermined pitch distance and bonding a second shunt material on top. The method further includes performing additional cutting processes to form one or more parallel series of thermoelectric unicouples in daisy chain configuration. The first shunt material is coupled to a cold-side heat sink and the second shunt material is coupled to a hot-side heat sink.

Owner:SYNERGY THERMOGEN INC +1

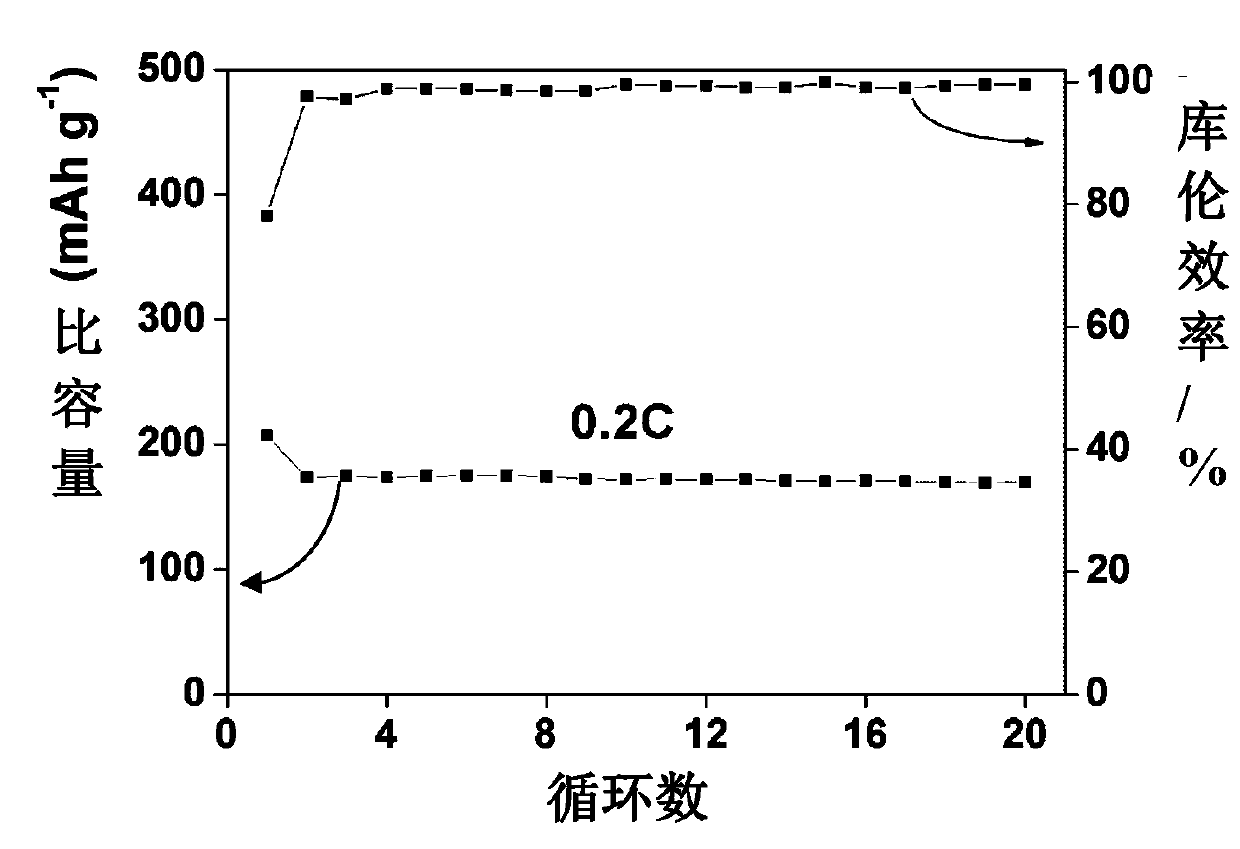

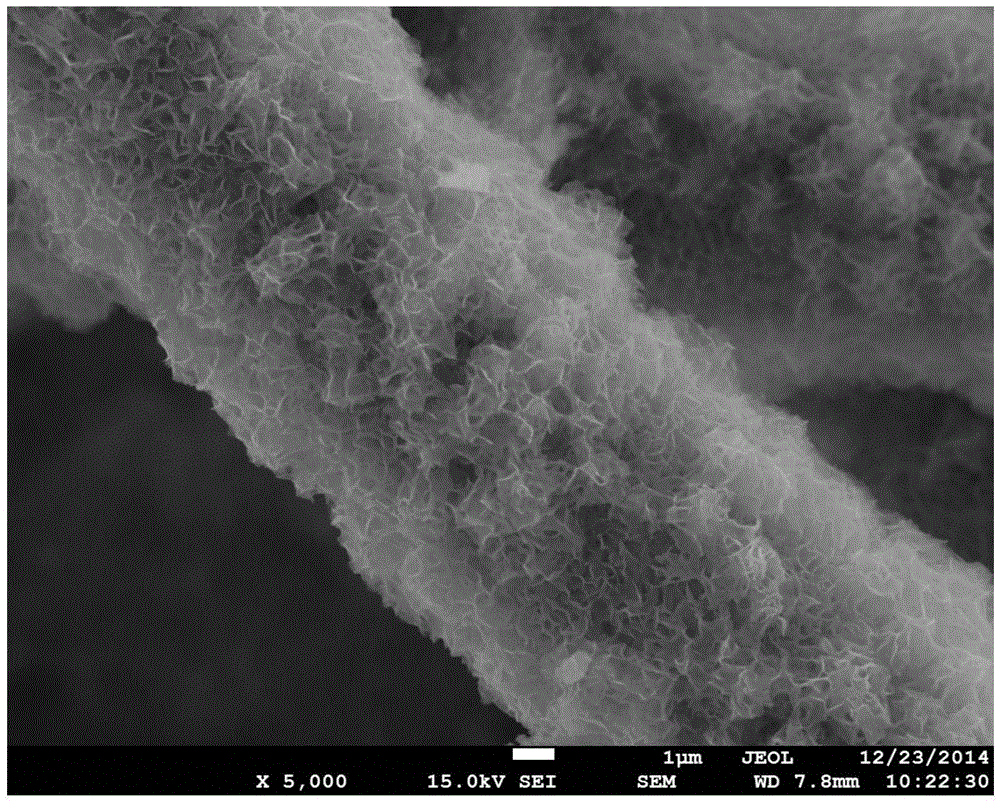

Integrated composite electrode for supercapacitor and preparation method of integrated composite electrode

InactiveCN105470000AUniform growthStrong loadHybrid capacitor electrodesHybrid/EDL manufactureMolybdateComposite electrode

The invention discloses an integrated composite electrode for a supercapacitor and a preparation method of the integrated composite electrode. The preparation method adopts a hydrothermal method and comprises the following steps of taking a carbon fabric as a conductive substrate, nickel acetate and ammonium molybdate as a precursor for synthesizing nickel molybdate and urea as an accelerant and a morphology modulation agent of the nickel molybdate to prepare a Co3O4@NiMoO4 core-shell composite structured electrode, and the prepared electrode material can be directly used for the supercapacitor. In the Co3O4@NiMoO4 core-shell composite structured integral electrode prepared according to the method, an electrode substance is firmly loaded on the surface of the carbon fabric and uniformly grown, the specific area of the electrode in a BET test reaches 251m<2> / g, the electrode has excellent electrochemical activity, and the contact interface of electrode-electrolyte is greatly improved.

Owner:GUANGDONG UNIV OF TECH

Non-influencing fastener for mounting a heat sink in contact with an electronic component

ActiveUS7345881B2Increase contact interfaceSnap fastenersSemiconductor/solid-state device detailsThermal contactElectronic component

A load frame has an open region exposing a surface of an electronic component. A heat sink is disposed on the load frame and has a surface in thermal contact with the surface of the electronic component. A non-influencing fastener is disposed within a bore in the heat sink and threaded into the load frame for securing the heat sink to the load frame. The non-influencing fastener includes a screw with a head; a tapered ring disposed below the head of the screw and having a tapered lower peripheral surface; a sealing ring engaging the tapered lower peripheral surface of the tapered ring; and a load washer disposed between the sealing ring and the load frame. Compression of the rings by turning of the screw into the load frame causes the sealing ring to expand against the bore of the heatsink. Preferably, the sealing ring has a curved outer surface.

Owner:LENOVO GLOBAL TECH INT LTD

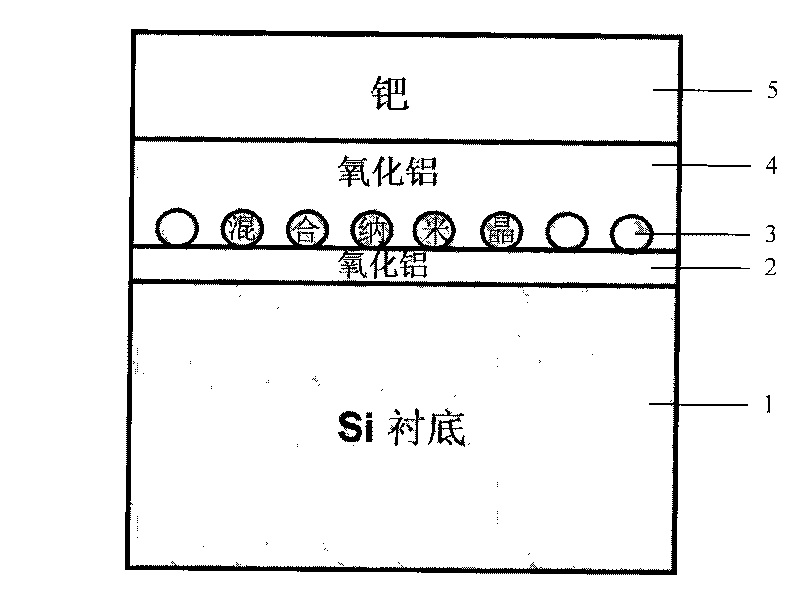

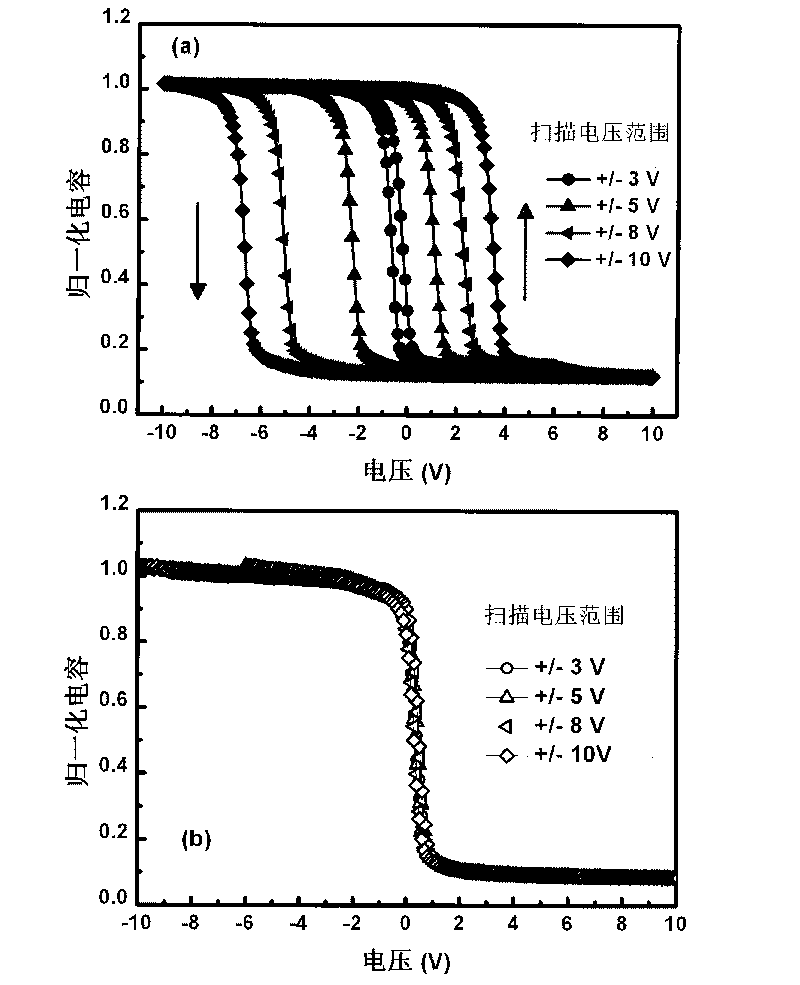

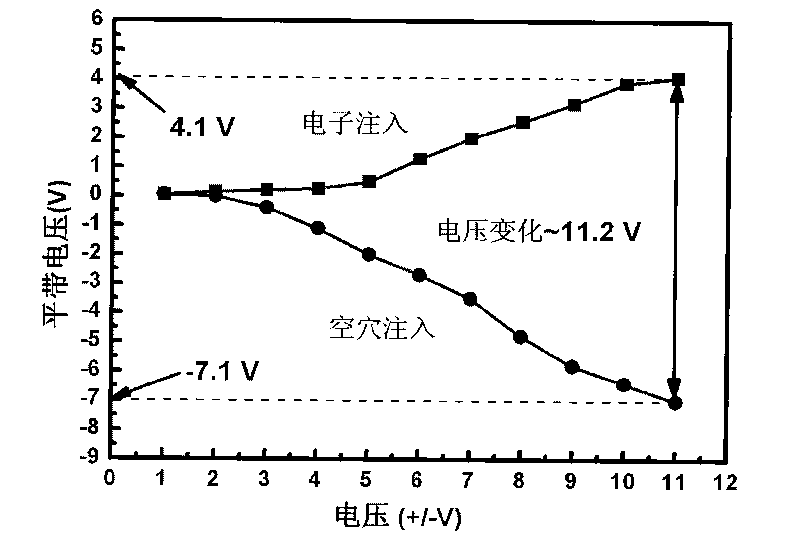

Capacitor structure of mixed nano-crystal memory and preparation method thereof

InactiveCN101692463AHigh densityControl thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceCharge retention

The invention belongs to the technical field of manufacturing semiconductor integrated circuits, and particularly relates to a capacitor of a nano-crystal memory and a preparation method thereof. The capacitor uses P-type monocrystalline silicon as a substrate, and an Al2O3 tunneling layer, a ruthenium and ruthenium oxide mixed nano-crystal, an Al2O3 blocking layer and a palladium electrode layer are arranged on the substrate in turn, wherein the Al2O3 layer is prepared by adopting an atomic layer deposition method; the mixed nano-crystal is formed by depositing a ruthenium layer through magnetron sputtering first and then performing rapid thermal annealing in a mixed gas atmosphere of nitrogen gas and a trace amount of oxygen gas; and the palladium electrode layer is formed by adopting a lift-off method. The capacitor structure of the memory has the excellent characteristics of good programming and erasing properties, long charge retention time and the like, and has a good application prospect on a flash memory.

Owner:FUDAN UNIV

Mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding

ActiveCN103537613AIncrease contact interfaceReduce porosityFoundry mouldsFoundry coresThermal fatiguePhysical chemistry

The invention provides a mold-releasing type complexing agent with effects of resisting a high temperature of more than 1450 DEG C, insulating heat and demolding and a preparation method thereof. The mold-releasing type complexing agent comprises the following raw materials in percentage by weight: 20-60% of nano colloidal silicon dioxide solution; 5-30% of composite oxide ultramicro (0.1-1.0 microns) powder including Na, Mg, Ca, Fe, Li, Al, Si, B, Zr and other elements; 0.2-2% of water-based dispersing agent;0.02-0.5% of water-based thickening agent and the balance of water; and the sum of the weight of the components is 100%. According to the mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding, the nano colloidal silicon dioxide solution is cooperated with the ultramicro (0.1-1.0 microns) multielement composite oxide powder, so that the excellent performances of high temperature resistance, heat insulation, demolding, environment protection and the like are achieved, the thermal fatigue resistance of the mold surface is effectively improved, and the service life of the mold is prolonged. The mold-releasing type complexing agent with effects of resisting high temperature, insulating heat and demolding is particularly applicable to using at the part of a mold directly contacting molten steel in fired mold casting and other high temperature forming technologies of metal.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

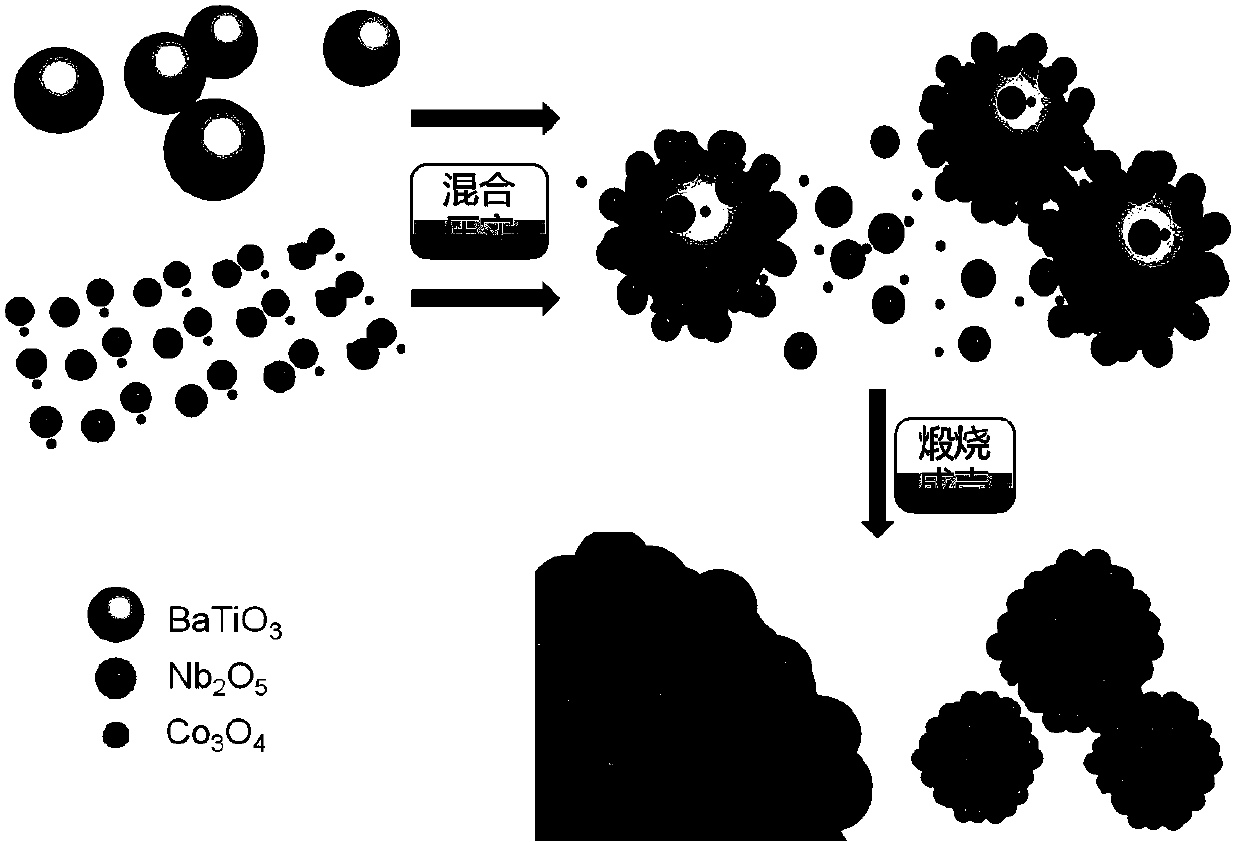

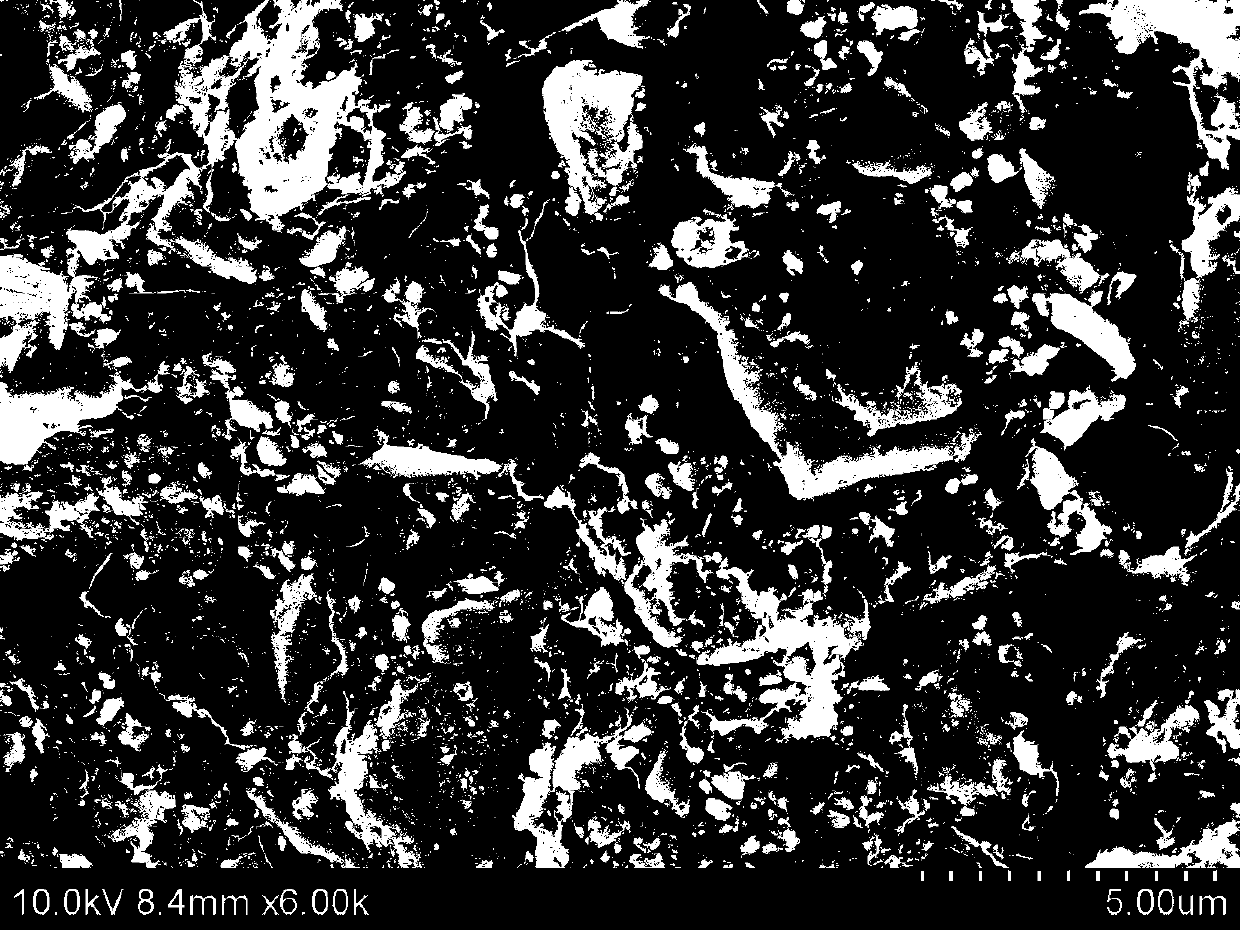

Epoxy-resin-based high-dielectric composite material and preparation method thereof

ActiveCN105949725AIncrease contact interfaceSignificant interface polarizationEpoxyCobalt(II,III) oxide

The invention discloses an epoxy-resin-based high-dielectric composite material and a preparation method thereof. According to the composite material, epoxy resin serves as a base body, modified barium titanate serves as filler, and the modified barium titanate is modified barium titanate BTNC doped with niobium pentoxide and cobaltosic oxide. The modified barium titanate BTNC is fully mixed with epoxy resin and a curing agent, heating and curing are conducted, and the BTNC / epoxy resin dielectric composite material is obtained. Compared with an epoxy resin composite material filled with barium titanate which is not modified, the composite material has a higher dielectric constant, lower dielectric consumption and better temperature stability.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

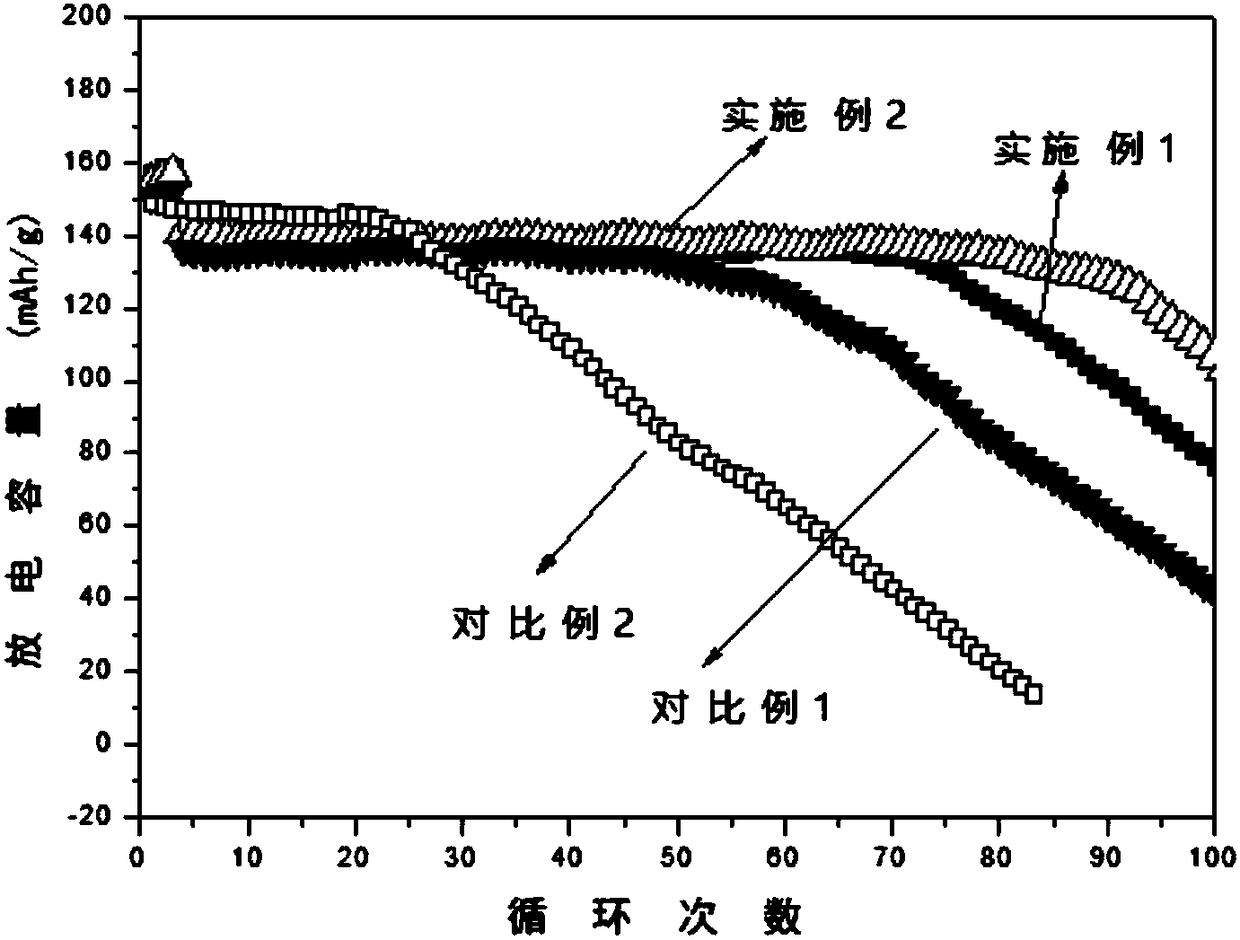

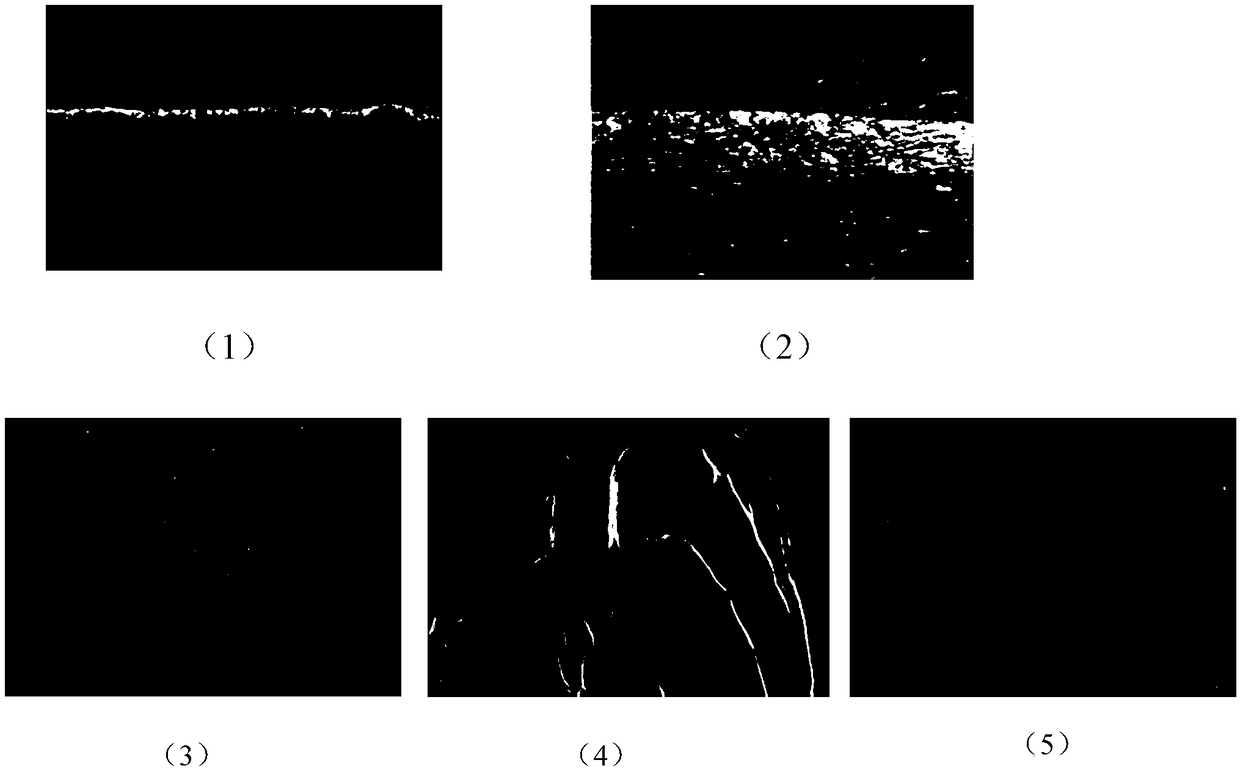

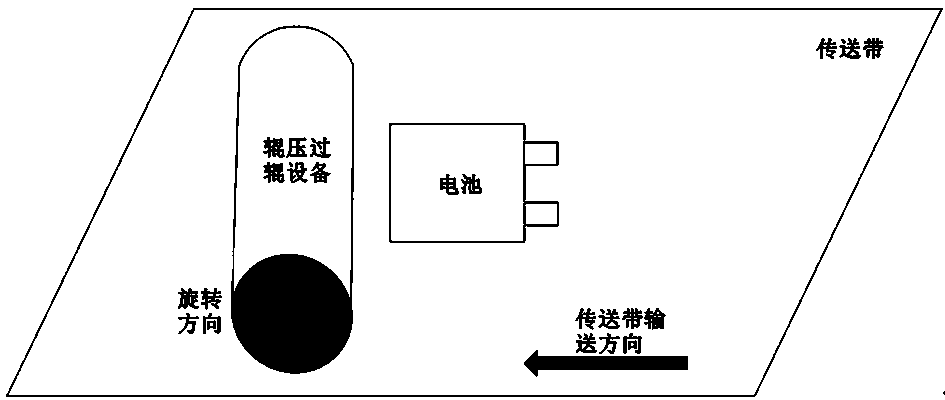

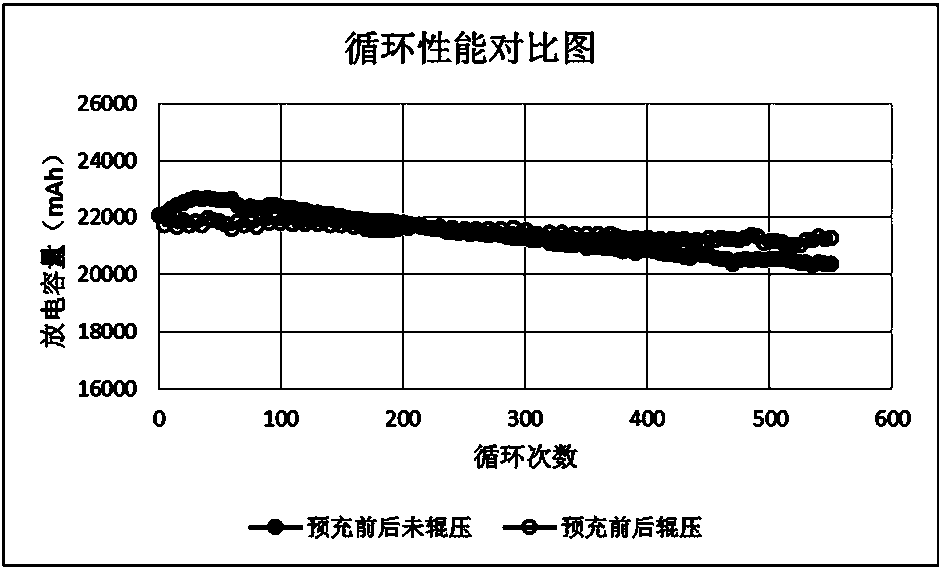

Novel control method for improving lithium ion soft-package laminated battery diaphragm fold

InactiveCN108155424AImprove performanceGuaranteed plastic effectFinal product manufactureSecondary cells charging/dischargingElectrical batteryPre-charge

The invention relates to a novel control method for improving lithium ion soft-package laminated battery diaphragm fold. The problem that the battery performance is influenced due to the fold of the soft-package laminated lithium ion battery diaphragm is solved. The control method comprises the following steps: laying down a battery after liquid injection, thereby ensuring that the electrolyte sufficiently infiltrates a pole piece; and then performing rolling on the lay-down battery, and controlling the pressure and speed of the rolling in the rolling process; pre-charging the battery after the rolling is ended; and performing secondary rolling on the completely pre-charged battery, further shaping the diaphragm, and releasing the gas to finish the secondary package. The contacting interface between a positive / negative pole piece and the diaphragm is better by comparing the lithium ion soft-package laminated battery prepared based on the control method with the battery without performing the rolling shaping, the dead lithium existing in the fold area caused by the diaphragm fold is avoided, thus the capacity of the positive / negative material is sufficiently played, and the batteryperformance is improved.

Owner:JIANGSU FRONT NEW ENERGY +1

Efficient composite desulfurizer

The invention discloses a high-efficiency compound desulfurizing agent, relating to the ladle desulphurization accessory field. In the existing ladle desulphurization, the uniserial desulfurizing agent is uniformly adopted, with narrower function, and non-agreeable desulphurization effect. Aiming at the condition that small and medium-sized steel mills do not have liquid iron pretreatment systems or desulphurization stations, and do not have powder spraying desulphurization devices, the desulfurizing agent of the invention adopts ingredient with multi-components, namely, the compound desulfurizing agent consisting of limestone, calcined soda, fluorite, calcium carbide, magnesium powder and caustic-calcined magnesite, with the weight proportion of 40 to 50, 10 to 20, 5 to 15, 10 to 20, 4 to 6 and 5 to 15 sequentially. The desulfurizing agent has the following advantages that: 1. the integral desulphurization capability is strong, and the sulfur content can be reduced to 20ppm; 2. sulfur substance can be contained, and resulfurization phenomenon can not be generated; 3. the desulfurizing agent can be directly poured, and equipment and investment are not needed to be increased; and 4. the desulphurization speed is high.

Owner:西峡县福盈冶金材料有限公司

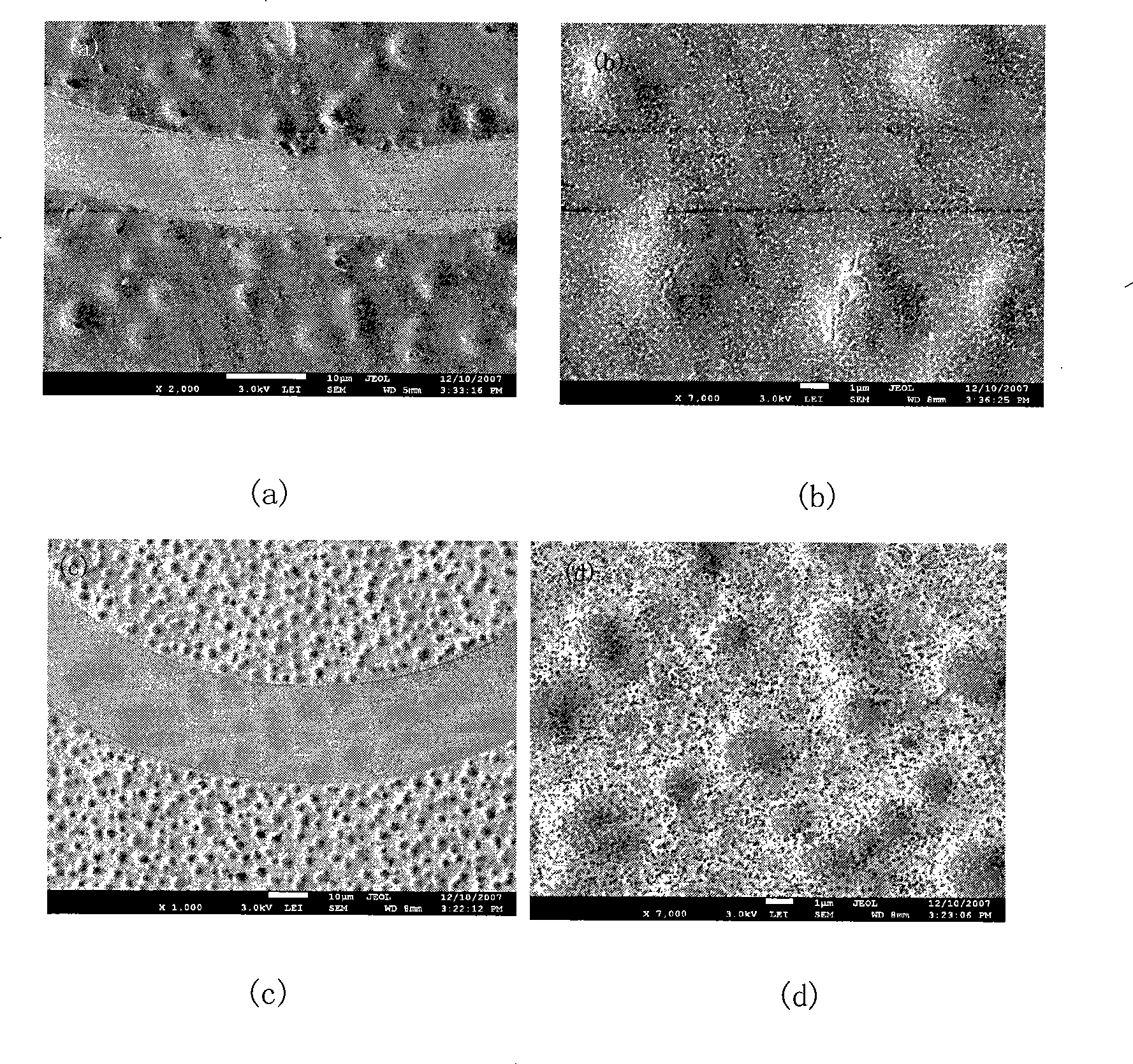

Ohm contact of gallium nitride base device and preparation method thereof

InactiveCN101369599AIncrease contact interfaceFully fixed lateral flowLaser detailsFinal product manufactureTitanium metalOhmic contact

The invention discloses an ohmic contact of a GaN-based apparatus and a manufacturing method thereof, belonging to the technical field of semiconductors. The ohmic contact of the GaN-based apparatus is composed of a titanium metal layer, an aluminum metal layer, a barrier metal layer and a gold metal layer; the titanium metal layer is contacted with the ohmic contact of the GaN-based apparatus, the aluminum metal layer is covered on the titanium metal layer, the barrier metal layer and the gold metal layer are covered on the titanium metal layer and the aluminum metal layer in sequence, wherein, the titanium metal layer and the aluminum metal layer are overlapped in two to ten periods. Compared with the prior ohmic contact structure, the invention balances low ohmic contact ratio based on the ohmic contact of a multilayer Ti / Al structure, has good surface appearance and high reliability, can improve the combination property of the ohmic contact, and has an important meaning for realizing the GaN-based apparatus with high performance and high reliability.

Owner:PEKING UNIV

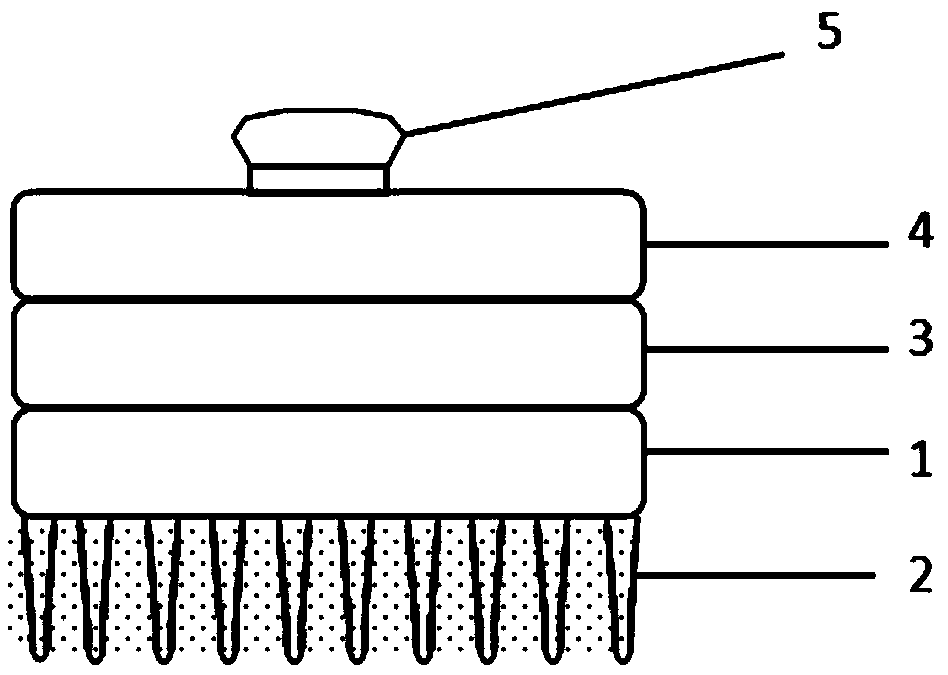

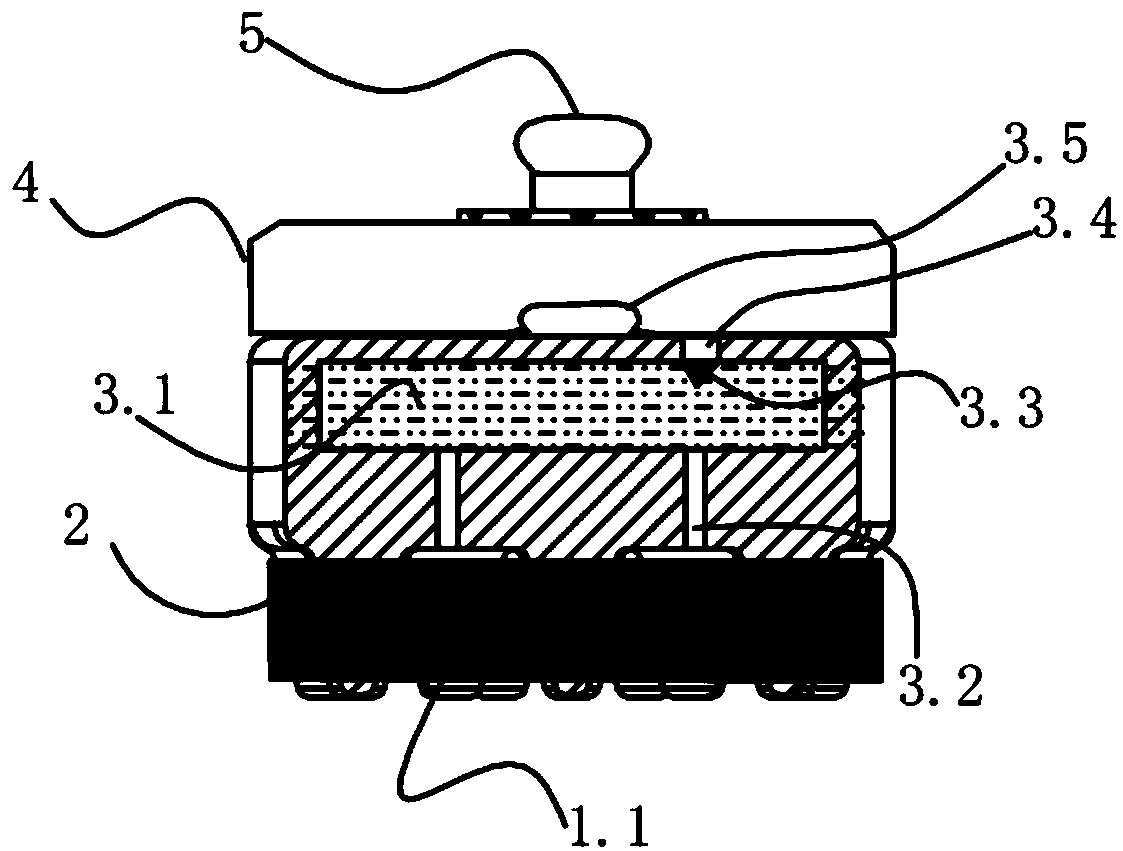

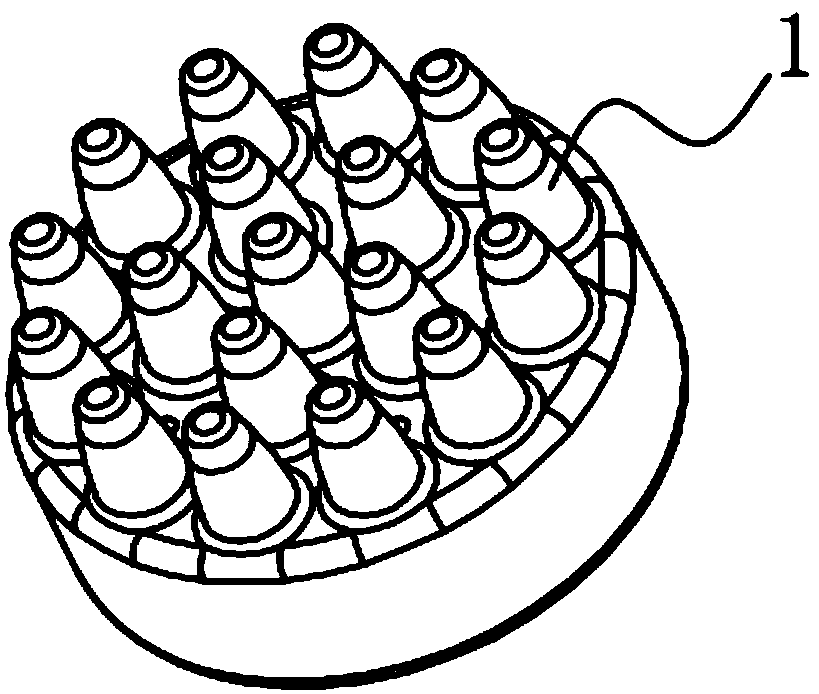

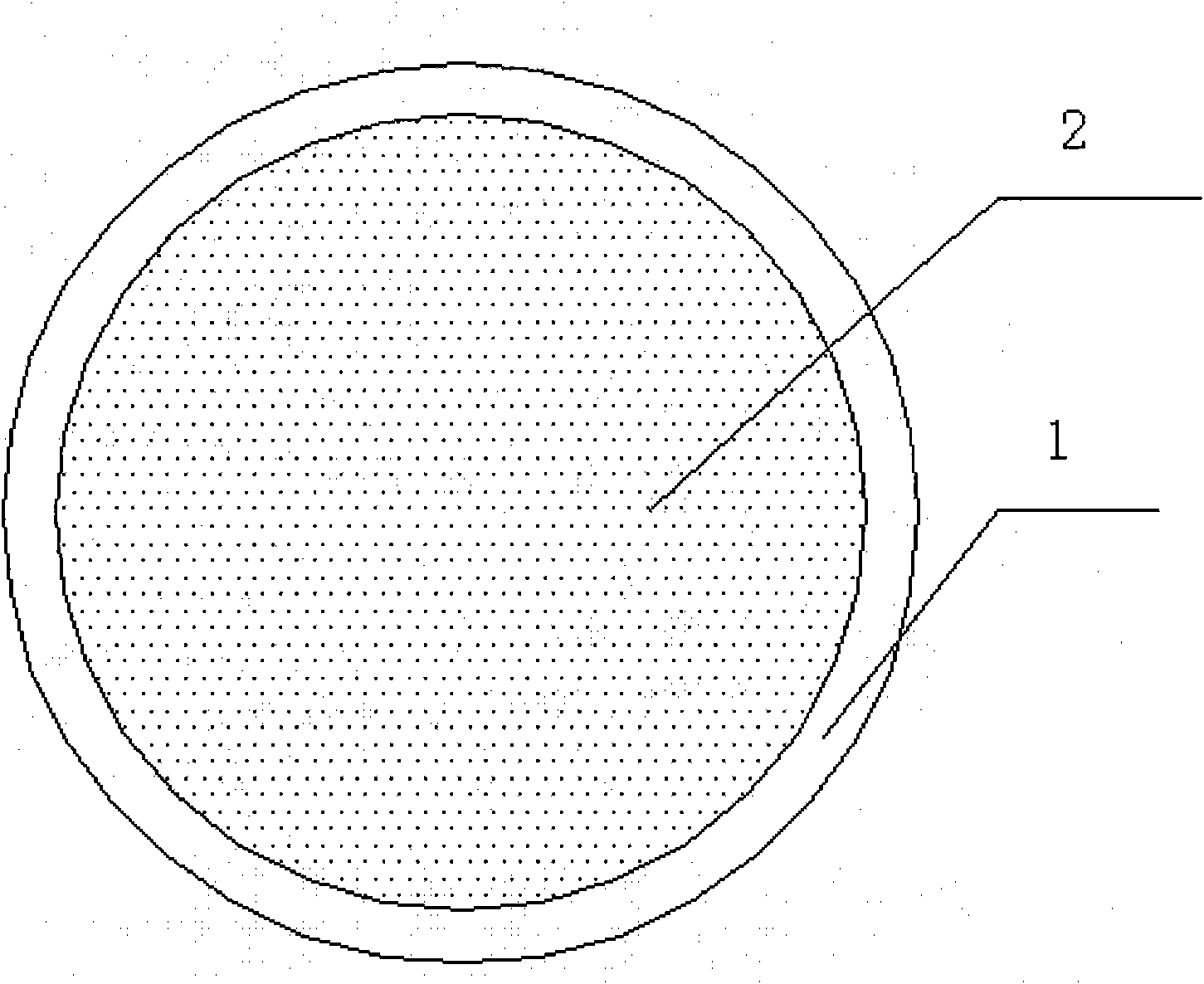

Flexible semi-dry multi-layer structure electrode for collecting electroencephalogram

PendingCN108652620AKeep moistReduce contact resistanceDiagnostic recording/measuringSensorsBiochemical engineeringElectrolyte

The invention belongs to medical instruments and wearable electronic products, and relates to a flexible semi-dry electrode which is of a multi-layer structure and used for collecting electroencephalogram. The electrode comprises a flexible electrode body layer, a foam layer and a liquid storage layer. A flexible probe in the flexible electrode body layer is of an array sensor structure; a plurality of through holes for the flexible probe to run through are arranged on the conductive foam cotton in the foam layer, and the plurality of through holes are arranged in accordance with the arrangement of the flexible probe; electrolyte is stored in the liquid storage layer and the liquid storage layer is provided with a release assembly for releasing the electrolyte to the conductive foam cottonin the foam layer. The flexible electrode has the advantages of convenient use, comfort, reasonable structure, low impedance, long-term stability and reliability, flexibility and comfort and safety of wearing.

Owner:SOUTH CHINA UNIV OF TECH

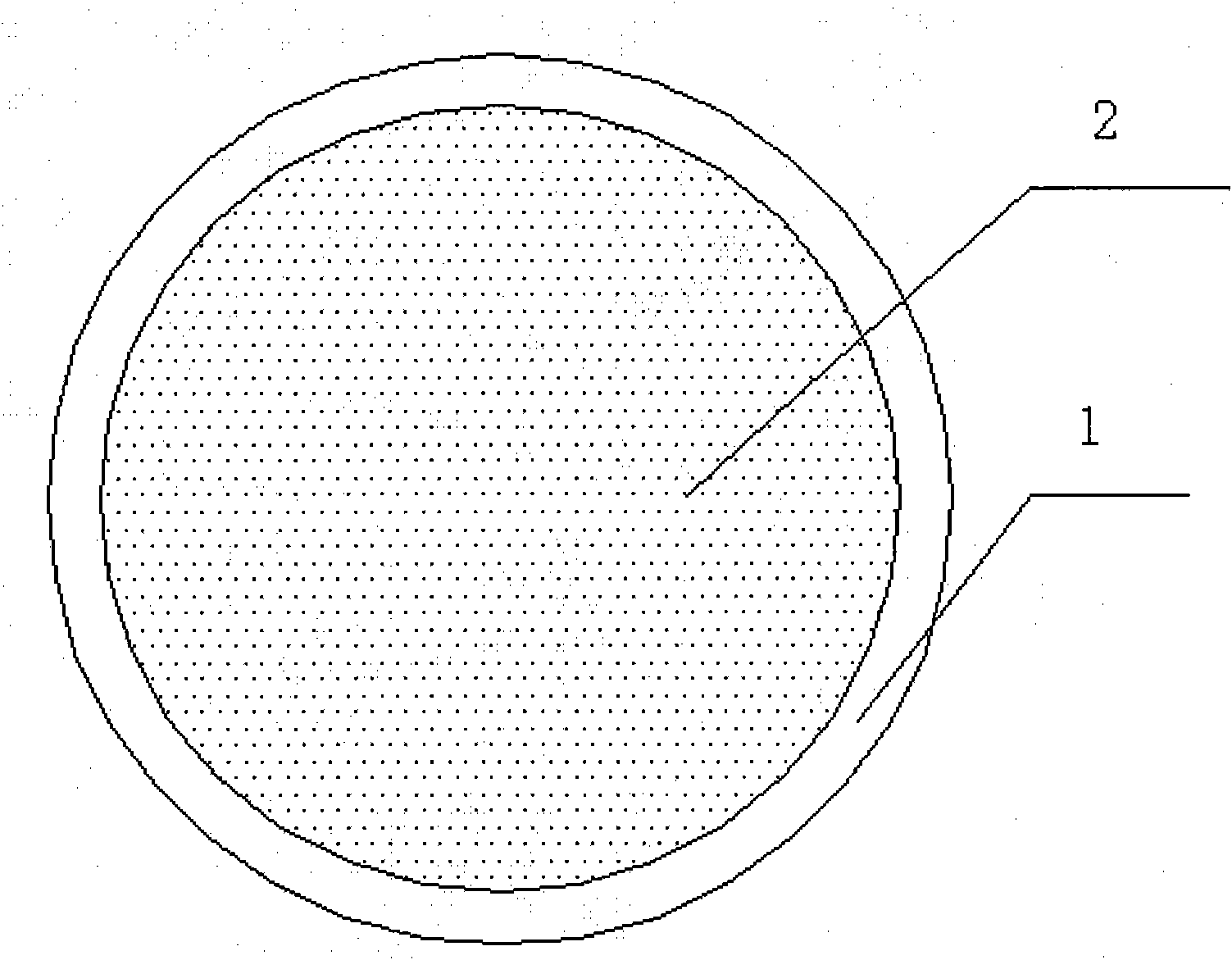

Recycled concrete member with additive and method for preparing same

ActiveCN101787771AHigh strengthReduce porosityStrutsSolid waste managementCalcium hydroxideUltimate tensile strength

The invention relates to a recycled concrete member, which comprises cement, water, an additive capable of releasing carbon dioxide and aggregate which is formed by using crushed waste concrete, wherein the cement, the water, the additive capable of releasing the carbon dioxide and the aggregate formed by using the crushed waste concrete are stirred and mixed in a ratio to form the recycled concrete. The recycled concrete member also comprises a columnar matrix which accommodates the recycled concrete and the recycled concrete is poured into and molded in the columnar matrix and then forms the recycled concrete member. The recycled concrete of the recycled member of the invention is prepared by stirring and mixing the cement, the water, the additive capable of releasing the carbon dioxide and the aggregate formed by using the crushed waste concrete in a ratio, calcium hydroxide in the recycled concrete and the carbon dioxide react to give calcium carbonate and the calcium carbonate mixed in the recycled concrete can improve contact interfaces of the waste aggregate and the cement, so the intensity of the recycled concrete is strengthened, the pores of the recycled concrete are reduced and the quality of the recycled concrete member is improved.

Owner:深圳市和美建筑节能科技发展有限公司

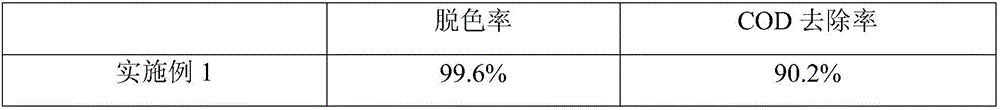

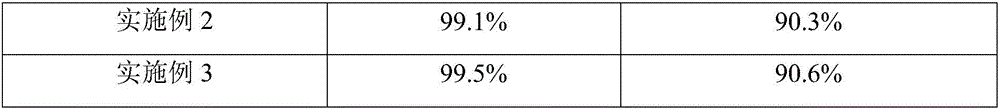

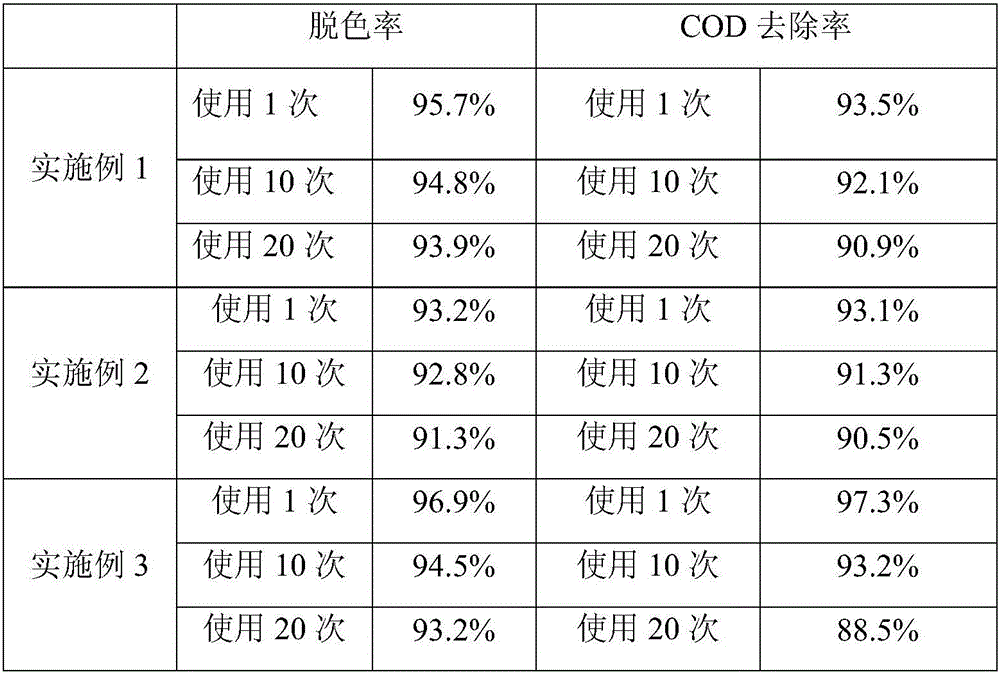

Method for preparing textile fiber/graphene/Bi2WO6 composite environmental catalytic material

InactiveCN106076430ALarge specific surface areaIncrease the areaWater/sewage treatment by irradiationWater treatment compoundsTextile fiberGraphene

The invention relates to a method for preparing a textile fiber / graphene / Bi2WO6 composite environmental catalytic material. The method comprises the steps: dipping textile fibers into a saturated dispersion solution of graphene oxide, then, carrying out baking, carrying out washing, then, putting the textile fibers into a reducer solution, carrying out a reaction for 0.5 to 1 hour at the temperature of 50 DEG C to 80 DEG C, carrying out washing, and carrying out baking, so as to obtain textile fiber / graphene; and adding the textile fiber / graphene into a solution of Bi(NO3)3 and Na3PO4, carrying out stirring, then, adding Na2WO4 and urea into the solution, carrying out a hydrothermal reaction for 3 to 8 hours at the temperature of 120 DEG C to 180 DEG C, carrying out cooling, then, carrying out washing, and carrying out baking, thereby obtaining the textile fiber / graphene / Bi2WO6 composite environmental catalytic material. The method disclosed by the invention is simple and is adaptable to industrial production; and the obtained composite material has a relatively good environment purification effect.

Owner:DONGHUA UNIV +1

A composite solid electrolyte with high ionic conductivity and a preparation method thereof

InactiveCN109148944AFast transferReduce contact interfaceSolid electrolytesSecondary cellsSolid state electrolyteMass ratio

The invention relates to a composite solid electrolyte with high ionic conductivity and a preparation method thereof, belonging to the technical field of solid electrolyte for lithium ion batteries. The composite solid electrolyte is composed of inorganic solid electrolyte, polymer electrolyte and lithium salt. The mass ratio of inorganic solid electrolyte, polymer electrolyte and lithium salt is0.2-0.8: 0.2-0.8: 0.05-0.5. The invention prepares inorganic solid electrolyte nanofibers by electrostatic spinning, prepares vertically oriented inorganic solid electrolyte skeleton by freeze castingmethod, and pours polymer and lithium salt to form composite solid electrolyte. Nanofibers instead of nanoparticles have obvious advantages in the preparation of intact and uniform inorganic solid electrolyte skeleton and the formation of fast Li + transport pathway, which can significantly improve the room temperature ionic conductivity of the electrolyte, up to 10<-4>S.cm<-1>. By adjusting thesize of nanofibers and freeze-casting conditions to control the skeleton structure, so as to regulate the comprehensive properties of the electrolyte.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

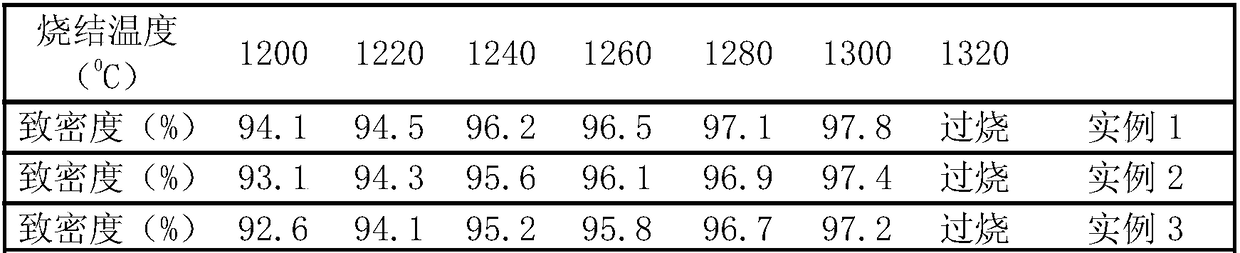

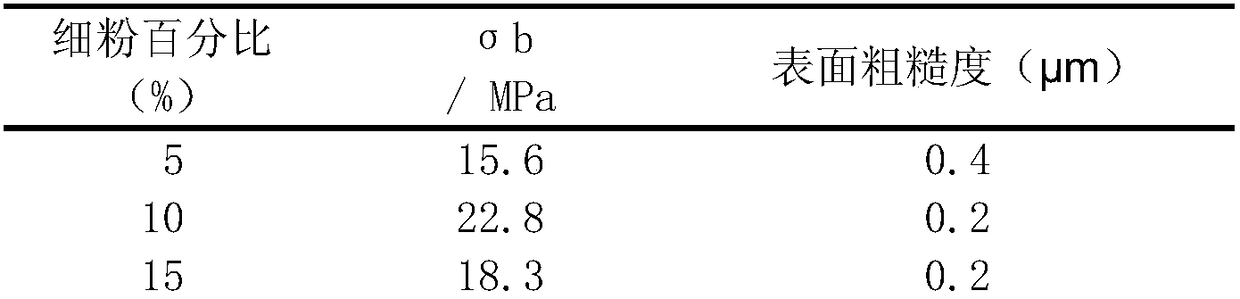

Preparation process of turbosuperchager nozzle ring blades for gasoline engines

ActiveCN108311701AImprove compactnessIncrease loading capacityTurbinesTransportation and packagingSurface finishTurbocharger

A preparation process of turbosuperchager nozzle ring blades for gasoline engines comprises the steps of powder grading, refining feeding, formed blank injection, degreased blank ultrasonic activationand sintering. The HK-30 stainless steel turbosuperchager nozzle ring blade parts are prepared through a powder injection forming technology, coarse powder and fine powder are used in cooperation, the strength of green bodies is effectively improved, the surface roughness is finally improved, the product surface smoothness is controlled to be within Ra0.1, subsequent processing shaping is omitted, the blade airflow conversion efficiency is improved, the technical process is effectively shortened, the production cost is reduced, and the product qualified rate is improved; power surface activity is improved through ultrasonic waves, a sintering window is broadened, and the rate of finished products is effectively increased; and the preparation process is quite suitable for preparing the precise complex turbosuperchager nozzle ring blade parts for the gasoline engines.

Owner:湖南英捷高科技有限责任公司

Fiber/CNT(carbon nano tube)/TiO2 three-dimensional recyclable efficient catalytic material, as well as preparation and application thereof

InactiveCN106732815ASpecial Interlayer PropertiesGood dispersionWater/sewage treatment by irradiationWater treatment compoundsHigh concentrationTextile fiber

The invention relates to a fiber / CNT(carbon nano tube) / TiO2 three-dimensional recyclable efficient catalytic material, as well as preparation and application thereof. A three-dimensional continuous structure is constructed on the surface of textile fiber by CNTs, and surfaces of the CNTs are loaded with nano TiO2. Preparation comprises: soaking fiber in a dispersion liquid containing CNT compound TiO2 and polyethylene glycol 2000, lasting reaction for 2-4 h at 60-80 DEG C, drying, washing with water, repeating processes of soaking, drying and washing with water for 3-5 times, and obtaining the material. The fiber / CNT / TiO2 three-dimensional recyclable efficient catalytic material is low in cost, the preparation method is simple, requirements on equipment is are low, and the operability is good; a water treatment agent provided by the invention can remove high-concentration organic pollutants in water, is suitable for advanced treatment of various wastewater, protects the environment, avoids secondary pollution, and has the advantages of being antibacterial, removing odor, absorbing other heavy metal ions, and the like.

Owner:DONGHUA UNIV

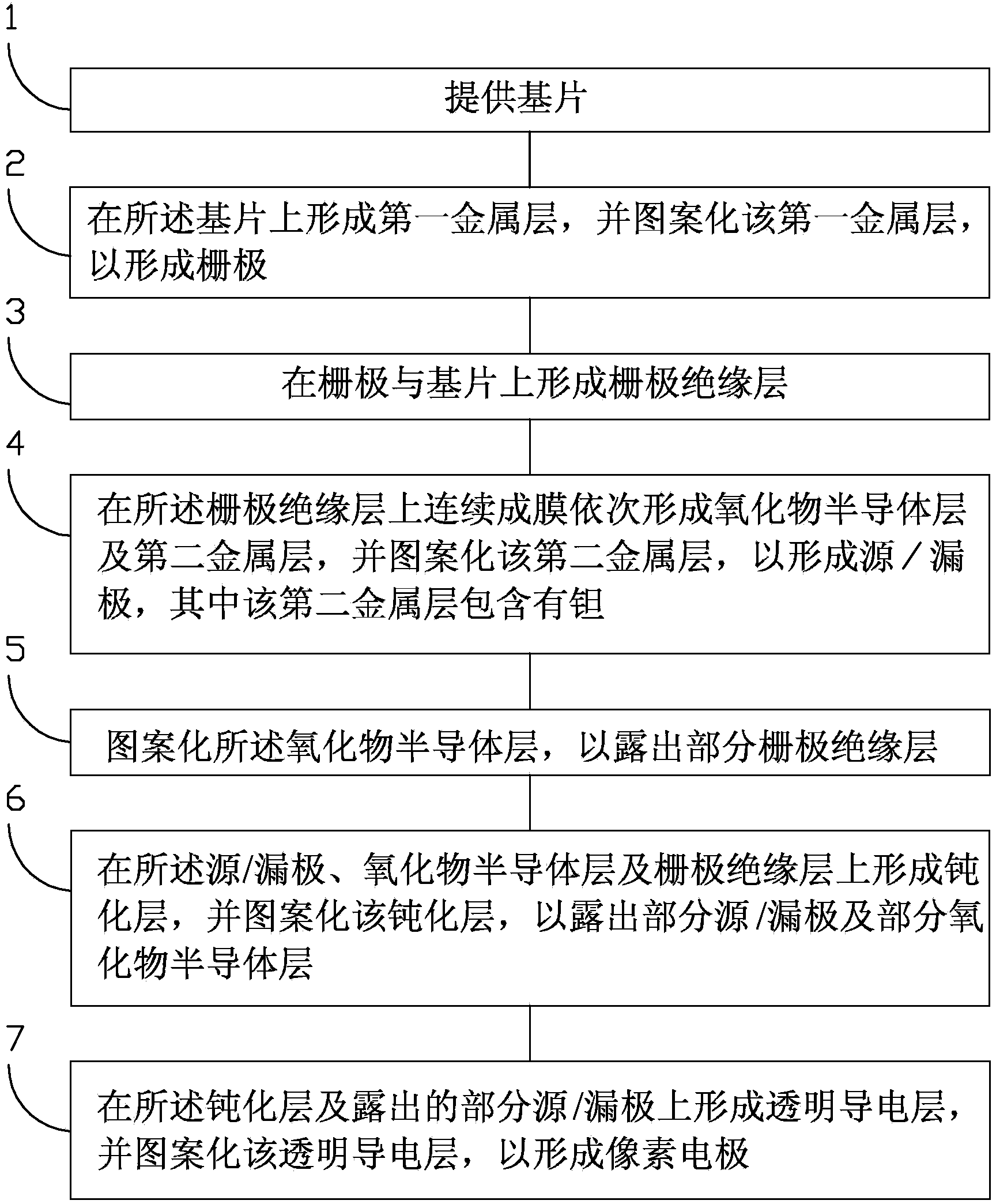

Method for manufacturing thin film transistor substrate

ActiveCN103730414AImprove qualitySimple structureSolid-state devicesSemiconductor/solid-state device manufacturingMetallic materialsBlocking layer

The invention provides a method for manufacturing a thin film transistor substrate. According to the method, the manufacture procedure is simple, a good contact interface is achieved through a continuous film forming oxide semiconductor layer and a source / drain electrode, and the crowding effect due to the fact that contact resistance is too large is avoided. Meanwhile, the source / drain electrode is made of metal materials containing tantalum, an etching solution containing hydrogen peroxide is used for etching the source / drain electrode in the etching manufacturing process, damage of a traditional etching solution to the oxide semiconductor layer is avoided, and the quality of the thin film transistor substrate is improved. Moreover, an etching blocking layer does not need to be additionally manufactured to protect the oxide semiconductor layer on a back channel, the high width to length ratio (W / L) of the channel is guaranteed, the structure of the thin film transistor substrate is simplified, the manufacturing procedures are reduced, production cost is lowered, and the yield rate is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

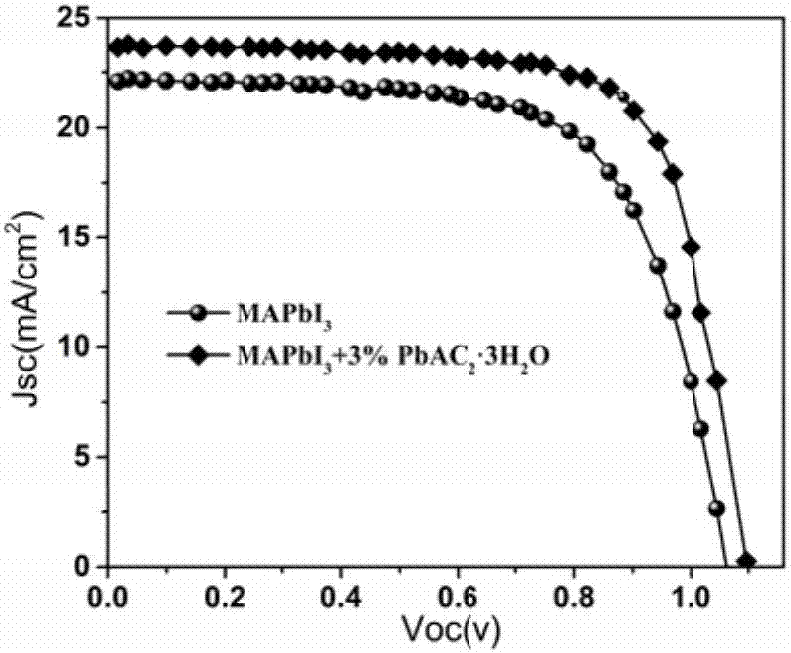

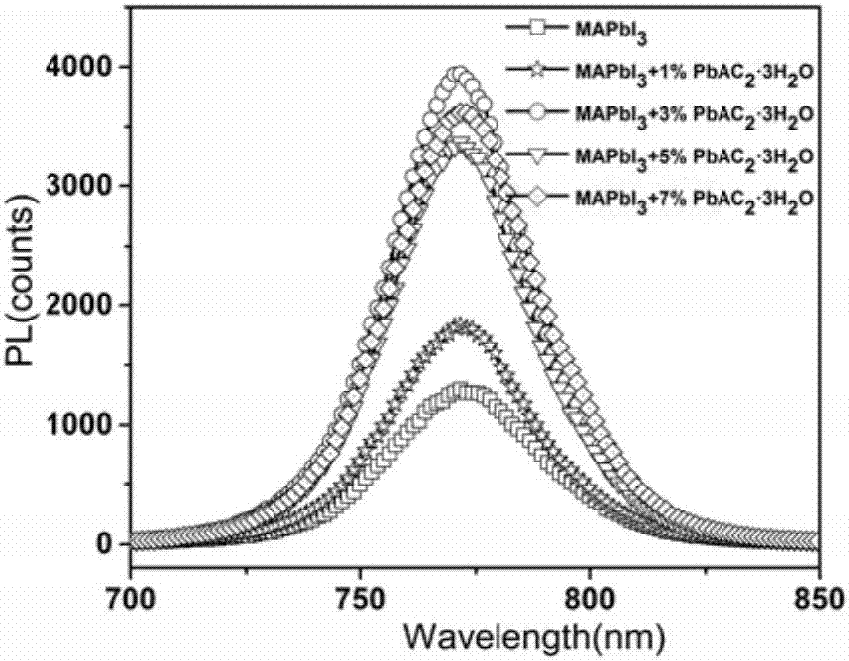

Trihydrate lead acetate doped perovskite solar cell and preparation method thereof

InactiveCN107369764AImprove performanceHigh crystallinityFinal product manufactureSolid-state devicesPerovskite solar cellLead acetate

The invention relates to the field of perovskite solar cells and provides a trihydrate lead acetate doped perovskite solar cell and preparation method thereof. The perovskite solar cell includes a transparent electrode, an electron transmission layer, a perovskitelight absorption layer, a cavity transmission layer and a metal electrode in sequence. The perovskite light absorption layer is obtained by doping trihydrate lead acetate in a perovskite polymeric pecursor solution. The doped trihydratelead acetate achieves an effect of passivating grain boundary, so that the composition of electron cavities is inhibited, the grain uniformity is improved and the mass of perovskite films is improved; and thus the photoelectric conversion efficiency of the perovskite cell is improved substantially. According to the invention, the pervskite light absorption layer enables substantial increase of battery efficiency from 15% to over 18%. Besides, the method is simple and easy in practice, low in preparation cost and wide in application prospect.

Owner:UNIV OF SCI & TECH BEIJING

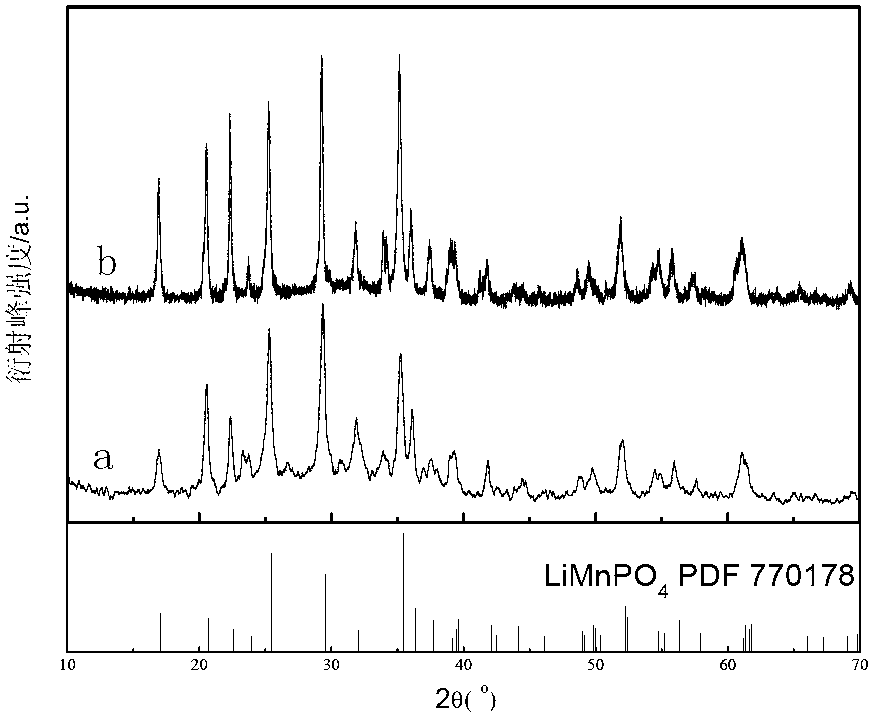

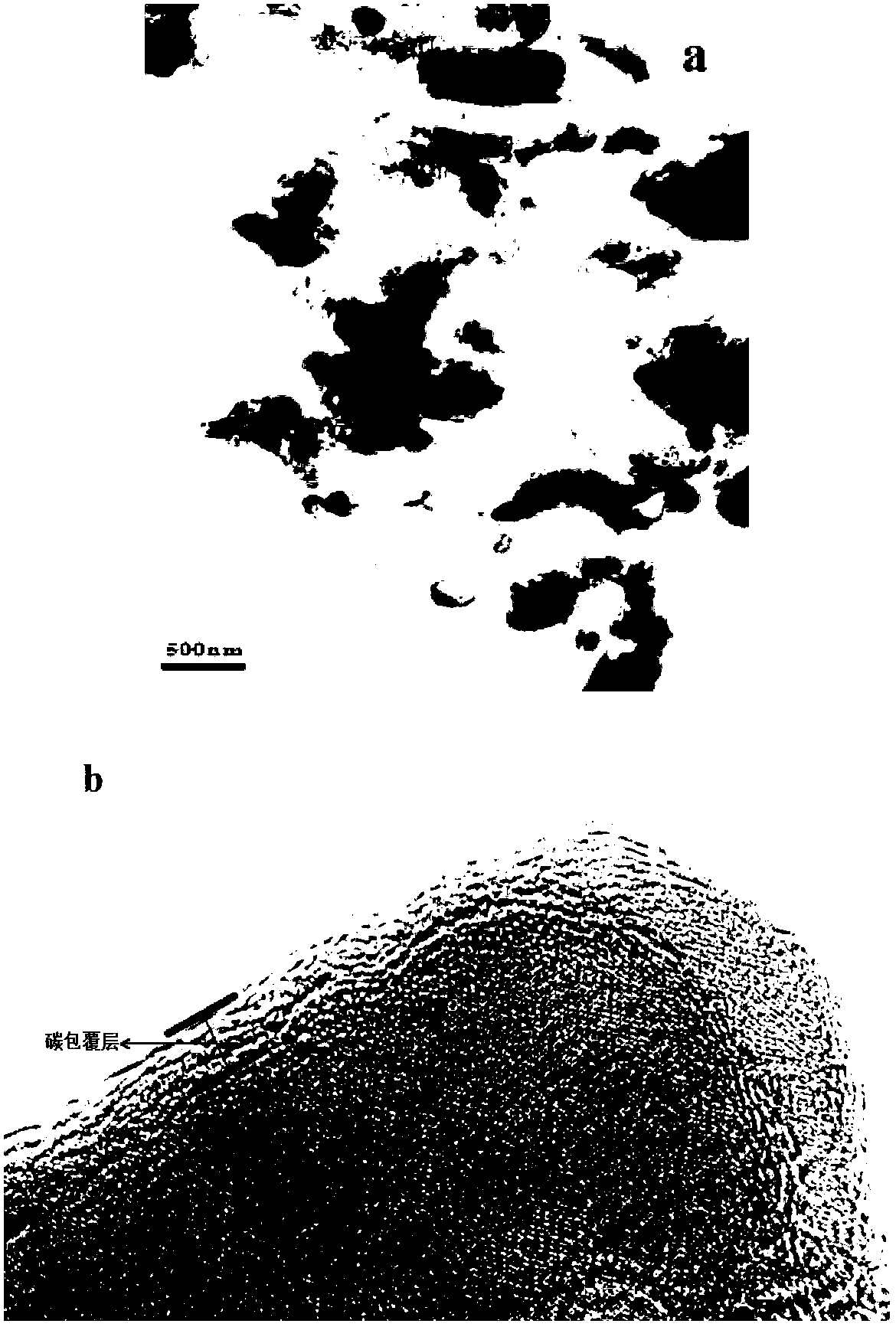

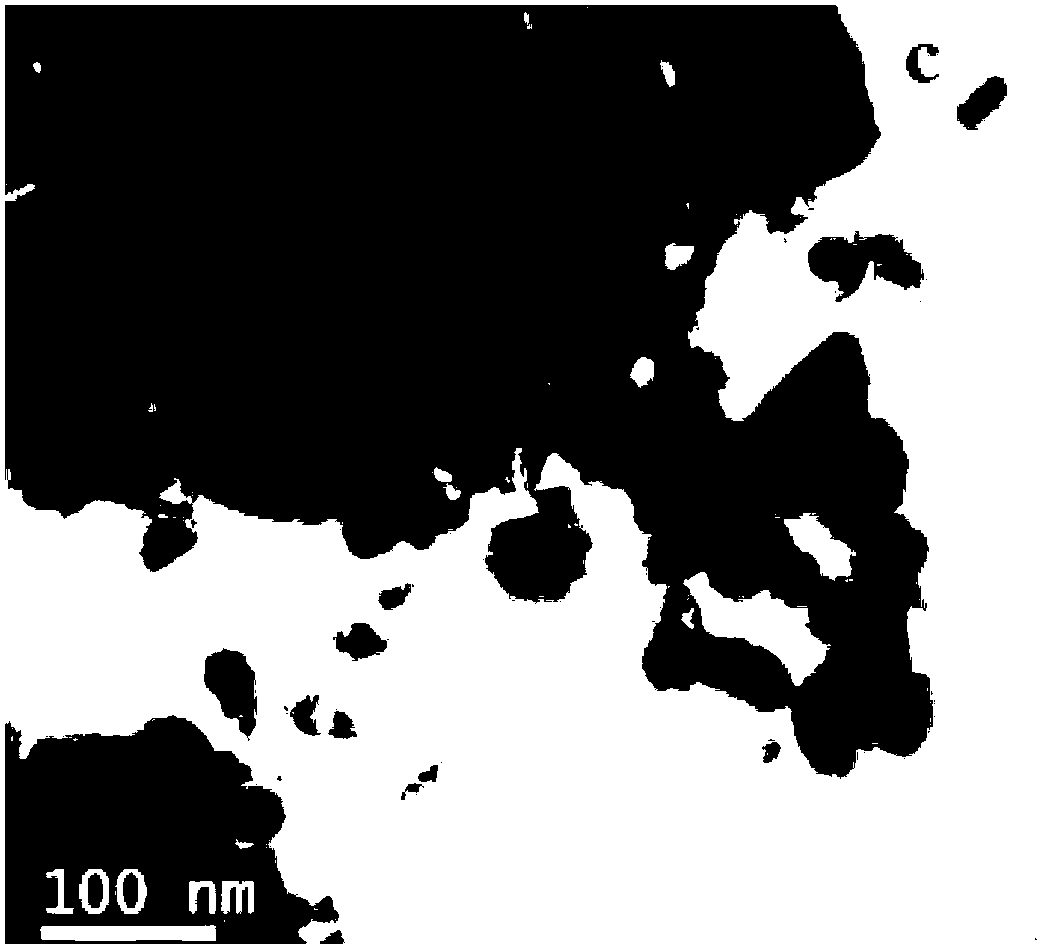

Synthesizing method of nano-grade lithium ion battery composite positive electrode material LiMnPO4/C

InactiveCN102931400AIncrease contact interfacePromote interdiffusionCell electrodesCarbon layerHigh energy

The invention relates to a synthesizing method of a nano-grade lithium ion battery composite positive electrode material LiMnPO4 / C. According to the invention, a lithium source, a phosphorous source, a manganese source and an organic carbon source are well mixed in a solvent medium; the mixture is processed for 2-7h in a high-energy ball mill, and a uniformly dispersed precursor slurry is obtained with the activation effect of mechanical forces; the precursor slurry is subjected to ultrasonic dispersion in a high-boiling-point polyol solvent, and is subjected to a reflux reaction; an obtained product is filtered and washed; and the product is subjected to a heat treatment for 1-10h under inert atmosphere protection and under a temperature of 600-800 DEG C, such that the nano-grade lithium manganese phosphate / carbon (LiMnPO4 / C) positive electrode material is obtained. According to the material provided by the invention, primary particles are well distributed nano-particles, and a conductive carbon layer is formed in-situ on the surfaces of the LiMnPO4 / C particles. The method provided by the invention is simple and highly efficient. With the method, no pollutant such as ammonia gas or wastewater is produced during the entire process. Therefore, a development requirement of green chemistry is satisfied.

Owner:CENT SOUTH UNIV

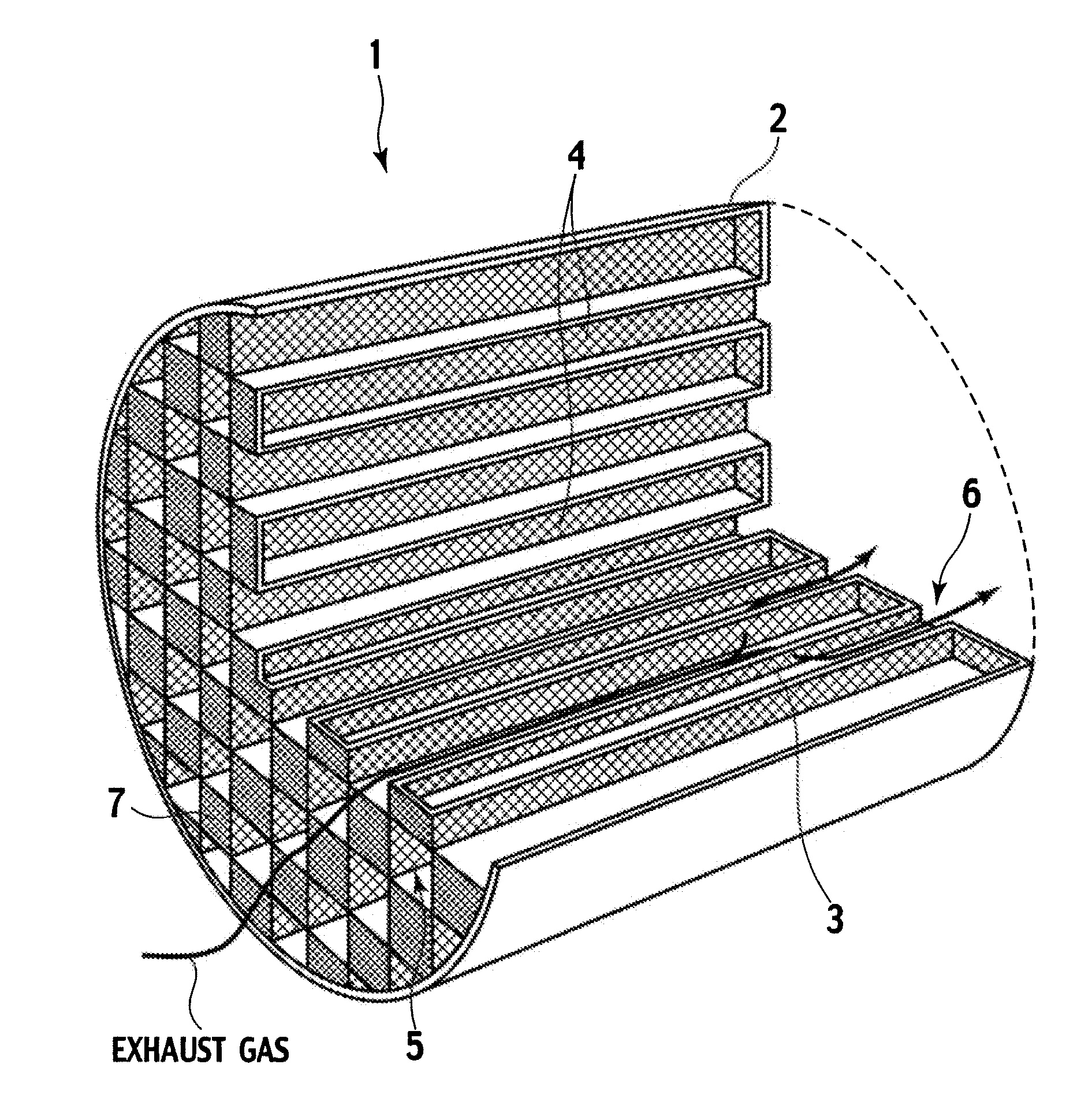

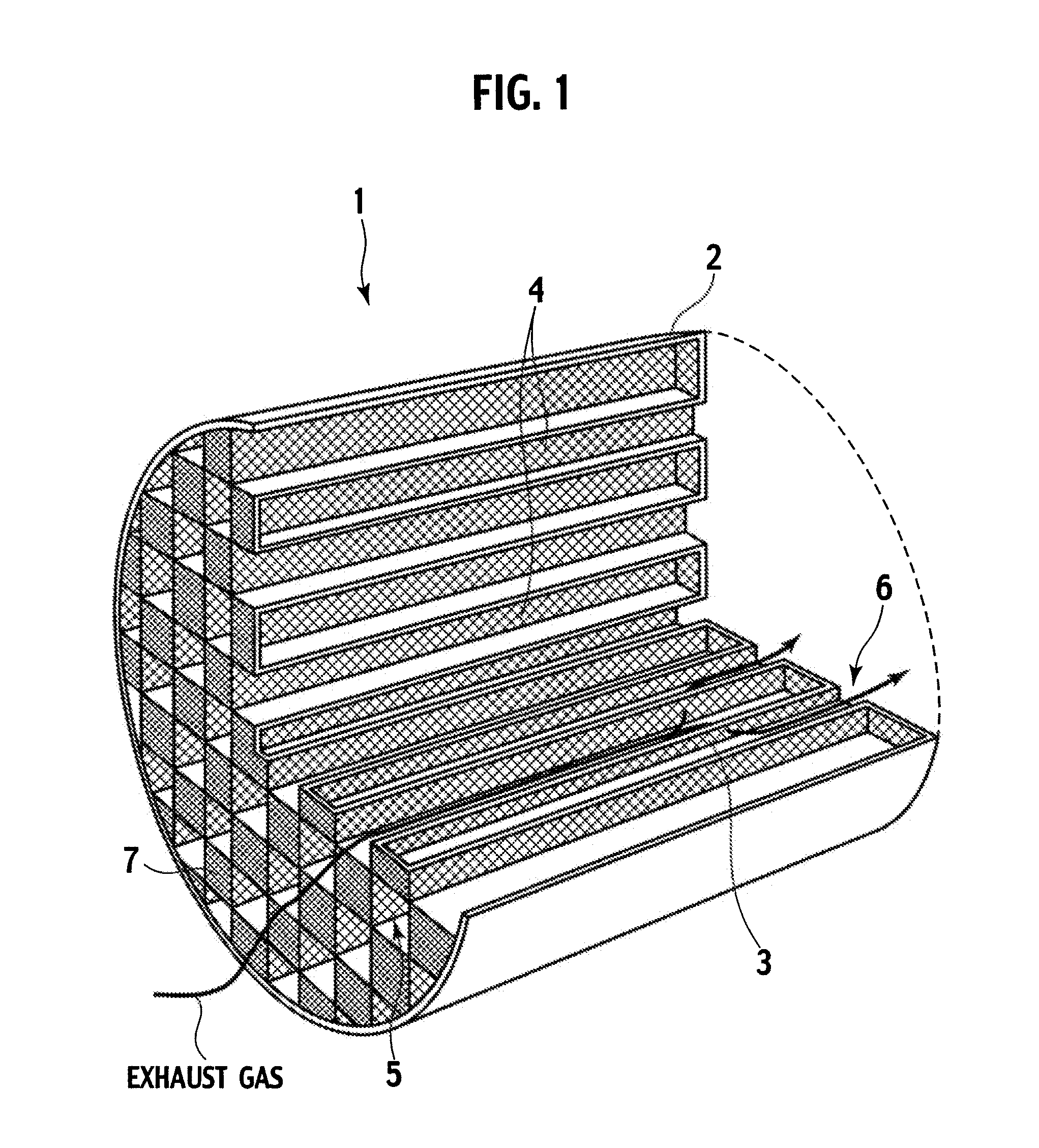

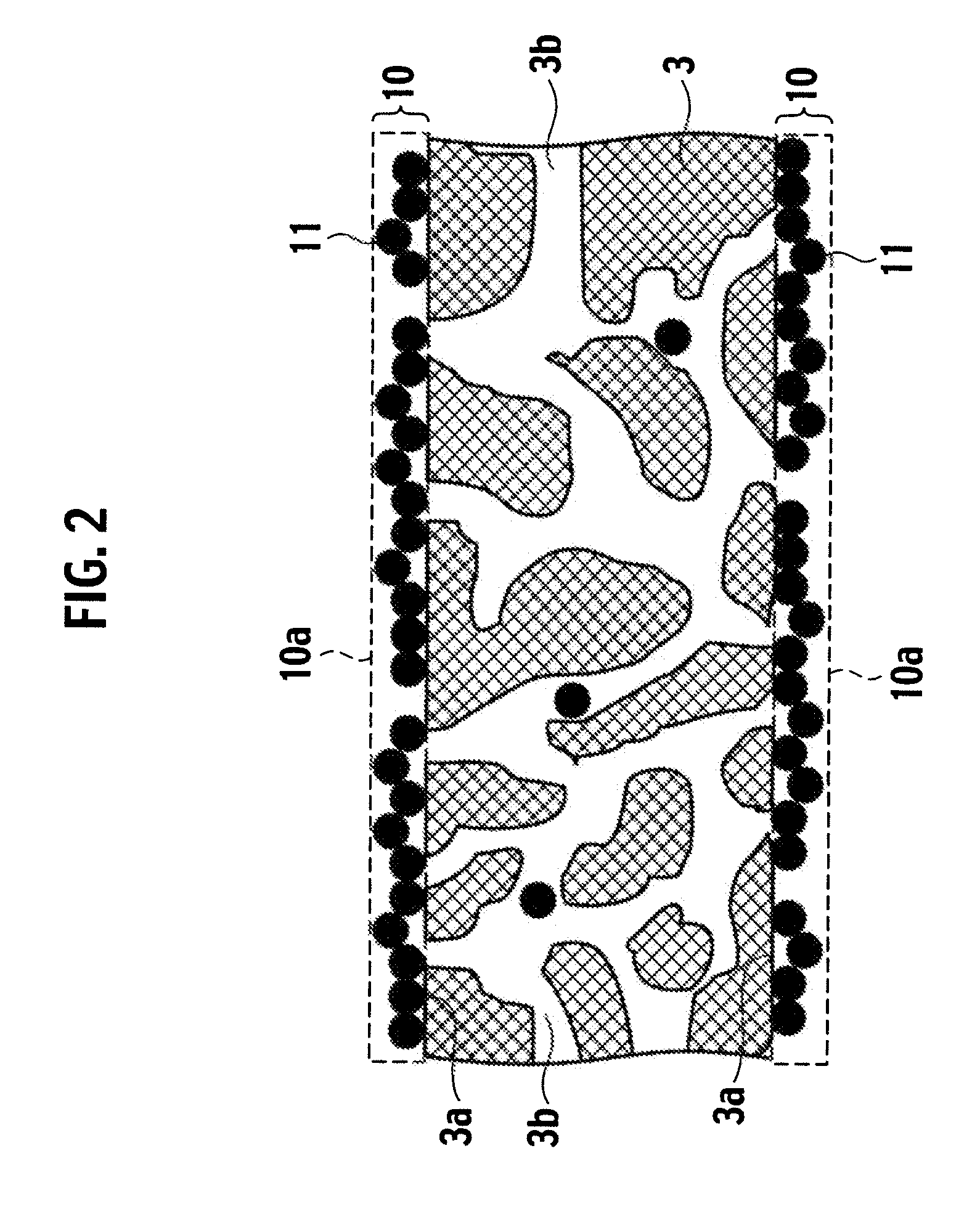

Catalytic converter and manufacturing method thereof

ActiveUS20080317646A1High catalytic activityIncrease contact interfaceCombination devicesGas treatmentPore diameterCell wall

A catalytic converter includes: a three-dimensional structural support having a plurality of cells partitioned by porous cell walls, in which a pore diameter of the cell walls is 10 μm to 50 μm and porosity of the cell walls is 40 vol % or more; and a catalyst-coated layer containing a catalyst component. The catalyst-coated layer is coated on surfaces of the cell walls of the three-dimensional structural support. 50 mass % or more of a total supported amount of the catalyst component on the three-dimensional structural support is present in a region from the surfaces of the cell walls of the three-dimensional structural support to surfaces of the catalyst-coated layer.

Owner:NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com