Epoxy-resin-based high-dielectric composite material and preparation method thereof

A technology of epoxy resin and composite material, which is applied in the field of nano-composite materials to achieve the effect of reducing dielectric loss and significant interface polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

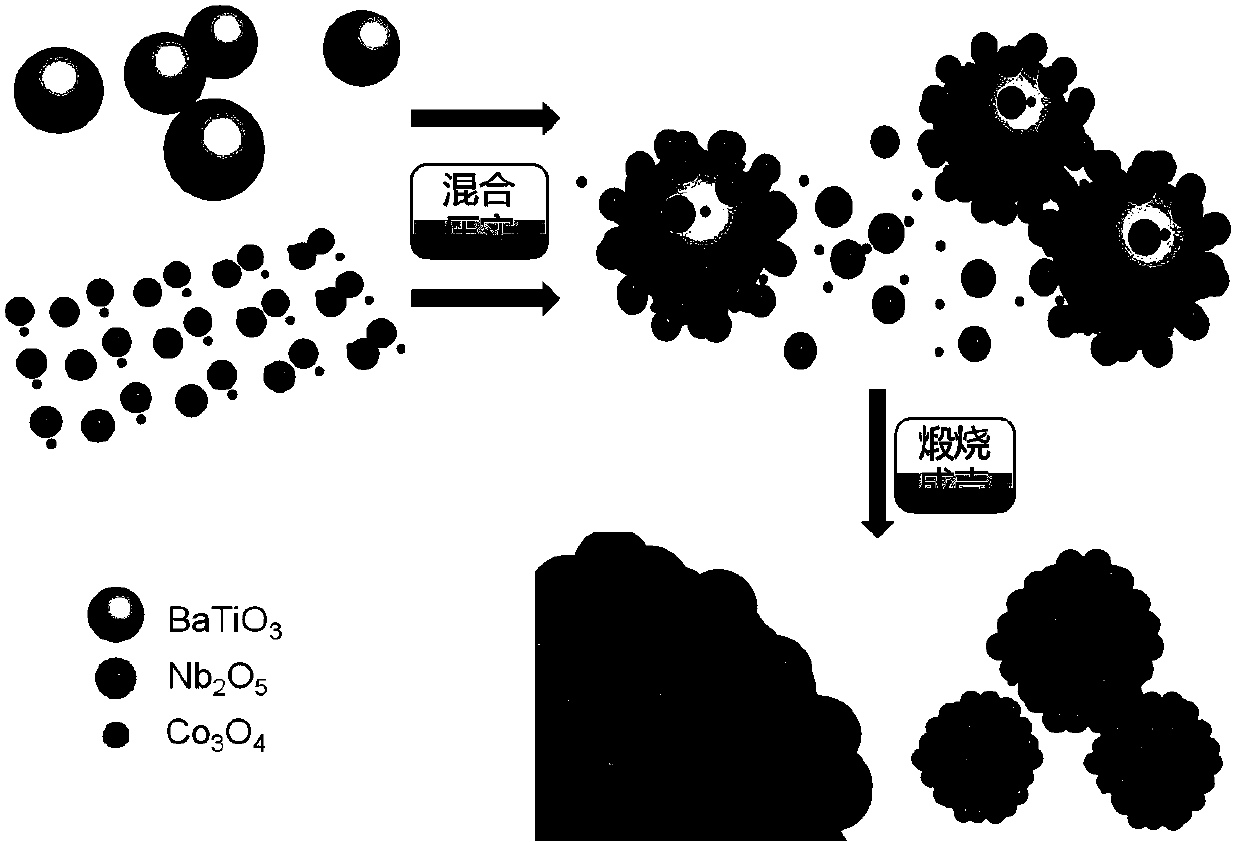

[0043] 1. Preparation of modified BTNC powder

[0044] (1) Weigh 9.9g BT powder, 0.07g Nb 2 o 5 and 0.03g Co 3 o 4 powder, put it in a mortar, grind and mix it, then pour it into a ball mill jar, and mill it on a ball mill at 300rpm for 1 hour, so that the three are fully mixed;

[0045] (2) Put the mixture obtained above in a porcelain boat, raise the temperature to 1400 °C at a rate of 20 °C / min in a tube furnace, and keep the temperature constant for 2 hours, then cool it naturally to obtain a relatively hard block calcined product;

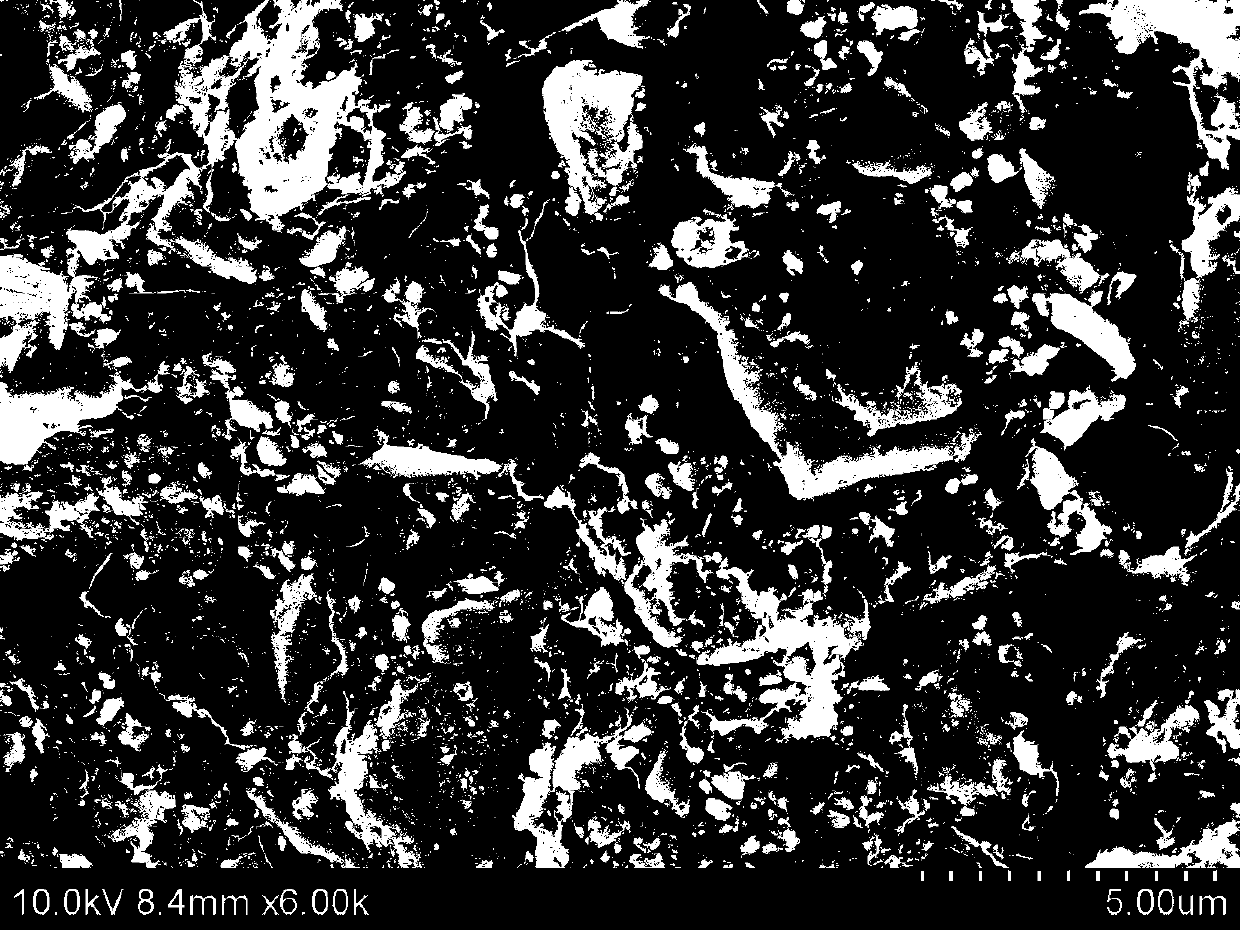

[0046] (3) Use an agate mortar to crush the obtained calcined product into particles with a particle size of less than 2 mm, and mill it on a ball mill at 400 rpm for 3 hours to obtain BTNC micron powder with a particle size of 0.2 μm to 2 μm, which is used to prepare composite materials.

[0047] 2. Preparation of BTNC / epoxy resin dielectric composites

[0048] (1) Weigh 0.5g of epoxy resin and place it in a polytetrafluoroethylene beake...

Embodiment 2

[0054] 1. Preparation of modified BTNC powder

[0055] (1) Weigh 9.7g BT powder, 0.21g Nb 2 o 5 and 0.09g Co 3 o 4 powder, put it in a mortar, grind and mix it, then pour it into a ball mill jar, and mill it on a ball mill at 300rpm for 2 hours, so that the three are fully mixed;

[0056] (2) Put the mixture obtained above in a porcelain boat, raise the temperature to 1300 °C at a rate of 10 °C / min in a tube furnace, and keep the temperature at a constant temperature for 3 hours, then allow it to cool naturally to obtain a relatively hard block calcined product;

[0057] (3) The obtained calcined product was crushed into particles with a particle size of less than 2 mm using an agate mortar, and ball milled on a ball mill at 400 rpm for 2 hours to obtain BTNC micron powder with a particle size of 0.2 μm to 2 μm, which was used to prepare composite materials.

[0058] 2. Preparation of BTNC / epoxy resin dielectric composites

[0059] (1) Weigh 0.5g of epoxy resin and place ...

Embodiment 3

[0064] 1. Preparation of modified BTNC powder

[0065] (1) Weigh 9.5g BT powder, 0.36g Nb 2 o 5 and 0.14g Co 3 o 4 powder, put it in a mortar, grind and mix it, then pour it into a ball mill jar, and mill it on a ball mill at 300rpm for 1.5h, so that the three are fully mixed;

[0066] (2) Put the mixture obtained above in a porcelain boat, heat up to 1320°C at a rate of 30°C / min in a tube furnace, and keep the temperature constant for 1 hour, then cool it naturally to obtain a relatively hard block calcined product;

[0067] (3) Use an agate mortar to crush the obtained calcined product into particles with a particle size of less than 2 mm, and mill it on a ball mill at 400 rpm for 4 hours to obtain BTNC micron powder with a particle size of 0.2 μm to 2 μm, which is used to prepare composite materials.

[0068] 2. Preparation of BTNC / epoxy resin dielectric composites

[0069] (1) Weigh 0.5g of epoxy resin and place it in a polytetrafluoroethylene beaker, add 0.12g of cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com