Method for preparing rare-earth yttrium containing super-high-strength wrought aluminium alloy

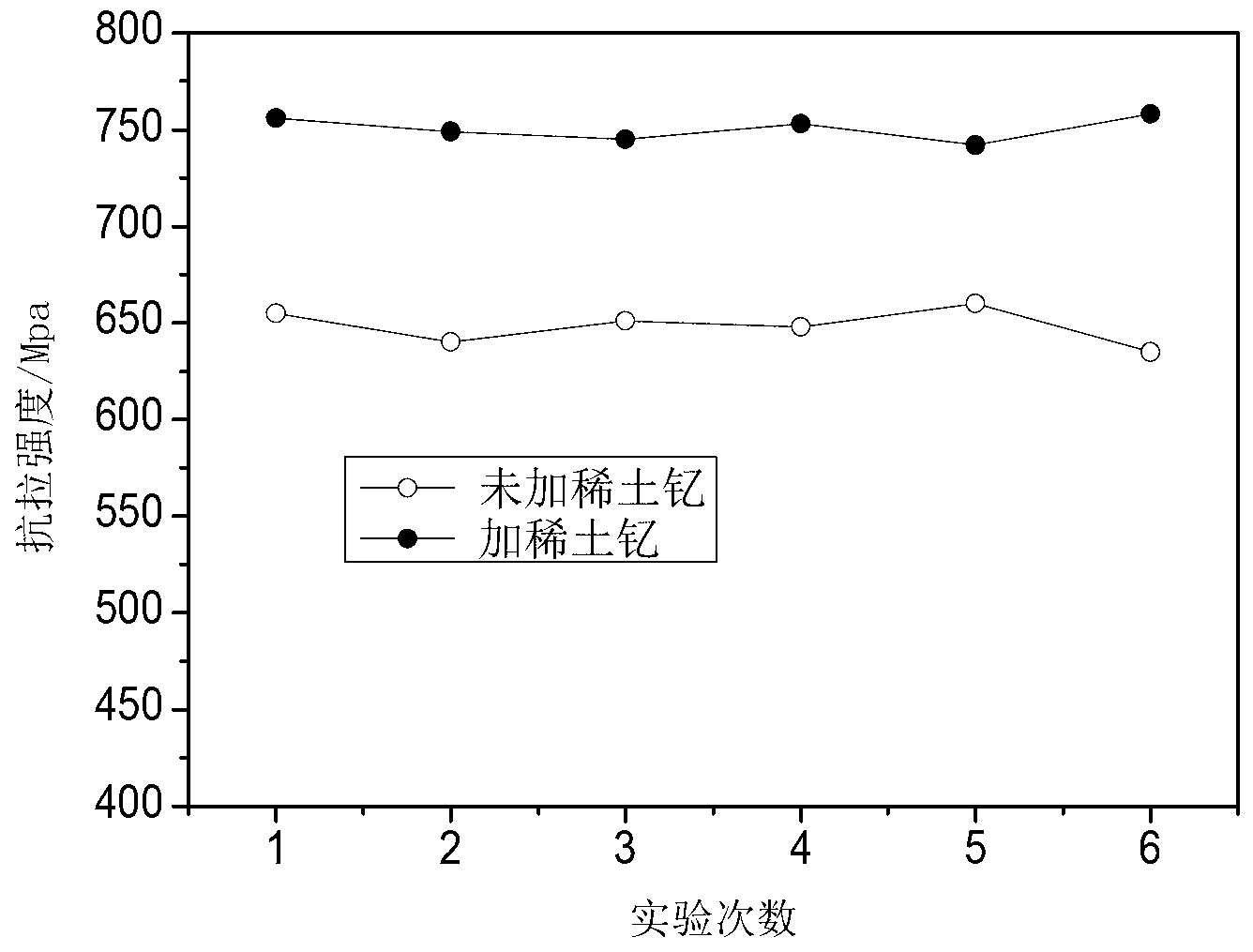

A deformed aluminum alloy, ultra-high-strength technology, which is applied in the field of ultra-high-strength aluminum alloy structural materials and deformed aluminum alloy material preparation, can solve the problems of high cost, achieve improved thermal strength, increase the number of eutectics, and refine recrystallized grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing an ultra-high-strength deformed aluminum alloy containing rare earth yttrium, the steps are as follows:

[0035] ⑴The total input material is 50Kg, weighing 4kg of metal zinc, 1.1kg of metal copper, 2.3kg of aluminum-magnesium master alloy (AlMg50), 2.3kg of aluminum-yttrium master alloy (AlY5), 0.8 of aluminum-zirconium master alloy (AlZr10), and 39.5 kg of refined aluminum ingot kg;

[0036] (2) Weigh 0.15kg of HGJ-2 type sodium-free refining slag remover produced by Shanghai Hongguang Metal Flux Factory, and weigh 0.12kg of XH-2 type magnesium alloy covering agent produced by Xuzhou Xuhui Aluminum Industry Co., Ltd.;

[0037] (3) Put metal zinc, metal copper, aluminum-magnesium master alloy, aluminum-yttrium master alloy, aluminum-zirconium master alloy, refined aluminum ingot, refining slag remover and magnesium alloy covering agent in steps ⑴ and step ⑵ respectively into the temperature of 240 ℃ Dry in a constant temperature preheating dryin...

Embodiment 2

[0048] A method for preparing an ultra-high-strength deformed aluminum alloy containing rare earth yttrium, the steps are as follows:

[0049] ⑴Total feed is 50kg, weighing 4.4kg of metal zinc, 1.25kg of metal copper, 2.8kg of aluminum-magnesium master alloy (AlMg50), 2.6kg of aluminum-yttrium master alloy (AlY5), 0.75kg of aluminum-zirconium master alloy (AlZr10), refined aluminum Ingot 38.2kg;

[0050] (2) Weigh 0.17kg of HGJ-2 type sodium-free refining slag remover produced by Shanghai Hongguang Metal Flux Factory, and weigh 0.14kg of XH-2 type magnesium alloy covering agent produced by Xuzhou Xuhui Aluminum Industry Co., Ltd.;

[0051] (3) Put metal zinc, metal copper, aluminum-magnesium master alloy, aluminum-yttrium master alloy, aluminum-zirconium master alloy, refined aluminum ingot, refining slag cleaning agent and magnesium alloy covering agent in a constant temperature of 280°C in step 1 and step 2 Dry in a preheated drying oven for 2 hours;

[0052] (4) Put the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com