Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Refined casting structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

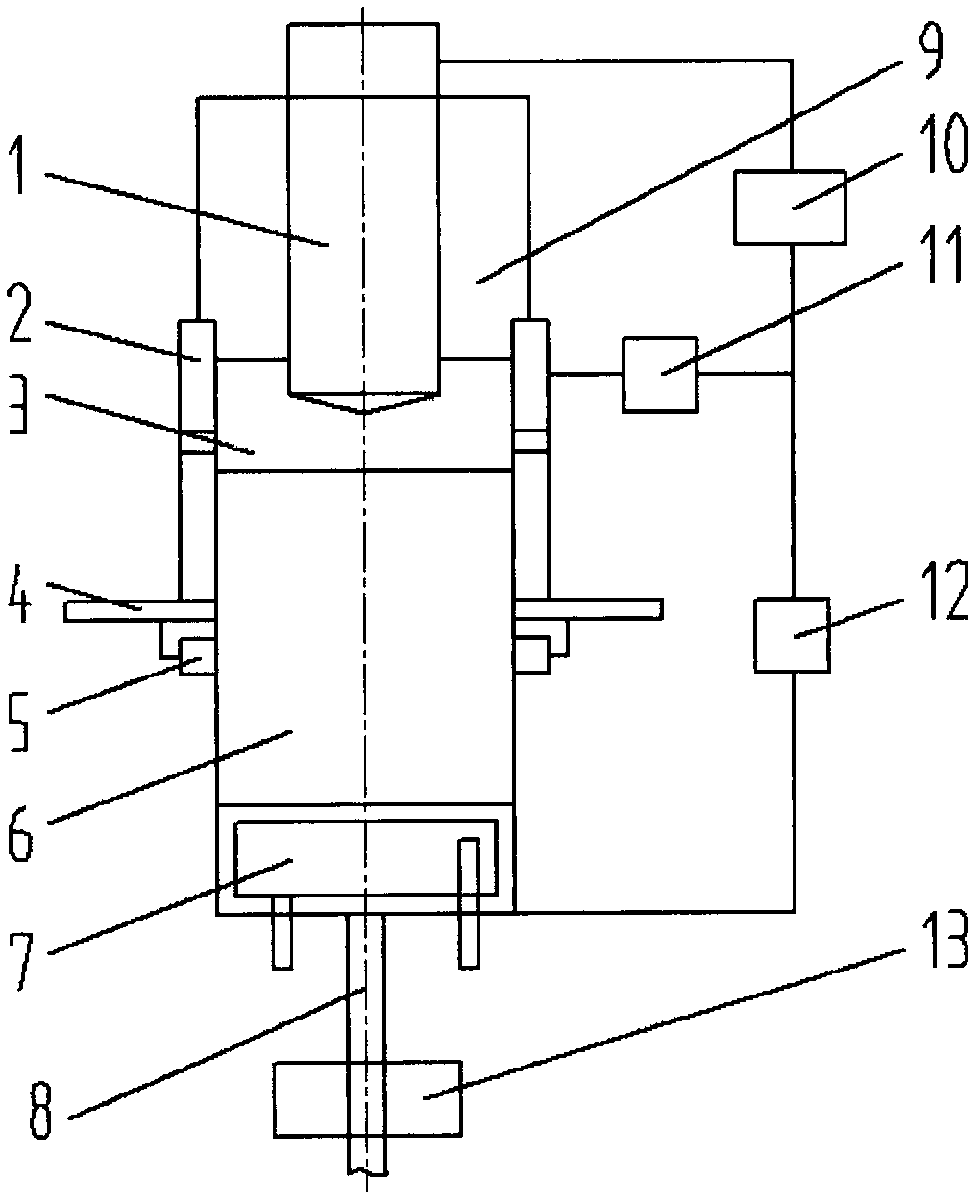

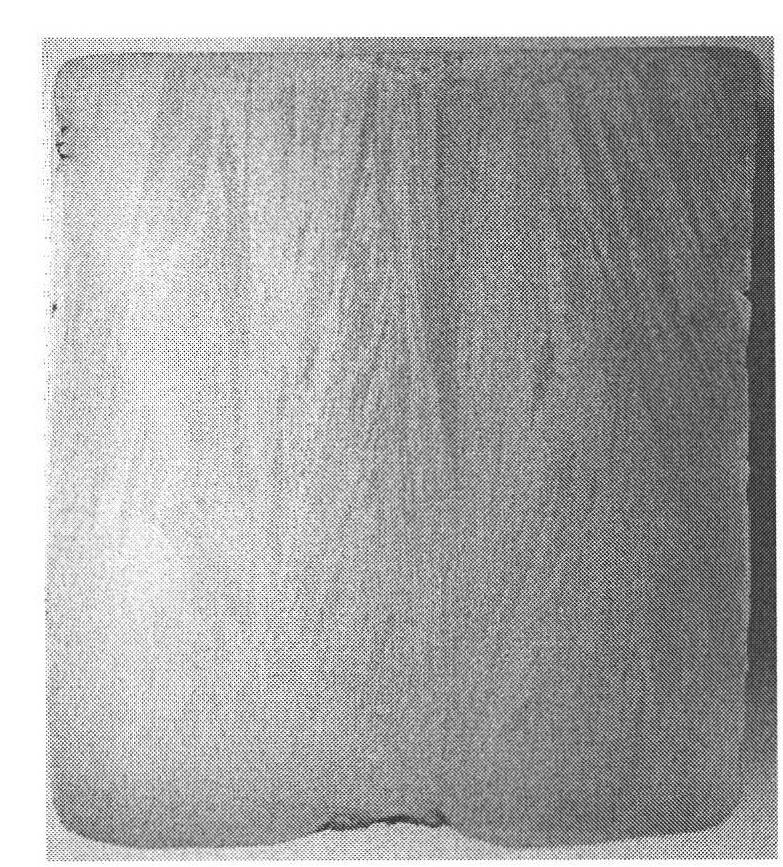

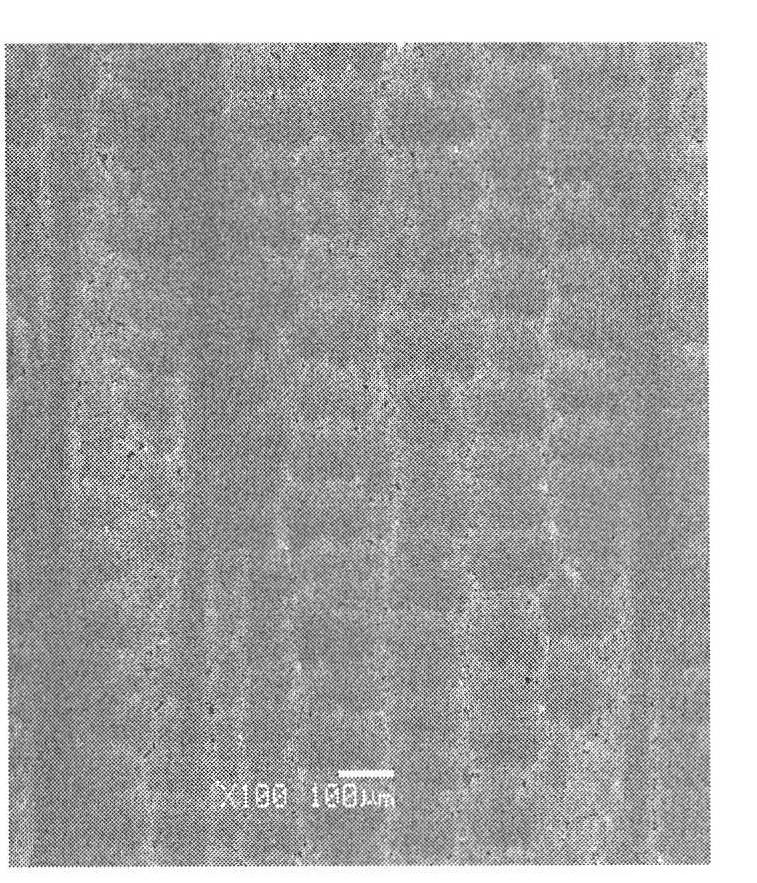

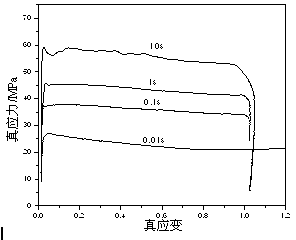

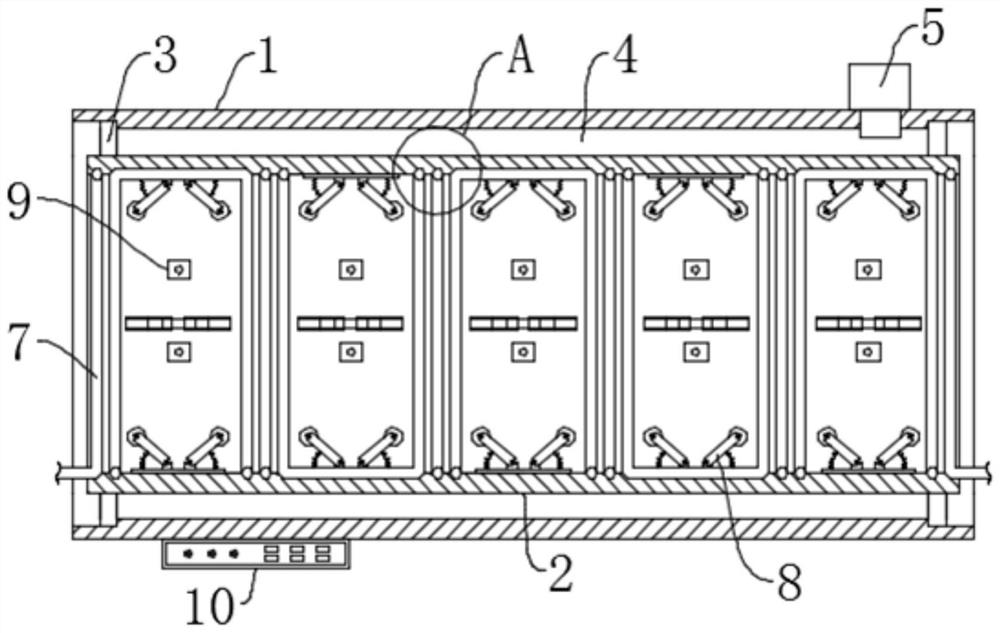

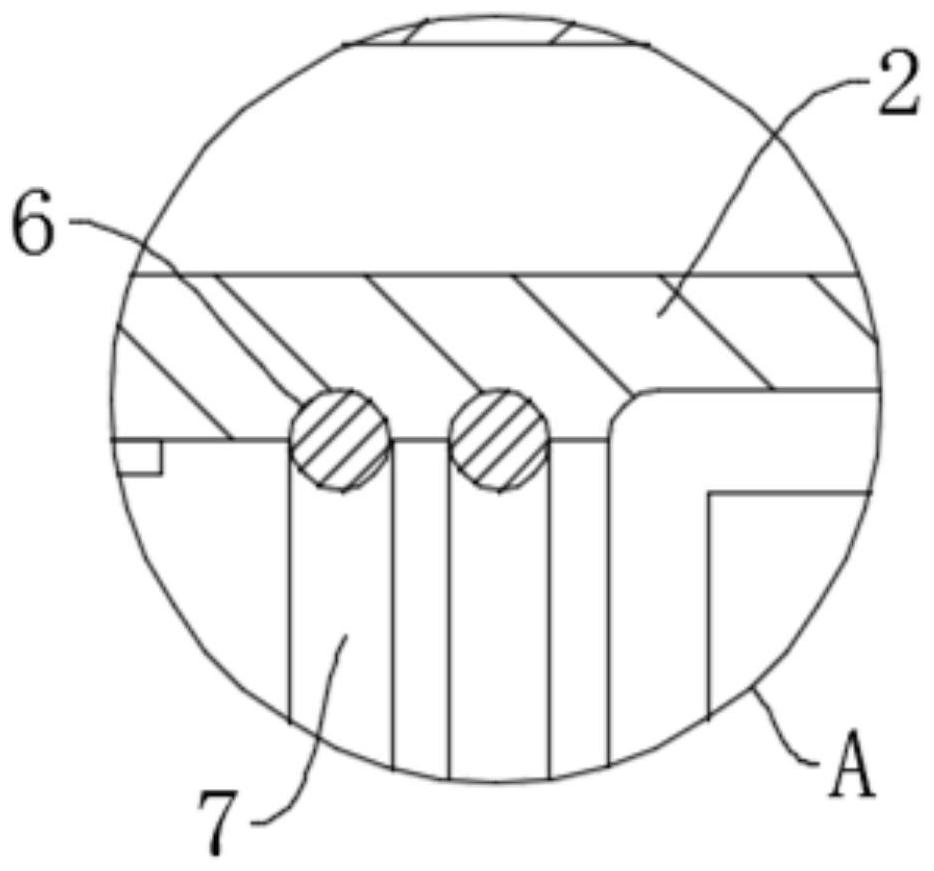

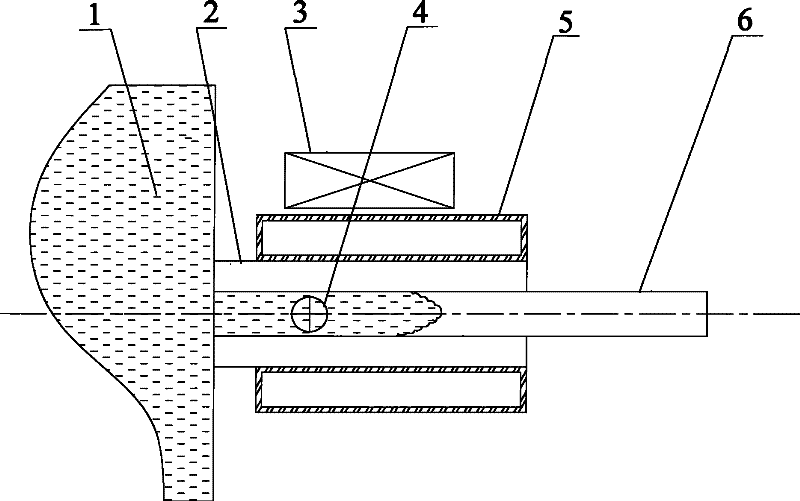

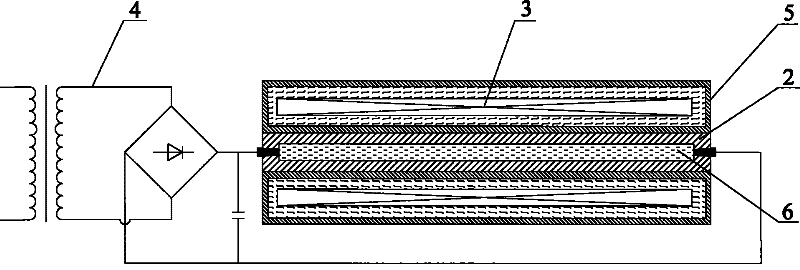

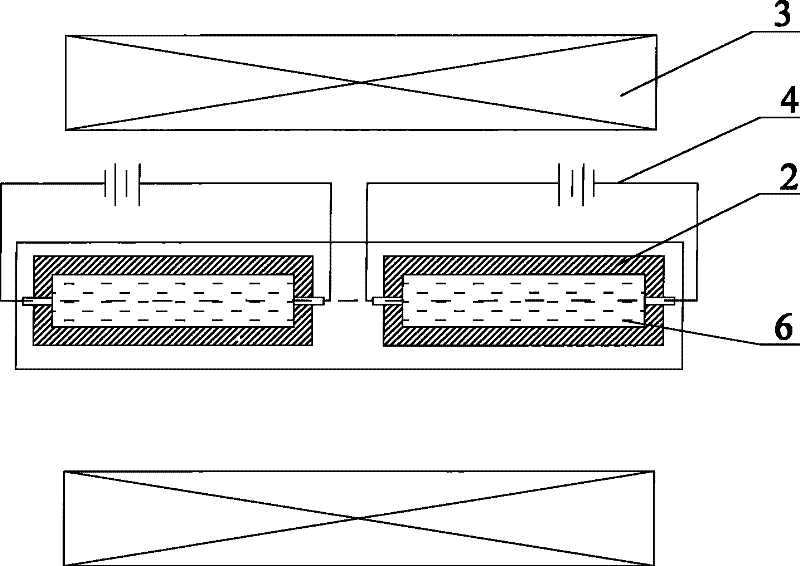

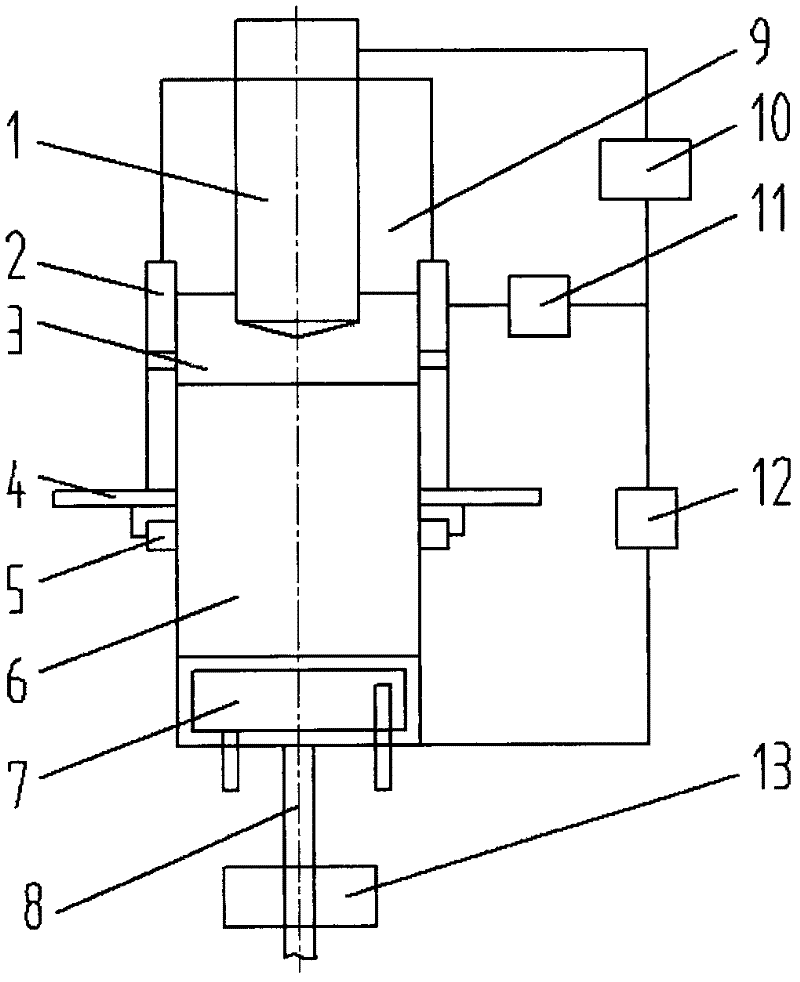

Vacuum/gas shield electroslag remelting continuous directional solidification device and method

ActiveCN102021348AEliminate aggregationEliminate coagulation and looseningElectricityHigh volume manufacturing

The invention relates to an electroslag remelting technique, in particular to a vacuum / gas shield electroslag remelting continuous directional solidification device and method. The device comprises a power supply, a consumable electrode (1), a water-cooling crystallizer (2) and a gas shield system, wherein the lower part of the water-cooling crystallizer (2) is provided with a water-cooling chassis (7) and a stripping device (13), and a two-circuit control mode is adopted by the consumable electrode (1) to make the stripping speed equivalent with the solidification speed of a cast ingot. The invention has simple operation and low cost, is convenient to control, can be used for producing large-dimension low-segregation directional solidification cast ingots and is suitable for mass production and application.

Owner:BEIJING CISRI GAONA TECH

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

High-energy-absorptivity aluminum alloy for automobile bodies

The invention relates to a high-energy-absorptivity aluminum alloy for automobile bodies, which comprises the following components in percentage by weight: 0.56%-0.64% of Mg, 0.42%-0.50% of Si, 0.17%-0.19% of Cu, 0.20%-0.22% of Fe, 0.028%-0.032% of Mn, 0.028%-0.032% of Cr, 0.028%-0.032% of Zn, 0.29%-0.31% of Ti, 0.29%-0.31% of Zr and the balance of Al. The preparation method comprises the following steps: preparing components according to weight percents, melting by heating to 740-750 DEG C, cooling, standing,, refining, and casting into a 250-300 DEG C iron mold; and carrying out homogenizing treatment on the cast ingot at 560 DEG C for 9 hours, quickly cooling with water, heating, extruding, carrying out water or fog quenching, and carrying out artificial aging at 180 DEG C. The invention has the advantages of reasonable component proportion, simple operating technique and favorable hot extrusion formability.

Owner:HUNAN UNIV

Energy absorption aluminum profile for railway vehicle body and manufacturing method thereof

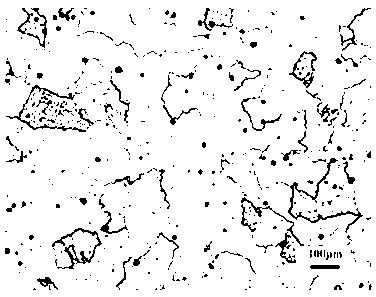

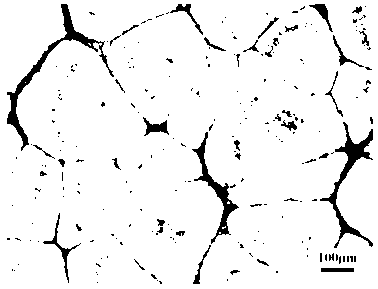

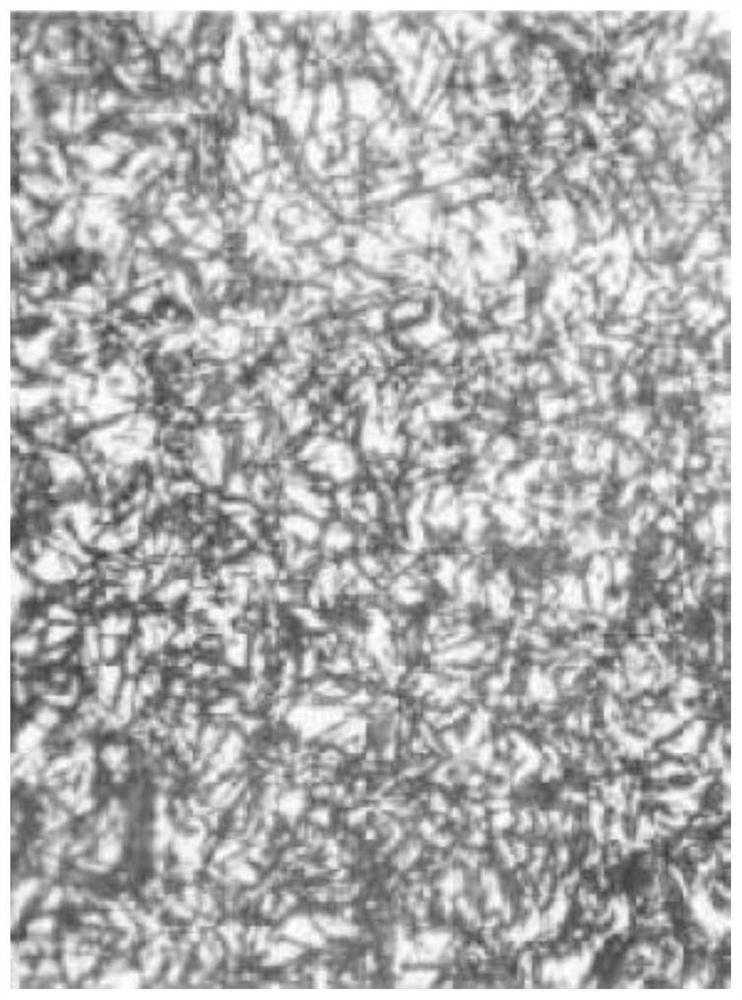

InactiveCN104988366ATo achieve the effect of densificationHigh strengthRailway wheel guards/bumpersEnergy absorptionCrystal structure

The invention relates to an energy absorption aluminum profile for a railway vehicle body and a manufacturing method thereof. The energy absorption aluminum profile comprises, by mass, 0.5%-0.7% of Si, 0-0.15% of Fe, 0.4%-0.6% of Mg, 0.2%-0.3% of Mn, 0-0.01% of Cu, 0.1%-0.2% of Cr, 0-0.01% of Zn, 0.04%-0.06% of Ti, 0.04%-0.1% of V, and the balance of Al. By adding the 0.04%-0.1% of V into the energy absorption aluminum profile, the columnar crystal structure of a cast ingot can be reduced, the cast structure can be refined, the effects of restraining recrystallization of deformed grains and growth of recrystallized grains can be achieved in the heat treatment and heat deformation processes of the alloy, the purpose of refining the profile structure is achieved, the strength, toughness, ductility and corrosion resistance of the profile are improved, and the energy absorption property of the profile is significantly improved.

Owner:龙口市丛林铝材有限公司

TiAl alloy plate rapid preparation method

The invention discloses a TiAl alloy plate rapid preparation method. The preparation method comprises the steps of preparation of a TiAl alloy plate blank, sheathing of the TiAl alloy plate blank, early-stage sheath rolling of a TiAl alloy, later-stage sheath rolling of the TiAl alloy, stress relief annealing and sheath removing. Through the method, the Al content of the TiAl alloy is not higher than 44.5%, it is ensured that a high-temperature structure of the alloy contains a certain number of unordered phases beta and phases alpha before rolling, and the alloy has excellent deformability. Rapid high-efficiency rolling on the plate can be implemented at low rolling temperature and large pass deformation, the whole rolling period is short, refining of crystal particles is facilitated, andthe mechanical performance of the plate is finally improved. The preparation method has the advantages that the process is simple, the cost is low, and the high-quality non-defective TiAl alloy platecan be prepared.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

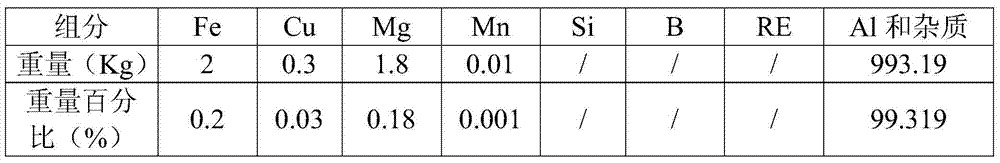

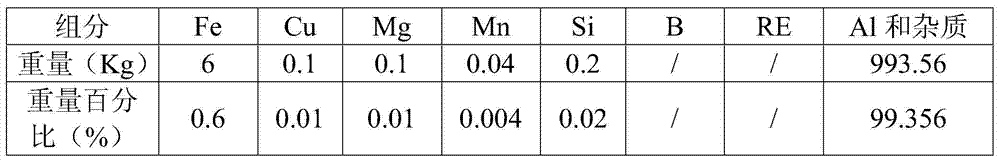

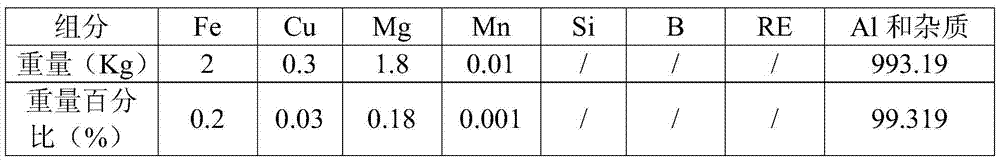

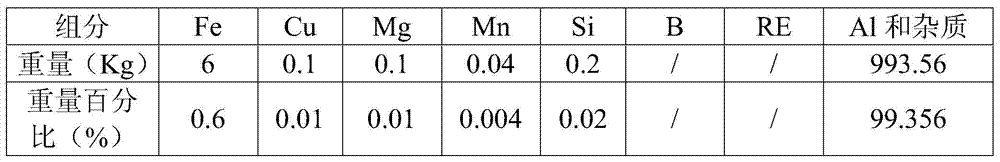

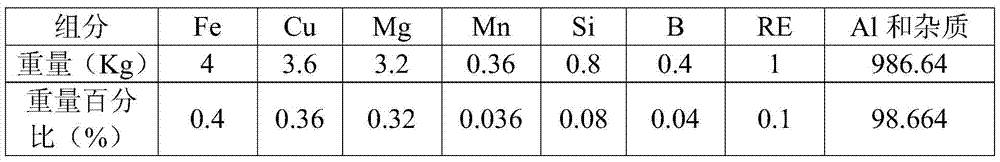

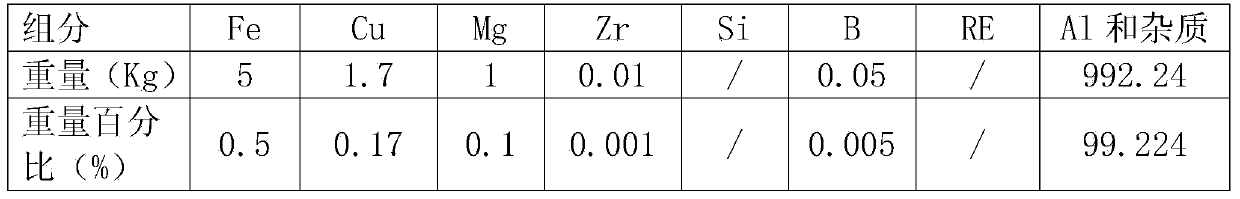

Al-Fe-Cu-Mg-Mn aluminum alloy used for coal mine cables and aluminum alloy cable

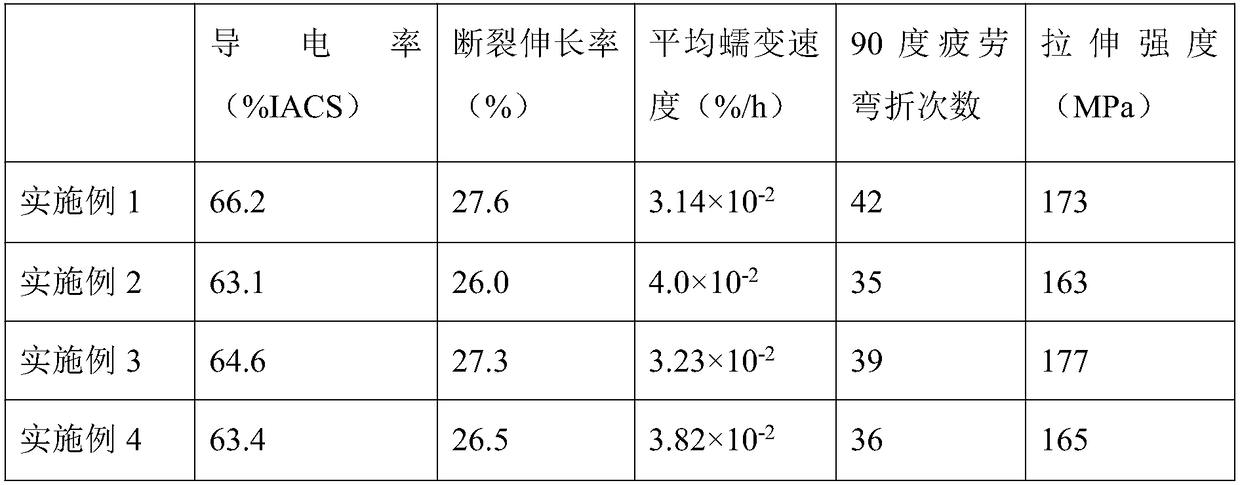

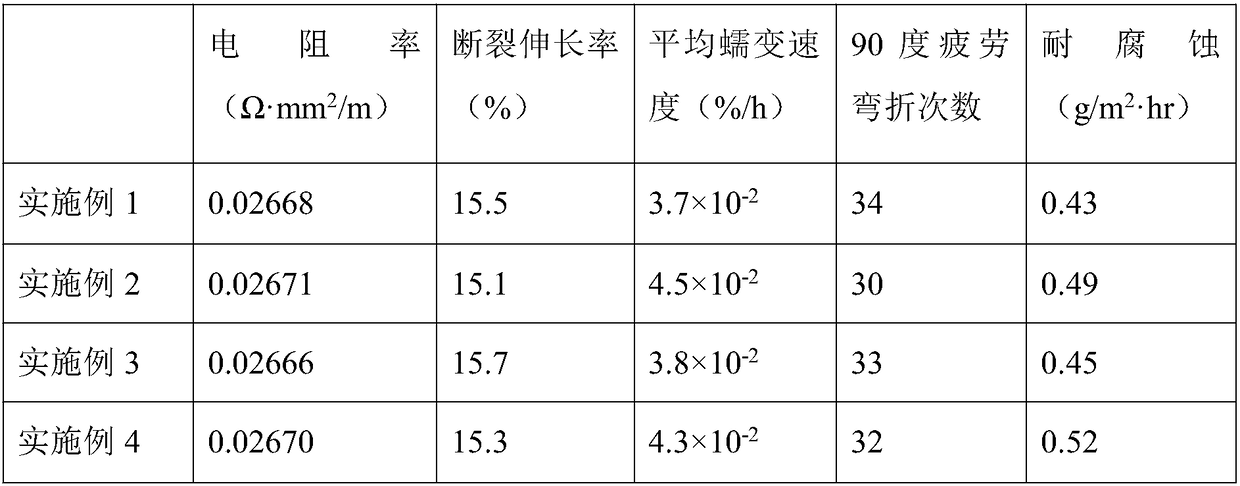

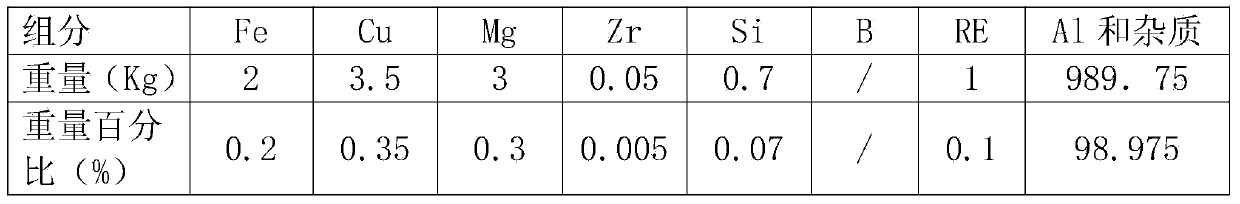

ActiveCN104299669AExtended service lifeImprove performanceNon-insulated conductorsMetal/alloy conductorsElectrical conductorImpurity

The invention discloses Al-Fe-Cu-Mg-Mn aluminum alloy used for coal mine cables and an aluminum alloy cable. The aluminum alloy material comprises, by weight, 0.2 percent-1.1 percent of Fe, 0.01 percent-0.4 percent of Cu, 0.01 percent-0.4 percent of Mg, 0.001 percent-0.1 percent of Mn, 0 percent-0.1 percent of Si, 0 percent-0.2 percent of B and the balance being Al and impurities. The aluminum alloy material is smelted, cast and rolled, so that an aluminum alloy rod is obtained; afterwards, the aluminum alloy rod is subjected to pulling, bunch stranding and softening, so that an aluminum alloy cable core is formed; next, the cable core is subjected to extruded insulation, cabling, sheath extrusion or armoring, so that the aluminum alloy cable is manufactured. The Al-Fe-Cu-Mg-Mn aluminum alloy used for the coal mine cables has the advantages of being high in strength, high in electric conductivity, good in bending performance and the like; the aluminum alloy cable made of the aluminum alloy can meet the requirements for cable performance in the field of coal mines.

Owner:安徽中青欣意铝合金电缆有限公司

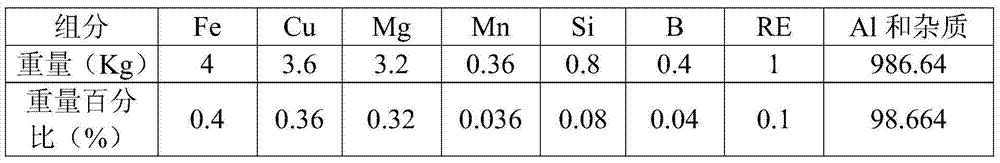

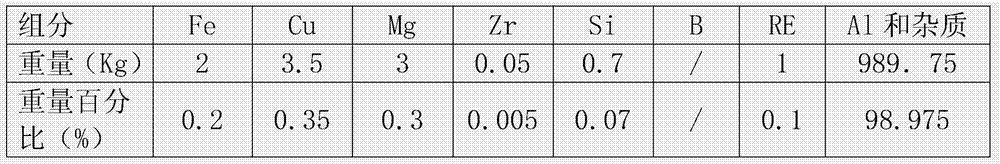

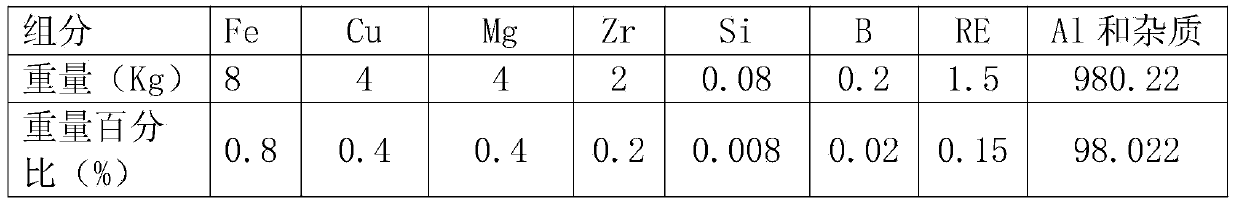

Al-Fe-Cu-Mg-Zr series aluminum alloy for cables for coal mines and aluminum alloy cable

ActiveCN104294089AImprove performanceHigh mechanical strengthFlexible cablesMetal/alloy conductorsElectrical conductorAdditive ingredient

The invention discloses an Al-Fe-Cu-Mg-Zr series aluminum alloy for cables for coal mines and an aluminum alloy cable. The aluminum alloy contains the ingredients in percentage by weight: 0.2-1.1% of Fe, 0.01-0.4% of Cu, 0.01-0.4% of Mg, 0.001-0.2% of Zr, 0-0.1% of Si, 0-0.2% of B and the balance of Al and impurities. The aluminum alloy cable is produced through enabling the aluminum alloy to be subjected to the processes of melting, casting and rolling, so as to obtain aluminum alloy rods, then, carrying out drawing, stranding and softening, so as to form aluminum alloy conductor wire cores, and then, carrying out extruded insulation, cabling and extruded sheathing or armoring on the conductor wire cores. The Al-Fe-Cu-Mg-Zr series aluminum alloy for the cables for the coal mines, disclosed by the invention, has the characteristics of high strength, high conductivity, good bending property and the like; the aluminum alloy cable produced from the aluminum alloy can meet the requirements on the properties of the cable in the field of the coal mines.

Owner:林泽民

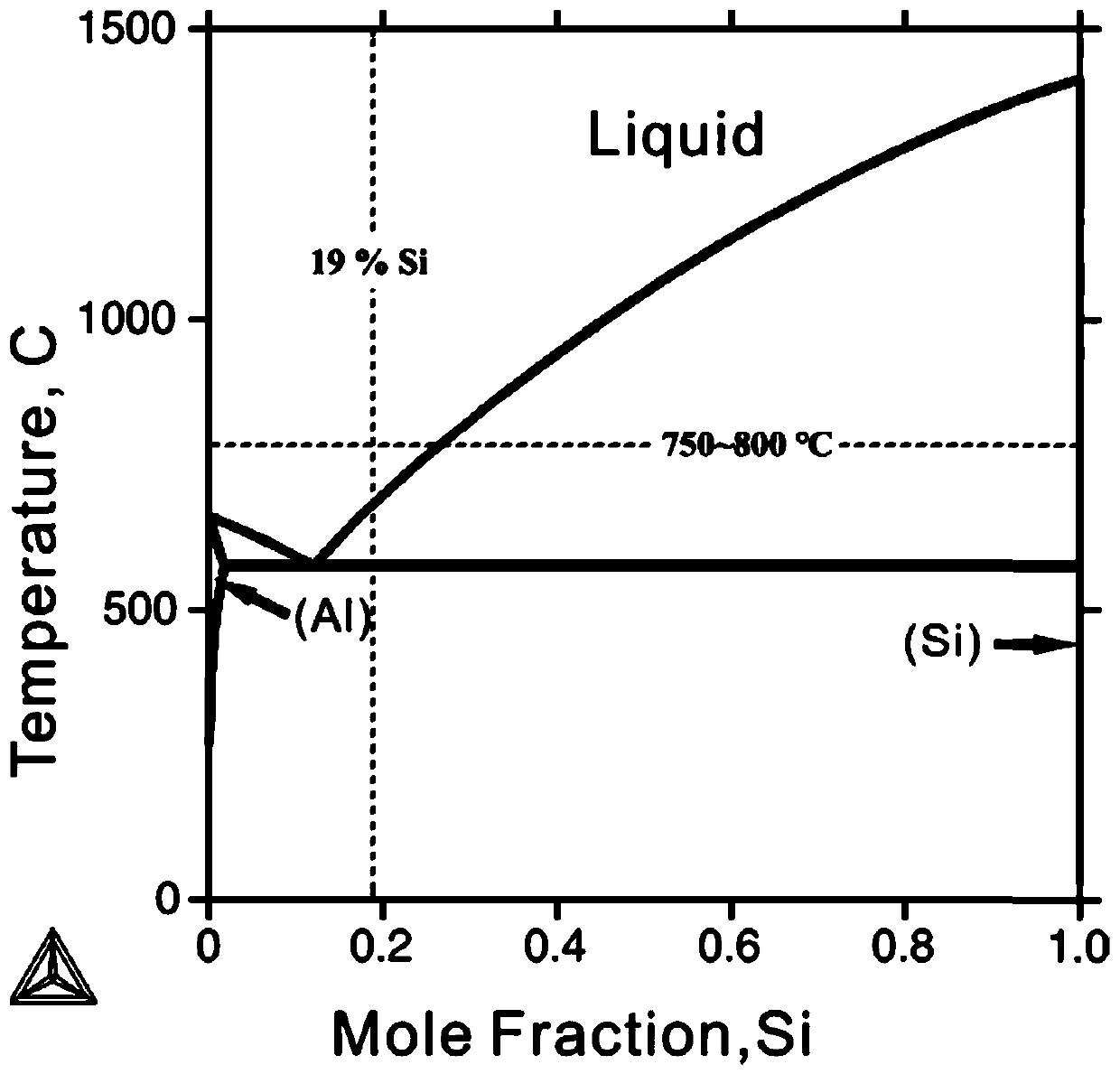

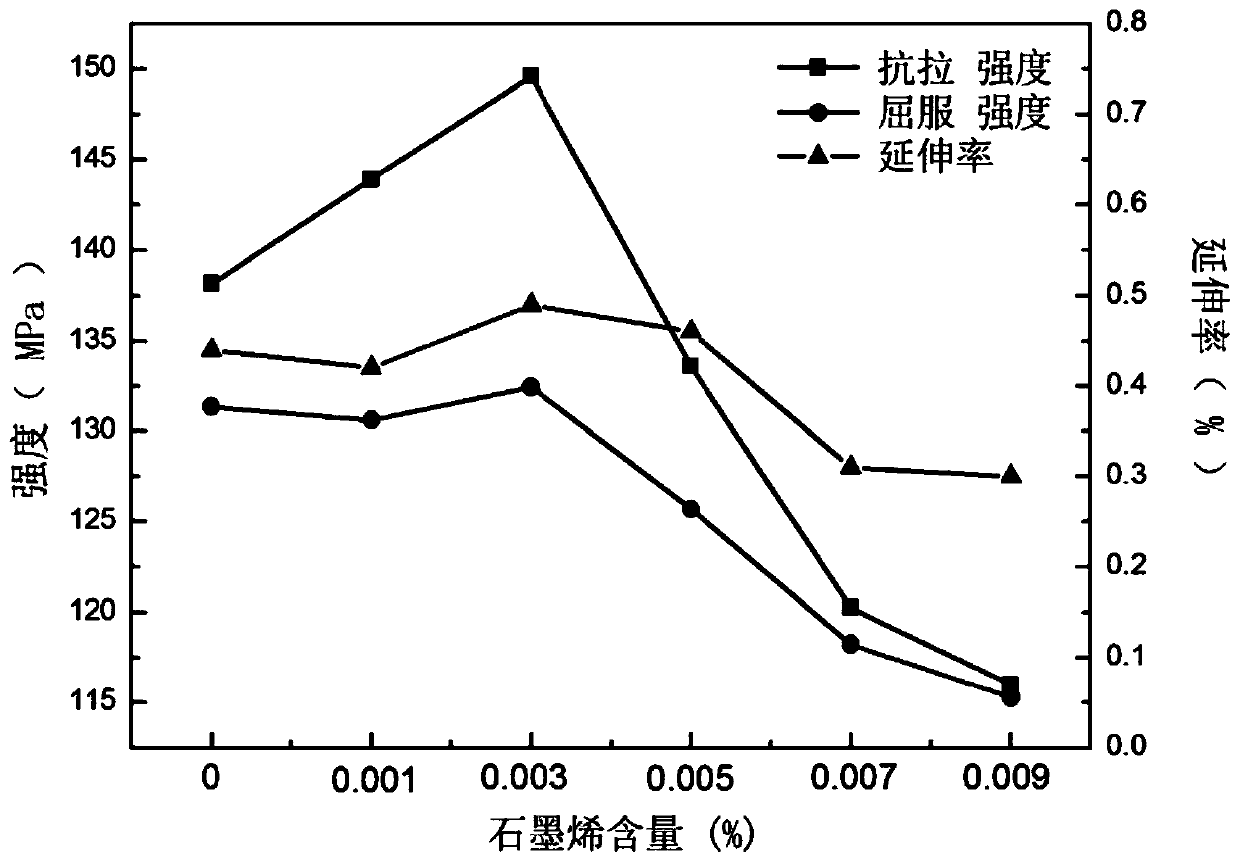

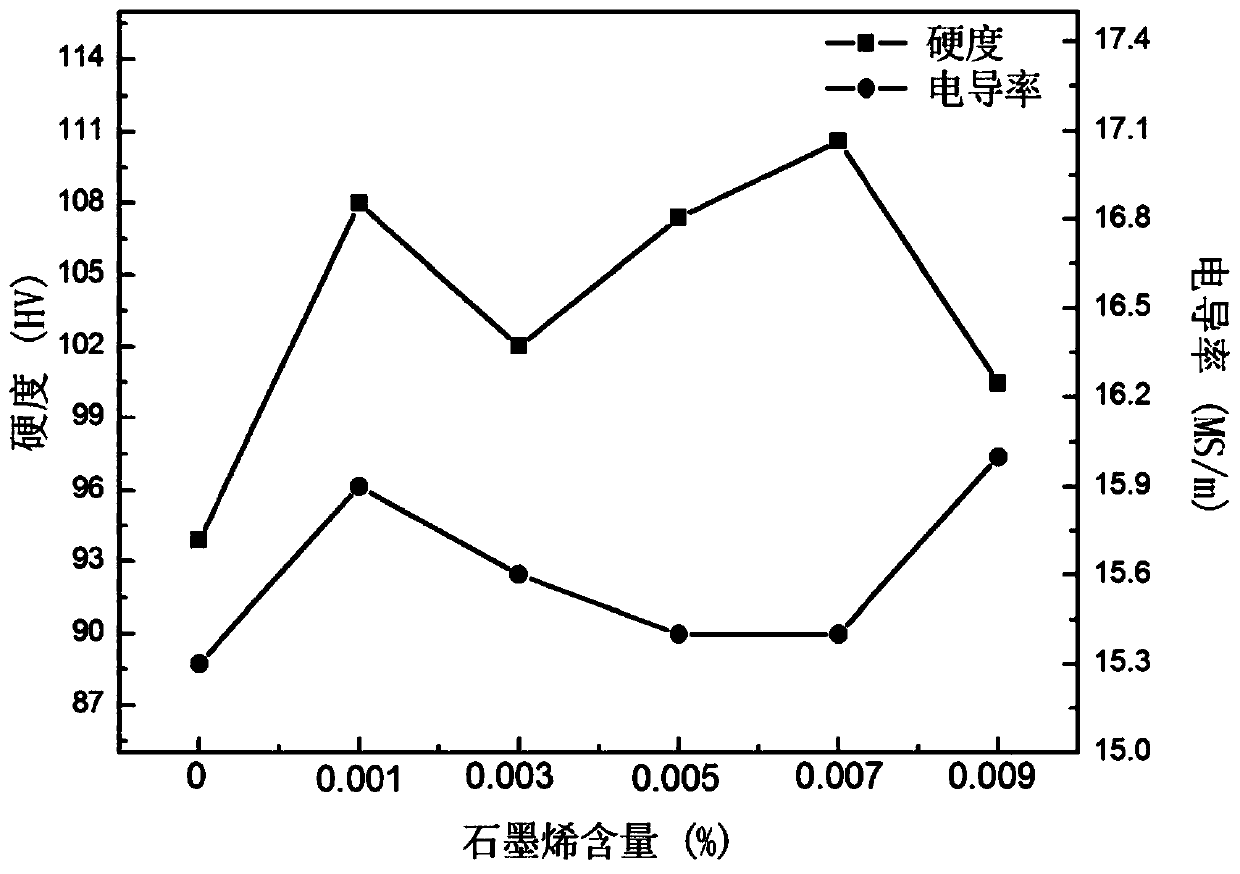

Graphene reinforced hypereutectic aluminum-silicon alloy and preparation method thereof

The invention provides graphene reinforced hypereutectic aluminum-silicon alloy and a preparation method of the graphene reinforced hypereutectic aluminum-silicon alloy. According to the chemical components, the graphene reinforced hypereutectic aluminum-silicon alloy comprises, by mass percentage, 18.0%-20.0% of Si, 0.45%-0.70% of Mg, 0.001%-0.009% of graphene, 0.1%-0.3% of Zr, smaller than or equal to 0.2% of Zn, smaller than or equal to 0.1% of Mn, smaller than or equal to 0.1% of Ti, smaller than or equal to 0.1% of Be, smaller than or equal to 0.05% of Sn, smaller than or equal to 0.1% ofPb, smaller than or equal to 0.03% of each of other unspecified impurity elements, smaller than or equal to 0.10% of total impurity elements and the balance Al. The content of graphene in the provided graphene reinforced hypereutectic aluminum-silicon alloy is much smaller than that of graphene of existing graphene composite aluminum alloy, the cost is reduced, the comprehensive mechanical properties of the obtained graphene reinforced hypereutectic aluminum-silicon alloy are remarkably improved, and the application of the graphene reinforced hypereutectic aluminum-silicon alloy in the industrial field is broadened.

Owner:广州埃米石墨烯科技有限公司

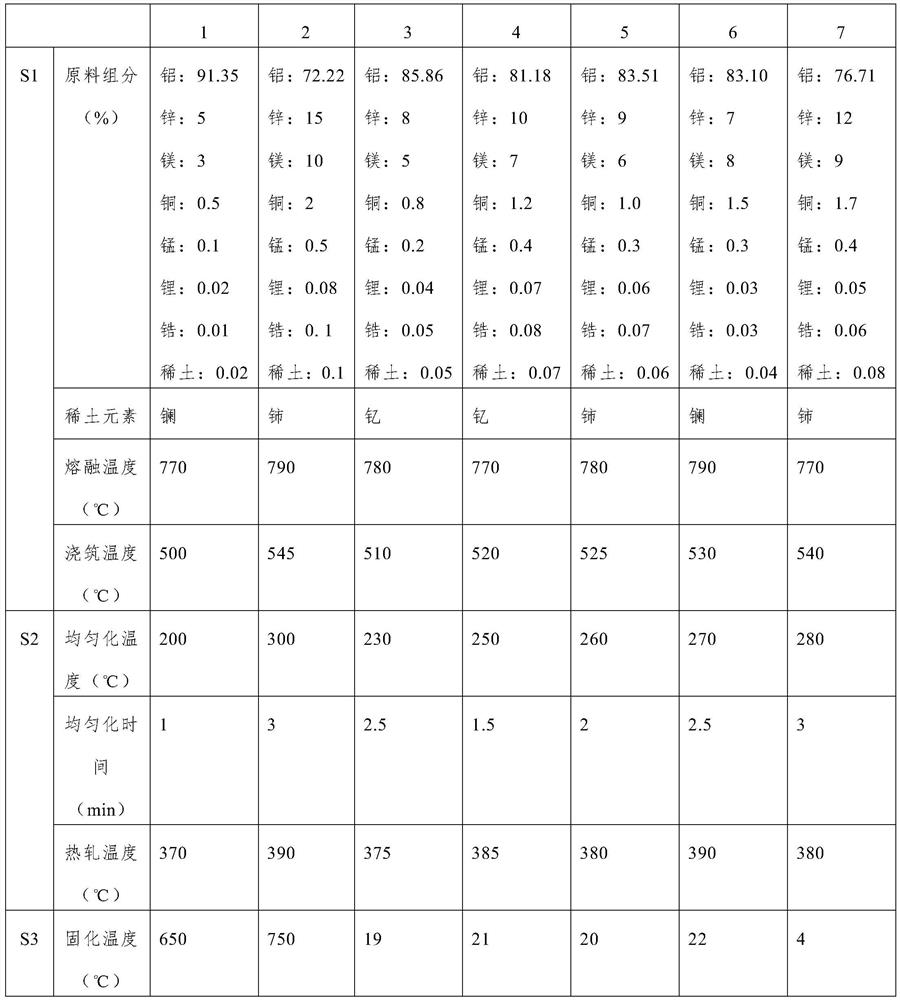

Aluminum alloy, and preparation method for plate of aluminum alloy

The invention relates to the technical field of aluminum alloy processing, in particular to an aluminum alloy which comprises, by weight, 5%-15% of zinc, 3%-10% of magnesium, 0.5%-2.0% of copper, 0.1%-0.5% of manganese, 0.02%-0.08% of lithium, 0.01%-0.1% of zirconium, 0.02%-0.1% of rare earth elements and the balance aluminum. The aluminum alloy is prepared from aluminum ingots, pure zinc, aluminum-magnesium intermediate alloy, aluminum-copper intermediate alloy, pure manganese, pure lithium, pure zirconium and rare earth according to the alloy content through smelting and ingot casting. In the aluminum alloy, an aluminum ingot is used as a base body, wherein the hardness of the aluminum alloy can be improved through the zinc, magnesium and copper greatly; the melting temperature and the porosity of the aluminum alloy can be reduced through the rare earth elements, and the density is improved; the hardness of the aluminum alloy can be improved through the lithium, and the weight of thealuminum alloy can be further reduced; the strength, hardness and elastic limit of the aluminum alloy can be improved through the manganese, and the corrosion resistance of the aluminum alloy can befurther improved; and the hardness, strength and corrosion resistance of the aluminum alloy can be improved through the zirconium, a casting structure can be refined through the zirconium, and the high-temperature plasticity of the alloy is improved.

Owner:湖南恒佳新材料科技有限公司

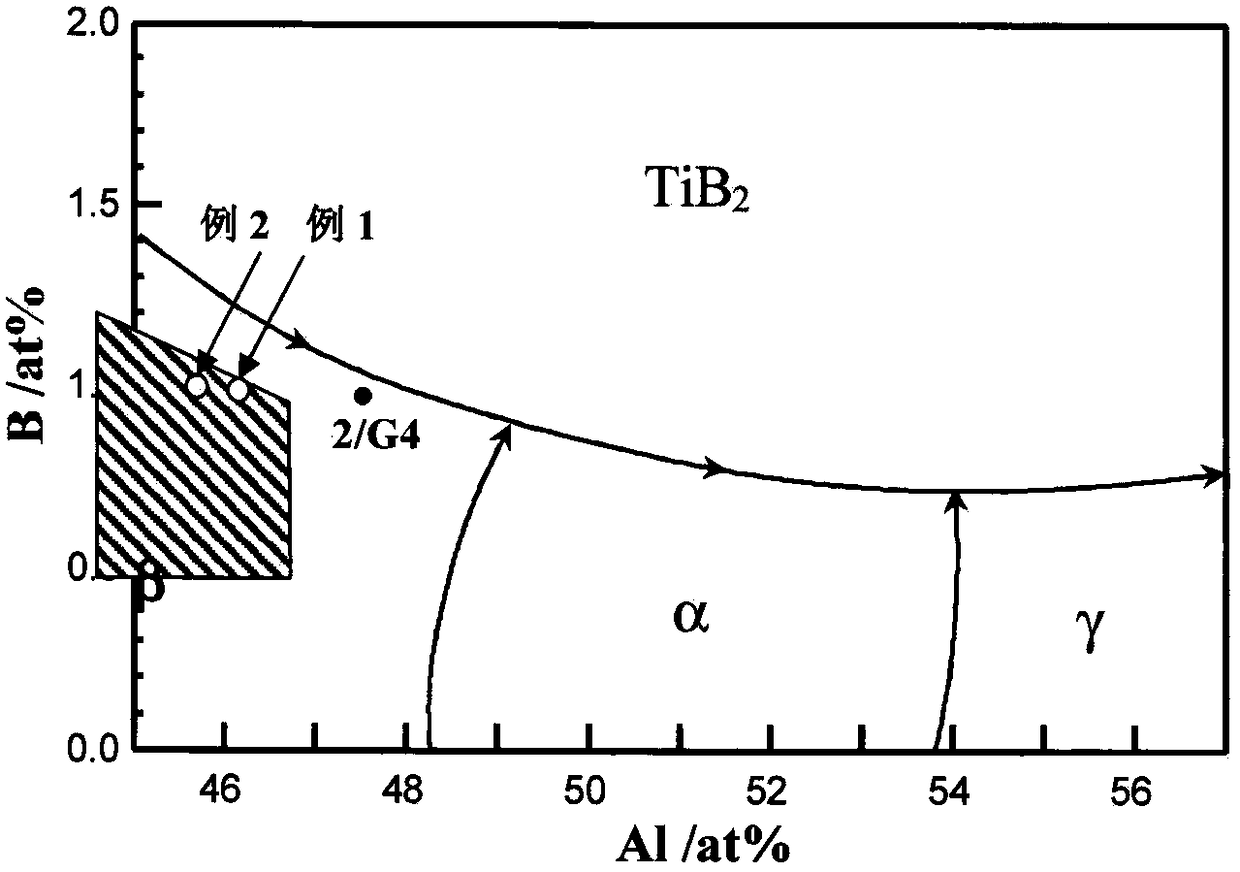

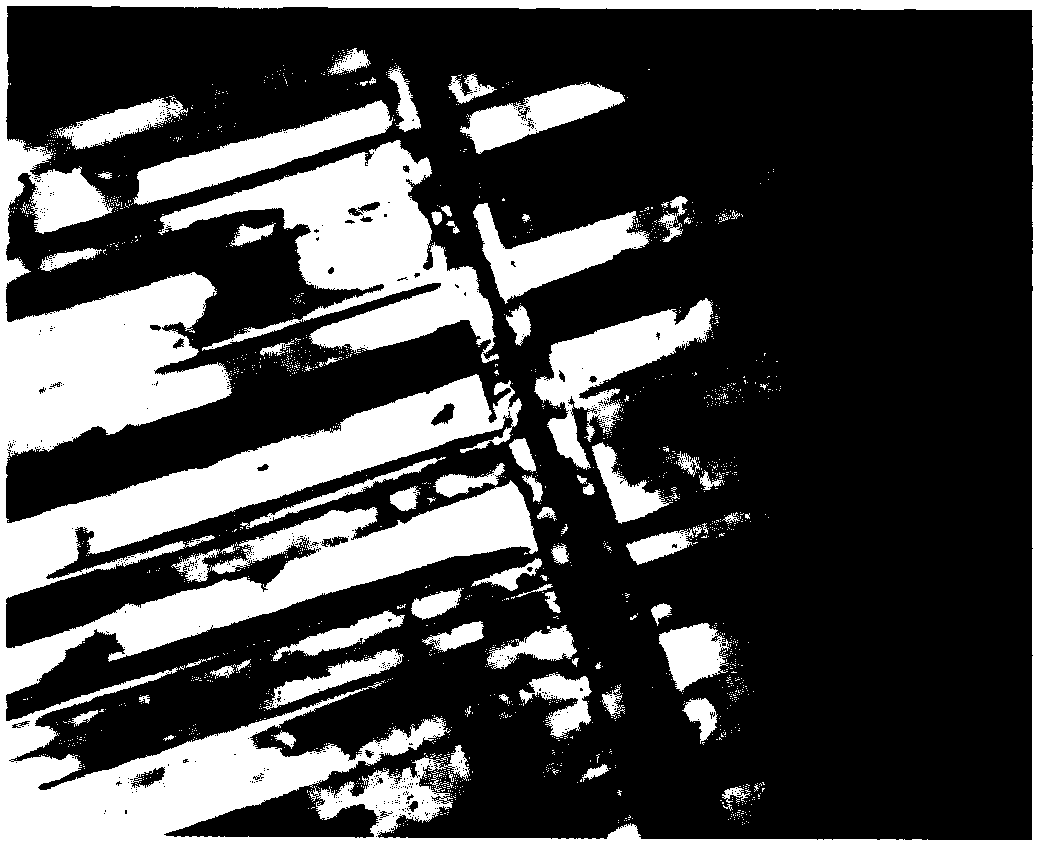

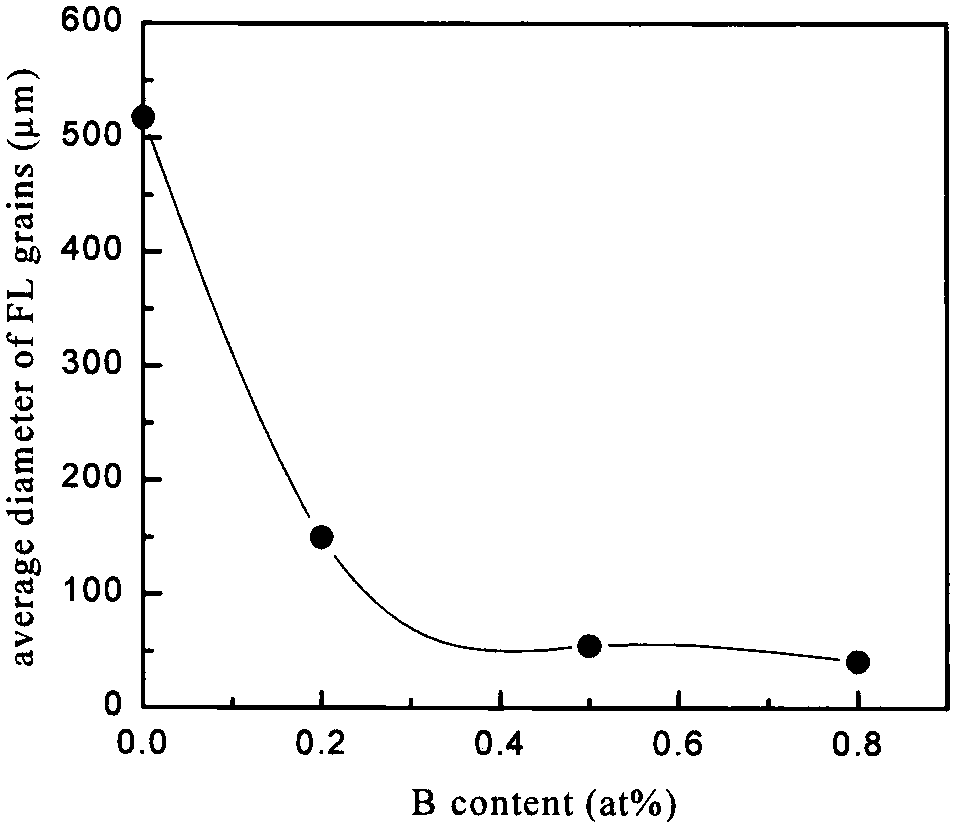

In-situ self-generated TiB2 whisker-reinforced TiAl-based composite material and preparation method thereof

InactiveCN108588590AImprove high temperature creep resistanceImprove high temperature durabilityRoom temperatureWhiskers

The invention belongs to the field of preparation of a TiAl alloy and a composite material adopting the TiAl alloy as a matrix, and relates to an in-situ self-generated TiB2 whisker-reinforced TiAl-based composite material and a preparation method thereof. The invention is applicable to the TiB2 / TiAl composite material and the preparation method thereof. Through a formula for calculating the controlled quantity of B elements added into the TiAl alloy mentioned by the invention, the appropriate amount of B elements is added into the TiAl alloy, an in-situ self-generated slim secondary TiB2 whisker obtained through the eutectic reaction of L to beta+TiB2 and L+beta to alpha+TiB2 is formed in the TiAl alloy, and meanwhile, the production of a thick granular primary TiB2 phase is avoided, so that the TiB2 whisker-reinforced TiAl-based composite material can be obtained. Then, the TiB2 / TiAl composite material prepared through an ingot metallurgy method is treated through a unique triple heat treatment process, so that a fine-grain mesh basket-shaped structure and a fine-grain full lamellar structure can be obtained. The TiB2 / TiAl composite material has excellent creep resistance and durability at the high temperature of 760 DEG C to 800 DEG C, and meanwhile, has better room-temperature ductility so as to have a favorable application prospect in the aerospace field.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Aluminum alloy material for cable

InactiveCN109097634AImprove conductivityImprove high temperature creep resistanceConductive materialMetal/alloy conductorsGrapheneZinc

The invention provides an aluminum alloy material for a cable. The aluminum alloy material comprises the following components of, by weight, 0.01-0.03% of Cu, 0.002-0.006% of Ca, 0.003-0.009% of V, 0.001-0.02% of Sn, 0.005-0.012% of Be, 0.002-0.01% of Bi, 0.001-0.005% of Sr, 0.16-0.32% of modified graphene, 0.06-2.3% of Re, and the balance Al and impurities. The modified graphene is mainly prepared by nano nickel oxide, silver powder, bismuth oxide, zinc powder and graphene powder. The aluminum alloy material for the cable is high in electrical conductivity, and good in creep-resistant performance and fatigue-resistant performance.

Owner:安庆市泽烨新材料技术推广服务有限公司

Precision forming aluminum alloy material suitable for high-toughness structural part of new energy automobile and preparation method of precision forming aluminum alloy material

The invention belongs to the technical field of aluminum alloy, and particularly relates to a precise forming aluminum alloy material suitable for a high-toughness structural part of a new energy automobile and a preparation method of the precise forming aluminum alloy material. 5.0 wt% to 7.0 wt% of Mg; zr: 0.2 wt% to 0.6 wt%; 0.1 wt% to 0.5 wt% of Sm; gd: 0.5 wt% to 0.8 wt%; cu: 0.8 wt% to 1.2 wt%; 0.6 wt% to 1.0 wt% of Zn; fe: lt; the aluminum alloy comprises the following components in percentage by weight: 0.5 wt% of Al, 3.0 wt%-7.0 wt% of silicon carbide whiskers, the sum of inevitable impurities such as Ti, B, Ca and the like is controlled to be 0.1 wt% or below, and the balance of Al. The yield strength of the material reaches 410-510 MPa, the tensile strength reaches 310-350 MPa, and meanwhile the ductility of the material is not lower than 12%.

Owner:苏州慧驰轻合金精密成型科技有限公司

Al-Cu-Mg-Zr series aluminum alloy for cable

InactiveCN109097619AImprove conductivityImprove high temperature creep resistanceConductive materialMetal/alloy conductorsGrapheneZinc

The invention provides an Al-Cu-Mg-Zr series aluminum alloy for a cable. The Al-Cu-Mg-Zr series aluminum alloy comprises the following components of, by weight, 0.03-0.09% of Cu, 0.01-0.03% of Zr, 0.02-0.08% of Mg, 0.2-0.4% of modified graphene, and the balance Al and impurities. The modified graphene is mainly prepared from nano-TiO2, Fe powder, lanthanum oxide, zinc powder and graphene powder. The aluminum alloy not only has low resistivity, but also has good creep resistance.

Owner:安庆市泽烨新材料技术推广服务有限公司

Novel copper and copper alloy plate belt electromagnetism assistant casting method and device

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Aluminum alloy for casting engine cylinder cover and preparation method of aluminum alloy

The invention relates to an aluminum alloy for casting an engine cylinder cover. The aluminum alloy is prepared from the following components in percentage by mass: 6.5 to 7.5 percent of Si, 0.25 to 0.45 percent of Mg, less than or equal to 0.17 percent of Fe, 0.08 to 0.25 percent of Ti, 0.005 to 0.015 percent of Sr and the balance of Al. The invention further relates to a preparation method of the aluminum alloy. The preparation method comprises the following steps: preparing the materials according to the above component requirements; heating pure aluminum ingots and pure silicon in a crucible furnace to 760 + / - 10 DEG C to melt the pure aluminum ingots and the pure silicon; pressing a pure magnesium, aluminum and titanium intermediate alloy into the bottom of an aluminum and silicon solution with a bell jar, and controlling the temperature at 810 to 860 DEG C for alloying; after the alloying is completed, controlling the temperature between 740 + / - 10 DEG C, and adding an aluminum-strontium intermediate alloy AlSr; feeding high-purity nitrogen for gas removal; adding a covering agent; performing stewing and drossing; and pouring an alloy solution into a preheating die to obtain the aluminum alloy for casting the engine cylinder cover. After the aluminum alloy is subjected to T6 thermal treatment, the tensile strength of the aluminum alloy is 305 to 325 MPa, the yield strength is 240 to 260 MPa, the hardness is 90 to 110 HBS, and the ductility is up to 6 percent; and the strength and the toughness can meet the performance requirements of an engine cylinder cover product.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

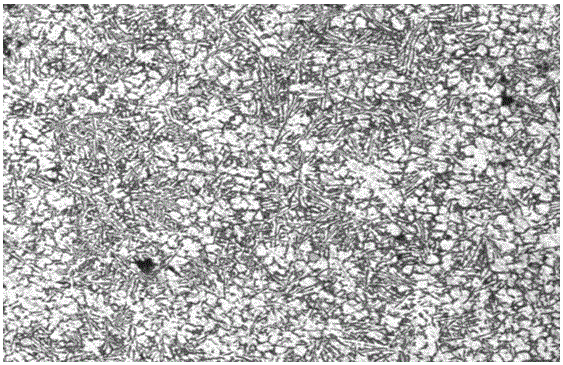

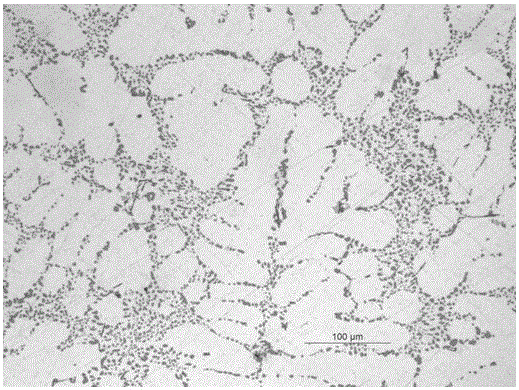

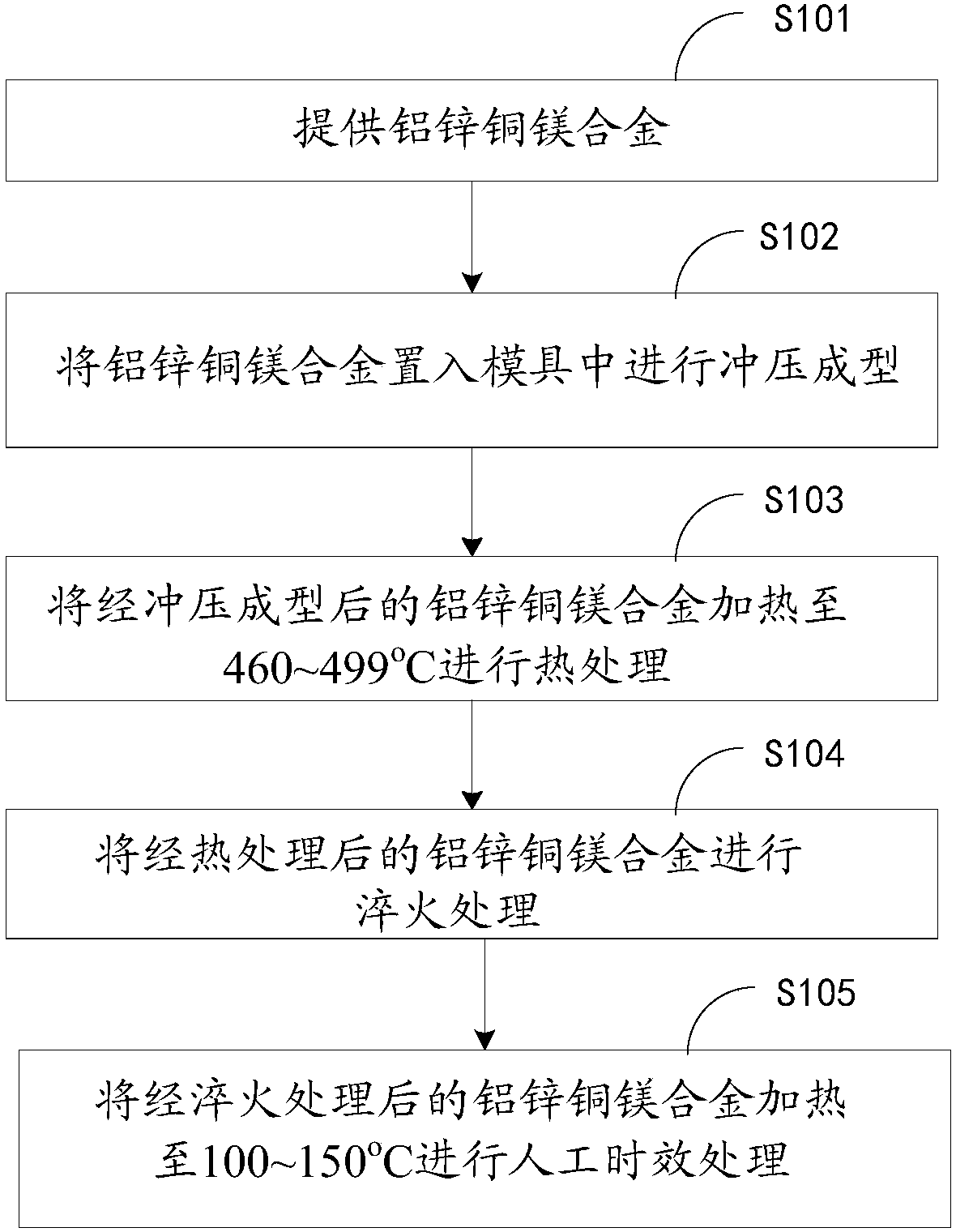

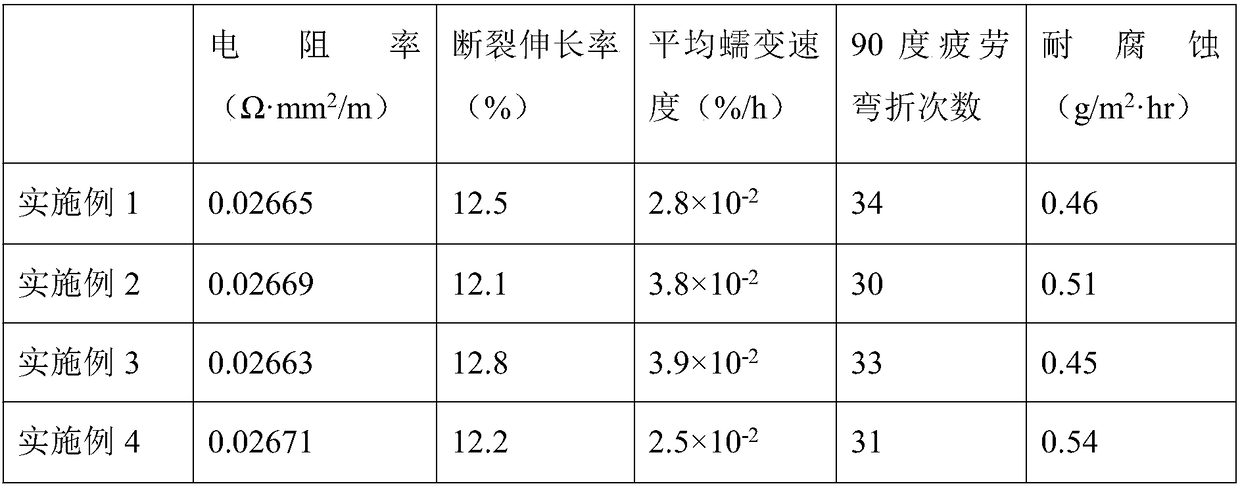

Aluminum, zinc, copper and magnesium alloy and machining process thereof

The invention discloses an aluminum, zinc, copper and magnesium alloy and a machining process thereof. The aluminum, zinc, copper and magnesium alloy comprises, by weight, 0.1%-0.15% of metallic zirconium and 0.03%-0.08% of metallic nickel. The process comprises the steps that the aluminum, zinc, copper and magnesium alloy is provided; the aluminum, zinc, copper and magnesium alloy is placed intoa die to be stamped and molded; the stamped and molded aluminum, zinc, copper and magnesium alloy is heated to 460 DEG C to 499 DEG C to be subject to heat treatment; the aluminum, zinc, copper and magnesium alloy subject to heat treatment is subject to quenching treatment; and the aluminum, zinc, copper and magnesium alloy subject to quenching treatment is heated to 100 DEG C to 150 DEG C to be subject to artificial aging treatment. By means of the above manner, the stamping and molding performance of the artificial aging treatment can be improved.

Owner:缪彬彬

Al-Cu-Sr-RE-Ge aluminium alloy wire for power cable and preparation method thereof

InactiveCN110923529AHigh tensile strengthHigh yield strengthApparatus for heat treatmentConductive materialPower cableThermal insulation

The invention provides an Al-Cu-Sr-RE-Ge aluminium alloy wire for a power cable and a preparation method thereof. The Al-Cu-Sr-RE-Ge aluminium alloy wire comprises the following components: 0.4-0.8wt%of Cu, 0.15-0.36wt% of Sr, 0.12-0.32wt% of RE, 0.13-0.28wt% of Ge, 0.11-0.18wt% of Si, 0.02-0.09wt% of Co, 0.03-0.07wt% of Ca, 0.01-0.05wt% of Cr and the balance of Al and unavoidable impurities. Thepreparation method comprises the following steps: 1, smelting and pouring; 2, quenching at 505-520 DEG C, and carrying out aging treatment at 210-225 DEG C; 3, extruding into an aluminium alloy rod at 485-510 DEG C; 4, drawing into a first aluminium alloy wire at 290-310 DEG C; 5, drawing into a second aluminium alloy wire with the diameter of 1-2.5mm at 330-360 DEG C; and 6, carrying out thermalinsulation on the second aluminium alloy wire for 3-5 hours at 350-380 DEG C, then reducing the temperature to 230-260 DEG C, carrying out thermal insulation for 6-10 hours, and air cooling to the room temperature. The Al-Cu-Sr-RE-Ge aluminium alloy wire has excellent electric conductivity and heat resistance and is high in strength, toughness and fatigue resistance.

Owner:安徽峰创云通数据科技有限公司

Al-Cu-Mg-Mn-series aluminum alloy for cable

InactiveCN109097633AImprove conductivityImprove high temperature creep resistanceConductive materialMetal/alloy conductorsAluminium alloyLanthanum oxide

The invention provides an Al-Cu-Mg-Mn-series aluminum alloy for a cable. The Al-Cu-Mg-Mn-series aluminum alloy comprises the following components of, by weight, 0.03-0.09% of Cu, 0.2-0.4% of Mn, 0.02-0.08% of Mg, 0.04-0.08% of Sc, 0.2-0.4% of modified graphene, and the balance Al and impurities. The modified graphene is mainly prepared by nano-TiO2, Fe powder, lanthanum oxide, zinc powder and graphene powder. The aluminum alloy is low in resistivity, and good in creep-resistant performance and fatigue-resistant performance.

Owner:安庆市泽烨新材料技术推广服务有限公司

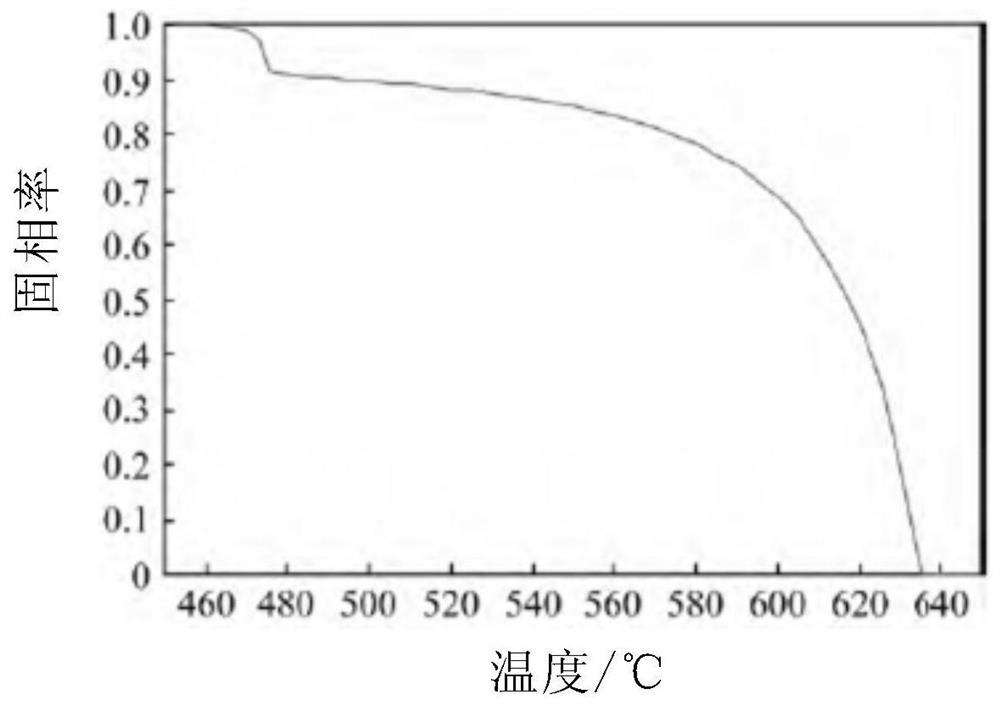

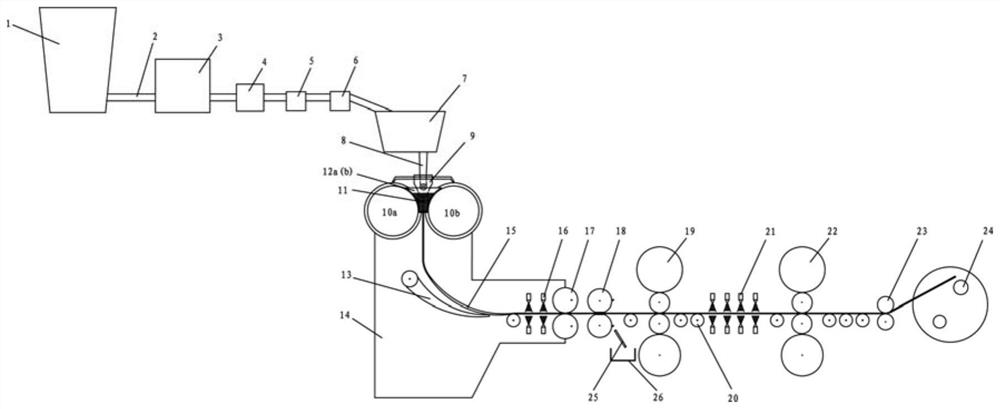

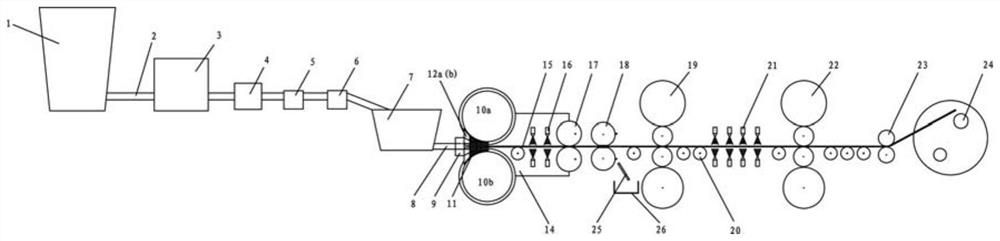

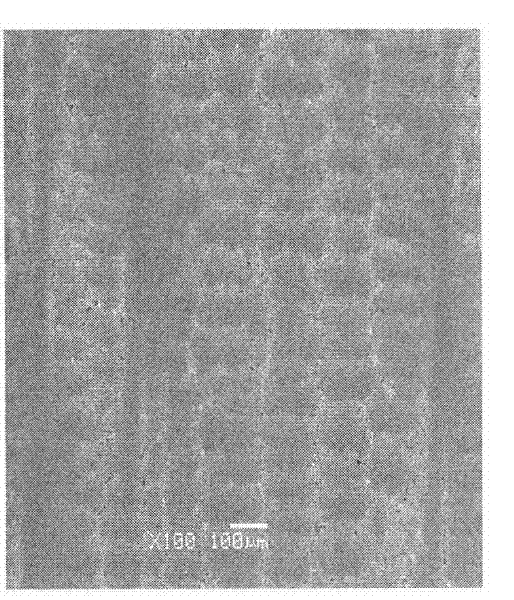

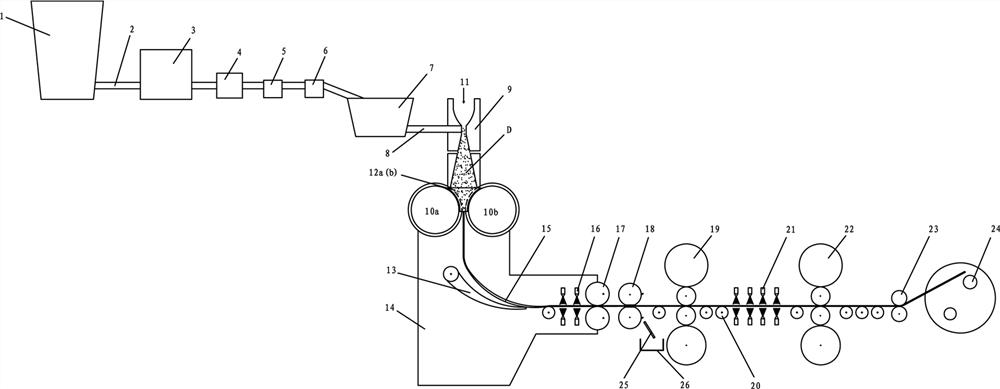

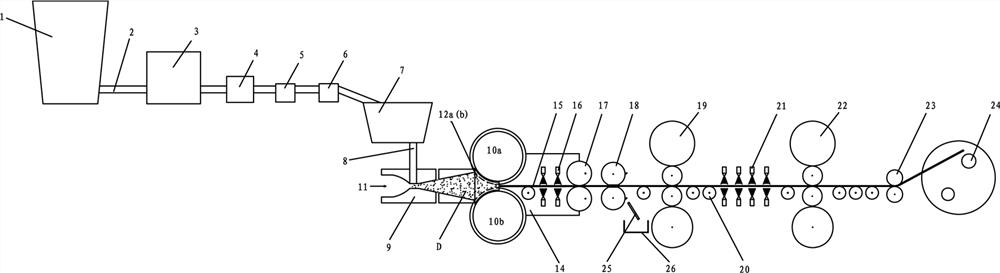

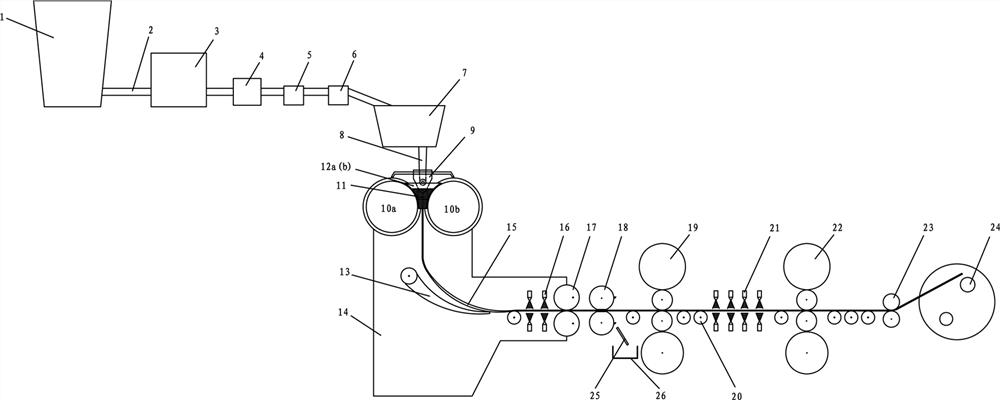

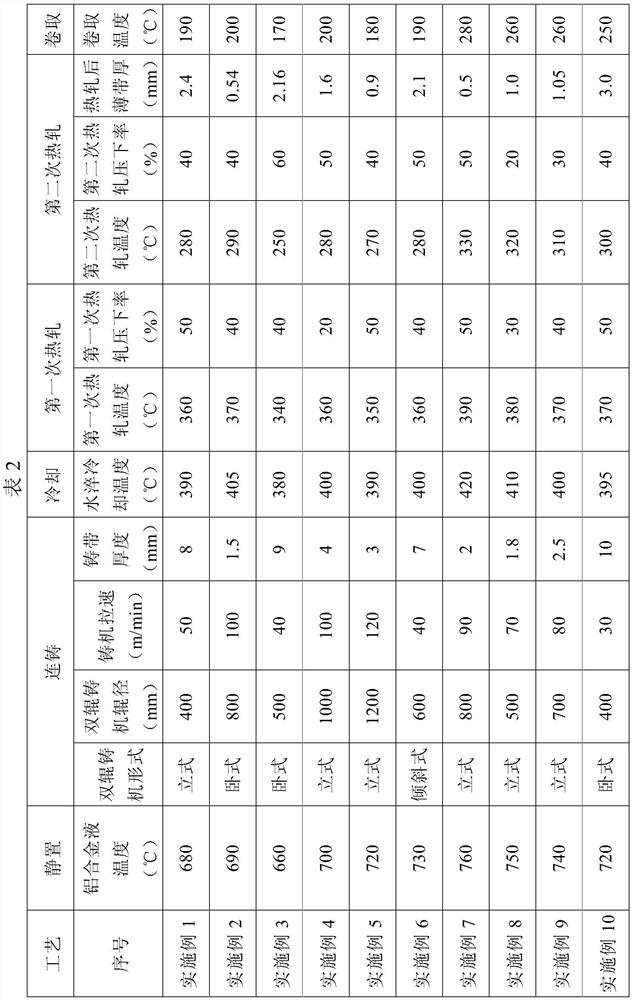

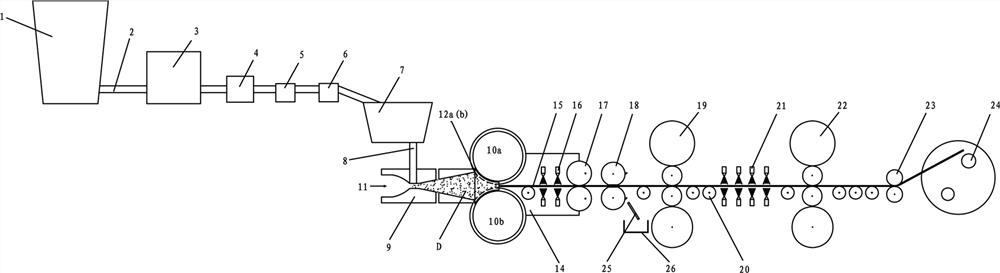

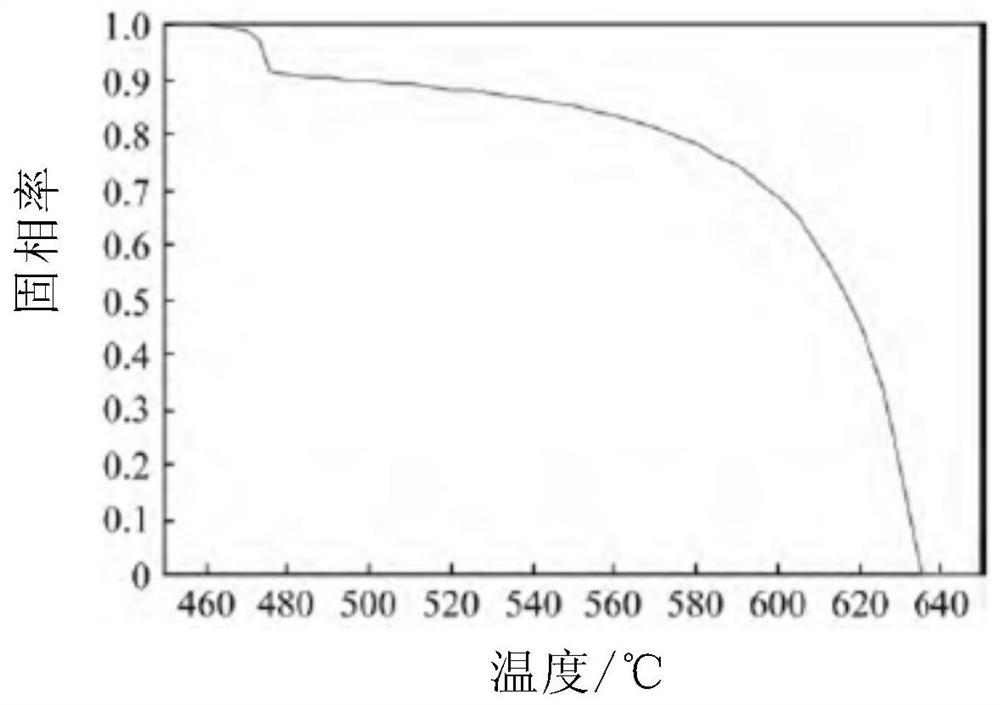

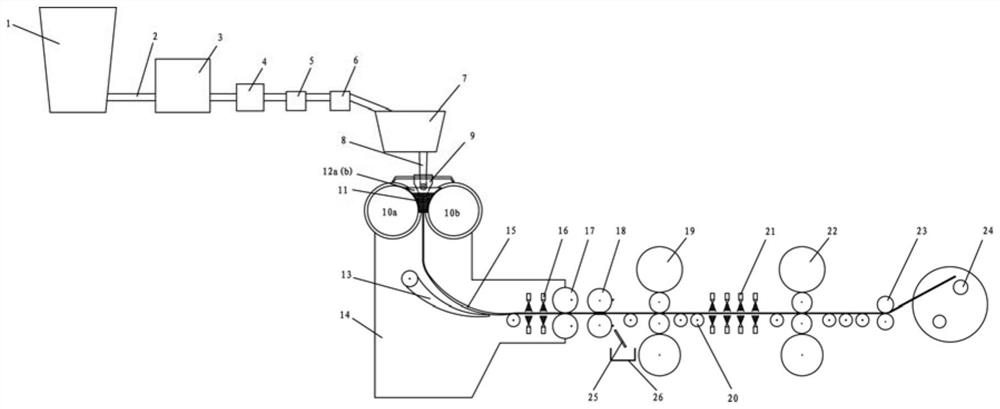

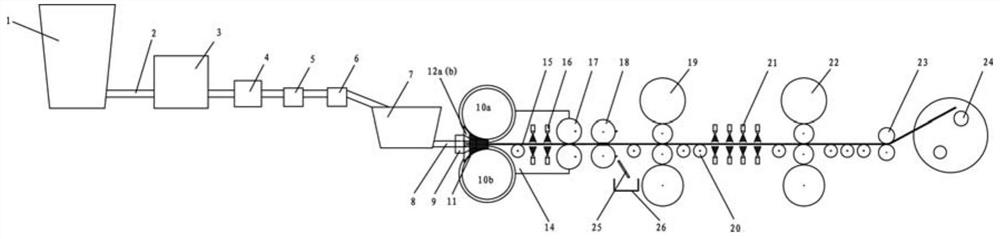

Preparation method of thin-strip continuous casting high-performance 7XXX aluminum alloy thin strip

ActiveCN114107762AHigh strengthHigh hardnessMetal rolling arrangementsSemi solidUltimate tensile strength

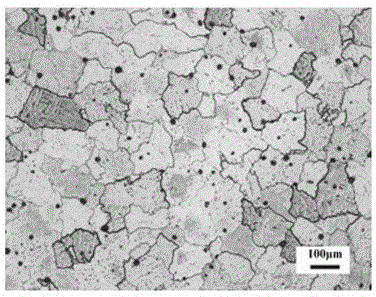

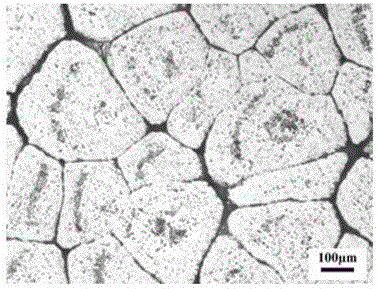

The invention relates to a preparation method of a thin-strip continuous casting high-performance 7XXX aluminum alloy thin strip, which comprises the following steps of: 1) smelting according to the following chemical components in percentage by weight: 4.8 to 6.3 percent of Zn, 1.6 to 2.5 percent of Mg, 1.6 to 2.5 percent of Cu, 0.1 to 0.15 percent of Zr and the balance of Al and other inevitable impurities; the single impurity content is less than or equal to 0.1%, and the total impurity content is less than or equal to 0.2 2) performing semi-solid state treatment; 3) continuous casting; 4) cooling; 5) primary hot rolling; (6) cooling and secondary hot rolling; (7) coiling; and 8) post-processing. The microstructure of the 7XXX aluminum alloy thin strip obtained through the method is a fine isometric crystal matrix structure, and compared with an existing 7XXX aluminum alloy, the strength is improved by 15% or above, and the ductility is improved by 25% or above; compared with a steel plate, the weight is reduced by more than 40%.

Owner:BAOSHAN IRON & STEEL CO LTD

Vacuum/gas shield electroslag remelting continuous directional solidification device and method

ActiveCN102021348BEliminate aggregationEliminate composition segregationElectricityHigh volume manufacturing

The invention relates to an electroslag remelting technique, in particular to a vacuum / gas shield electroslag remelting continuous directional solidification device and method. The device comprises a power supply, a consumable electrode (1), a water-cooling crystallizer (2) and a gas shield system, wherein the lower part of the water-cooling crystallizer (2) is provided with a water-cooling chassis (7) and a stripping device (13), and a two-circuit control mode is adopted by the consumable electrode (1) to make the stripping speed equivalent with the solidification speed of a cast ingot. The invention has simple operation and low cost, is convenient to control, can be used for producing large-dimension low-segregation directional solidification cast ingots and is suitable for mass production and application.

Owner:BEIJING CISRI GAONA TECH

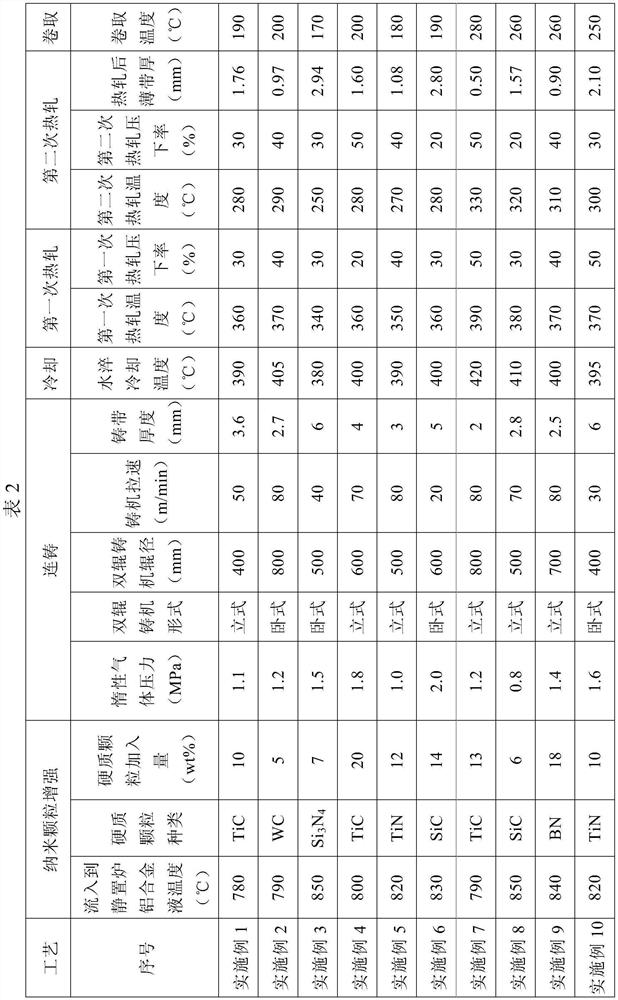

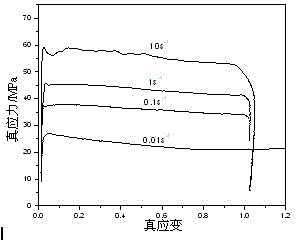

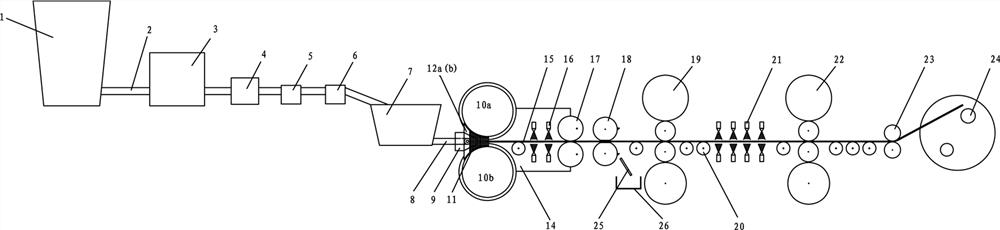

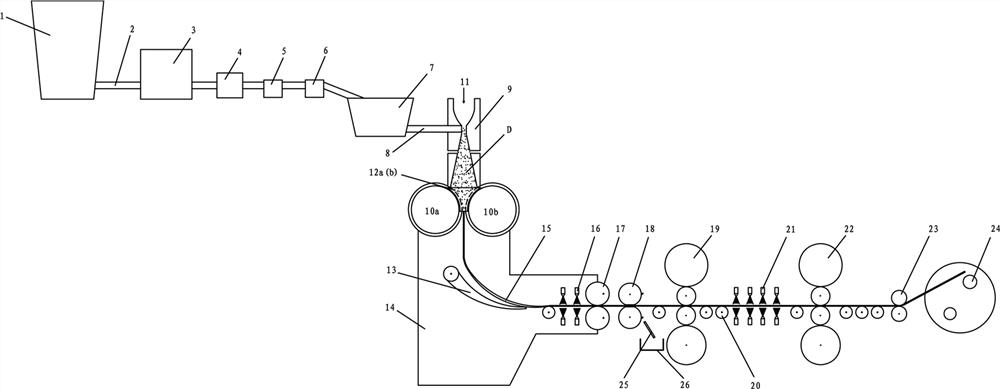

Preparation method of novel 7XXX aluminum alloy thin strip with high performance through jet casting and rolling

The invention relates to a preparation method of a novel 7XXX aluminum alloy thin strip with high performance by jet casting, which comprises the following steps of: 1) smelting according to the following chemical components in percentage by weight: 4.8 to 6.3 percent of Zn, 1.6 to 2.5 percent of Mg, 1.6 to 2.5 percent of Cu, 0.1 to 0.15 percent of Zr and the balance of Al and other inevitable impurities; the single impurity content is less than or equal to 0.1%, and the total impurity content is less than or equal to 0.2 (2) nano-particle enhancement; 3) spray deposition and continuous casting; 4) cooling; 5) primary hot rolling; (6) cooling and secondary hot rolling; (7) coiling; and 8) post-processing. Compared with an existing 7XXX aluminum alloy, the 7XXX aluminum alloy thin strip cast and rolled through the spray deposition combined double-roller thin strip cast rolling technology has the advantages that the strength is improved by 25% or above, and the ductility is improved by 35% or above; compared with a steel plate, the weight is reduced by 50% or more.

Owner:BAOSHAN IRON & STEEL CO LTD

High energy-absorbing aluminum alloy for automobile body

The invention relates to a high-energy-absorptivity aluminum alloy for automobile bodies, which comprises the following components in percentage by weight: 0.56%-0.64% of Mg, 0.42%-0.50% of Si, 0.17%-0.19% of Cu, 0.20%-0.22% of Fe, 0.028%-0.032% of Mn, 0.028%-0.032% of Cr, 0.028%-0.032% of Zn, 0.29%-0.31% of Ti, 0.29%-0.31% of Zr and the balance of Al. The preparation method comprises the following steps: preparing components according to weight percents, melting by heating to 740-750 DEG C, cooling, standing,, refining, and casting into a 250-300 DEG C iron mold; and carrying out homogenizing treatment on the cast ingot at 560 DEG C for 9 hours, quickly cooling with water, heating, extruding, carrying out water or fog quenching, and carrying out artificial aging at 180 DEG C. The invention has the advantages of reasonable component proportion, simple operating technique and favorable hot extrusion formability.

Owner:HUNAN UNIV

High-heat-strength aluminum-silicon alloy material and manufacturing method thereof

InactiveCN113502417APinned wellInhibition of recrystallization behaviorSilicon alloyUltimate tensile strength

The invention discloses a high-heat-strength aluminum-silicon alloy material and a manufacturing method thereof. According to the technical scheme, the high-heat-strength aluminum-silicon alloy material is characterized by comprising, by mass, 8.5%-10% of Si, 3.0%-4.5% of Cu, 2.0%-3.0% of Ni, 1.0%-2.5% of Mg, 0.05%-0.3% of Zr, 0.05%-0.3% of Ti, 0.05%-0.3% of Er, 0.05%-0.23% of Pt and the balance Al. The high-heat-strength aluminum-silicon alloy material has the advantages that the better high-temperature creep resistance and the better high heat strength are achieved, grains are refined, and the metallographic structure is more uniform.

Owner:江苏华星机电制造有限公司

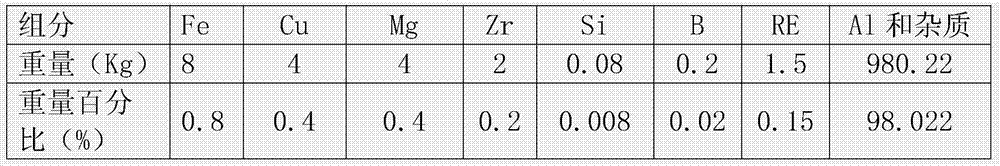

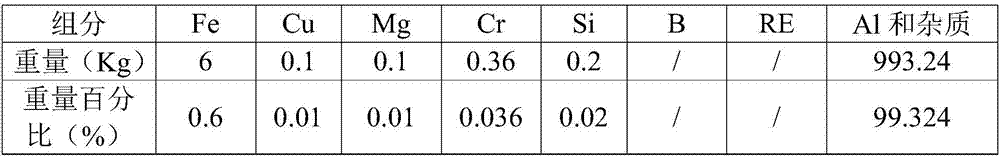

Al‑fe‑cu‑mg‑cr aluminum alloy and aluminum alloy cables for coal mine cables

ActiveCN104294096BExtended service lifeImprove performanceConductive materialMetal/alloy conductorsAdditive ingredientHigh conductivity

The invention discloses an Al-Fe-Cu-Mg-Cr series aluminum alloy for cables for coal mines and an aluminum alloy cable. The aluminum alloy contains the ingredients in percentage by weight: 0.2-1.1% of Fe, 0.01-0.4% of Cu, 0.001-0.4% of Mg, 0.005-0.2% of Cr, 0-0.1% of Si, 0-0.2% of B and the balance of Al and impurities. The aluminum alloy cable is produced through enabling the aluminum alloy to be subjected to the processes of melting, casting and rolling, so as to obtain aluminum alloy rods, then, carrying out drawing, stranding and softening, so as to form aluminum alloy wire cores, and then, carrying out extruded insulation, cabling and extruded sheathing or armoring on the conductor wire cores. The Al-Fe-Cu-Mg-Cr series aluminum alloy for the cables for the coal mines, disclosed by the invention, has the characteristics of high strength, high conductivity, good bending property and the like; the aluminum alloy cable produced from the aluminum alloy can meet the requirements on the properties of the cable in the field of the coal mines.

Owner:安徽中青欣意铝合金电缆有限公司

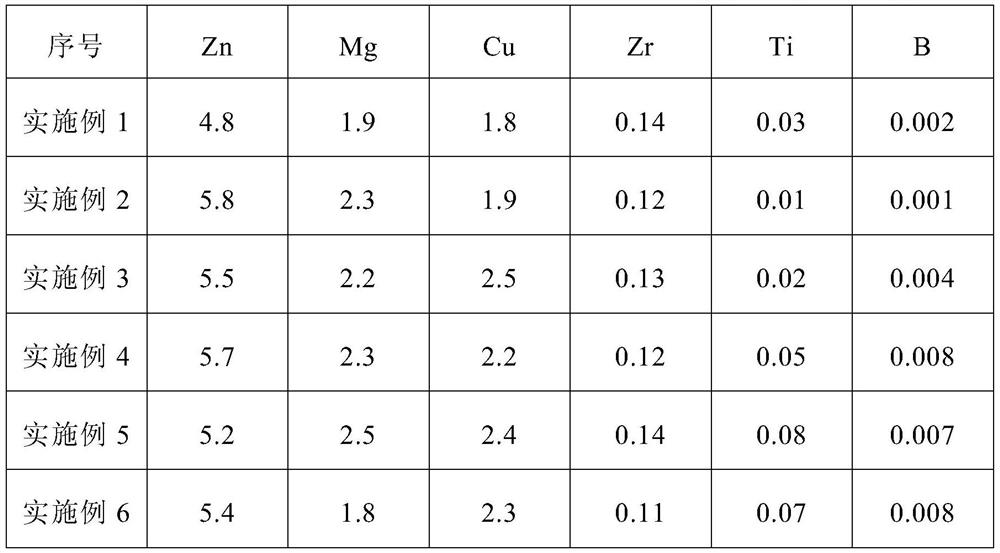

Novel 7XXX aluminum alloy thin strip for thin strip continuous casting and preparation method of novel 7XXX aluminum alloy thin strip

The invention relates to a strip continuous casting novel 7XXX aluminum alloy strip and a preparation method thereof, the aluminum alloy comprises the following components by mass percent: 4.8-6.3% of Zn, 1.6-2.5% of Mg, 1.6-2.5% of Cu, 0.1-0.15% of Zr, 0.01-0.08% of Ti, 0.001-0.008% of B, and the balance of Al and other inevitable impurities, the single impurity content is less than or equal to 0.1%, and the total impurity content is less than or equal to 0.2%. The aluminum alloy thin strip is prepared through the double-roller thin strip continuous casting technology, the microscopic structure of the aluminum alloy thin strip is a fine equiaxed crystal matrix structure, and compared with an existing 7XXX aluminum alloy, the strength of the aluminum alloy thin strip is improved by 10% or above, and the ductility of the aluminum alloy thin strip is improved by 20% or above; compared with a steel plate, the weight is reduced by 30% or more. The material can be widely applied to the field of aerospace, such as various aircraft fuselages, wing beams, cabin wallboards, aircraft high-stress structural parts, aircraft skins, high-strength structural parts in aircraft rockets and the like, and can provide a wide space for aerospace high reinforcement, light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

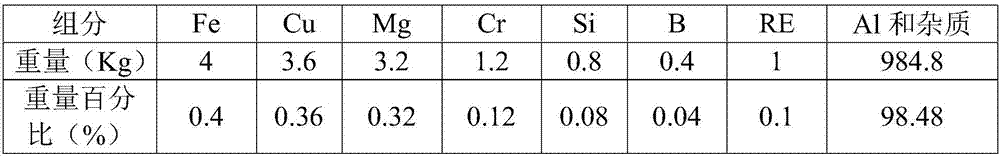

al‑fe‑cu‑mg‑mn series aluminum alloy and aluminum alloy cable for coal mine cables

ActiveCN104299669BExtended service lifeImprove performanceNon-insulated conductorsMetal/alloy conductorsElectrical conductorMaterials science

The invention discloses an Al-Fe-Cu-Mg-Mn series aluminum alloy and an aluminum alloy cable for coal mine cables, wherein the components included in the aluminum alloy material and the weight percentages of each component are as follows: Fe: 0.2-1.1% ; Cu: 0.01-0.4%; Mg: 0.01-0.4%; Mn: 0.001-0.1%; Si: 0-0.1%; B: 0-0.2%; the balance is Al and impurities; , casting, and rolling processes to obtain aluminum alloy rods, which are then drawn, stranded, and softened to form aluminum alloy cores, and then the conductor cores are made into aluminum alloy rods through extrusion insulation, cable formation, extrusion sheathing or armoring. alloy cable. The Al-Fe-Cu-Mg-Mn series aluminum alloy used for the coal mine cable has the characteristics of high strength, high electrical conductivity, and good bending performance; the aluminum alloy cable made of this aluminum alloy can meet the performance requirements of the cable in the coal mine field Require.

Owner:安徽中青欣意铝合金电缆有限公司

Jet cast rolling high-performance 7XXX aluminum alloy thin strip and preparation method thereof

ActiveCN114107764AImprove mechanical propertiesReduced hot cracking tendencyMetal rolling arrangementsNacelleFlight vehicle

The invention relates to a jet cast rolling high-performance 7XXX aluminum alloy thin strip and a preparation method thereof, the aluminum alloy thin strip comprises the following components in percentage by mass: 4.8-6.3% of Zn, 1.6-2.5% of Mg, 1.6-2.5% of Cu, 0.1-0.15% of Zr, 0.01-0.08% of Ti, 0.001-0.008% of B, and the balance of Al and other inevitable impurities, the content of a single impurity is less than or equal to 0.1%, and the content of total impurities is less than or equal to 0.2%. Compared with an existing 7XXX aluminum alloy, the 7XXX aluminum alloy thin strip prepared through the spray deposition and double-roller thin strip cast rolling combined technology has the advantages that the strength is higher by 20% or above, and the ductility is higher by 30% or above; compared with a steel plate, the weight is reduced by more than 40%. The produced aluminum alloy thin strip can be widely applied to the field of aerospace, such as various aircraft fuselages, wing beams, cabin wallboards, aircraft high-stress structural parts, aircraft skins, high-strength structural parts in aircraft rockets and the like, and a wide space can be provided for aerospace high strengthening, light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

Al‑fe‑cu‑mg‑zr aluminum alloy and aluminum alloy cable for coal mine cables

ActiveCN104294089BImprove performanceHigh mechanical strengthFlexible cablesMetal/alloy conductorsElectrical conductorCoal

Owner:林泽民

Preparation method of high-performance novel 7XXX aluminum alloy thin strip

The invention relates to a preparation method of a high-performance novel 7XXX aluminum alloy thin strip, which comprises the following steps of: 1) smelting: smelting according to the following chemical components in percentage by weight: 4.8 to 6.3 percent of Zn, 1.6 to 2.5 percent of Mg, 1.6 to 2.5 percent of Cu, 0.1 to 0.15 percent of Zr and the balance of Al and other inevitable impurities; the single impurity content is less than or equal to 0.1%, and the total impurity content is less than or equal to 0.2 (2) carrying out semi-solid treatment and nano-particle enhancement; 3) continuous casting; 4) cooling; 5) primary hot rolling; (6) cooling and secondary hot rolling; (7) coiling; and 8) post-processing. The microstructure of the 7XXX aluminum alloy thin strip prepared through the method is a fine isometric crystal matrix structure and dispersively distributed hard particles, and compared with an existing 7XXX aluminum alloy, the strength of the 7XXX aluminum alloy thin strip is improved by 25% or above, and the ductility of the 7XXX aluminum alloy thin strip is improved by 35% or above; compared with a steel plate, the weight is reduced by 50% or more.

Owner:BAOSHAN IRON & STEEL CO LTD

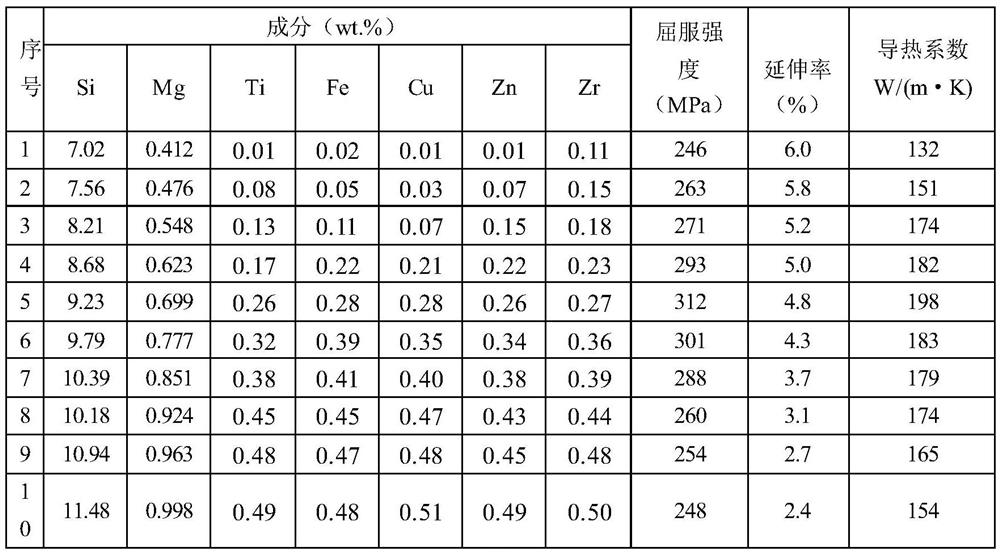

A semi-solid aluminum alloy material suitable for new energy vehicle battery packs and its preparation method

The invention belongs to the technical field of aluminum alloys, and in particular relates to a semi-solid aluminum alloy material suitable for new energy vehicle battery packs and a preparation method thereof. The alloy includes Si: 7.0wt%-11.5wt%; Mg: 0.4wt%- 1.0wt%; Zr: 0.1wt%‑0.5wt%; Ti: <0.5wt%; B<0.5wt%; Fe: <0.5wt%; Cu<0.5wt%; 0.05wt% or less, and the balance is Al. Compared with the prior art, the present invention selects Zr, Ti and B elements to be doped into the aluminum alloy, utilizes the properties of the Zr, Ti and B elements, greatly improves the mechanical properties of the semi-solid aluminum alloy material, and makes the yield strength of the material Reach 240-310MPa.

Owner:苏州慧驰轻合金精密成型科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com