Energy absorption aluminum profile for railway vehicle body and manufacturing method thereof

A technology for rail vehicles and aluminum profiles, applied in the field of Al-Mg-Si new energy-absorbing aluminum alloy profiles containing element V and its preparation, can solve the problems of secondary injury to passengers, poor energy-absorbing effect, and easy tearing, etc. Achieve the effects of inhibiting grain growth, improving energy absorption characteristics, and refining the casting structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

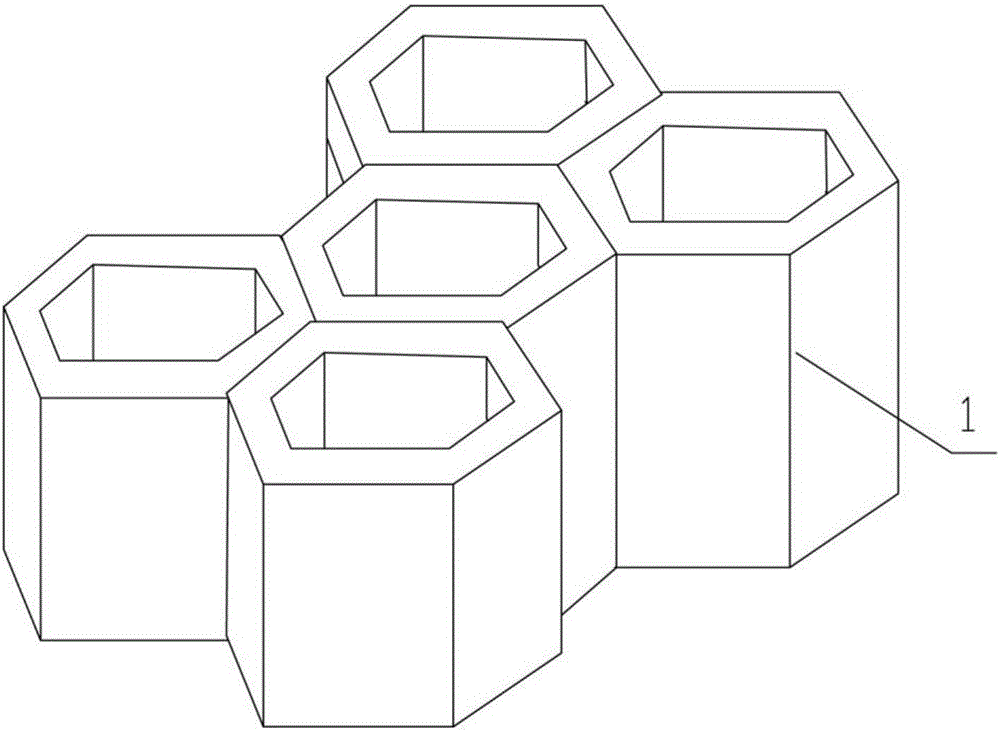

Image

Examples

Embodiment 1

[0026] Example 1: 0.5% Si, 0.15% Fe, 0.4% Mg, 0.2% Mn, 0.01% Cu, 0.1% Cr, 0.01% Zn, 0.04% Ti, 0.04% V, and The amount is Al.

Embodiment 2

[0027] Example 2: 0.6% Si, 0.1% Fe, 0.5% Mg, 0.25% Mn, 0.005% Cu, 0.15% Cr, 0.005% Zn, 0.05% Ti, 0.06% V, and The amount is Al.

Embodiment 3

[0028] Example 3: 0.7% Si, 0.15% Fe, 0.6% Mg, 0.3% Mn, 0.01% Cu, 0.2% Cr, 0.01% Zn, 0.06% Ti, 0.1% V, and The amount is Al.

[0029] In the energy-absorbing aluminum profile of the present invention, by adding 0.04%-0.1% V element to the energy-absorbing aluminum profile, the columnar crystal structure of the ingot can be reduced, the casting structure can be refined, and at a relatively high solution treatment temperature, Fine VAl can be precipitated 11 These dispersed phases have high density and high thermal stability, pinning dislocations and grain boundaries during alloy heat treatment and thermal deformation, hindering dislocation rearrangement and grain boundary migration, and inhibiting recrystallization of deformed grains and The role of recrystallization grain growth achieves the purpose of refining the structure of the profile, so that the strength and toughness of the ingot can be improved, the plasticity and corrosion resistance can be improved, and the energy a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com