Al‑fe‑cu‑mg‑zr aluminum alloy and aluminum alloy cable for coal mine cables

A technology of aluminum alloy and aluminum alloy wire, which is applied in the field of coal mine cables, can solve the problems that the electrical conductivity and mechanical strength properties cannot meet the requirements of coal mine cables, and the mechanical properties and corrosion resistance are poor, so as to improve the mechanical strength and tensile properties, Improvement of yield strength and elongation, effect of modified fatigue resistance bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In the present invention, the preparation method of the aluminum alloy conductor wire core used in the aluminum alloy cable for coal mine comprises the following steps:

[0036] a. Obtain casting materials by casting molten aluminum alloys: add the aluminum alloy components mentioned in the present invention in proportion, carry out the smelting process at 700-800°C, and then cast at 650-680°C to obtain cast ingot;

[0037] b. Solid solution treating the ingot obtained in step a for 2-6 hours in the range of 460-550°C, and then rapidly quenching in cooling water at 20-100°C;

[0038] c. aging the ingot obtained in step b for 6-10 hours in the range of 150-250°C, then heating up to 300-400°C, and rolling it into an alloy rod;

[0039] d. In the range of 280-300 ° C, the alloy rod rolled in step c is subjected to drawing treatment, so that the cross-sectional area is reduced to 50-60% of the cross-sectional area of the alloy rod in step c, and an aluminum alloy wire is...

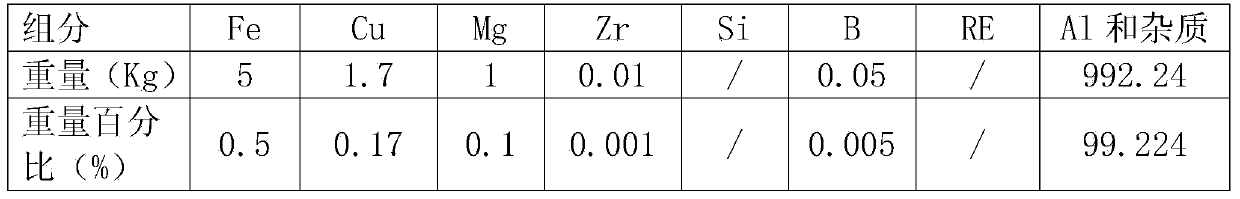

Embodiment 1

[0045] A kind of Al-Fe-Cu-Mg-Zr series aluminum alloy for coal mine cable, the components and the weight percent of each component are as follows (total weight: 1T):

[0046]

[0047] In the above-mentioned aluminum alloy materials, it is preferable to add a certain amount of B. As an aluminum alloy component, B can improve the performance of the alloy, especially the electrical performance and elongation performance, and the performance of the alloy can be guaranteed through a reasonable ratio of each component.

[0048] The method for preparing an aluminum alloy conductor core by using the above-mentioned aluminum alloy material, the specific steps are as follows:

[0049] a. Casting molten aluminum alloys to obtain casting materials: adding the above-mentioned aluminum alloy components according to the above ratios, performing a melting process at 700°C, and then casting at 650°C to obtain ingots;

[0050] b. Solid solution treating the ingot obtained in step a for 3 hou...

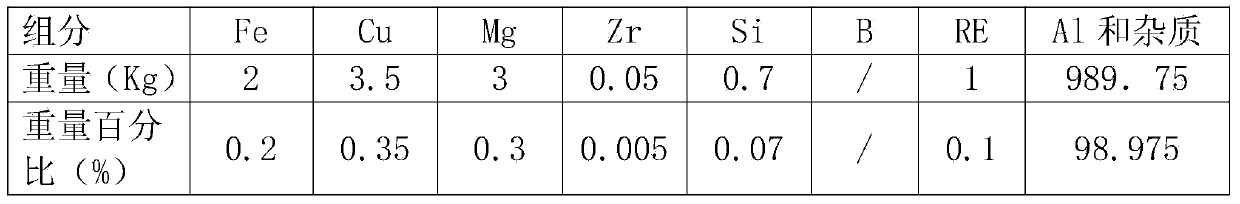

Embodiment 2

[0062] An aluminum alloy for coal mine cables, the components and the weight percentages of each component are as follows (total weight: 1T):

[0063]

[0064] In the above aluminum alloy materials, a certain amount of Si and rare earth elements are added, Mg and Si interact to form a MgSi strengthening phase, increase the recrystallization temperature and change the aging behavior, so that the recrystallized grains of the product can be further refined, and the strength and toughness can be improved. Improvement, plasticity and corrosion resistance are improved, yield strength and elongation of aluminum alloy are increased, reprocessing of aluminum alloy products is avoided, production efficiency is improved, and production cost is reduced.

[0065] Rare earth elements can not only significantly improve the electrical properties of the alloy, but also have the effect of improving the fatigue resistance and bending performance of the alloy, prolonging the service life of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com