In-situ self-generated TiB2 whisker-reinforced TiAl-based composite material and preparation method thereof

A composite material and in-situ technology, which is applied in the field of preparation of TiAl alloys and composite materials with TiAl alloys as the matrix, can solve the problems of reduced room temperature plasticity, reduced performance of composite materials, difficulty in preparing TiAl matrix composite materials, etc., and achieves good room temperature. The effect of plasticity, excellent high temperature creep resistance, and excellent high temperature durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] TiB of this embodiment 1 2 / TiAl composites were prepared by the following steps:

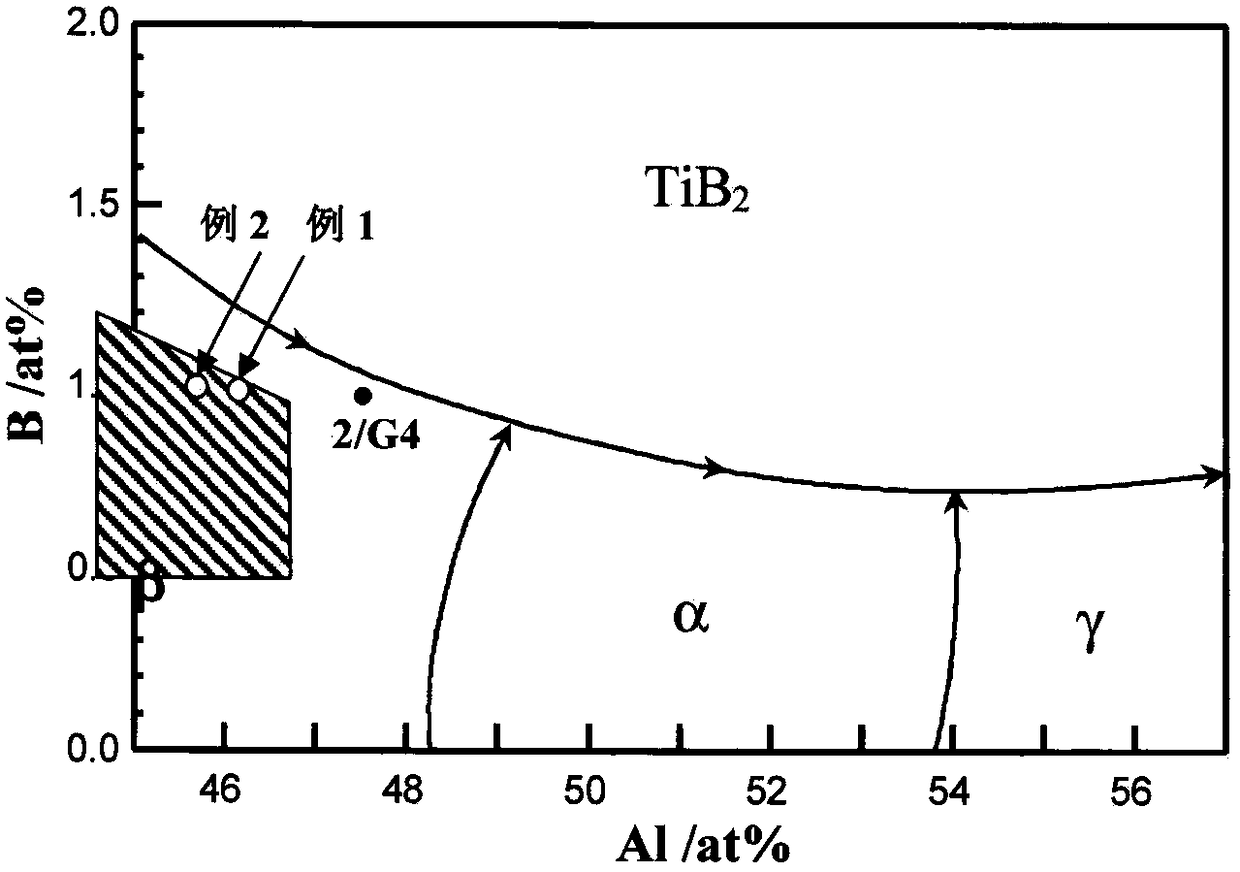

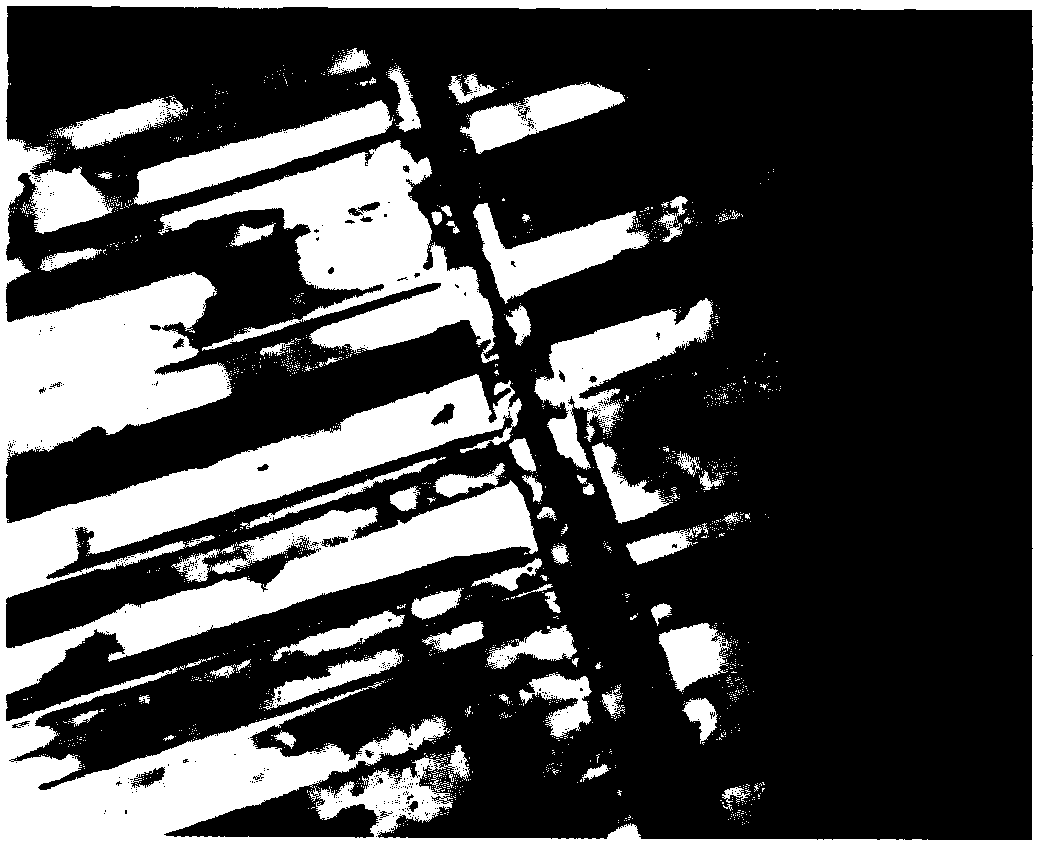

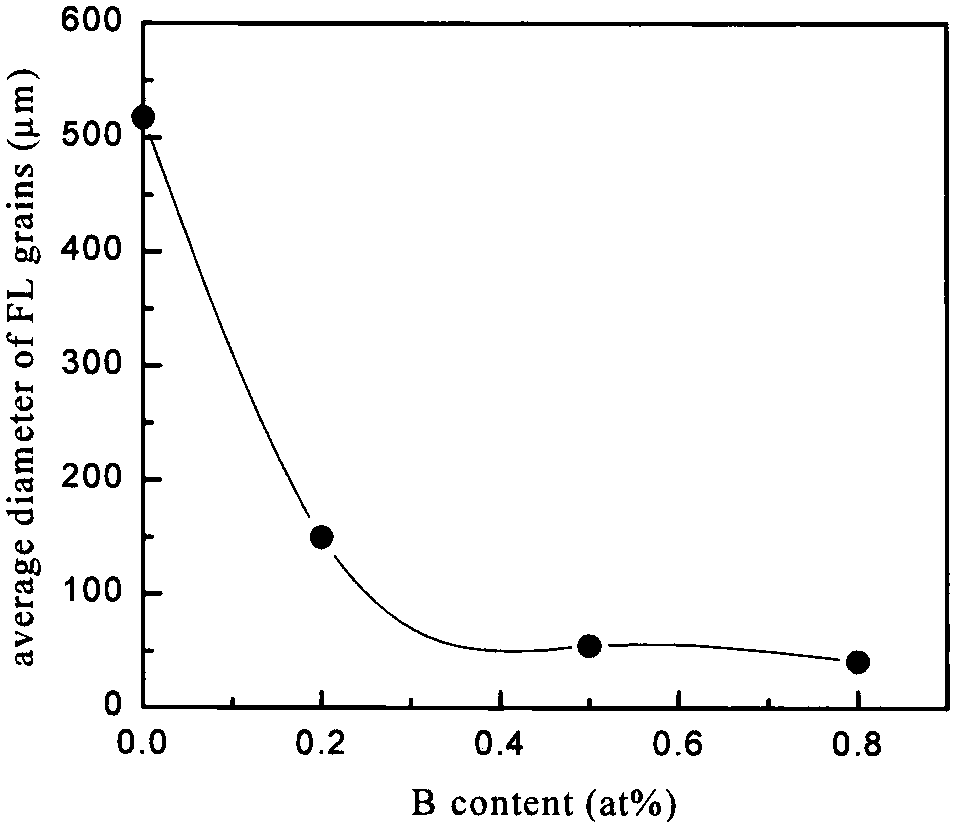

[0052] 1. TiB 2 The / TiAl composite material uses zero-grade sponge titanium, A00-grade high-purity aluminum, metal Cr, Al-Nb master alloy, Al-W master alloy, Al-Si master alloy and boron powder as raw materials. Contains by atomic percentage: 47.5% Al, 1% Cr, 4% Nb, 0.2% W, 0.2% Si, 1% B, and the rest is Ti. The Al content and B content of the composite material in this example fall in figure 1 In the shaded part, the composition range defined by formula (1) is satisfied, so TiB can be generated in situ 2 whiskers, see Figure 4 shown.

[0053] 2. After mixing the raw materials evenly, press them into an electrode block on a press. After the electrode block is welded, the first melting is carried out in a vacuum consumable melting furnace, the melting vacuum is lower than 5Pa, the melting current is 1.5KA, the melting voltage is 24V, and the primary ingot with a diameter of Φ100mm...

Embodiment 2

[0059] TiB of this embodiment 2 2 / TiAl composites were prepared by the following steps:

[0060] 1. TiB 2 / TiAl composite material uses zero-grade sponge titanium, A00 grade high-purity aluminum, metal Cr, Al-Nb master alloy and boron powder as raw materials. Contains by atomic percentage: 47% Al, 2% Cr, 2% Nb, 1% B, and the rest is Ti. The Al content and B content of the composite material in this example fall in figure 1 In the shaded part, the composition range defined by formula (1) is satisfied.

[0061] 2. After mixing the raw materials evenly, press them into an electrode block on a press. After the electrode blocks are welded, the first melting is carried out in a vacuum consumable melting furnace, the melting vacuum is lower than 5Pa, the melting current is 3.5KA, the melting voltage is 25V, and a primary ingot with a diameter of Φ220mm is melted.

[0062] 3. Put TiB 2The primary ingot of / TiAl composite material is placed in a vacuum consumable solidification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com