Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108results about How to "Good plasticity at room temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature resistant titanium and aluminum based alloy and manufacturing method thereof

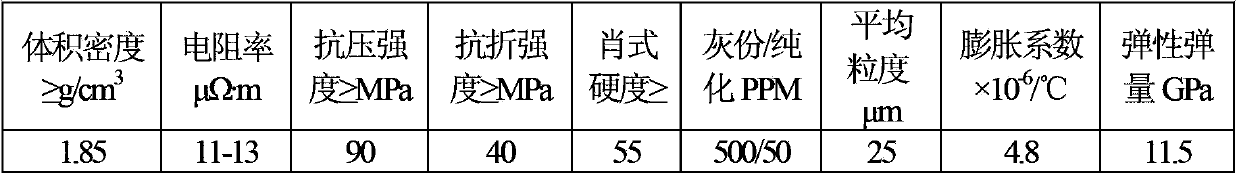

The invention provides a high temperature resistant titanium-aluminium base alloy and a method for preparing the same, wherein, the alloy which belongs to gamma-TiAl alloy has components of Al of 44.0-48.0at%, Nb of 3.0-5.0at%, Cr of 0.2-2.0at%, Ni of 0.1-0.8at%, Si of 0-0.8at% and the rest are Ti and ineluctable impurity elements; the method comprises steps of using titanium sponge, AlNb alloy, AlCr alloy, Ni, Al and Si as the raw material, smelting, casting and shaping the raw material in a vacuum consumable electrode electrical arc skull crucible or a vacuum induction furnace, and when the casting process is performed, Ti-Al alloy casting ingot can be casted after vacuum melting or be casted after argon-filling smelting.The alloy of the invention has characteristics of favorable room-temperature plasticity, creep-resistance capability and anti-oxygenic property, can be used under a temperature of 800-900 DEG C, is suitable for the casting of parts with thin walls, can improve the use characteristics of aircraft engines and car engines, and has a wide market outlook.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Molten salt corrosion resistant nickel-based superalloy with excellent performance

ActiveCN103966476AImproved resistance to molten salt corrosionImprove durabilityNuclear reactorMetallic materials

Belonging to the technical field of metal materials, the invention discloses a molten salt corrosion resistant nickel-based superalloy with excellent performance. In terms of weight percentage, the alloy comprises: less than or equal to 0.08% of C (preferably in the range of 0.03-0.06%), 0.5-5% of Fe, 6.0-8.0% of Cr, 12-18% of Mo, less than or equal to 2% of Ta, less than or equal to 2% of Ti, less than or equal to 2% of Nb, and the balance Ni, wherein the sum of Ti, Nb and Ta is greater than or equal to 1% and less than or equal to 2%. In addition to excellent room temperature plasticity, high temperature structure stability and high mechanical properties under high temperature, the alloy also has good resistance to molten salt corrosion, and can meet the use demands of molten salts and irradiation environments with high use temperature and performance requirements. Thus, the molten salt corrosion resistant nickel-based superalloy is suitable for high-temperature structural materials of molten salt nuclear reactors.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Composite heat-resisting enhance titanium alloy

InactiveCN101074464AImprove high temperature strengthImprove creep resistanceThermal stabilityUltimate tensile strength

Owner:浙江嘉钛金属科技有限公司

Nickel-copper alloy liquid for chemical plating and electroplating and method for preparing nickel-copper alloy noncrystalline-based composite coating

ActiveCN102703887AImprove performanceImprove wear resistanceLiquid/solution decomposition chemical coatingChemical platingNickel salt

The invention provides nickel-copper alloy liquid for chemical plating and electroplating. The nickel-copper alloy liquid for the chemical plating and the electroplating comprises 1-10g / L of copper salt, 20-60g / L of nickel salt, 10-20g / L of complexing agent and 1-10g / L of reducing agent by taking deionized water as a solvent. By using the nickel-copper alloy liquid, a nickel-copper alloy composite coating is prepared on the surface of a metal base by adopting a method of chemical plating and electroplating synergetic deposition. The coating not only is of a nanocrystalline structure but also is of a noncrystalline structure, and moreover, nanocrystallines are evenly distributed in a noncrystalline continuous phase. The coating is a nickel-copper alloy noncrystalline-based composite coating. The nickel-copper alloy noncrystalline-based composite coating has the properties of the noncrystalline structure and the crystalline structure, thus, the combination property of the coating is obviously improved, such as corrosion resistance, wear resistance, high strength, high hardness and excellent room-temperature ductility, and the application range of a metal matrix is greatly broadened.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Tungsten carbide material with Ni3Al as cementing phase and preparation thereof

InactiveCN101323925AReduce material costsLow priceIncreasing energy efficiencyCobaltConstant current

The invention relates to a plastic forming technique and a powder metallurgy technique and provides a tungsten carbide material which adopts Ni3Al as binder phase and a preparation method thereof. The tungsten carbide material adopts toughening intermetallic compound Ni3Al to substitute cobalt with traditional binder phase and contains the following components according to mass percentage: 86 to 95 percent of WC, 5 to 14 percent of toughening Ni3Al. The preparation method comprises the steps: ball grinding is carried out to the raw materials according to the percentages until the size of WC powder crystal grain is thinned to be less than 100nm; current rapid sintering method is adopted to form solidified ball grinding powder, and the conditions of current rapid sintering process are as follows: types of sintering current: square wave pulsed current or constant current; sintering pressure: 10MPa to 50MPa; sintering time: 2 to 8 minutes. The plastic forming technique, the powder metallurgy technique and the tungsten carbide material of the invention can not only save strategic material cobalt, reduce material cost, but also effectively improve the performance of high temperature resistant and corrosion resistant performance of the material and have good promotion and application prospect.

Owner:SOUTH CHINA UNIV OF TECH

TiAl-based composite material and thermal mechanical treatment method thereof

PendingCN110643851AThere is no interface reaction problemImprove thermal processing performancePlastic propertyPosterior composites

The invention relates to a TiAl-based composite material enhanced by a TiB2 crystal whisker self-generated in situ as well as a thermal mechanical treatment method thereof. A proper amount of elementB is added in TiAl alloy according to an element B adding control quantity calculation formula, a slight secondary TiB2 crystal whisker is self-generated in situ through eutectic reaction of L->beta+TiB2 and L+beta->alpha+TiB2 and generation of thick granular primary TiB2 phase is avoided, so that the TiB2 crystal whisker enhanced TiAl-based composite material can be prepared by a ingot metallurgymethod. Then, the TiB2 / TiAl composite material can be prepared into a thin crystal bar material or a thin crystal cake blank through package sheathing hot extrusion or package sheathing forging, theslight TiB2 crystal whisker is crushed into short crystal whiskers, and a thin crystal mesh basket-shaped tissue or a thin crystal full-slice-sheet tissue can be obtained through treatment by a special heat treatment process. The TiB2 / TiAl composite material has high strength from room temperature to high temperature (850 DEG C) and has excellent room-temperature plasticity, so the TiB2 / TiAl composite material has good prospect in the field of aerospace.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

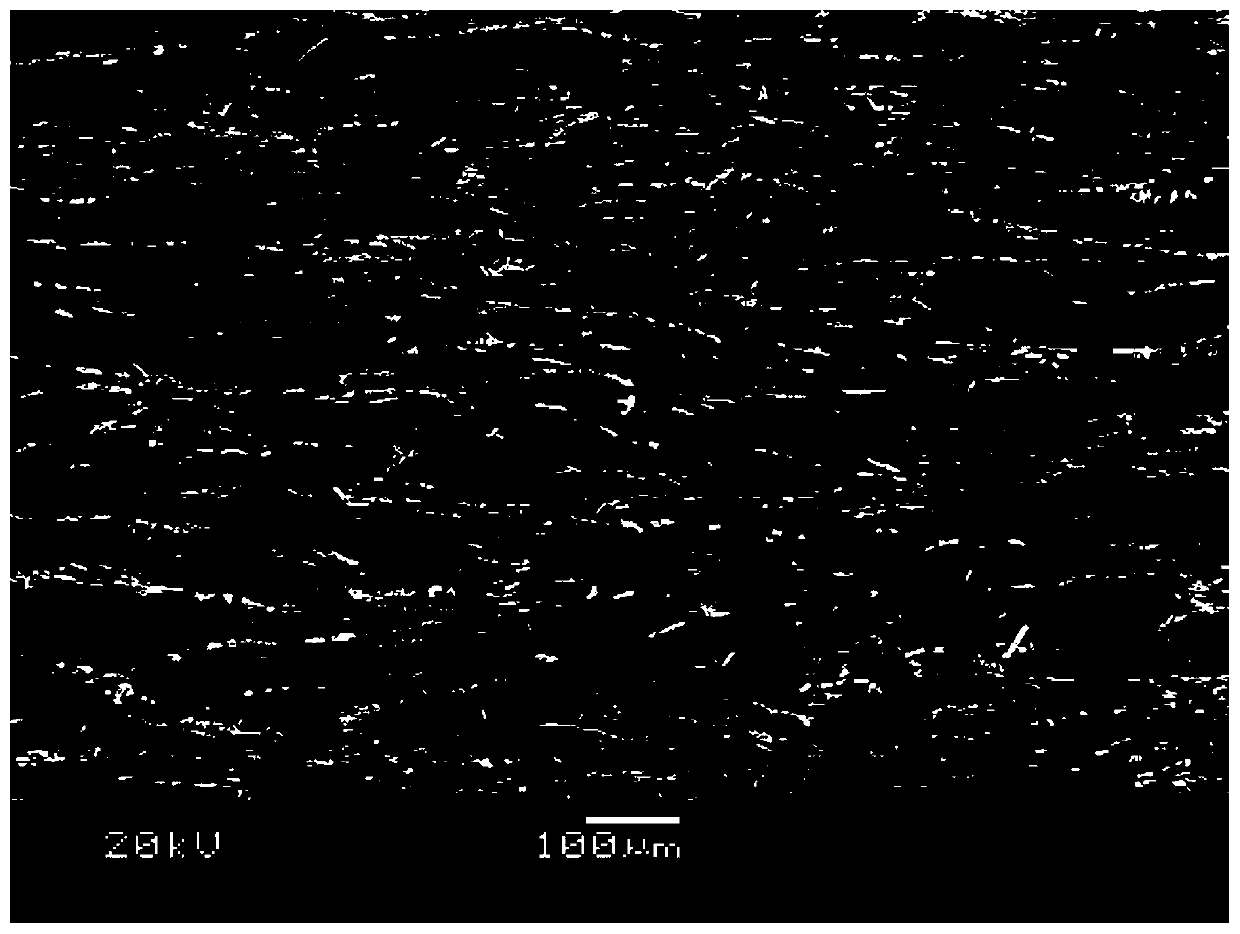

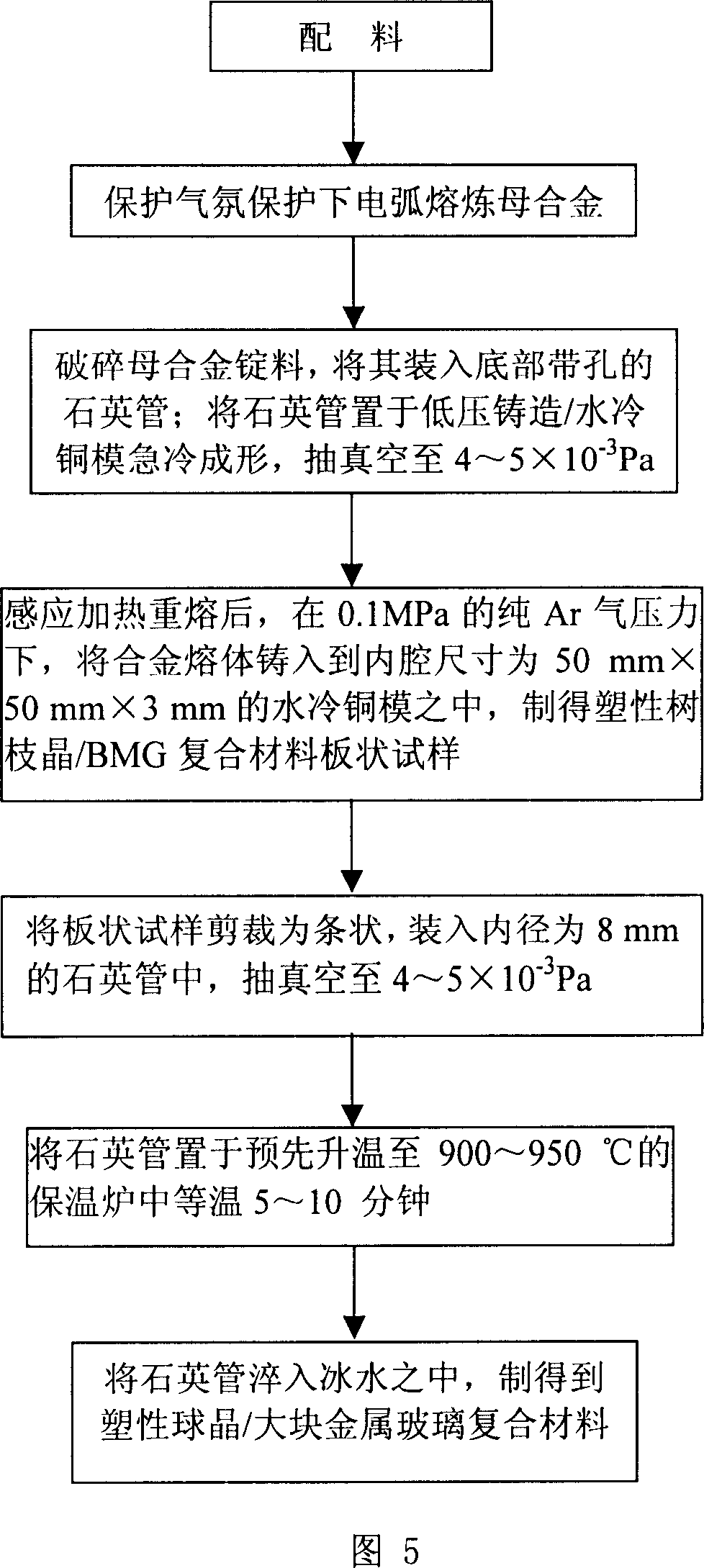

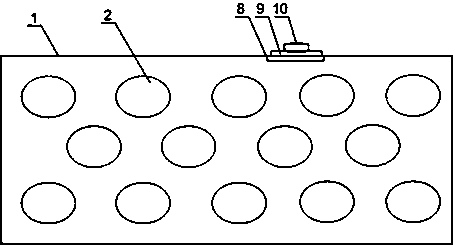

Method for branch crystal balling in large block metal glass composite

This invention relates to the method for producing plastification geode / massive metal glass composite material. The steps are: first, selecting alloy components having strong glass formation ability, regulating the components to make them offset eutectic point, and solid solution phase being separated earlier; second, the components being smelted under shield gas, then producing foundry alloy ingot; then, said ingots being broken, resmelted, subjected to low pressure casting / water-cooling copper mould quick cooling formation to produce branch like crystal / massive metal glass composite material sheet, finally, said sheet being subjected to isothermal treatment and then water-quenching to produce this invented product. The plastificiation beta phase is no longer having branch like shape but having ball shape.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of amorphous alloy gradient composite material

ActiveCN112935251AEasy to manufactureSimple processImage analysisChemical processes analysis/designNerve networkIsothermal crystallization

The invention belongs to the field of amorphous alloy composite material preparation, and particularly relates to a preparation method of an amorphous alloy gradient composite material. According to the preparation method of the amorphous alloy gradient composite material, an isothermal crystallization rule of an amorphous alloy matrix is obtained through an experiment, and a nonlinear mapping relation between sintering process parameters and reinforcement phase characteristic parameters is established through a neural network; a required temperature field is reversely deduced by combining reinforcement phase distribution characteristics of a target amorphous alloy gradient composite material, and then a sintering mold is designed by taking amorphous alloy powder or a block as a raw material and adopting a spark plasma sintering technology and combining numerical simulation, and spark plasma sintering treatment is carried out on the amorphous alloy powder under the required sintering process parameters and temperature field to obtain the amorphous alloy gradient composite material with continuous gradient distribution of the reinforced phase. According to the preparation method of the amorphous alloy gradient composite material, flexible design and preparation forming of the large-size bulk amorphous alloy gradient composite material can be achieved, the process is simple and efficient, a reinforced phase is obtained in an in-situ endogenous mode, and the interface bonding state is good.

Owner:HUAZHONG UNIV OF SCI & TECH

High-plasticity non-necking high-entropy alloy and preparation method thereof

The invention provides a high-plasticity non-necking high-entropy alloy which is characterized by comprising the element of Co, Fe, Ni, V and Mo in mole percent. The general formula of the high-entropy alloy is CoaFebNicVdMoe, wherein a is equal to 0.5-2.5; b is equal to 0.5-2.5; c is equal to 1.8-2.5; d is equal to 0.2-1.0; and e is equal to 0.2-1.2. The high-entropy alloy is high in plasticity and relatively high in strength within the wide temperature range. The invention further discloses a preparation method of the above high-entropy alloy. The preparation method comprises the following steps in sequence: material blending; preparation before melting; and melting and casting. The high-entropy alloy provided by the invention has the advantage of being high in plasticity and relatively high in strength within the wide temperature range; and the preparation method is easy to operate, safe, reliable, economical and practical.

Owner:DALIAN UNIV OF TECH

TiAl-based alloy material with excellent high-temperature property and preparation method thereof

InactiveCN101948967AGood high temperature performanceHigh temperatureOxidation resistantAluminium alloy

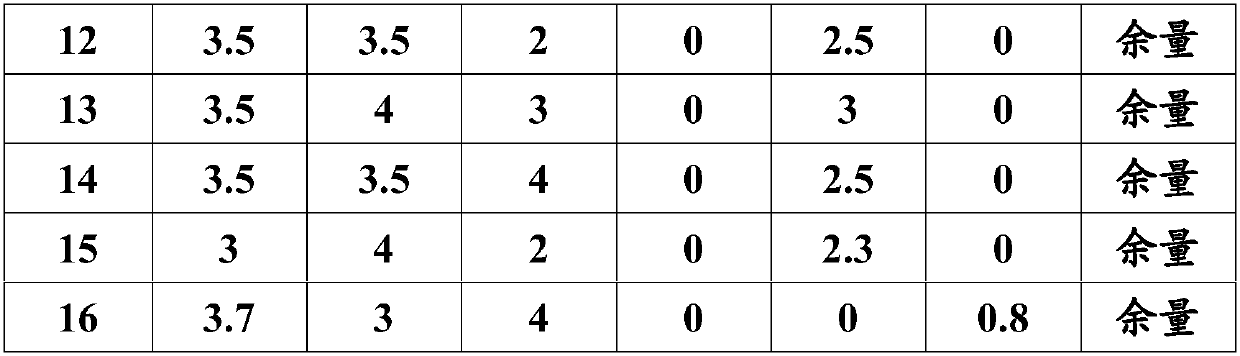

The invention introduces a TiAl-based alloy material with excellent high-temperature property. The TiAl-based alloy belongs to gamma-TiAl alloy and comprises the following chemical compositions in percentage by weight: 44.0 to 48.0 percent of Al, 3.0 to 5.0 percent of Nb, 0.1 to 3.0 percent of Mo, 0 to 0.8 percent of Ni, 0 to 0.8 percent of Si and the balance of Ti and inevitable impurities. A preparation method comprises a step of smelting and casting the materials in a vacuum consumable-electrode arc kish furnace or vacuum induction furnace, wherein a TiAl alloy ingot is subjected to vacuum melting or argon-filling melting first and then is cast in the casting process. Compared with the common TiAl alloy, the TiAl-based alloy material with excellent high-temperature property has higher usage temperature of up to 900 DEG C and has the advantages of good plasticity at room temperature, good creep-deformation resistance and oxidation resistance, good casting property, suitability for casting thin-wall components and great market prospect.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Method for manufacturing high-plasticity/formability deforming magnesium alloy plate

The invention discloses a method for manufacturing a high-plasticity / formability deforming magnesium alloy plate. The method comprises the following steps: a) providing a magnesium alloy composed of 2.5-4.5 wt.% of Zn, 0-0.5 wt.% of Zr, 0-0.3 wt.% of Ca, 0-1.6 wt.% of RE, less than 0.02 wt.% of total impurity elements and the balance of Mg, wherein the RE is selected from one or more of Y, Gd and Nd; b) carrying out low-temperature extrusion on the magnesium alloy, wherein the initial temperature of the magnesium alloy is room temperature to 200 DEG C; c) carrying out multipass cooling asynchronous rolling on the pre-extruded magnesium alloy, wherein the accumulated strain amount is 0.8-3.0; carrying out one-pass cold rolling reshaping; and d) directly carrying out annealing treatment on the rolled magnesium alloy plate, thereby obtaining the high-plasticity / formability deforming magnesium alloy plate.

Owner:HARBIN INST OF TECH AT WEIHAI

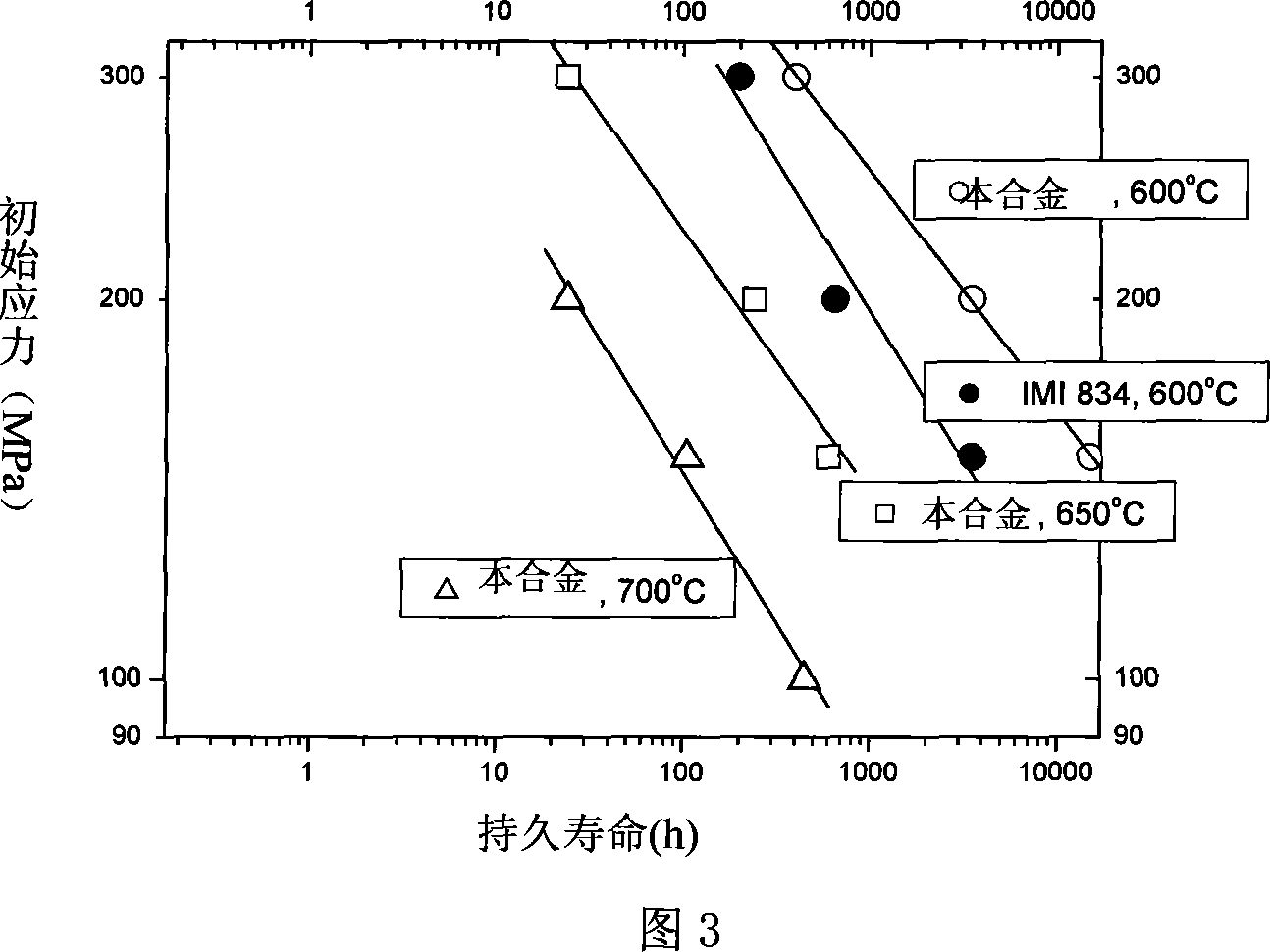

High-temperature titanium alloy

InactiveCN104561656AImprove high temperature strengthImprove solderabilityChemical compositionRoom temperature

The invention discloses high-temperature titanium alloy, which comprises the following chemical components in percentage by weight: 5.5%-7.5% of Al, 1.0%-3.0% of Sn, 3.0%-6.0% of Zr and Hf, 1.5%-3.5% of Mo, 1.5-%4.5% of Nb, 0.3%-0.6% of Si, 0.05%-0.20% of C and the balance of Ti. The equivalent range of the Al in the alloy is 7.97%-9.80%; control on the content of Al, Sn, Zr and O in the alloy can ensure that the equivalent range of the Al in the alloy is 7.97%-9.80%. According to the alloy disclosed by the invention, compound reinforcement is achieved by adding the elements such as Al, Sn, Mo, Zr, Hf, Si and C; the high-temperature tensile strength and the high-temperature large stress lasting strength of the alloy are improved; the room-temperature toughness and plasticity of the alloy are improved by adding a great amount of Nb elements; and the alloy is suitable for application at a high temperature over 650 DEG C from 30 minutes to 20 hours.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High-strength hydrogen-brittleness-resistant austenite alloy with mark of J75 and preparation method of high-strength hydrogen-brittleness-resistant austenite alloy

The invention relates to the field of precipitation strengthening austenite alloy, in particular to high-strength hydrogen-brittleness-resistant austenite alloy with the mark of J75 and a preparation method of the high-strength hydrogen-brittleness-resistant austenite alloy. The high-strength hydrogen-brittleness-resistant austenite alloy comprises, by weight, 0.0008-0.0025% of B, smaller than or equal to 0.020% of C, smaller than or equal to 0.006% of S, smaller than or equal to 0.006% of P, 0.10-0.30% of Si, 29.00-32.00% of Ni, 13.50-16.50% of Cr, 1.00-1.60% of Mo, 0.15-0.35% of V, 1.80-2.40% of Ti, 0.10-0.40% of Al, and the balance Fe. The alloy is formed by forging and / or rolling through vacuum induction and vacuum arc self-consuming smelting, hot-rolled bars with the diameters not larger than 80 mm is not lower than level 6, and hot-rolled bars and forged materials with the diameters larger than 80 mm are not lower than the level 5. The inspection result of bars with the diameters not larger than 65 mm needs to conform to the AA-level specification in GB / T 4162, and the inspection result of bars with the diameters larger than 65 mm needs to conform to the A-level specification in GB / T 4162.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Thermo-hydrogen processing technology for improving room temperature plasticity of TC21 titanium alloy

The invention discloses a thermo-hydrogen processing technology for improving room temperature plasticity of TC21 titanium alloy. The thermo-hydrogen processing technology is characterized in that a TC21 sample is put into a furnace tube of a tubular furnace, the surface of the TC21 sample is covered by a layer of titanium scraps to prevent the TC21 sample from being oxidized, vacuum pumping is conducted, when the vacuum degree in the furnace tube is lower than 1*10-3 Pa, the furnace tube is heated, the temperature is increased to 750 DEG C, nitrogen is led into the furnace tube, the nitrogen pressure in the furnace tube is stabilized to 15-25 kPa, the temperature is preserved for 1-2 hours, the furnace tube is pulled out from the furnace and naturally cooled to the room temperature, and the TC21 sample in the furnace tube is taken out.

Owner:HEFEI UNIV OF TECH

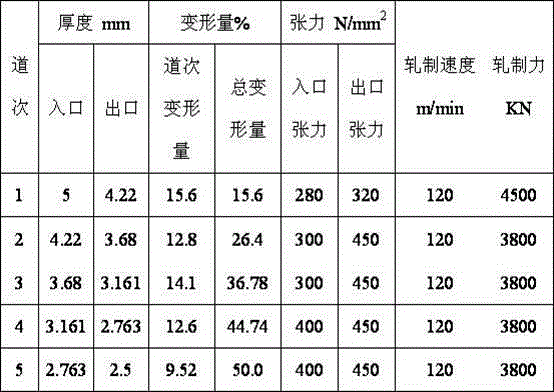

Wide pure-nickel strip cold-rolling process

InactiveCN104998902AOptimized rolling processReduce deformation resistanceRoll force/gap control deviceTension/compression control deviceMaterials scienceRolling mill

The invention discloses a wide pure-nickel strip cold-rolling process. The wide pure-nickel strip cold-rolling process is characterized in that an annealed pure-nickel strip with a thickness of 4-6.0 mm is rolled by 5-10 passes to a target thickness of 0.8-2.5 mm by adopting a twenty-roll reversible type cold-rolling mill unit, wherein the rolling force is 3000-8000 KN; the deformation per pass is 8%-30%; the deformation at next pass is 75%-94% of the deformation at the last pass; the rolling speed is kept at 30-120m / min; and outlet tension is 1.1-1.5 times inlet tension. According to the wide pure-nickel strip cold-rolling process, in the rolling process, proportion of front and back tension and changes of rolling force are strictly controlled; the deformation per pass is controlled to 8%-30%; difference of rolling force between passes is within 800 KN; the strip shape and the thickness can be controlled very well; and the nickel strip which is 1300-1400 mm wide can still obtain good strip shape without strip breakage even the thickness of the nickel strip is reduced after multi-pass rolling.

Owner:BAOJI TITANIUM IND

Low-cost high-speed-extruded magnesium alloy material and preparation process thereof

The invention discloses a low-cost high-speed-extruded magnesium alloy material and a preparation process thereof and belongs to the technical field of metal materials. The extruded material comprises the following chemical components by weight percent: 0.1-0.9% of Zn, 0.1-0.5% of Ca, 0-0.5% of Mn and the balance Mg and inevitable impurities, wherein the total content of the alloy elements (Zn, Ca and Mn) does not exceed 1.5 wt%. Production is performed at the extrusion outlet speed of more than or equal to 24 m / min, the extrusion production efficiency is high, the cost of the extruded material is lowered, the extruded material is smooth in surface and has no surface cracks, and therefore, the yield of the extruded material is guaranteed; and meanwhile, the extruded material has a weak non-basal texture with the maximum density value of less than or equal to 4. The extruded material is low in content of alloy elements, does not contain rare earth elements or other noble metal elements, and therefore, is low in cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of TC16 titanium alloy wire with superfine grain structures

The invention relates to a preparation method of a TC16 titanium alloy wire with superfine grain structures. The method comprises the following steps: carrying out surface treatment on a TC16 titaniumalloy wire blank, the alpha phase and beta phase dimensions of which are about 1-2[mu]m, after hot working deformation; and carrying out multi-pass room temperature roll-die drawing deformation withthe accumulated deformation reaching 75-90% to obtain the superfine grain TC16 titanium alloy wire, the alpha phase and beta phase average dimensions of which are smaller than 0.5[mu]m. According to the method, phenomena such as restoration and recrystallized softening are seldom generated when the TC16 titanium alloy grains are refined as the alloy is deformed at room temperature, so that the grain refining effect is remarkable. The preparation method provided by the invention is particularly suitable for industrially preparing the superfine wires, is simple in production step and has a goodapplication prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

W-Ta-Mo-Nb-Zr high-temperature high-entropy alloy and preparation method thereof

ActiveCN111235455AOvercoming pollutionSimple preparation stepsHigh entropy alloysUltimate tensile strength

The invention provides a W-Ta-Mo-Nb-Zr high-temperature high-entropy alloy and a preparation method thereof. The high-temperature high-entropy alloy is composed of W, Ta, Mo, Nb and Zr according to anequal or an unequal atomic ratio. The preparation method of the high-temperature high-entropy alloy is further provided and comprises the steps that 1) W, Ta, Mo, Nb and Zr raw materials with the needed weight are weighed; and 2) vacuum electric arc melting is carried out. The W-Ta-Mo-Nb-Zr high-temperature high-entropy alloy prepared through the method can be used for overcoming the strength defect of a nickel-based high-temperature alloy at the temperature of 120 DEG C or above, and replaces the nickel-based high-temperature alloy to be used for the field of high-temperature structures.

Owner:NAT INNOVATION INST OF DEFENSE TECH PLA ACAD OF MILITARY SCI +1

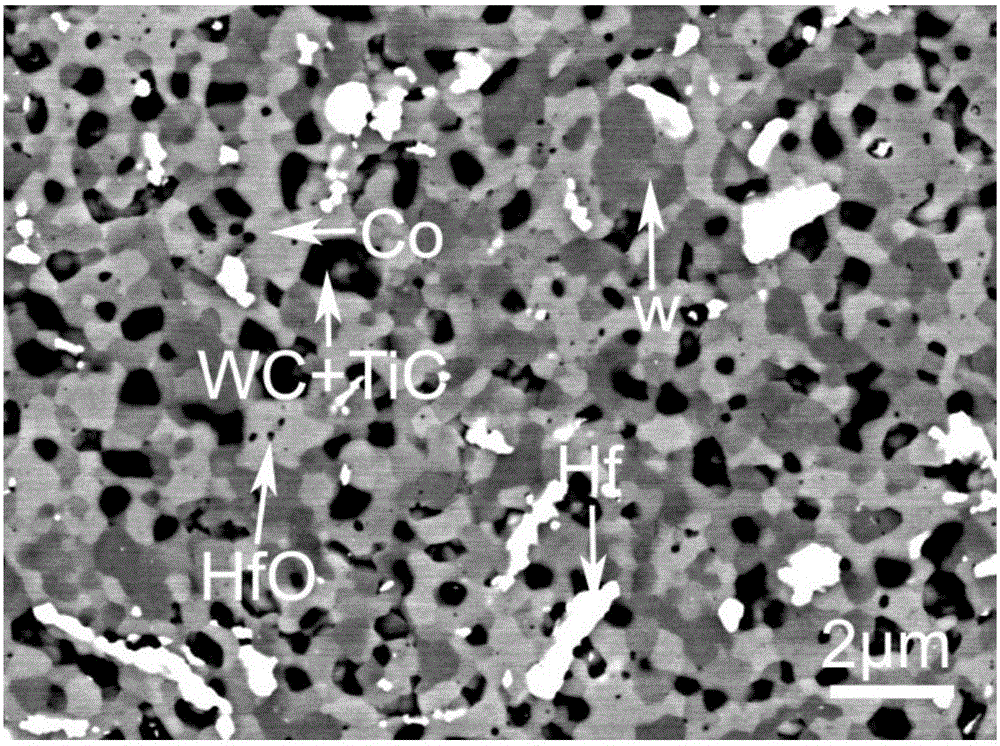

W-WC-TiC-Hf-Co alloy rod and preparation method thereof

The invention discloses a W-WC-TiC-Hf-Co alloy rod and a preparation method thereof, and relates to the technical field of alloy materials. The W-WC-TiC-Hf-Co alloy rod is prepared from the following raw materials in percentage by mass: 1 to 5 percent of WC, 2 to 8 percent of TiC, 1 to 5 percent of Hf, 1 to 5 percent of Co and the balance of W and unavoidable impurities; the preparation method of the W-WC-TiC-Hf-Co alloy rod comprises the following steps: (1) uniformly mixing tungsten powder, tungsten carbide powder, titanium carbide powder, hafnium powder and cobalt powder by adopting a wet ball milling method, and performing vacuum drying to obtain mixed powder; (2) performing vacuum sintering to obtain a sintering body; (3) smelting 2 to 5 times by electron beams to obtain an ingot; (4) performing thermal extruding to obtain a semi-finished rod blank; (5) performing thermal extruding to obtain an alloy rod. The W-WC-TiC-Hf-Co alloy rod disclosed by the invention has high hardness, high strength and excellent comprehensive mechanical properties, and has wide application prospect in aerospace field, national defence industry, electronic information, energy resources and the like.

Owner:XIAN HUASHAN METAL PROD CO LTD

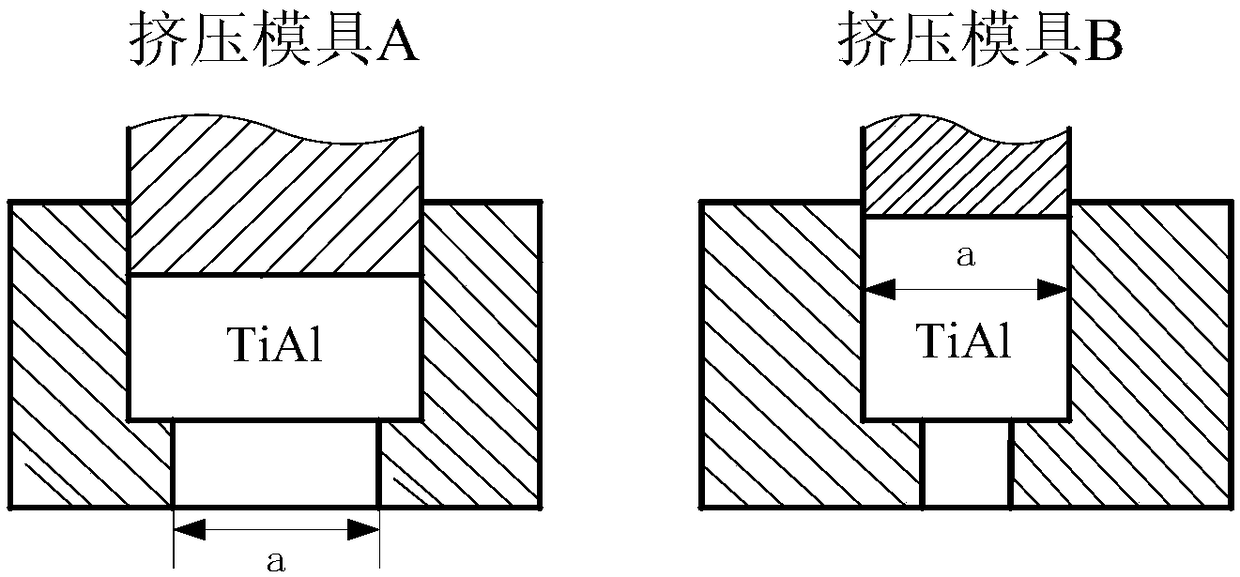

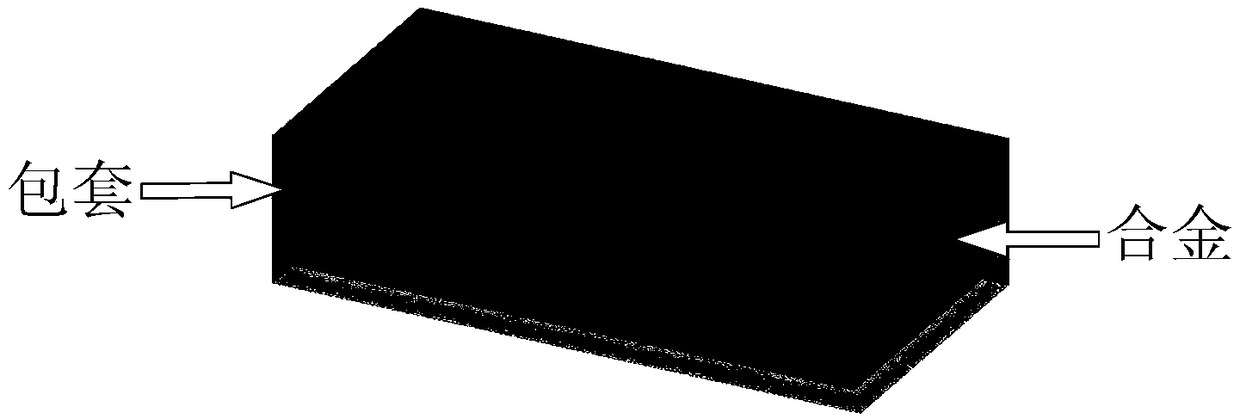

One-step large-deformation rolling method of beta solidification TiAl alloy plate

ActiveCN108787750AAvoid bulkyAvoid small amount of deformation in a single passForging/pressing devicesFurnace typesBeta phaseRoom temperature

The invention provides a one-step large-deformation rolling method of a beta solidification TiAl alloy plate. The method comprises the following steps that 1, raw materials are weighed; 2, a TiAl alloy casted ingot is manufactured by utilizing a vacuum induction melting technology, and heat treatment is carried out; 3, two-step hot extrusion deformation is carried out on the alloy; and 4, one-steplarge-deformation packing rolling is carried out on the alloy, and a pack is removed so as to obtain the TiAl alloy plate which is uniform and fine in structure. According to the one-step large-deformation rolling method of the beta solidification TiAl alloy plate, the beta solidification TiAl alloy with excellent high-temperature deformation capability is adopted, the beta phase content is controlled to be 15%-25%, and the excellent high-temperature deformation capability of the TiAl alloy is ensured; meanwhile, the alloy structure of a blank is refined violently through the two-step extrusion so as to remarkably improve the structure uniformity of the alloy, and therefore, one-step large-deformation rolling of the blank can be guaranteed, finally, the TiAl alloy plate with the uniform and fine structure and good room temperature plasticity is obtained, and the problems that in the prior art, a TiAl alloy rolled blank is coarse in structure, plate forming is difficult, and the platestructure uniformity is poor are solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Gamma-TiAl intermetallic compound laser welding device and method with preheating device

InactiveCN111843203AReduce crackingImprove mechanical propertiesLaser beam welding apparatusTemperature controlErbium lasers

The invention discloses a gamma-TiAl intermetallic compound laser welding device and method with a preheating device. The device comprises the preheating device, a powder feeding device, a laser device, a gas protection device and a welding clamp, wherein the preheating device is a heating table capable of achieving temperature control, the powder feeding device consists of an argon bottle, a scraper type powder feeder and a coaxial powder feeding head, and the argon bottle, the scraper type powder feeder and the coaxial powder feeding head are sequentially connected with one another; the welding clamp comprises a fixed support, a threaded rod and a gasket, the fixed support is clamped on the heating table, the threaded rod penetrates through the fixed support, the lower end of the threaded rod is connected with the gasket, and a to-be-welded sample is placed between the gasket and the table top of the heating table; a closed hood is arranged above the heating table, the coaxial powderfeeding head is located above a welded joint of the to-be-welded sample, and the gas protection device is used for feeding inert gas into the closed hood. According to the device, the brittleness ofa gamma-TiAl intermetallic compound can be reduced in the laser welding process of the gamma-TiAl intermetallic compound, the possibility of crack initiation in the welded joint is reduced, and then the mechanical property of the welded joint is improved.

Owner:HOHAI UNIV CHANGZHOU

Beta-single-phase solidification TiAl-based alloy and structure control method thereof

InactiveCN107354344AImprove plasticityImprove high temperature strengthPolycrystalline material growthFrom frozen solutionsCrucibleIngot

The invention belongs to the technical field of high-temperature alloy structure control and particularly relates to a beta-single-phase solidification TiAl-based alloy and a structure control method thereof. According to the beta-single-phase solidification TiAl-based alloy and the structure control method thereof, the problem that the plasticity of an existing beta solidification TiAl alloy is poor is solved. The alloy component of the beta-single-phase solidification TiAl-based alloy is composed, by atom, of 44% of Al, 5.0% of Nb, 1.5-3.5% of Cr, 0.5-1.5% of W, 0.1-0.5% of Si and the balance Ti. The structure control method comprises the steps that firstly, a master alloy ingot is prepared through a water cooling copper crucible induction smelting method; and secondly, the master alloy ingot is cut into a cylindrical rod, and directional solidification is conducted with the temperature gradient being 10-30 DEG C / mm at a pulling rate of 3-100 [mu]m / s, and the beta-single-phase solidification TiAl-based alloy is obtained.

Owner:HARBIN INST OF TECH

High-plasticity magnesium alloy and preparation method thereof

ActiveCN109402429AImprove flame retardant performanceGood plasticity at room temperatureChemical compositionRoom temperature

The invention relates to high-plasticity magnesium alloy and a preparation method thereof. The alloy is Mg-Bi-Nd-Mn magnesium alloy, and comprises the following chemical components in percentages by mass: 2-8 wt% of Bi, 1.5-4 wt% of Nd, 0.05-0.15 wt% of Mn, and the balance of Mg and inevitable impurities, and moreover, the mass ratio of Bi to Nd equals to 1.3-2: 1. The process is simple, the plasticity of deformed magnesium alloy at the room temperature is excellent, the ductility at the room temperature reaches 43% or above, and meanwhile, the flame retardant property is good.

Owner:HEBEI UNIV OF TECH

Method for improving hot-working performance and room-temperature plasticity of high-boron stainless steel

ActiveCN106702287AGood plasticity at room temperatureIncreased elongation at room temperatureSS - Stainless steelQuenching

A method for improving the hot-working performance and the room-temperature plasticity of high-boron stainless steel is carried out through the following steps that firstly, molten steel is smelted, and a high-boron stainless steel cast ingot is obtained in a die casting manner, wherein the high-boron stainless steel cast ingot comprises 17.0%-19.5% of Cr, 12.0%-15.0% of Ni, 1.5%-2.0% of Mn, 1.75%-2.25% of B, smaller than 0.08% of C and the balance Fe; secondly, cutting and surface finishing are carried out on the high-boron stainless steel cast ingot; thirdly, cutting and surface finishing are carried out on austenitic stainless steel plates; fourthly, surface washing is carried out; fifthly, the austenitic stainless steel plates are arranged on the upper face and the lower face of the square high-boron stainless steel billet, the austenitic stainless steel plates and the square high-boron stainless steel billet are aligned, and welding is carried out on the vacuum condition; sixthly, hot rolling is carried out; and seventhly, water quenching is carried out after solution treatment is completed. By means of the method, the production procedures are short, the production cost is low, only slight edge cracking occurs to the high-boron stainless steel in the hot rolling process, and the finally obtained high-boron stainless steel clad plate has relatively excellent room temperature plasticity.

Owner:NORTHEASTERN UNIV

Heater for camping house

InactiveCN103591631AHigh strengthAvoid deformationLighting and heating apparatusElectric heating systemElectricityNormal level

The invention discloses a heater for a camping house. The heater comprises a shell, heating wires, binding posts and a plurality of metal pipes, wherein the metal pipes are arranged inside the shell in a staggered mode. A plurality of through holes are formed in the shell, the heating wires are installed inside the metal pipes, the two ends of each metal pipe are provided with plugs, and the binding posts penetrate through the plugs to be connected with the heating wires and are connected with an external power source. The heater further comprises an insulator and an overheat protective device, the insulator is arranged between the heating wires and the metal pipes, and the overheat protective device is installed in the through holes inside the shell and is connected with the binding posts. When the temperature inside the shell rises to the maximum, the overheat protective device in the through holes cuts off the external power source until the temperature is reduced to the normal level, the external power source continues to supply power, the heating wires continue to emit heat, the phenomenon that the heating wires are burned out due to high temperature is avoided, meanwhile, the working stability of the heater is improved, and the long service life of the heater is guaranteed.

Owner:CHENGDU KESHENG PETROLEUM TECH

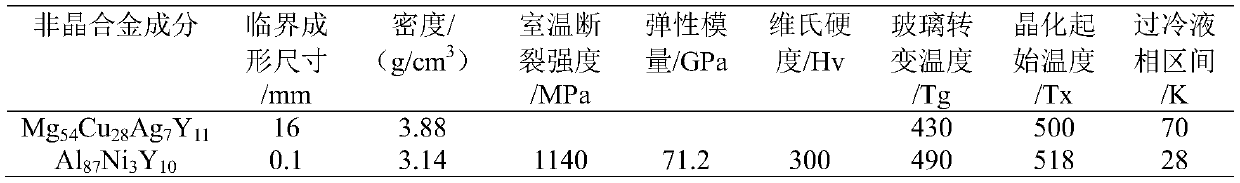

Preparation method for large-dimension light magnesium-aluminum based amorphous alloy

ActiveCN110724885AHigh strengthGood plasticity at room temperatureLaser additive manufacturingAlloy composition

The invention belongs to the field of amorphous alloys, and particularly relates to a preparation method for a large-dimension light magnesium-aluminum based amorphous alloy. The preparation method comprises the following steps: weighing powered magnesium based amorphous alloy and aluminum based amorphous alloy according to a target alloy component proportion, and uniformly mixing the magnesium based amorphous alloy with the aluminum based amorphous alloy to obtain magnesium-aluminum based amorphous alloy mixed powder; enabling a super-cooling liquid phase zone of the magnesium based amorphousalloy to be superposed with a super-cooling liquid phase zone of the aluminum based amorphous alloy; and preparing magnesium-aluminum based amorphous alloy through a powder sintering process or a laser additive manufacturing technology. The preparation method utilizes aluminum based amorphous alloy as a toughening phase to improve room-temperature plasticity of the magnesium based amorphous alloyor utilizes magnesium based amorphous alloy as a reinforcing phase to improve strength of the aluminum based amorphous alloy; and large-dimension light high-strength magnesium-aluminum based amorphous alloy is prepared by the powder sintering process or the laser additive manufacturing technology, so that the technical problem that the prepared composite material is not high in performance as relatively great difference exists between a crystal second phase and an amorphous matrix internal structure, deformation mode difference is relatively great, and interface metallurgical bonding is difficult is solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for branch crystal balling in large block metal glass composite

Owner:NANJING UNIV OF SCI & TECH

Ta-W-Al-Al2O3 alloy rod and preparation method thereof

InactiveCN109234560AGood plasticity at room temperatureHigh tensile strengthArgon atmosphereBall mill

The invention discloses a Ta-W-Al-Al2O3 alloy rod and a preparation method thereof, and relates to the technical field of alloy rods. The alloy rod is prepared from the following raw materials by masspercent: 5%-15% of W, 2%-6% of Al, 1%-4% of Al2O3, and the balance of Ta. The preparation method is characterized in that place tantalum powder, tungsten powder, aluminum powder and aluminium oxide powder in a ball mill, and perform ball mill mixing under the protection of an argon atmosphere to obtain a mixed powder; press to obtain a billet; place the billet in an enclosure, and seal the enclosure after vacuuming; perform high temperature isostatic pressing to obtain a sintered body of Ta-W-Al-Al2O3 alloy; perform thermal extrusion to obtain a Ta-W-Al-Al2O3 alloy rod. The alloy rod preparedby the invention has good room temperature plasticity and tensile strength, as well as excellent high temperature strength and oxidation resistance, and can be used in an air environment of 1,500 DEGC.

Owner:XIAN HUASHAN METAL PROD CO LTD

Method for improving room-temperature tensile property of Ti-48Al-2Cr-2Nb alloy through adding of nano Y2O3

InactiveCN105821232AImprove plasticityIncreased tensile strength at room temperatureCrucibleRoom temperature

The invention discloses a method for improving the room-temperature tensile property of a Ti-48Al-2Cr-2Nb alloy through adding of nano Y2O3, and belongs to the field of room-temperature mechanical properties of metal materials. The method for improving the room-temperature tensile property of the Ti-48Al-2Cr-2Nb alloy through adding of the nano Y2O3 aims at solving the problem that an existing directly-casted Ti-48Al-2Cr-2Nb alloy is coarse in structure, and serious in segregation. The method comprises the steps that nano Y2O3 particles are added in the Ti-48Al-2Cr-2Nb alloy, a water cooled copper crucible is adopted to induce a solidification shell smelting furnace, and under the high-vacuum / argon environment, through the melt reaction, a full-lamellar structure with the fine Y2O3 particles evenly distributed in a dispersed manner is directly generated. After the nano Y2O3 is added, the room-temperature tensile strength of the alloy is obviously improved, and the room-temperature plasticity of the alloy is greatly improved.

Owner:HARBIN INST OF TECH

Titanium alloy and machining method thereof

The invention provides a titanium alloy and a machining method thereof. The method for machining the titanium alloy comprises the following steps that (1) the titanium alloy needing to be machined isheated to be T beta+55-T beta+65 DEG C, heat preservation is conducted, then forging is conducted, and cooling is conducted; (2) the titanium alloy obtained in the step (1) is heated to be T beta-35-Tbeta-25 DEG C, heat preservation is conducted, then forging is conducted, and cooling is conducted; (3) the titanium alloy obtained in the step (2) is heated to be T beta+15-T beta+25 DEG C, heat preservation is conducted, then forging is conducted, and cooling is conducted; (4) the titanium alloy obtained in the step (3) is heated to be T beta-75-T beta-65 DEG C, heat preservation is conducted,then forging is conducted, and cooling is conducted; (5) the titanium alloy obtained in the step (4) is heated to be T beta-120-T beta-90 DEG C, heat preservation is conducted, then forging is conducted, and cooling is conducted; and (6) the titanium alloy obtained in the step (5) is heated to be T beta-350-T beta-300 DEG C, heat preservation is conducted, and cooling is conducted. The titanium alloy which is machined by adopting the method has an improved mechanical property, and particularly the indoor temperature ductility is improved.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com