Beta-single-phase solidification TiAl-based alloy and structure control method thereof

A control method and alloy-based technology, applied in self-solidification, chemical instruments and methods, single crystal growth, etc., can solve the problems of poor plasticity of β-solidified TiAl alloys, improve high-temperature oxidation resistance, and improve high-temperature creep resistance Performance, the effect of improving high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Embodiment 1: The alloy composition of a β single-phase solidified TiAl-based alloy according to the present embodiment is composed of 44% Al, 5.0% Nb, 1.5%-3.5% Cr, 0.5%- Composition of 1.5% W, 0.1%-0.5% Si and the rest Ti.

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the alloy composition of a β single-phase solidified TiAl-based alloy is 44% Al, 5.0% Nb, 2.5% Al Composition of Cr, 1.0% of W, 0.3% of Si and the balance of Ti. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

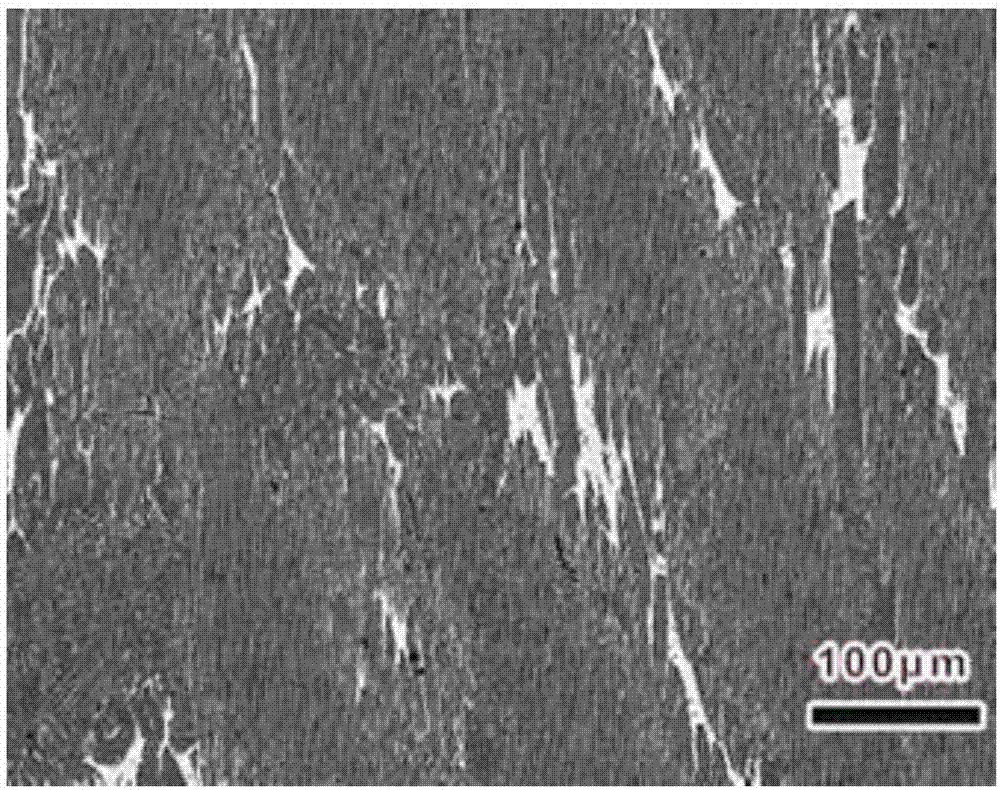

[0023] Specific implementation mode three: a microstructure control method of a β single-phase solidified TiAl-based alloy according to this implementation mode is carried out according to the following steps:

[0024] 1. Weigh sponge titanium, high-purity aluminum, aluminum-niobium master alloy, aluminum-chromium Master alloys, aluminum-tungsten master alloys and high-purity silicon, using water-cooled copper crucible induction melting method to prepare master alloy ingots;

[0025] 2. Cut the master alloy ingot obtained in step 1 into a cylindrical rod, polish the surface to remove the oxide layer, and then put it into a cylindrical rod with Y 2 o 3 Coated Al 2 o 3 In the ceramic tube, connect the ceramic tube to the pull rod in the Bridgman directional solidification device protected by high-purity argon, start the heating system of the Bridgman directional solidification device, heat to a temperature of 1500-1800 ° C, and at 1500-1800 Keep warm for 10min to 40min under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com