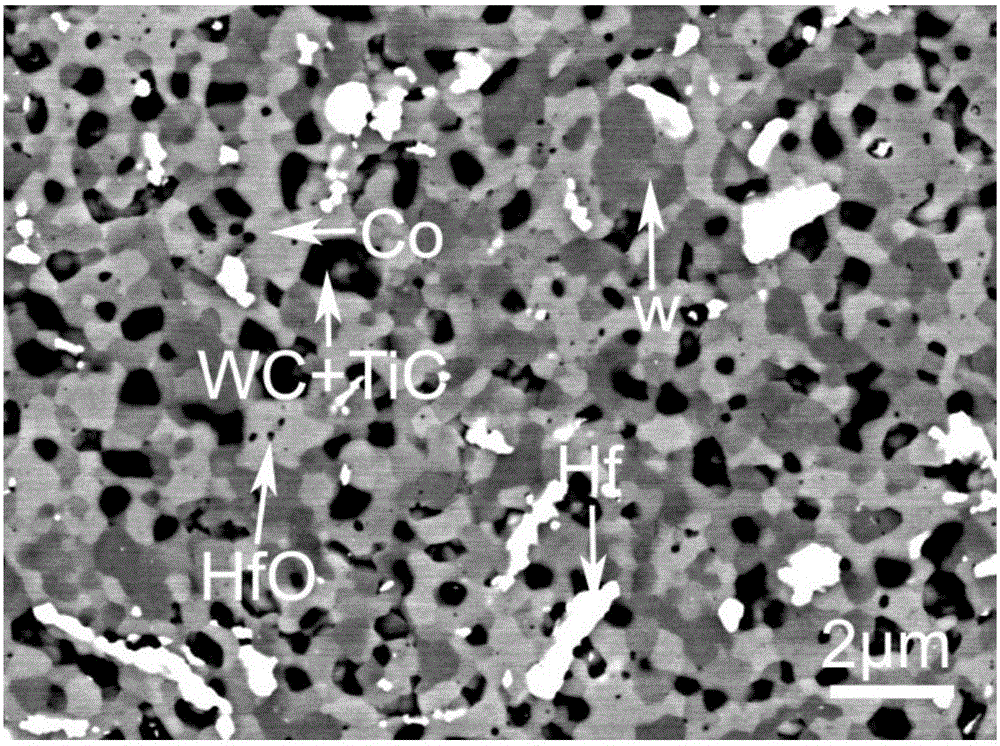

W-WC-TiC-Hf-Co alloy rod and preparation method thereof

An alloy rod, WC1%-5% technology, applied in the field of W-WC-TiC-Hf-Co alloy rod and its preparation, can solve the problems that the comprehensive mechanical properties cannot be greatly improved, and achieve low oxygen content, reduce Extrusion temperature and extrusion ratio, the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of W-WC-TiC-Hf-Co alloy rod, its preparation steps are:

[0028] (1) Mix tungsten carbide powder, titanium carbide powder, hafnium powder, cobalt powder and tungsten powder uniformly by wet ball milling, and obtain mixed powder after vacuum drying;

[0029] (2) Compress the mixed powder described in step (1) to obtain a billet, and then place the billet in a vacuum sintering furnace at a vacuum degree not greater than 5×10 -2 Pa, under the condition of 1200°C-1500°C, heat preservation for 2h-3h for sintering treatment, and obtain a sintered body after cooling with the furnace;

[0030] (3) The sintered body described in step (2) is placed in an electron beam melting furnace, and the vacuum degree is not greater than 1×10 -2 Electron beam smelting under the condition of Pa for 2-5 times, after natural cooling, peeling treatment is carried out to obtain ingots; the current of the electron beam smelting is 3A-5A, and the voltage of the electro...

Embodiment 1

[0037] Example 1: A W-WC-TiC-Hf-Co alloy rod, composed of the following components by mass percentage: WC 3%, TiC 5%, Hf 3%, Co 3%, the balance is W and unavoidable of impurities.

[0038] The preparation method of the present embodiment W-WC-TiC-Hf-Co alloy bar comprises the following steps:

[0039] (1) Put tungsten carbide powder, titanium carbide powder, hafnium powder, cobalt powder and tungsten powder in a ball mill, use absolute ethanol as a dispersant, wet method under the conditions of rotation speed 350rpm and ball-to-material ratio 3:1 Ball milling for 5 hours, drying under vacuum conditions after ball milling to obtain mixed powder; the volume of the absolute ethanol is 2.5 times the sum of the mass of tungsten carbide powder, titanium carbide powder, hafnium powder, cobalt powder and tungsten powder, wherein the volume The unit is mL, and the unit of mass is g. The mass purity of the tungsten carbide powder, titanium carbide powder, hafnium powder, cobalt powder ...

Embodiment 2

[0046] Example 2: A W-WC-TiC-Hf-Co alloy rod consisting of the following components by mass percentage: WC 1%, TiC 2%, Hf 1%, Co 1%, the balance is W and unavoidable of impurities.

[0047] The preparation method of the present embodiment W-WC-TiC-Hf-Co alloy bar comprises the following steps:

[0048] (1) Put tungsten carbide powder, titanium carbide powder, hafnium powder, cobalt powder and tungsten powder in a ball mill, use absolute ethanol as a dispersant, wet method under the conditions of rotation speed 350rpm and ball-to-material ratio 3:1 Ball milling for 5 hours, drying under vacuum conditions after ball milling to obtain mixed powder; the volume of the absolute ethanol is 2.5 times the sum of the mass of tungsten carbide powder, titanium carbide powder, hafnium powder, cobalt powder and tungsten powder, wherein the volume The unit is mL, and the unit of mass is g. The mass purity of the tungsten carbide powder, titanium carbide powder, hafnium powder, cobalt powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com