Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Defence industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

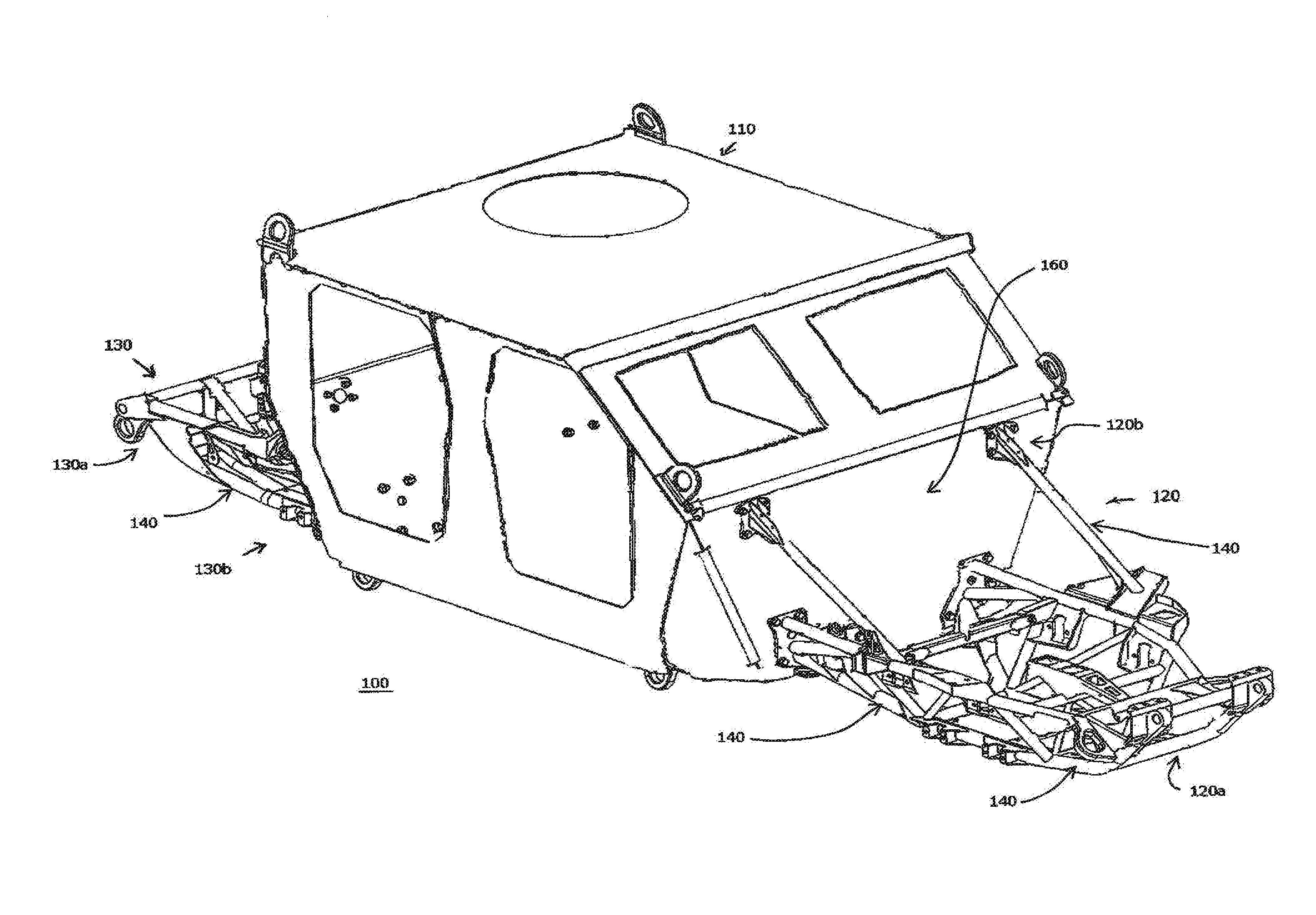

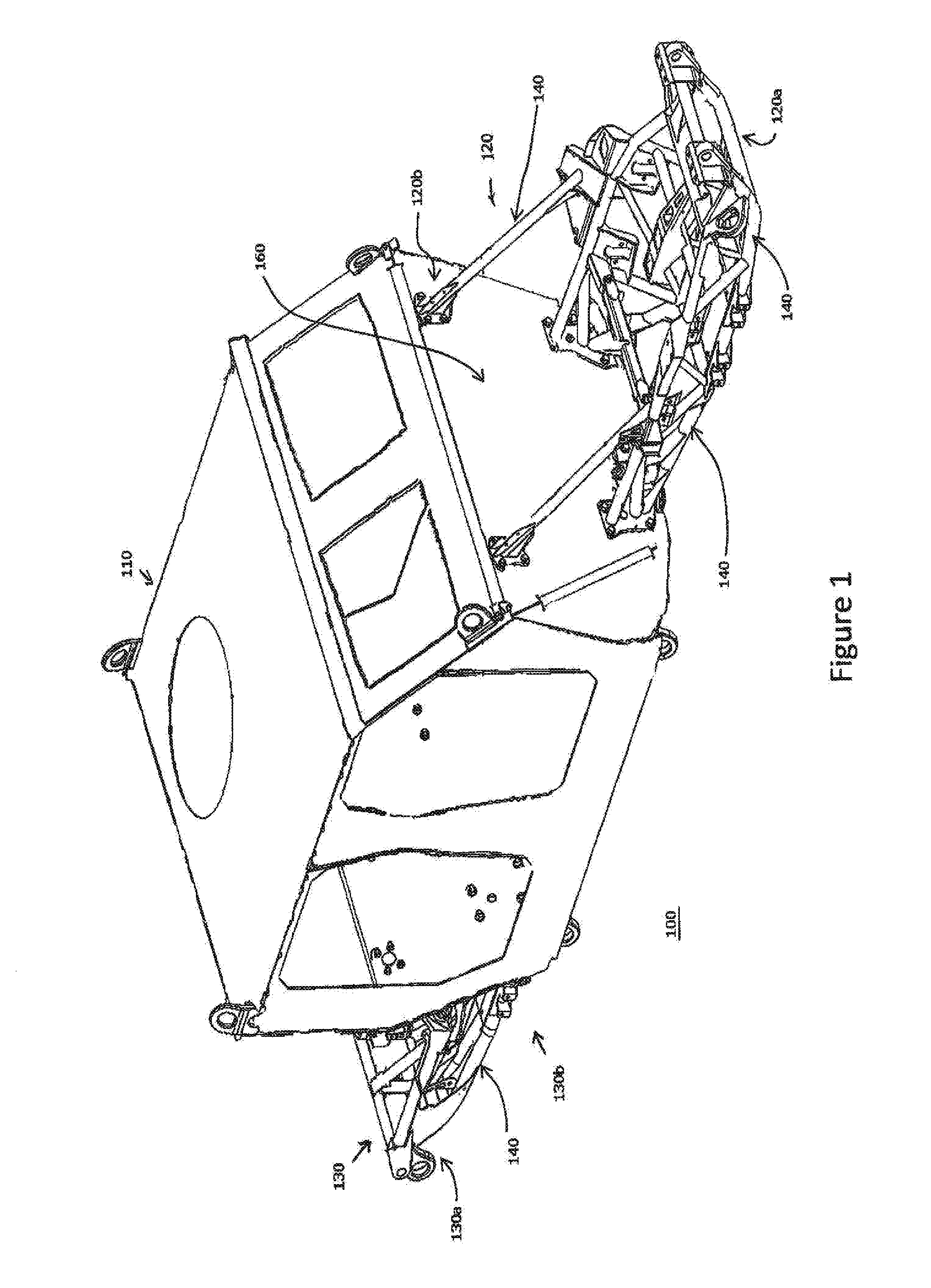

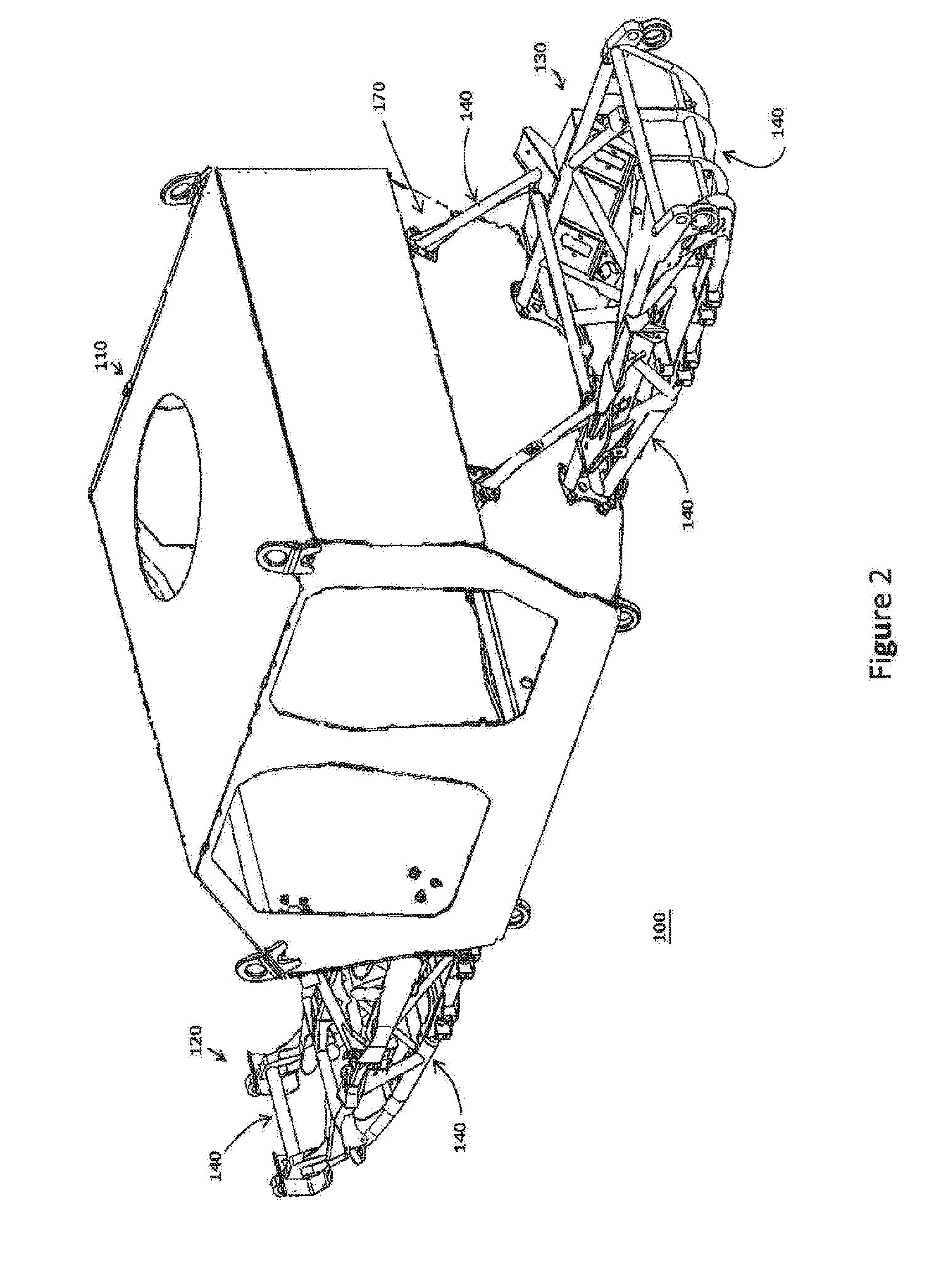

Modular Vehicle Architecture

InactiveUS20160257360A1Minimize connectionDissipating shearing loadsAgricultural vehiclesArmoured vehiclesModularityEngineering

The present invention relates to the field of mechanical engineering, in particular, vehicles. In one form, the invention relates to military or defence industry protected (armoured) vehicles with a modular vehicle architecture comprising: a capsule adapted for accommodating at least one occupant; at least one sub-frame detachably operatively connected to the capsule; wherein at least the sub-frame construction comprises members of tubular structure having a cross section corresponding to a conic section.

Owner:THALES AUSTRALIA

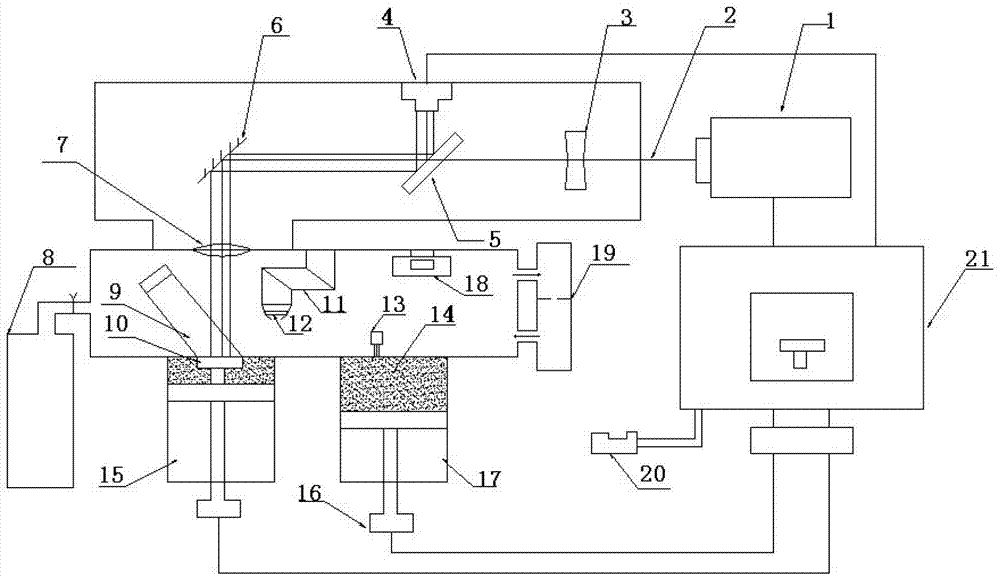

Method and equipment for manufacturing metal part with embedded FRID (Radio Frequency Identification) label with SLM (Selective Laser Melting)

ActiveCN103400165AImprove production efficiencyOvercoming distractionsCo-operative working arrangementsIncreasing energy efficiencySelective laser meltingLength wave

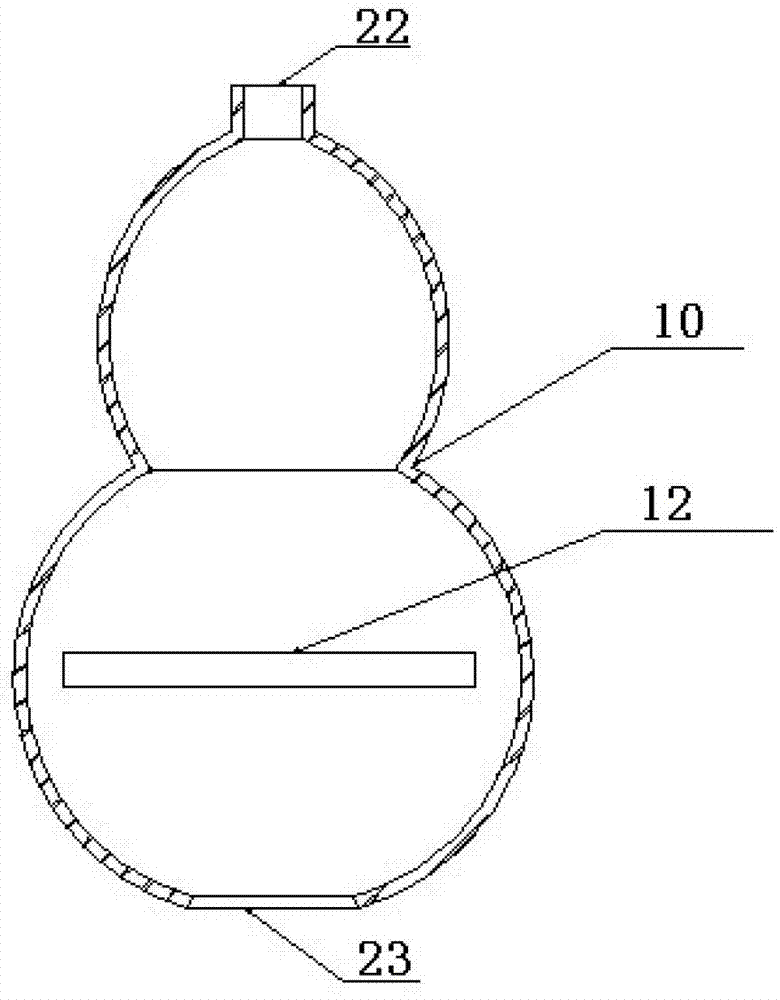

The invention discloses a method and equipment for manufacturing a metal part with an embedded FRID (Radio Frequency Identification) label with SLM (Selective Laser Melting), which belongs to the field of laser melting and solves the problem that the current selective laser melting is mutually independent with the FRID. The equipment is technically characterized by comprising a beam focusing system, a near wavelength coaxial visual positioning system, a gas protection system, a real-time monitor, a label embedding system and the like. The FRID label being embedded in the metal part has a high requirement on the manufacturing method, and the traditional processing method cannot realize one-step formation. The method adopts the combination of the SLM and the FRID to overcome the limitation that the traditional process cannot realize the one-step formation. The method and the equipment reasonably control the distance between the label and metal to eliminate a heat effect, and a metal-resisting film is pasted on the label to solve the problem. The method and the equipment overcome manufacturing difficulties, successfully manufacture the metal part with the embedded FRID label, are mainly applied to the defense industry and can also be applied to industries such as workpiece tracking and positioning in a special environment.

Owner:SOUTH CHINA UNIV OF TECH

Ceramic particle reinforced aluminium-based composite material and powder metallurgical process to prepare the material

The present invention belongs to the field of composite material preparation technology. The composite material has the chemical expression of: AlaMgbBcMd, Where a is 50-96, b 1-7, c3-30 and d 0-13; M is one or several of Si, Cu, Ni, Ti, Fe, Cr, La, Mn, Ce, Zn, V and Zr. The preparation process is one combined powder metallurgy and in-situ reaction process and includes mixing material powder, cold pressing the mixture for forming, heating the formed mixture and hot pressing for the material powder to produce chemical reaction at temperature over 950 deg.c. Inside the aluminum alloy base, A1MgB14 ceramic phase particle as reinforcing phase is formed to prepare the composite aluminum alloy material. The ceramic particle reinforced composite aluminum alloy material. The ceramic particle reinforced composite aluminum alloy material has light weight and high strength, integrated functions, and may be used widely in transport industry and national defence industry.

Owner:SHANGHAI JIAO TONG UNIV

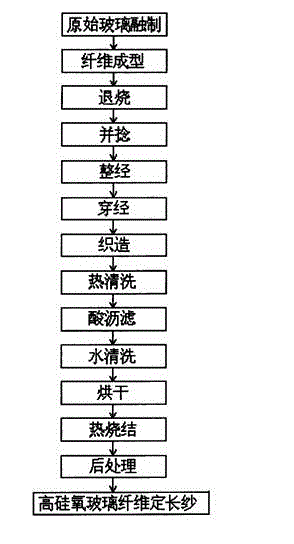

Process for manufacturing multielement composition high silica glass fibre fixed-length yarn

The invention relates to a high-temperature resistant material, belongs to the field of special glass fibre materials and particularly relates to a multielement composition high silica glass fibre fixed-length yarn. The process comprises the following steps of: melting and processing sodium-boron-silicon three-element composition original glass as a raw material so as to perform fibre forming; sequentially carrying out calcination, cabling, warping and drawing-in to manufacture a yarn bundle; and then carrying out thermal treatment, acid leaching, water treatment, baking, thermal sintering and aftertreatment working procedures, so as to obtain the multielement composition high silica glass fibre fixed-length yarn. The process is reasonable in design and provides revelation for processing multielement composition high silica glass fibre products, so that the process can be widely applied to the production of various high silica glass fibre continuous filaments, short shreds, fabrics, mesh fabrics, gore text fabrics, punched felts, belts, sleeves and rope products, and the like. The multielement composition high silica glass fibre fixed-length yarn product is wider in application range, and is mainly used as an anti-ablation and heat-insulated insulating material in the aerospace and defence industry field, and used for high-temperature metal liquid filtration in the field of precision casting of cast copper, cast iron and the like, and heat insulation, protection, insulation and the like in the chemical engineering, metallurgy and building materials industries.

Owner:安徽成华新材料有限公司

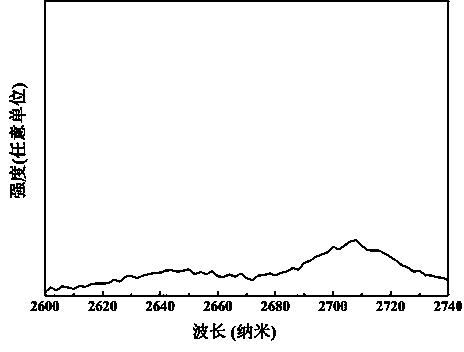

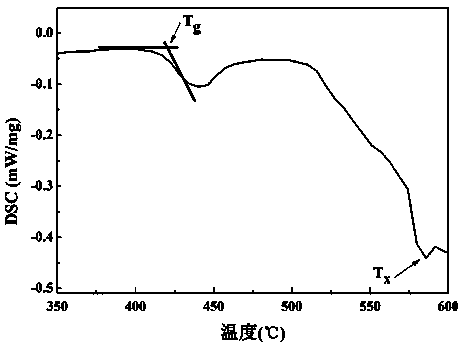

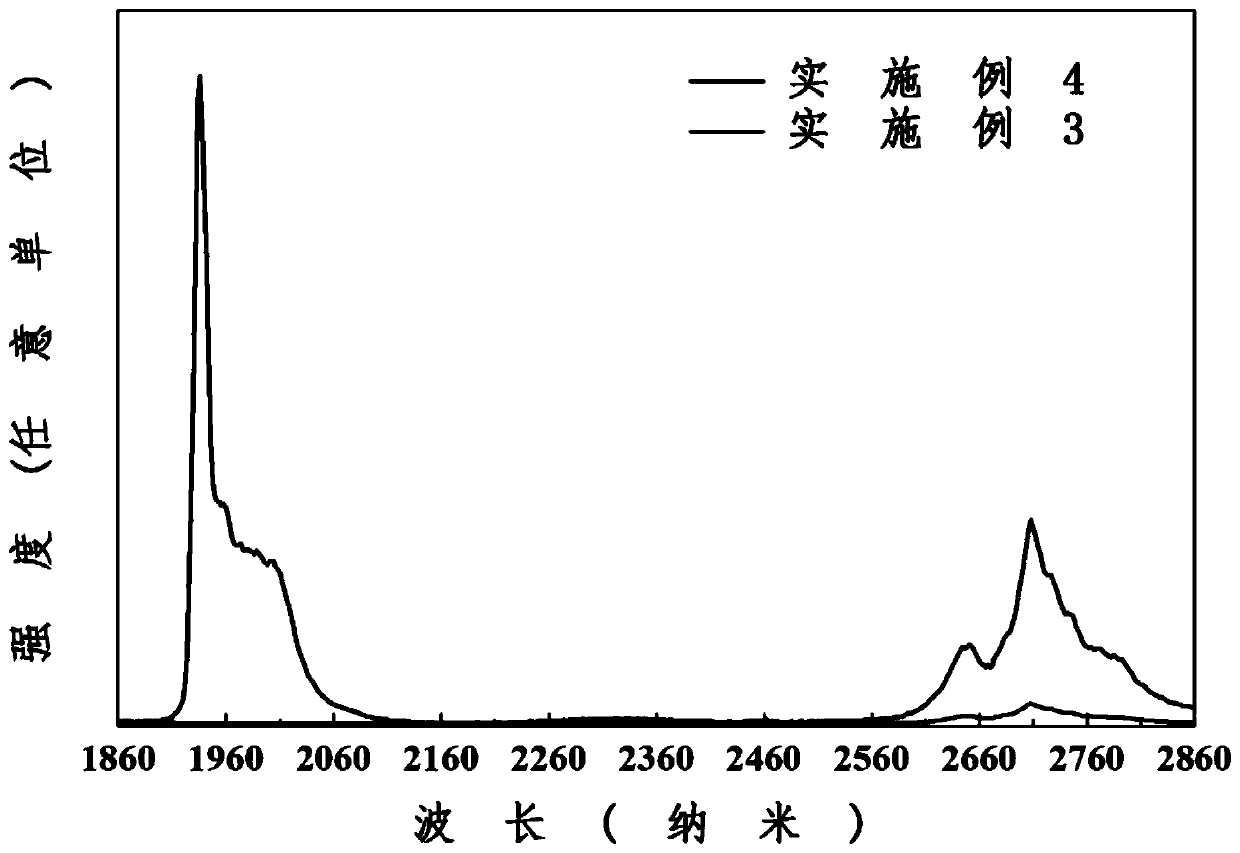

Erbium and terbium co-doped fluoride halide phosphate laser glass as well as preparation method and application thereof

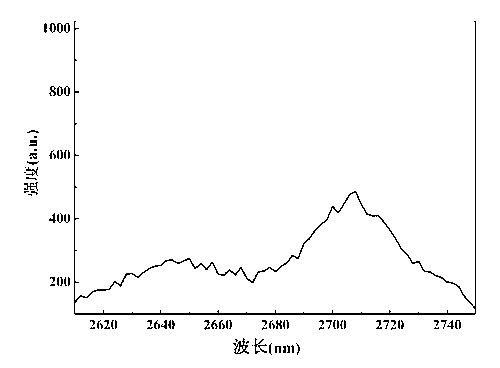

ActiveCN103183472AGood anti-devitrification performanceMeet practical requirementsTransmittanceErbium lasers

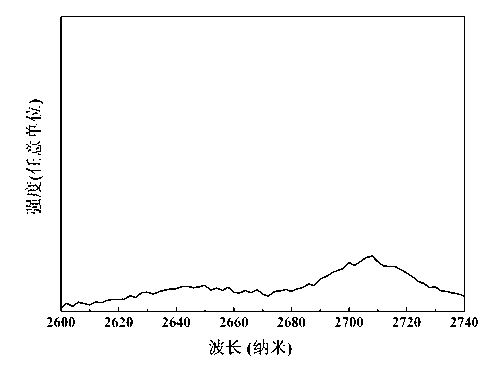

The invention discloses erbium and terbium co-doped fluoride halide phosphate laser glass which comprises components in percentage by mole as follows: 15% to 20% of Ba(H2PO4)2, 15% to 20% of Mg(PO3)2, 5% to 10% of AlF3, 10% to 20% of BaF2, 15% to 30% of MgF2, 20% to 30% of NaX, 1% to 5% of ErF3 and 4% to 10% of TbF3, wherein X is a combination of any one or more of F, Cl, Br and I. The fluoride halide phosphate laser glass is transparent and free of crystallization, the infrared transmittance is high in an area nearby 3 mu m, physical and chemical properties are excellent, the laser glass can be applied in a 3 m fiber laser and can be hopefully applied to defense industry, military and civilian areas.

Owner:合肥天奕激光医疗器械有限公司

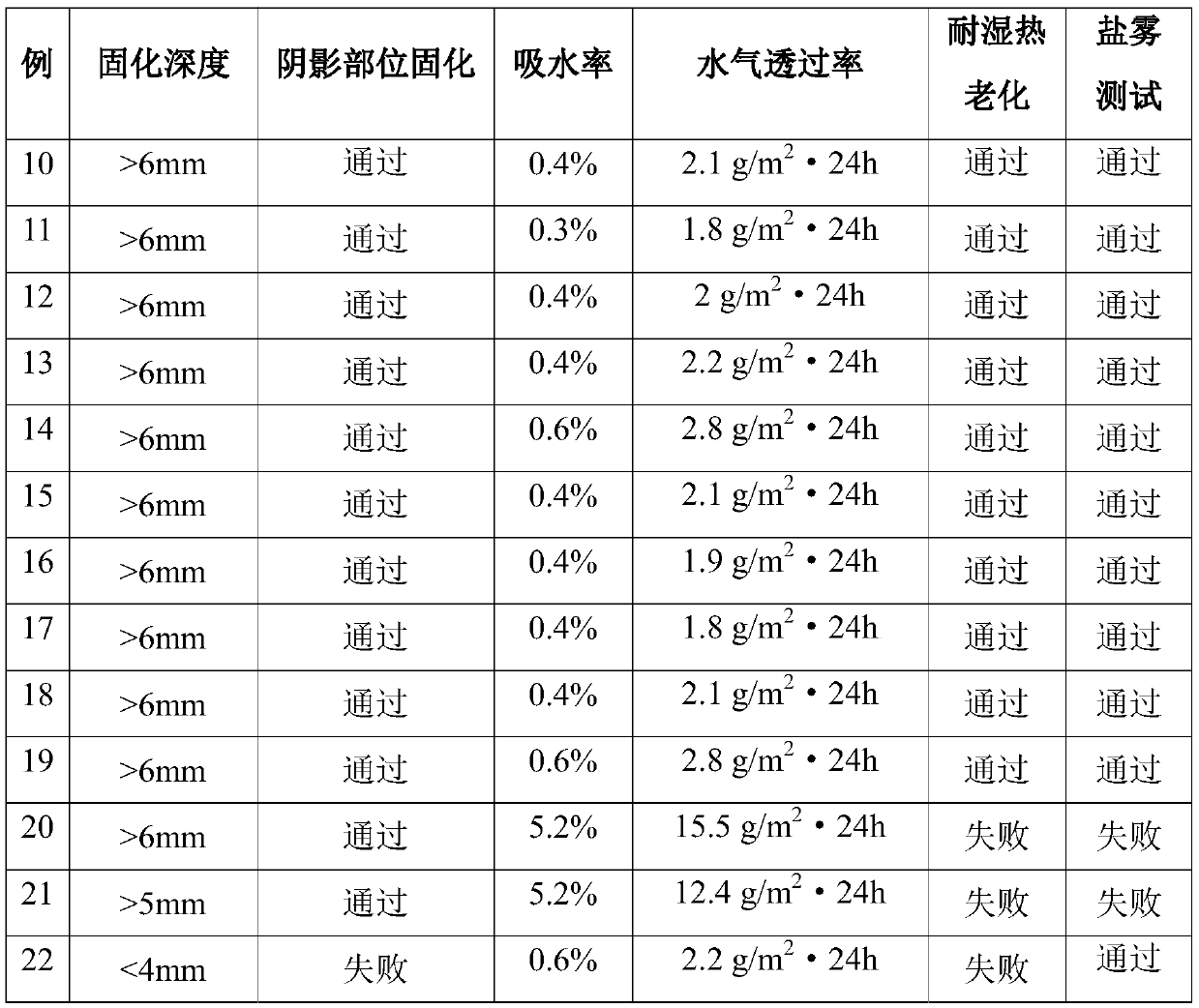

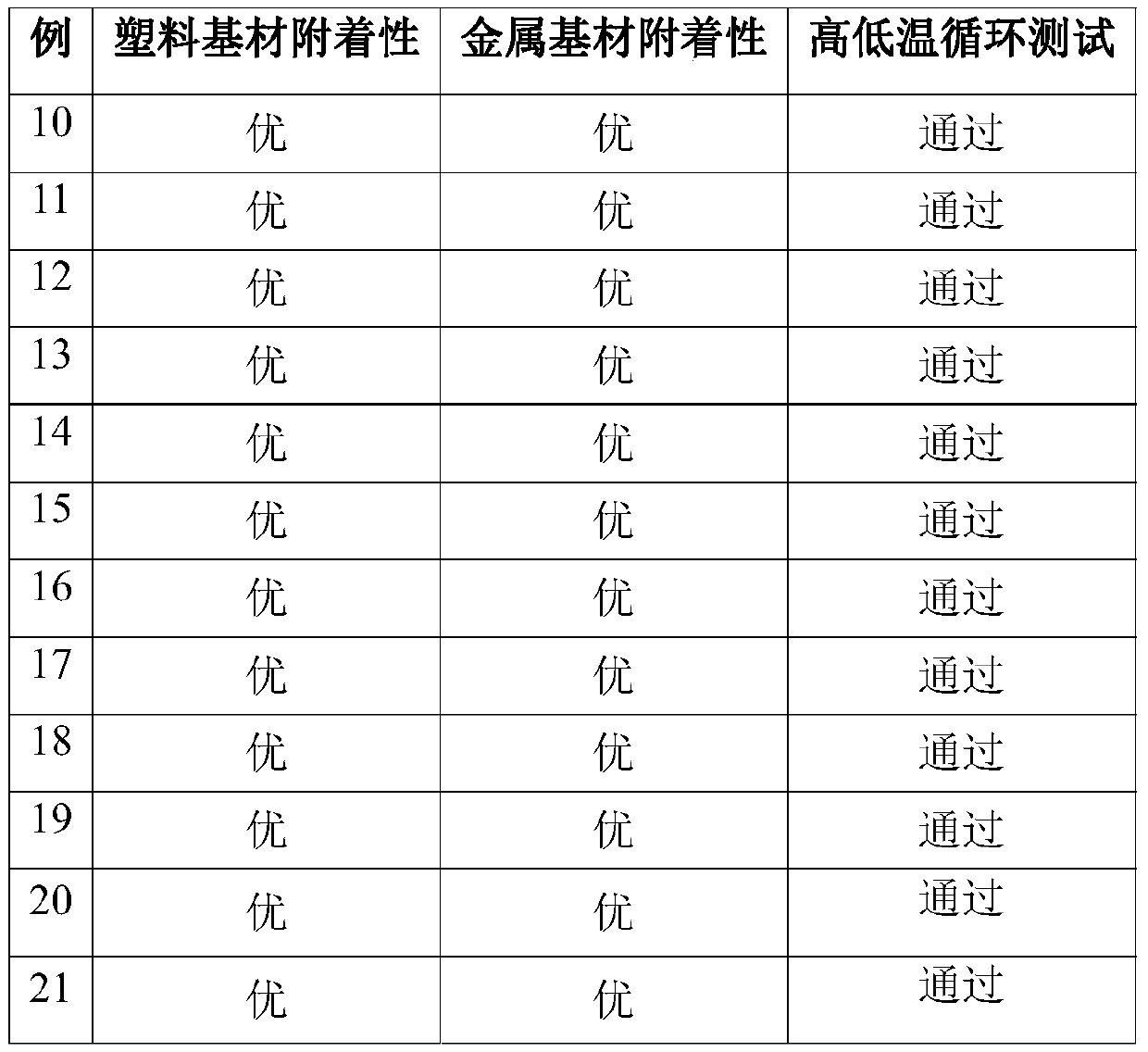

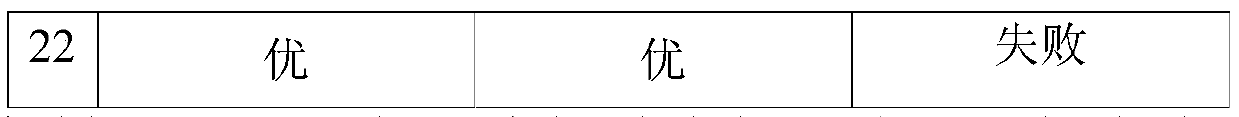

Photo-moisture curing adhesive with high-efficiency moisture barrier property and ultralow water absorption

InactiveCN110885664AOvercome deepOvercome limitationsPolyureas/polyurethane adhesivesUltraviolet lightsEngineering

The invention discloses a cured resin which can be cured in a photo-moisture or light condition, and further discloses a photo-moisture curing adhesive with high-efficiency moisture barrier property and ultralow water absorption. The photo-moisture curing adhesive is prepared from the following raw materials in parts by weight: 5-70 parts of photo-moisture curing resin, 0-40 parts of photo-curingresin, 10-60 parts of a reactive diluent, 0.5-10 parts of a photoinitiator and 0-20 parts of a functional assistant. The adhesive overcomes the limitations of the ultraviolet light curing technology in the aspects that a deep layer and a shadow area are difficult to cure and the like, achieves the efficient moisture barrier property, the ultralow water absorption rate and the excellent damp-heat resistance, is suitable for application of component structure bonding, component sealing bonding protection, component potting protection, circuit board protection, welding spot bonding protection andthe like, and has wide application prospects in various industries, such as the electronic industry, the automobile industry, the aerospace industry, the national defense industry, the bioengineeringindustry and the like.

Owner:今商科技(上海)有限公司

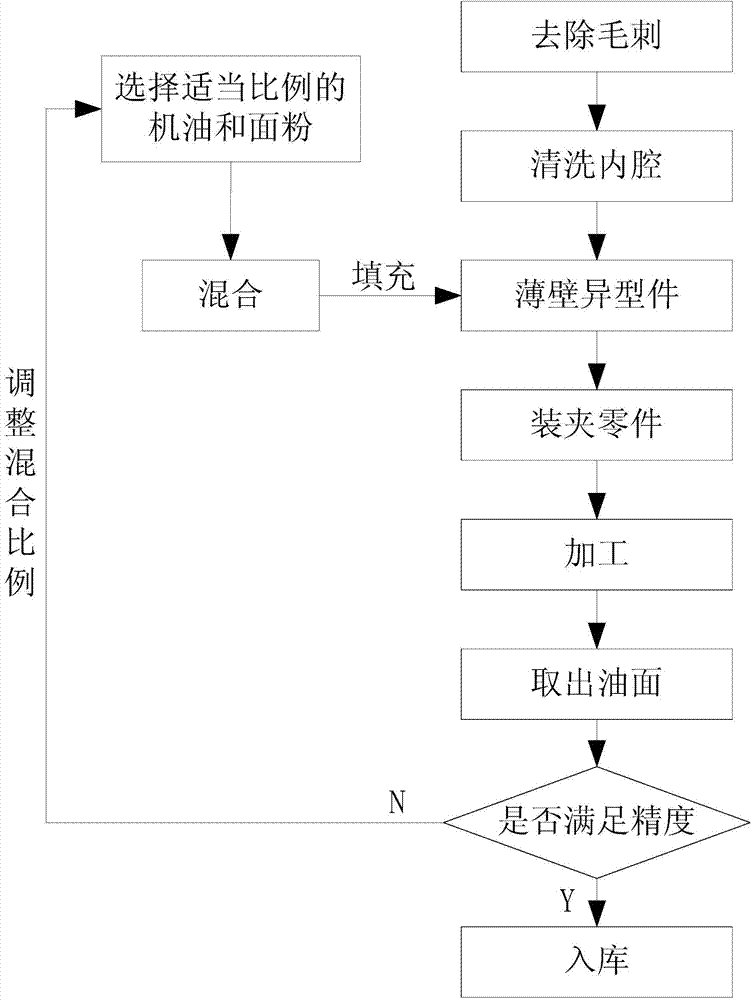

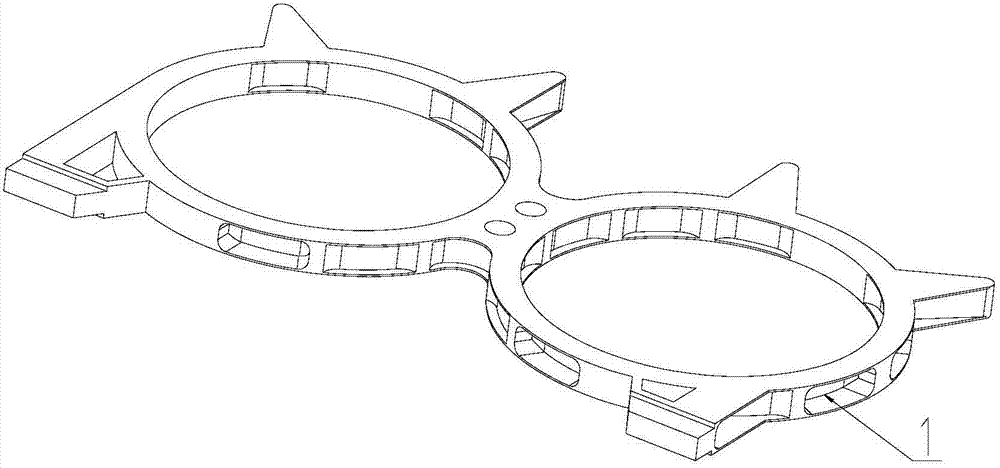

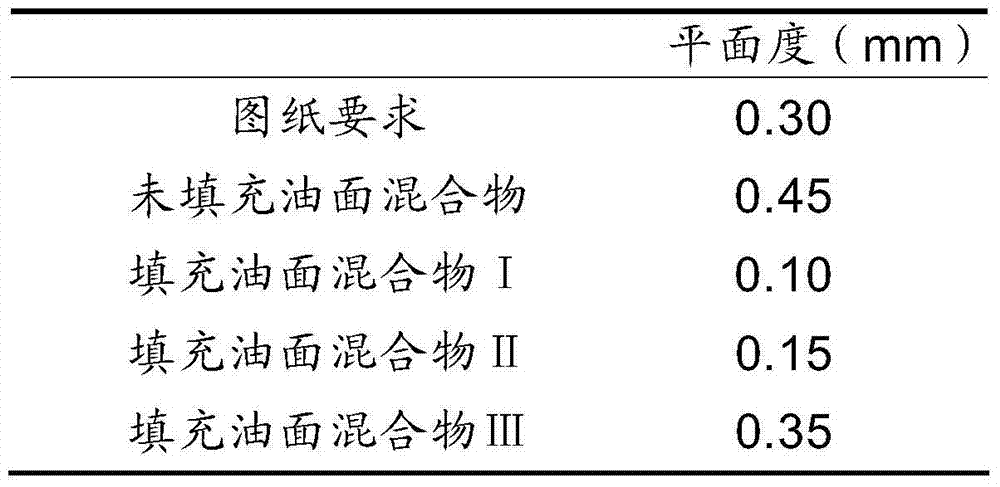

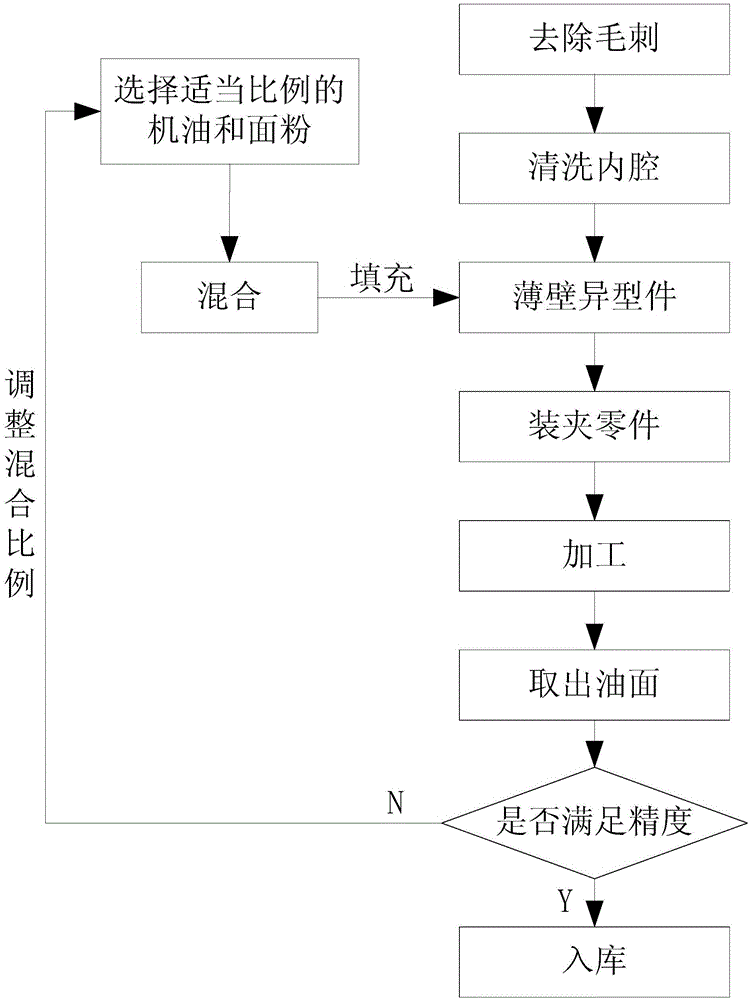

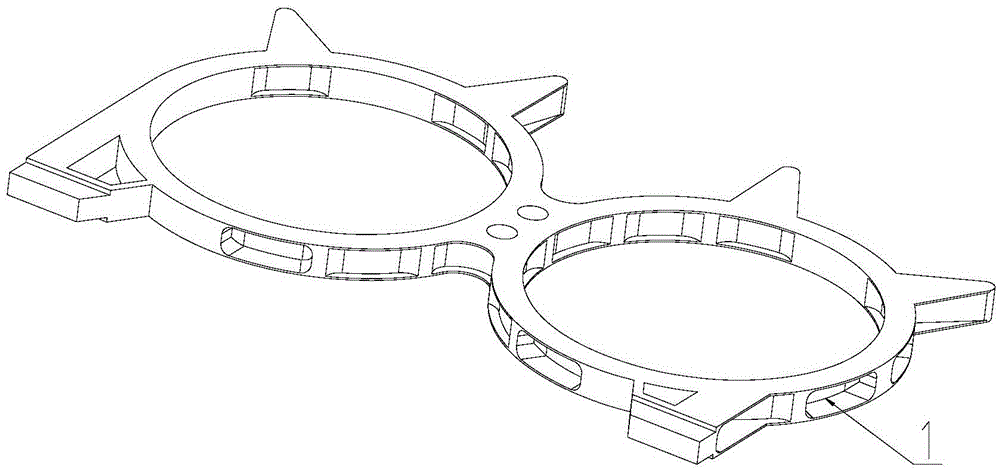

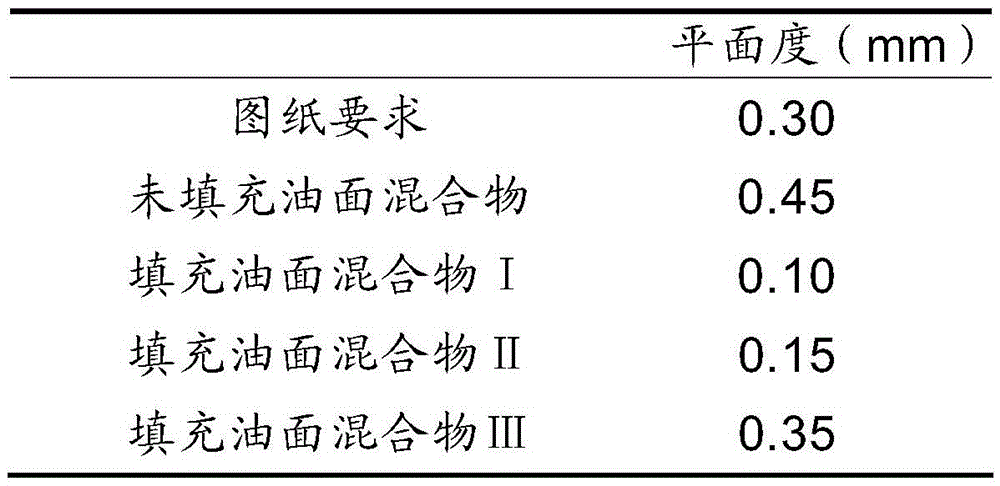

Padding supporting method for enhancing thin-walled workpiece machined rigidity

ActiveCN104259883AEasy to makeLow costPositioning apparatusMetal-working holdersAviationMachining deformation

Disclosed is a padding supporting method for enhancing thin-walled workpiece machined rigidity. Engine oil and flour are mixed according to a specific ratio and then padded into a cavity of a thin-walled workpiece, the whole rigidity of the thin-walled workpiece is improved, natural vibration frequency of the workpiece is changed, flutter is reduced, cut machined deformation of the thin-walled workpiece is reduced, the problem that workpiece surface qualities are affected due to poor rigidity and flutter can be solved, and machining accuracy and surface qualities of the thin-walled workpiece can be guaranteed. By means of the successful development of the padding supporting method, the difficulty of machining of the thin-walled workpiece during model development can be technologically solved, the machining scheme of the thin-walled workpiece and mixing ratio parameter of engine oil and flour can provide high reference value and certain guiding significance for high-efficiency precise machining of numerous thin-walled irregular workpieces which are high in accuracy requirements, complicated in structures and especially not easy to clamp in national defence industry fields of aviation, aerospace, weaponry and the like, and the padding supporting method for enhancing the thin-walled workpiece machined rigidity can be used for guiding actual production.

Owner:BEIJING SATELLITE MFG FACTORY

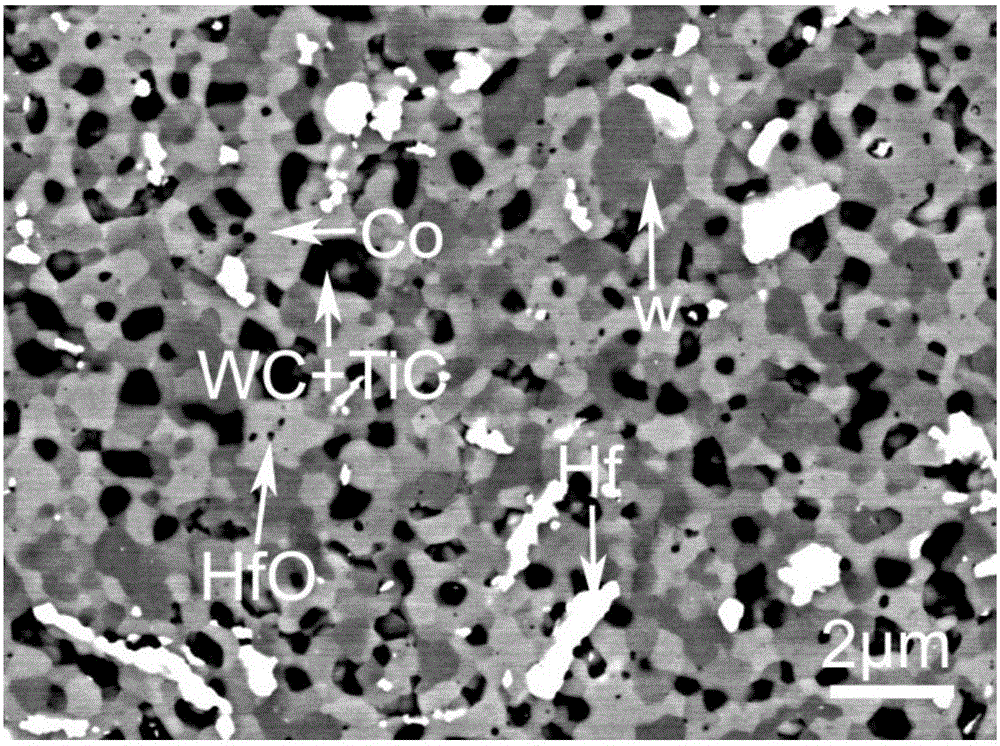

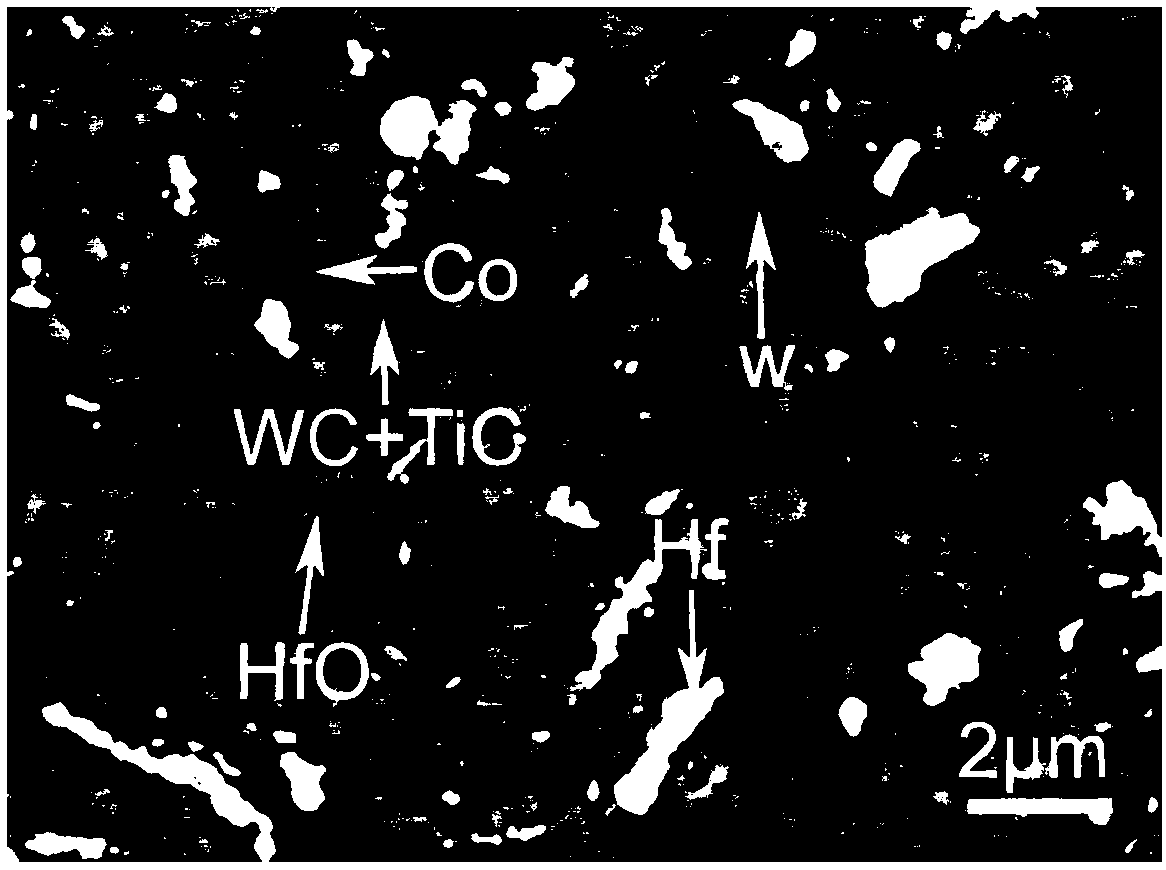

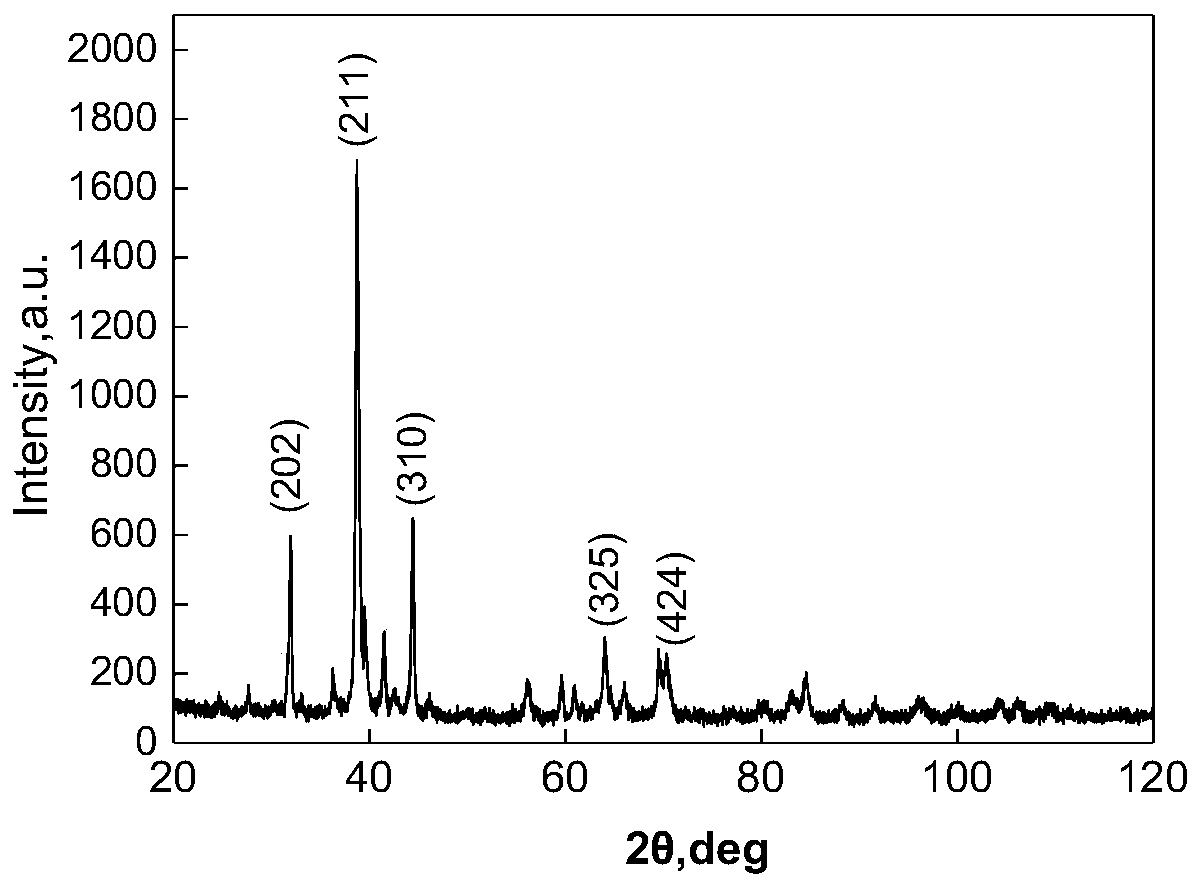

W-WC-TiC-Hf-Co alloy rod and preparation method thereof

The invention discloses a W-WC-TiC-Hf-Co alloy rod and a preparation method thereof, and relates to the technical field of alloy materials. The W-WC-TiC-Hf-Co alloy rod is prepared from the following raw materials in percentage by mass: 1 to 5 percent of WC, 2 to 8 percent of TiC, 1 to 5 percent of Hf, 1 to 5 percent of Co and the balance of W and unavoidable impurities; the preparation method of the W-WC-TiC-Hf-Co alloy rod comprises the following steps: (1) uniformly mixing tungsten powder, tungsten carbide powder, titanium carbide powder, hafnium powder and cobalt powder by adopting a wet ball milling method, and performing vacuum drying to obtain mixed powder; (2) performing vacuum sintering to obtain a sintering body; (3) smelting 2 to 5 times by electron beams to obtain an ingot; (4) performing thermal extruding to obtain a semi-finished rod blank; (5) performing thermal extruding to obtain an alloy rod. The W-WC-TiC-Hf-Co alloy rod disclosed by the invention has high hardness, high strength and excellent comprehensive mechanical properties, and has wide application prospect in aerospace field, national defence industry, electronic information, energy resources and the like.

Owner:XIAN HUASHAN METAL PROD CO LTD

Method for preparing thin thermal battery electrolyte pole piece based on slurry coating method

InactiveCN104681778AImprove electrochemical performanceGood chemical propertiesDeferred-action cellsPrimary cell electrodesElectrical batteryCell fabrication

The invention belongs to the field of battery manufacturing, and in particular relates to a method for preparing a thin thermal battery electrolyte pole piece based on a slurry coating method. The method comprises the following steps: mixing thermal battery electrolyte powder material, an adhesive and an organic dispersing agent so as to form uniform slurry, coating the slurry on a conductive substrate, molding, drying, and curing, thereby obtaining the thin thermal battery electrolyte pole piece. Compared with a conventional powder tabletting forming process, the method is relatively low in cost, simple in process and applicable to large-scale industrial product, is innovative in the small-size / thinning field of thermal batteries, and has very high values for promoting development of the national defense industry, the thickness of the thin thermal battery electrolyte pole piece prepared by using the method can be reduced by 1 / 3-1 / 2, and the thickness of the thin thermal battery electrolyte pole piece can be adjusted within dozens of to hundreds of micrometers.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

Method for preparing thin thermal battery heating powder piece based on slurry coating method

InactiveCN104681776AAchieve preparationAdjustable thicknessElectrode manufacturing processesPrimary cell electrodesCell fabricationAdhesive

The invention belongs to the field of battery manufacturing, and in particular relates to a method for preparing a thin thermal battery heating powder piece based on a slurry coating method. The method comprises the following steps: mixing thermal battery heating powder, an adhesive and an organic dispersing agent so as to form uniform slurry, coating the slurry on a conductive substrate, molding, drying, and curing, thereby obtaining the thin thermal battery heating powder piece. Compared with a conventional powder tabletting forming process, the method is relatively low in cost, simple in process and applicable to large-scale industrial product, is innovative in the small-size / thinning field of thermal batteries, and has very high values for promoting development of the national defense industry, the thickness of the thin thermal battery heating powder piece prepared by using the method can be reduced by 1 / 3-1 / 2, and the thickness of the thin thermal battery heating powder piece can be adjusted within dozens of to hundreds of micrometers.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

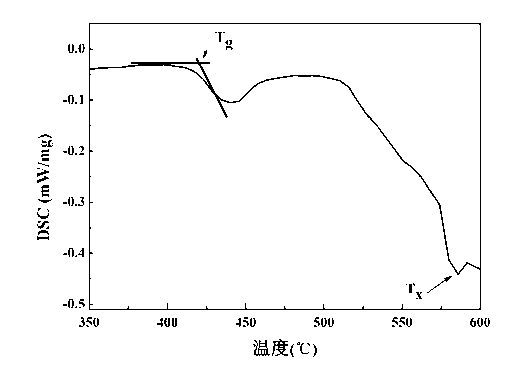

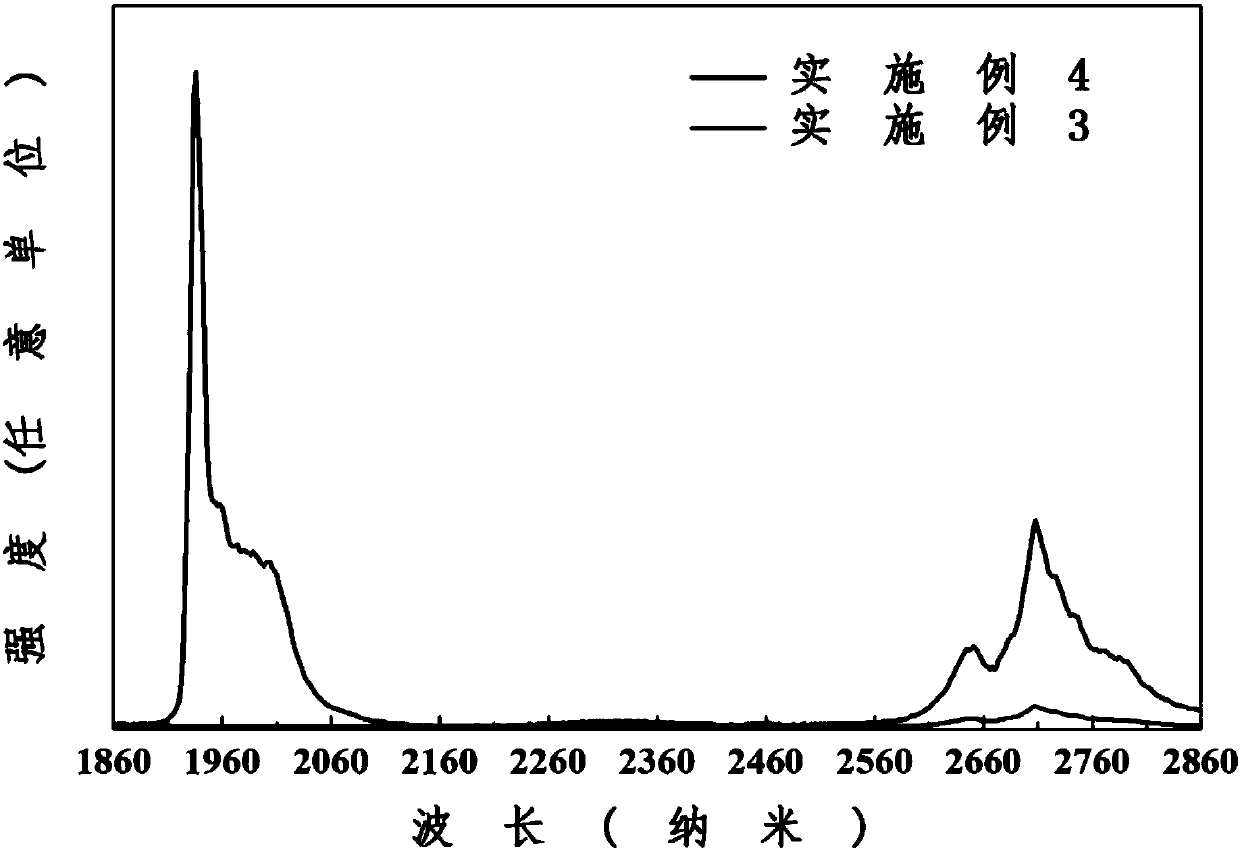

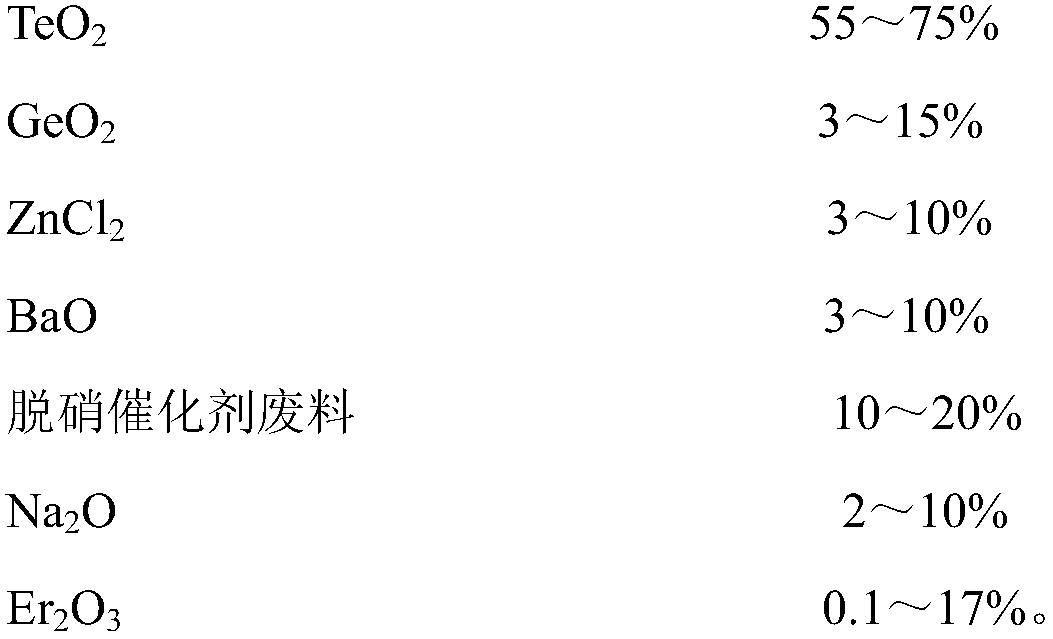

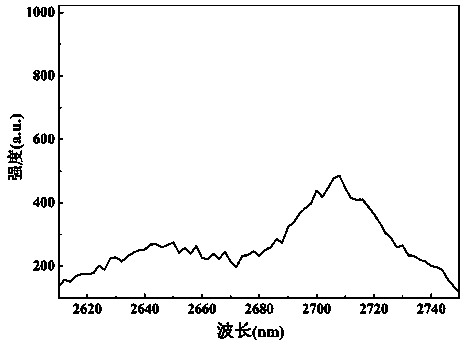

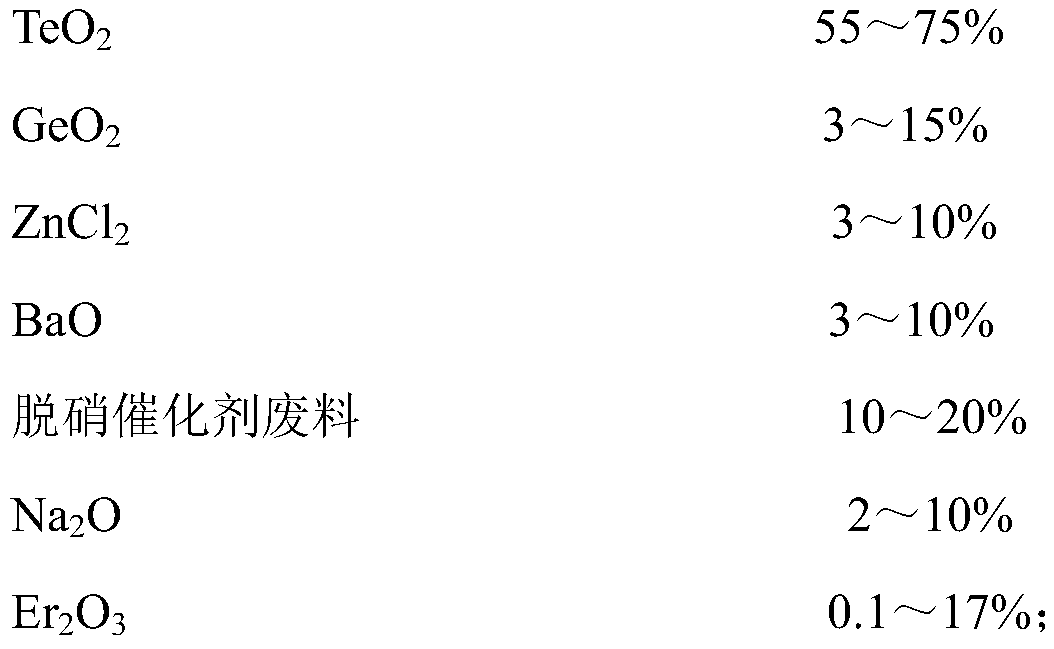

High-doped erbium intermediate infrared tellurium germinate glass and preparation method thereof

The invention discloses high-doped erbium intermediate infrared tellurium germinate glass. The high-doped erbium intermediate infrared tellurium germinate glass comprises the components of TeO2, GeO2,ZnCl2, BaO, a denitration catalyst waste, Na2O, and Er2O3. According to the glass prepared through a melting method, the intermediate infrared light intensity is high, the doping concentration of rare earth is high, the glass is excellent in thermal stability, and is quite promising high-optical quality glass; the wasted denitration catalyst waste is used to strengthen the hardness of the glass and improve the thermal stability of the glass, the preparation method is simple and convenient, the preparation period is short, and the glass is expected to be applied to national defence industry aswell as military and civil fields.

Owner:CHINA JILIANG UNIV

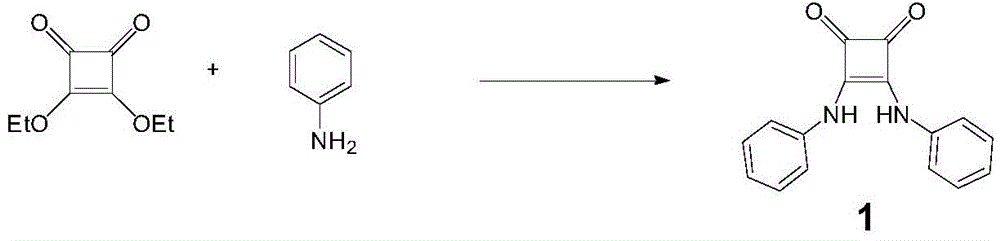

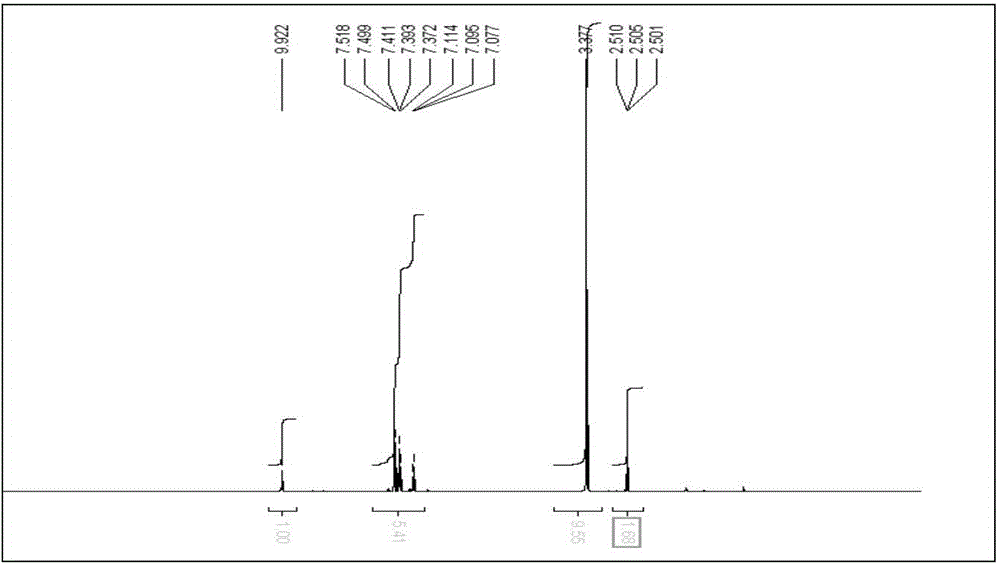

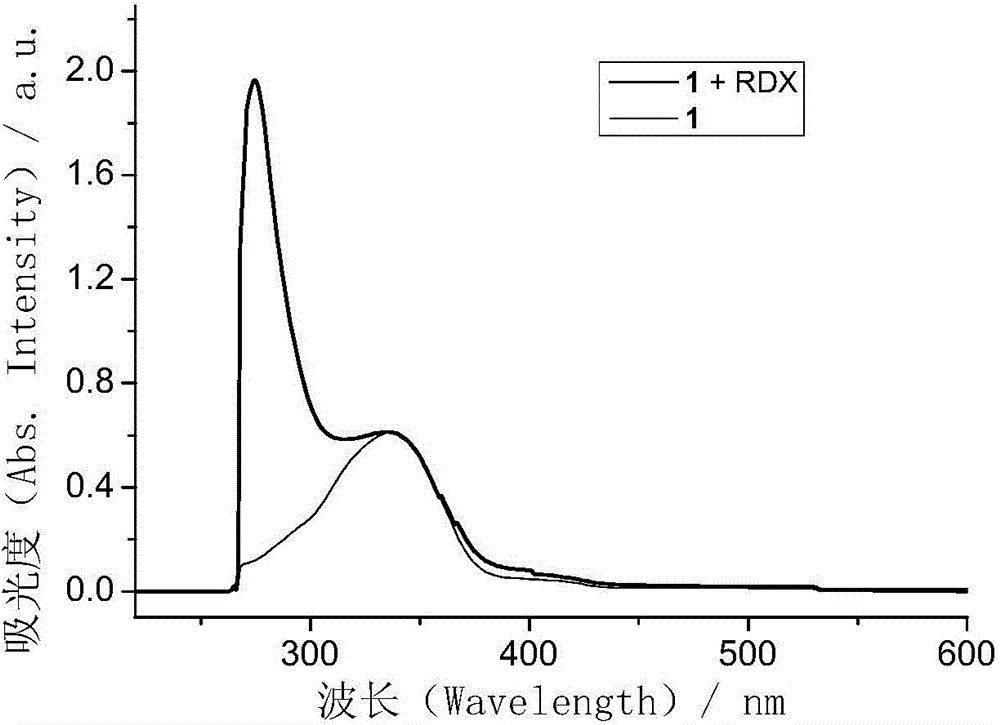

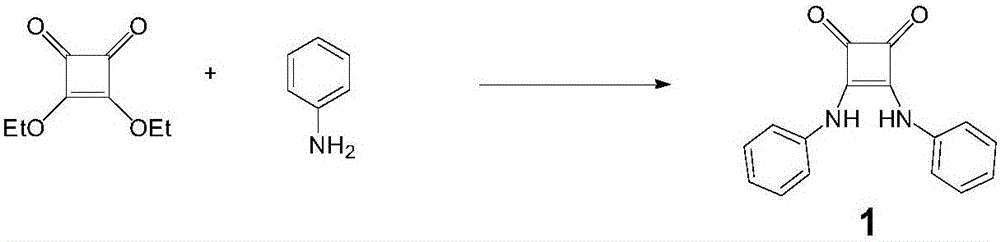

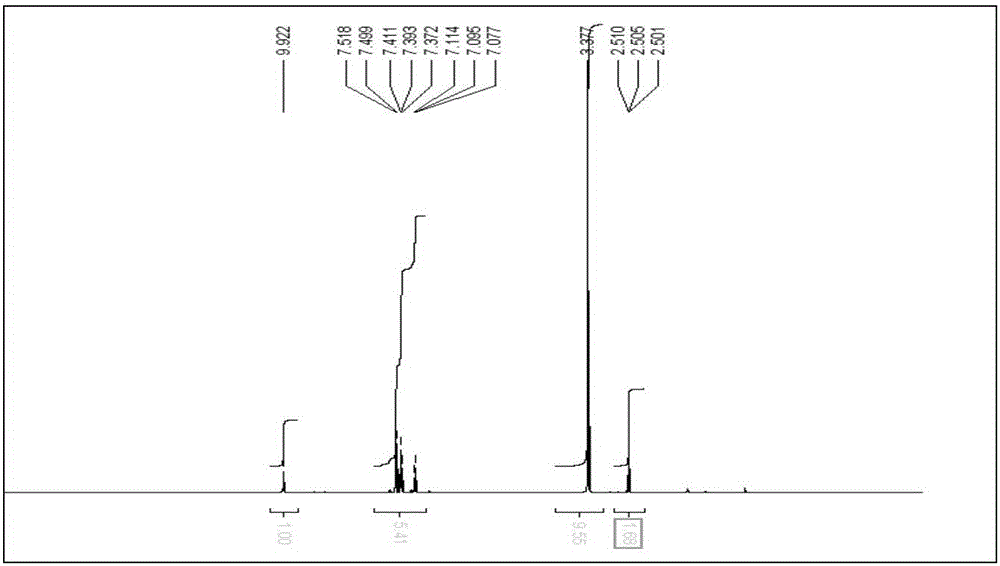

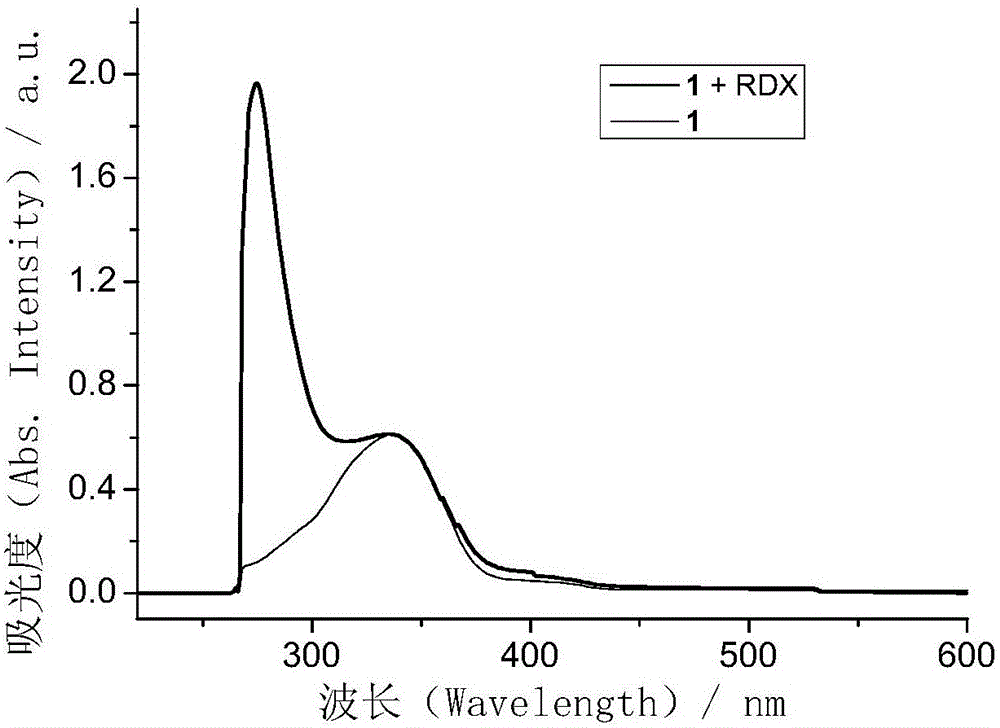

Method for detecting RDX explosive by using square amide derivative

InactiveCN104155255AQuick checkEasy to detectMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsHydrogenSynthesis methods

The invention relates to a method for detecting an RDX explosive by using a square amide derivative, which belongs to the field of chemical sensing materials. According to the method disclosed by the invention, by adopting a square amido substituted chemical sensor with optical activity, after an interaction with RDX molecules through intermolecular hydrogen bonding, the absorption strength of an ultraviolet absorption spectrum of the sensor near the waveband of 322nm is remarkably improved. The square amido substituted chemical sensor used by the method is simple in synthesis method, wide in detection range, and high in detection sensitivity, is suitable for rapid detection of RDX, and can be widely applied to the fields of national defence industries and explosive detection.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

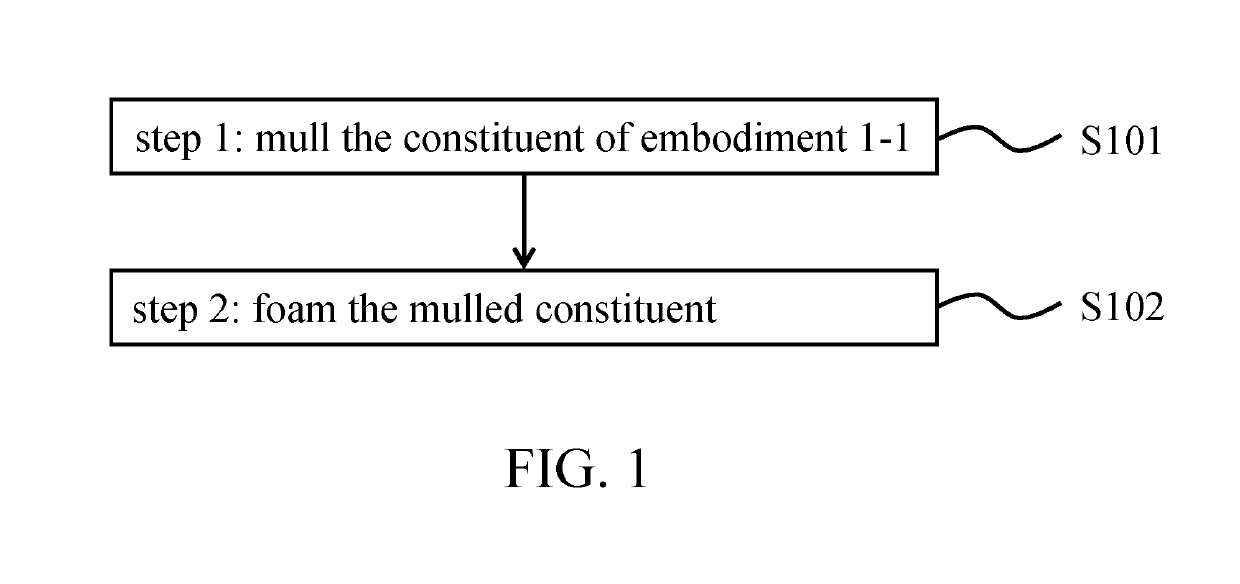

Constituent for producing shock-absorbing composite material, shock-absorbing composite material, and production method thereof

ActiveUS20190144623A1High active substance contentIncrease dampingProtective garmentSpecial outerwear garmentsThermoplastic elastomerSports equipment

A constituent for producing a shock-absorbing composite material comprises 50-80 wt % primary matrix including vinyl acetate; ethylene / vinyl acetate copolymer; 10-40 wt % secondary matrix including polyethylene; styrene-butadiene rubber; a thermoplastic elastomer; and 1-20 wt % additive. A shock-absorbing composite material which contains the constituent and a production method thereof are further introduced. The shock-absorbing composite material is applicable to sports equipment (say, shoe pads, clubs and rackets), medical care (say, care-oriented clothes for the elderly, the sick, the injured, and the handicapped), and applications related to impact protection (say, helmets and bumpers.) The shock-absorbing composite material is applied to defense industry.

Owner:NAT CHUNG SHAN INST SCI & TECH

In situ self-generation aluminum nitride enhanced magnesium-base composite material and preparation method thereof

InactiveCN100552072CEvenly distributedImprove mechanical propertiesMagnesium matrix compositeDefence industry

An in-situ self-generated aluminum nitride-reinforced magnesium-based composite material and a preparation method thereof, wherein the composite material contains 80%-95% by weight of the magnesium alloy matrix, and 5%-20% by weight of AlN ceramic particles. %. The weight percent content of aluminum in the magnesium alloy matrix is 0%-9%. The preparation method is as follows: (1) under the protection condition of 10vol.%SF6+90vol.%CO2 mixed gas, completely melt the magnesium-aluminum alloy raw material; (2) then press the Mg3N2 powder wrapped with aluminum foil into the magnesium-aluminum melt ; (3) After adding Mg3N2 powder into the melt, keep it warm to ensure that the Mg3N2 powder reacts completely with Al in the melt. (4) After the heat preservation is completed, stir the melt with a graphite disk, remove the scum on the surface, and cast it in a metal mold to solidify to obtain the material. The composite material prepared by the invention has the characteristics of light weight, high strength, high modulus, high temperature resistance, etc., and can be widely used in transportation industry and national defense industry.

Owner:SHANGHAI JIAOTONG UNIV

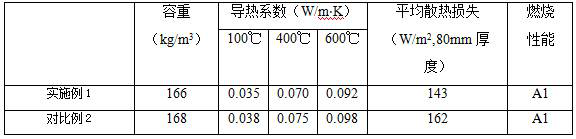

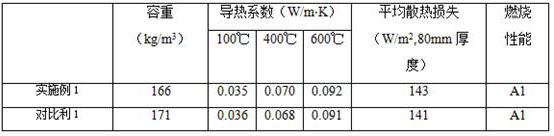

Novel porous composite silicate thermal insulation material and preparation method thereof

The invention discloses a novel porous composite silicate thermal insulation material and a preparation method thereof, and belongs to the technical field of inorganic thermal insulation materials. The material disclosed by the invention is prepared by compounding main materials including soluble fibers and vitrified microbeads with a dispersing agent, an adhesive, a penetrating agent, sepiolite fabric, calcium sulfate whiskers, silicon dioxide and an anti-thermal radiation material. The soluble fibers are used to replace the traditional ceramic fibers, and the soluble fibers have sufficient solubility in the human body fluid, such that the residence time in the human body is shortened, and the damage of the traditional ceramic fibers to the human body is reduced to the minimum. Asbestos is not contained, so that the environment is not polluted. The thermal insulation material prepared by the invention is suitable for thermal equipment of departments such as electric power, petroleum,chemical industry, light industry and national defense industry, transportation, metallurgy and the like, cold (heat) preservation engineering of the inner wall of a chimney and a kiln shell, heat preservation and insulation of pipelines and the like, and has the advantages of environmental friendliness, no toxicity, low heat conductivity coefficient, high temperature resistance, good thermal stability, good mechanical property, convenience in construction and the like.

Owner:山东民烨耐火纤维有限公司

Method for preparing thin thermal battery negative electrode pole piece based on slurry coating method

InactiveCN104681779AAchieve preparationHigh specific powerPrimary cell electrodesElectrical batteryCell fabrication

The invention belongs to the field of battery manufacturing, and relates to a method for preparing a thin thermal battery negative electrode pole piece based on a slurry coating method. The method comprises the following steps: mixing a thermal battery negative electrode powder material, an adhesive and an organic dispersing agent so as to form uniform slurry, coating the slurry on a conductive substrate, molding, drying, and curing, thereby obtaining the thin thermal battery negative electrode pole piece. Compared with a conventional powder tabletting forming process, the method is relatively low in cost, simple in process and applicable to large-scale industrial product, is innovative in the small-size / thinning field of thermal batteries, and has very high values for promoting development of the national defense industry, the thickness of the thin thermal battery negative electrode pole piece prepared by using the method can be reduced by 1 / 3-1 / 2, and the thickness of the thin thermal battery negative electrode pole piece can be adjusted within dozens of to hundreds of micrometers.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

Erbium and terbium co-doped fluoride halide phosphate laser glass as well as preparation method and application thereof

The invention discloses erbium and terbium co-doped fluoride halide phosphate laser glass which comprises components in percentage by mole as follows: 15% to 20% of Ba(H2PO4)2, 15% to 20% of Mg(PO3)2, 5% to 10% of AlF3, 10% to 20% of BaF2, 15% to 30% of MgF2, 20% to 30% of NaX, 1% to 5% of ErF3 and 4% to 10% of TbF3, wherein X is a combination of any one or more of F, Cl, Br and I. The fluoride halide phosphate laser glass is transparent and free of crystallization, the infrared transmittance is high in an area nearby 3 mu m, physical and chemical properties are excellent, the laser glass can be applied in a 3 m fiber laser and can be hopefully applied to defense industry, military and civilian areas.

Owner:合肥天奕激光医疗器械有限公司

A kind of highly erbium-doped mid-infrared germanate tellurite glass and its preparation method

ActiveCN107640893BHigh hardnessImprove thermal stabilityGlass shaping apparatusRare earthErbium doping

The invention discloses high-doped erbium intermediate infrared tellurium germinate glass. The high-doped erbium intermediate infrared tellurium germinate glass comprises the components of TeO2, GeO2,ZnCl2, BaO, a denitration catalyst waste, Na2O, and Er2O3. According to the glass prepared through a melting method, the intermediate infrared light intensity is high, the doping concentration of rare earth is high, the glass is excellent in thermal stability, and is quite promising high-optical quality glass; the wasted denitration catalyst waste is used to strengthen the hardness of the glass and improve the thermal stability of the glass, the preparation method is simple and convenient, the preparation period is short, and the glass is expected to be applied to national defence industry aswell as military and civil fields.

Owner:CHINA JILIANG UNIV

A kind of w-wc-tic-hf-co alloy bar and its preparation method

The invention discloses a W-WC-TiC-Hf-Co alloy rod and a preparation method thereof, and relates to the technical field of alloy materials. The W-WC-TiC-Hf-Co alloy rod is prepared from the following raw materials in percentage by mass: 1 to 5 percent of WC, 2 to 8 percent of TiC, 1 to 5 percent of Hf, 1 to 5 percent of Co and the balance of W and unavoidable impurities; the preparation method of the W-WC-TiC-Hf-Co alloy rod comprises the following steps: (1) uniformly mixing tungsten powder, tungsten carbide powder, titanium carbide powder, hafnium powder and cobalt powder by adopting a wet ball milling method, and performing vacuum drying to obtain mixed powder; (2) performing vacuum sintering to obtain a sintering body; (3) smelting 2 to 5 times by electron beams to obtain an ingot; (4) performing thermal extruding to obtain a semi-finished rod blank; (5) performing thermal extruding to obtain an alloy rod. The W-WC-TiC-Hf-Co alloy rod disclosed by the invention has high hardness, high strength and excellent comprehensive mechanical properties, and has wide application prospect in aerospace field, national defence industry, electronic information, energy resources and the like.

Owner:XIAN HUASHAN METAL PROD CO LTD

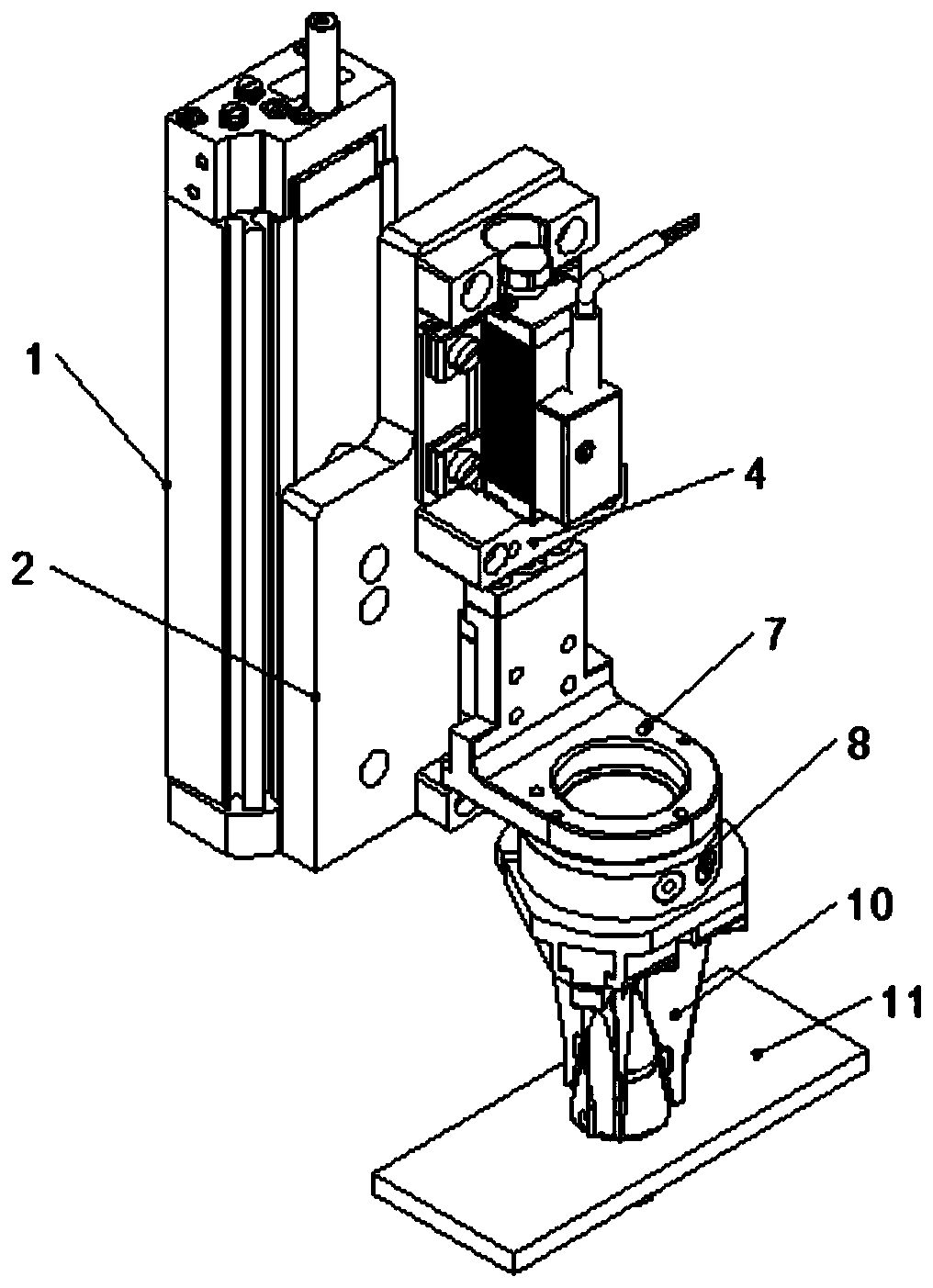

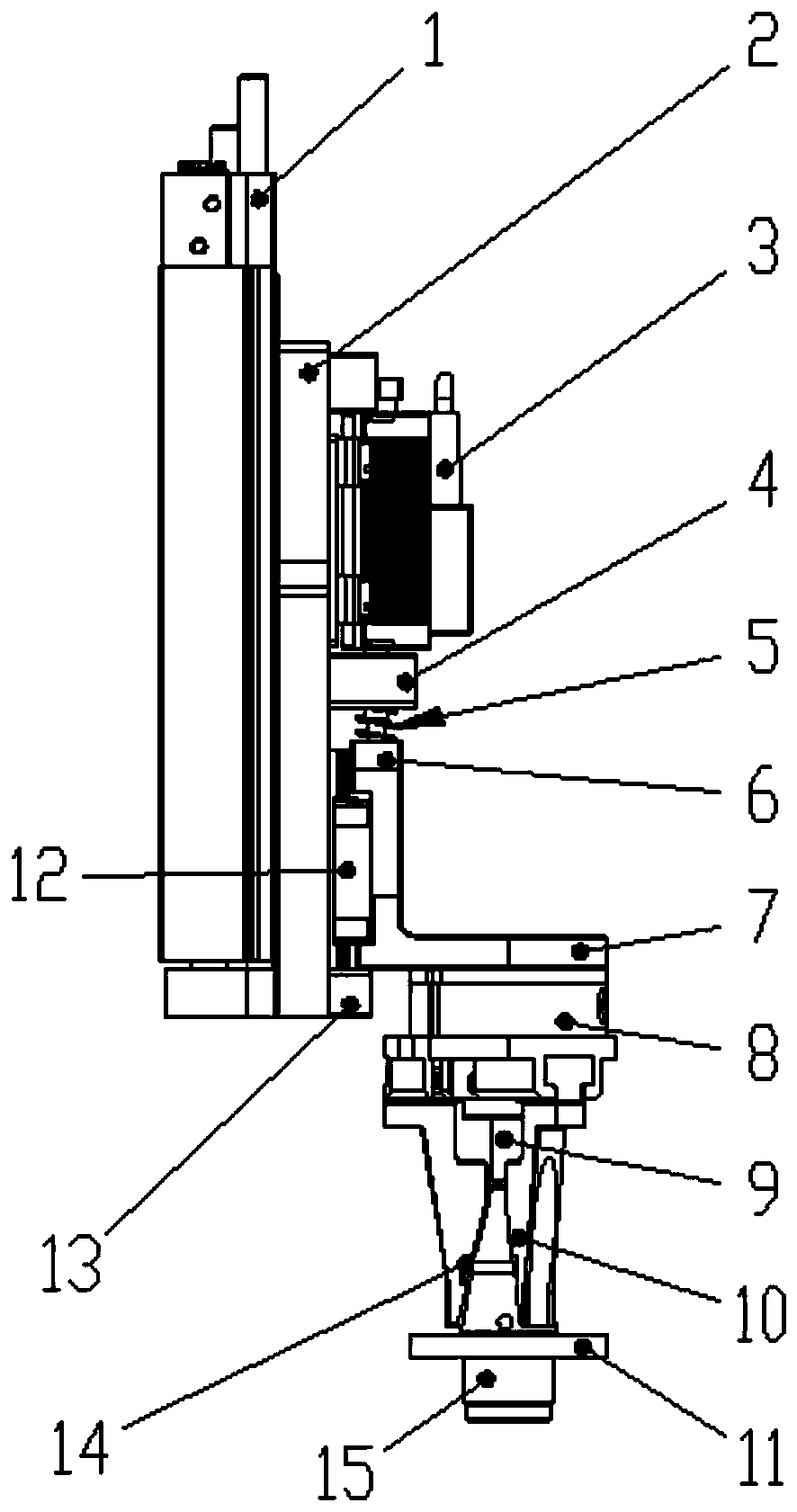

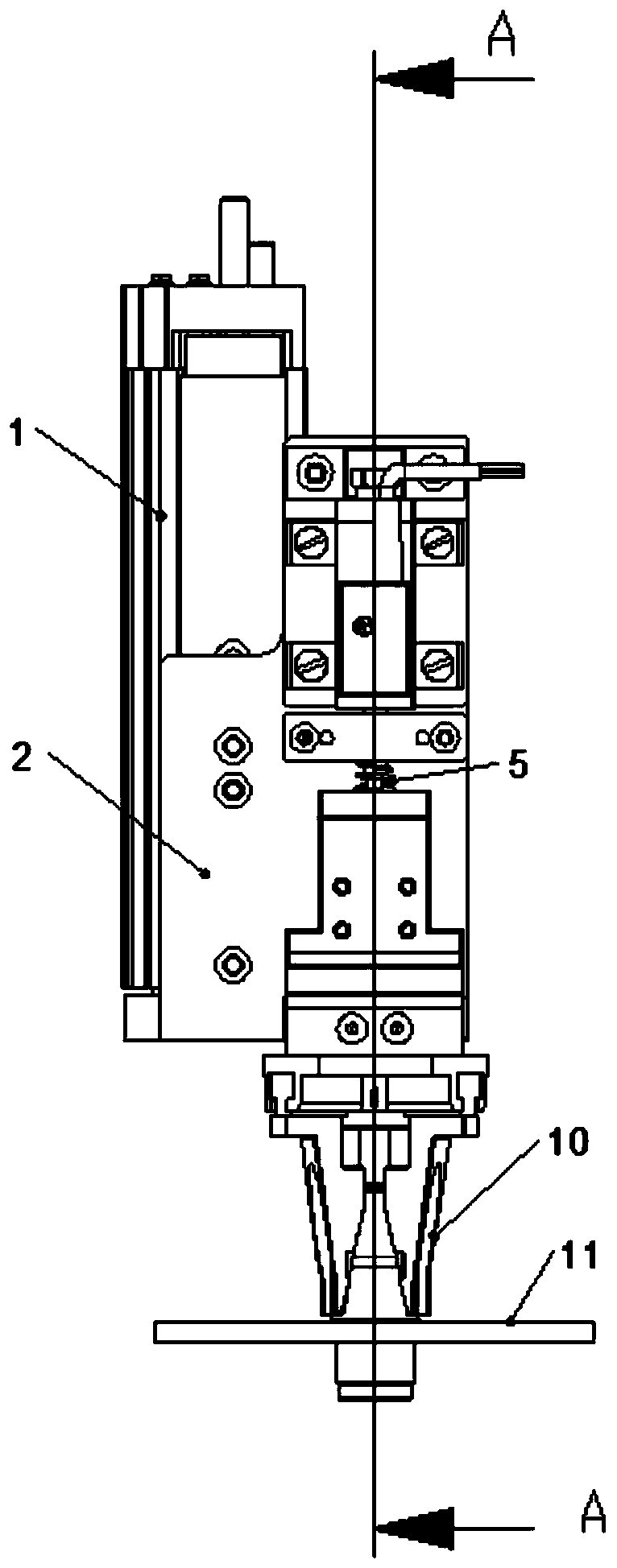

Anti-explosion clamping jaw mechanism with height measuring function

PendingCN111496827AMeet the requirements of electrical explosion-proof places such as assemblySimple structureGripping headsMechanical engineeringDefence industry

The invention discloses an anti-explosion clamping jaw mechanism with a height measuring function. The anti-explosion clamping jaw mechanism comprises a lifting cylinder. A piston rod of the lifting cylinder is connected with a large mounting plate. The large mounting plate is connected with an anti-explosion displacement sensor. A sensing rod of the anti-explosion displacement sensor penetrates through a supporting block and a spring. The sensing rod of the anti-explosion displacement sensor makes contact with a transition plate. The supporting block is connected with the large mounting plate. The transition plate is connected with a clamping jaw mounting plate. The large mounting plate is connected with a guide rail. The clamping jaw mounting plate is connected with a sliding base of theguide rail. A clamping jaw cylinder is mounted at the bottom of the clamping jaw mounting plate. The bottom of the clamping jaw cylinder is provided with a push rod. The clamping jaw cylinder is provided with clamping jaws. The large mounting plate is connected with a stop block. An anti-explosion clamping jaw system can float up and down within a small distance and realizes synchronous completion of grabbing and measuring. The equipment is simplified. The production efficiency is improved. Meanwhile, the anti-explosion clamping jaw mechanism can meet the requirements for electrical explosion-proof occasions for national defense industry ammunition assembly and the like, can achieve the purpose of omitting an independent detection device, simplifies the technological process and is very easy to operate.

Owner:中国兵器工业火炸药工程与安全技术研究院

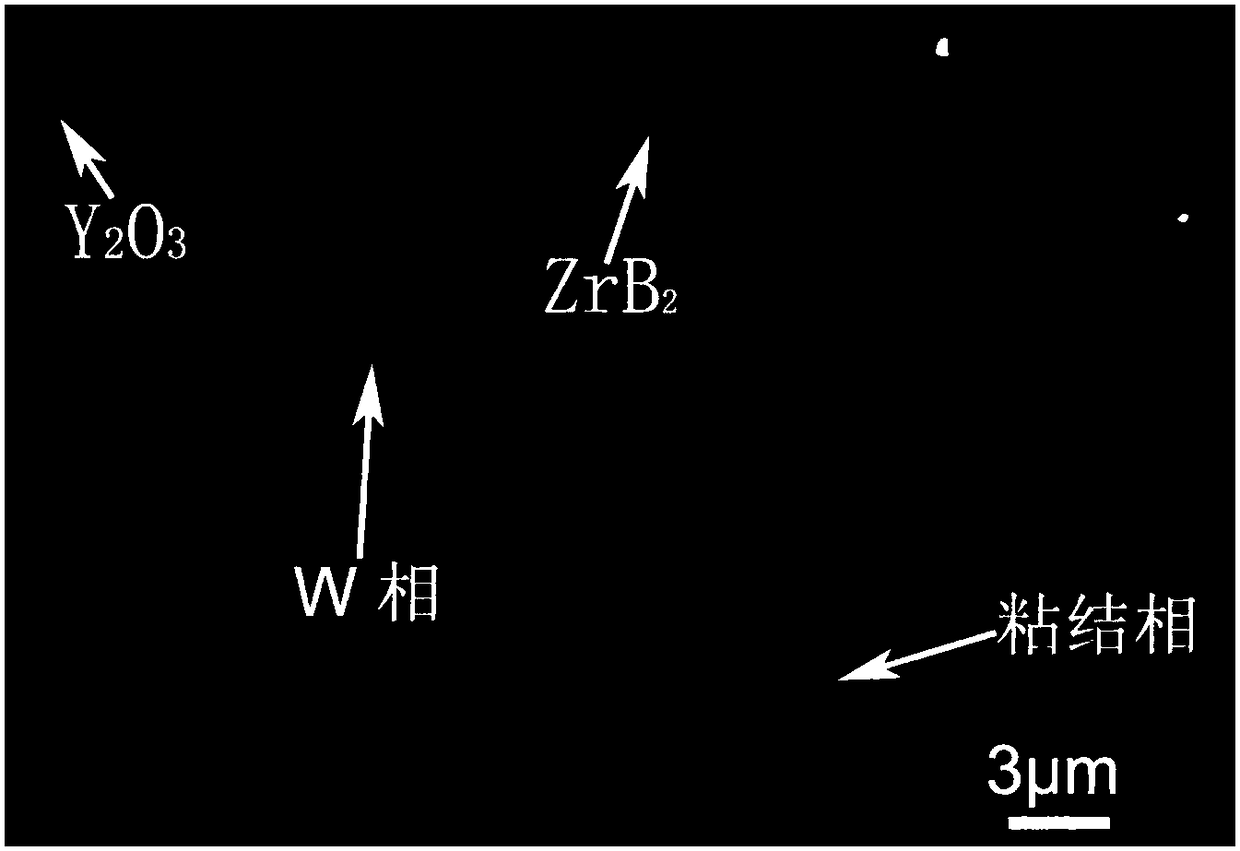

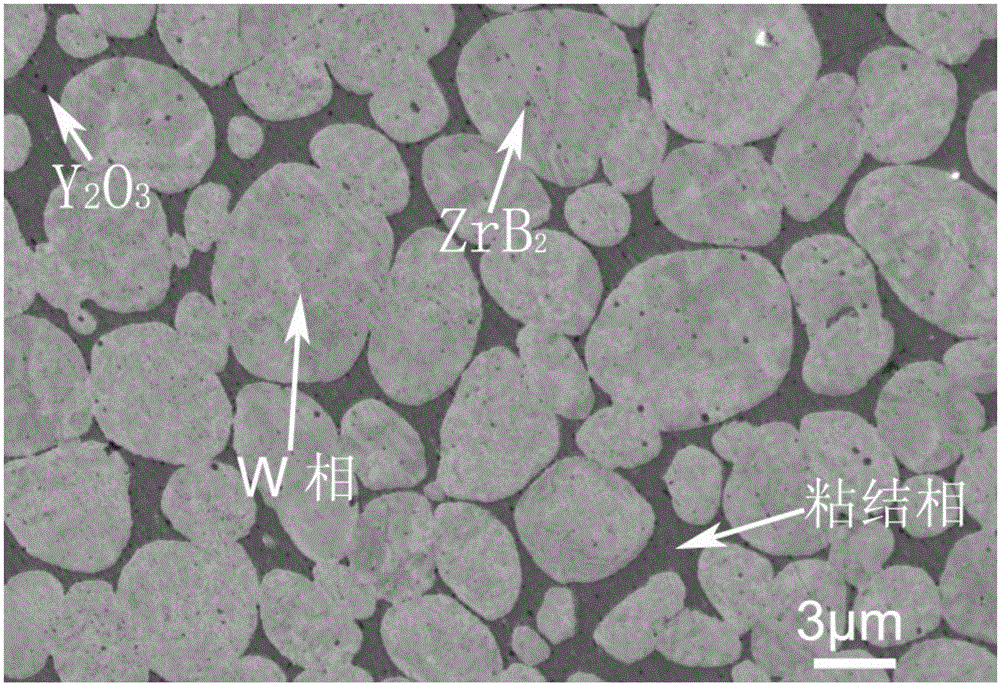

A kind of w-ni-fe-y-zrb2 multiphase alloy material and preparation method thereof

The invention discloses a W-Ni-Fe-Y-ZrB2 multi-phase alloy material and a preparation method thereof, and relates to the technical field of multi-phase materials. The W-Ni-Fe-Y-ZrB2 multi-phase alloy material is prepared from the following raw materials in percentage by mass: 2 to 8 percent of Ni, 1 to 4 percent of Fe, 5 to 11 percent of Y, 1 to 5 percent of ZrB2, and the balance of W; the preparation method of the W-Ni-Fe-Y-ZrB2 multi-phase alloy material comprises the following steps: (1) weighing various raw materials in percentage by mass, and then performing ball milling on the weighed raw materials under the protection of argon and mixing uniformly to obtain mixed powder; (2) preparing shells, filling the shells with the mixed powder, and sealing the shells after vacuumizing; (3) hot isostatic pressing sintering to obtain the W-Ni-Fe-Y-ZrB2 multi-phase alloy material. The multi-phase alloy material disclosed by the invention has the characteristics of high room-temperature and high-temperature strength, high plasticity, low thermal expansion coefficient and oxidation resistance, and has wide application prospect in top science field, national defence industry and civil industry.

Owner:XIAN HUASHAN METAL PROD CO LTD

A method for producing wave-absorbing materials from industrial waste liquid rich in ferromanganese

ActiveCN103739281BSolve wasteNo emissionsOther chemical processesInorganic material magnetismSpray GranulationIndustrial effluent

The invention relates to an industrial effluent treatment method and particularly relates to a method for preparing a wave-absorbing material by using industrial effluent rich in manganese iron. The method comprises the following steps: 1, desilicication treatment; 2, drying; 3, component measurement and adjustment; 4, dry powder mixing; 5, presintering; 6, sanding; 7, pulping; 8, spray granulation and formation; 9, sintering. The industrial effluent treatment method provided by the invention can be used for sufficiently recycling manganese iron elements in an effluent, so that the problem of resource waste is solved; in addition, no harmful substances are discharged, so that no secondary pollution is caused, and the industrial effluent treatment method is very environment-friendly; a manganese zinc ferrite wave-absorbing material manufactured by using the method has the characteristics of high permeability, wide band and high electromagnetic wave absorption efficiency so as to be widely applied to various electronic products and national defence industry products.

Owner:山东春光磁电科技有限公司

A kind of nb-si-c alloy rod and preparation method thereof

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for preparing wave-absorbing material by using industrial effluent rich in manganese iron

ActiveCN103739281ASolve wasteNo emissionsOther chemical processesInorganic material magnetismHazardous substanceManganese

The invention relates to an industrial effluent treatment method and particularly relates to a method for preparing a wave-absorbing material by using industrial effluent rich in manganese iron. The method comprises the following steps: 1, desilicication treatment; 2, drying; 3, component measurement and adjustment; 4, dry powder mixing; 5, presintering; 6, sanding; 7, pulping; 8, spray granulation and formation; 9, sintering. The industrial effluent treatment method provided by the invention can be used for sufficiently recycling manganese iron elements in an effluent, so that the problem of resource waste is solved; in addition, no harmful substances are discharged, so that no secondary pollution is caused, and the industrial effluent treatment method is very environment-friendly; a manganese zinc ferrite wave-absorbing material manufactured by using the method has the characteristics of high permeability, wide band and high electromagnetic wave absorption efficiency so as to be widely applied to various electronic products and national defence industry products.

Owner:山东春光磁电科技有限公司

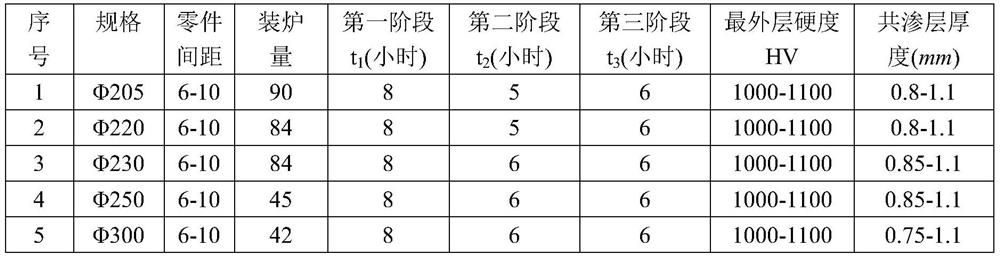

Three-stage carbon-nitrogen-boron ternary gas deep co-infiltration method for low carbon nickel molybdenum steel

ActiveCN110592524BHigh hardnessImprove wear resistanceSolid state diffusion coatingBoridePtru catalyst

Owner:XI'AN PETROLEUM UNIVERSITY

W-Ni-Fe-Y-ZrB2 multi-phase alloy material and preparation method thereof

The invention discloses a W-Ni-Fe-Y-ZrB2 multi-phase alloy material and a preparation method thereof, and relates to the technical field of multi-phase materials. The W-Ni-Fe-Y-ZrB2 multi-phase alloy material is prepared from the following raw materials in percentage by mass: 2 to 8 percent of Ni, 1 to 4 percent of Fe, 5 to 11 percent of Y, 1 to 5 percent of ZrB2, and the balance of W; the preparation method of the W-Ni-Fe-Y-ZrB2 multi-phase alloy material comprises the following steps: (1) weighing various raw materials in percentage by mass, and then performing ball milling on the weighed raw materials under the protection of argon and mixing uniformly to obtain mixed powder; (2) preparing shells, filling the shells with the mixed powder, and sealing the shells after vacuumizing; (3) hot isostatic pressing sintering to obtain the W-Ni-Fe-Y-ZrB2 multi-phase alloy material. The multi-phase alloy material disclosed by the invention has the characteristics of high room-temperature and high-temperature strength, high plasticity, low thermal expansion coefficient and oxidation resistance, and has wide application prospect in top science field, national defence industry and civil industry.

Owner:XIAN HUASHAN METAL PROD CO LTD

A method for detecting rdx explosives with squaramide derivatives

InactiveCN104155255BQuick checkEasy to detectMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsHydrogenSynthesis methods

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A filling support method for enhancing the processing rigidity of thin-walled parts

ActiveCN104259883BEasy to makeLow costPositioning apparatusMetal-working holdersAviationMachining deformation

Owner:BEIJING SATELLITE MFG FACTORY

Method for scaling-up purification of ethyl dicyclopentadienyl iron

The ethyl ferrpcene is the intermediate to compose the efficient burning speed activator [2, 2-double (the ethyl ferrocene) the dimethylmethane] and has the important applied cost in aerospace industry and the national defence industry. So, the producing on a large scale and the purifying the ethyl ferrocene are very important. The impurity in the ethyl ferrocene is mainly the ferrocene and other ramification of the ferrocene. Generally, the vacuum distillation is adopted to purify the ethyl ferrocene; the impurity such as the ferrocene can be extracted with the ethyl ferrocene distillate during the reduced pressure distillation process, so the effect of the vacuum distillation is not good. The impurity can't be eliminated only by the vacuum distillation when producing the ethyl ferrocene on a large scale; So,the method is invented. The invention is easy and convenient.The invention wipe off the impurity by the ordinary case;so the ethyl ferrocene can be purified on a large scale. The invention has the important applied cost to the producing the ramification of the ferrocene on a large scale.

Owner:邱吉辉 +1

Constituent for producing shock-absorbing composite material, shock-absorbing composite material, and production method thereof

ActiveUS10442909B2Improve liquidityEffective material contentProtective garmentSpecial outerwear garmentsThermoplastic elastomerSports equipment

Owner:NAT CHUNG SHAN INST SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com