Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Good anti-devitrification performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

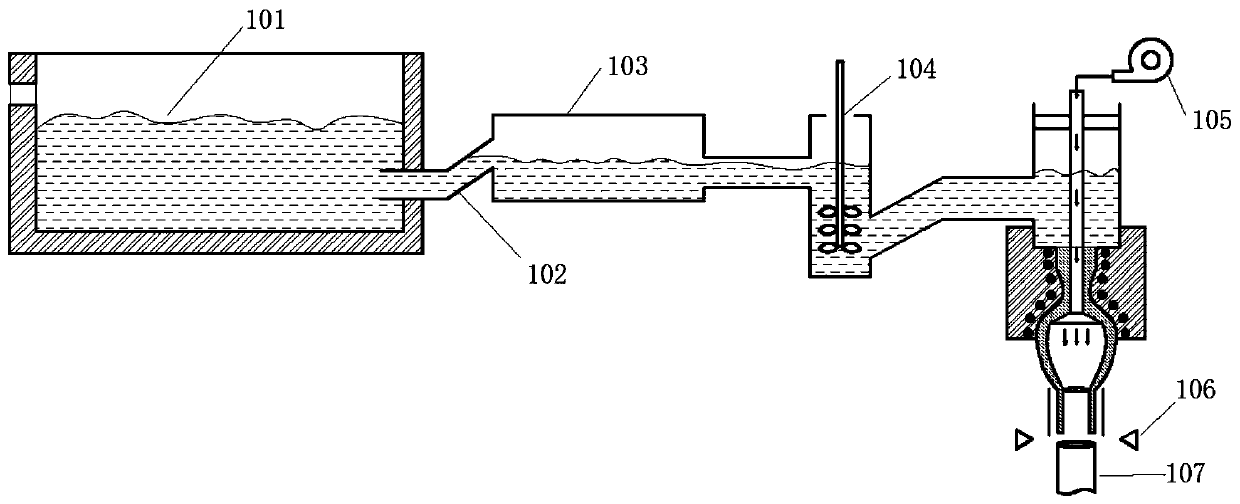

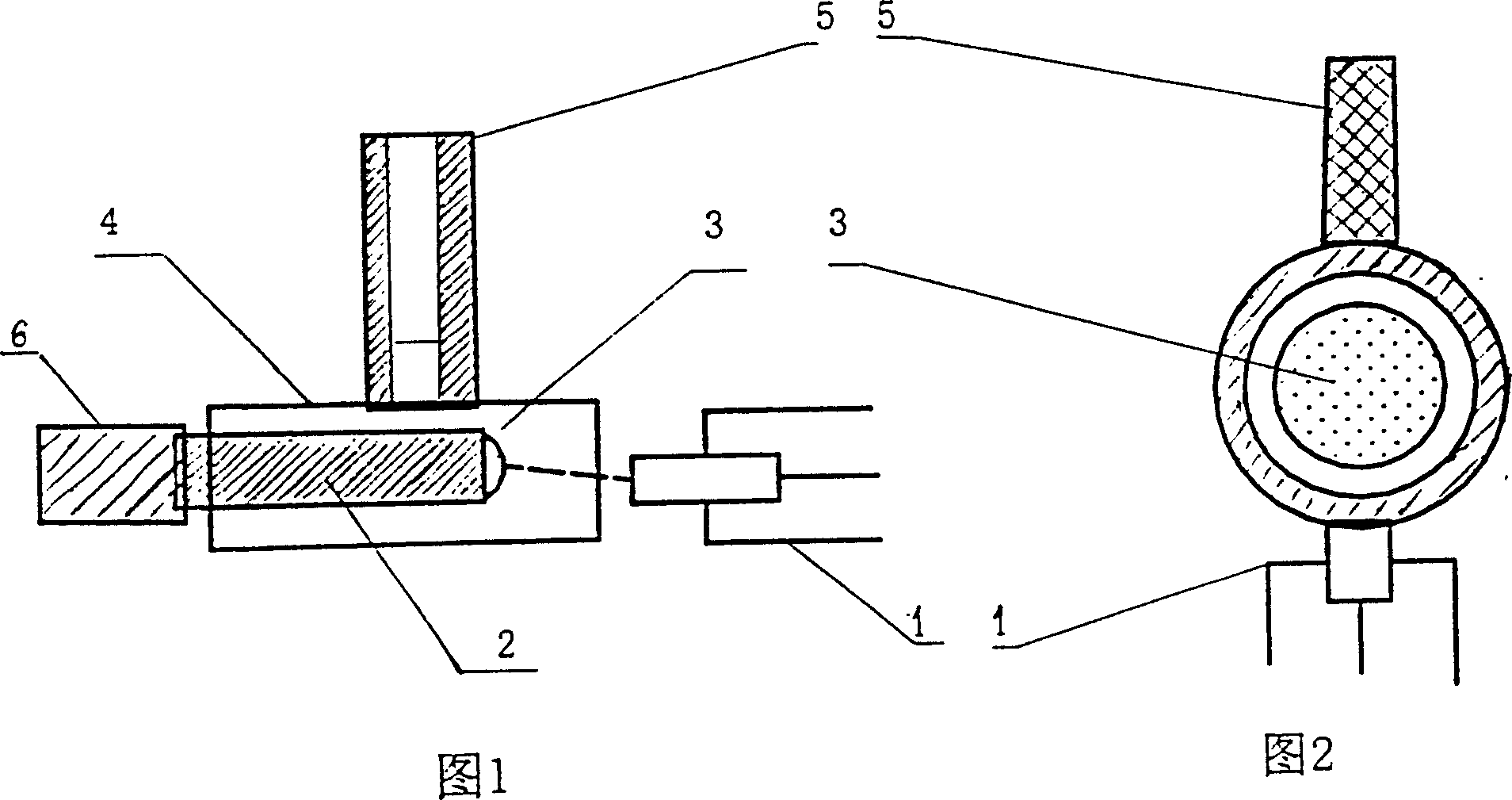

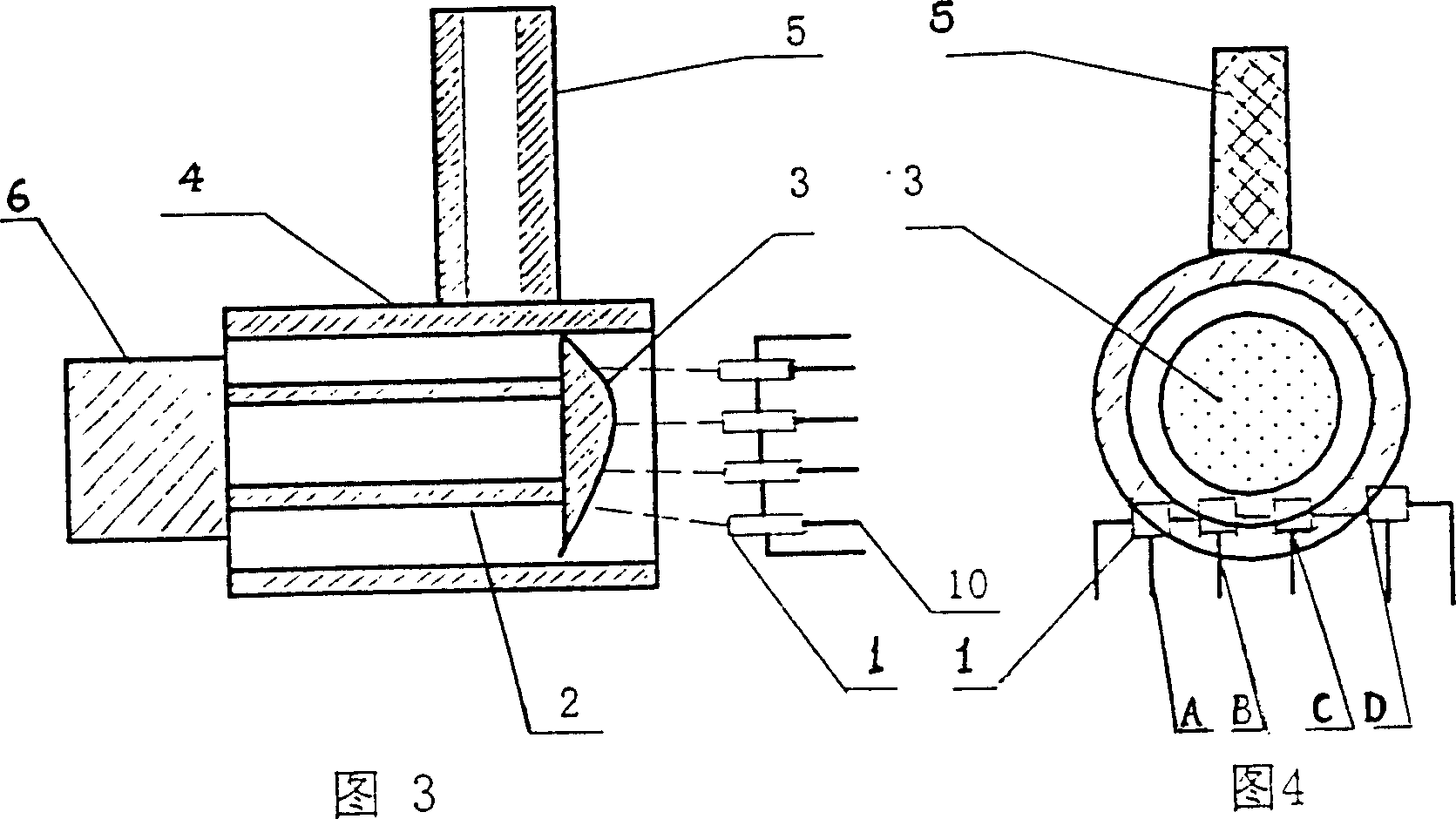

Method for producing glass beads used for curing high-level nuclear wastes

InactiveCN101857355AGood anti-devitrification performanceLow viscosityGlass shaping apparatusRotary furnaceRaw material

The invention provides a method for producing glass beads used for curing high-level nuclear wastes. The method comprises the following steps of: uniformly mixing raw materials, melting the raw materials into glass solution by using an all-electric glass melting furnace at the temperature of between 1,300 and 14,000 DEG C, clarifying and homogenizing the glass solution for 5 to 8 hours, cooling the glass solution to obtain glass block green bodies, and preparing glass blocks by specifications of finished products from the obtained glass block green bodies; uniformly mixing each 100 parts of the obtained glass blocks with 10 to 25 parts of charcoal powder and 1 to 3 parts of carbon black, and throwing a mixture into a glass bead electrothermal rotary furnace, of which the running speed is 20 to 30 revolution per minute, at a speed of 0.7 to 1.0 kilogram per minute at the temperature of between 850 and 940 DEG C through the glass bead electrothermal revolving furnace, and rolling the mixture to form a ball-shaped mixture; and finally annealing and cooling the ball-shaped mixture to obtain the glass beads used for curing the nuclear wastes. The glass beads used for curing the high-level nuclear wastes produced by the method has ideal high-temperature viscosity, high mechanical strength and high anti-crystallization performance.

Owner:天台精工西力玻璃珠有限公司

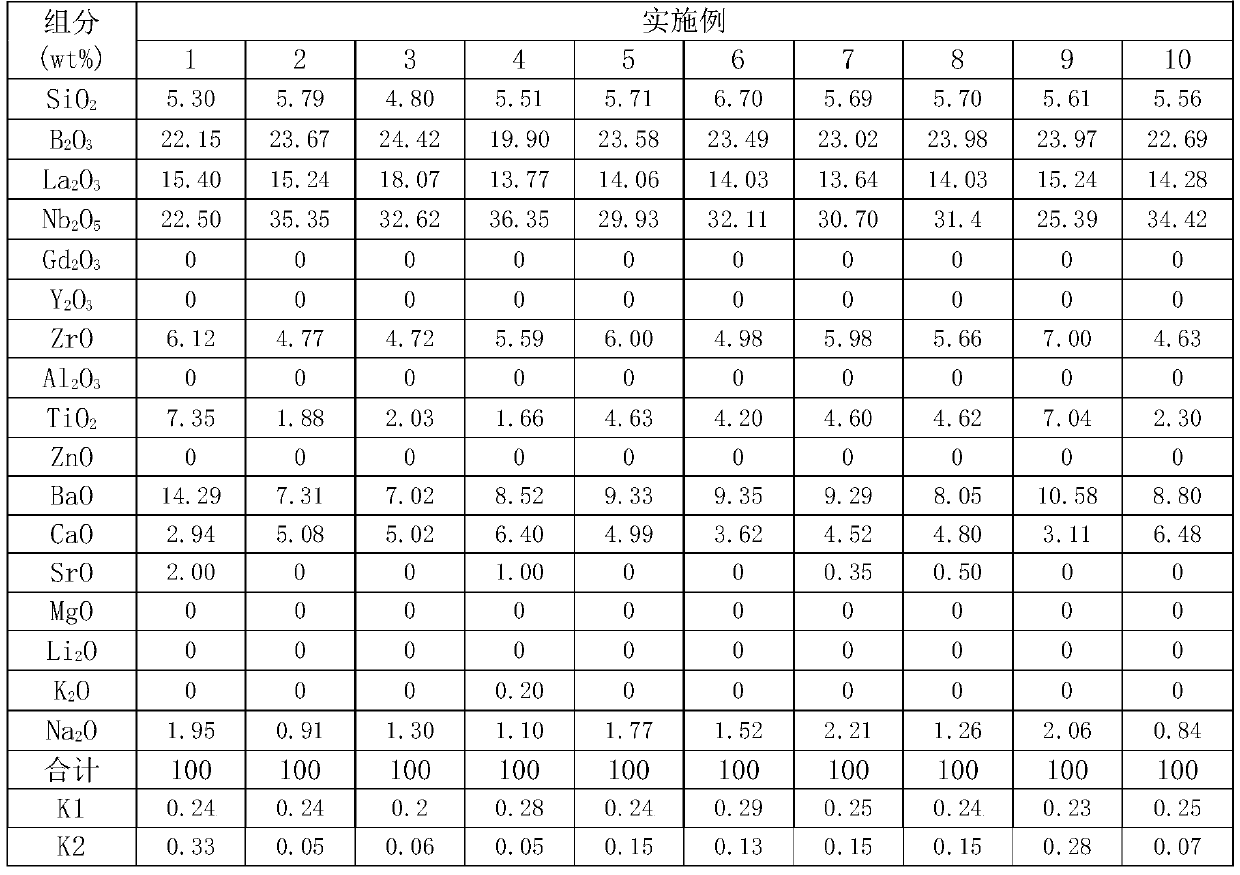

Optical glass, prefabticated member thereof, optical element and optical instrument

ActiveCN109264989AHigh resistance to devitrificationGood chemical stabilityOptical elementsDevitrificationRefractive index

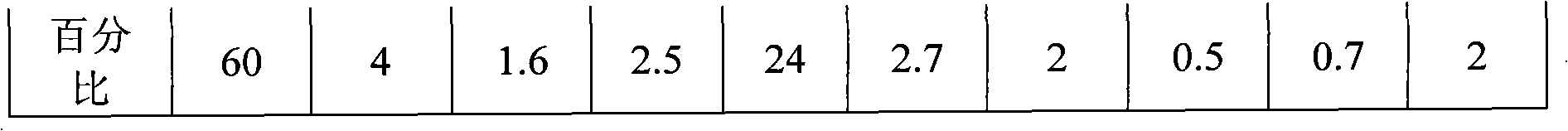

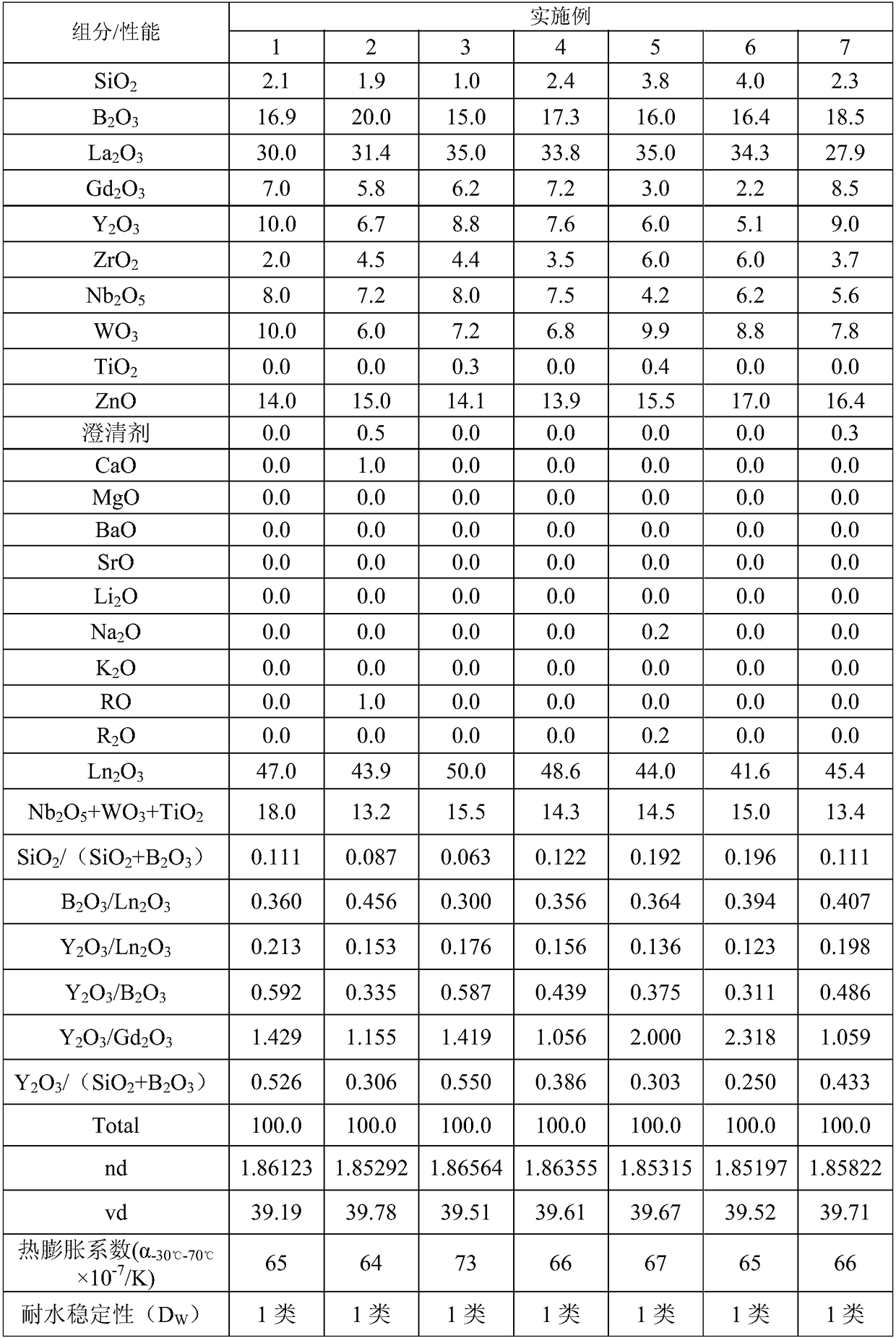

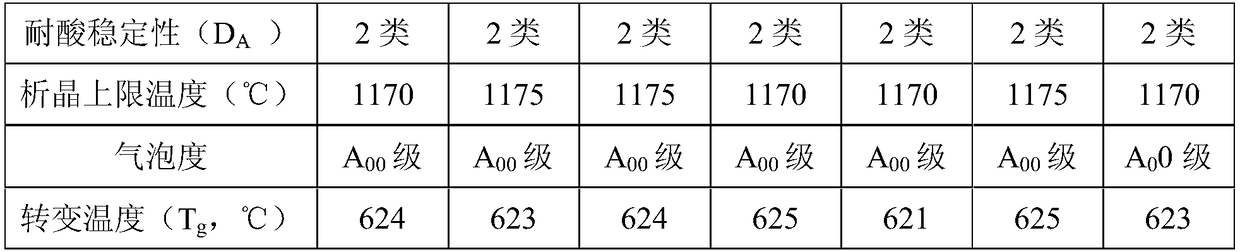

The invention relates to optical glass, a prefabticated member thereof, an optical element and an optical instrument, and provides the optical glass which is prepared from the following components inpercentage by weight: 0 to 10% of SiO2, 5 to 25% of B2O3, 0 to 15% of ZrO2, 10 to 25% of ZnO, 2 to 30% of TiO2 plus Nb2O5 plus WO3 and 30 to 55% of Ln2O3. The content of the Ln2O3 is total content ofLa2O3, Gd2O3, Y2O3 and Yb2O3, wherein a ratio of B2O3 to Ln20O3 is 0.3 to 0.8, and a ratio of Y2O3 to Gd2O3 is 0.3 to 3. The optical glass has a refractive index (nd) of 1.84 to 1.87 and an abbe number (vd) of 38 to 41, and meanwhile, is excellent in devitrification resistance and crystallization resistance and high in chemical stability.

Owner:CDGM OPTICAL GLASS

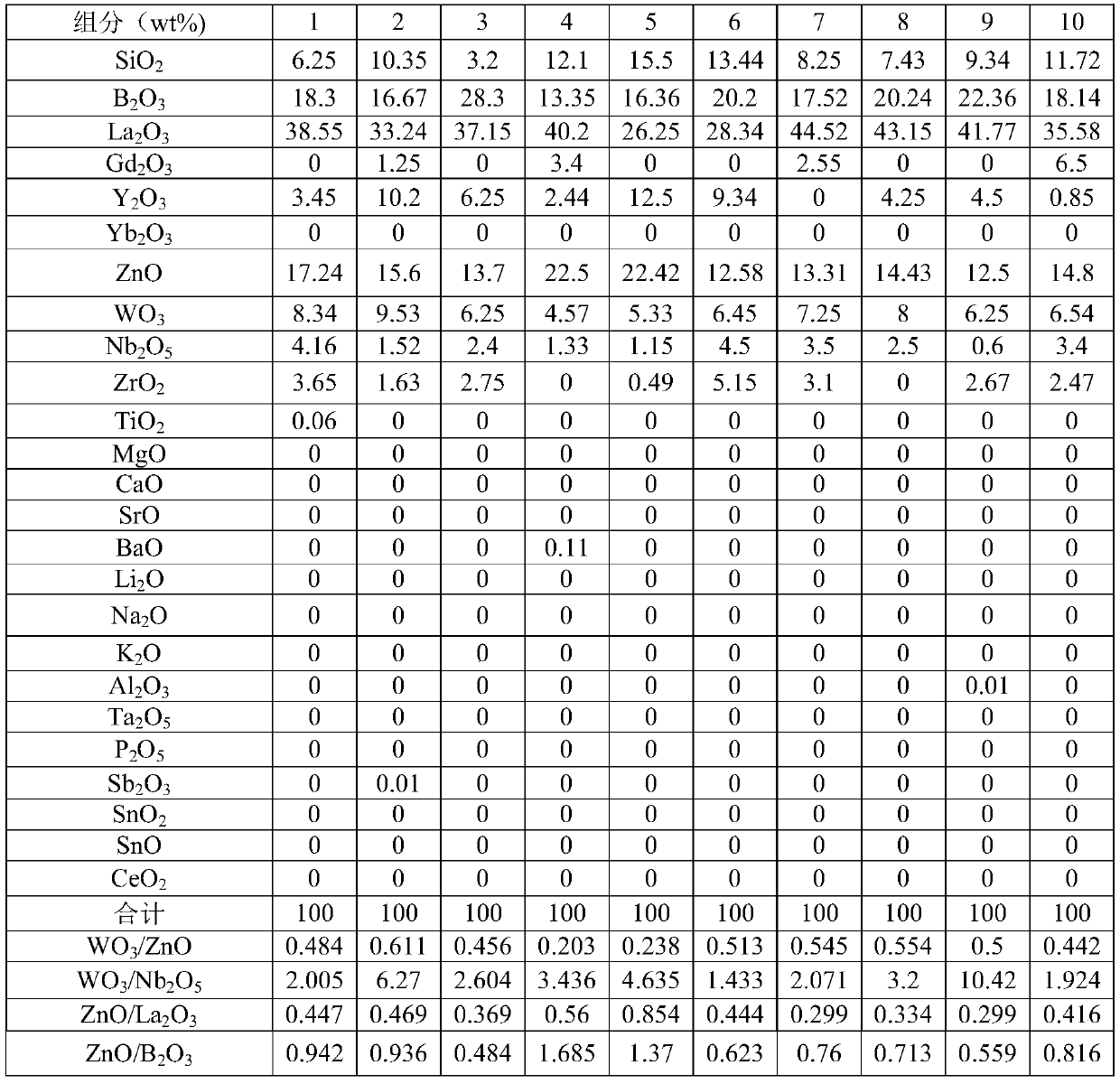

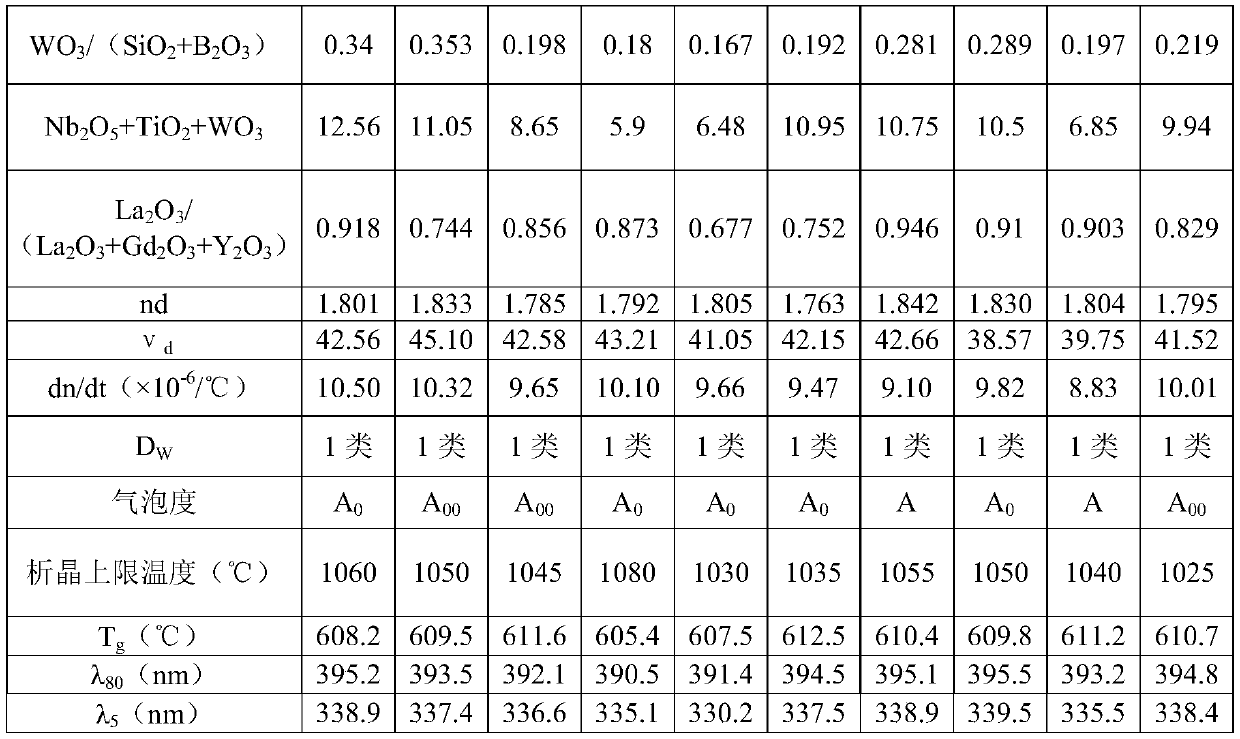

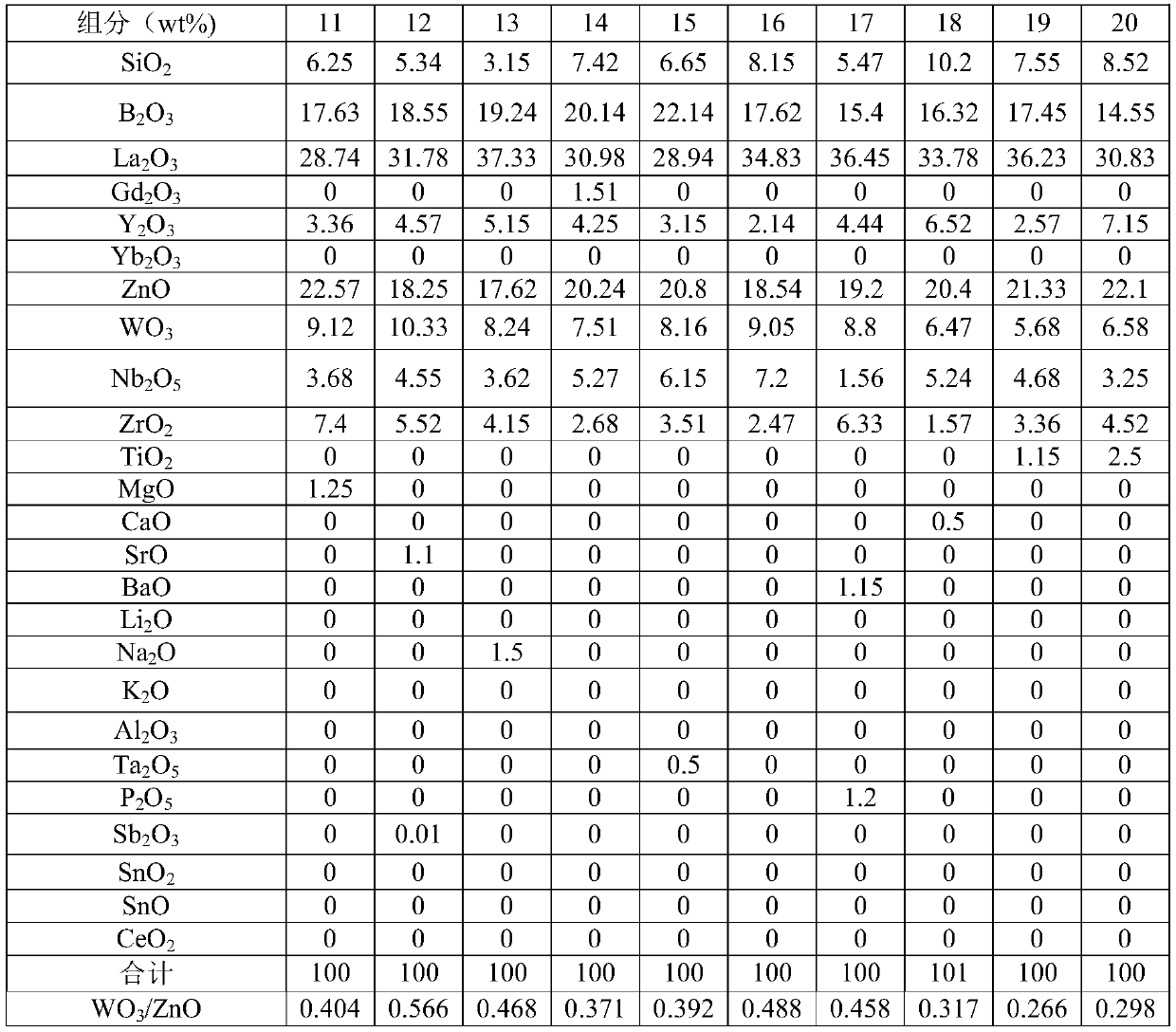

Optical glass, glass preform, optical element and optical instrument

ActiveCN109721241ALarge positive temperature coefficient of refractionGood anti-devitrification performanceRefractive indexOptical instrument

The invention provides an optical glass, which comprises, by weight, 0-20% of SiO2, 10-30% of B2O3, 20-50% of La2O3, 0-15% of Gd2O3, 0-15% of Y2O3, 12-30% of ZnO, 4-20% of WO3, 0-15% of Nb2O5, and 0-10% of ZrO2, wherein WO3 / ZnO is 0.15-1.5. According to the present invention, through the reasonable component design, the obtained optical glass has a large positive refractive index temperature coefficient and excellent anti-crystallization property in the case of the obtaining of desired refractive index, desired Abbe number and other desired optical performances.

Owner:CDGM OPTICAL GLASS

Optical glass

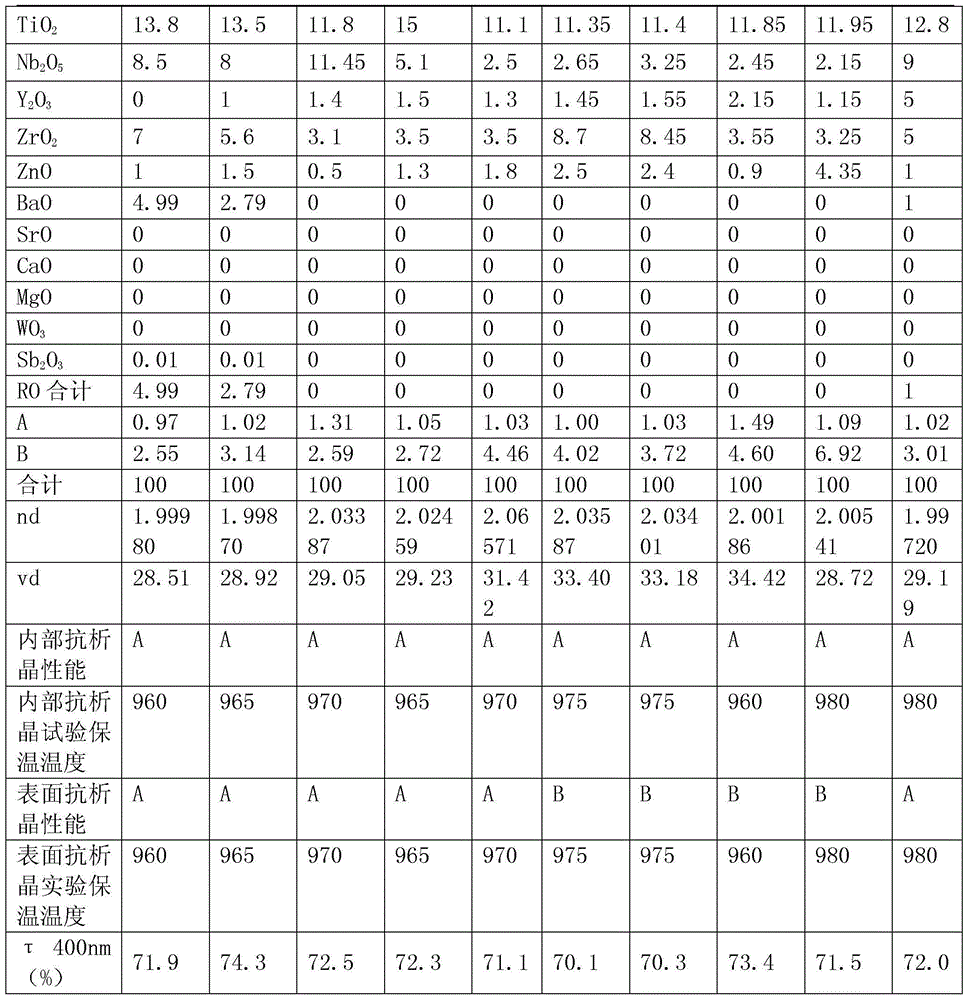

ActiveCN112125511AGood anti-devitrification performanceHigh dispersionGlass shaping apparatusOptical elementsAlkali metal oxidePhysical chemistry

The invention provides optical glass. The optical glass comprises the following components in percentage by weight: 25-45% of SiO2; 2-15% of ZrO2; 35-60% of Nb2O5; 1-10% of Li2O; 2-15% of Na2O; and 0-10% of k2O. According to the optical glass of the invention, the optical glass has excellent crystallization resistance by containing a proper amount of SiO2, alkali metal oxide and other components;the optical glass with high refractive index and high dispersion is obtained by containing Nb2O5, ZrO2 and other oxide components with high refractive index; through reasonable component design, the optical glass has low relative partial dispersion.

Owner:CDGM OPTICAL GLASS

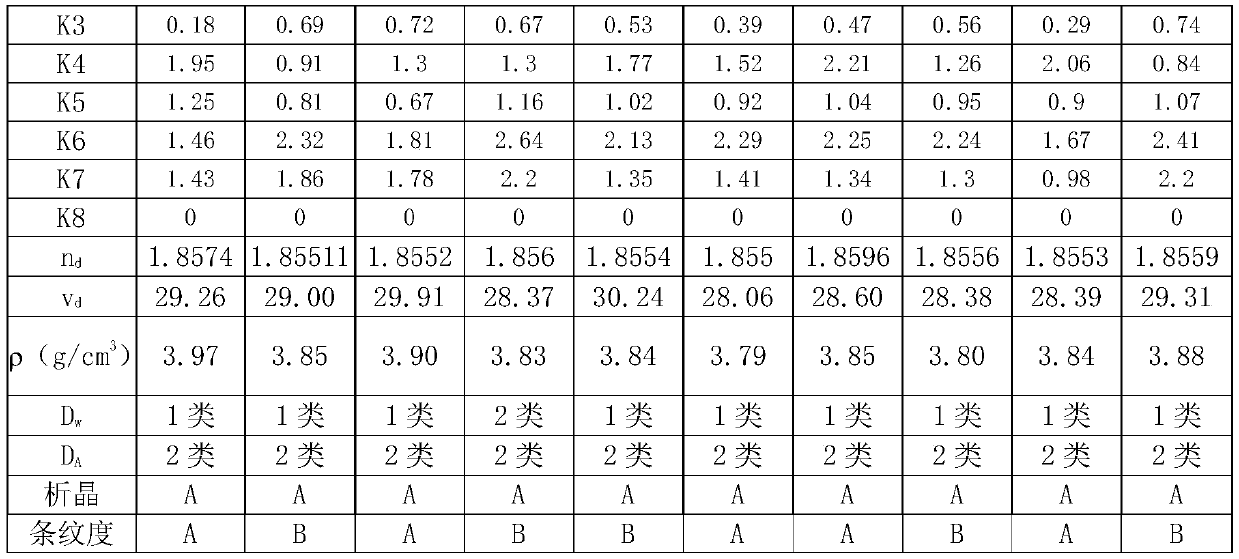

High-refractive index high-dispersive index optical glass, optical element, and optical instrument

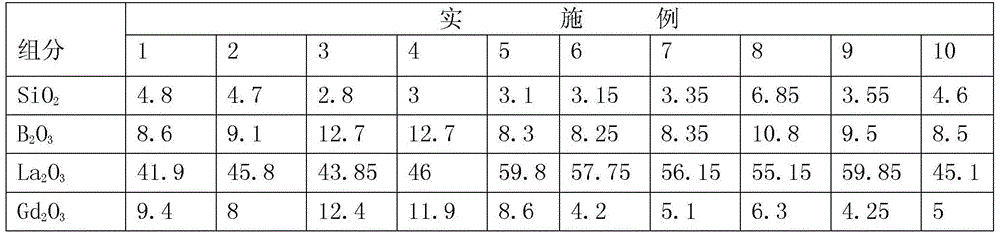

A high refractivity and high dispersion optical glass with light transmissivity and good devitrification resistance. The high refractivity and high dispersion optical glass, including: 1 wt % to 13 wt % of SiO2, 6 wt % to 15 wt % of B2O3, 5 wt % to 22 wt % of TiO2, 35 wt % to 60 wt % of La2O3, 1 wt % to 15 wt % of Gd2O3, 2 wt % to 10 wt % of ZrO2, 1 wt % to 15 wt % of Nb2O5, 0.5 wt % to 8 wt % of ZnO, 0 to 8 wt % of WO3 and 0 to 10 wt % of Y2O3, with Ta2O5 and GeO2 excluded. The optical glass has degree of pigmentation and light transmissivity due to no pigmenting Bi2O3, and has low cost due to no valuable oxides such as Ta2O5 and GeO2. The optical glass has devitrification resistance with a refractive index of 1.95-2.07 and Abbe number of 25-35.

Owner:CDGM OPTICAL GLASS

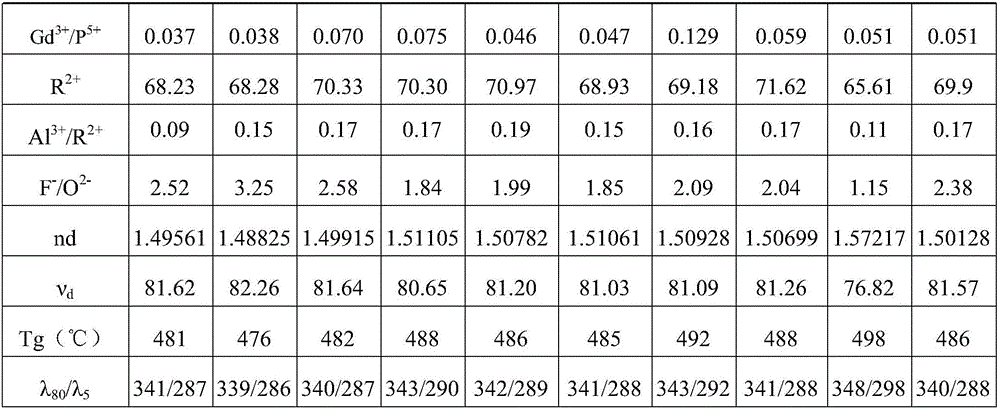

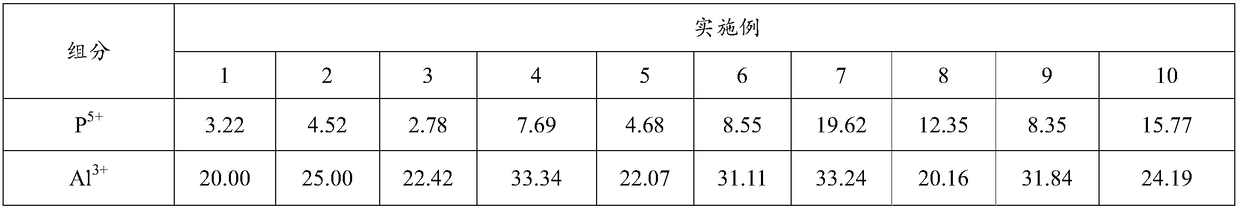

Optical glass, optical preform and optical element

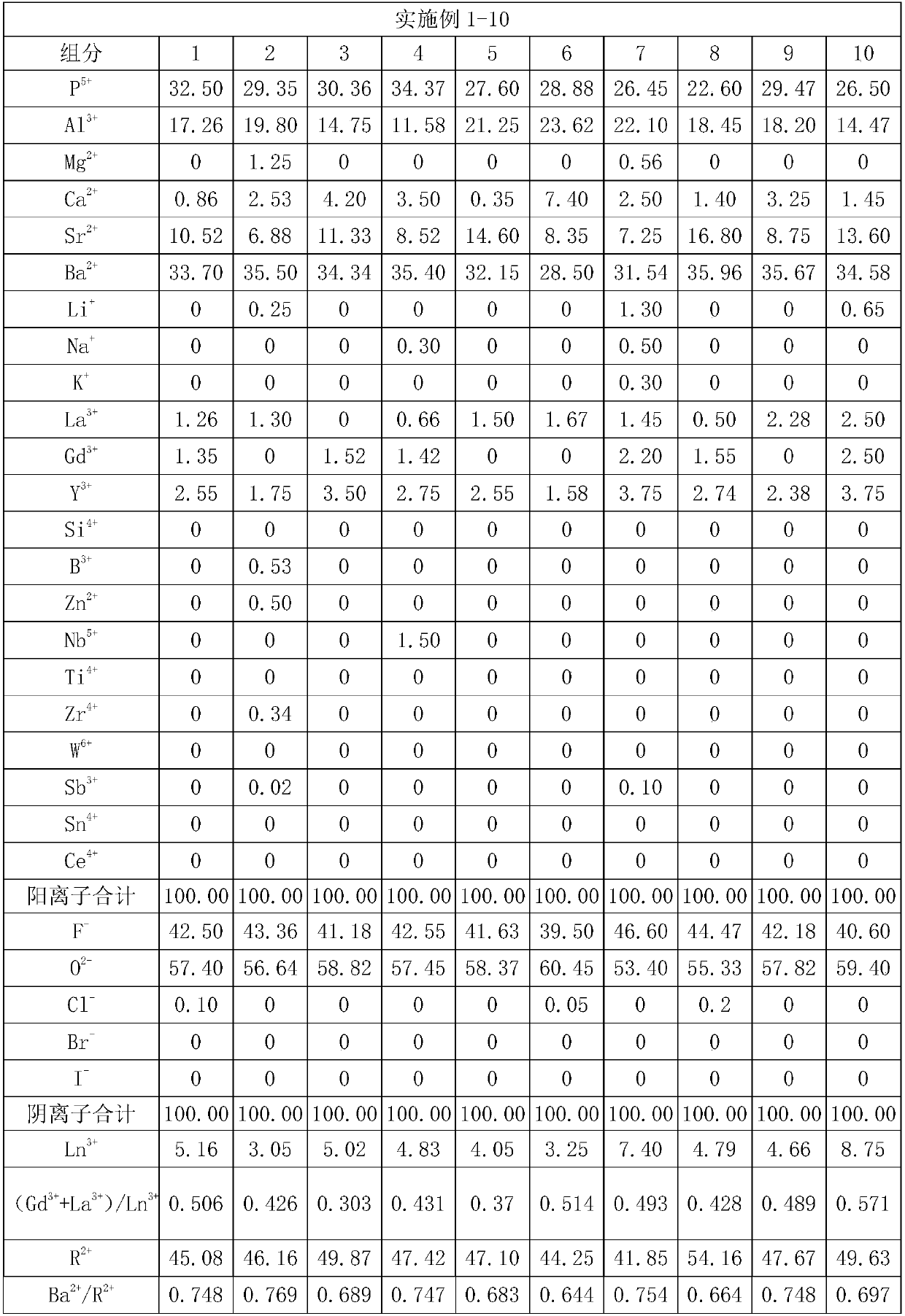

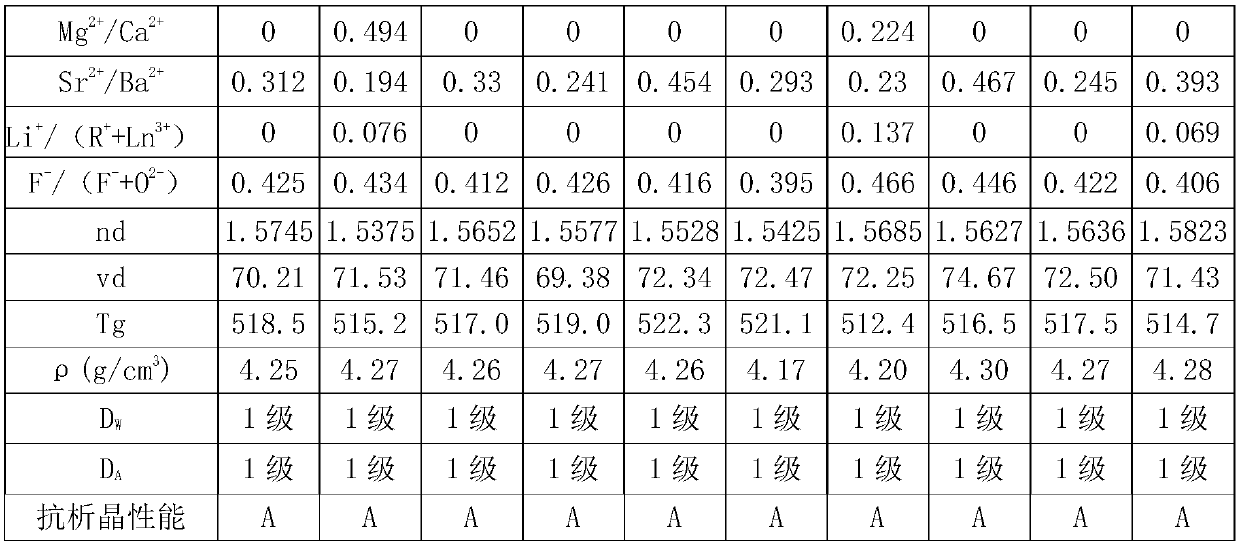

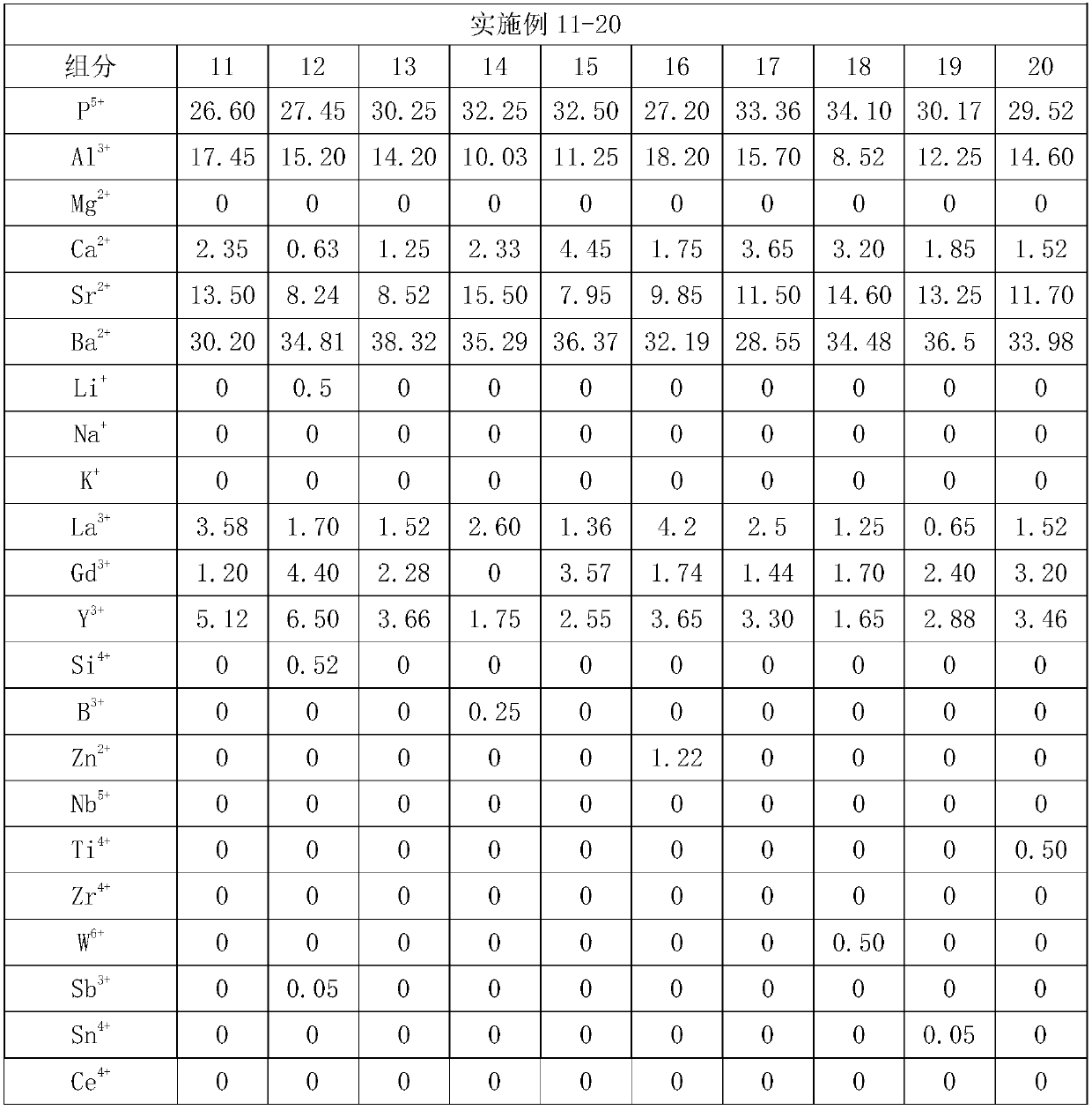

PendingCN110606660AGood anti-devitrification performanceGood chemical stabilityOptical elementsRefractive indexOptical glass

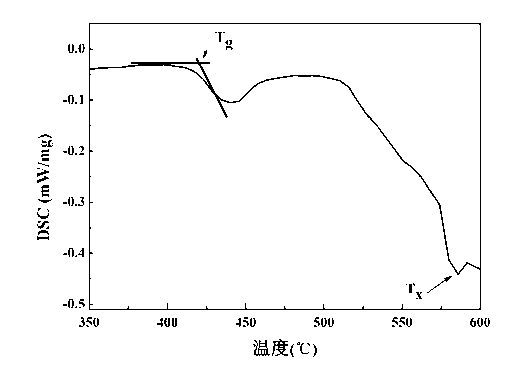

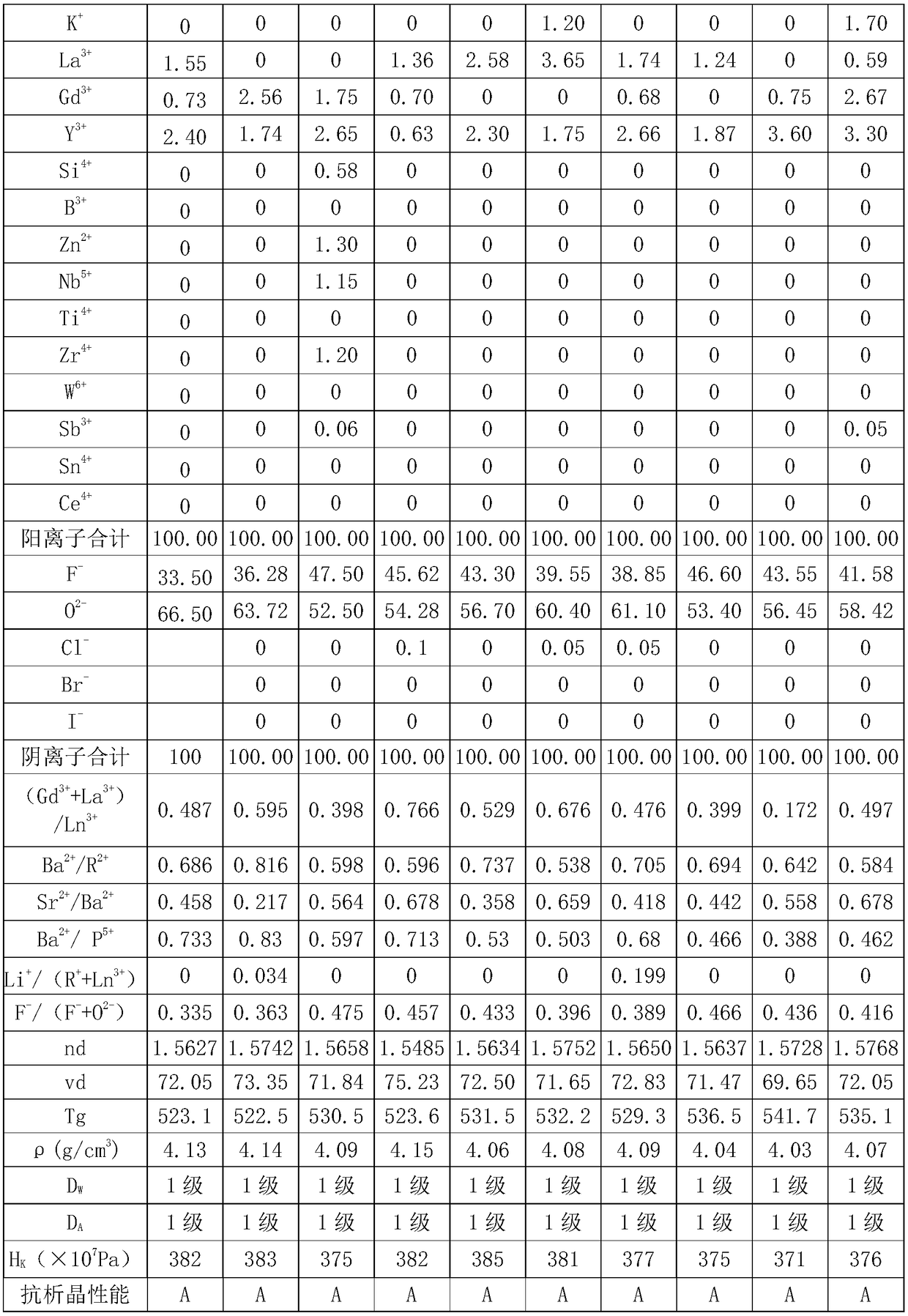

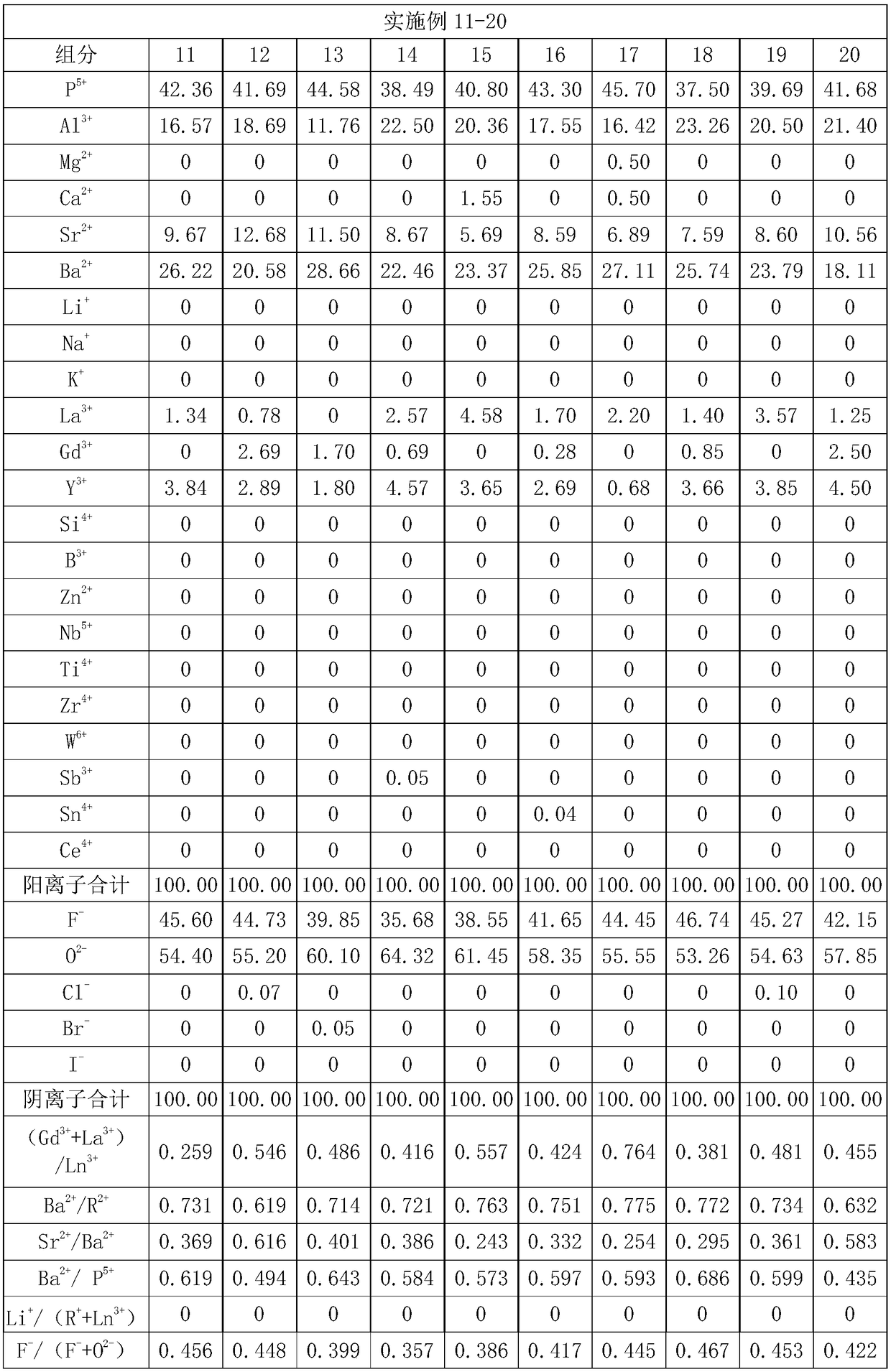

The invention provides optical glass with excellent crystallization resistance and chemical stability. The optical glass comprises the following components in percentage by mole of cations: 20-50% ofP<5+>, 5-25% of Al<3+>, 0-30% of Ln<3+> and 20-75% of R<2+>, wherein Ln<3+> is the total content of La<3+>, Gd<3+> and Y<3+>, and R<2+> is the total content of Ba<2+>, Sr<2+>, Ca<2+> and Mg<2+>; the anion contains F<-> and O<2->, wherein the molar ratio F<-> / (F<-> + O<2->) of the F<-> content to the total content ranges from 0.35 to 0.55. By reasonably adjusting the ratio of the components, the fluorophosphate optical glass disclosed by the invention has excellent crystallization resistance and chemical stability while having a refractive index of 1.53 or more and an Abbe number of 65 or more,and meets the development requirements of the modern photoelectric field.

Owner:CDGM OPTICAL GLASS

Glass used for absorbing optical spectrum with wavelength being 430-900nm for optical fiber panel and preparation process thereof

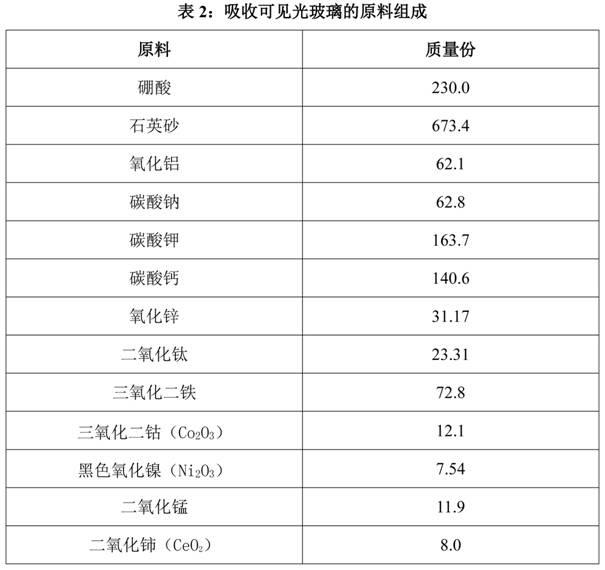

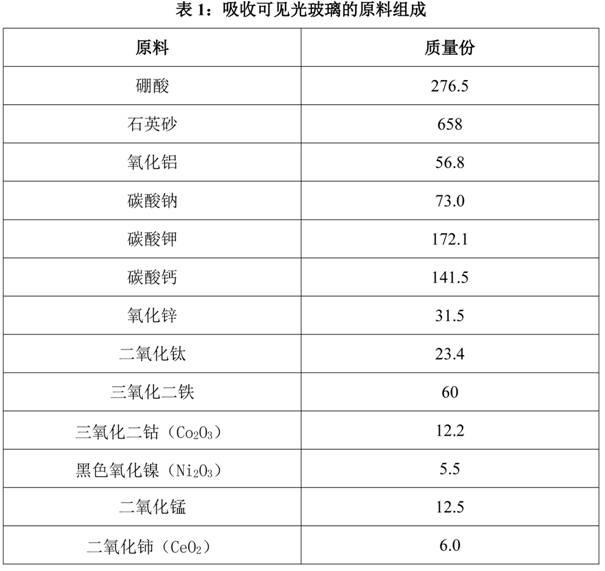

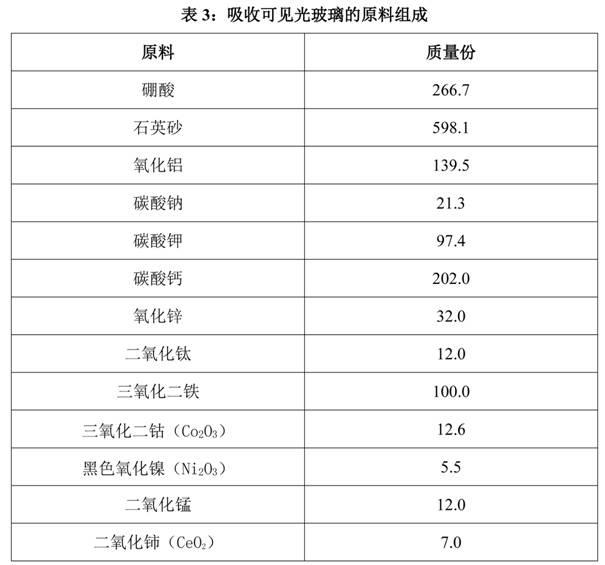

The invention discloses glass used for absorbing an optical spectrum with the wavelength being 430-900nm for an optical fiber panel. The glass is prepared by the following raw materials in parts by weight: 200-300 parts of boric acid, 590-700 parts of quartz sand, 50-150 parts of aluminum oxide, 20-100 parts of sodium carbonate, 80-180 parts of potassium carbonate, 140-210 parts of calcium carbonate, 30-40 parts of zinc oxide, 10-30 parts of titanium dioxide, 50-100 parts of iron trioxide, 10-20 parts of cobalt sesquioxide, 5-10 parts of nickel peroxide, 10-15 parts of manganese dioxide and 5-10 parts of cerium dioxide. The glass used for absorbing the optical spectrum with the wavelength being 430-900nm for the optical fiber panel is obtained. At the thickness being 0.40 plus or minus 0.01mm, the optical spectrum penetration ratio of the glass is smaller than or equal to 5%. The melting glass does not contain stones, and the glossiness of the glass is high. The softening temperature is controlled to be 600 DEG C-700 DEG C, the temperature of 820 DEG C is kept for 2h, the devitrification cannot be generated, the devitrification resistance is good, and the chemical stability is good.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS

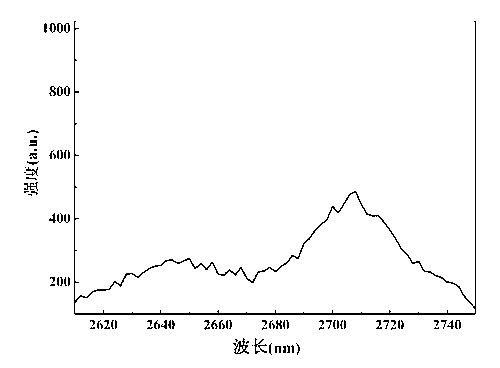

Erbium and terbium co-doped fluoride halide phosphate laser glass as well as preparation method and application thereof

ActiveCN103183472AGood anti-devitrification performanceMeet practical requirementsTransmittanceErbium lasers

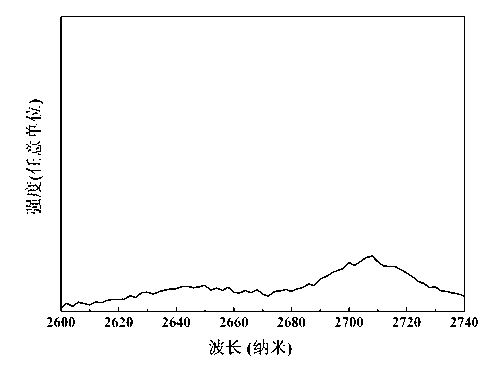

The invention discloses erbium and terbium co-doped fluoride halide phosphate laser glass which comprises components in percentage by mole as follows: 15% to 20% of Ba(H2PO4)2, 15% to 20% of Mg(PO3)2, 5% to 10% of AlF3, 10% to 20% of BaF2, 15% to 30% of MgF2, 20% to 30% of NaX, 1% to 5% of ErF3 and 4% to 10% of TbF3, wherein X is a combination of any one or more of F, Cl, Br and I. The fluoride halide phosphate laser glass is transparent and free of crystallization, the infrared transmittance is high in an area nearby 3 mu m, physical and chemical properties are excellent, the laser glass can be applied in a 3 m fiber laser and can be hopefully applied to defense industry, military and civilian areas.

Owner:合肥天奕激光医疗器械有限公司

Optical glass, optical prefabticated member and optical element

ActiveCN108751698AGood anti-devitrification performanceGood chemical stabilityDevitrificationRefractive index

The invention provides optical glass with excellent anti-devitrification performance, chemical stability and hardness. The optimal glass is prepared from the following ingredients in a cationic mole percent: 30-50% of P<5+>, 5-25% of Al<3+>, 15-30% of Ba<2+>, 0-20% of Sr<2+>, 0-10% of Gd<3+>, 0-10% of Y<3+> and 0-10% of La<3+>, wherein (Gd<3+>+ La<3+>) / Ln<3+> is equal to 0.1-0.8; anions contain F<->and O<2->, wherein the molar ratio F<-> / (F<->+O<2->) of the content of F<-> to the total amount of F<->and O<2-> is equal to 0.3-0.5. According to the optical glass, a ratio of all components is reasonably regulated, so that the fluorophosphates optical glass has excellent anti-devitrification performance, chemical stability and hardness while the fluorophosphate optical glass has the refractiveindex of 1.54-1.61 and the Abbe number of 69-76.

Owner:CDGM OPTICAL GLASS

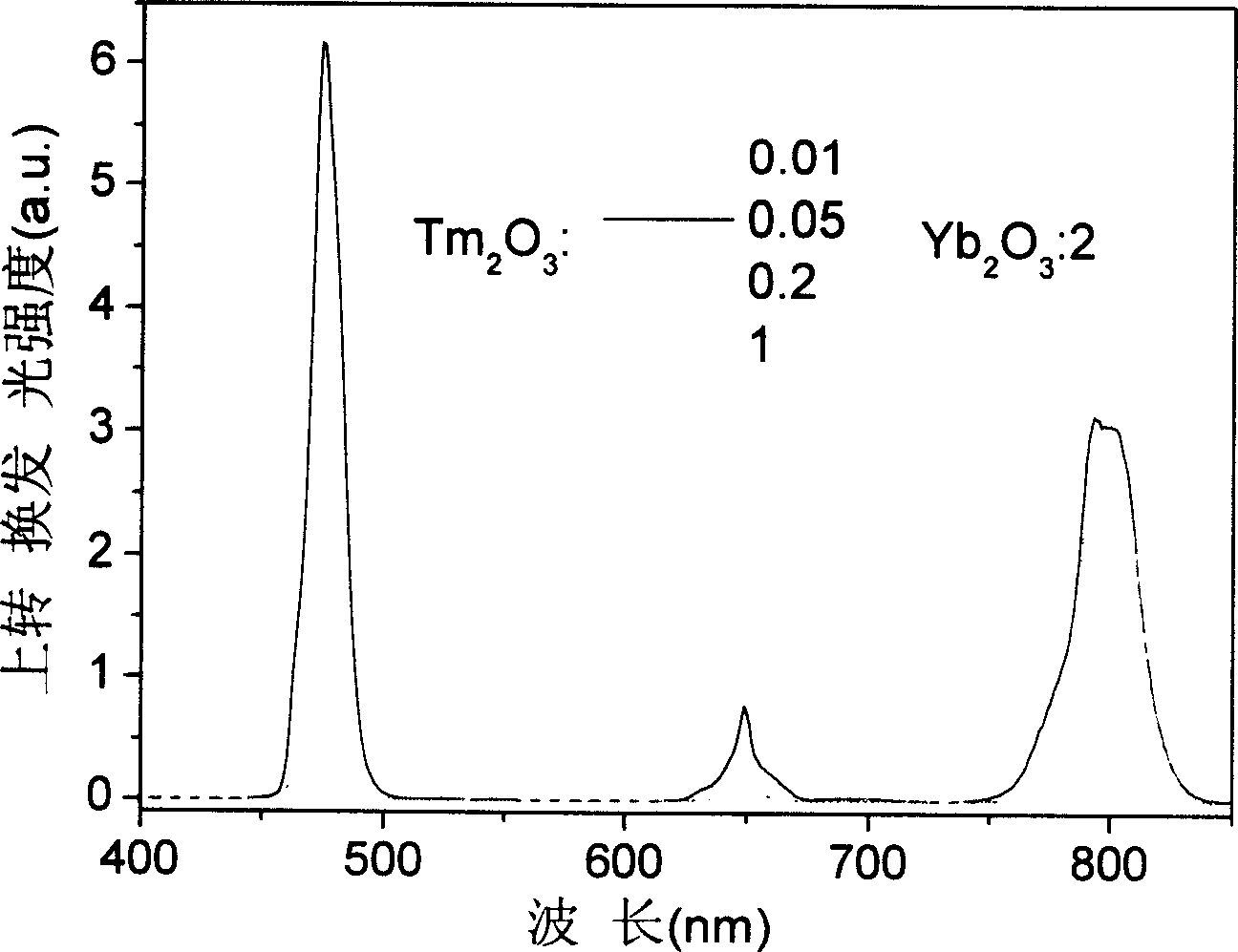

Tm/Yb codoped oxyfluoro tellurate glass and its preparation method

InactiveCN1618753AGood anti-devitrification performanceMeet practical requirementsLight sourceTellurite glass

A Tm3+ / Yb3+ codoped oxyfluorotellurate glass with high up-conversion power to strong blue light is prepared by fusion method. It contains TeO2, B2O3, PbF2, WO3, ZnF2, Tm2O3 and Yb2O3 proportionally. Its advantages are high transparency, excellent physical and chemical properties, and strong blue light converting power.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

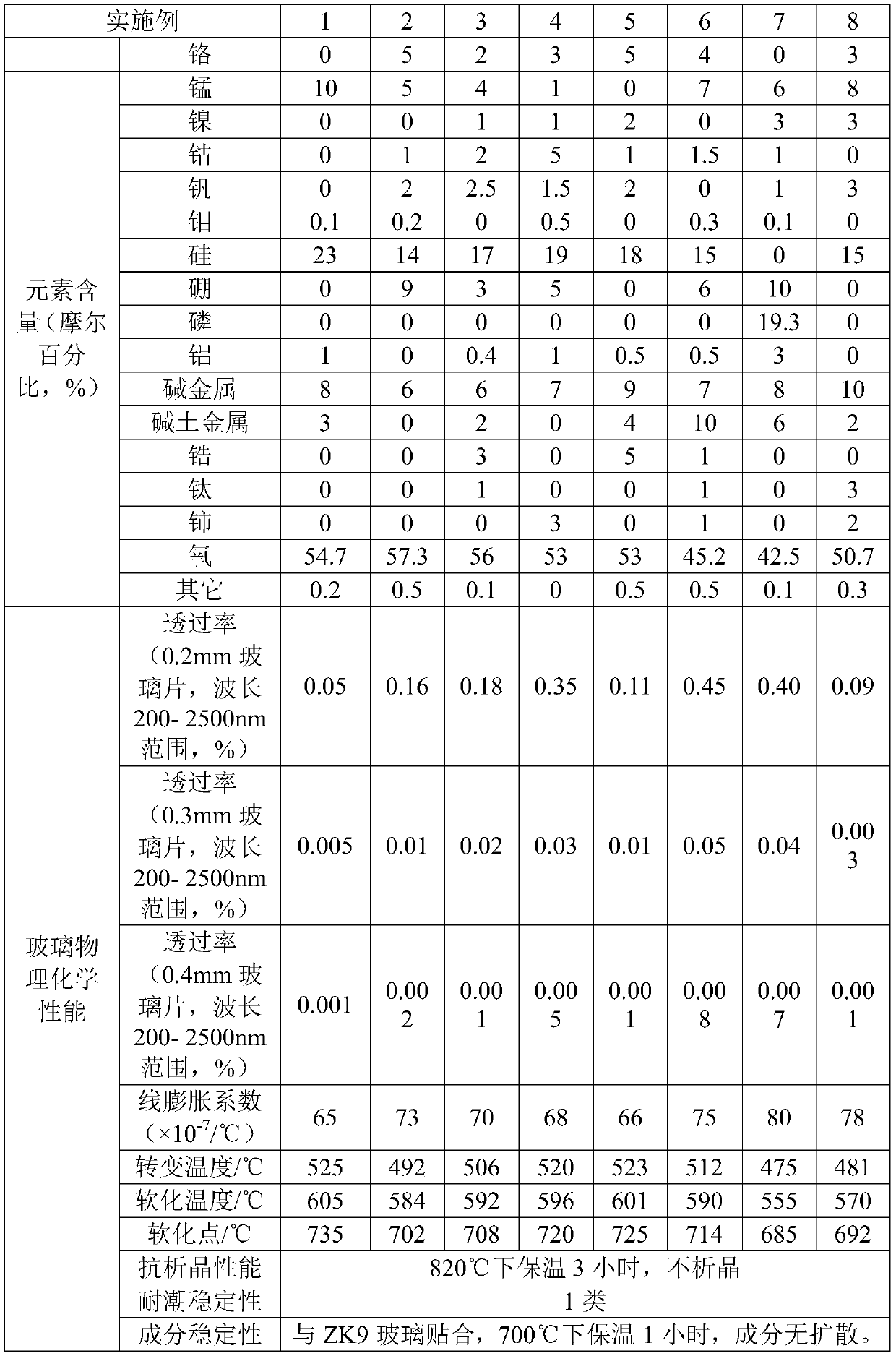

Visible light absorbing glass and preparation method and application thereof

ActiveCN110040941AHigh light absorption effectMelt molding is easyGlass shaping apparatusOptical elementsTransmittanceCaking

The invention provides visible light absorbing glass which comprises the following elements in mole percent: 0-10% of a manganese element, 0-5% of a chromium element; 0-3% of a nickel element, 0-3% ofa cobalt element, 0-3% of a vanadium element and 0-0.5% of a molybdenum element, wherein the sum of the mole percentages of the manganese, chromium, cobalt and vanadium elements is more than or equalto 5%. The invention also provides a preparation method and application of the visible light absorbing glass. The visible light absorption glass prepared by the method of the invention has higher light absorption effect in the range of 300-700 nm; and the transmittance of the visible light absorbing glass is less than or equal to 0.5% under the thickness of 0.20 mm. At the same time, the visiblelight absorbing glass is easy to melt and form, has no internal defects such as bubbles, caking, stripes and the like, has good devitrification resistance, moisture resistance and composition stability, and meets the preparation process requirements of optical fiber imaging elements in thermal performance.

Owner:CHINA BUILDING MATERIALS ACAD

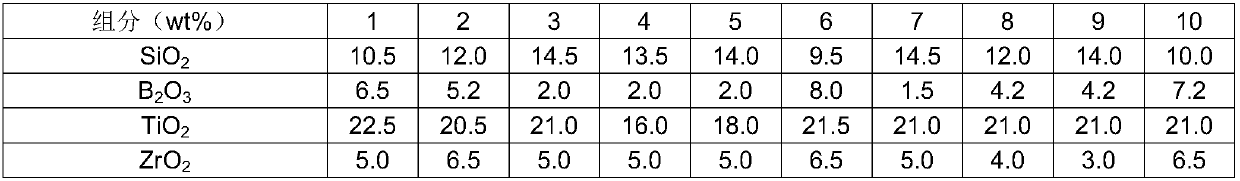

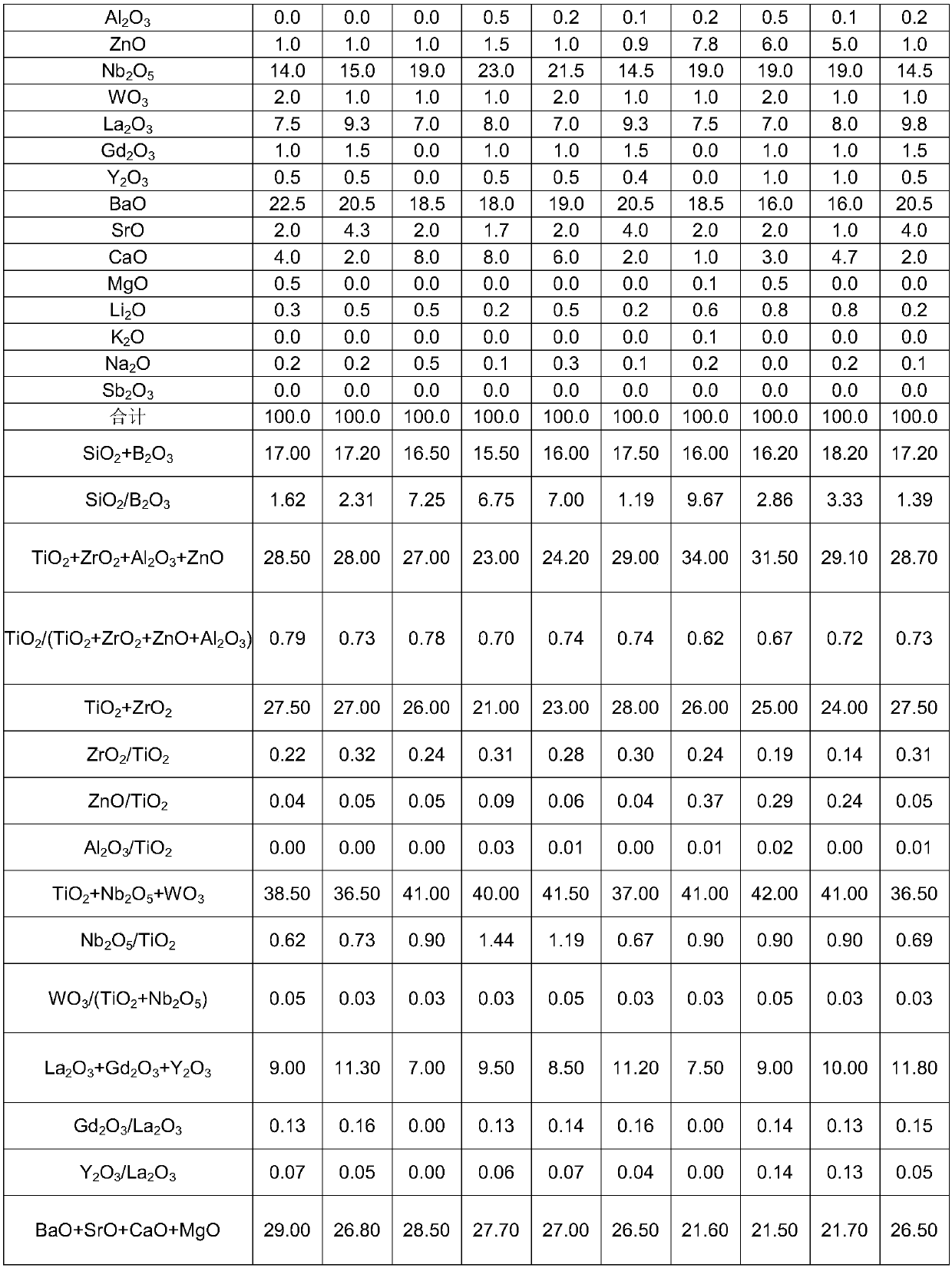

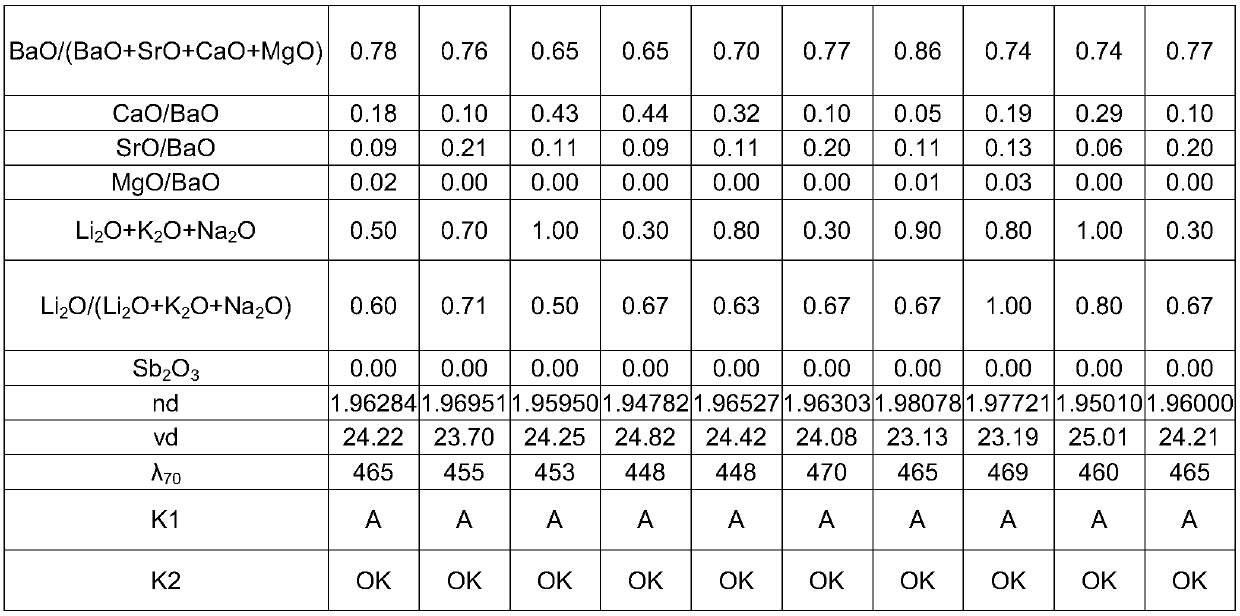

Optical glass, preformed glass member, optical element and optical instrument

ActiveCN109665714AImprove transmittanceGood anti-devitrification performanceOptical elementsTransmittanceOptical instrument

The invention provides an ultrahigh-refractive-index flint glass belonging to a borosilicate system. The ultrahigh-refractive-index flint glass is composed of, by weight percentage, 10-25% of SiO2+B2O3, 15-50% of TiO2+ZrO2+Al2O3+ZnO, 25-60% of TiO2+Nb2O5+WO3 and 14-35% of BaO+SrO+CaO+MgO. Through reasonable composition, under a refractive index of 1.92-2.00 and an abbe number of 20-30, the ultrahigh-refractive-index flint glass achieves excellent transmittance and good devitrification resistance and facilitates production and secondary compression.

Owner:CDGM OPTICAL GLASS

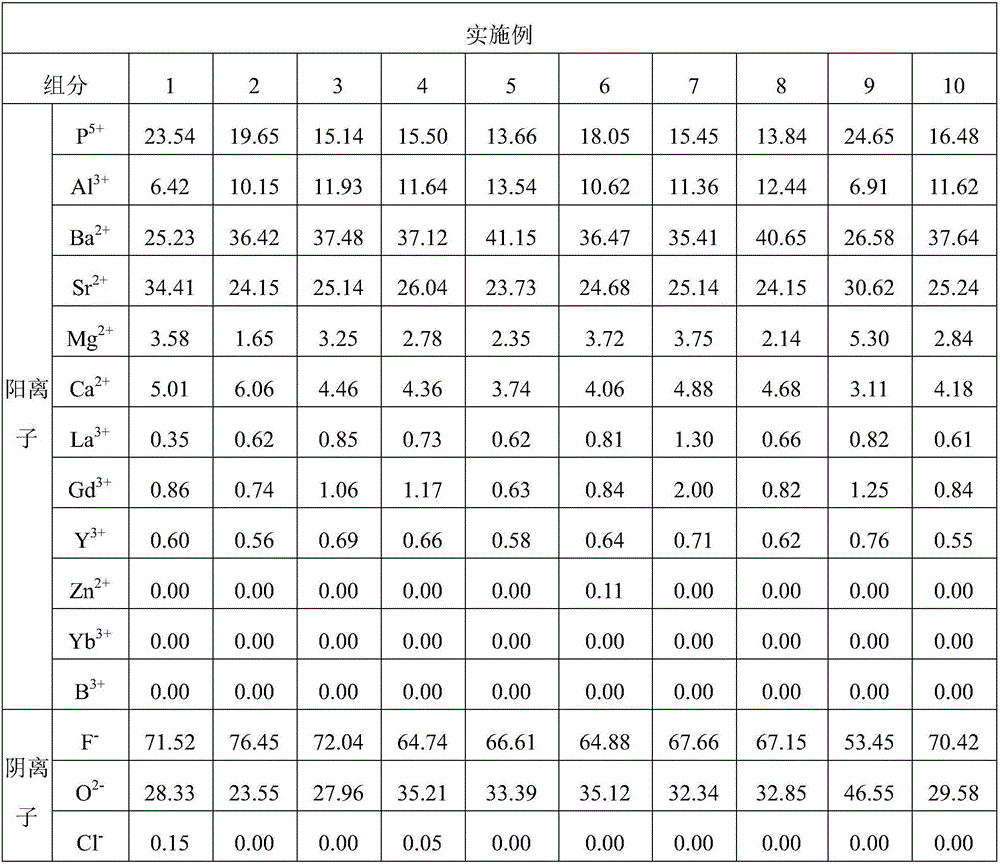

Optical glass

The invention provides optical glass which is excellent in interior quality and has excellent transmittance and anti-devitrification property. The optical glass comprises the components in percentages by weight: positive ion: 8-25% of P<5+>, 5-20% of Al<3+>, 20-50% of Ba<2+>, 15-40% of Sr<2+>, 0.5-8% of Mg<2+>, 1-10% of Ca<2+>, 0-10% of La<3+>, 0-10% of Gd<3+> and 0-10% of Y<3+>; negative ions: 40-90% of F<-> and 10-60% of O<2->. Through a reasonable formula design, the optical glass has the excellent interior equality, transmittance and anti-devitrification property while has the refractive index of 1.48-1.58 and the abbe number of 75-83.

Owner:CDGM OPTICAL GLASS

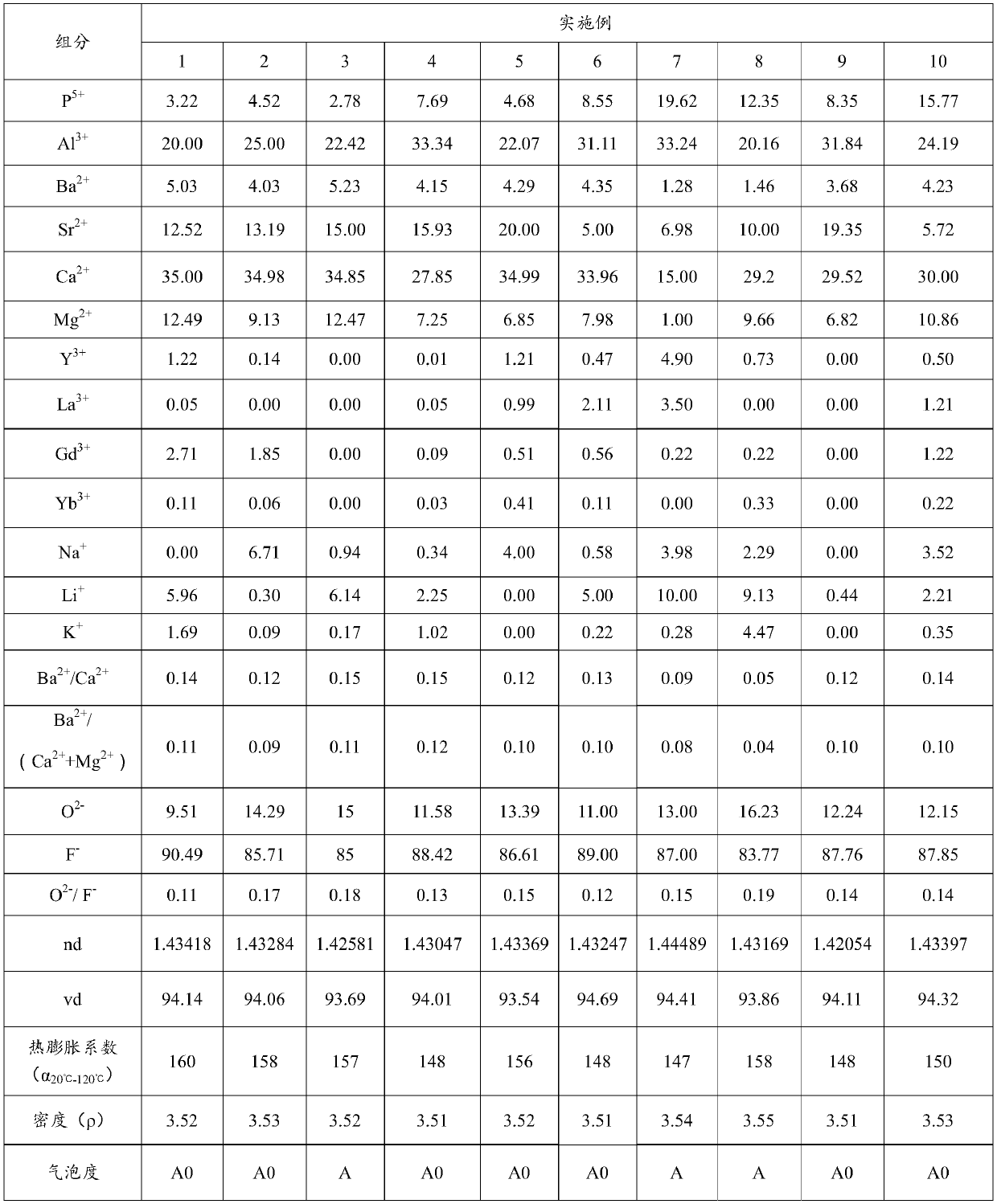

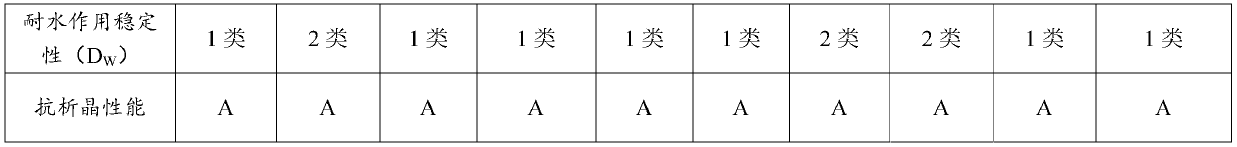

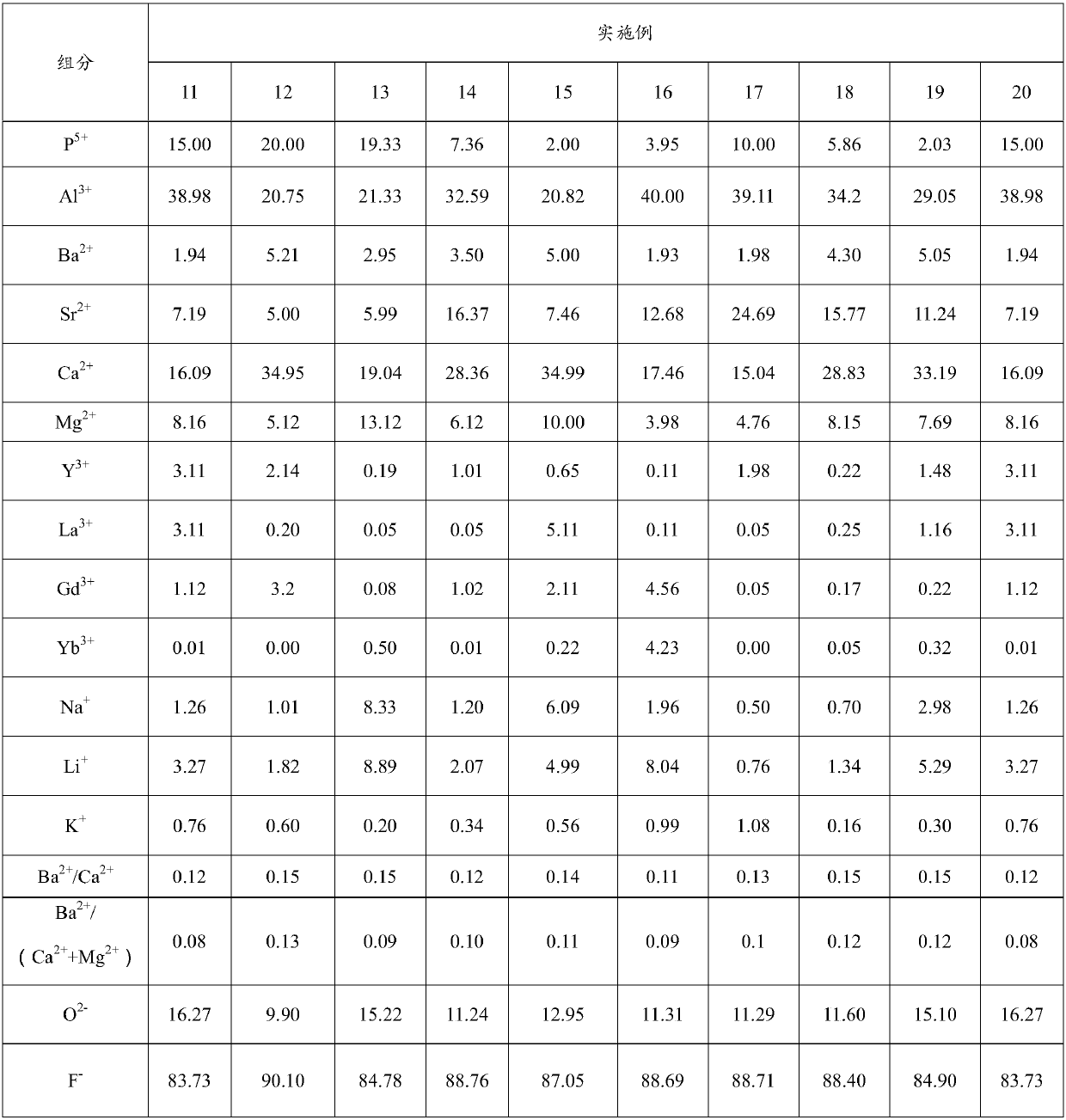

Fluorophosphate optical glass, optical prefabricated component, optical element and optical apparatus

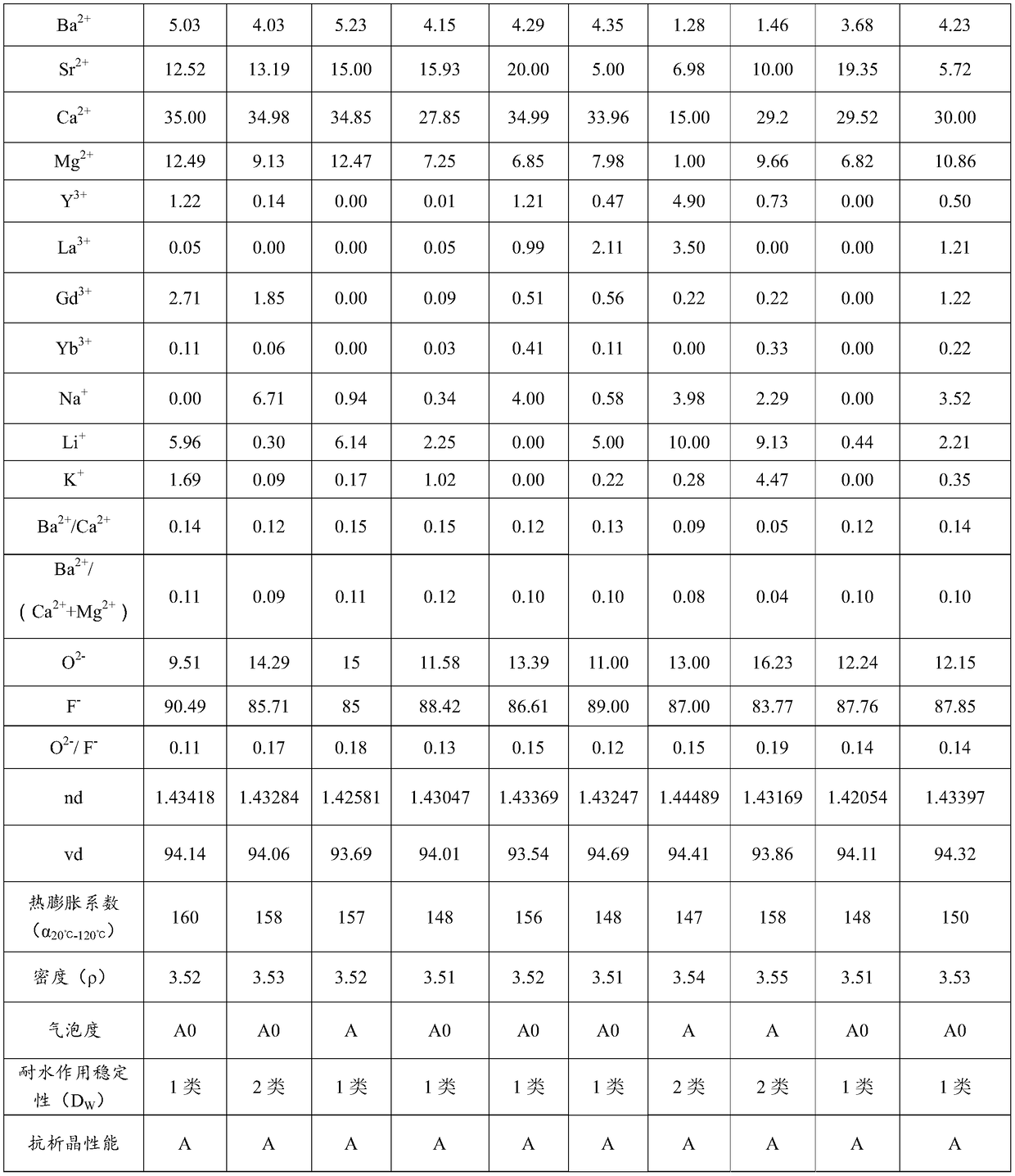

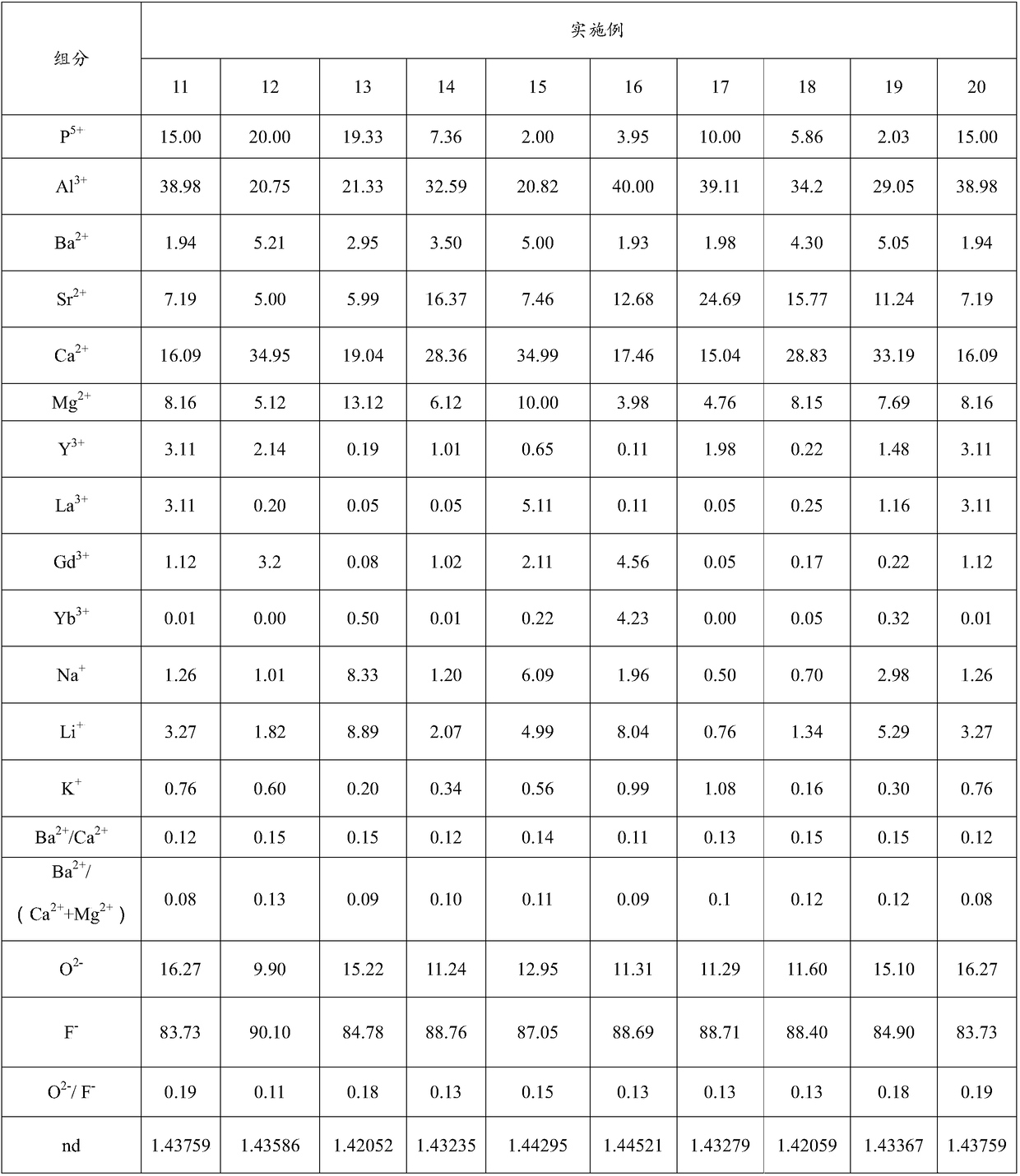

InactiveCN109160728ALow densityIncrease the level of air bubblesOptical elementsRefractive indexThermal expansion

The invention provides fluorophosphate optical glass, an optical prefabricated component, an optical element and an optical apparatus, and belongs to the technical field of optical glass. The opticalglass contains the following components in percentage by mol based on cations: 2-20% of P<5+>, 20-40% of Al<3+>, 0.5-10% of Ba<2+>, 5-25% of Sr<2+>, 15-35% of Ca<2+> and 1-15% of Mg<2+>, wherein Ba<2+> / Ca<2+> is 0.01-0.155; anions contain the following components in percentage by mol based on anions: F<-> and O<2->, wherein O<2-> / F<-> is 0.105-0.2. According to the fluorophosphate optical glass, the optical prefabricated component, the optical element and the optical apparatus disclosed by the invention, the Ba<2+> / Ca<2+> content proportion is adjusted, so that the density of the optical glassis reduced, and the bubble degree grade and the crystallization resistance performance of the optical glass are improved; the O<2-> / F<-> content proportion is adjusted, so that the thermal expansioncoefficient of the optical glass is reduced, the optical glass is unlikely to be damaged in the die pressing course and the hot processing course, and the glass formation stability is improved. The refractive index (nd) of the fluorophosphate optical glass is 1.42-1.45, the Abbe number (vd) is 93-96, the density (rho) is 3.55 g / cm<3> or below, the bubble degree is B level or above, the thermal expansion coefficient is 160*10<-7> / K or below, the water resistant effect stability (Dw) is 2 type or above, and the crystallization resistance performance is excellent.

Owner:CDGM OPTICAL GLASS

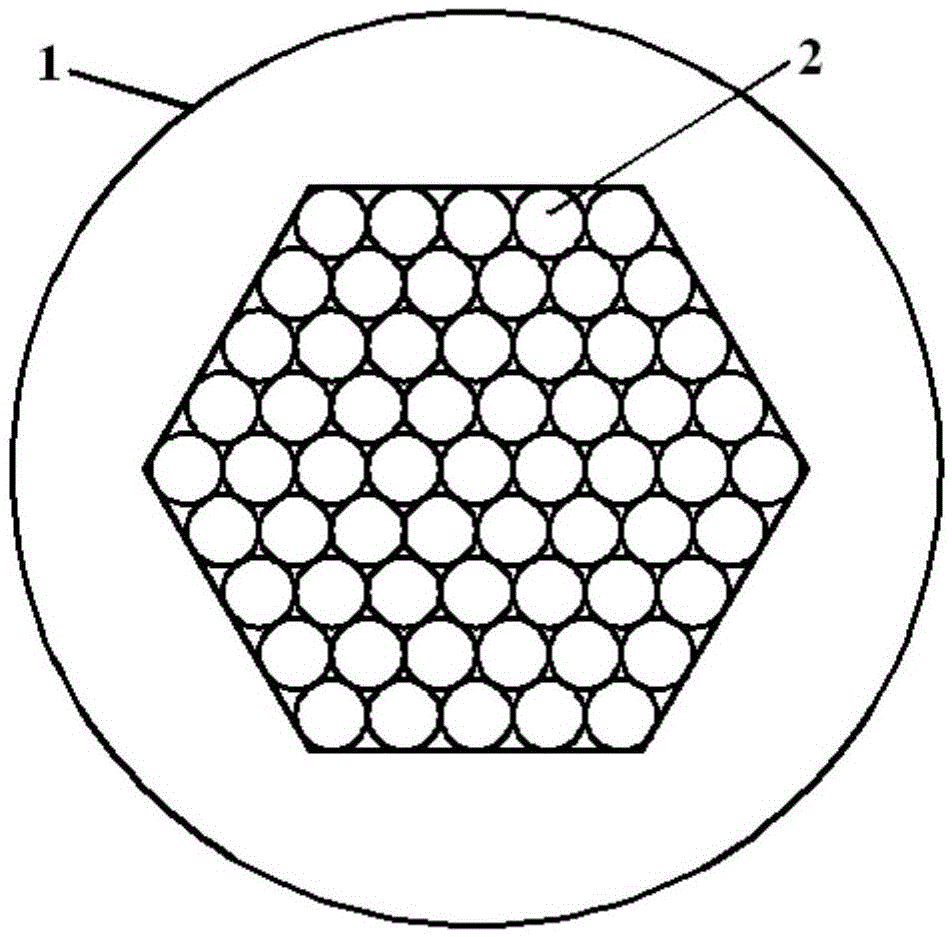

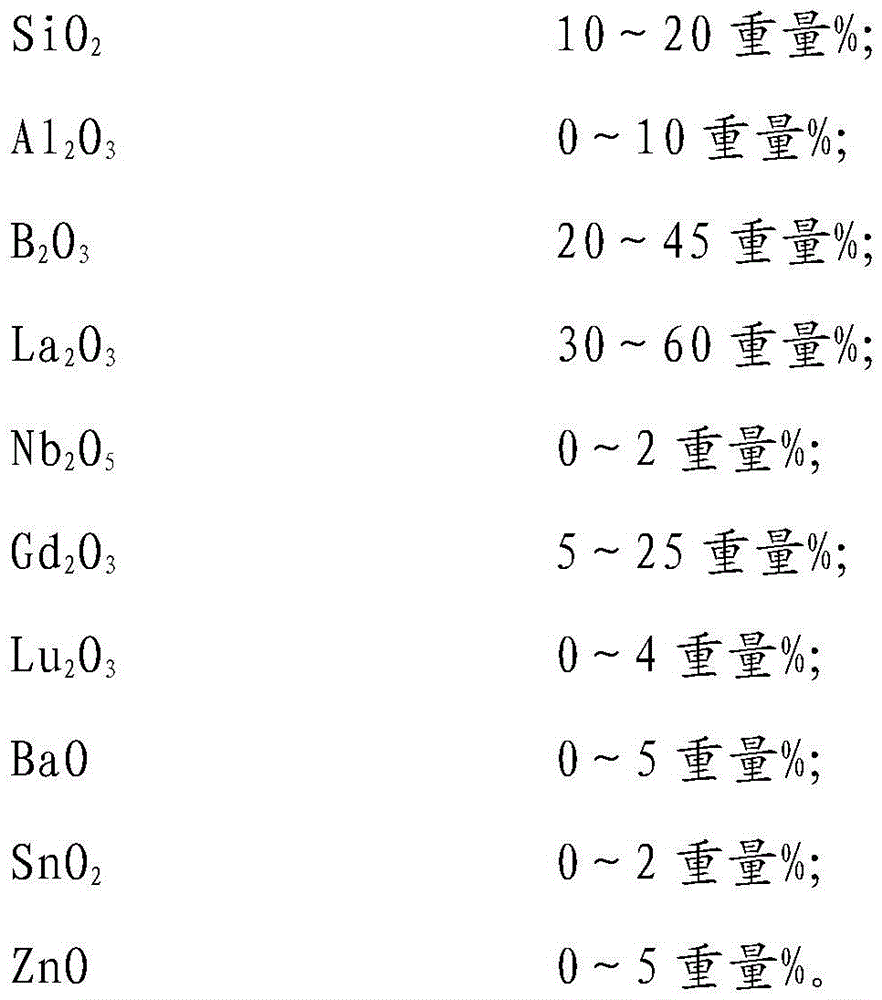

Composition and preparation method of scintillation glass used for preparation of scintillation fiber-optic faceplate

ActiveCN105481245AEasy to adjustStrong ability to formX-ray/infra-red processesGlass furnace apparatusCrucibleScintillation counter

The invention discloses a composition and preparation method of scintillation glass used for preparation of a scintillation fiber-optic faceplate. The composition comprises, by weight, 10 to 20% of SiO2, 0 to 10% of Al2O3, 20 to 45% of B2O3, 30 to 60% of La2O3, 0 to 2% of Nb2O5, 5 to 25% of Gd2O3, 0 to 4% of Lu2O3, 0 to 5% of BaO, 0 to 2% of SnO and 0 to 5% of ZnO. The invention also provides the preparation method for the scintillation glass used for preparation of the scintillation fiber-optic faceplate. The method comprises the following steps: (1) weighing the raw materials according to the above-mentioned weight percentages, mixing all the raw materials, and grinding the raw materials until the raw materials are uniform so as to obtain a batch; (2) pouring the batch into a crucible and fusing the batch so as to prepare a glass melt; (3) casting the glass melt on a preheated heat-resistant steel die, maintaining the temperature of the die in a muffle furnace and then carrying out cooling and annealing; and (4) carrying out cutting, surface grinding and polishing so as to obtain the scintillation glass. The prepared scintillation glass has the advantages of good chemical stability, high scintillation light luminescence efficiency and capacity of realizing fiber drawing.

Owner:中建材光子科技有限公司

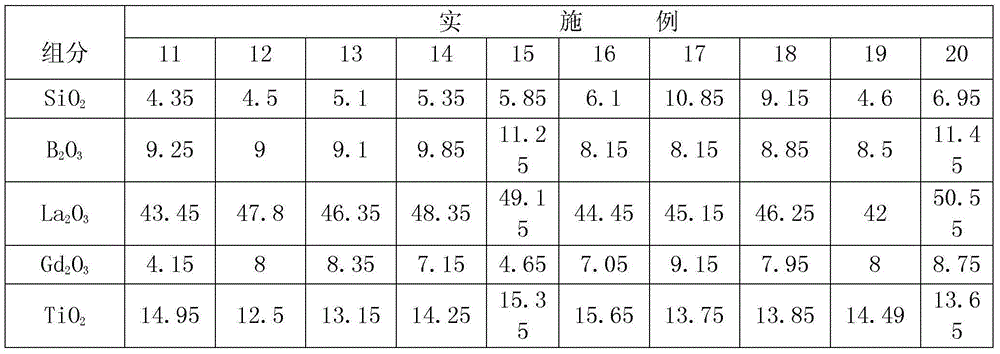

High-refractive index and low-dispersion heavy lanthanum flint optical glass

The invention relates to a high-refractive index and low-dispersion heavy lanthanum flint optical glass which is prepared from the following components in percentage by mass of oxides: 9.25-13.37 percent of B2O3, 5.48-7.34 percent of SiO2, 43.60-51.63 percent of La2O3, 3.53-9.12 percent of Y2O3, 4.18-10.23 percent of Gd2O3, 3.47-6.52 percent of Nb2O5, 3.47-6.62 percent of ZrO2, 0.81-1.50 percent of WO3, 3.96-6.95 percent of TiO2, 3.28-6.79 percent of ZnO and 0.61-1.52 percent of Al2O3; and in the composition, the following conditions are also met: B / Si is larger than 1.33 and smaller than 2.54 (by mass percentage), a sum of the mass percentages of La2O3, Y2O3 and Gd2O3 is 58.61-60.32 percent, and a sum of the mass percentages of WO3 and TiO2 is 4.85-8.34 percent. The optical glass does not contain Ta2O3 with high cost to facilitate reduction of the cost of the glass, does not contain alkali metals, alkaline-earth metals and toxic components including Pb, As and Cd either, has the refractive index nd being 1.883-1.915 and an abbe number vd being 35.65-38.32, is excellent in crystallization resistance and is suitable for batch production.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Optical glass, glass prefabricated component, optical element and optical instrument

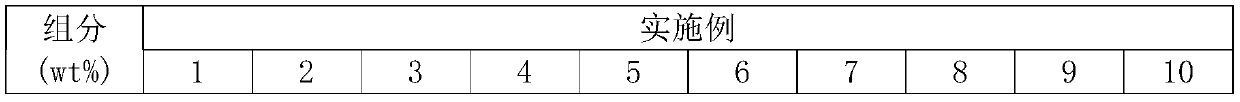

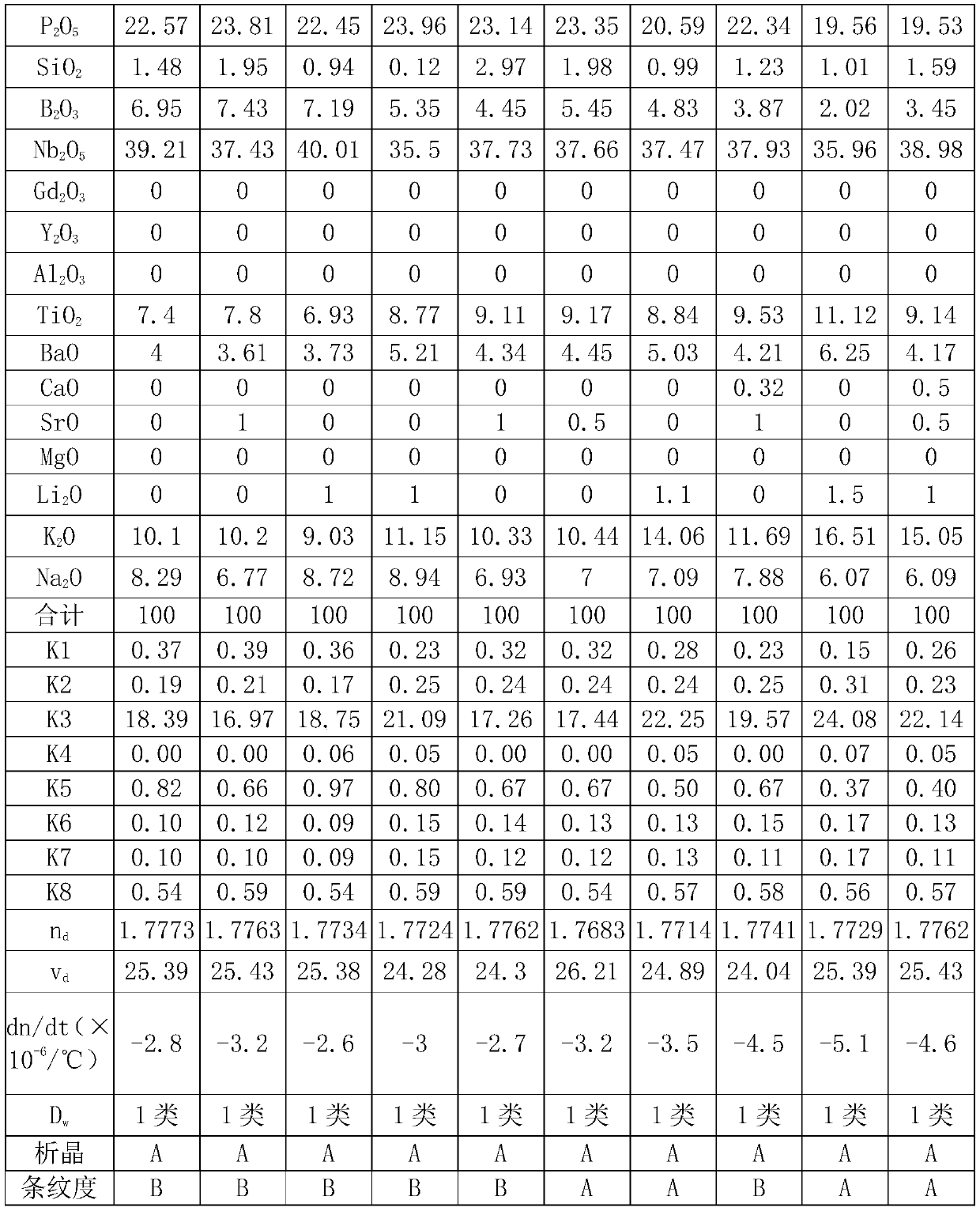

ActiveCN110937801ALow temperature coefficient of refraction indexIncrease freedomGlass productionOptical elementsPrime lensOptical instrumentation

The invention provides optical glass which comprises the following components in percentage by weight: 4-30% of P2O5, 0 to 20% of BaO, 10 to 45% of Nb2O5, 0 to 35% of Li < 2 > O + K < 2 > O + Na < 2 >O; wherein BaO / Nb2O5 ranges from 0 to 0.5. Through reasonable component design, the optical glass provided by the invention has expected refractive index and Abbe number, and also has a low refractive index temperature coefficient, thus bringing greater degree of freedom for correcting temperature drift of a prime lens; the optical glass has excellent chemical stability and crystallization resistance, the transmittance is not obviously reduced after long-term use, and the optical glass is very suitable for vehicle-mounted lenses, and is particularly suitable for imaging applications needing to bear severe working environments such as sand storm, muddy and sharp temperature change.

Owner:CDGM OPTICAL GLASS

Optical glass, glass perform, optical element and optical instrument

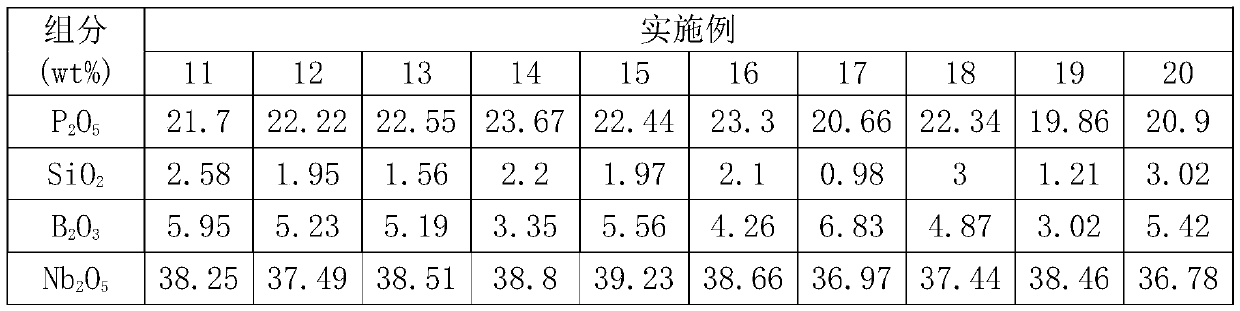

ActiveCN109987835AHigh hardnessHigh refractive indexGlass shaping apparatusOptical elementsRefractive indexHardness

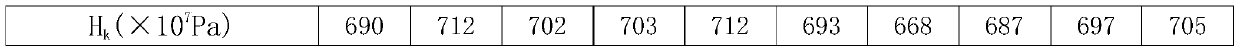

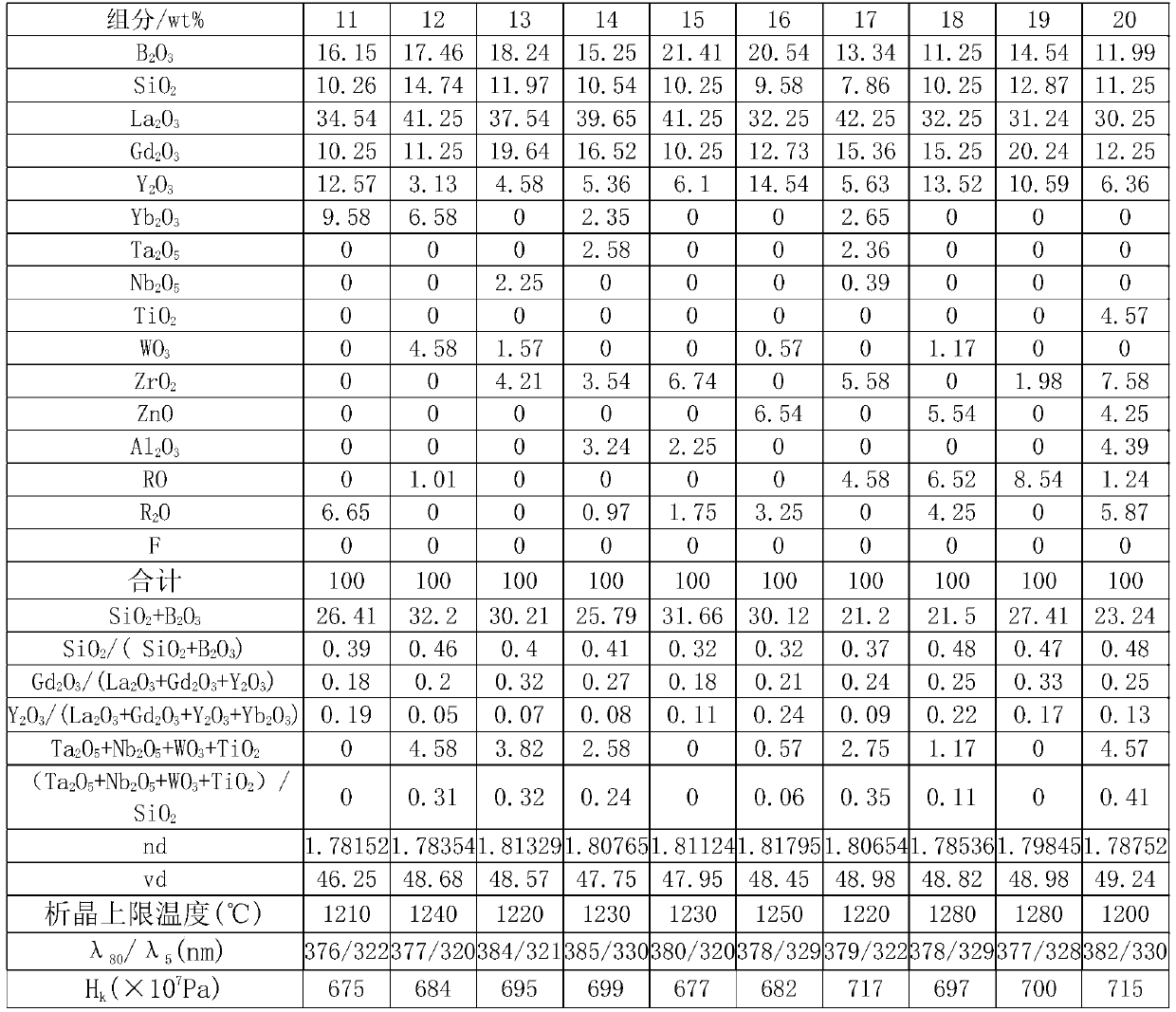

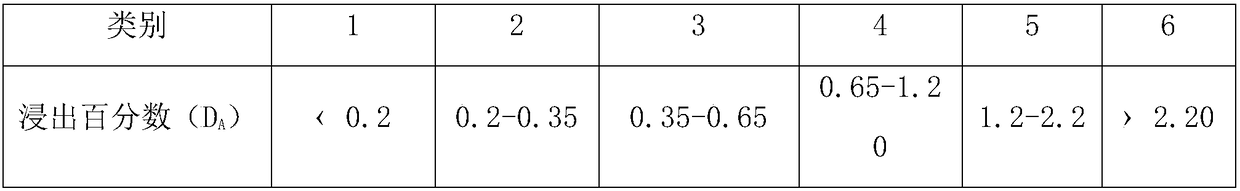

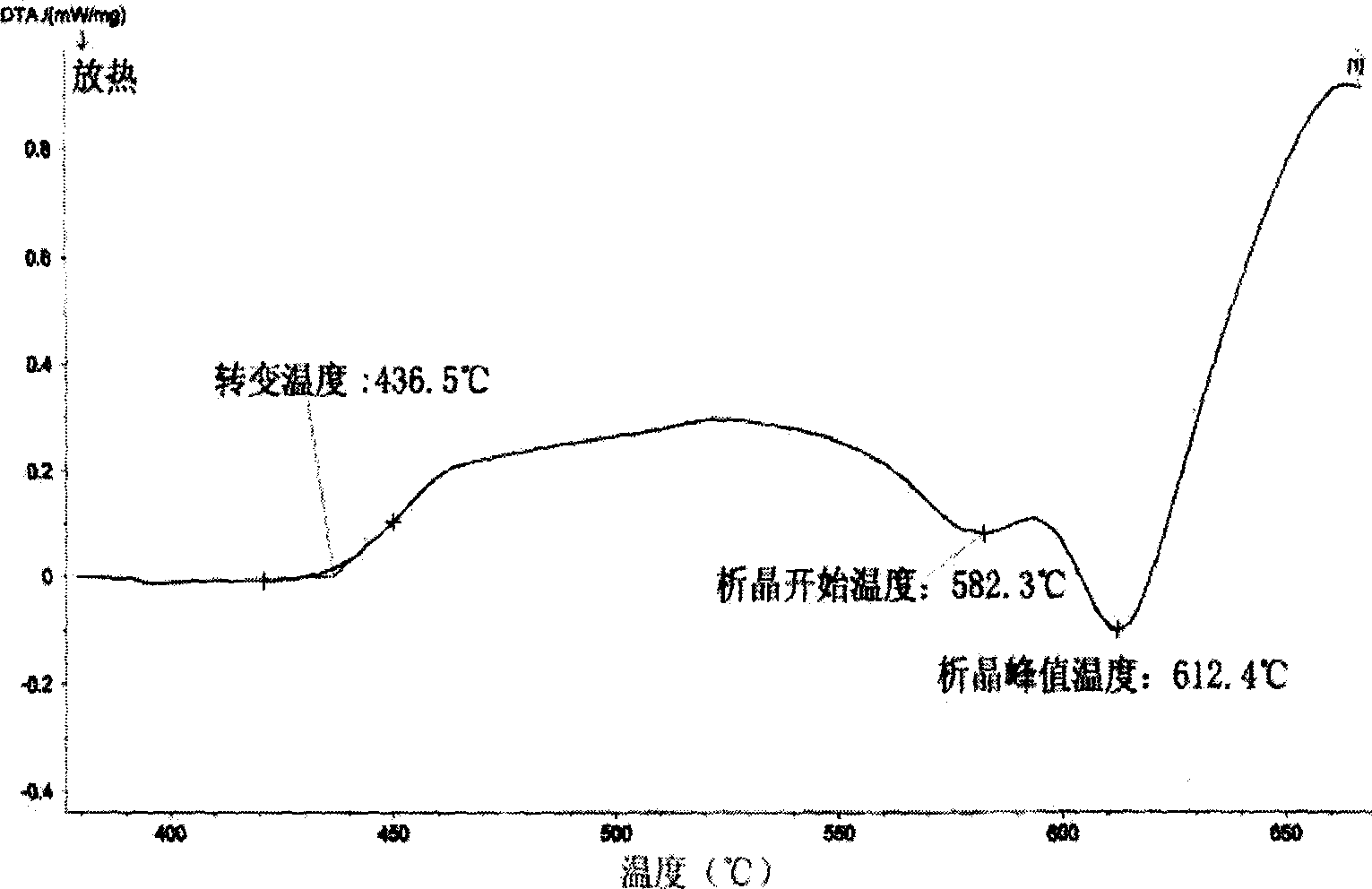

The invention provides optical glass with a refractive index of 1.75-1.82 and an Abbe number greater than 46-53. The optical glass comprises the following components in percentage by weight: 10-30% ofB2O3, 5-18% of SiO2, 30-50% of La2O3, 10-25% of Gd2O3 and 3-15% of Y2O3, wherein the ratio of the Gd2O3 to the sum of the La2O3, the Gd2O3 and the Y2O3 is in a range of 0.15-0.4. Through the reasonable component ratio, the high-refraction low-dispersion optical glass disclosed by the invention has relatively high hardness and excellent anti-crystallization performance, and is suitable for the fields of vehicle mounting, monitoring and the like.

Owner:CDGM OPTICAL GLASS

Optical glass

The invention provides optical glass which has reduced or no tantalum, low cost and good bubbles and stripes and is easy to be stably produced. The optical glass comprises 10-30% by weight of SiO2, 20-45% by weight of B2O3, 10-35% by weight of La2O3, 12-30% by weight of BaO, 0-10% by weight of ZrO2, and 0-10% by weight of ZnO. Through reasonable refractive index design, the refractive index of theoptical glass is 1.62-1.70, and the Abbe number is 55-62. The optical glass has low cost, good chemical stability, excellent anti-crystallization property and good transmittance. At the same time, the bubbles and stripes of the glass are good, and the optical glass is easy to be stably produced, and can be widely applied to digital cameras, digital video cameras, camera cell phones and the like.

Owner:CDGM OPTICAL GLASS

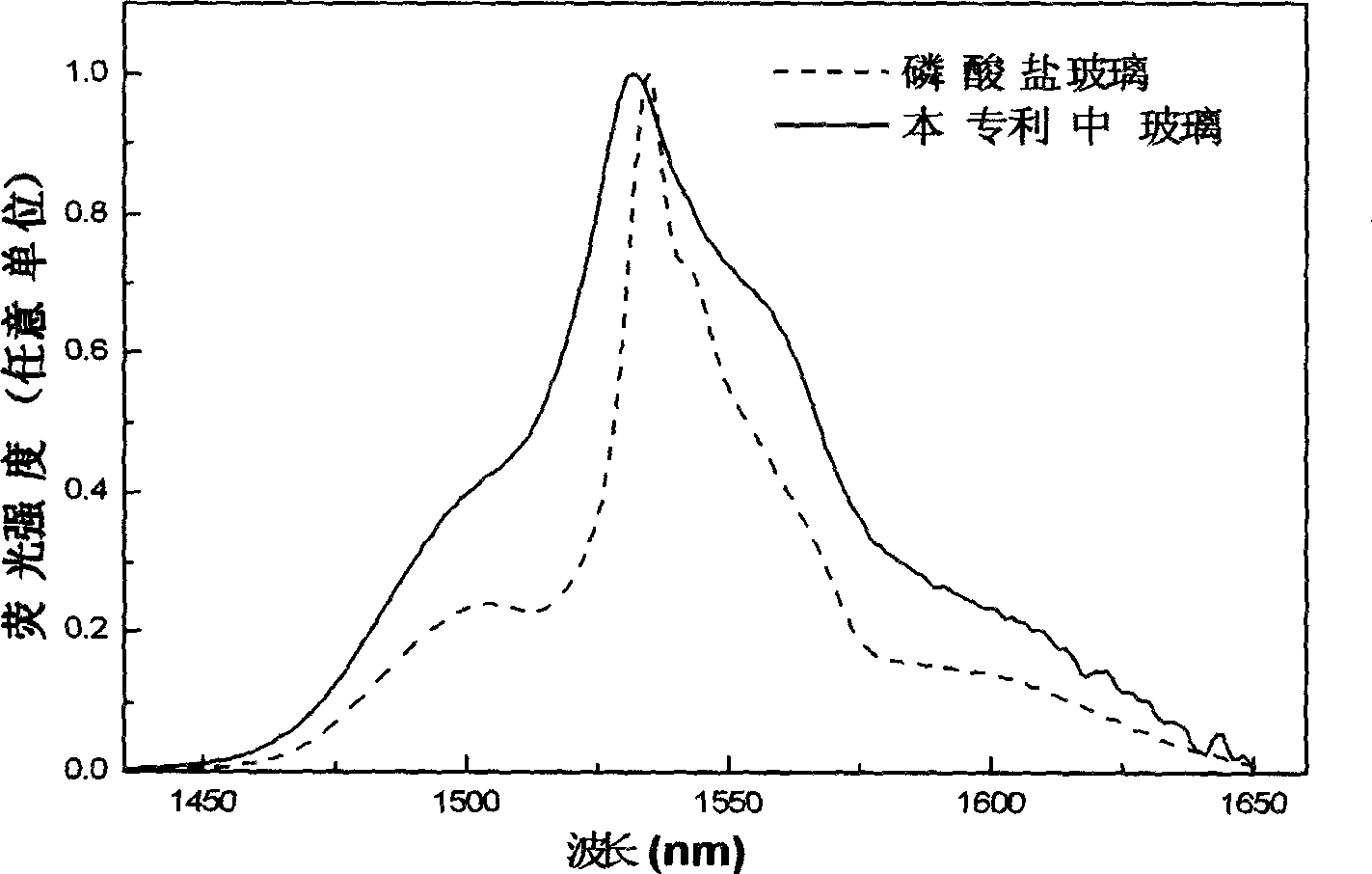

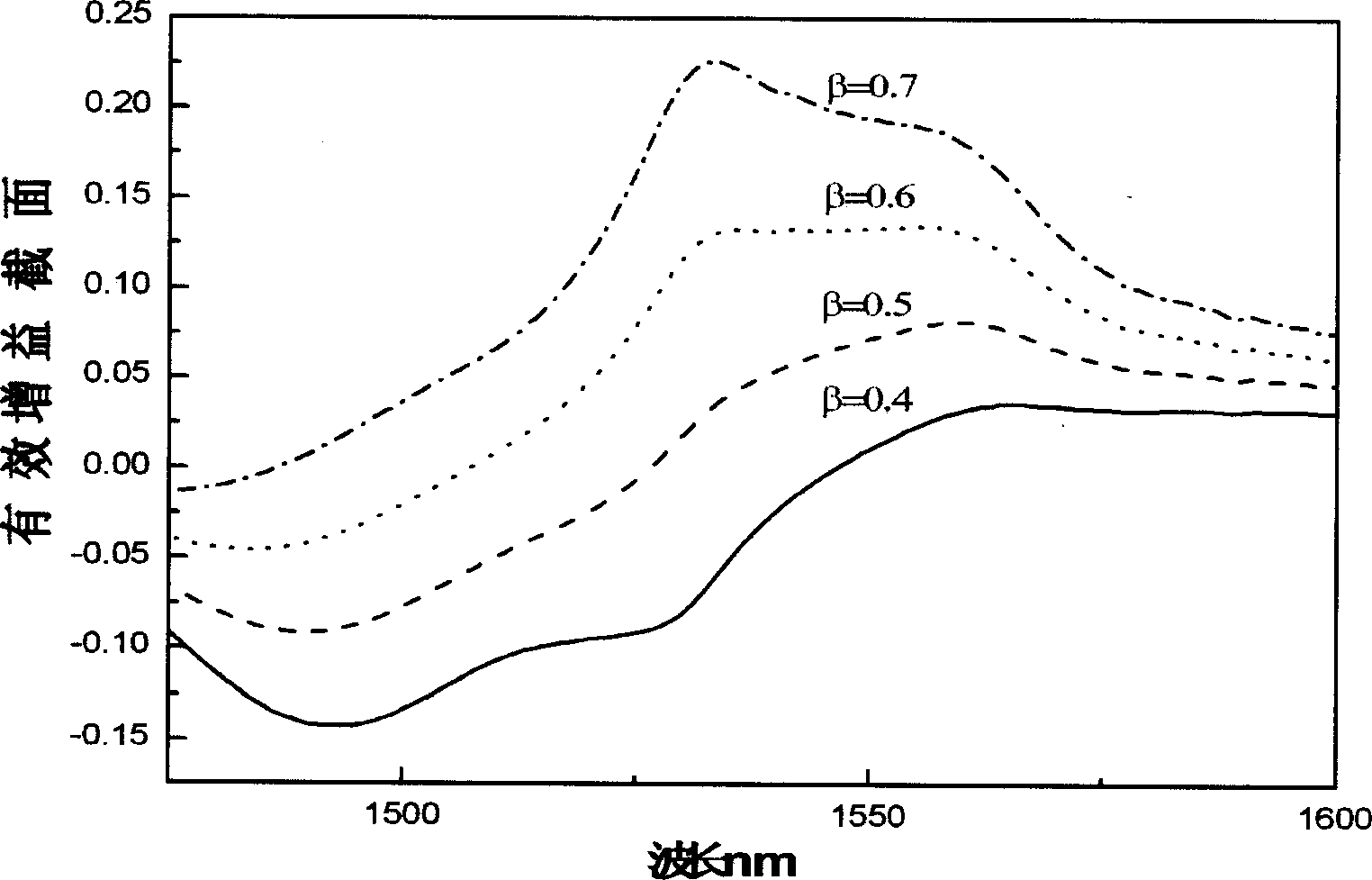

Low refractive index high concentration Er3 doped fluorine phosphate glass and its preparing method

InactiveCN1594160ARaise the transition temperatureGood anti-devitrification performanceHigh concentrationAlkaline earth metal

The invention provides a low refractive index high concentration Er doped fluorine phosphate glass and its preparing method, wherein the compositions (by weigh percent) of the glass include, AlF3 30-35%, alkaline earth fluoride RF2 38-46%, YF3 9-11%, KF 0-6%, ErF3 6%, alkaline earth dihydric phosphate R (H2PO4) 2-5%, MgHPO4 3H2O 0-2%, Al(PO#-[3])#-[3] 0-2%. The conventional fusion method is employed to prepare a series of glass based on the composition and technological requirements.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

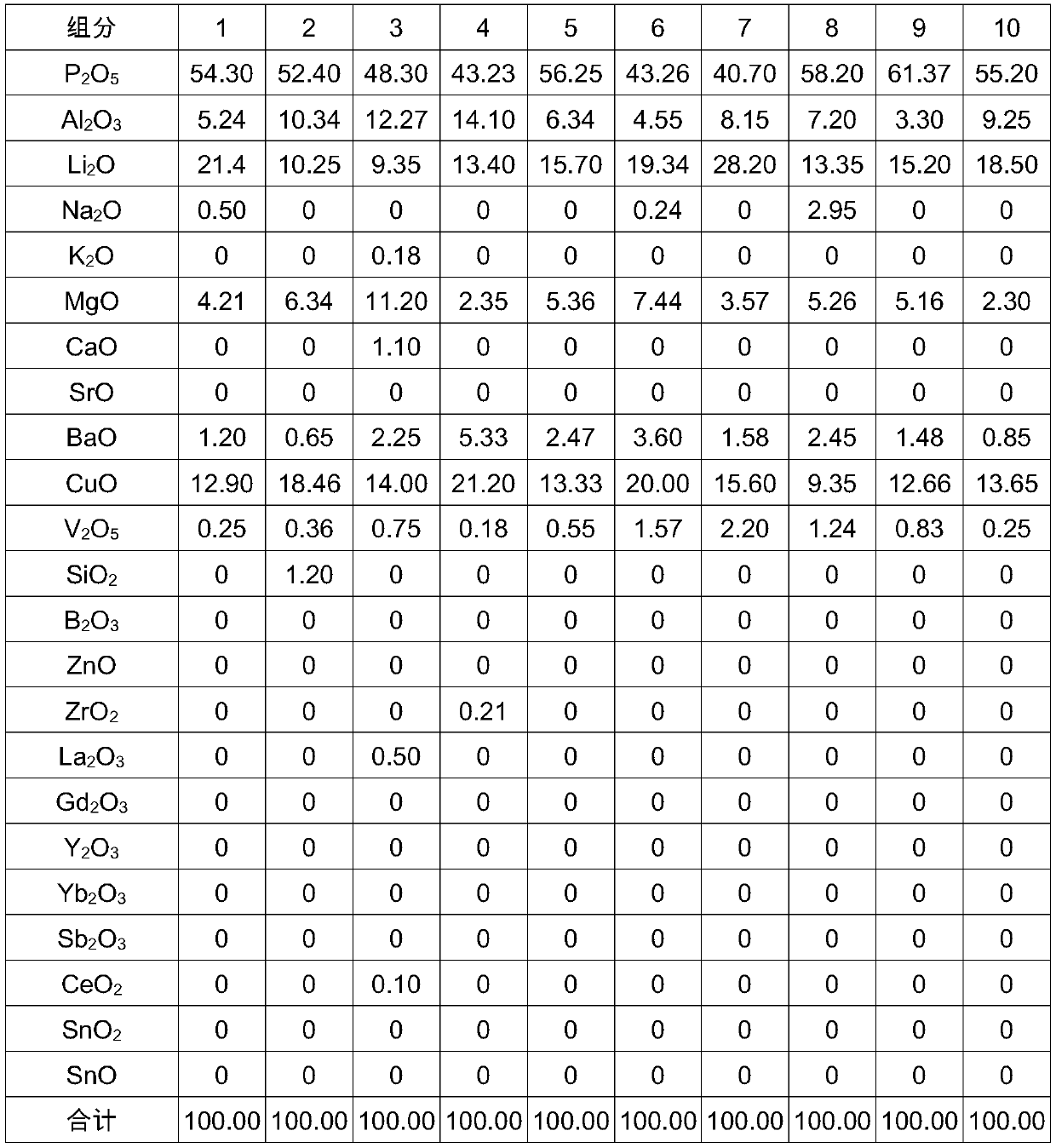

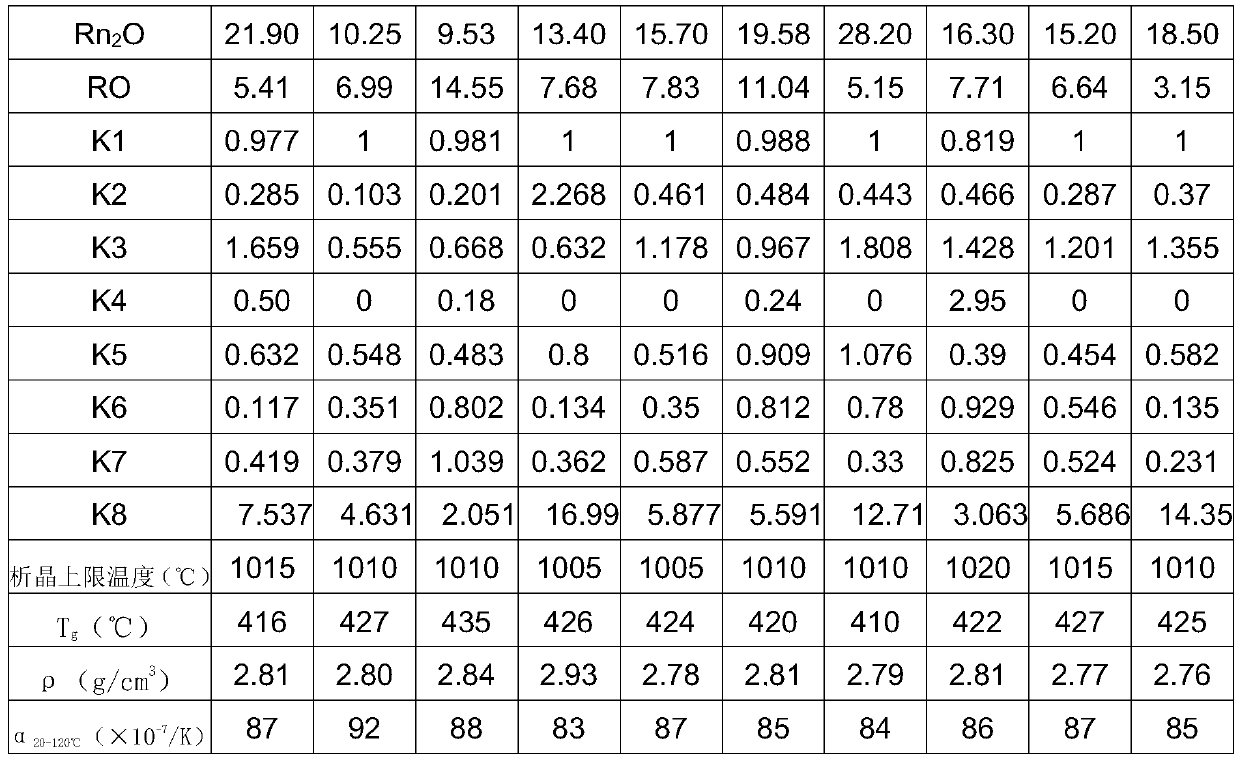

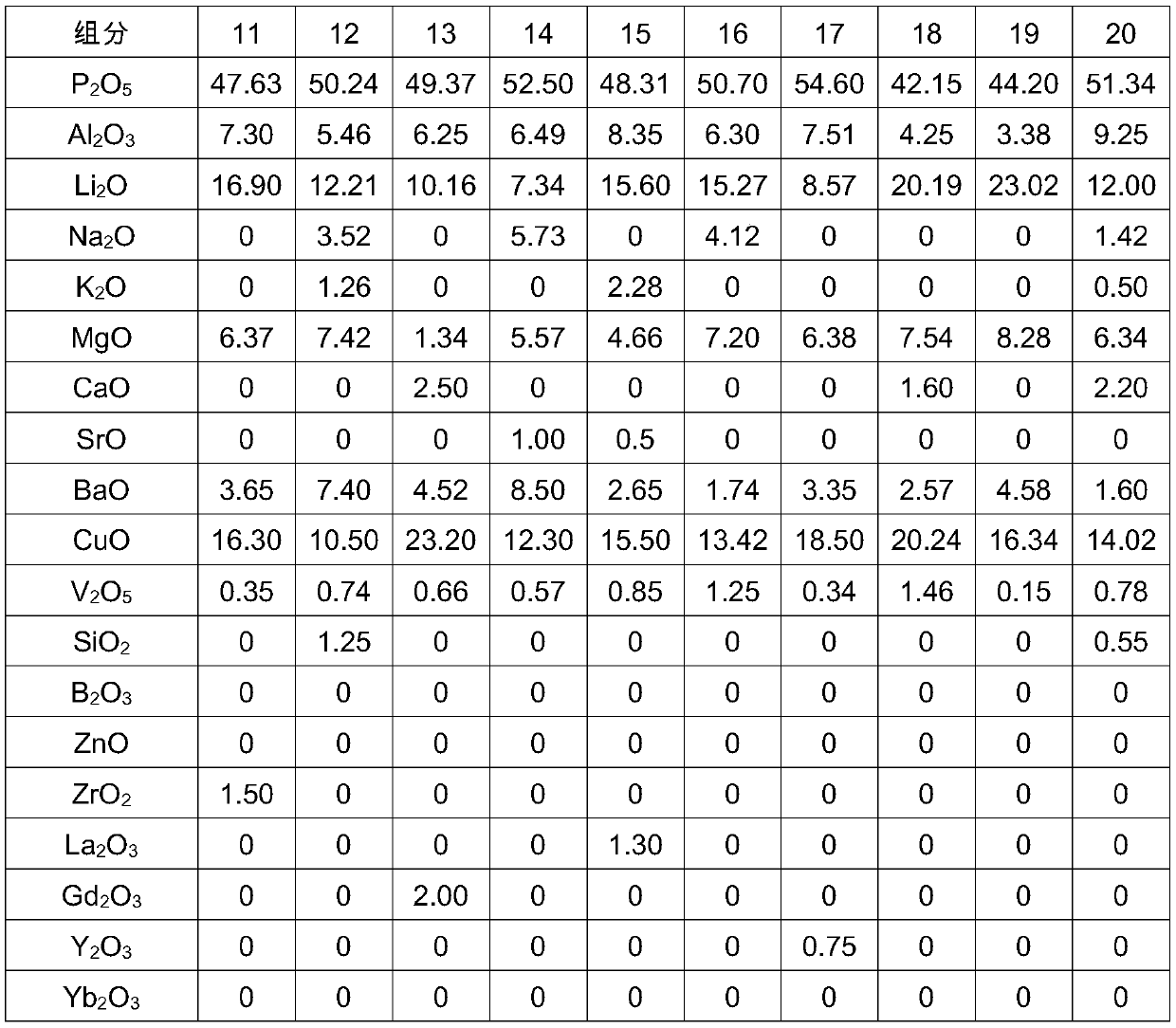

Glass, glass product and preparation method of glass product

ActiveCN110255897AHigh Cu contentGood anti-devitrification performanceOptical elementsPhotochemistryCrystallization

The invention provides glass. The glass comprises the following components, in percentages by mole: 38-65% of P2O5, 2-15% of Al2O3, 8-25% of CuO, 5-40% of Rn2O, 1-30% of RO, and 0-3% of V2O5, wherein a ratio of the Li2O to the Rn2O is 0.4 to 1.0, a ratio of (the Li2O+the CuO) to the P2O5 is 0.3 to 1.2, a content of the Rn2O is a total content of Li2O, Na2O and K2O, and a content of the RO is a total content of MgO, CaO, SrO and BaO. According to the glass provided by the invention, through reasonable component design, the glass obtained by the invention has excellent anti-crystallization property in the case of having a high Cu content; and at the same time, the glass is suitable for chemical strengthening, and a glass product obtained by chemical strengthening has excellent bending strength.

Owner:CDGM OPTICAL GLASS

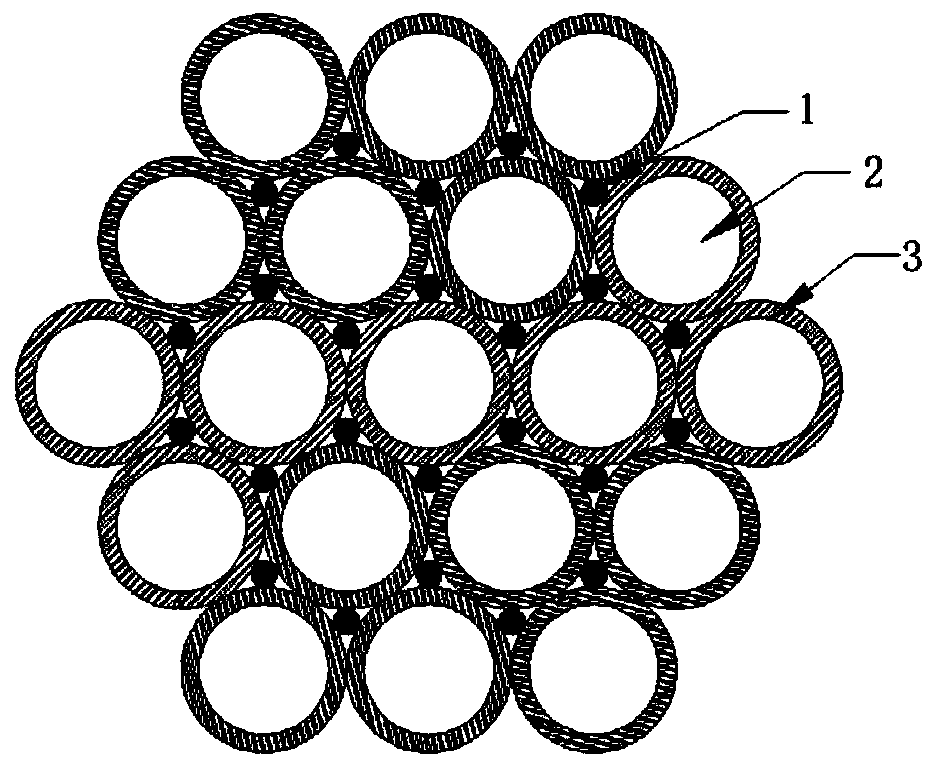

Acid soluble glass for acid soluble method flexible optical fiber image transmitting beam

The invention discloses the composition of an acid-dissolved glass for flexible optical fiber image-transmission bundle, which is characteristic in: (1) well acid dissolved feature; (2) well chemical reliability in air; (3) well resistance to separate crystal for good technical match; (4) without impregnation phenomenon with the material glass.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Low barium high refractive index glass micropearl

InactiveCN1792915AImprove the ability to formLower melting temperatureRefractive indexPhotochemistry

A high-refractivity low-Ba glass micro-bead is a TiO2-ZrO2-SiO2 system and is proportionally prepared from TiO2, ZrO2, SiO2, Al2O3, B2O3, ZnO and BaO. The content of its free Ba is less than 1000 mg / kg.

Owner:济南华明微珠材料有限责任公司

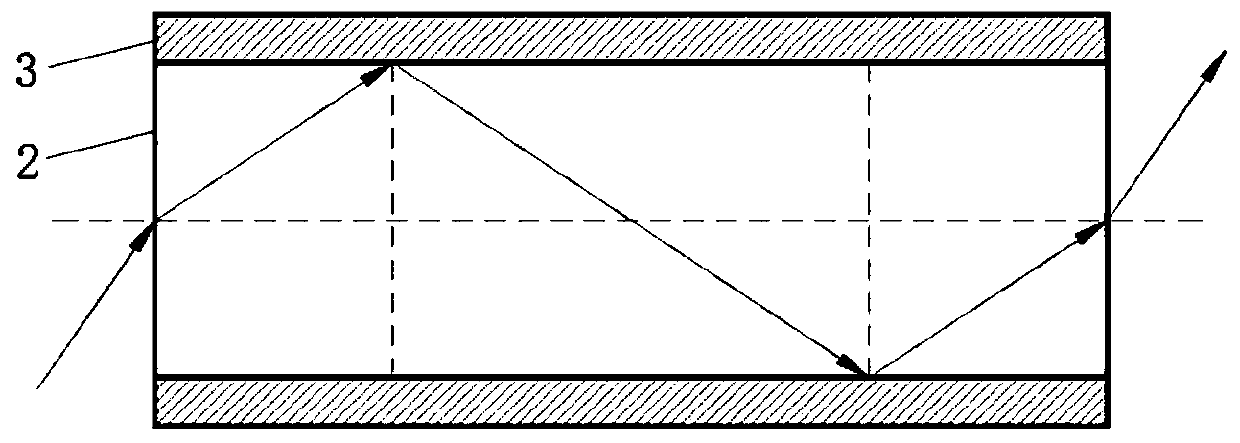

Optical fiber skin layer glass for optical fiber image transmission element and mechanical pipe-drawing forming method of optical fiber skin layer glass

ActiveCN110183108AGood anti-devitrification performanceImprove featuresCladded optical fibreGlass forming apparatusRefractive indexEngineering

The invention discloses an optical fiber skin layer glass for an optical fiber image transmission element and a mechanical pipe-drawing forming method of the optical fiber skin layer glass. The optical fiber skin layer glass composition for the optical fiber image transmission element comprises the following components in percentage by mole: 72.0-80.0% of SiO2, 5.5-7.0% of Al2O3, 2.0-8.0% of B2O3,3.0-8.0% of Na2O, 2.0-7.0% of K2O, 1.0-3.0% of CaO, 0.1-2.0% of SrO, 0.1-2.0% of ZnO, 0.1-0.9% of ZrO2, 0.1-0.9% of TiO2 and 0.1-0.2% of Sb2O3. The preparation method by the mechanical pipe-drawing forming comprises the following steps: melting glass; carrying out clarifying and homogenizing; carrying out pipe-drawing forming; and carrying out cutting and annealing. The disclosed skin material for the optical fiber image transmission element is excellent in chemical property, stable in glass composition, low in refractive index and excellent in anti-crystallization property.

Owner:CHINA BUILDING MATERIALS ACAD

Formula for light environment-friendly alkali-free boron-alumina silicate glass used in liquid crystal display (LCD)

Provided is a formula for light environment-friendly alkali-free boron-alumina silicate glass used in a liquid crystal display (LCD). SnO in the formula can be obtained easily, is nontoxic and can eliminate bulbs in alkali-free glass when being separately used as a glass clarifying agent. Melting temperature of ZnO can be reduced so that liquidus temperature can be reduced, and excellent crystallization-resisting properties can be achieved. Basic physical properties of the liquid crystal substrate prepared through the formula can stably reach that: coefficient of thermal expansion is lower than 35*10-7 / DEG C, temperature of strain point is higher than 670 DEG C, density is lower than 2.41g / cm<3>, liquidus temperature is lower than 1100 DEG C, liquidus viscosity is larger than 250,000 poises, and bulbs with diameter larger than 0.1mm in per kilogram of glass are invisible.

Owner:北京远大信达科技有限公司

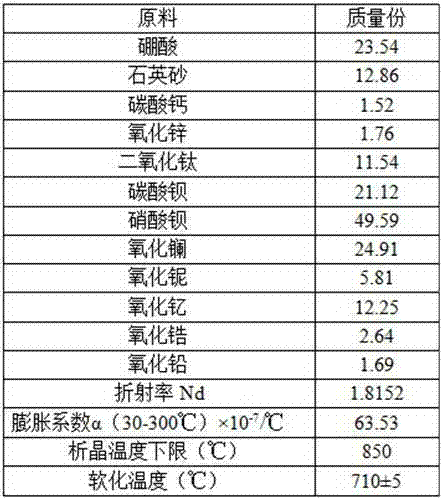

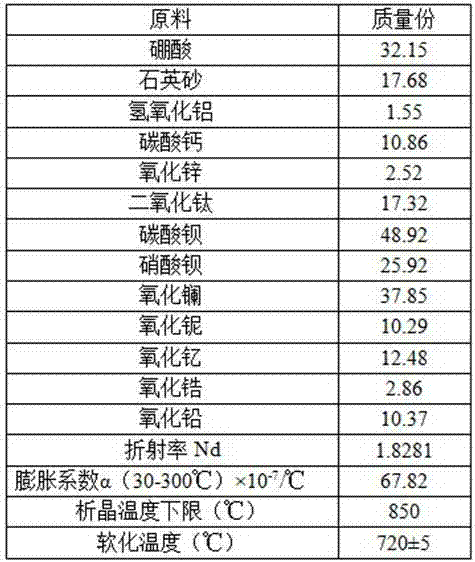

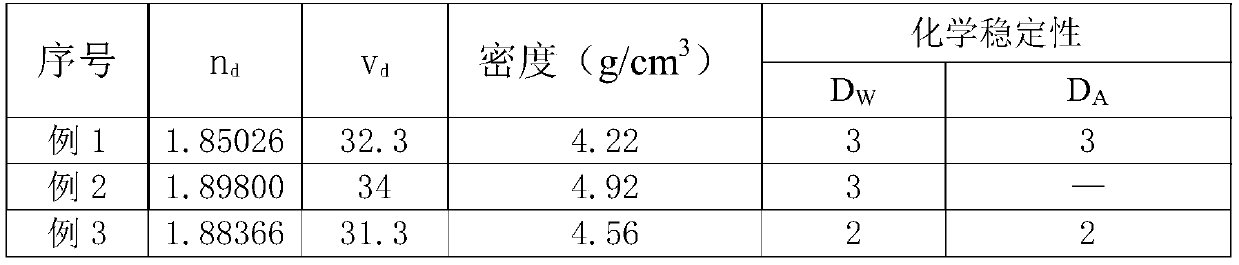

High refractive index middle-expansion core material glass for middle-expansion optical fiber image inverter, and preparation method thereof

ActiveCN103755140AHigh glass transmittanceGood anti-devitrification performanceGlass making apparatusLanthanumTitanium oxide

The present invention discloses a high refractive index middle-expansion core material glass for a middle-expansion optical fiber image inverter. The high refractive index middle-expansion core material glass comprises the following raw materials: boric acid, quartz sand, aluminum hydroxide, calcium carbonate, zinc oxide, titanium dioxide, barium carbonate, barium nitrate, zirconium oxide, lanthanum oxide, niobium oxide, yttrium oxide and lead oxide. The preparation method for the high refractive index middle-expansion core material glass comprises: 1) adding raw materials to a platinum crucible; 2) after raw material addition is completed, heating to achieve a clarification temperature so as to clarify; 3) after completing clarification, cooling to achieve a pouring temperature, and carrying out pouring molding to obtain a glass rod; and 4) carrying out demolding on the molded glass rod, annealing, carrying out thermal insulation, cooling, and discharging from the furnace at a room temperature. According to the present invention, the formula system can be used for the core material glass of the middle-expansion optical fiber image inverter, wherein the refractive index of the glass is more than 1.80, the expansion coefficient is (68+ / -5)*10<-7> / DEG C, the glass transmittance is high, the softening temperature is 650-750 DEG C, crystallization is not generated after thermal insulation for 2 h at a temperature of 850 DEG C, and the chemical stability is good.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS +1

Optical glass, glass preform, optical element and optical instrument

PendingCN110950531ALow densityIncrease freedomGlass productionOptical elementsRefractive indexTransmittance

The invention provides optical glass which comprises the following components in percentage by weight: 2-20% of SiO2; 8-30% of B2O3; 8-25% of La2O3; 15-43% of Nb2O5 and 1 to 15% of BaO, wherein the ratio of Nb2O5 / La2O3 is 0.8 to 3.0. Through reasonable component design, the obtained optical glass has the expected refractive index and Abbe number, meanwhile, the density of the glass is low, and a larger degree of freedom is brought to light weight of an optical system; the optical glass has excellent chemical stability and crystallization resistance, the transmittance cannot be obviously reduced after long-term use, and the optical glass is very suitable for being applied to imaging application needing to bear a severe working environment.

Owner:CDGM OPTICAL GLASS

Fluorophosphate optical glass, optical preform, element and instrument

InactiveCN110963706AGood chemical stabilityGood anti-devitrification performanceOptical elementsThermal dilatationRefractive index

The invention provides fluorophosphate optical glass, an optical preform, an element and an instrument, which belong to the technical field of optical glass. The optical glass comprises the followingcomponents: in terms of the molar percentage of cations, 2-20% of P<5+>, 20-40% of Al<3+>, 0.5-10% of Ba<2+>, 5-25% of Sr<2+>, 15-35% of Ca<2+> and 1-15% of Mg<2+>, and in terms of the molar percentage of anions, 83-95% of F<-> and 5-17% of O<2->. The fluorophosphate optical glass has a refractive index (nd) of 1.42-1.45, an Abbe number (vd) of 93-96, a density (rho) of 3.55 g / cm<3> or less, a bubble degree of B grade or more, a thermal expansion coefficient of 160*10<-7> / K or less, a water resistance stability (Dw) of grade 2 or more, and excellent crystallization resistance.

Owner:CDGM OPTICAL GLASS

Optical fiber faceplate core glass with refractive index of 1.5-1.6 and method for preparing optical fiber faceplate core glass

InactiveCN109485256AGood anti-devitrification performanceRaise the lower limit of crystallization temperatureGlass shaping apparatusRefractive indexChemical stability

The invention discloses optical fiber faceplate core glass with the refractive index of 1.5-1.6 and a method for preparing the optical fiber faceplate core glass. The optical fiber faceplate core glass with the refractive index of 1.5-1.6 comprises boric acid, quartz sand, aluminum hydroxide, calcium carbonate, zinc oxide, potassium carbonate, sodium carbonate, barium carbonate, lanthanum oxide and diarsenic trioxide. The optical fiber faceplate core glass with the refractive index of 1.5-1.6 and the method for preparing the optical fiber faceplate core glass have the advantages that glass formulas and the method can be used for core glass for optical fiber faceplates, the refractive index of the optical fiber faceplate core glass is within the range of 1.50-1.60, the expansion coefficientof the optical fiber faceplate core glass is (87+ / -5)*10<-7> / DEG C, and the optical fiber faceplate core glass is high in transmittance; the softening temperature of the optical fiber faceplate coreglass is 630-720 DEG C under the control, the lower limit of the crystallization temperature of the optical fiber faceplate core glass is higher than or equal to 850 DEG C, crystallization can be prevented under the condition of heat preservation at the temperature of 850 DEG C for 2 hours, and accordingly the optical fiber faceplate core glass is good in crystallization-resistant performance andchemical stability.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS

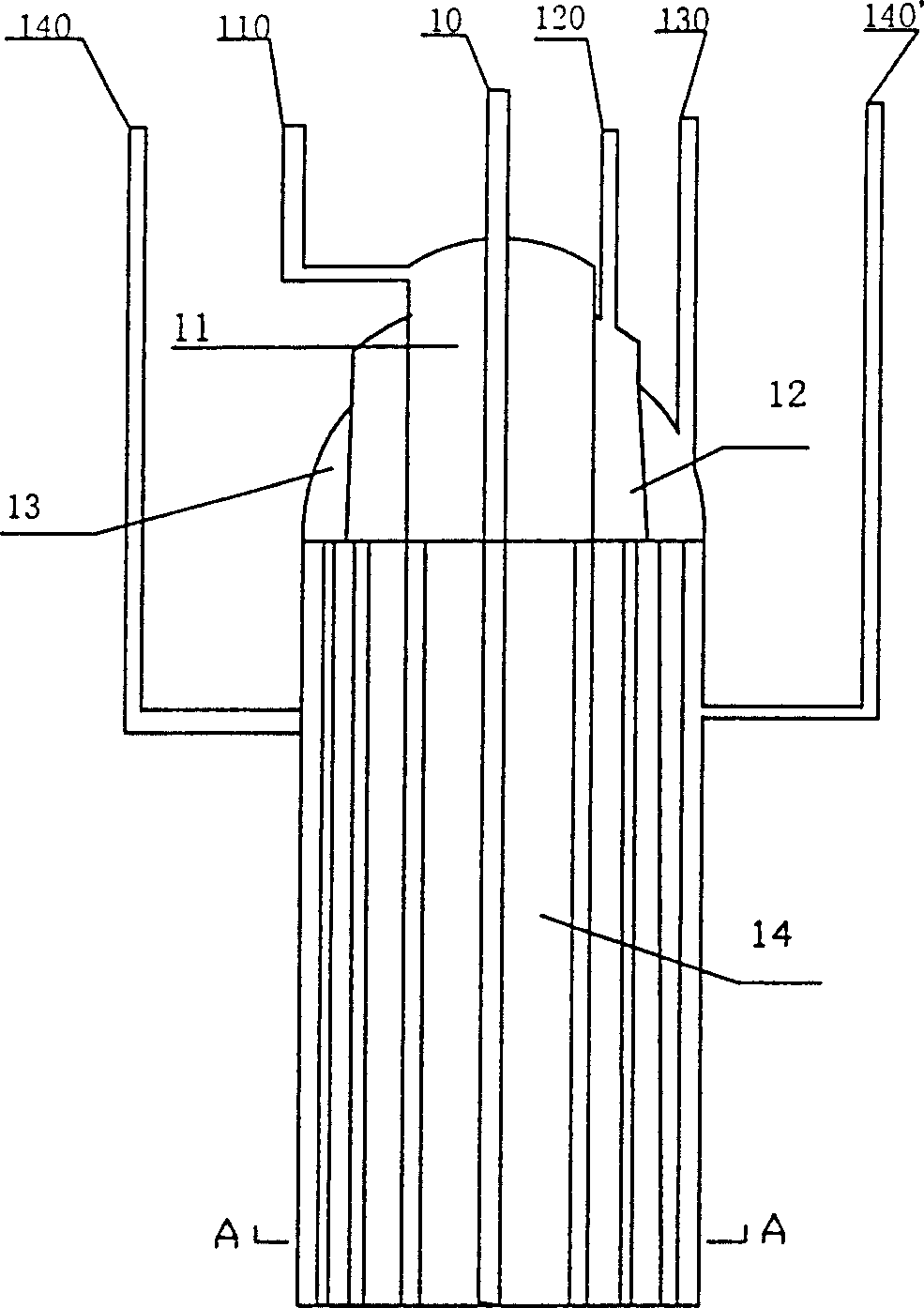

Process for synthesizing quartz glass by horizontal silicon tetrachloride vapor deposition

ActiveCN1837113AImprove deposition environmentLose weightGlass shaping apparatusGlass deposition burnersOxygenTubing types

The invention discloses a horizontal silicon chloride vapour deposition synthesizing quartz glass method, which comprises the following parts: chimney, furnace body, deposition target surface, burner, basis bar and lathe, wherein the furnace body is blocked style furnace body; the front of furnace installs burner; the burner includes multiple-layer oxygen chamber; every oxygen chamber has a loop of oxygen lamp wick pipe; the bottom of multiple-layer oxygen chamber installs a hydrogen gas chamber; the bilateral oxygen chamber sets up two hydrogen air feeders; the basis bar forms hollow tube type, which places in furnace body; the number of the burners can be two to ten. The invention is characterized by the following: it makes the product weight reach to 100-200Kg; the diameter ratio of the quartz glass ingot is more than 250mm; the deposition rate can reach the speed at 180-500 grams an hour; the production efficiency can be improved three to five times than traditional.

Owner:CHINA BUILDING MATERIALS ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

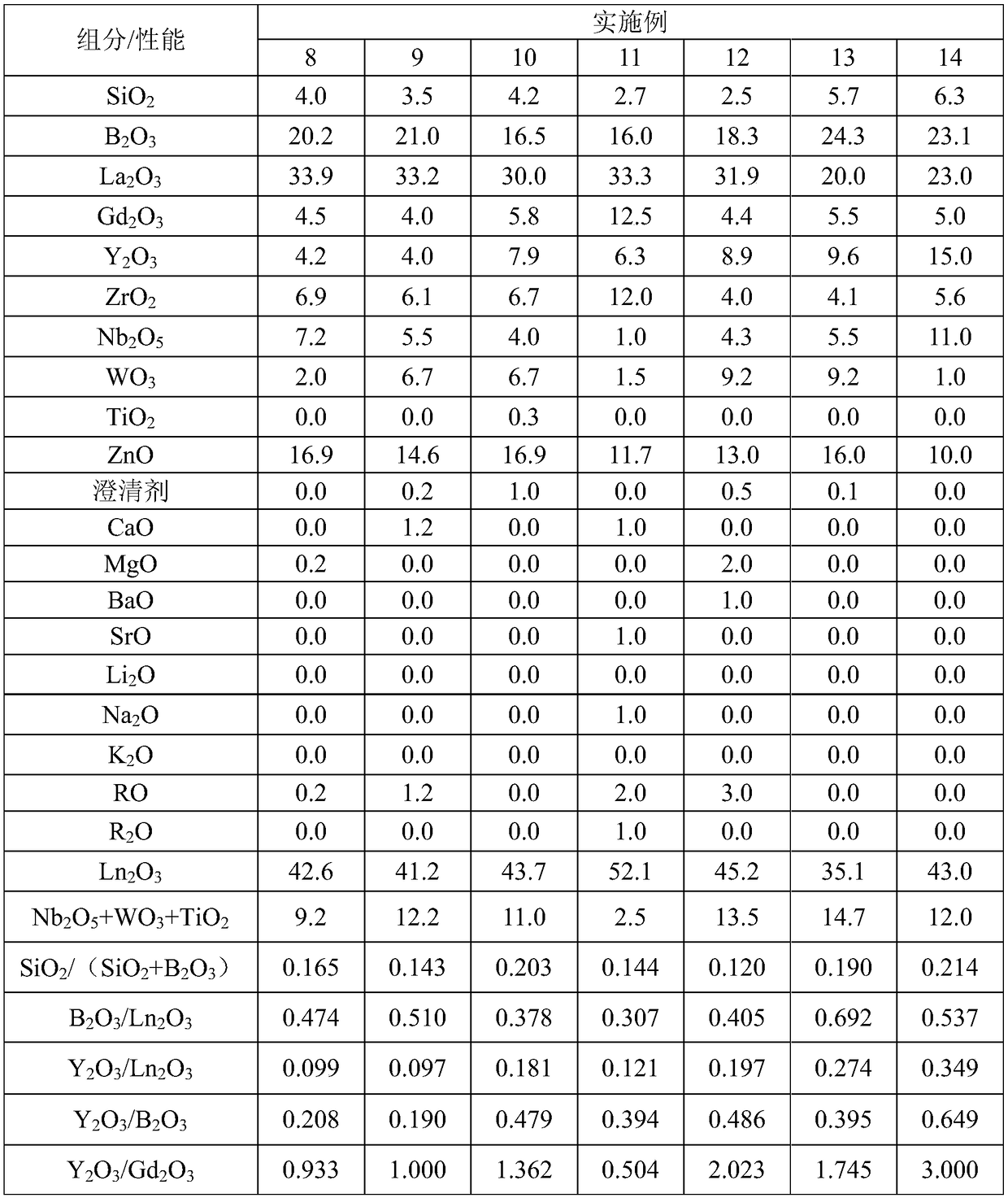

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com