Method for producing glass beads used for curing high-level nuclear wastes

A production method and highly radioactive technology, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increased or decreased leaching rate, increased specific surface area of solidified body, etc., and achieve good anti-devitrification ability, anti- The effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Weigh the raw materials according to the data in Table 1, mix the raw materials evenly and melt them in an all-electric glass melting furnace at a temperature of 1330°C to make a glass solution, clarify and homogenize for 7 hours, and then cool to room temperature to form a glass block. The final composition of this glass frit is shown in Table 2:

[0030] Table 1

[0031]

sand

oxidation

aluminum

oxidation

sand

acid

Titanium dioxide

pink

oxidation

number of copies

61

6

1

13

21.3

6

4.4

[0032] Table 2

[0033] Component

SiO 2

Al 2 o 3

MgO

Na 2 o

B 2 o 3

CaO

K 2 o

Li 2 o

TiO 2

ZrO 2

...

Embodiment 2

[0039] 1. Weigh the raw materials according to the data in Table 3, mix them evenly, and melt them in an all-electric glass melting furnace at 1300°C to make a glass solution, clarify and homogenize for 7 hours, and then cool to room temperature to form a glass block. The final composition of this glass frit is shown in Table 4:

[0040] table 3

[0041]

stone

oxidation

aluminum

oxidation

sand

boron

acid

carbonic acid

carbonic acid

carbonic acid

Titanium dioxide

pink

oxidation

number of copies

62

5

1.2

16.2

13.8

6.3

3.7

4.4

[0042] Table 4

[0043] Component

SiO 2

al 2 o 3

MgO

Na 2 o

B 2 o 3

CaO

K 2 o

Li 2 o

TiO 2

ZrO 2

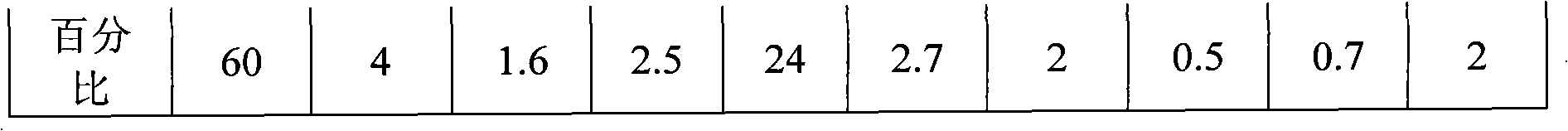

percentage

...

Embodiment 3

[0049] 1. Weigh the raw materials according to the data in Table 5, mix them evenly and melt them in an all-electric glass melting furnace at 1320°C to make a glass solution, clarify and homogenize for 8 hours, and then cool to room temperature to become a glass frit. The final composition of this glass frit is shown in Table 6:

[0050] table 5

[0051]

stone

oxidation

aluminum

oxidation

boron

sand

boron

acid

carbonic acid

carbonic acid

carbonic acid

Titanium dioxide

pink

oxidation

number of copies

57.5

4.5

1.4

19.5

11.6

5.4

4.4

3.9

2.5

[0052] Table 6

[0053] Component

SiO 2

al 2 o 3

MgO

Na 2 o

B 2 o 3

CaO

K 2 o

Li 2 o

TiO 2

ZrO 2

perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com