Fluorophosphate optical glass, optical preform, element and instrument

A technology of optical glass and fluorophosphate, which is applied in the field of optical prefabricated parts, components and instruments, and fluorophosphate optical glass. It can solve the problems of poor chemical stability, devitrification resistance, damage, and high thermal expansion coefficient, and achieve excellent performance. The effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

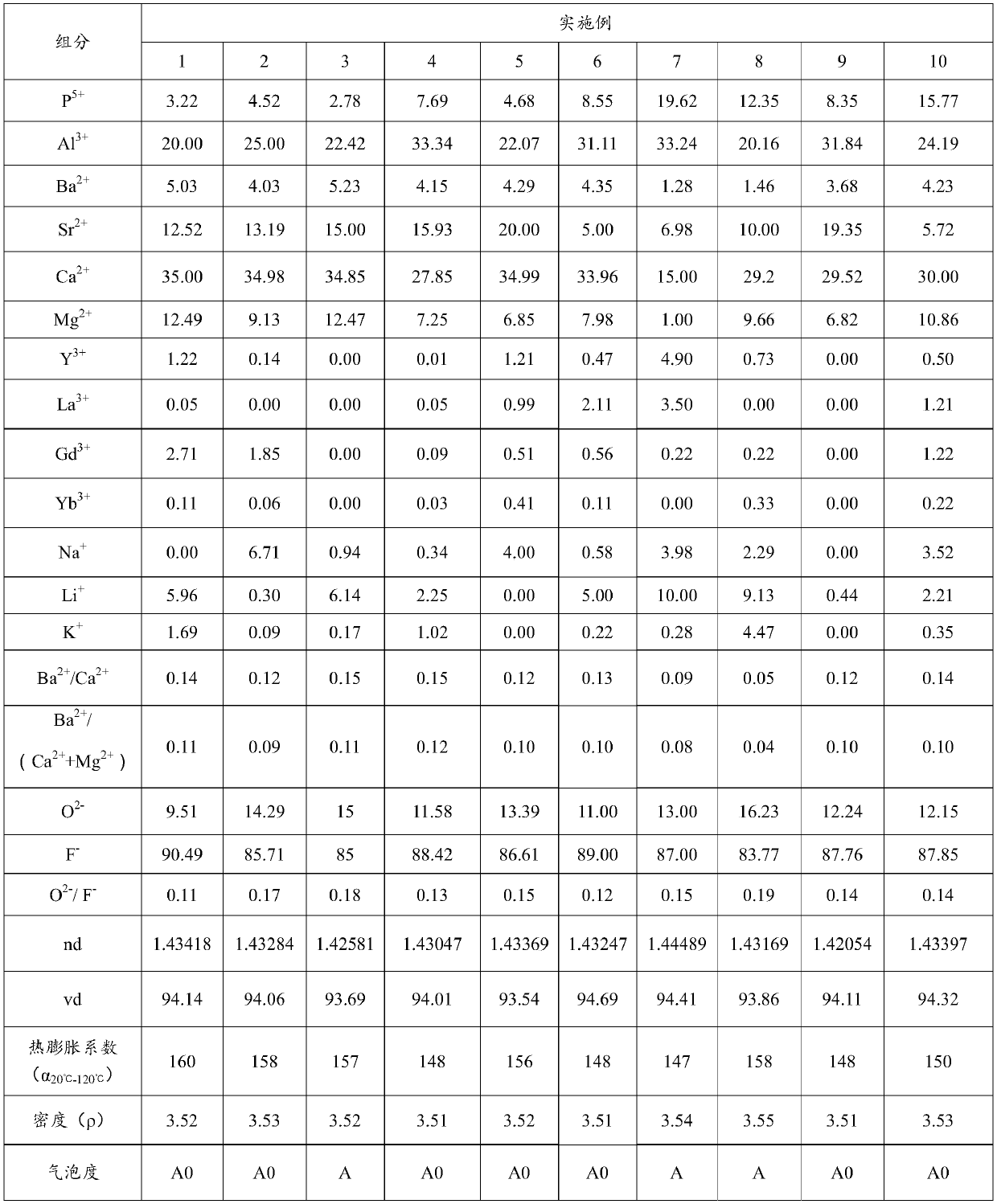

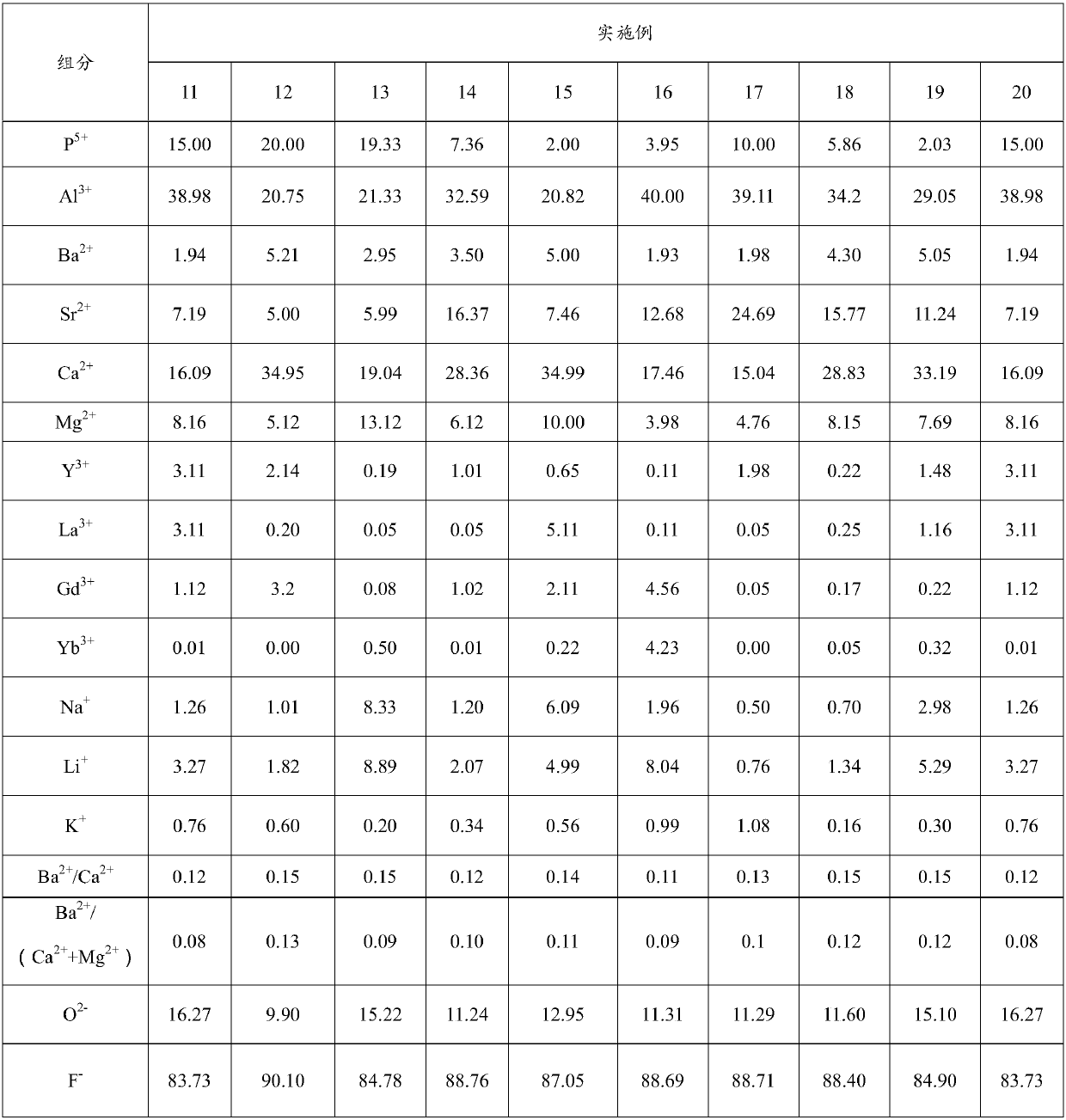

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0025] The functions and limited ranges of the components contained in the fluorophosphate optical glass of the present invention will be explained in detail below in combination with specific principles.

[0026] It should be noted that, in this specification, each cationic component and the total content of cationic components are expressed as “cation mole percent”, and each anion component and the total content of anion components are expressed as “anion mole percent”. "Cation molar percentage" refers to the percentage of a certain cationic component in the molar content of all cationic species, and "anion molar percenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com